| ÐлекÑÑоннÑй компоненÑ: AD53508JP | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

AD53508

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1999

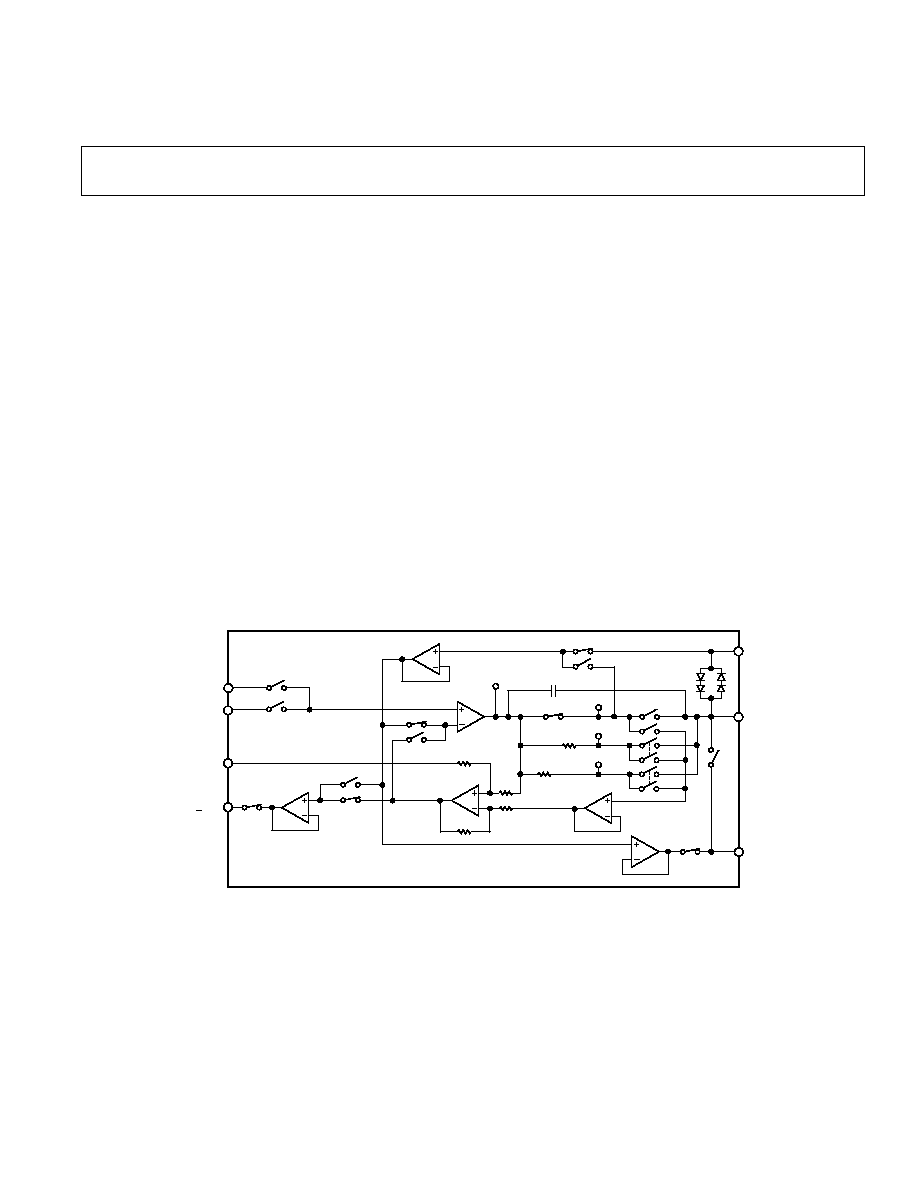

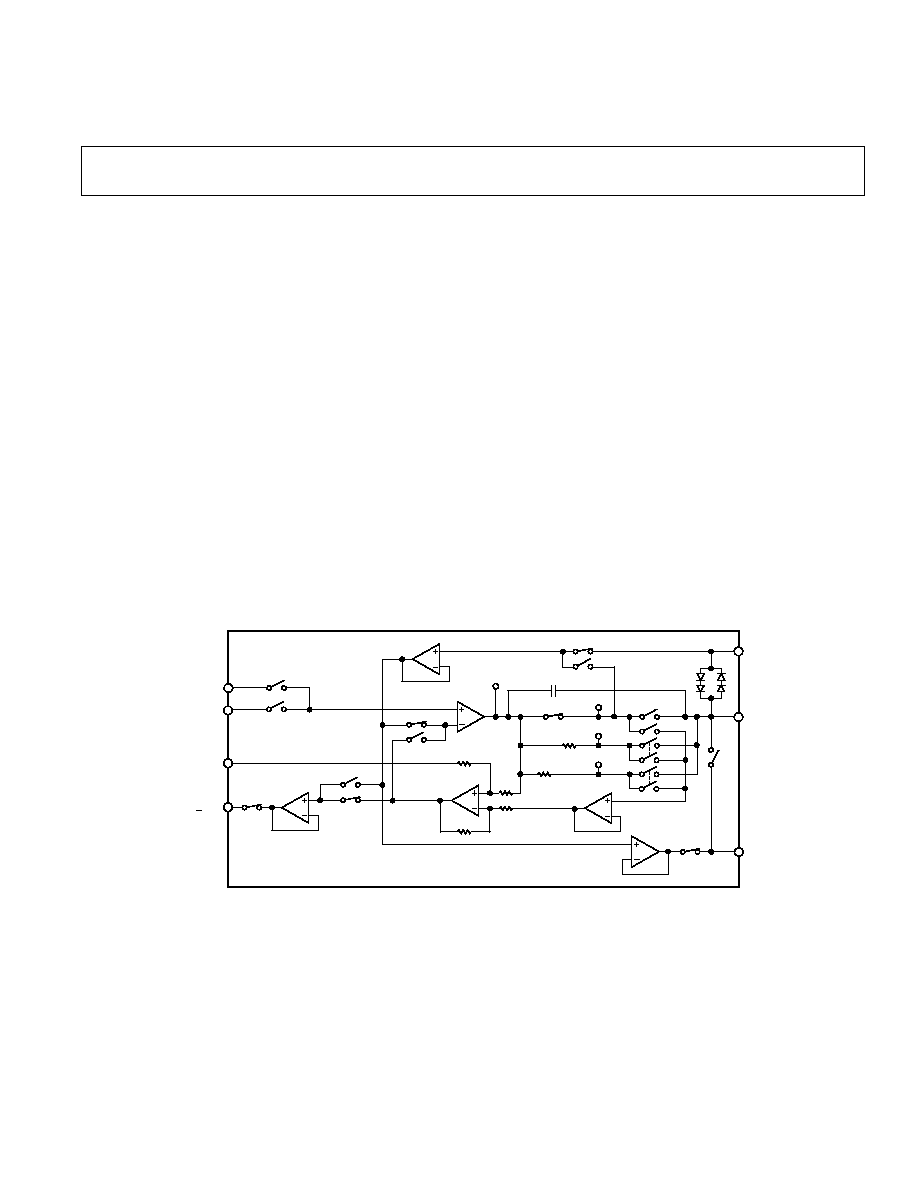

PPMU Circuit

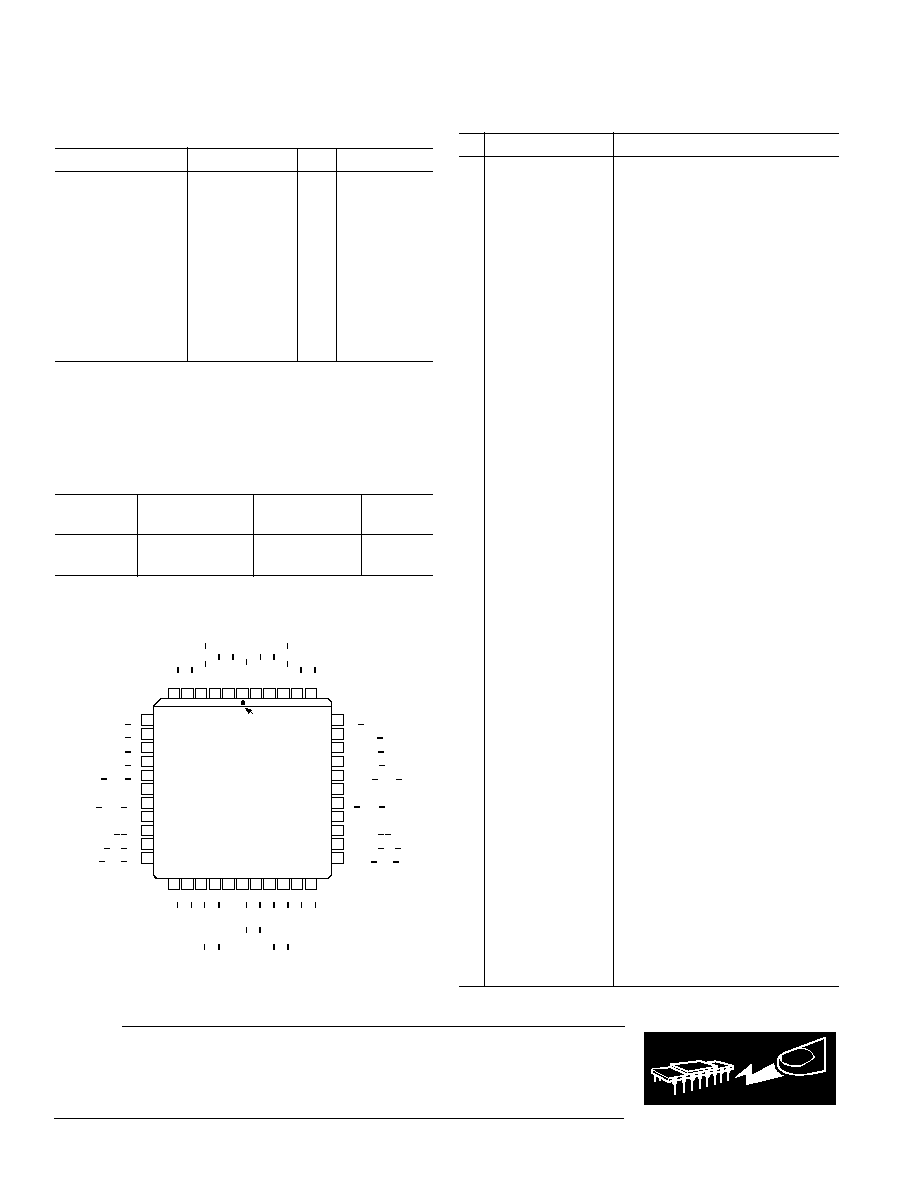

FUNCTIONAL BLOCK DIAGRAM

S11

S12

S13

S14

S15

S16

INT/IM

R1

R2

INTEGRATE

S10

UNITY

DIFF

VF

S4

IF

S5

C1

1k

2mA

10k

200 A

EXT RC

SENSE

S8

S9

S2

S3

VM

IM

ENABLE

S1

CON

+2.5V

S6

S7

DAC1

DAC2

DSR

MEAS OUT

40pF

S17

GUARD

FORCE

SENSE

R

R

1.25R

1.25R

MAIN

GUARD

S18

AD53508

OUTPUT

FEATURES

Dual Measurement Channels

Precision Four-Quadrant-Per-Pin V/I Source

Programmable Current Force Ranges

204.8 A and 2.048 mA

Five Current Measurement Ranges

204.8 nA to 2.048 mA

Output Voltage Range: 4 V to +9 V

Power Supplies: +15 V, +5 V, and 10 V

44-Lead Plastic J-Leaded Chip Carrier Package

APPLICATIONS

Can Be Used with the AD53032 DCL to Extend Current

Force Range to 35 mA

GENERAL DESCRIPTION

The AD53508 is a custom dual-channel parametric measure-

ment circuit for use in semiconductor automatic test equipment.

It contains programmable modes to force a pin voltage and

measure its current or to integrate and hold a current value.

Alternatively, a current can be forced and the compliance volt-

age measured.

The device provides a remote force/sense capability to ensure

accuracy at the tester pin. A guard output is available to drive

the shield of a force/sense pair.

Two input references per channel permit controlled switching to

different voltage or current levels. The forced voltage or current

levels can be switched back to the measurement system to read

back the analog levels for system calibration.

The circuit is powered by +15 V, +5 V and 10 V supplies and

dissipates 230 mW nominally.

Recommended Use of the PPMU with AD53032 DCL

The PPMU can be used with the AD53032 DCL to extend the

Current Force Range beyond 2 mA VCOM can be set to the

maximum spec allowance of 8 V, which would allow the maxi-

mum Current Force of IOL of 35 mA. The combination of the

PPMU and the DCL would have a few benefits including:

1. Accurately measuring low currents.

2. Can take parallel measurements by using one PMU per pin.

2

REV. 0

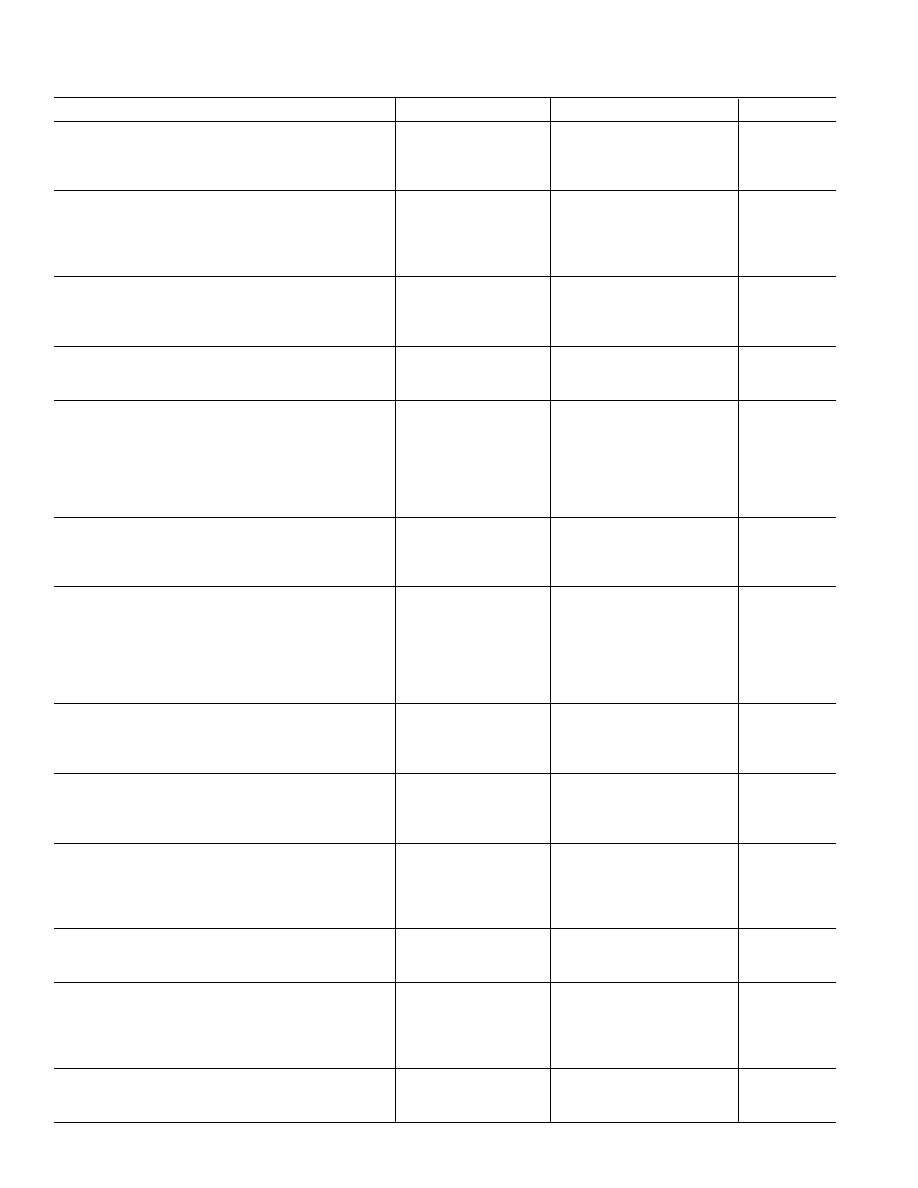

AD53508SPECIFICATIONS

Parameter

Condition

Min

Typ

Max

Unit

1

VOLTAGE FORCE/MEASURE MODE

Voltage Swing,

±2 mA Range

±2 mA Drive

4

+9

V

±100 µA Drive

5

+12

V

ACCURACY

Gain (

±0.1% Tolerance)

0.999

1.001

V/V

Offset Error

±15

mV

Gain Nonlinearity (Relative to Endpoints)

±0.02

% of Span

Current Measure CMRR (at MEAS_OUT)

±0.31

mV/V

DRIFT

Gain Error Temperature Coefficient

±20

ppm (PV

or MV)/

°C

Offset Drift

±100

µV/°C

CURRENT FORCE/MEASURE MODE RANGES

0 (High)

±2.0

mA

1 (Low)

±200

µA

ACCURACY--HIGH RANGE

Transconductance (

±3% Tolerance)

Force Mode

0.776

0.8

0.824

mA/V

Transresistance (

±3% Tolerance)

Measure Mode

1.21

1.25

1.29

V/mA

Offset Error

±40

µA

Gain Nonlinearity (Relative to Endpoints)

±0.05

% of Span

Output Compliance Voltage-Induced

Transconductance/Error

Force Mode

0.2

+0.4

µA/V

DRIFT--HIGH RANGE

Gain Error Temperature Coefficient

+10/60

ppm (PV

or MV)/

°C

Offset Drift

±400

nA/

°C

ACCURACY--LOW RANGE

Transconductance (

±3% Tolerance)

Force Mode

77.6

80

82.4

µA/V

Transresistance (

±3% Tolerance)

Measure Mode

12.1

12.5

12.9

V/mA

Offset Error

±4

µA

Gain Nonlinearity (Relative to Endpoints)

±0.05

% of Span

Output Compliance Voltage-Induced

Transconductance/Error

Force Mode

0.02

+0.04

µA/V

DRIFT--LOW RANGE

Gain Error Temperature Coefficient

+10/60

ppm (PV

or MV)/

°C

Offset Drift

±40

nA/

°C

CURRENT MEASURE INTEGRATE MODE RANGES

High

±20.0

µA

Medium

±2.0

µA

Low

±200

nA

ACCURACY--HIGH RANGE

Transresistance Error (

±3% Tolerance)

0.121

0.125

0.129

V/

µA

Offset Error

±400

nA

Gain Nonlinearity (Relative to Endpoints)

±0.05

% of Span

Output Compliance Voltage-Induced Transresistance Error

±2.5

nA/V of Output

DRIFT--HIGH RANGE

Gain Error Temperature Coefficient

±20

ppm MV/

°C

Offset Drift

±2

nA/

°C

ACCURACY--MEDIUM RANGE

Transresistance Error (

±3% Tolerance)

1.21

1.25

1.29

V/

µA

Offset Error

±40

nA

Gain Nonlinearity (Relative to Endpoints)

±0.05

% of Span

Output Compliance Voltage-Induced Transresistance Error

±0.25

nA/V of Output

DRIFT-- MEDIUM RANGE

Gain Error Temperature Coefficient

±20

ppm MV/

°C

Offset Drift

±250

pA/

°C

(T

A

= 25 C, rated power supplies unless otherwise noted)

3

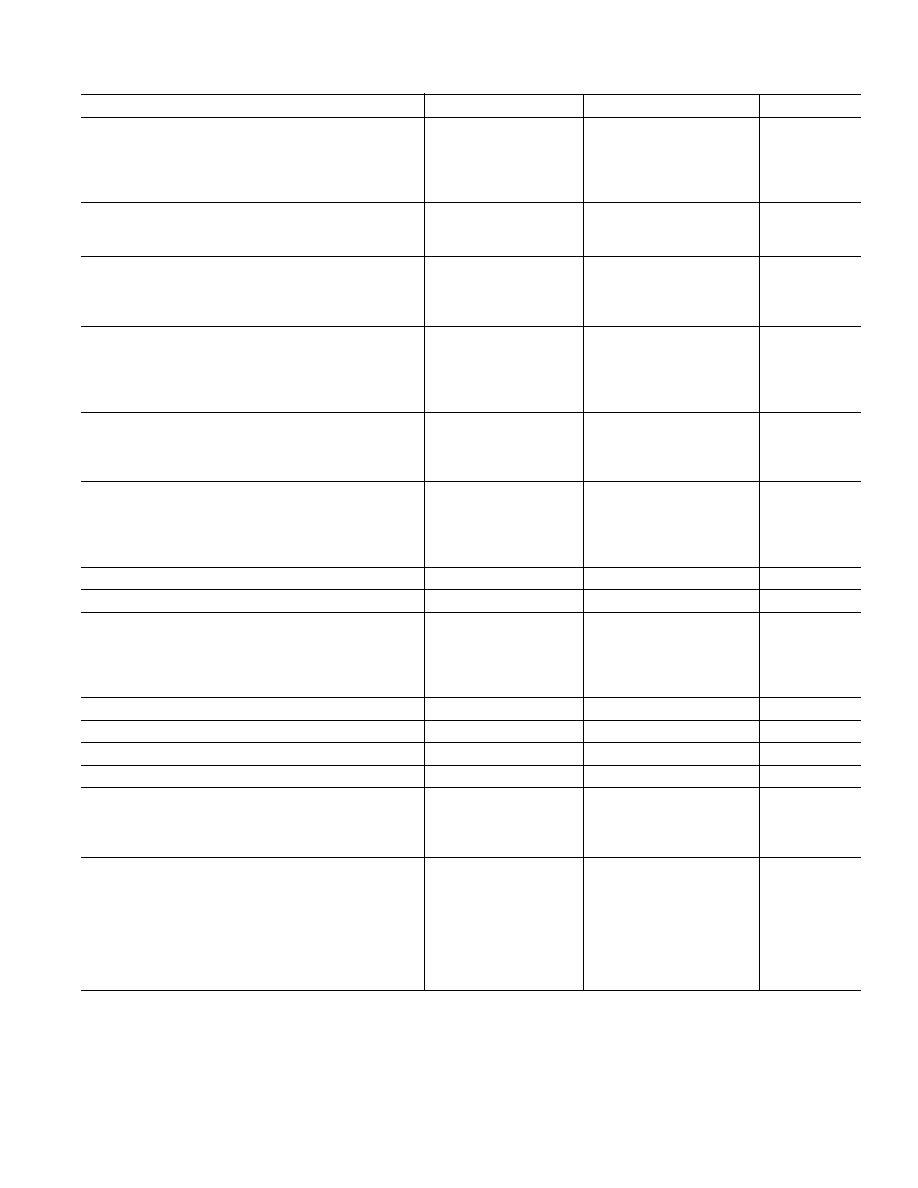

REV. 0

AD53508

Parameter

Condition

Min

Typ

Max

Unit

1

ACCURACY--LOW RANGE

Transresistance Error (

±3% Tolerance)

0.0121

0.0125

0.0129

V/nA

Offset Error

±4

nA

Gain Nonlinearity (Relative to Endpoints)

±0.05

% of Span

Output Compliance Voltage-Induced Transresistance Error

±0.025

nA/V of Output

DRIFT--LOW RANGE

Gain Error Temperature Coefficient

±20

ppm MV/

°C

Offset Drift

±70

pA/

°C

DISABLE MODE

2

Voltage Swing,

±2 mA Range

±2 mA Drive

4

+9

V

±100 µA Drive

5

+12

V

ACCURACY

Gain (

±0.1% Tolerance)

0.999

1.001

V/V

Offset Error

±15

mV

Gain Nonlinearity (Relative to Endpoints)

±0.02

% of Span

Current Measure CMRR (at MEAS_OUT)

±0.31

mV/V

DRIFT

Gain Error Temperature Coefficient

±20

ppm (PV or

MV)/

°C

Offset Drift

±100

µV/°C

OTHER SPECIFICATIONS

Power Supply Rejection Ratio

f < 40 Hz, V

CC

70

dB

f < 40 Hz, V

EE

60

dB

f = 40 kHz, V

CC

35

dB

f = 40 kHz, V

EE

25

dB

CURRENT MEASURE HOLD MODE LEAKAGE

T

AMB

= +70

°C

±1.2

nA

CROSSTALK

3

±0.02

% of Span

SETTLING TIMES TO 0.01%

Voltage Force and Guard Voltage

C

LOAD

= 100 pF

20

µs

C

LOAD

= 2000 pF

2

ms

Current Force (200

µA Range)

Z

LOAD

= 100 pF 50 k

50

µs

MEAS_OUT Pin

C

LOAD

= 20 pF

2

µs

SHORT CIRCUIT CURRENT LIMIT MAGNITUDE

Any Output Except Guards

8.5

20

mA

GUARD SCC LIMIT MAGNITUDE

2.5

10

mA

GUARD OFFSET (FROM SENSE INPUT PIN)

65

25

0

mV

I

B

(DAC1, DAC2) CURRENT

±1.0

µA

DIGITAL INPUTS

V

IH

2.4

V

V

IL

0.8

V

I

IN

(Input leakage current)

10

µA

POWER SUPPLIES

V

CC

(Positive Analog Supply Voltage)

14.0

15.0

15.75

V

V

EE

(Negative Analog Supply Voltage)

10.5

10.0

9.0

V

V

DD

(Logic Supply Voltage)

4.75

5.0

5.25

V

I

CC

(Positive Analog Supply Current)

5

15

mA

I

EE

(Negative Analog Supply Current)

15

5

mA

I

DD

(Logic Supply Current Is 0 with Inputs at Rails,

Worst Case @ 2.4 V

IN

)

8

mA

NOTES

1

PV = Programmed Value, MV = Measured Value, FSR = Full-Scale Range = span.

2

Output connected: DAC2 and 2 mA range selected, unconditionally.

3

f < 40 Hz, both channels in current force mode; other channel output voltage swinging rail to rail.

Specifications subject to change without notice.

AD53508

4

REV. 0

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD53508 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

PIN FUNCTION DESCRIPTIONS

Pin Name

Description

1

DSR_2.5

2.5 V Reference Input

2

DAC2_A

First of Two Switchable Inputs

3

DAC1_A

Second of Two Switchable Inputs

4

EXT_RC_A

External R

S

and C Common

5

C1_A

External Capacitor

6

R1_A

External Resistor

7

R2_A

External Resistor

8

SENSE_A

Sense Input

9

FORCE_A

Force Output

10

GUARD_A

Guard Drive Output

11

MEAS_OUT_A

Measurement Output

12

VCC

+15 V Analog Supply

13

M_CON_A

*

Connect Measure Output to Bus

14

VEE

10 V Analog Supply

15

FORCE_I_A

*

Force V (When Hi) or I (When Lo)

16

FORCE_EN_A

*

Control Input

17

DAC1_SEL_A

*

Select DAC1 (When Lo) or DAC2

18

INTEG_A

*

Control Input

19

HOLD_A

*

Control Input

20

I_RANGE0_A

*

Select 2 mA Range (Active Lo)

21

I_RANGE1_A

*

Select 200

µA Range (Active Lo)

22

VERIFY*

Measure Forced Voltage or Current

23

OUTPUT_CON_A

*

Connect Pin Drive (Active Lo)

24

OUTPUT_CON_B

*

Connect Pin Drive (Active Lo)

25

I_RANGE1_B

*

Select 200

µA Range (Active Lo)

26

I_RANGE0_B

*

Select 2 mA Range (Active Lo)

27

HOLD_B

*

Control Input

28

INTEG_B

*

Control Input

29

DAC1_SEL_B

*

Select DAC1 (When Lo) or DAC2

30

FORCE_EN_B

*

Control Input

31

FORCE_I_B

*

Force V (When Hi) or I (When Lo)

32

DIGGND

Digital Ground

33

M_CON_B

*

Connect Measure Output to Bus

34

VDD

+5 V Digital Supply

35

MEAS_OUT_B

Measurement Output

36

GUARD_B

Guard Drive Output

37

FORCE_B

Force Output

38

SENSE_B

Sense Input

39

R2_B

External Resistor

40

R1_B

External Resistor

41

C1_B

External Capacitor

42

EXT_RC_B

External R

S

and C Common

43

DAC1_B

Second of Two Switchable Inputs

44

DAC2_B

First of Two Switchable Inputs

*

= Active Lo

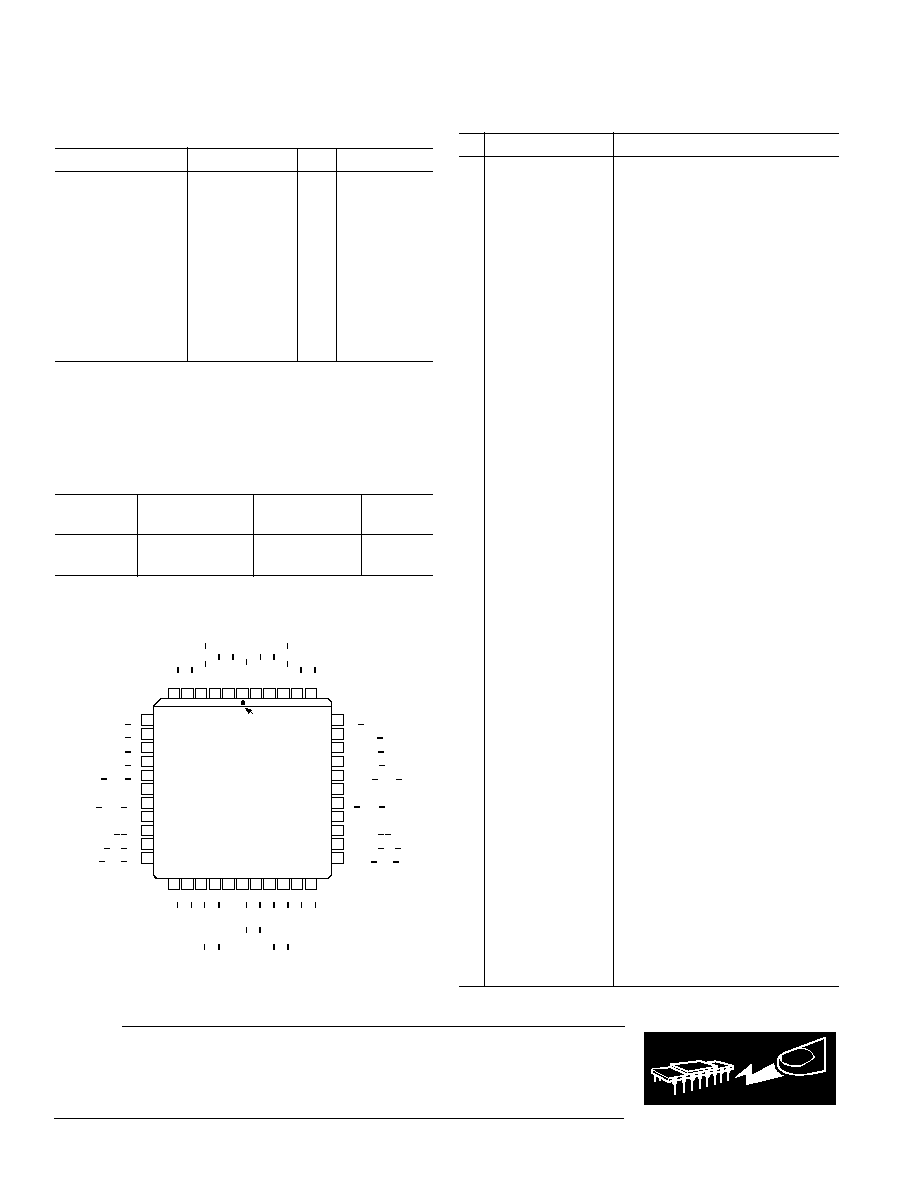

ABSOLUTE MAXIMUM RATINGS

*

(T

A

= 25

°C unless otherwise noted)

Min

Max

Unit

Condition

VDD to VEE

0.3

+26.4

V

VCC to VEE

0.3

+26.4

V

VDD to DGND

0.3

+6

V

Digital Inputs to DGND 0.3

VCC+0.3 V

Power Dissipation

700

mW

T

A

+75°C

Operating Temperature

Range

25

70

°C

Storage Temperature

60

+125

°C

Lead Temperature

+300

°C

Soldering (10 sec)

Force/Sense Outputs

VEE0.8 VCC+0.8 V

Or 75 mA,

Whichever Is Less

*

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. These are stress ratings only; functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Temperature

Package

Package

Model

Range

Description

Option

AD53508JP

25

°C to 70°C

Plastic Leaded

P-44A

Chip Carrier

PIN CONFIGURATION

6 5 4 3 2 1 44 43 42 41 40

PIN 1

IDENTIFIER

TOP VIEW

(Not to Scale)

39

38

37

36

35

34

33

32

31

30

29

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21 22 23 24 25 26 27 28

* = ACTIVE LO

R2 B

SENSE B

FORCE B

GUARD B

MEAS OUT B

VDD

M CON B*

DIGGND

FORCE I B*

FORCE EN B*

DAC1 SEL B*

R2 A

SENSE A

FORCE A

GUARD A

MEAS OUT A

VCC

M CON A*

VEE

FORCE I A*

FORCE EN A*

DAC1 SEL A*

R1

A

C1

A

EXT

RC

A

DAC1

A

DAC2

A

DSR

2.5

DAC2

B

INTEG

A*

HOLD

A*

I

RANGE0

A*

I

RANGE1

A*

OUTPUT

CON

A*

OUTPUT

CON

B*

I

RANGE1

B*

I

RANGE0

B*

HOLD

B*

INTEG

B*

VERIFY*

DAC1

B

EXT

RC

B

C1

B

R1

B

AD53508

AD53508

5

REV. 0

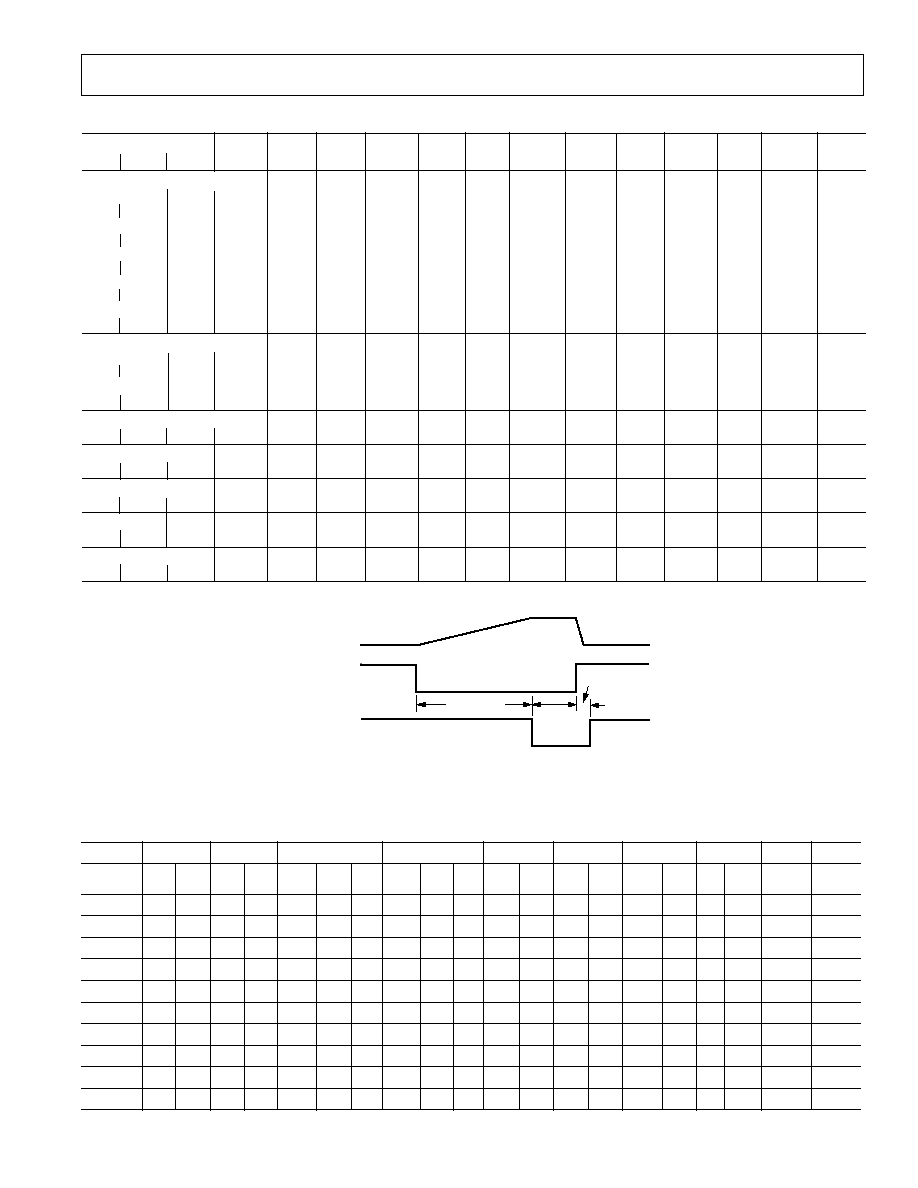

Table I. Data Table

Data Latch Bits

S13,

S15,

S1

S2

S3

S4

S5

S6

S7

S9

S17

S8

S10

S14

S16

S11

S12

S18

Voltage Force/Current Measure

Irange 0

On

Off

On

On

Off

On

Off

Off

Off

On

On

On

Off

Off

Off

On

Irange 1

On

Off

On

On

Off

On

Off

Off

Off

On

On

Off

On

Off

Off

On

Integrate Range

On

Off

On

On

Off

On

Off

Off

Off

On

On

Off

Off

On

On

On

Integrate

On

Off

On

On

Off

On

Off

Off

Off

On

Off

Off

Off

On

On

On

Hold/Measure

On

Off

On

On

Off

On

Off

On

On

Off

Off

Off

Off

Off

On

On

Current Force/Voltage Measure

Irange 0

On

On

Off

Off

On

On

Off

Off

Off

On

On

On

Off

Off

Off

On

Irange 1

On

On

Off

Off

On

On

Off

Off

Off

On

On

Off

On

Off

Off

On

Disable Mode: Output Connected

X

X

X

On

Off

Off

On

Off

Off

On

X

On

Off

Off

Off

On

Verify/Voltage Force

On

On

Off

On

Off

On

Off

Off

Off

On

On

On

Off

Off

Off

On

Verify/Current Force

On

Off

On

Off

On

On

Off

Off

Off

On

On

On

Off

Off

Off

On

Disconnect

X

X

X

On

Off

X

X

On

Off

Off

On

Off

Off

Off

On

Off

DAC2 Select: Enabled

X

X

X

X

X

Off

On

X

X

X

X

X

X

X

X

X

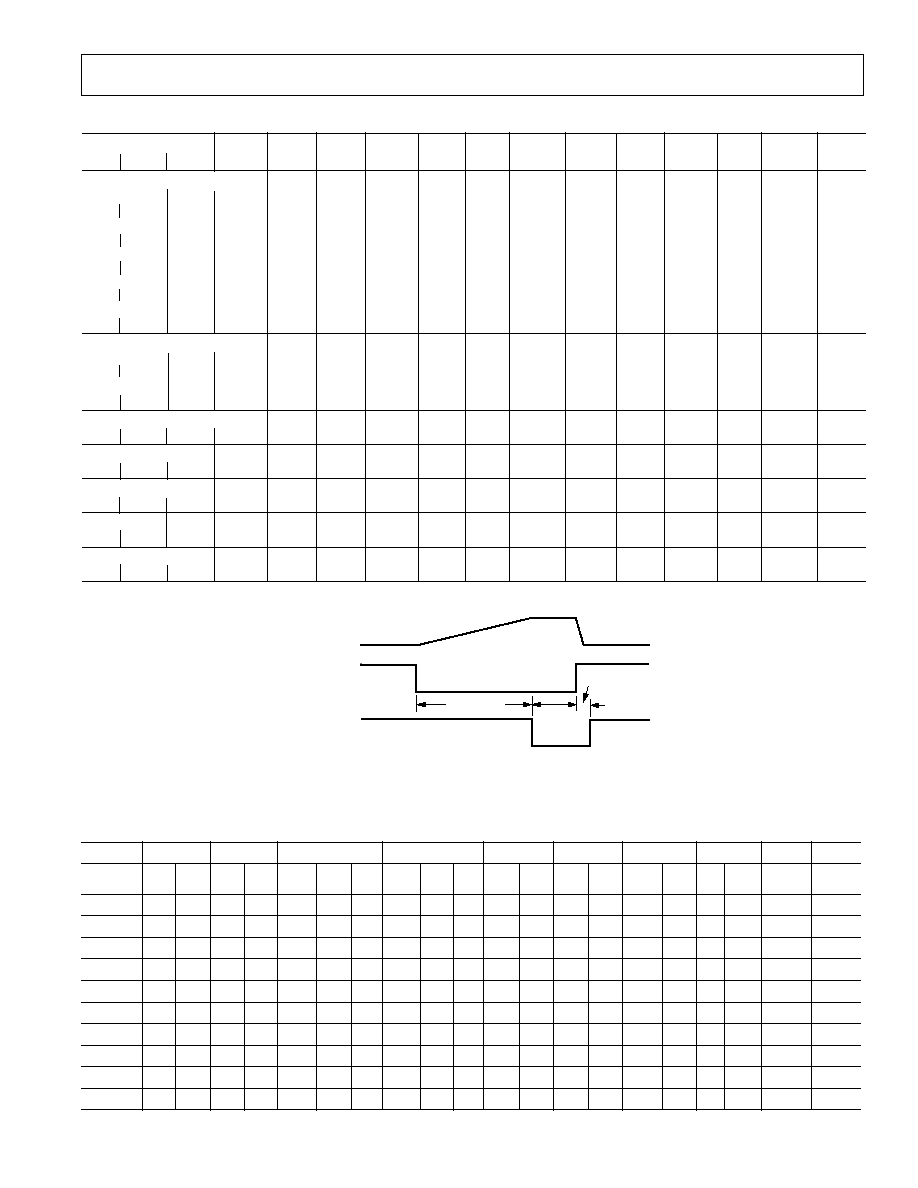

CAPACITOR

CHARGE

INTEGRATE*

HOLD*

INTEGRATE

HOLD

DISCHARGE

CAPACITOR

* = ACTIVE LO

Figure 1. Integrate/Current Measure Timing Diagram

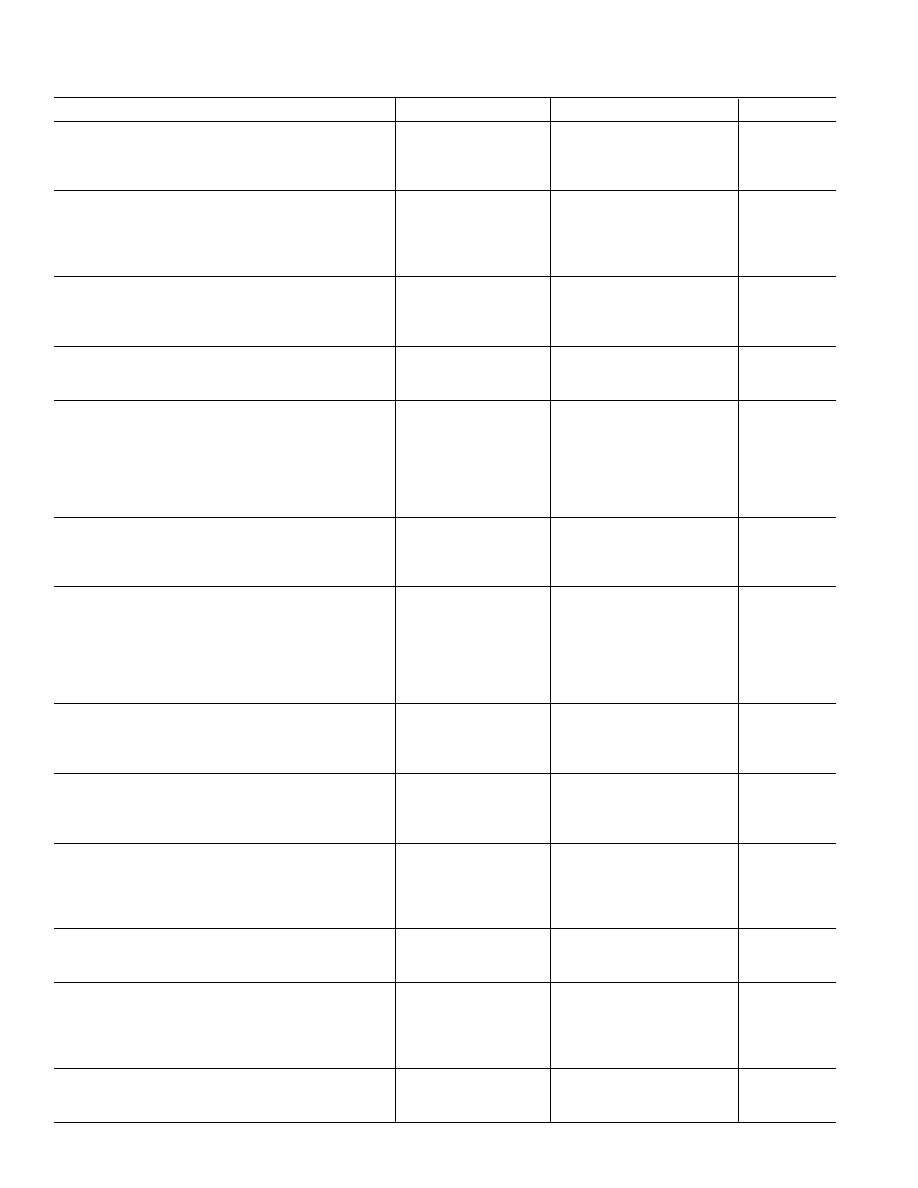

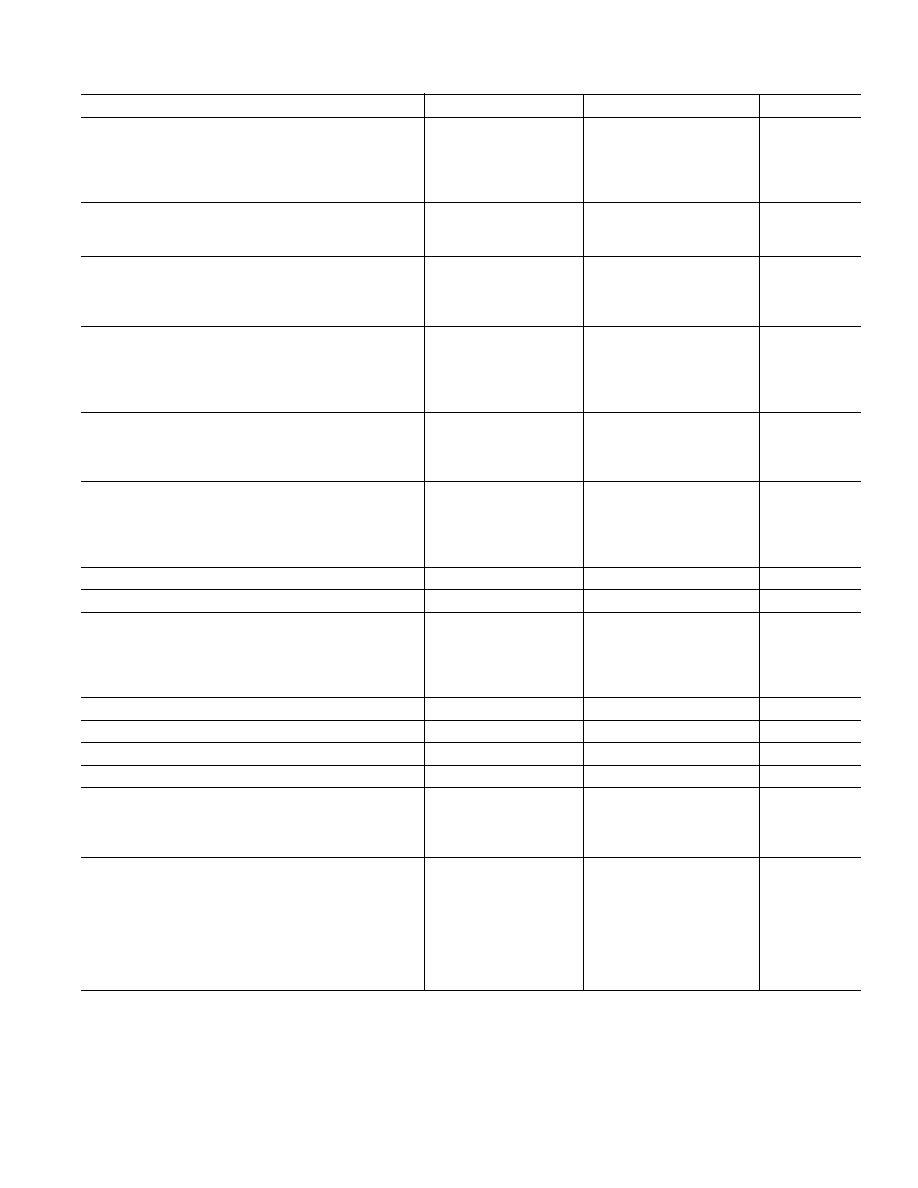

Table II. Truth Table

* = Active LO

FV/MI 2 mA

FV/MI 200 mA

FV/MI Integrate DAC1

FV/MI Integrate DAC 2

FI/MV 2 mA

FI/MV 200

µA

FV/Verify

FI/Verify

Disconnect

Disable

Control

Voltage

Inte-

Voltage

Inte-

Output

Input

DAC1

DAC2

DAC1

DAC2

Settle

grate

Hold

Settle

grate

Hold

DAC1

DAC2

DAC1

DAC2

DAC1

DAC2

DAC1

DAC2

Connected

M_CON*

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

X

X

VERIFY*

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

LO

LO

LO

LO

X

X

FORCE_I*

HI

HI

HI

HI

HI

HI

HI

HI

HI

HI

LO

LO

LO

LO

HI

HI

LO

LO

X

X

FORCE_EN*

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

X

HI

DAC1_SEL*

LO

HI

LO

HI

LO

LO

LO

HI

HI

HI

LO

HI

LO

HI

LO

HI

LO

HI

X

X

INTEG*

HI

HI

HI

HI

HI

LO

LO

HI

LO

LO

HI

HI

HI

HI

HI

HI

HI

HI

X

X

HOLD*

HI

HI

HI

HI

HI

HI

LO

HI

HI

LO

HI

HI

HI

HI

HI

HI

HI

HI

X

X

I_RANGE0*

LO

LO

HI

HI

HI

HI

HI

HI

HI

HI

LO

LO

HI

HI

X

X

X

X

X

X

I_RANGE1*

HI

HI

LO

LO

HI

HI

HI

HI

HI

HI

HI

HI

LO

LO

X

X

X

X

X

X

OUTPUT_CON*

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

HI

LO