| ÐлекÑÑоннÑй компоненÑ: AD592BN | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

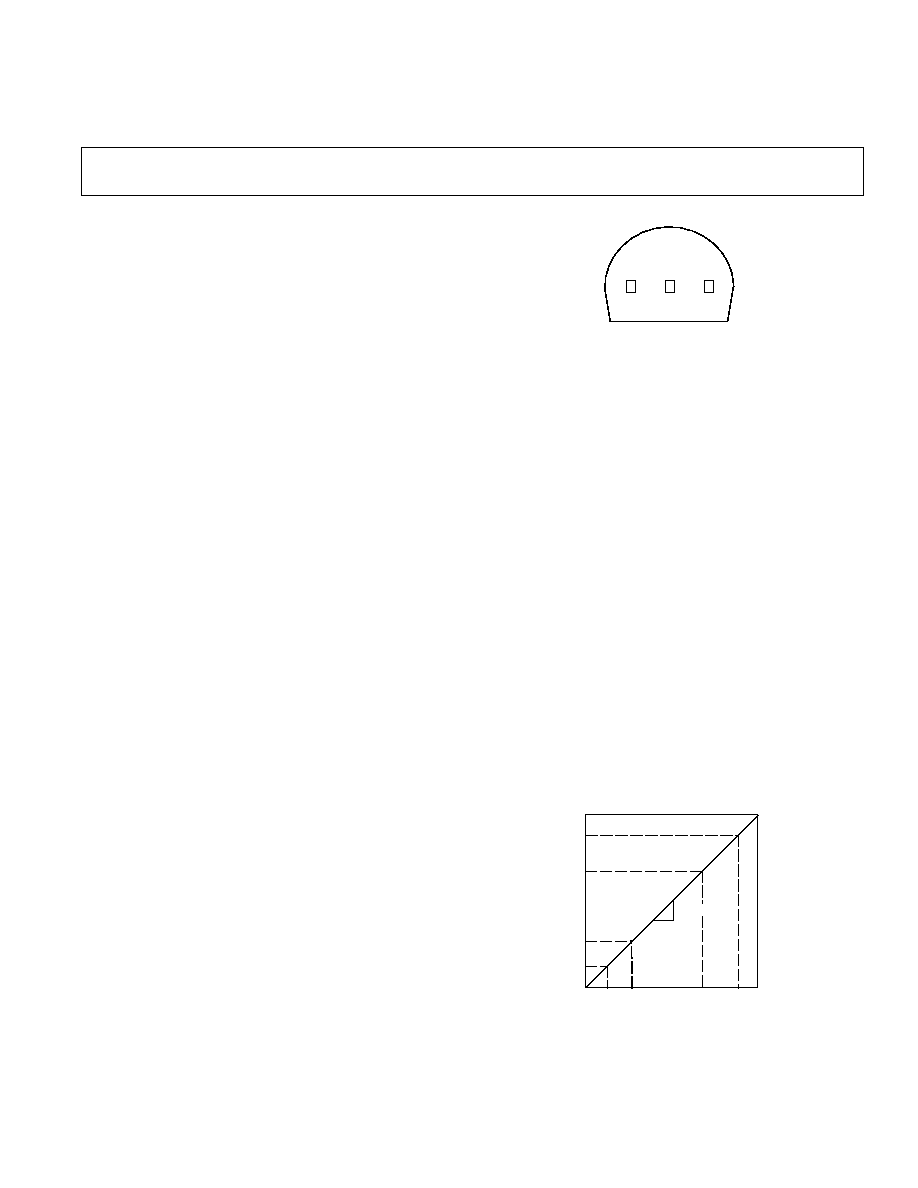

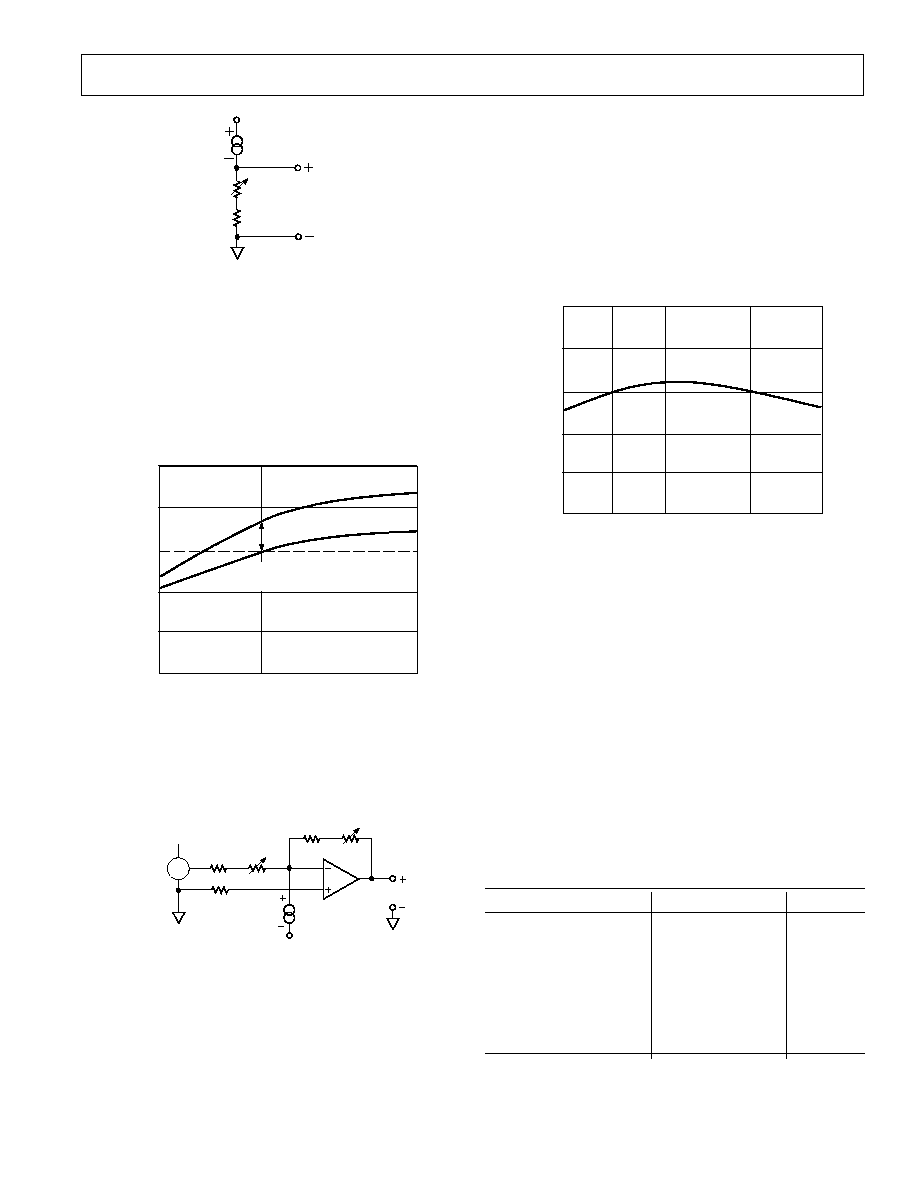

CONNECTION DIAGRAM

PIN 3

PIN 2

PIN 1

()

(NC)

(+)

PIN 2 CAN BE EITHER ATTACHED OR UNCONNECTED

BOTTOM VIEW

*

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

AD592*

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700

Fax: 617/326-8703

Low Cost, Precision IC

Temperature Transducer

FEATURES

High Precalibrated Accuracy: 0.5 C max @ +25 C

Excellent Linearity: 0.15 C max (0 C to +70 C)

Wide Operating Temperature Range: 25 C to +105 C

Single Supply Operation: +4 V to +30 V

Excellent Repeatability and Stability

High Level Output: 1

A/K

Two Terminal Monolithic IC: Temperature In/

Current Out

Minimal Self-Heating Errors

PRODUCT DESCRIPTION

The AD592 is a two terminal monolithic integrated circuit tem-

perature transducer that provides an output current propor-

tional to absolute temperature. For a wide range of supply

voltages the transducer acts as a high impedance temperature

dependent current source of 1

µ

A/K. Improved design and laser

wafer trimming of the IC's thin film resistors allows the AD592

to achieve absolute accuracy levels and nonlinearity errors previ-

ously unattainable at a comparable price.

The AD592 can be employed in applications between 25

°

C

and +105

°

C where conventional temperature sensors (i.e., ther-

mistor, RTD, thermocouple, diode) are currently being used.

The inherent low cost of a monolithic integrated circuit in a

plastic package, combined with a low total parts count in any

given application, make the AD592 the most cost effective tem-

perature transducer currently available. Expensive linearization

circuitry, precision voltage references, bridge components, resis-

tance measuring circuitry and cold junction compensation are

not required with the AD592.

Typical application areas include: appliance temperature sens-

ing, automotive temperature measurement and control, HVAC

(heating/ventilating/air conditioning) system monitoring, indus-

trial temperature control, thermocouple cold junction compen-

sation, board-level electronics temperature diagnostics,

temperature readout options in instrumentation, and tempera-

ture correction circuitry for precision electronics. Particularly

useful in remote sensing applications, the AD592 is immune to

voltage drops and voltage noise over long lines due to its high

impedance current output. AD592s can easily be multiplexed;

the signal current can be switched by a CMOS multiplexer or

the supply voltage can be enabled with a tri-state logic gate.

The AD592 is available in three performance grades: the

AD592AN, AD592BN and AD592CN. All devices are pack-

aged in a plastic TO-92 case rated from 45

°

C to +125

°

C. Per-

formance is specified from 25

°

C to +105

°

C. AD592 chips are

also available, contact the factory for details.

*Protected by Patent No. 4,123,698.

PRODUCT HIGHLIGHTS

1. With a single supply (4 V to 30 V) the AD592 offers

0.5

°

C temperature measurement accuracy.

2. A wide operating temperature range (25

°

C to +105

°

C)

and highly linear output make the AD592 an ideal sub-

stitute for older, more limited sensor technologies (i.e.,

thermistors, RTDs, diodes, thermocouples).

3. The AD592 is electrically rugged; supply irregularities

and variations or reverse voltages up to 20 V will not

damage the device.

4. Because the AD592 is a temperature dependent current

source, it is immune to voltage noise pickup and IR

drops in the signal leads when used remotely.

5. The high output impedance of the AD592 provides

greater than 0.5

°

C/V rejection of supply voltage drift and

ripple.

6. Laser wafer trimming and temperature testing insures

that AD592 units are easily interchangeable.

7. Initial system accuracy will not degrade significantly over

time. The AD592 has proven long term performance

and repeatability advantages inherent in integrated cir-

cuit design and construction.

378

343

273

248

1µA/

o

K

45

25

0

+70

+105 +125

TEMPERATURE

o

C

I

OUT

µA

ORDERING GUIDE

Max Cal

Max Error

Max Nonlinearity

Package

Model

Error @ +25 C

25 C to +105 C

25 C to +105 C

Option

AD592CN

0.5

°

C

1.0

°

C

0.35

°

C

TO-92

AD592BN

1.0

°

C

2.0

°

C

0.4

°

C

TO-92

AD592AN

2.5

°

C

3.5

°

C

0.5

°

C

TO-92

AD592SPECIFICATIONS

AD592AN

AD592BN

AD592CN

Model

Min

Typ

Max

Min

Typ

Max

Min Typ

Max

Units

ACCURACY

Calibration Error @ +25

°

C

1

1.5

2.5

0.7

1.0

0.3

0.5

°

C

T

A

= 0

°

C to +70

°

C

Error over Temperature

1.8

3.0

0.8

1.5

0.4

0.8

°

C

Nonlinearity

2

0.15

0.35

0.1

0.25

0.05

0.15

°

C

T

A

= 25

°

C to +105

°

C

Error over Temperature

3

2.0

3.5

0.9

2.0

0.5

1.0

°

C

Nonlinearity

2

0.25

0.5

0.2

0.4

0.1

0.35

°

C

OUTPUT CHARACTERISTICS

Nominal Current Output

@ +25

°

C (298.2K)

298.2

298.2

298.2

µ

A

Temperature Coefficient

1

1

1

µ

A/

°

C

Repeatability

4

0.1

0.1

0.1

°

C

Long Term Stability

5

0.1

0.1

0.1

°

C/month

ABSOLUTE MAXIMUM RATINGS

Operating Temperature

25

+105

25

+105

25

+105

°

C

Package Temperature

6

45

+125

45

+125

45

+125

°

C

Forward Voltage (+ to )

44

44

44

V

Reverse Voltage ( to +)

20

20

20

V

Lead Temperature

(Soldering 10 sec)

300

300

300

°

C

POWER SUPPLY

Operating Voltage Range

4

30

4

30

4

30

V

Power Supply Rejection

+4 V < V

S

< +5 V

0.5

0.5

0.5

°

C/V

+5 V < V

S

< +15 V

0.2

0.2

0.2

°

C/V

+15 V < V

S

< +30 V

0.1

0.1

0.1

°

C/V

NOTES

1

An external calibration trim can be used to zero the error @ +25

°

C.

2

Defined as the maximum deviation from a mathematically best fit line.

3

Parameter tested on all production units at +105

°

C only. C grade at 25

°

C also.

4

Maximum deviation between +25

°

C readings after a temperature cycle between 45

°

C and +125

°

C. Errors of this type are noncumulative.

5

Operation @ +125

°

C, error over time is noncumulative.

6

Although performance is not specified beyond the operating temperature range, temperature excursions within the package temperature range will not damage the device.

Specifications subject to change without notice.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

(typical @ T

A

= +25 C, V

S

= +5 V, unless otherwise noted)

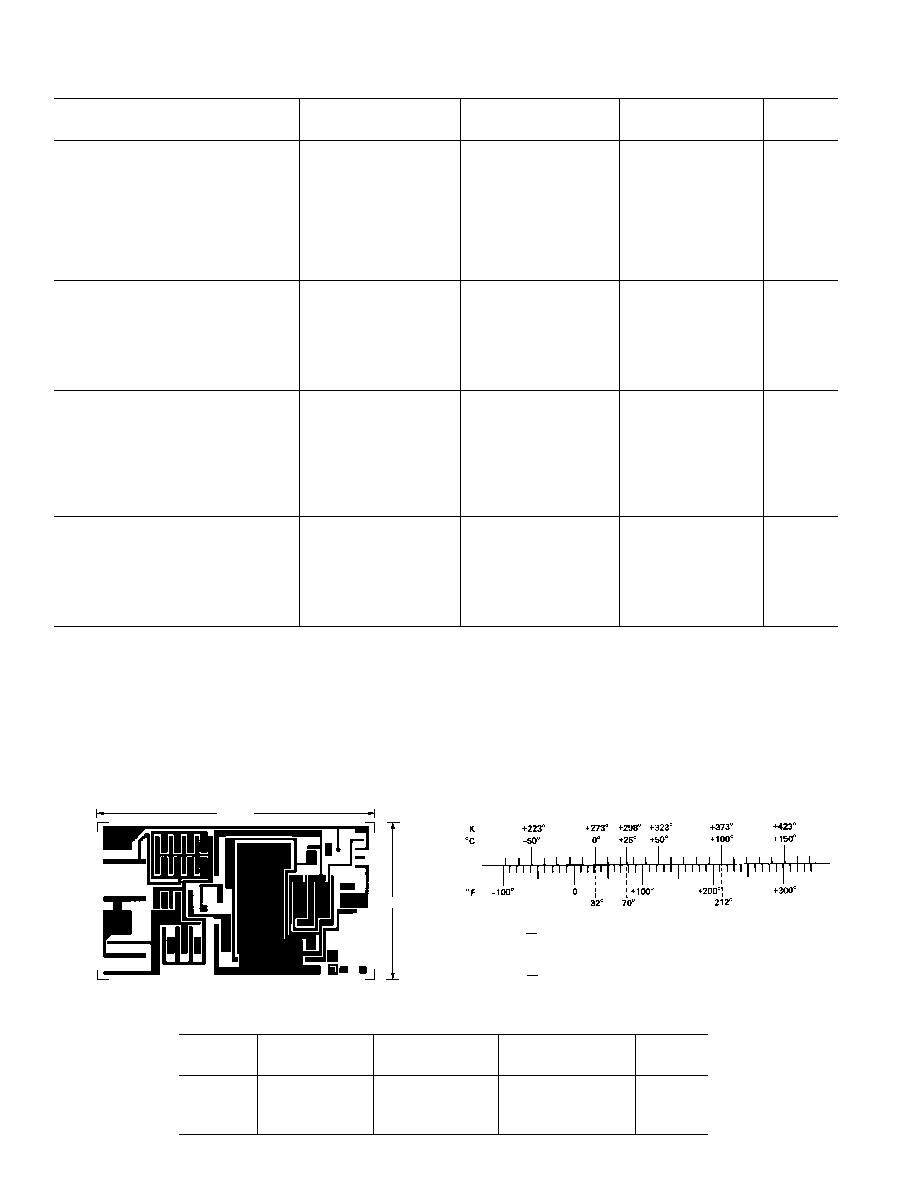

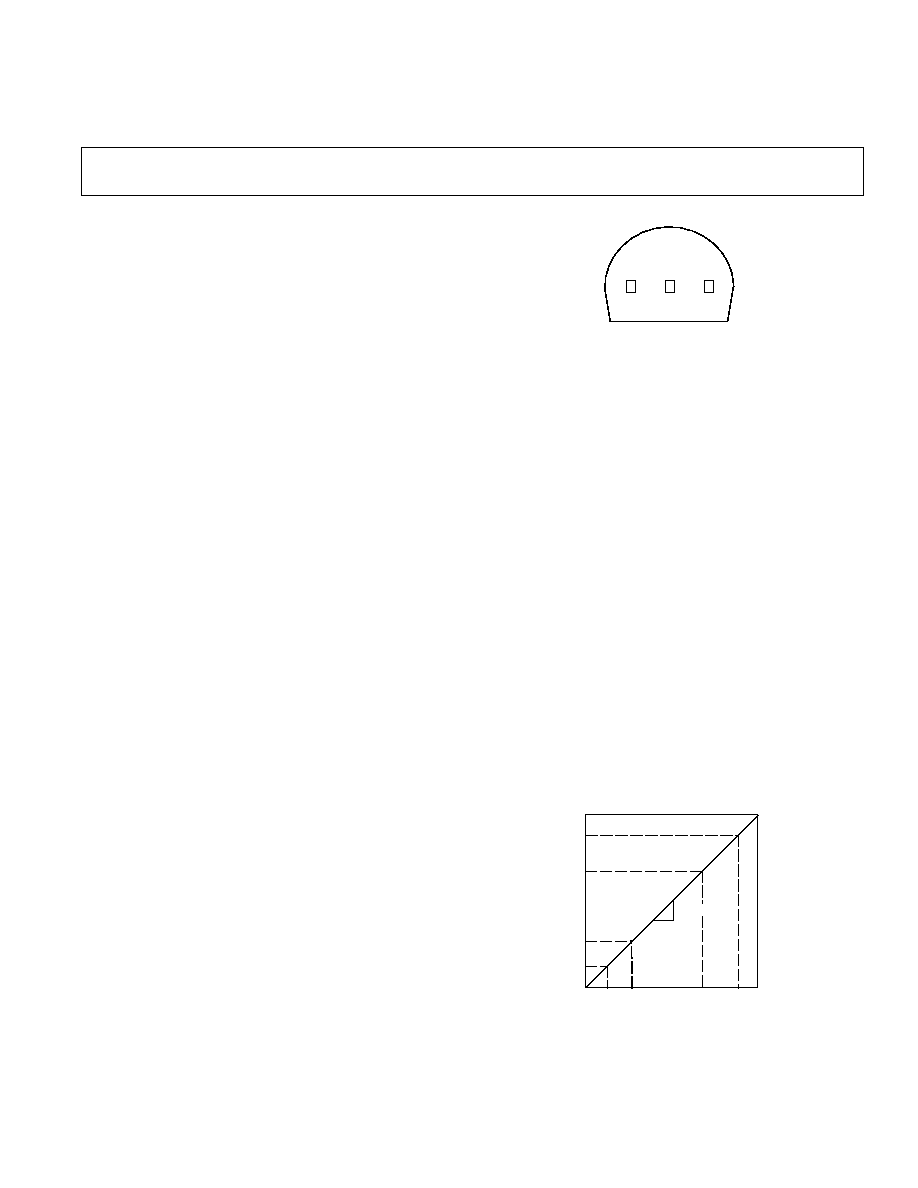

TEMPERATURE SCALE CONVERSION EQUATIONS

METALIZATION DIAGRAM

66MILS

42MILS

V+

V

REV. A

2

°

R =

°

F +459.7

K =

°

C +273.15

C =

5

9

( F 32)

F =

9

5

C +32

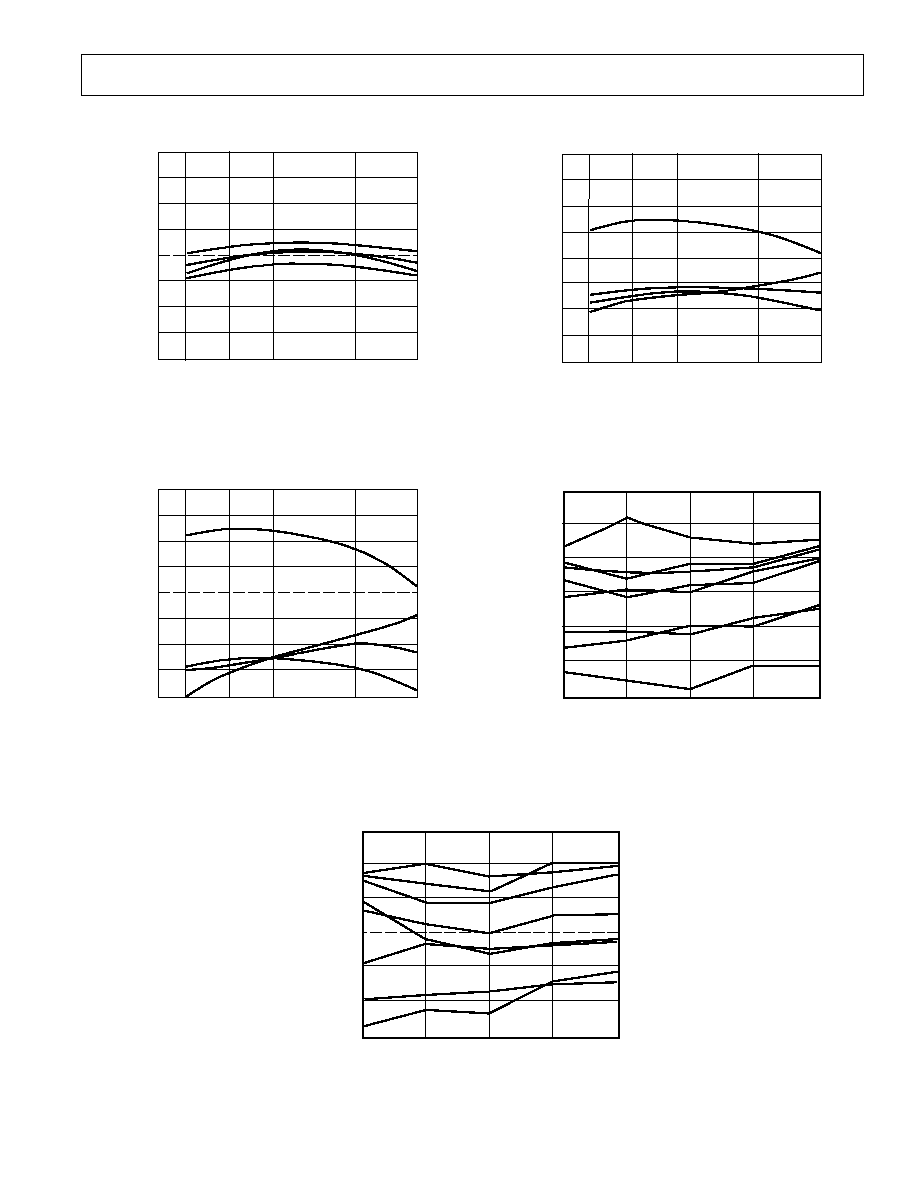

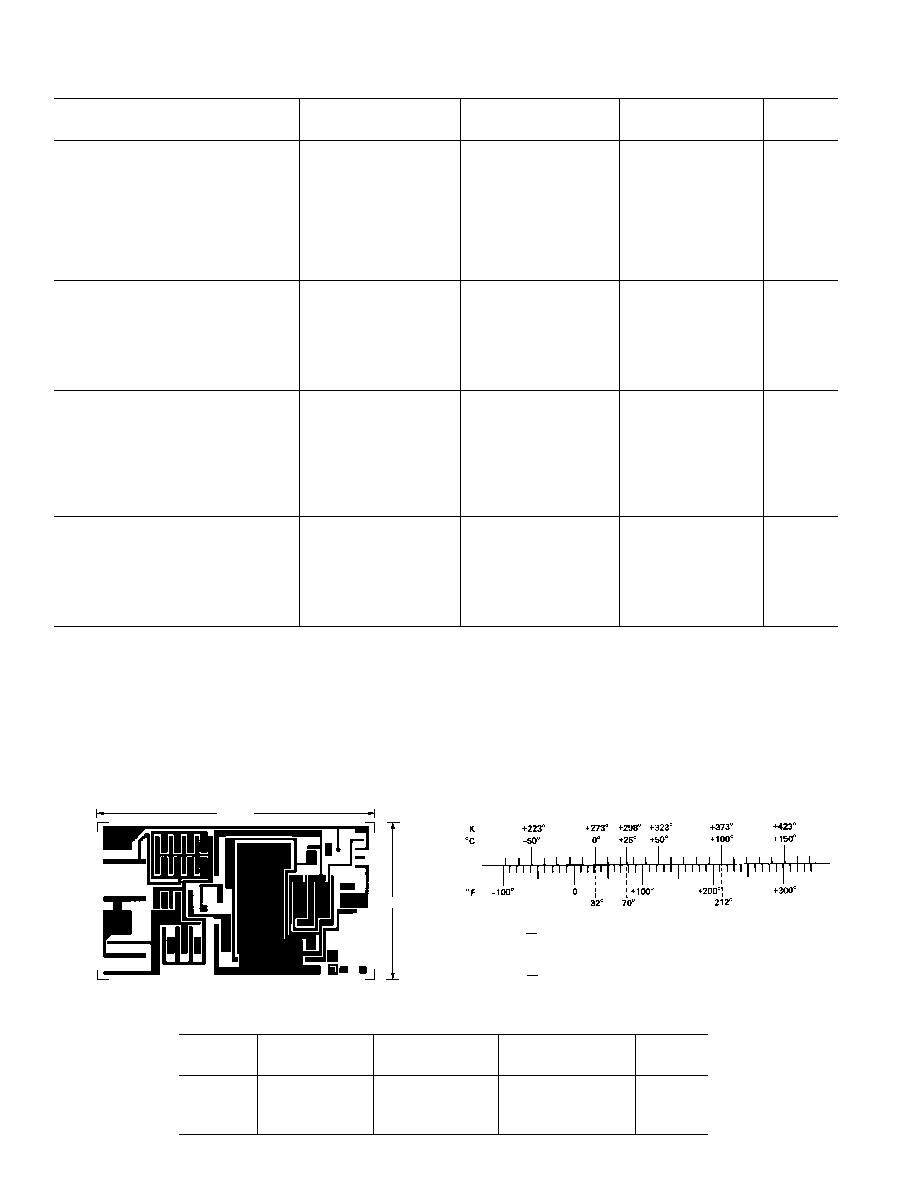

Typical Performance CurvesAD592

Typical @ V

S

= +5 V

TOTAL ERROR

o

C

TEMPERATURE

o

C

25

0

+25

+70

+105

+2.0

+1.5

+1.0

+0.5

0

0.5

1.0

1.5

2.0

AD592CN Accuracy Over Temperature

+2.0

+1.5

+1.0

+0.5

0

0.5

1.0

1.5

2.0

25

0

+25

+70

+105

TEMPERATURE

o

C

TOTAL ERROR

o

C

AD592AN Accuracy Over Temperature

TOTAL ERROR

o

C

TEMPERATURE

o

C

25

0

+25

+70

+105

+2.0

+1.5

+1.0

+0.5

0

0.5

1.0

1.5

2.0

AD592BN Accuracy Over Temperature

0.75

0.50

0.25

0

0.25

0.50

0.75

0

500

1000

1500

2000

TIME Hours

TOTAL ERROR

o

C

Long-Term Stability @ +85

°

C and 85% Relative Humidity

REV. A

3

0.75

0.50

0.25

0

0.25

0.50

0.75

0

500

1000

1500

2000

TIME Hours

TOTAL ERROR

o

C

Long-Term Stability @ +125

°

C

AD592

REV. A

4

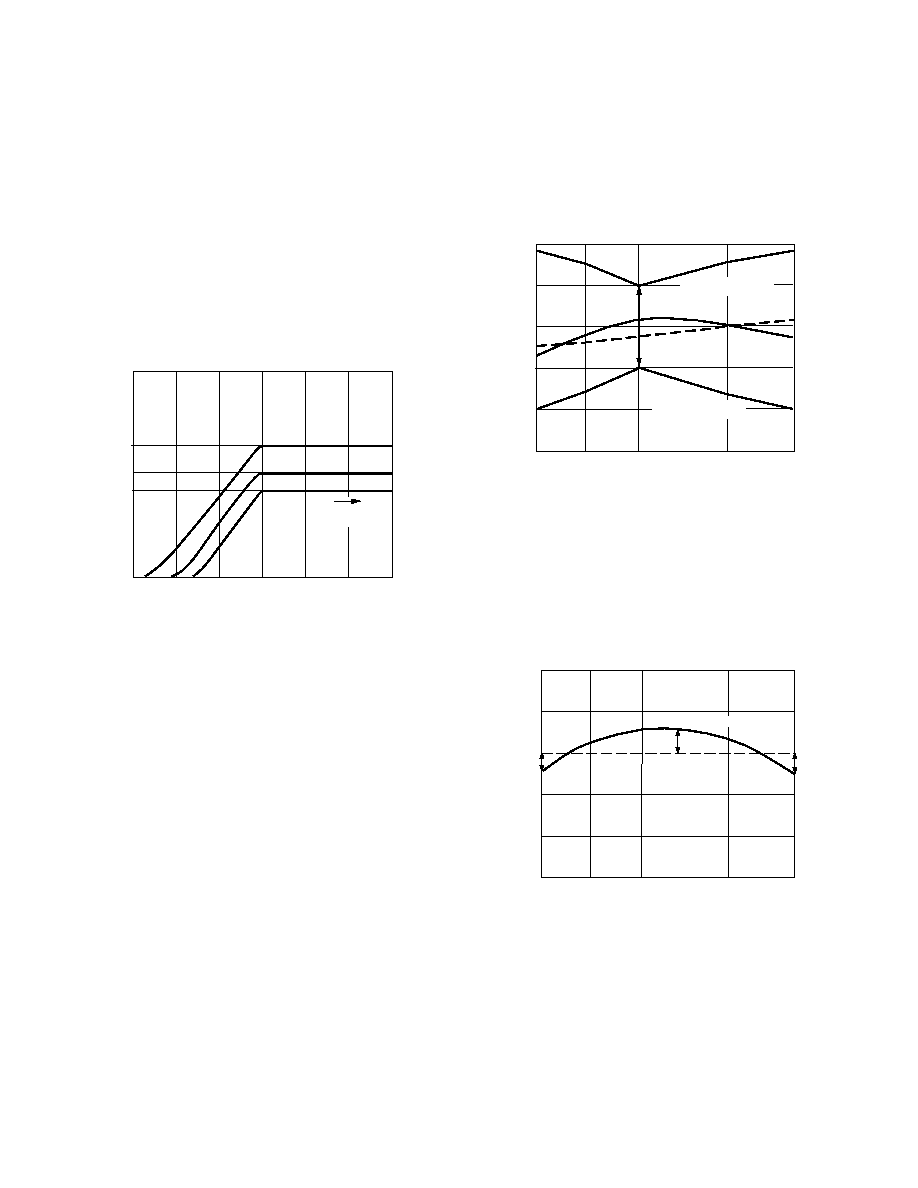

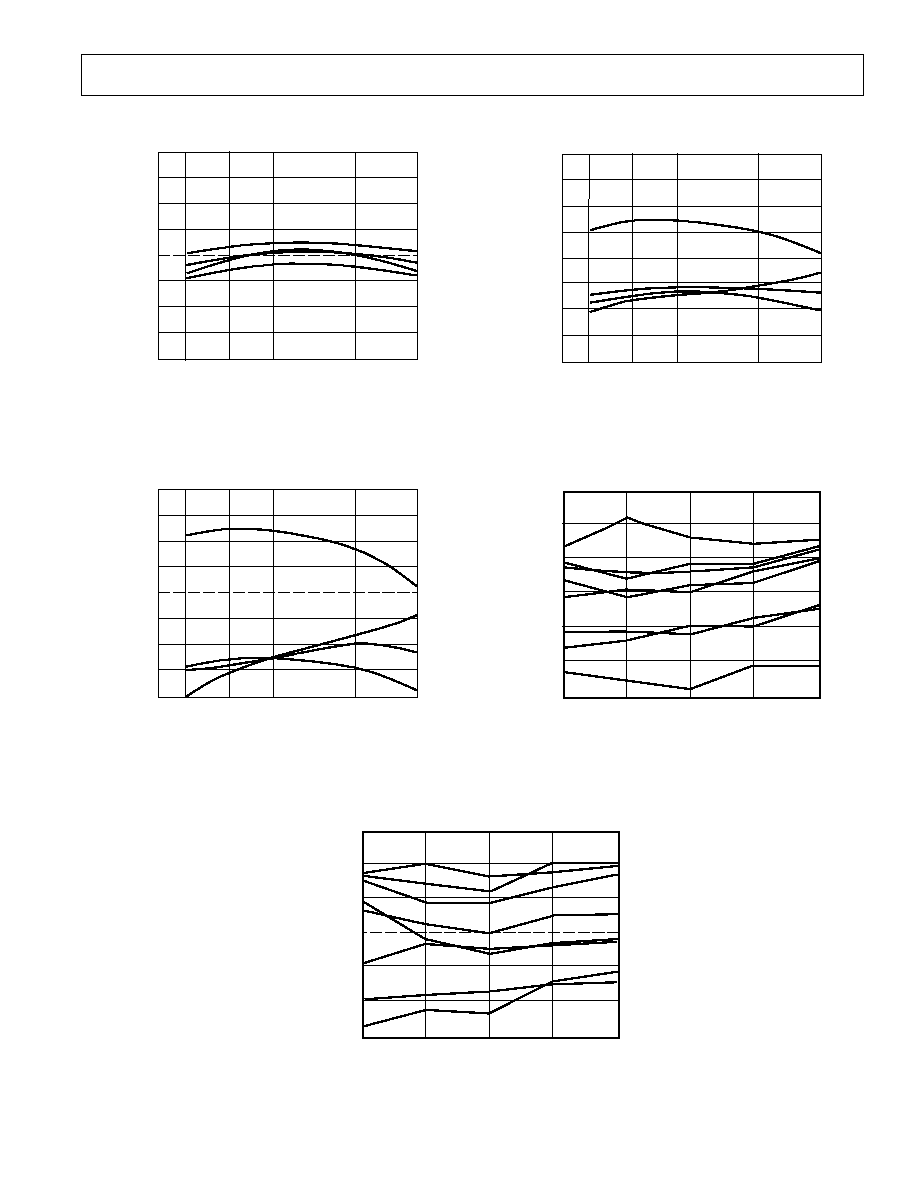

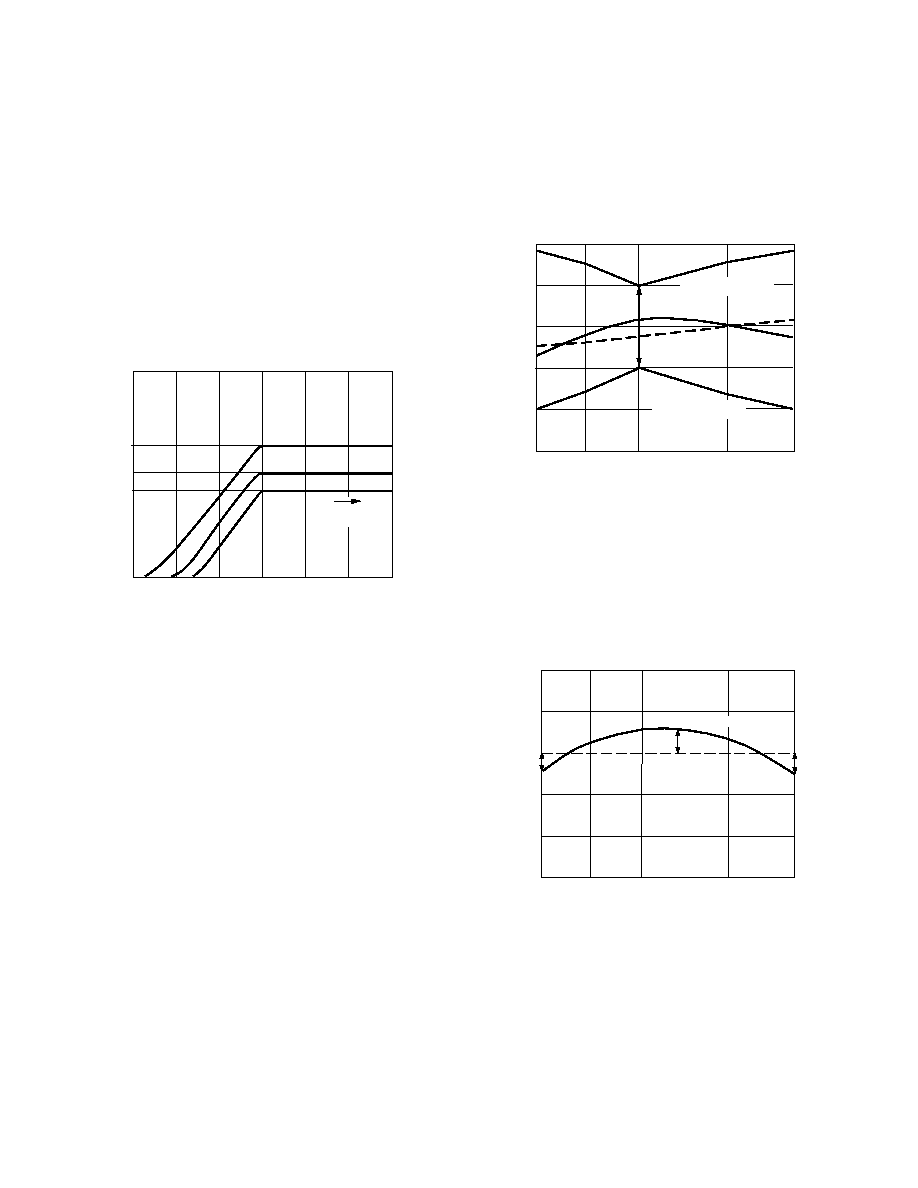

THEORY OF OPERATION

The AD592 uses a fundamental property of silicon transistors

to realize its temperature proportional output. If two identical

transistors are operated at a constant ratio of collector current

densities, r, then the difference in base-emitter voltages will be

(kT/q)(ln r). Since both k, Boltzman's constant and q, the

charge of an electron are constant, the resulting voltage is

directly Proportional To Absolute Temperature (PTAT). In the

AD592 this difference voltage is converted to a PTAT current

by low temperature coefficient thin film resistors. This PTAT

current is then used to force the total output current to be pro-

portional to degrees Kelvin. The result is a current source with

an output equal to a scale factor times the temperature (K) of

the sensor. A typical V-I plot of the circuit at +25

°

C and the

temperature extremes is shown in Figure 1.

SUPPLY VOLTAGE Volts

378

248

0

6

1

I

OUT

µA

2

3

4

5

298

+105

o

C

+25

o

C

25

o

C

UP TO

30V

Figure 1. V-I Characteristics

Factory trimming of the scale factor to 1

µ

A/K is accomplished

at the wafer level by adjusting the AD592's temperature reading

so it corresponds to the actual temperature. During laser trim-

ming the IC is at a temperature within a few degrees of 25

°

C

and is powered by a 5 V supply. The device is then packaged

and automatically temperature tested to specification.

FACTORS AFFECTING AD592 SYSTEM PRECISION

The accuracy limits given on the Specifications page for the

AD592 make it easy to apply in a variety of diverse applications.

To calculate a total error budget in a given system it is impor-

tant to correctly interpret the accuracy specifications, non-

linearity errors, the response of the circuit to supply voltage

variations and the effect of the surrounding thermal environ-

ment. As with other electronic designs external component se-

lection will have a major effect on accuracy.

CALIBRATION ERROR, ABSOLUTE ACCURACY AND

NONLINEARITY SPECIFICATIONS

Three primary limits of error are given for the AD592 such that

the correct grade for any given application can easily be chosen

for the overall level of accuracy required. They are the calibra-

tion accuracy at +25

°

C, and the error over temperature from

0

°

C to +70

°

C and 25

°

C to +105

°

C. These specifications cor-

respond to the actual error the user would see if the current out-

put of an AD592 were converted to a voltage with a precision

resistor. Note that the maximum error at room temperature,

over the commercial IC temperature range, or an extended

range including the boiling point of water, can be directly read

from the specifications table. All three error limits are a combi-

nation of initial error, scale factor variation and nonlinearity de-

viation from the ideal 1

µ

A/K output. Figure 2 graphically

depicts the guaranteed limits of accuracy for an AD592CN.

TEMPERATURE

o

C

+1.0

+0.5

25

+105

0

+25

+70

0

0.5

1.0

TOTAL ERROR

o

C

MAXIMUM ERROR

OVER TEMPERATURE

TYPICAL ERROR

CALIBRATION

ERROR LIMIT

MAXIMUM ERROR

OVER TEMPERATURE

Figure 2. Error Specifications (AD592CN)

The AD592 has a highly linear output in comparison to older

technology sensors (i.e., thermistors, RTDs and thermo-

couples), thus a nonlinearity error specification is separated

from the absolute accuracy given over temperature. As a maxi-

mum deviation from a best-fit straight line this specification rep-

resents the only error which cannot be trimmed out. Figure 3 is

a plot of typical AD592CN nonlinearity over the full rated tem-

perature range.

TYPICAL NONLINEARITY

+0.2

+0.1

25

+105

0

+25

+70

0

0.1

0.2

TEMPERATURE

o

C

NONLINEARITY

o

C

Figure 3. Nonlinearity Error (AD592CN)

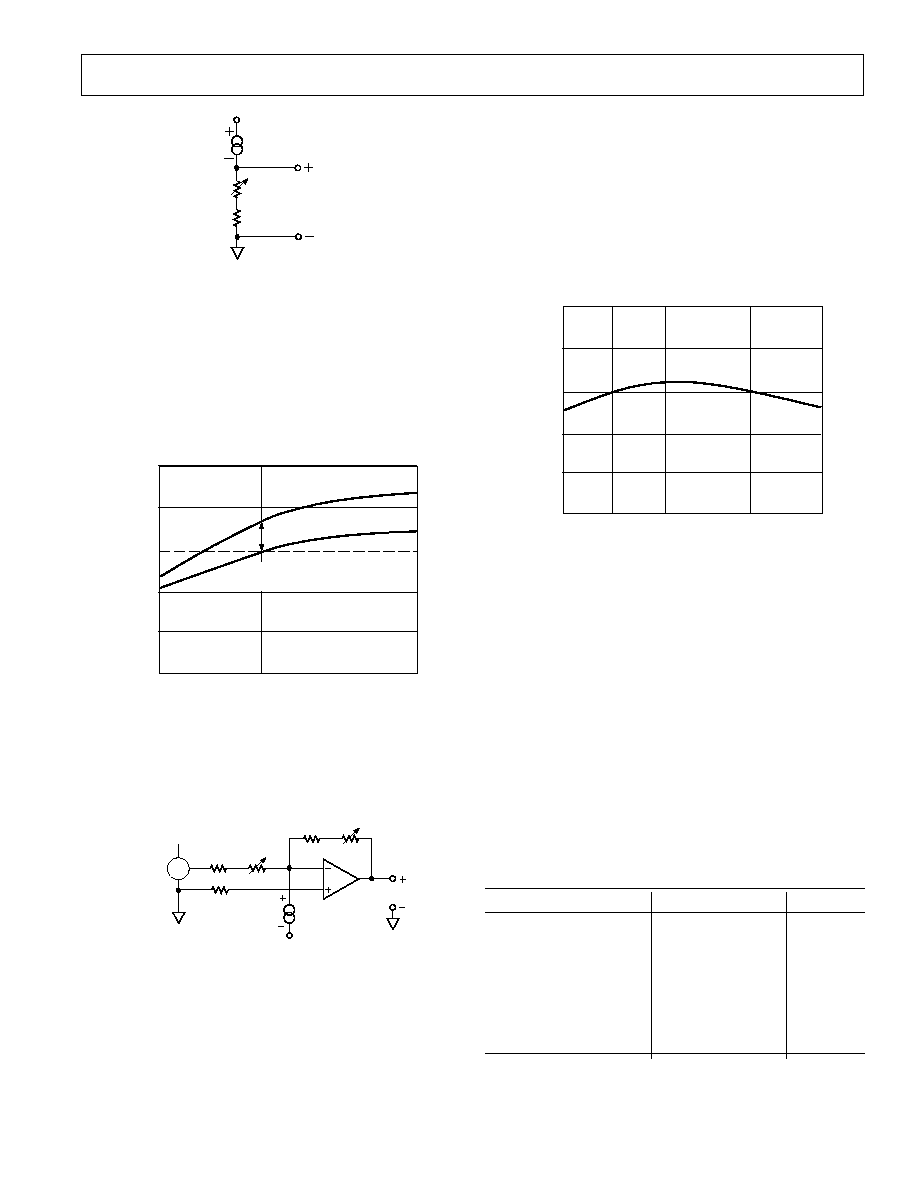

TRIMMING FOR HIGHER ACCURACY

Calibration error at 25

°

C can be removed with a single tempera-

ture trim. Figure 4 shows how to adjust the AD592's scale fac-

tor in the basic voltage output circuit.

AD592

REV. A

5

+V

AD592

R

100

950

V

OUT

= 1mV/K

Figure 4. Basic Voltage Output (Single Temperature Trim)

To trim the circuit the temperature must be measured by a ref-

erence sensor and the value of R should be adjusted so the out-

put (V

OUT

) corresponds to 1 mV/K. Note that the trim

procedure should be implemented as close as possible to the

temperature highest accuracy is desired for. In most applications

if a single temperature trim is desired it can be implemented

where the AD592 current-to-output voltage conversion takes

place (e.g., output resistor, offset to an op amp). Figure 5 illus-

trates the effect on total error when using this technique.

AFTER SINGLE

TEMPERATURE

CALIBRATION

ACCURACY

WITHOUT TRIM

+1.0

+0.5

25

+105

+25

0

0.5

1.0

TEMPERATURE

o

C

TOTAL ERROR

o

C

Figure 5. Effect of Scale Factor Trim on Accuracy

If greater accuracy is desired, initial calibration and scale factor

errors can be removed by using the AD592 in the circuit of

Figure 6.

8.66k

R1

1k

97.6k

R2

5k

7.87k

AD741

V

OUT

= 100mV/

o

C

+5V

AD1403

V

AD592

Figure 6. Two Temperature Trim Circuit

With the transducer at 0

°

C adjustment of R1 for a 0 V output

nulls the initial calibration error and shifts the output from K to

°

C. Tweaking the gain of the circuit at an elevated temperature

by adjusting R2 trims out scale factor error. The only error

remaining over the temperature range being trimmed for is

nonlinearity. A typical plot of two trim accuracy is given in

Figure 7.

SUPPLY VOLTAGE AND THERMAL ENVIRONMENT

EFFECTS

The power supply rejection characteristics of the AD592 mini-

mizes errors due to voltage irregularity, ripple and noise. If a

supply is used other than 5 V (used in factory trimming), the

power supply error can be removed with a single temperature

trim. The PTAT nature of the AD592 will remain unchanged.

The general insensitivity of the output allows the use of lower

cost unregulated supplies and means that a series resistance of

several hundred ohms (e.g., CMOS multiplexer, meter coil

resistance) will not degrade the overall performance.

+2.0

+1.0

25

+105

+25

0

1.0

2.0

TEMPERATURE

o

C

TOTAL ERROR

o

C

0

+75

Figure 7. Typical Two Trim Accuracy

The thermal environment in which the AD592 is used deter-

mines two performance traits: the effect of self-heating on accu-

racy and the response time of the sensor to rapid changes in

temperature. In the first case, a rise in the IC junction tempera-

ture above the ambient temperature is a function of two vari-

ables; the power consumption level of the circuit and the

thermal resistance between the chip and the ambient environ-

ment (

JA

). Self-heating error in

°

C can be derived by multiply-

ing the power dissipation by

JA

. Because errors of this type can

vary widely for surroundings with different heat sinking capaci-

ties it is necessary to specify

JA

under several conditions. Table

I shows how the magnitude of self-heating error varies relative

to the environment. In typical free air applications at +25

°

C

with a 5 V supply the magnitude of the error is 0.2

°

C or less. A

common clip-on heat sink will reduce the error by 25% or more

in critical high temperature, large supply voltage situations.

Table I. Thermal Characteristics

Medium

JA

(

°

C/watt)

(sec)*

Still Air

Without Heat Sink

175

60

With Heat Sink

130

55

Moving Air

Without Heat Sink

60

12

With Heat Sink

40

10

Fluorinert Liquid

35

5

Aluminum Block**

30

2.4

NOTES

*

is an average of five time constants (99.3% of final value). In cases where the

thermal response is not a simple exponential function, the actual thermal re-

sponse may be better than indicated.

**With thermal grease.