| ÐлекÑÑоннÑй компоненÑ: ADXL105J | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

ADXL105 DS

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

ADXL105*

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1999

i

MEM

S

is a registered trademark of Analog Devices, Inc.

*Patent Pending.

FEATURES

Monolithic IC Chip

2 m

g Resolution

10 kHz Bandwidth

Flat Amplitude Response ( 1%) to 5 kHz

Low Bias and Sensitivity Drift

Low Power 2 mA

Output Ratiometric to Supply

User Scalable

g Range

On-Board Temperature Sensor

Uncommitted Amplifier

Surface Mount Package

+2.7 V to +5.25 V Single Supply Operation

1000

g Shock Survival

APPLICATIONS

Automotive

Accurate Tilt Sensing with Fast Response

Machine Health and Vibration Measurement

Affordable Inertial Sensing of Velocity and Position

Seismic Sensing

Rotational Acceleration

GENERAL DESCRIPTION

The ADXL105 is a high performance, high accuracy and com-

plete single-axis acceleration measurement system on a single

monolithic IC. The ADXL105 offers significantly increased

bandwidth and reduced noise versus previously available micro-

machined devices. The ADXL105 measures acceleration with a

full-scale range up to

±

5 g and produces an analog voltage out-

put. Typical noise floor is 225

µ

g

Hz allowing signals below

2 mg to be resolved. A 10 kHz wide frequency response enables

vibration measurement applications. The product exhibits signifi-

cant reduction in offset and sensitivity drift over temperature

compared to the ADXL05.

The ADXL105 can measure both dynamic accelerations, (typi-

cal of vibration) or static accelerations (such as inertial force,

gravity or tilt).

Output scale factors from 250 mV/g to 1.5 V/g are set using the

on-board uncommitted amplifier and external resistors. The

device features an on-board temperature sensor with an output

of 8 mV/

°

C for optional temperature compensation of offset vs.

temperature for high accuracy application.

The ADXL105 is available in a hermetic 14-lead surface mount

Cerpak with versions specified for the 0

°

C to +70

°

C, and

40

°

C to +85

°

C temperature ranges.

High Accuracy 1

g to 5 g Single Axis

i

MEM

S

®

Accelerometer with Analog Input

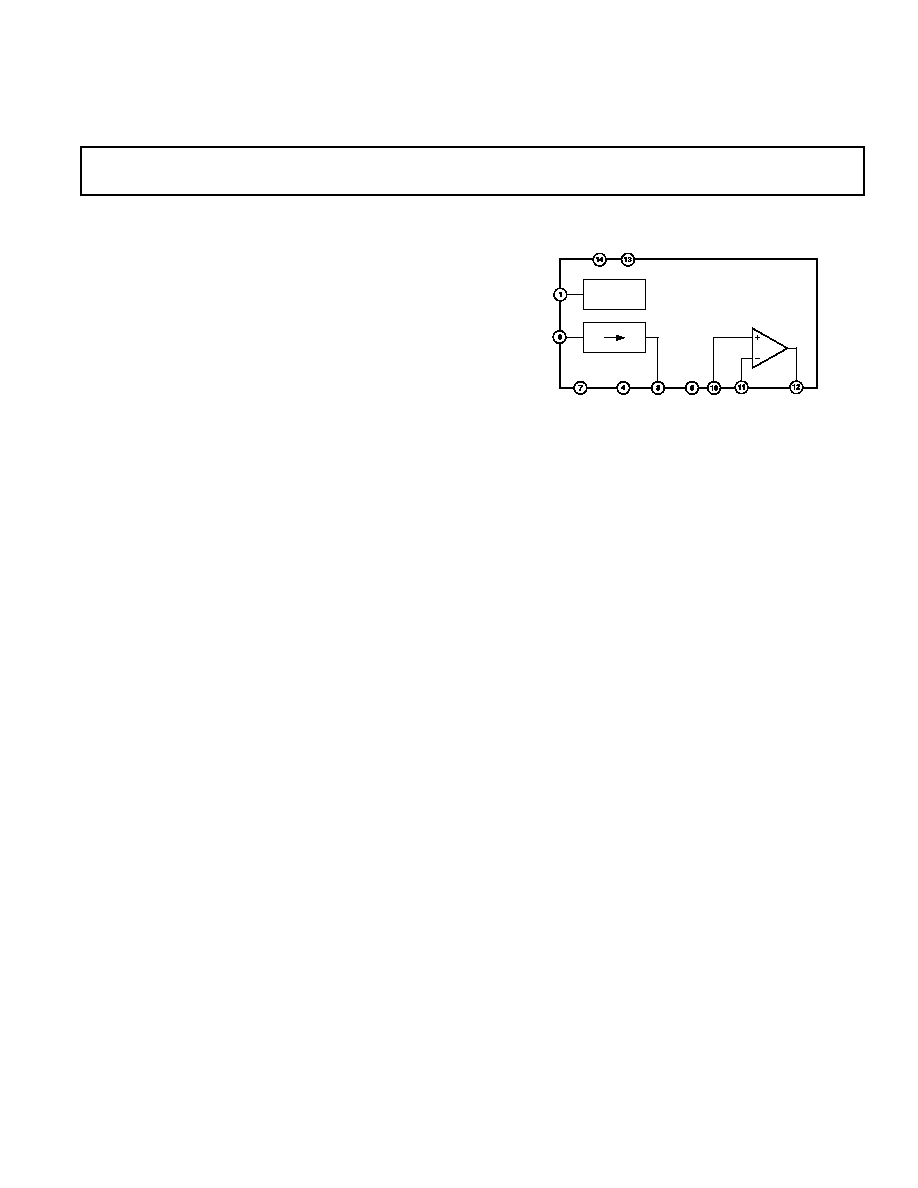

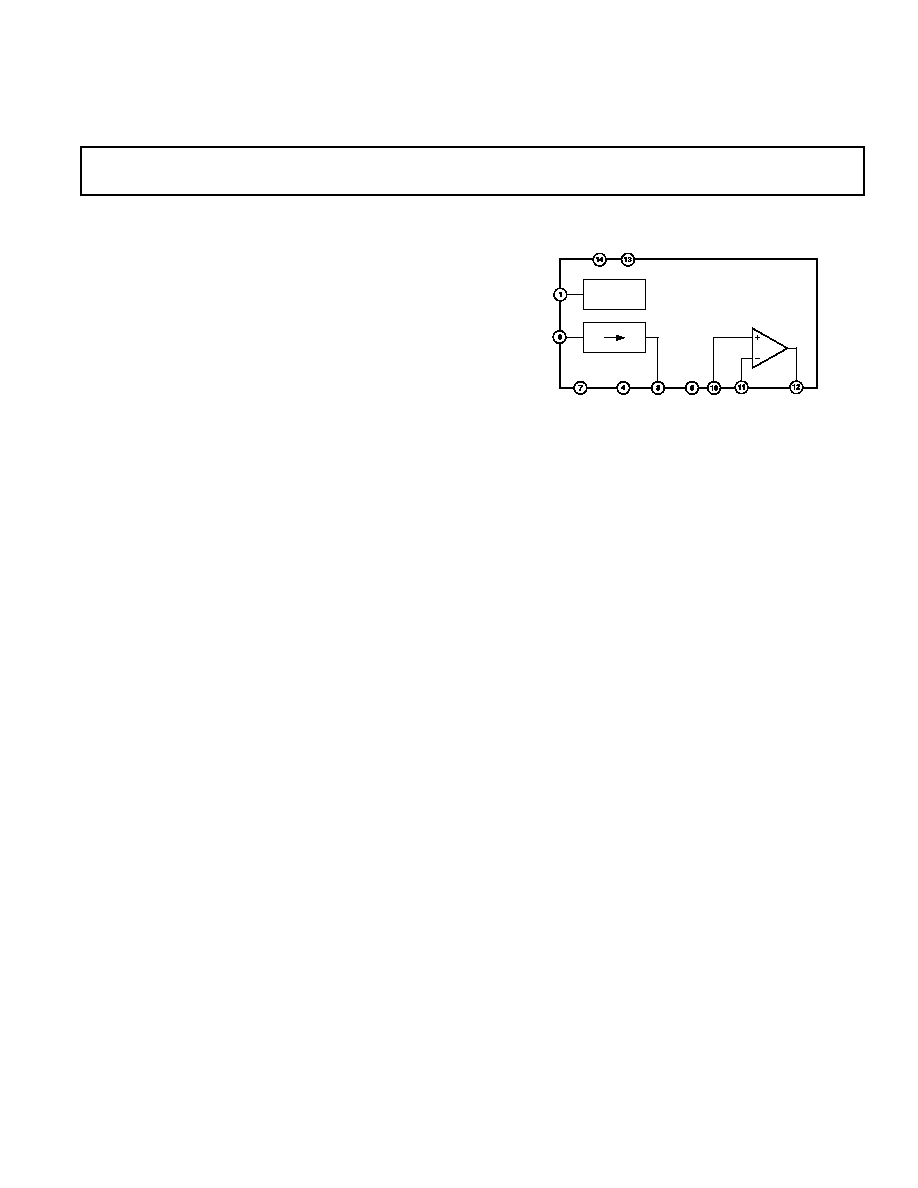

FUNCTIONAL BLOCK DIAGRAM

V

DD

T

OUT

ST

COM

A

OUT

V

MID

V

IN

V

NIN

UCA

OUT

UNCOMMITTED

AMPLIFIER

ADXL105

X SENSOR

TEMP

SENSOR

COM

REV. A

2

ADXL105SPECIFICATIONS

ADXL105J/A

Parameter

Conditions

Min

Typ

Max

Units

SENSOR INPUT

Measurement Range

1

±

5

±

7

g

Nonlinearity

Best Fit Straight Line

0.2

% of FS

Alignment Error

2

±

1

Degrees

Cross Axis Sensitivity

3

Z Axis, @ +25

°

C

±

1

±

5

%

SENSITIVITY

4

(Ratiometric)

At A

OUT

Initial

225

250

275

mV/g

V

S

= 2.7 V

80

105

120

mV/g

vs. Temperature

5, 6

±

0.5

%

ZERO g BIAS LEVEL

5

(Ratiometric)

At A

OUT

Zero g Offset Error

From +2.5 V Nominal

625

+625

mV

vs. Supply

20

+20

mV/V

DD

/V

vs. Temperature

5, 7

50

mV

NOISE PERFORMANCE

Voltage Density

7

@ +25

°

C

225

325

µ

g/

Hz

Noise in 100 Hz Bandwidth

2.25

mg rms

FREQUENCY RESPONSE

3 dB Bandwidth

10

12

kHz

Sensor Resonant Frequency

13

18

kHz

TEMP SENSOR

4

(Ratiometric)

Output Error at +25

°

C

From +2.5 V Nominal

100

+100

mV

Nominal Scale Factor

8

mV/

°

C

Output Impedance

10

k

V

MID

4

(Ratiometric)

Output Error

From +2.5 V Nominal

15

+15

mV

Output Impedance

10

k

SELF-TEST

(Proportional to V

DD

)

Voltage Delta at A

OUT

Self-Test "0" to "1"

100

500

mV

Input Impedance

8

30

50

k

A

OUT

Output Drive

I =

±

50

µ

A

0.50

V

S

0.5

V

Capacitive Load Drive

1000

pF

UNCOMMITTED AMPLIFIER

Initial Offset

25

+25

mV

Initial Offset vs. Temperature

5

µ

V/

°

C

Common-Mode Range

1.0

4.0

V

Input Bias Current

9

25

nA

Open Loop Gain

100

V/mV

Output Drive

I =

±

100

µ

A

0.25

V

S

0.25

V

Capacitive Load Drive

1000

pF

POWER SUPPLY

Operating Voltage Range

2.70

5.25

V

Quiescent Supply Current

At 5.0 V

1.9

2.6

mA

At 2.7 V

1.3

2.0

mA

Turn-On Time

700

µ

s

TEMPERATURE RANGE

Operating Range J

0

+70

°

C

Specified Performance A

40

+85

°

C

NOTES

1

Guaranteed by tests of zero g bias, sensitivity and output swing.

2

Alignment of the X axis is with respect to the long edge of the bottom half of the Cerpak package.

3

Cross axis sensitivity is measured with an applied acceleration in the Z axis of the device.

4

This parameter is ratiometric to the supply voltage V

DD

. Specification is shown with a 5.0 V V

DD

. To calculate approximate values at another V

DD

, multiply the specification by

V

DD

/5 V.

5

Specification refers to the maximum change in parameter from its initial value at +25

°

C to its worst case value at T

MIN

to T

MAX

.

6

See Figure 3.

7

See Figure 2.

8

CMOS and TTL Compatible.

9

UCA input bias current is tested at final test.

All min and max specifications are guaranteed. Typical specifications are not tested or guaranteed.

Specifications subject to change without notice.

(T

A

= T

MIN

to T

MAX

, T

A

= +25 C for J Grade Only, V

S

= +5 V, @ Acceleration = 0

g,

unless otherwise noted)

REV. A

3

ADXL105

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . .1000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . . . 500 g

+V

S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7.0 V

Output Short Circuit Duration

(Any Pin to Common) . . . . . . . . . . . . . . . . . . . . Indefinite

Operating Temperature . . . . . . . . . . . . . . . . 55

°

C to +125

°

C

Storage Temperature . . . . . . . . . . . . . . . . . . 65

°

C to +150

°

C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Package Characteristics

Package

JA

JC

Device Weight

14-Lead Cerpak

110

°

C/W

30

°

C/W

<2 Grams

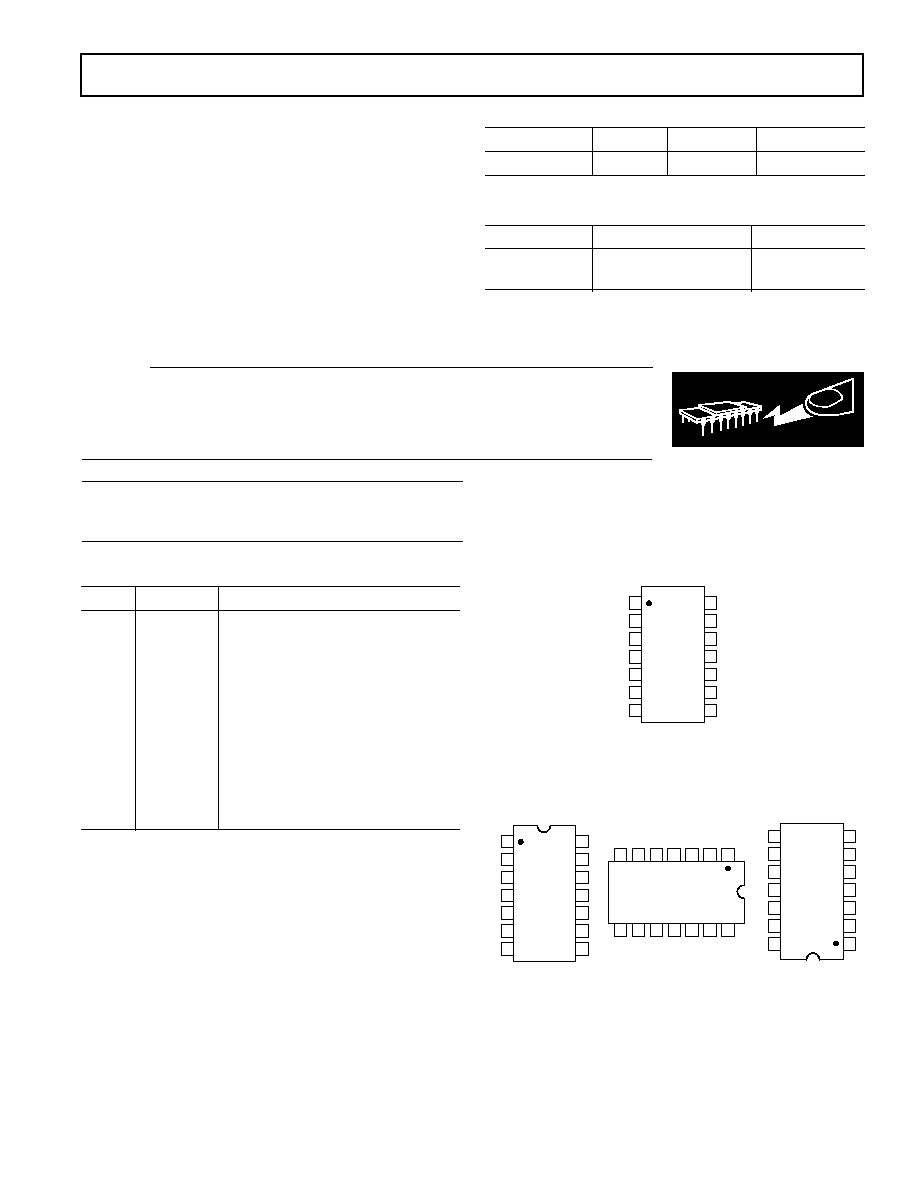

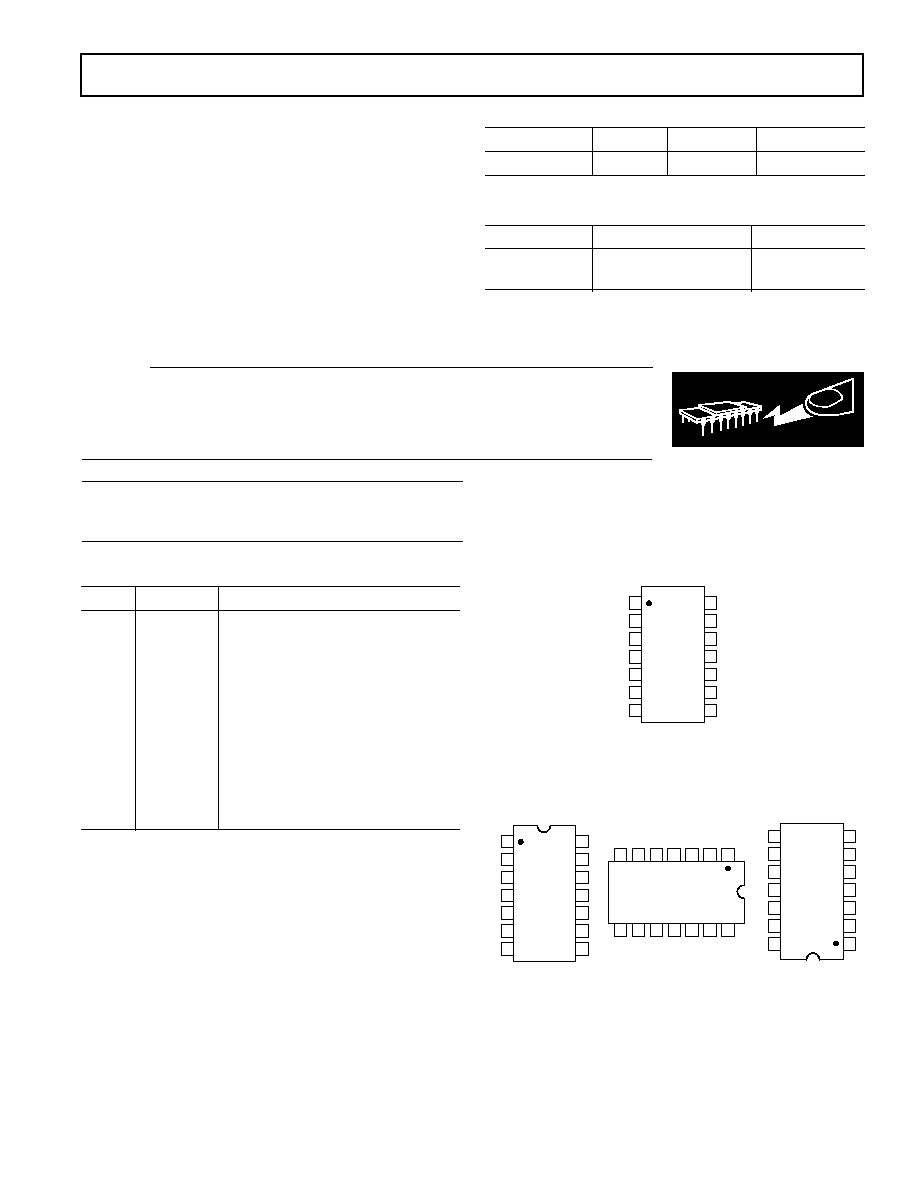

ORDERING GUIDE

Model

Temperature Range

Package Option

ADXL105JQC

0

°

C to +70

°

C

QC-14

ADXL105AQC

40

°

C to +85

°

C

QC-14

PIN FUNCTION DESCRIPTIONS

Pin No.

Name

Description

1

T

OUT

Temperature Sensor Output

2, 3, 5

NC

No Connect

4

COM

Common

6

ST

Self-Test

7

COM

Common (Substrate)

8

A

OUT

Accelerometer Output

9

V

MID

V

DD

/2 Reference Voltage

10

V

NIN

Uncommitted Amp Noninverting Input

11

V

IN

Uncommitted Amp Inverting Input

12

UCA

OUT

Uncommitted Amp Output

13, 14

V

DD

Power Supply Voltage

PIN CONFIGURATION

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL105 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

Drops onto hard surfaces can cause shocks of greater than 1000 g

and exceed the absolute maximum rating of the device. Care should

be exercised in handling to avoid damage.

14

13

12

11

10

9

8

1

2

3

4

5

6

7

14

13

12

11

10

9

8

1

2

3

4

5

6

7

14

13

12

11

10

9

8

1

2

3

4

5

6

7

A

OUT

= 2.75V

A

OUT

= 2.50V

A

OUT

= 2.25V

Figure 1. ADXL105 Response Due to Gravity

TOP VIEW

(Not to Scale)

14

13

12

11

10

9

8

1

2

3

4

5

6

7

NC = NO CONNECT

NC

NC

COM

NC

ST

COM

V

DD

UCA

OUT

V

IN

V

NIN

V

MID

A

OUT

T

OUT

ADXL105

V

DD

REV. A

ADXL105

4

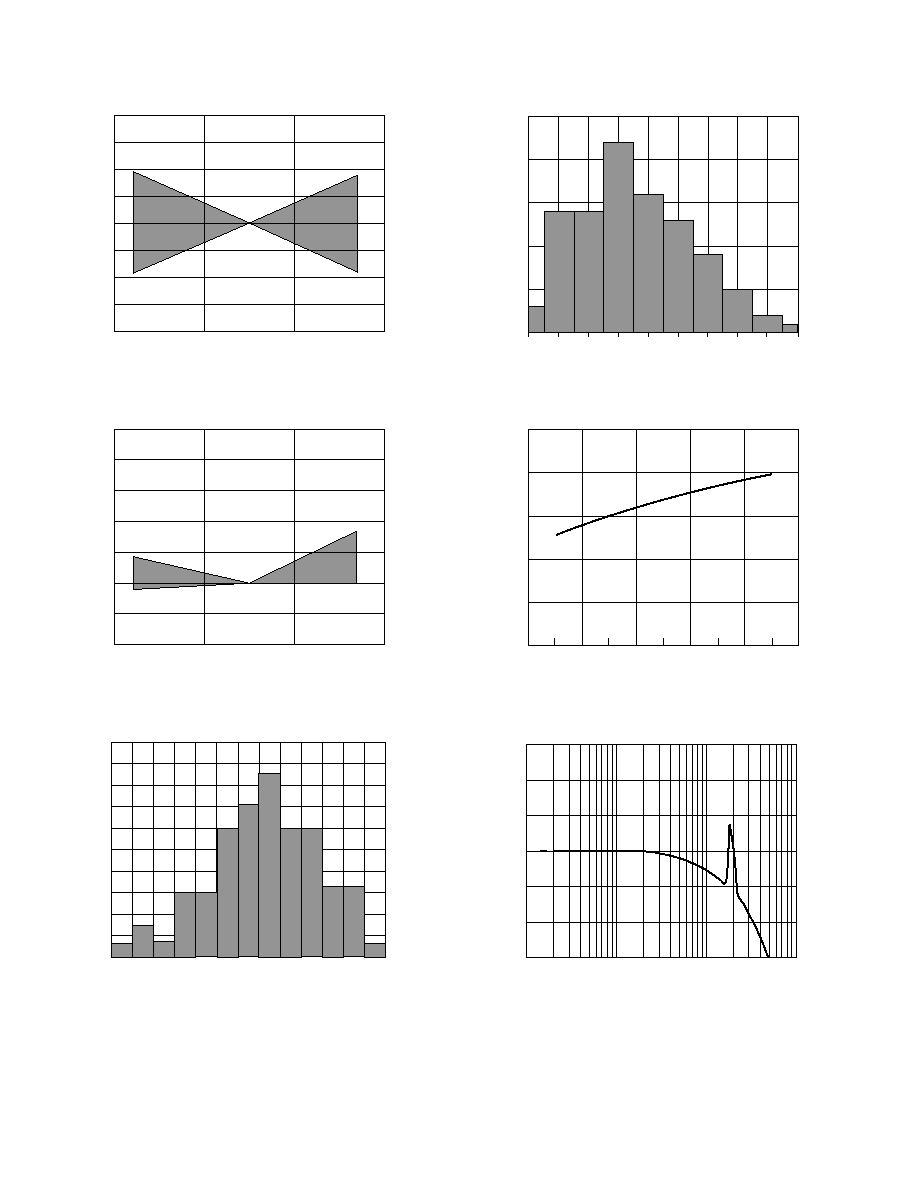

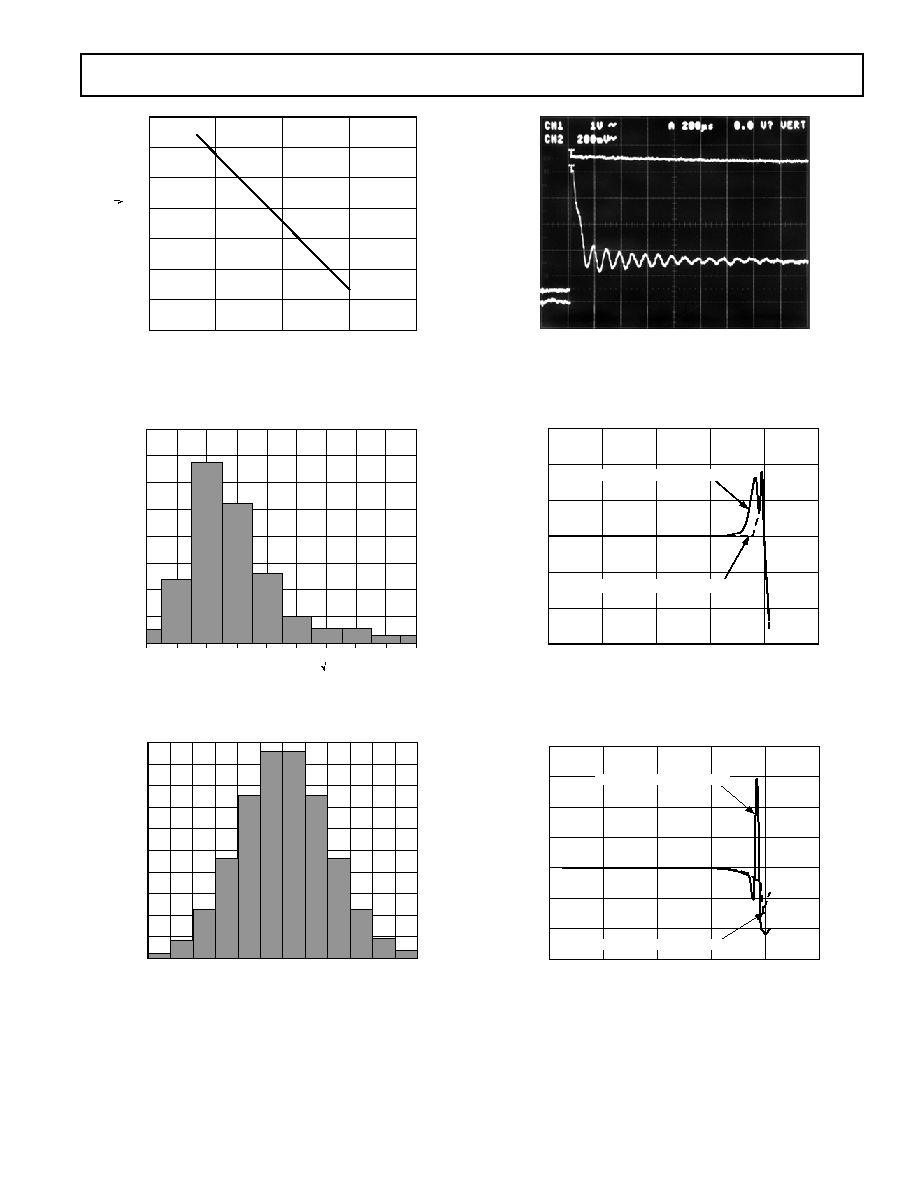

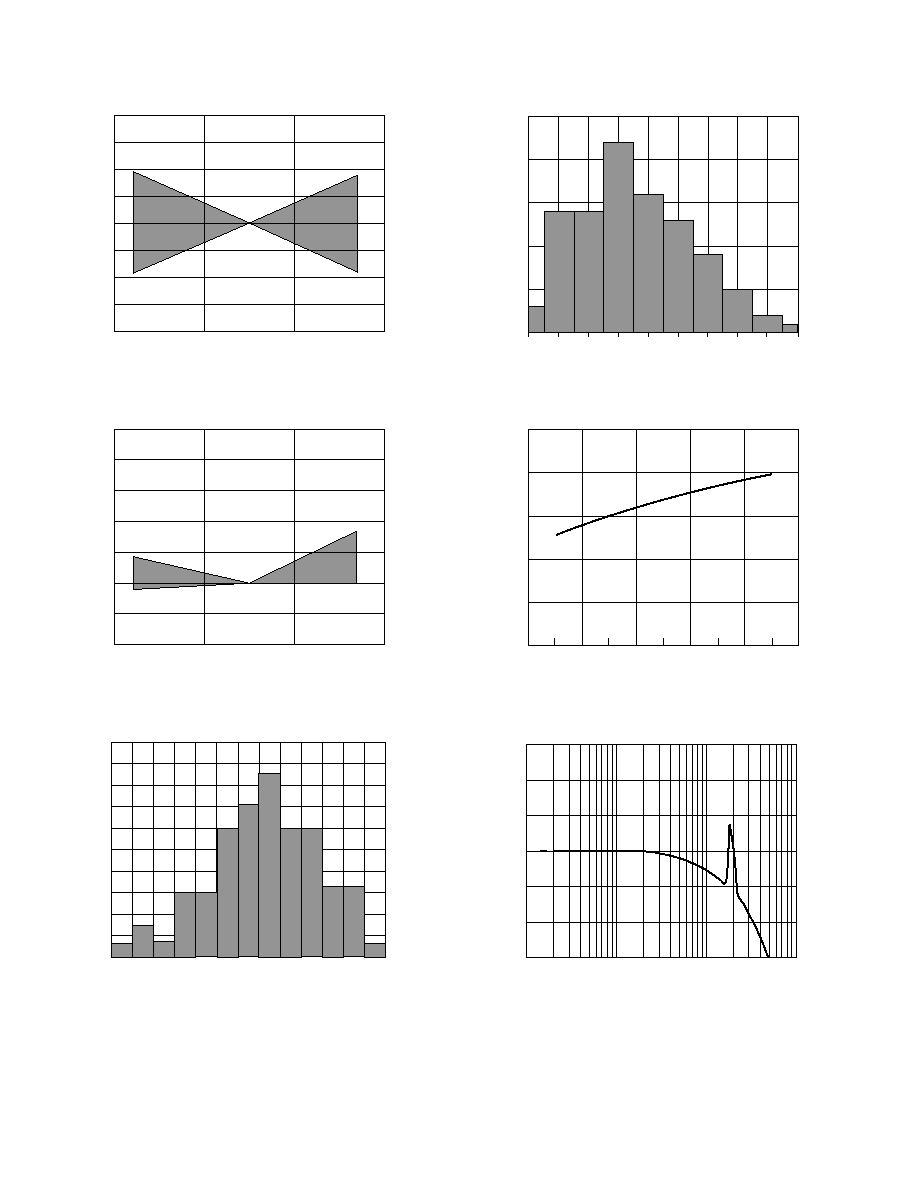

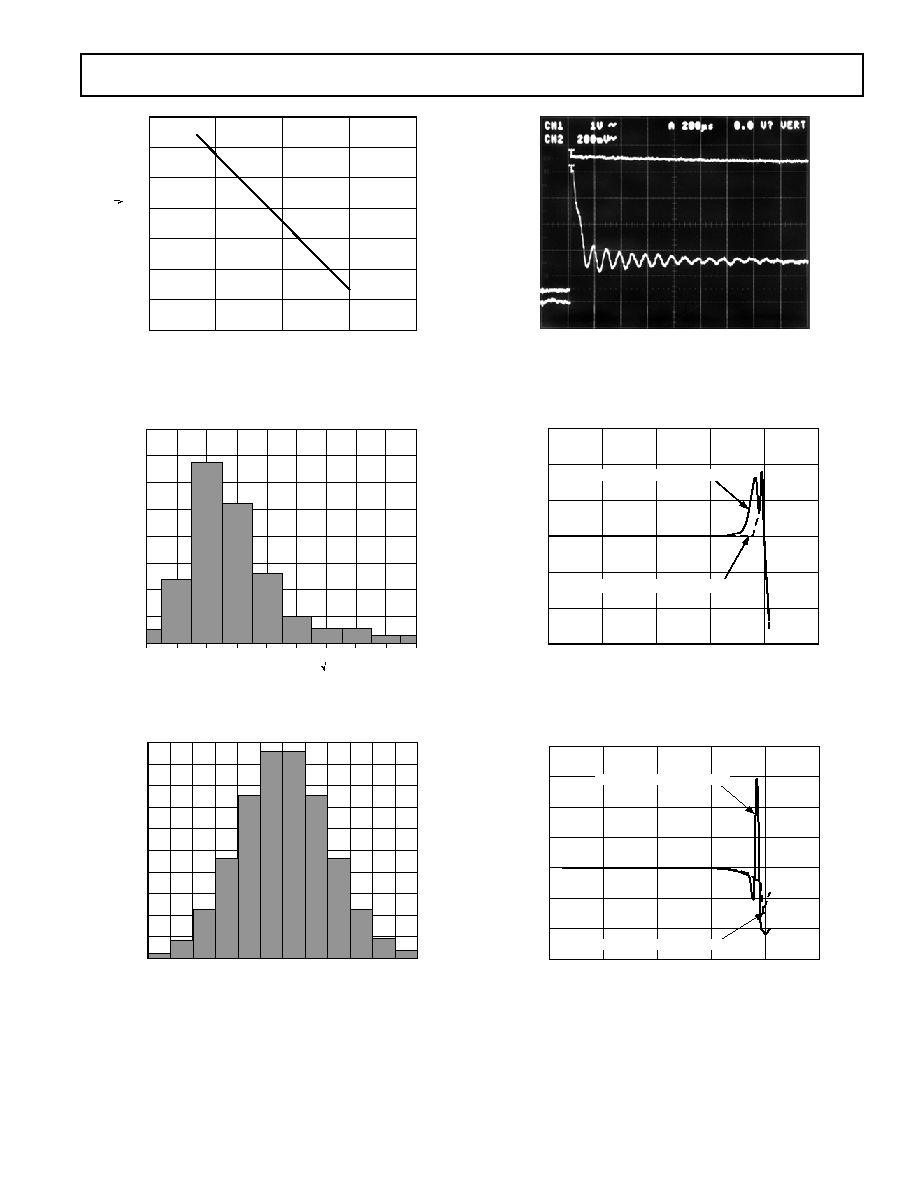

Typical Performance Characteristics

TEMPERATURE C

120

120

50

100

0

g

OFFSET SHIFT mV

0

50

30

0

90

60

30

60

90

Figure 2. Typical 0 g Shift vs. Temperature*

TEMPERATURE C

5

2

50

100

SENSITIVITY CHANGE %

0

50

2

1

4

3

0

1

Figure 3. Typical Sensitivity Shift vs. Temperature*

OUTPUT V

20

6

0

2.2 2.25

% OF UNITS

2.3 2.35 2.4 2.45 2.5 2.55 2.6 2.65 2.7 2.75 2.8

18

8

4

2

14

10

16

12

Figure 4. 0 g Output Distribution*

SENSITIVITY V/

g

25

0

0.242

0.260

0.244

% OF UNITS

0.246 0.248 0.250 0.252 0.254

0.258

10

5

20

15

0.256

Figure 5. Sensitivity Distribution*

SUPPLY VOLTAGE

2.5

0

2.7

5.5

CURRENT mA

3.3

4

1

0.5

2

1.5

5

Figure 6. Typical Supply Current vs. Supply Voltage

FREQUENCY Hz

6

18

100

100000

OUTPUT dB

12

10000

1000

12

0

6

18

Figure 7. Noise Graph

*Data from several characterization lots.

REV. A

5

ADXL105

SUPPLY VOLTAGE

500

2

6

NOISE

g

/

Hz

3

4

5

450

400

350

300

250

200

150

Figure 8. Typical Noise Density vs. Supply Voltage

NOISE DENSITY

g

/

Hz

40

0

205

250

210

% OF UNITS

215

220

225

230

235

245

25

20

35

30

240

15

10

5

Figure 9. Noise Distribution*

DEGREES OF MISALIGNMENT

20

0

1.375

0.625

% OF PARTS

0.375

0.0125

0.0125

0.375

0.625

1.125

14

12

18

16

0.875

10

8

6

0.875

1.125

1.375

4

2

Figure 10. Rotational Die Alignment*

Figure 11. Typical Self-Test Response at V

DD

= 5 V

FREQUENCY Hz

1

10000

OUTPUT dB

10

100

1000

15

10

5

0

5

10

15

100000

ADXL105 SOLDERED AND GLUED TO PCB

ADXL105 SOLDERED TO PCB

Figure 12. Frequency Response

FREQUENCY Hz

1

10000

PHASE Degrees

10

100

1000

400

300

200

100

0

100

200

100000

ADXL105 SOLDERED AND GLUED TO PCB

ADXL105 SOLDERED TO PCB

300

Figure 13. Phase Response

*Data from several characterization lots.

REV. A

ADXL105

6

THEORY OF OPERATION

The ADXL105 is a complete acceleration measurement system

on a single monolithic IC. It contains a polysilicon surface-

micromachined sensor and BiMOS signal conditioning circuitry

to implement an open loop acceleration measurement architec-

ture. The ADXL105 is capable of measuring both positive and

negative accelerations to a maximum level of

±

5 g. The acceler-

ometer also measures static acceleration such as gravity, allow-

ing it to be used as a tilt sensor.

The sensor is a surface micromachined polysilicon structure

built on top of the silicon wafer. Polysilicon springs suspend the

structure over the surface of the wafer and provide a resistance

against acceleration-induced forces. Deflection of the structure

is measured with a differential capacitor structure that consists

of two independent fixed plates and a central plate attached to

the moving mass. A 180

°

out-of-phase square wave drives the

fixed plates. An acceleration causing the beam to deflect, will

unbalance the differential capacitor resulting in an output square

wave whose amplitude is proportional to acceleration. Phase sensi-

tive demodulation techniques are then used to rectify the signal

and determine the direction of the acceleration.

An uncommitted amplifier is supplied for setting the output

scale factor, filtering and other analog signal processing.

A ratiometric voltage output temperature sensor measures the

exact die temperature and can be used for optional calibration

of the accelerometer over temperature.

V

DD

The ADXL105 has two power supply (V

DD

) pins, 13 and 14.

The two pins should be connected directly together. The output

of the ADXL105 is ratiometric to the power supply. Therefore a

0.22

µ

F decoupling capacitor between V

DD

and COM is re-

quired to reduce power supply noise. To further reduce noise,

insert a resistor (and/or a ferrite bead) in series with the V

DD

pin. See the EMC and Electrical Noise section for more details.

COM

The ADXL105 has two common (COM) pins, 4 and 7. These

two pins should be connected directly together and Pin 7

grounded.

ST

The ST pin (Pin 6) controls the self-test feature. When this pin

is set to V

DD

, an electrostatic force is exerted on the beam of the

accelerometer causing the beam to move. The change in output

resulting from movement of the beam allows the user to test for

mechanical and electrical functionality. This pin may be left

open-circuit or connected to common in normal use. The self-

test input is CMOS and TTL compatible.

A

OUT

The accelerometer output (Pin 8) is set to a nominal scale fac-

tor of 250 mV/g (for V

DD

= 5 V). Note that A

OUT

is guaranteed

to source/sink a minimum of 50

µ

A (approximately 50 k

out-

put impedance). So a buffer may be required between A

OUT

and

some A-to-D converter inputs.

V

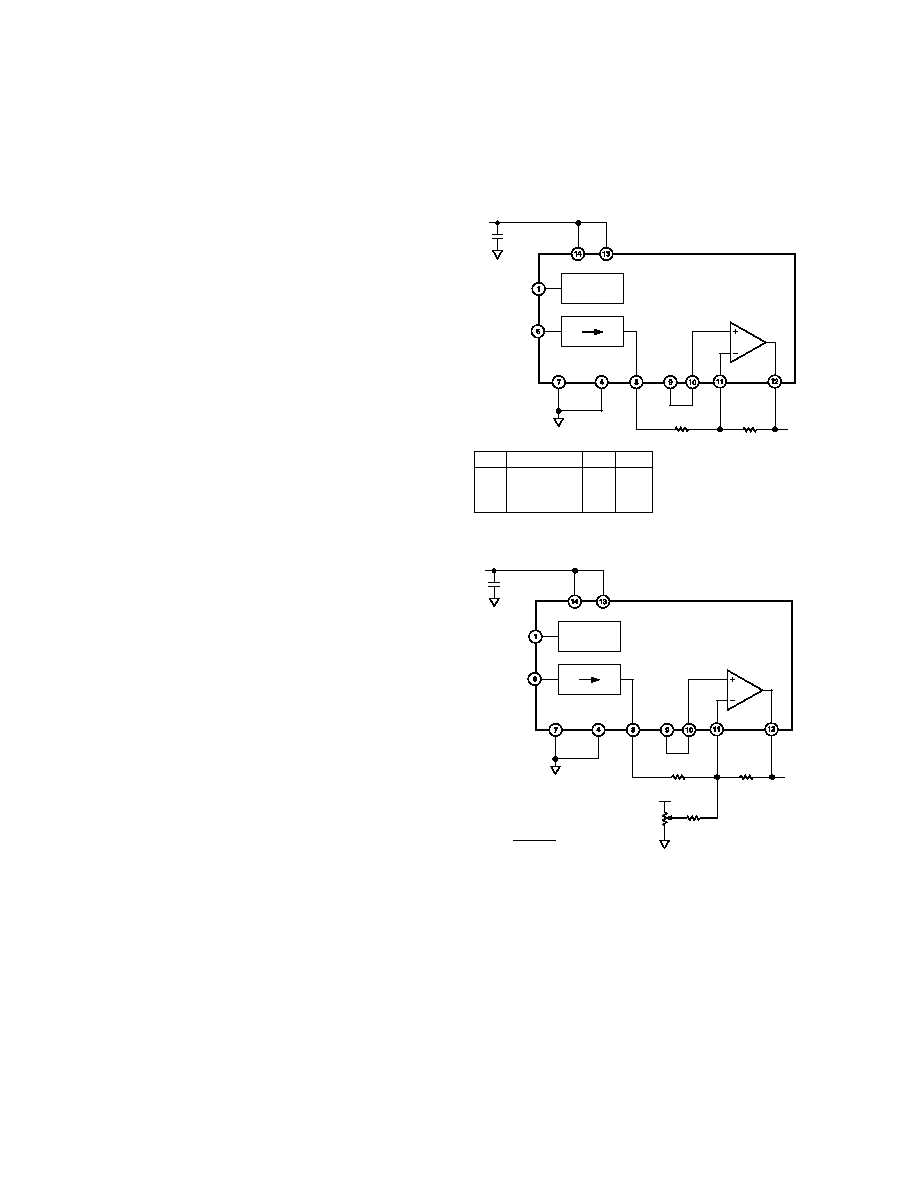

MID

V

MID

is nominally V

DD

/2. It is primarily intended for use as a

reference output for the on board uncommitted amplifier (UCA)

as shown in Figures 14a and 14b. Its output impedance is ap-

proximately 10 k

.

V

DD

T

OUT

ST

COM

A

OUT

V

MID

V

IN

V

NIN

UCA

OUT

UNCOMMITTED

AMPLIFIER

ADXL105

X SENSOR

TEMP

SENSOR

OUTPUT

V

DD

R1

R2

+V

COM

0.22 F

GAIN

1

2

3

4

250

500

750

1000

50k

50k

50k

50k

50k

100k

150k

200k

SCALE mV/

g

R1

R2

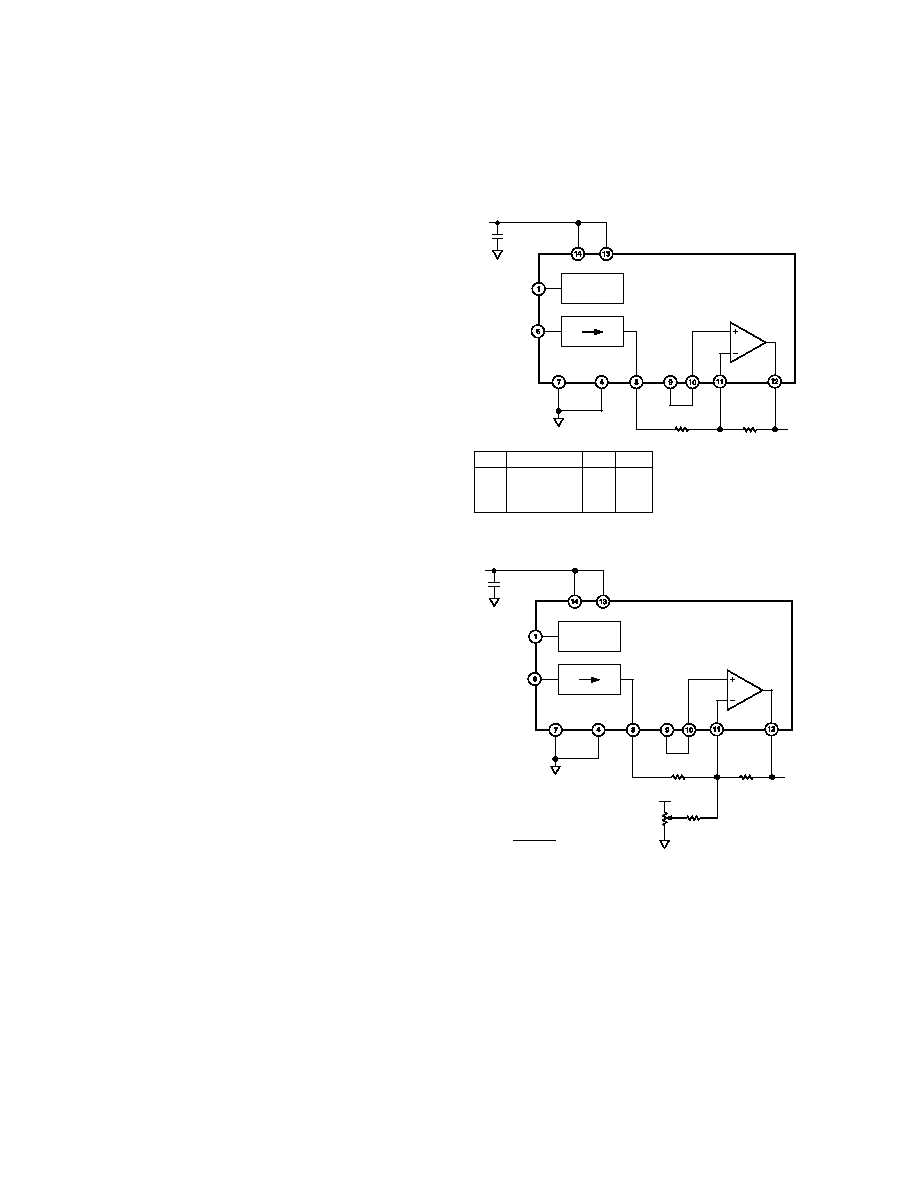

a. Using the UCA to Change the Scale Factor

V

DD

T

OUT

ST

COM

A

OUT

V

MID

V

IN

V

NIN

UCA

OUT

UNCOMMITTED

AMPLIFIER

ADXL105

X SENSOR

TEMP

SENSOR

OUTPUT

V

DD

R1

R2

+V

COM

0.22 F

+V

10k

R3

R3 = 5R1

R1 > 20k

SCALE =

(250) R2

R1

mV/

g

b. Using the UCA to Change the Scale Factor

and Zero g Bias

Figure 14. Application Circuit for Increasing Scale Factor

T

OUT

The temperature sensor output is nominally 2.5 V at +25

°

C and

typically changes 8 mV/

°

C, and is optimized for repeatability

rather than accuracy. The output is ratiometric with supply

voltage.

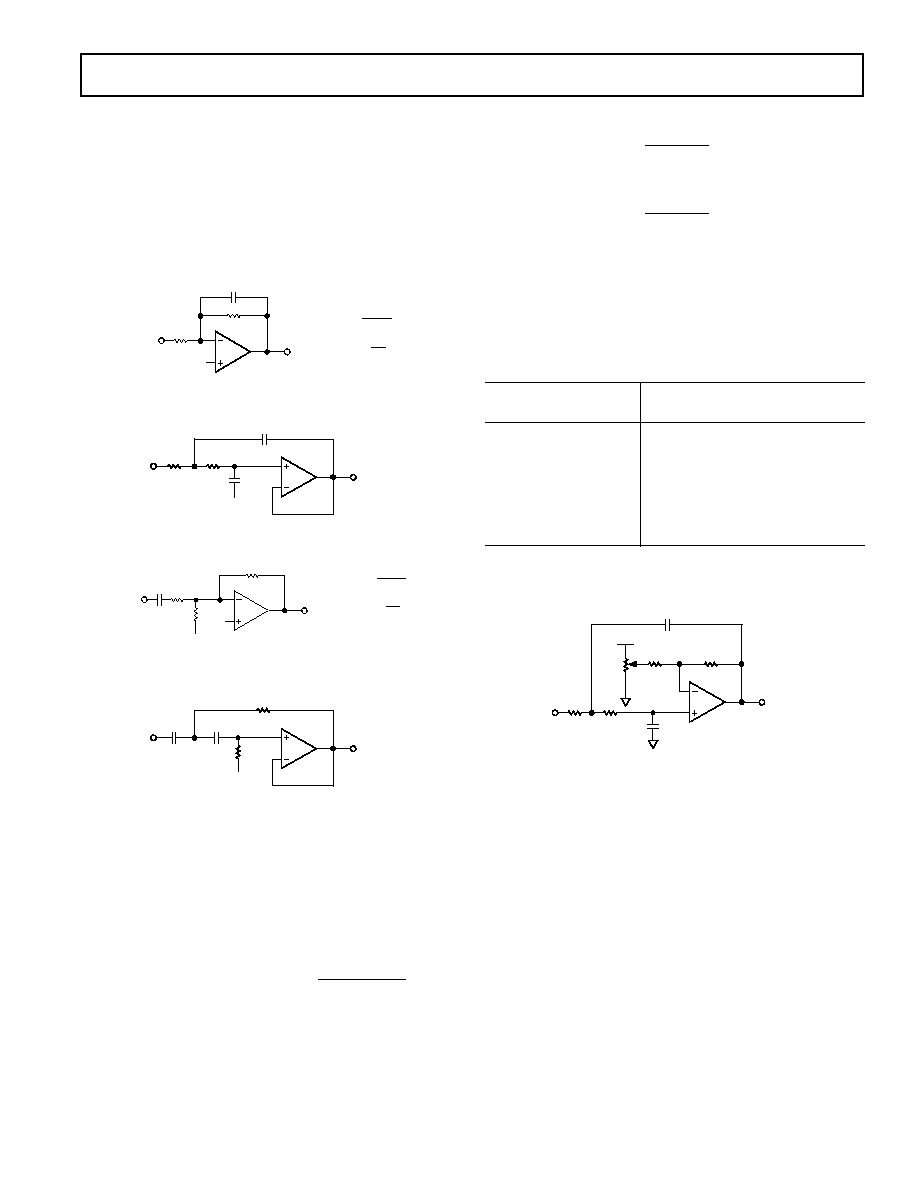

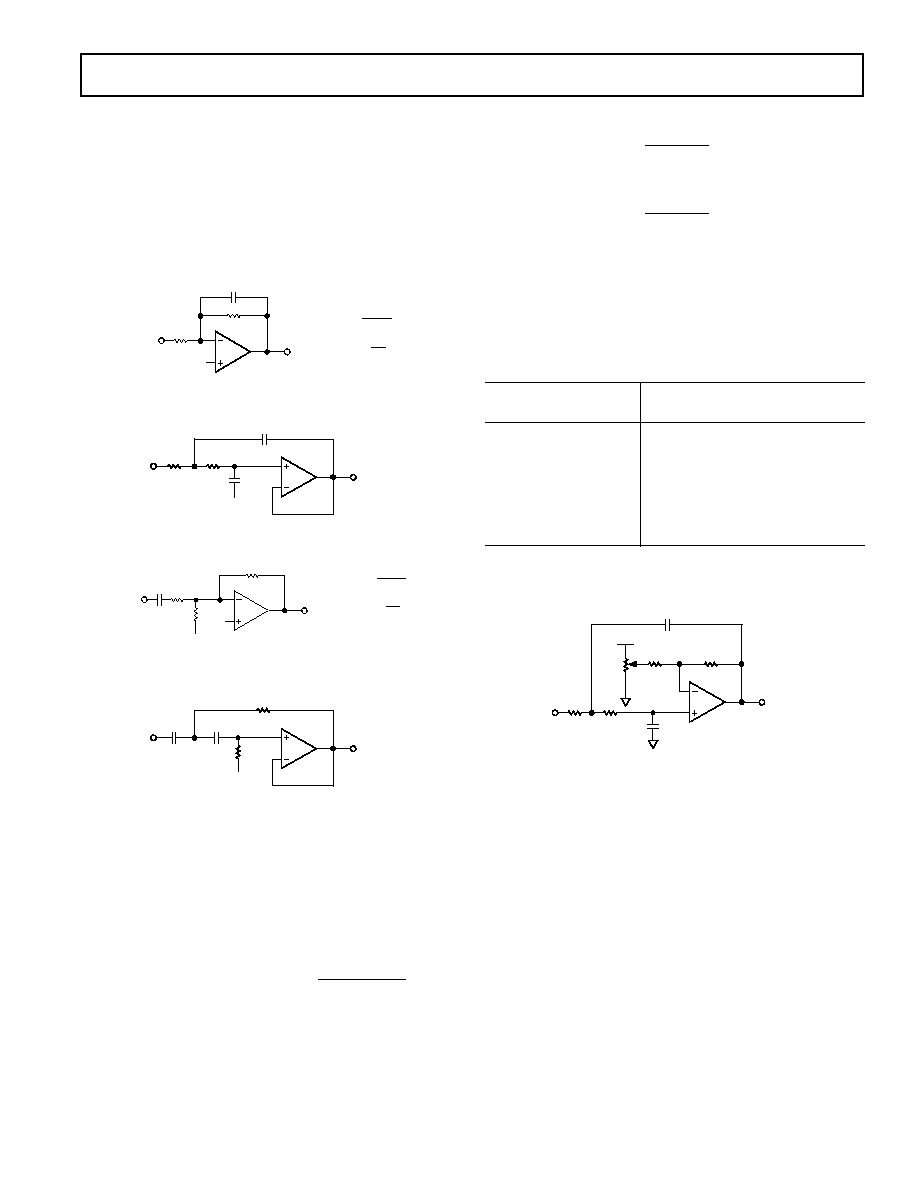

Uncommitted Amplifier (UCA)

The uncommitted amplifier has a low noise, low drift bipolar

front end design. The UCA can be used to change the scale

factor of the ADXL105 as shown in Figure 14. The UCA may

also be used to add a 1- or 2-pole active filter as shown in Fig-

ures 15a through 15d.

REV. A

7

ADXL105

Output Scaling

The acceleration output (A

OUT

) of the ADXL105 is nominally

250 mV/g. This scale factor may not be appropriate for all appli-

cations. The UCA may be used to increase the scale factor. The

simplest implementation would be as shown in Figure 14a.

Since the 0 g offset of the ADXL105 is 2.5 V

±

625 mV, using a

gain of greater than 4 could result in having the UCA output at

0 V or 5 V at 0 g. The solution is to add R3 and VR1, as shown

in Figure 14b, turning the UCA into a summing amplifier. VR1

is adjusted such that the UCA output is V

DD

/2 at 0 g.

C

R1

OUT

R2

IN

f

3dB

=

1

2 CR1

GAIN =

R1

R2

V

MID

a. 1-Pole Low-Pass Filter

0.22 F

OUT

20k

IN

f

3dB

= 30Hz

20k

0.18 F

V

MID

b. 2-Pole Bessel Low-Pass Filter

R1

OUT

R2

IN

f

3dB

=

1

2 CR2

GAIN =

R1

R2

C

R3

R3 2.5 R1

~

~

V

MID

V

MID

c. 1-Pole High-Pass Filter

44.2k

OUT

IN

f

3dB

= 10Hz

59k

0.39 F

0.39 F

V

MID

d. 2-Pole Bessel High-Pass Filter

Figure 15. UCA Used as Active Filters*

Device Bandwidth vs. Resolution

In general the bandwidth selected will determine the noise floor

and hence, the measurement resolution (smallest detectable

acceleration) of the ADXL105. Since the noise of the ADXL105

has the characteristic of white Gaussian noise that contributes

equally at all frequencies, the noise amplitude may be reduced

by simply reducing the bandwidth. So the typical noise of the

ADXL105 is:

Noise (rms) = (225

µ

g/

Hz)

× (

Bandwidth

×

K)

Where

K

1.6 for a single-pole filter

K

1.4 for a 2-pole filter

So given a bandwidth of 1000 Hz, the typical rms noise floor of

an ADLX105 will be:

Noise = (225

µ

g/

Hz)

×

(

1000

×

1.6)

= 9 mg rms for a single-pole filter

and

Noise = (225

µ

g/

Hz)

×

(

1000

×

1.4)

= 8.4 mg rms for 2-pole filter

Often the peak value of the noise is desired. Peak-to-peak noise

can only be estimated by statistical means. Table I may be used

for estimating the probabilities of exceeding various peak values

given the rms value. The peak-to-peak noise value will give the

best estimate of the uncertainty in a single measurement.

Table I. Estimation of Peak-to-Peak Noise

Nominal Peak-to-

% of Time that Noise Will

Peak Value

Exceed Peak-to-Peak Value

2

×

rms

32%

3

×

rms

13%

4

×

rms

4.6%

5

×

rms

1.2%

6

×

rms

0.27%

7

×

rms

0.047%

8

×

rms

0.0063%

The UCA may be configured to act as an active filter with gain

and 0 g offset control as shown in Figure 16.

0.1 F

OUT

IN

GAIN = 2

f

3dB

= 30Hz

0.1 F

100k

47k

47k

10k

V

DD

47k

Figure 16. UCA Configured as an Active Low-Pass Filter

with Gain and Offset

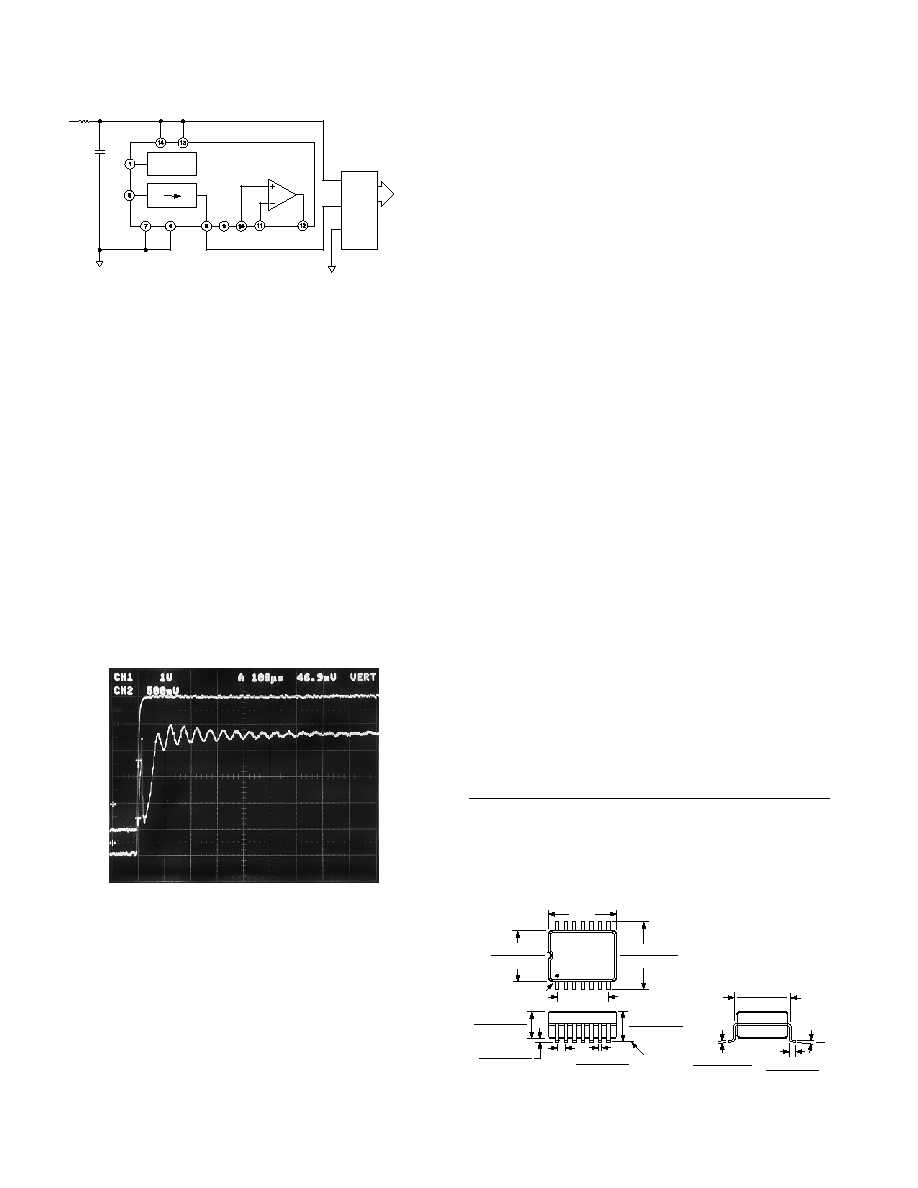

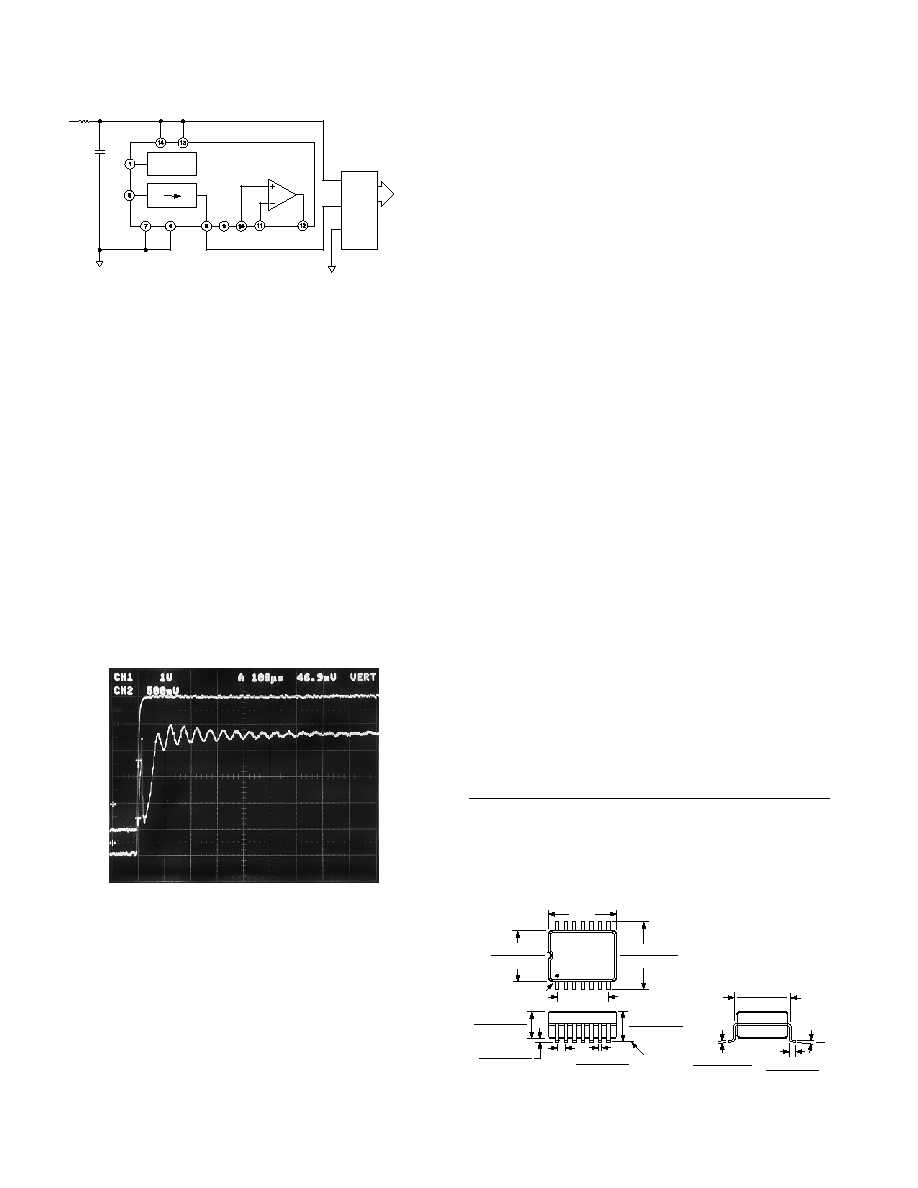

EMC and Electrical Noise

The design of the ADXL105 is such that EMI or magnetic

fields do not normally affect it. Since the ADXL105 is ratiomet-

ric, conducted electrical noise on V

DD

does affect the output.

This is particularly true for noise at the ADXL105's internal

clock frequency (200 kHz) and its odd harmonics. So maintain-

ing a clean supply voltage is key in preserving the low noise and

high resolution properties of the ADXL105.

One way to ensure that V

DD

contains no high frequency noise is

to add an R-C low-pass filter near the V

DD

pin as shown in

Figure 17. Using the component values shown in Figure 17,

noise at 200 kHz is attenuated by approximately 23 dB. As-

suming the ADXL105 consumes 2 mA, there will be a 100 mV

drop across R1. This can be neglected simply by using the

ADXL105's V

DD

as the A-to-D converter's reference voltage as

shown in Figure 17.

*For other corner frequencies, consult an active filter handbook.

REV. A

ADXL105

8

C3549a19/99

PRINTED IN U.S.A.

Dynamic Operation

In applications where only dynamic accelerations (vibration) are

of interest, it is often best to ac-couple the accelerometer output

as shown in Figures 15c and 15d. The advantage of ac coupling

is that 0g offset variability (part to part) and drifts are eliminated.

Low Power Operation

The most straightforward method of lowering the ADXL105's

power consumption is to minimize its supply voltage. By lower-

ing V

DD

from 5 V to 2.7 V the power consumption goes from

9.5 mW to 3.5 mW. There may be reasons why lowering the

supply voltage is impractical in many applications, in which case

the best way to minimize power consumption is by power cycling.

The ADXL105 is capable of turning on and giving an accurate

reading within 700

µ

s (see Figure 18). Most microcontrollers

can perform an A-to-D conversion in under 25

µ

s. So it is prac-

tical to turn on the ADXL105 and take a reading in under 750

µ

s. Given a 100 Hz sample rate the average current required at

2.7 V would be:

100 samples/s

×

750

µ

s

×

1.3 mA = 97.5

µ

A

Figure 18. Typical Turn-On Response at V

DD

= 5 V

Note that if a filter is used in the UCA, sufficient time must be

allowed for the settling of the filter as well.

Broadband Operation

The ADXL105 has a number of characteristics that permits

operation over a wide frequency range. Its frequency and phase

response is essentially flat from dc to 10 kHz (see Figures 12

and 13). Its sensitivity is also constant over temperature (see

Figure 3). In contrast, most accelerometers do not have linear

response at low frequencies (in many cases, no response at very

low frequencies or dc), and often have a large sensitivity tem-

perature coefficient that must be compensated for. In addi-

tion, the ADXL105's noise floor is essentially flat from dc to

5 kHz where it gently rolls off (see Figure 7). The beam reso-

nance at 16 kHz can be seen in Figure 7 where there is a small

noise peak (+5 dB) at the beam's resonant frequency. There are

no other significant noise peaks at any frequency.

The resonant frequency of the beam in the ADXL105 deter-

mines its high frequency limit. However the resonant frequency

of the Cerpak package is typically around 7 kHz. As a result, it

is not unusual to see 6 dB peaks occurring at the package reso-

nant frequency (as shown in Figures 12 and 13). Indeed, the

PCB will often have one or more resonant peaks well below

7 kHz. Therefore, if the application calls for accurate operation

at or above 6 kHz the ADXL105 should be glued to the PCB in

order to eliminate the amplitude response peak due to the pack-

age, and careful consideration should be given to the PCB

mechanical design.

CALIBRATING THE ADXL105

The initial value of the offset and scale factor for the ADXL105

will require dc calibration for applications such as tilt

measurement.

For low g applications, the force of gravity is the most stable,

accurate and convenient acceleration reference available. An

approximate reading of the 0 g point can be determined by

orienting the device parallel to the Earth's surface and then

reading the output. For high accuracy, a calibrated fixture must

be used to ensure exact 90 degree orientation to the 1 g gravity

signal.

An accurate sensitivity calibration method is to make a measure-

ment at +1 g and 1 g. The sensitivity can be determined by the

two measurements. This method has the advantage of being less

sensitive to the alignment of the accelerometer because the on

axis signal is proportional to the Cosine of the angle. For ex-

ample, a 5

°

error in the orientation results in only a 0.4% error

in the measurement.

To calibrate, the accelerometer measurement axis is pointed

directly at the Earth. The 1 g reading is saved and the sensor is

turned 180

°

to measure 1 g. Using the two readings and sensi-

tivity is calculated:

Sensitivity = [1 g Reading (1 g Reading)]/2 V/g

V

DD

T

OUT

ST

COM

A

OUT

V

MID

V

IN

V

NIN

UCA

OUT

UNCOMMITTED

AMPLIFIER

ADXL105

X SENSOR

TEMP

SENSOR

V

DD

0.22 F

50

COM

+V

A-TO-D

CONVERTER

DOUT

VREF

AIN

COM

Figure 17. Reducing Noise on V

DD

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

14-Lead Cerpak

(QC-14)

1

7

8

14

0.310 (7.874)

0.275 (6.985)

0.415 (10.541)

MAX

PIN 1

0.300 (7.62)

0.419 (10.643)

0.394 (10.008)

0.345 (8.763)

0.290 (7.366)

0.050 (1.270)

0.016 (0.406)

8

0

0.0125 (0.318)

0.009 (0.229)

SEATING

PLANE

0.170 (4.318)

0.135 (3.429)

0.190 (4.826)

0.140 (3.556)

0.020 (0.508)

0.013 (0.330)

0.050

(1.27)

BSC

0.020 (0.508)

0.004 (0.102)