| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SSM2018T | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

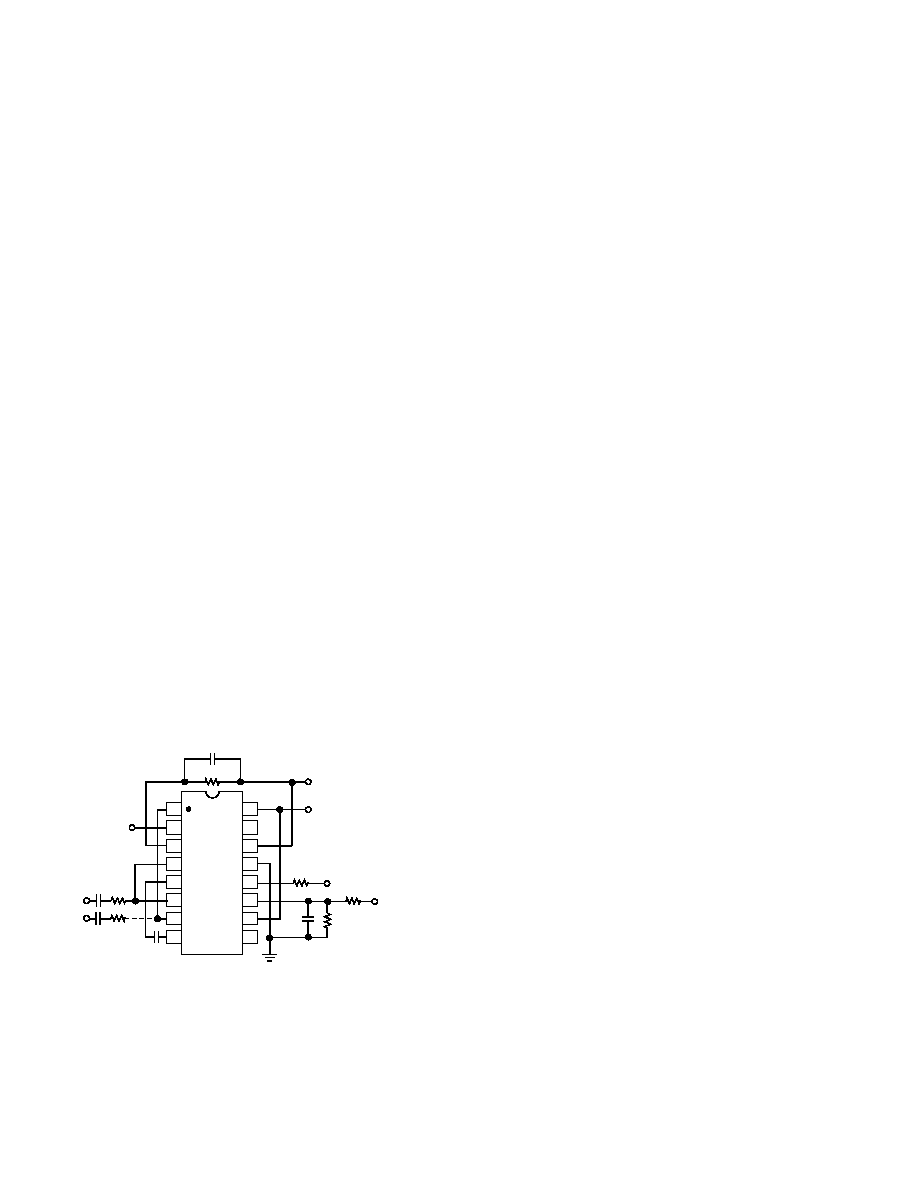

FUNCTIONAL BLOCK DIAGRAMS

GENERAL DESCRIPTION

The SSM2018T and SSM2118T represent continuing evolu-

tion of the Frey Operational Voltage Controlled Element

(OVCE) topology that permits flexibility in the design of high

performance volume control systems. Voltage (SSM2018T)

and differential current (SSM2118T) output versions are of-

fered, both laser-trimmed for gain core symmetry and offset. As

a result, the SSM2018T is the first professional audio quality

VCA to offer trimless operation. The SSM2118T is ideal for

low noise summing in large VCA based systems.

Due to careful gain core layout, the SSM2018T/SSM2118T

combine the low noise of Class AB topologies with the low dis-

tortion of Class A circuits to offer an unprecedented level of

sonic transparency. Additional features include differential in-

puts, a 140 dB gain range, and a high impedance control port.

The SSM2018T provides an internal current-to-voltage con-

verter; thus no external active components are required. The

SSM2118T has fully differential current outputs that permit

high noise-immunity summing of multiple channels.

Both devices are offered in 16-pin plastic DIP and SOIC pack-

ages and guaranteed for operation over the extended industrial

temperature range of ≠40

∞

C to +85

∞

C.

*Protected by U.S. Patent Nos. 4,471,320 and 4,560,947.

FEATURES

117 dB Dynamic Range

0.006% Typical THD+N (@ 1 kHz, Unity Gain)

140 dB Gain Range

No External Trimming Required

Differential Inputs

Complementary Gain Outputs

Buffered Control Port

I≠V Converter On-Chip (SSM2018T)

Differential Current Outputs (SSM2118T)

Low External Parts Count

Low Cost

Trimless

Voltage Controlled Amplifiers

SSM2018T/SSM2118T*

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106,

U.S.A. Tel: 617/329-4700

Fax: 617/326-8703

REV. A

a

V

C

≠IN

+IN

V

G

V

1≠G

≠I

G

≠I

1≠G

GAIN

CORE

G

1≠G

SSM-2018T

V

C

≠IN

+IN

+I

G

V

1≠G

≠I

G

≠I

1≠G

GAIN

CORE

G

1≠G

SSM-2118T

REV. A

≠2≠

SSM1018T/SSM2118T≠SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

Parameter

Conditions

Min

Typ

Max

Units

AUDIO PERFORMANCE

1

Noise

V

IN

= GND, 20 kHz Bandwidth

≠95

≠93

dBu

Headroom

Clip Point = 1% THD+N

+22

dBu

Total Harmonic Distortion plus Noise

2nd and 3rd Harmonics Only (+25

∞

C to +85

∞

C)

A

V

= 0 dB, V

IN

= +10 dBu

0.006

0.025

%

A

V

= +20 dB, V

IN

= ≠10 dBu

0.013

0.04

%

A

V

= ≠20 dB, V

IN

= +10 dBu

2

0.013

0.04

%

INPUT AMPLIFIER

Bias Current

V

CM

= 0 V

0.25

1

µ

A

Offset Voltage

V

CM

= 0 V

1

15

mV

Offset Current

V

CM

= 0 V

10

100

nA

Input Impedance

4

M

Common-Mode Range

±

13

V

Gain Bandwidth

VCA Configuration

0.7

MHz

VCP Configuration

14

MHz

Slew Rate

5

V/

µ

s

OUTPUT AMPLIFIER (SSM2018T)

Offset Voltage

V

IN

= 0 V, V

C

= +4 V

1.0

15

mV

Output Voltage Swing

I

OUT

= 1.5 mA

Positive

+10

+13

V

Negative

≠10

≠14

V

Minimum Load Resistance

For Full Output Swing

9

k

CONTROL PORT

Bias Current

0.36

1

µ

A

Input Impedance

1

M

Gain Constant

Device Powered in Socket > 60 sec

≠30

mV/dB

Gain Constant Temperature Coefficient

≠3500

ppm/

∞

C

Control Feedthrough

0 dB to ≠40 dB Gain Range

±

1

±

4

mV

Maximum Attenuation

V

C

= +4 V

100

dB

POWER SUPPLIES

Supply Voltage Range

±

5

±

18

V

Supply Current

11

15

mA

Power Supply Rejection Ratio

80

dB

NOTES

1

SSM2118T tested and characterized using OP275 as current-to-voltage converter, see figure next page.

2

Guaranteed by characterization data and testing at A

V

= 0 dB.

Specifications subject to change without notice.

[V

S

=

±

15 V, A

V

= 0 dB, R

L

= 100 k

, f = 1 kHz, 0 dBu = 0.775 V rms, simple VCA application

circuit with 18 k

resistors, ≠V

IN

floating, and Class AB gain core bias (R

B

= 150 k

), ≠40

∞

C < T

A

< +85

∞

C, unless otherwise noted. Typical

specifications apply at T

A

= +25

∞

C.]

REV. A

≠3≠

SSM2018T/SSM2118T

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage

Dual Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

18 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

V

S

Operating Temperature Range . . . . . . . . . . . . . ≠40

∞

C to +85

∞

C

Storage Temperature . . . . . . . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

Junction Temperature (T

J

) . . . . . . . . . . . . . . . . . . . . . +150

∞

C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . +300

∞

C

THERMAL CHARACTERISTICS

Thermal Resistance

2

16-Pin Plastic DIP

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

∞

C/W

JC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

∞

C/W

16-Pin SOIC

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

∞

C/W

JC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

∞

C/W

TRANSISTOR COUNT

Number of Transistors

SSM2018T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

SSM2118T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

ESD RATINGS

883 (Human Body) Model . . . . . . . . . . . . . . . . . . . . . . . 500 V

EIAJ Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 V

1

Stresses above those listed under "Absolute Maximum Ratings" may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operation section of this specification is not implied. Exposure to absolute maxi-

mum rating conditions for extended periods may affect device reliability.

2

JA

is specified for worst-case conditions, i.e.,

JA

is specified for device in socket

for P-DIP and device soldered in circuit board for SOIC package.

ORDERING GUIDE

Model

Temperature Range

Package Option*

SSM2018TP

≠40

∞

C to +85

∞

C

N-16

SSM2018TS

≠40

∞

C to +85

∞

C

R-16

SSM2118TP

≠40

∞

C to +85

∞

C

N-16

SSM2118TS

≠40

∞

C to +85

∞

C

R-16

*N = Plastic DIP; R = SOL.

PIN CONFIGURATIONS

16-Lead Plastic DIP

and SOL

16-Lead Plastic DIP

and SOL

+I

1≠G

V+

BAL

COMP 1

+IN

≠IN

MODE

V

C

V≠

≠I

1≠G

≠I

G

V

G

GND

COMP 2

COMP 3

1

2

16

15

5

6

7

12

11

10

3

4

14

13

8

9

TOP VIEW

(Not to Scale)

SSM2018T

V

1≠G

+I

1≠G

V+

BAL

COMP 1

+IN

≠IN

MODE

V

C

V≠

≠I

1≠G

GND

COMP 2

COMP 3

1

2

16

15

5

6

7

12

11

10

3

4

14

13

8

9

TOP VIEW

(Not to Scale)

SSM2118T

V

1≠G

≠I

G

+I

G

SSM2018T Typical Application Circuit

SSM2118T Typical Application Circuit

1

µ

F 18k

V

IN+

V≠

150k

A1

10k

10k

18k

18k

500k

50pF

V

OUT

GLOBAL

SYMMETRY

TRIM

FROM

ADDITIONAL

SSM2118Ts

V≠

1

µ

F 18k

V

IN≠

47pF

1

µ

F

3k

V

CONTROL

V+

50pF

*

470k

OPTIONAL

TRIM

47k

47k

A1, A2: OP275

1

2

5

6

7

3

4

8

16

15

12

11

10

14

13

9

SSM2118T

A2

1k

*

FOR MORE THAN 2 SSM2118Ts

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the SSM2018T/SSM2118T features proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

V+

1

µ

F

150k

18k

V+

18k

V

IN+

1

µ

F 18k

V

IN≠

47pF

1

µ

F

50pF

1k

V

CONTROL

3k

V

OUT

V≠

1

2

16

15

5

6

7

12

11

10

3

4

14

13

8

9

SSM2018T

≠4≠

SSM2018T/SSM2118T≠Typical Characteristics

REV. A

0.1

0.010

0.001

THD + N ≠ %

20

100

1k

10k

20k

FREQUENCY ≠ Hz

AV = +20dB

AV = ≠20dB

AV = 0dB

T

A

= +25

∞

C

V

S

=

±

15V

R

F

= 18k

Figure 1. SSM2018T THD + N Frequency (80 kHz Low-Pass

Filter, for A

V

= 0 dB, V

IN

= 3 V rms; for A

V

= +20 dB,

V

IN

= 0.3 V rms; for A

V

= ≠20 dB, V

IN

= 3 V rms)

100

0

0.025

30

10

20

0.000

60

40

50

70

80

90

0.020

0.015

0.010

0.005

DISTORTION ≠ %

UNITS

T

A

= +25

∞

C

A

V

= 0dB

300 UNITS

V

IN

= 10dBu

V

S

=

±

15V

Figure 2. SSM2018T Distortion Distribution

1

0.1

0.010

0.001

THD + N ≠ %

0.1

1

10

20

AMPLITUDE ≠ V

RMS

T

A

= +25

∞

C

R

F

= 18k

V

S

=

±

15V

Figure 3. SSM2018T THD + N vs. Amplitude (Gain = 0 dB,

f

IN

= 1 kHz, 80 kHz Low-Pass Filter)

1

0.1

0.010

0.001

THD + N ≠ %

10m

0.1

1

2

AMPLITUDE ≠ V

RMS

T

A

= +25

∞

C

V

S

=

±

15V

R

F

= 18k

Figure 4. SSM2018T THD + N vs. Amplitude

(Gain = +20 dB, f

IN

=1 kHz, 80 kHz Low-Pass Filter)

1.0

0.01

0.001

≠60

≠40

20

≠20

0.1

0

40

T

A

= +25

∞

C

V

S

=

±

15V

R

F

= 18k

GAIN ≠ dB

THD + N ≠ %

Figure 5. SSM2018T THD + N vs. Gain (f

IN

= 1 kHz;

for ≠60 dB

A

V

≠20 dB, V

IN

= 10 V rms;

for 0 dB

A

V

+20 dB, V

IN

= 1 V rms)

THD + N ≠ %

0.1

0.001

0

±

12

0.01

T

A

= +25

∞

C

R

F

= 18k

±

3

±

6

±

9

±

15

±

18

SUPPLY VOLTAGE ≠ Volts

Figure 6. SSM2018T THD + N vs. Supply Voltage

(A

V

= 0 dB, V

IN

= 1 V rms, f

IN

= 1 kHz, 80 kHz

Low-Pass Filter)

REV. A

≠5≠

SSM2018T/SSM2118T

LOAD RESISTANCE ≠

MAXIMUM OUTPUT SWING ≠ V

PEAK

±

15

±

12

0

100

1k

100k

10k

±

9

±

6

±

3

R

F

= 18k

T

A

= +25

∞

C

V

S

=

±

15V

Figure 10. SSM2018T Maximum Output Swing vs.

Load Resistance, (THD = 1 % max)

100

0

40

30

10

≠60

20

≠80

60

40

50

70

80

90

20

0

≠20

≠40

T

A

= +25

∞

C

V

S

=

±

15V

GAIN ≠ dB

OUTPUT OFFSET ≠ mV

Figure 11. SSM2018T Output Offset vs. Gain

+10

0

≠15

1k

1M

100k

10k

100

≠5

≠10

+5

FREQUENCY ≠ Hz

T

A

= +25

∞

C

V

S

=

±

15V

GAIN ≠ dB

0

≠135

≠45

≠90

PHASE ≠ Degrees

GAIN

PHASE

Figure 12. SSM2018T Gain/Phase vs. Frequency

Figure 7. SSM2018T Noise Density vs. Frequency

0

±

15

±

5

±

5

±

10

0

±

20

±

20

±

15

±

10

SUPPLY VOLTAGE ≠ Volts

OUTPUT VOLTAGE SWING ≠ V

PEAK

R

L

=

R

L

= 10k

R

F

= 18k

T

A

= +25

∞

C

Figure 8. SSM2018T Maximum Output Swing vs.

Supply Voltage (THD = 1% max)

FREQUENCY ≠ Hz

MAXIMUM OUTPUT SWING ≠ V

PEAK

R

L

=

R

L

= 10k

R

F

= 18k

T

A

= +25

∞

C

V

S

=

±

15V

±

9

0

1k

10k

100k

±

3

±

6

±

12

±

15

Figure 9. SSM2018T Maximum Output Swing vs.

Frequency (THD = 1 % max)

500

300

0

100

100k

10k

1k

10

200

100

400

FREQUENCY ≠ Hz

NOISE DENSITY ≠ nV/

Hz

T

A

= +25

∞

C

V

S

=

±

15V

REV. A

≠6≠

SSM2018T/SSM2118T≠Typical Characteristics

60

40

≠80

100

1k

10M

1M

100k

10k

20

0

≠20

≠40

≠60

FREQUENCY ≠ Hz

T

A

= +25

∞

C

V

S

=

±

15V

GAIN ≠ dB

Figure 13. SSM2018T Gain vs. Frequency

THD + N ≠ %

0.1

0.010

0.001

20

100

1k

10k

20k

FREQUENCY ≠ Hz

T

A

= +25

∞

C

R

F

= 18k

A

V

= 0dB

A

V

= +20dB

A

V

= ≠20dB

Figure 14. SSM2118T THD + N Frequency (80 kHz

Low-Pass Filter, for A

V

= 0 dB, V

IN

= 1 V rms;

for A

V

= +20 dB, V

IN

= 0.1 V rms; for A

V

= ≠20 dB,

V

IN

= 10 V rms)

100

0

0.025

30

10

20

0.000

60

40

50

70

80

90

0.020

0.015

0.010

0.005

DISTORTION ≠ %

UNITS

T

A

= +25

∞

C

A

V

= 0dB

300 UNITS

V

IN

= 10dBu

V

S

=

±

15V

Figure 15. SSM2118T Distortion Distribution

AMPLITUDE ≠ V

RMS

T

A

= +25

∞

C

V

S

=

±

15V

0.1

1

10

20

1

0.1

0.010

0.001

THD + N ≠ %

Figure 16. SSM2118T THD + N vs. Amplitude

(Gain = 0 dB, f

IN

= 1 kHz, 80 kHz Low-Pass Filter)

AMPLITUDE ≠ V

RMS

T

A

= +25

∞

C

V

S

=

±

15V

10m

0.1

1

2

1

0.1

0.010

0.001

THD + N ≠ %

Figure 17. SSM2118T THD + N vs. Amplitude

(Gain = +20 dB, f

IN

= 1 kHz, 80 kHz Low-Pass Filter)

1.0

0.001

≠60

≠40

≠20

0

+20

+40

0.1

0.01

GAIN ≠ dB

THD + N ≠ %

T

A

= +25

∞

C

V

S

=

±

15V

Figure 18. SSM2118T THD + N vs. Gain (f

IN

= 1 kHz;

for ≠60 dB

A

V

≠20 dB, V

IN

= 10 V rms;

for 0 dB

A

V

+20 dB, V

IN

= 1 V rms)

REV. A

≠7≠

SSM2018T/SSM2118T

SUPPLY VOLTAGE ≠ Volts

THD + N ≠ %

T

A

= +25

∞

C

0.1

0.01

0.001

0

±

3

±

6

±

9

±

12

±

15

±

18

Figure 19. SSM2118T THD + N vs. Supply Voltage

(A

V

= 0 dB, V

IN

= 1 V rms, f

IN

= 1 kHz, 80 kHz

Low-Pass Filter)

Figure 20. SSM2118T Noise Density vs. Frequency

0

±

15

±

5

±

10

0

±

5

±

10

±

15

±

20

±

20

SUPPLY VOLTAGE ≠ Volts

OUTPUT VOLTAGE SWING ≠ V

PEAK

R

L

=

±

20

T

A

= +25

∞

C

Figure 21. SSM2118T Maximum Output Swing vs.

Supply Voltage (THD = 1% max)

±

9

0

1k

10k

100k

±

3

±

6

±

12

±

15

FREQUENCY ≠ Hz

MAXIMUM OUTPUT SWING ≠ V

PEAK

T

A

= +25

∞

C

V

S

=

±

15V

Figure 22. SSM2118T Maximum Output Swing vs.

Frequency (THD = 1 % max)

10

0

40

3

1

≠60

2

≠80

6

4

5

7

8

9

20

0

≠20

≠40

GAIN ≠ dB

OUTPUT OFFSET CURRENT ≠ µA

T

A

= +25

∞

C

V

S

=

±

15V

Figure 23. SSM2118T Output Offset Current vs. Gain

+10

0

≠15

1k

1M

100k

10k

100

≠5

≠10

+5

FREQUENCY ≠ Hz

GAIN ≠ dB

0

≠135

≠45

≠90

PHASE ≠ Degrees

T

A

= +25

∞

C

V

S

=

±

15V

PHASE

GAIN

Figure 24. SSM2118T Gain/Phase vs. Frequency

500

300

0

10 100 1k 10k

100k

200

100

400

T

A

= +25

∞

C

V

S

=

±

15V

FREQUENCY ≠ Hz

NOISE DENSITY ≠ nV/

Hz

REV. A

≠8≠

SSM2018T/SSM2118T

60

40

≠80

100

1k

10M

1M

100k

10k

20

0

≠20

≠40

≠60

FREQUENCY ≠ Hz

GAIN ≠ dB

T

A

= +25

∞

C

V

S

=

±

1.5V

OP275 AS

I/V CONV.

Figure 25. SSM2118T Gain vs. Frequency

0.06

0

100

0.03

0.01

≠20

0.02

≠40

0.05

0.04

80

40

20

0

60

TEMPERATURE ≠

∞

C

DISTORTION ≠ %

T

A

= +25

∞

C

V

S

=

±

15V

V

IN

= 10dBu

A

V

= ≠20dB

AND

V

IN

= ≠10dBu

A

V

= 20dB

V

IN

= 10dBu

A

V

= 0dB

Figure 26. SSM2018T and SSM2118T Distortion vs.

Temperature

≠60

≠110

40

≠80

≠100

≠40

≠90

≠60

≠70

20

0

≠20

GAIN ≠ dB

OUTPUT NOISE ≠ dBu

T

A

= +25

∞

C

V

S

=

±

15V

Figure 27. SSM2018T and SSM2118T Output Noise vs.

Gain (V

IN

= GND, 20 kHz Bandwidth)

100

0

30

10

20

60

40

50

70

80

90

UNITS

CONTROL FEEDTHROUGH ≠ mV

T

A

= +25

∞

C

0V < V

C

< 1.2V

FREQ = 0Hz

300 UNITS

≠3.0

≠2.0

≠1.0

0

1.0

2.0

Figure 28. SSM2018T Control Feedthrough Distribution

0

≠20

≠100

100

1k

100k

10k

≠40

≠60

≠80

FREQUENCY ≠ Hz

V

S

=

±

15V

T

A

= +25

∞

C

V

C

= 100mV

RMS

CONTROL FEEDTHROUGH ≠ dB

Figure 29. SSM2018T and SSM2118T Control

Feedthrough vs. Frequency

3

≠3

100

0

≠2

≠20

≠1

≠40

2

1

80

40

20

0

60

TEMPERATURE ≠

∞

C

CONTROL FEEDTHROUGH ≠ mV

V

S

=

±

15V

0V < V

C

< 1.2V

FREQ = 0Hz

Figure 30. SSM2018T and SSM2118T Control

Feedthrough vs. Temperature

REV. A

≠9≠

SSM2018T/SSM2118T

≠20

≠40

≠40

100

≠25

≠35

≠20

≠30

60

80

40

20

0

TEMPERATURE ≠

∞

C

GAIN CONSTANT ≠ mV/dB

V

S

=

±

15V

Figure 31. SSM2018T and SSM2118T Gain Constant vs.

Temperature

≠28

≠33

60

≠30

≠32

≠60

≠31

≠80

≠29

40

20

0

≠20

≠40

GAIN ≠ dB

GAIN CONSTANT ≠ mV/dB

T

A

= +25

∞

C

V

S

=

±

15V

Figure 32. SSM2018T and SSM2118T Gain Constant

Linearity vs. Gain

0.1

0.0

≠0.4

100

1k

100k

10k

≠0.1

≠0.2

≠0.3

FREQUENCY ≠ Hz

GAIN ≠ dB

T

A

= +25

∞

C

V

S

=

±

15V

A

V

= 0dB

V

IN

= 100V

RMS

Figure 33. SSM2018T and SSM2118T Gain Flatness vs.

Frequency

0

≠40

≠100

100

100k

10k

1k

10

≠60

≠80

≠20

FREQUENCY ≠ Hz

CMRR ≠ dB

V

S

=

±

15V

T

A

= +25

∞

C

Figure 34. SSM2018T and SSM2118T CMRR vs.

Frequency

T

A

= +25

∞

C

15.0

0

±

15

7.5

2.5

±

5

5.0

0

12.5

10.0

±

10

SUPPLY VOLTAGE ≠ Volts

SLEW RATE ≠ V/µs

+ SLEW RATE

≠ SLEW RATE

Figure 35. SSM2018T and SSM2118T Slew Rate vs.

Supply Voltage

0

≠40

≠100

100

100k

10k

1k

10

≠60

≠80

≠20

FREQUENCY ≠ Hz

+ PSRR

≠ PSRR

V

S

=

±

15V

T

A

= +25

∞

C

PSRR ≠ dB

Figure 36. SSM2018T and SSM2118T PSRR vs. Frequency

REV. A

≠10≠

SSM2018T/SSM2118T

to run it in the noninverting single-ended mode. If either input

is unused, the associated 18 k

resistor and coupling capacitor

should be removed to prevent any additional noise.

The common-mode rejection in balanced mode is typically

55 dB up to 1 kHz, decreasing at higher frequencies as shown in

Figure 34. To ensure good CMRR in the balanced configura-

tion, the input resistors must be balanced. For example, a 1%

mismatch results in a CMRR of 40 dB. To achieve 55 dB,

these resistors should have an absolute tolerance match of 0.1%.

The output of the basic VCA is taken from Pin 14, which is the

output of an internal amplifier. Notice that the second voltage

output (Pin 16) is connected to the negative supply. This is

normal and actually disables that output amplifier ensuring that

it will not oscillate and cause interference problems. Shorting

the output to the negative supply does not cause the supply cur-

rent to increase. This amplifier is only used in the "OVCE" ap-

plication explained later.

The control port follows a 30 mV/dB control law. The applica-

tion circuit shows a 3 k

and 1 k

resistor divider from a con-

trol voltage. The choice of these resistors is arbitrary and could

be any values to properly scale the control voltage. In fact, these

resistors could be omitted if the control voltage is already prop-

erly scaled. The 1

µ

F capacitor is in place to provide some fil-

tering of the control signal. Although the control feedthrough is

trimmed at the factory, the feedthrough increases with fre-

quency (Figure 29). Thus, high frequency noise can

feedthrough and add to the noise of the VCA. Filtering the

control signal helps minimize this source of noise.

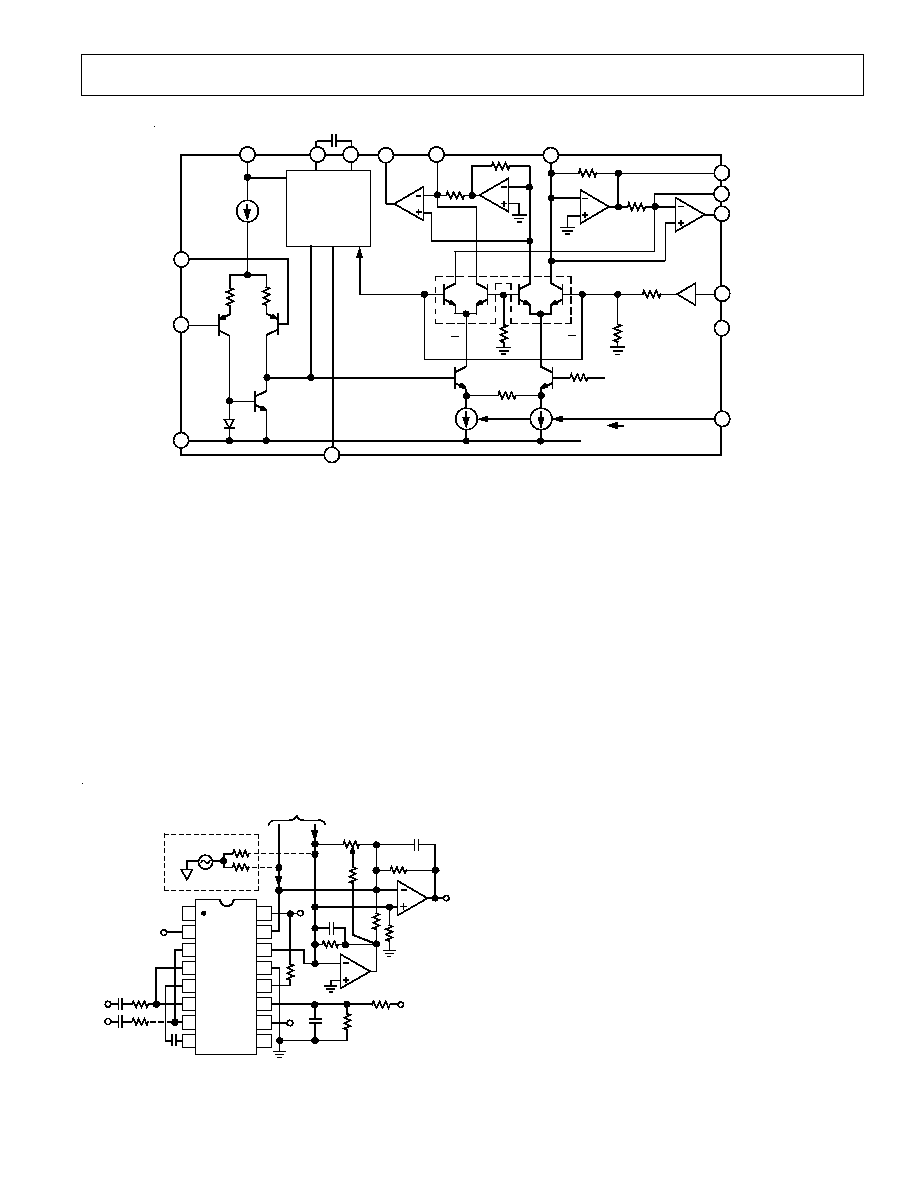

Theory of Operation of the SSM2018T

The SSM2018T has the same internal circuitry as the original

SSM2018. The detailed diagram in Figure 38 shows the main

components of the VCA. The essence of the SSM2018T is the

gain core, which is comprised of two differential pairs (Q1≠Q4).

When the control voltage, V

C

, is adjusted, current through the

gain core is steered to one side or the other of the two differen-

tial pairs. The tail current for these differential pairs is set by

the mode bias of the VCA (Class A or AB), which is labeled as

I

M

in the diagram. I

M

is then modulated by a current propor-

tional to the input voltage, labeled I

S

. For a positive input volt-

age, more current is steered (by the "Splitter") to the left

differential pair, and the opposite is true for a negative input.

To understand how the gain control works, a simple example is

best. Take the case of a positive control voltage on Pin 11. No-

tice that the bases of Q2 and Q3 are connected to ground via a

200

resistor. A positive control voltage produces a positive

voltage on the bases of Q1 and Q4. Concentrating on the left

most differential pair, this raises the base voltage of Q1 above

that of Q2. Thus, more of the tail current is steered through Q1

than through Q2. The current from the collector of Q2 flows

through the external 18 k

feedback resistor around amplifier

A3. When this current is reduced, the output voltage is also re-

duced. Thus, a positive control voltage results in an attenuation

of the input signal, which explains why the gain constant is

negative.

The collector currents of Q2 and Q3 produce the output volt-

age. The output of Q3 is mirrored by amplifier A1 to add to the

overall output voltage. On the other hand, the collector cur-

rents of Q1 and Q4 are used for feedback to the differential in-

puts. Because Pins 6 and 4 are shorted together, any input

voltage produces an input current which flows into Pin 4. The

APPLICATIONS

The SSM2018T is a trimless Voltage Controlled Amplifier

(VCA) for volume control in audio systems. The SSM2018T is

identical to the original SSM2018 in functionality and pinout;

however, it is the first professional quality audio VCA

in the marketplace that does not require an external trim-

ming potentiometer to minimize distortion. Instead, the

SSM2018T is laser trimmed before it is packaged to ensure the

specified THD and control feedthrough performance. This has

a significant savings in not only the cost of external trimming

potentiometers, but also the manufacturing cost of performing

the trimming during production.

The SSM2118T is identical to the SSM2018T except that dif-

ferential current outputs are provided as opposed to a voltage

output. This output configuration is ideal for bus summing ap-

plications where multiple audio signals are summed together.

These signals often require long lead lengths or cable runs to

reach the summing stage. Transmitting the signals in a differen-

tial current mode minimizes the chance for noise pickup and for

line impedances to upset the balance of the system. The

SSM2118T is also factory trimmed to minimize distortion and

control feedthrough. Thus, no individual trim is required for

each part. One global trim at the summing amplifier stage may

be necessary to properly balance the resistors in this stage, as ex-

plained later.

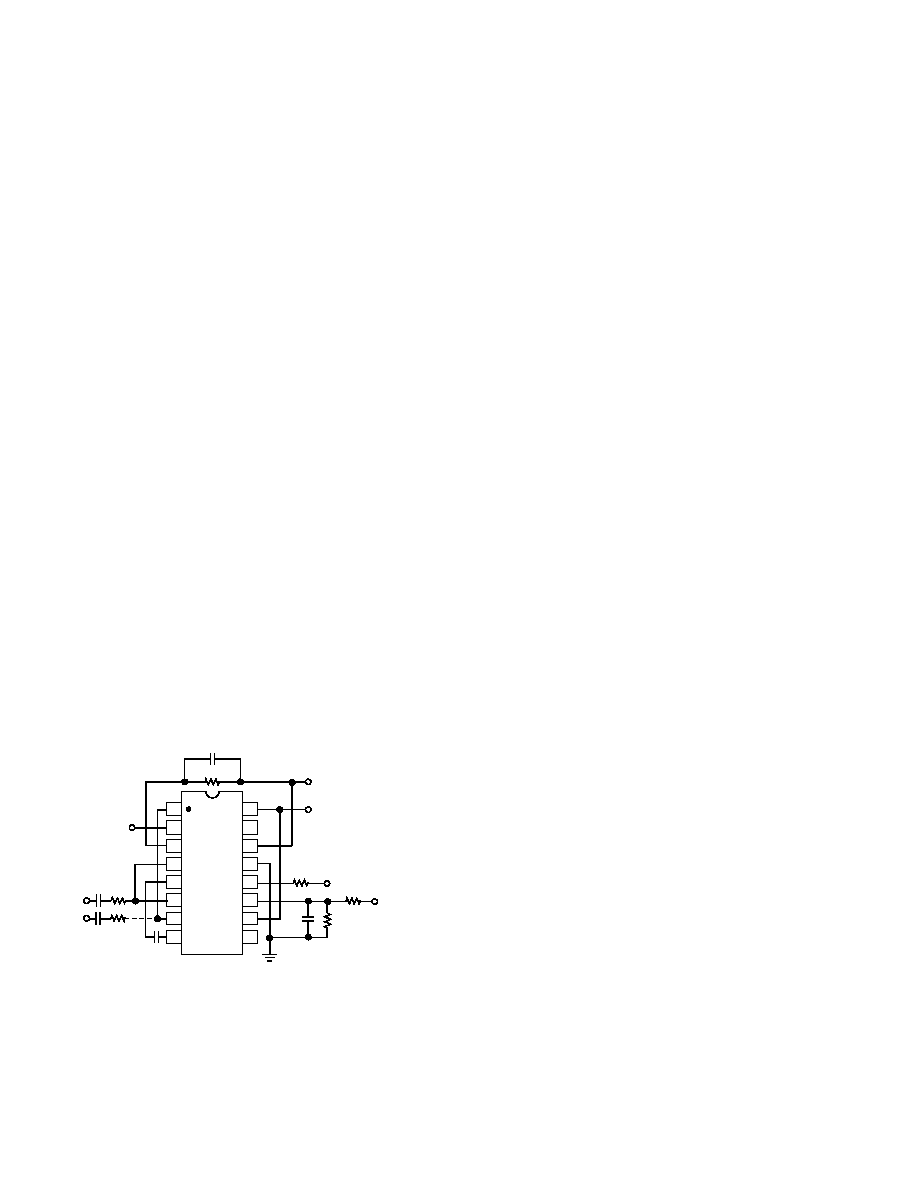

Basic VCA Configuration

The primary application circuit for the SSM2018T is the basic

VCA configuration, which is shown in Figure 37. This configu-

ration uses differential current feedback to realize the VCA. A

complete description of the internal circuitry of the VCA and

this configuration is given in the Theory of Operation section

below. The SSM2018T and SSM2118T are trimmed at the factory

for operation in the basic VCA configuration with class AB biasing.

Thus, for optimal distortion and control feedthrough perfor-

mance, the same configuration and biasing should be used. All

of the graphs for the SSM2018T in the data sheet have been

measured using the circuit of Figure 37.

V+

1

µ

F

R

B

150k

18k

V+

18k

V

IN+

1

µ

F 18k

V

IN≠

47pF

1

µ

F

50pF

1k

V

CONTROL

3k

V

OUT

V≠

1

2

16

15

5

6

7

12

11

10

3

4

14

13

8

9

SSM2018T

Figure 37. SSM2018T Basic VCA Application Circuit

In the simple VCA configuration, the SSM2018T inputs are at a

virtual ground. Thus, 18 k

resistors are required to convert

the input voltages to input currents. The schematic also shows

ac coupling capacitors. These are inserted to minimize dc off-

sets generated by bias current through the resistors. Without the

capacitors, the dc offset due to the input bias current is typically

5 mV. The input stage has the flexibility to run either inverting,

noninverting, or balanced. The most common configuration is

REV. A

≠11≠

SSM2018T/SSM2118T

same is true for the inverting input, which is connected to Pin 1.

The overall feedback ensures that the current flowing through

the input resistors is balanced by the collector currents in Q1

and Q4.

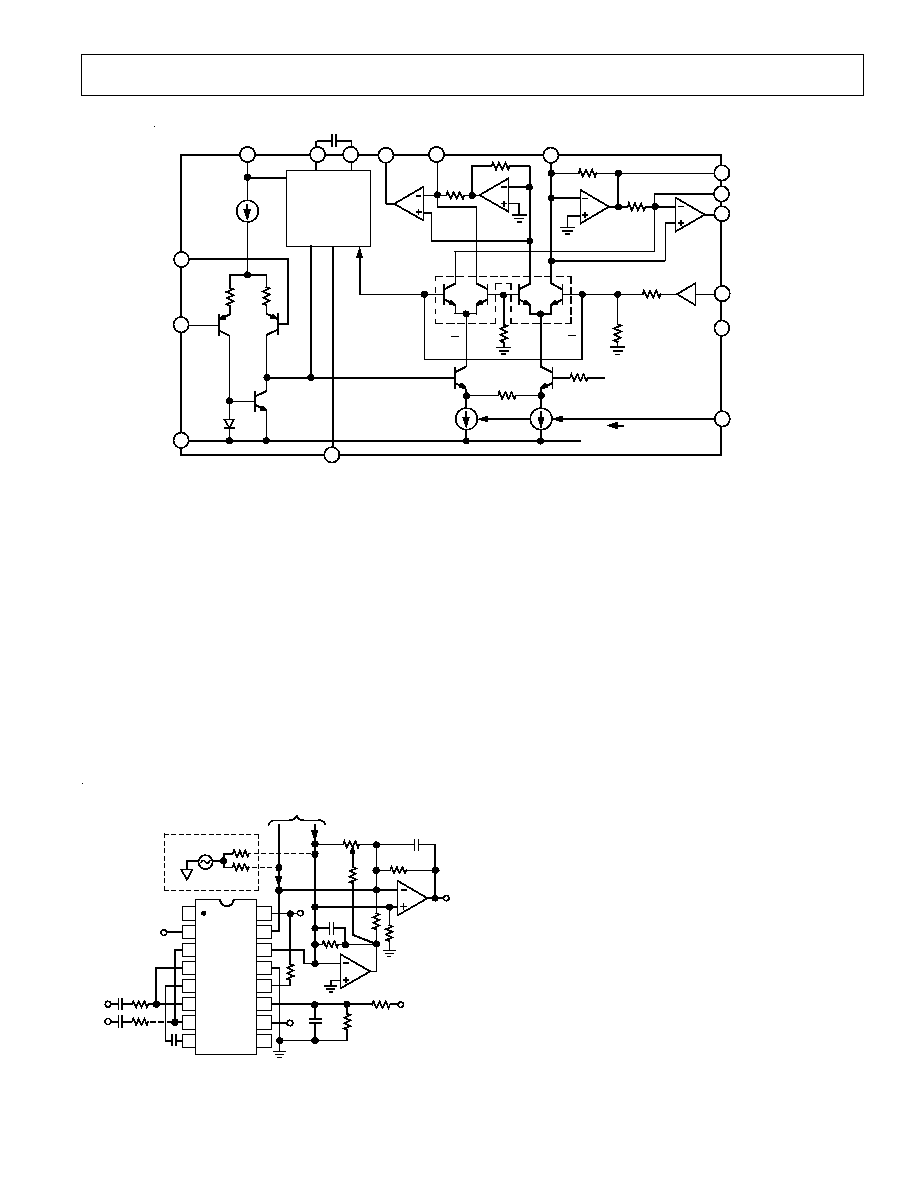

Basic VCA Configuration for the SSM2118T

The SSM2118T behaves very much in the same way as the

SSM2018T except that it has differential current outputs in-

stead of a voltage output. The basic VCA configuration is

shown in Figure 39. A dual output amplifier is needed to re-

place the internal amplifiers in the SSM2018T. However, mul-

tiple SSM2118Ts can share the output amplifiers. The op amps

are configured so that the SSM2118T's output current is flow-

ing into a virtual ground. This same virtual ground is presented

to all the VCAs, allowing their currents to be summed without

interaction.

1

µ

F 18k

V

IN+

V≠

150k

A1

10k

10k

18k

18k

500k

50pF

V

OUT

GLOBAL

SYMMETRY

TRIM

FROM

ADDITIONAL

SSM2118Ts

V≠

1

µ

F 18k

V

IN≠

47pF

1

µ

F

3k

V

CONTROL

V+

50pF

*

470k

OPTIONAL

TRIM

47k

47k

A1, A2: OP275

1

2

5

6

7

3

4

8

16

15

12

11

10

14

13

9

SSM2118T

A2

1k

*

FOR MORE THAN 2 SSM2118Ts

Figure 39. SSM2118T Typical Bus Summing Application

A global symmetry trim may be necessary, but since it is at the

output amplifiers, only one trim is needed for any number of

SSM2118Ts connected to the summing bus. This trim bal-

ances the resistors around the two amplifiers. If precision,

matched resistors are used, the trim can be removed. However,

to achieve 0.006% distortion, these resistors need to be matched

to approximately 0.01%.

If the choice is made to perform the trim, then one of two meth-

ods may be used. The first method minimizes the distortion of

an audio signal with the SSM2118T in the circuit. To perform

the trim, a 0 dBu, 1 kHz sine wave is applied to one of the

VCAs, and the output distortion is monitored. As the symmetry

trim is adjusted, the output distortion will vary. The optimal

adjustment produces the lowest distortion over the entire trim

range. The second method is to insert a common mode signal

by connecting two 47 k

resistors (matched to 0.01%) to the

inverting inputs of each amplifier, as shown in the Figure 39.

The signal is typically a 0 dBu, 1 kHz sine wave, although other

signals can be used. The output is monitored with an oscillo-

scope, and the potentiometer is adjusted to achieve a minimum

output signal.

The SSM2118T has the exact same input and gain core con-

struction as the SSM2018T. Thus, any discussion of these por-

tions of the SSM2018T apply equally to the SSM2118T. The

main difference, which is apparent by comparing Figure 40 to

Figure 38, is the removal of two output amplifiers, A1 and A3.

Instead, the output currents come directly from the collectors of

Q2 and Q3. Notice that the two external amplifiers in Figure

39 are configured the same as the internal amplifiers in the

SSM2018T.

Two important characteristics of these current outputs must be

considered: the output compliance and the effects of capacitive

loading. Normally, the outputs are connected to a virtual

ground node at the summing stage, which is biased at ground.

This bias point can be altered somewhat. The part maintains

good distortion performance for an output compliance from

A4

Q3 Q4

Q1 Q2

200

1≠G

G

G

1≠G

200

1.8k

GAIN

CORE

14

8

5

2

COMP 1

COMPENSATION

NETWORK

9

V

REF

Im

SPLITTER

A1

A3

V

G

+I

1-G

3

1

15

4

16

11

13

12

BAL

≠I

1-G

V

1-G

V

C

GND

MODE

≠I

G

COMP 3

COMP 2

V+

7

6

10

V≠

+IN

≠IN

Im+(Is)

2

Im≠(Is)

2

A2

A4

Figure 38. SSM2018T Detailed Functional Diagram

REV. A

≠12≠

SSM2018T/SSM2118T

A2

A4

Q3 Q4

Q1 Q2

200

1≠G

G

G

1≠G

200

1.8k

GAIN

CORE

14

8

5

16

COMP 2

COMP 1

9

V

REF

Im

SPLITTER

+I

G

3

1

15

4

2

11

13

12

BAL

≠I

1≠G

V

1≠G

V

C

GND

MODE

≠I

G

COMP 3

7

6

10

V≠

+IN

≠IN

+I

1≠G

V+

COMPENSATION

NETWORK

Im≠(Is)

2

Im+(Is)

2

A4

≠0.1 V to +6.0 V. The negative compliance is much smaller be-

cause the gain core transistors (Q1 and Q3) begin to saturate

when the collector potential is brought below their base poten-

tial. These outputs have high immunity to capacitive loads. In

fact, the load on either or both outputs can be as large as 10 nF

with no change in the distortion performance. For values above

10 nF, the distortion does start to increase. For example, a

100 nF load causes the distortion to increase from 0.006% to

0.02% at 1 kHz.

The noise performance of a single SSM2118T with an OP275

output amplifier is shown in Figure 20. When multiple

SSM2118T parts are operated in parallel, the noise does in-

crease by a factor equal to the square root of the number of

parts paralleled. For example, if five parts are in parallel, the

total output noise is 100 nV

(Hz)

◊

5

= 220 nV/

Hz

.

Compensating the SSM2018T and SSM2118T

Both parts employ the same compensation network. This net-

work uses an adaptive compensation scheme that adjusts the op-

timum compensation level for a given gain. The control voltage

not only adjusts the gain core steering, it also adjusts the com-

pensation. The SSM2018T and SSM2118T have three com-

pensation pins: COMP1, COMP2, and COMP3. COMP3 is

normally left open. Grounding this pin actually defeats the

adaptive compensation circuitry, giving the VCA a fixed com-

pensation point. The only time that this is desirable is when the

VCA has fixed feedback, such as the Voltage Controlled Panner

(VCP) circuit shown later in the data sheet. Thus, for the Basic

VCA circuit or the OVCE circuit, COMP3 should be left open.

A compensation capacitor does need to be added between

COMP1 and COMP2. Because the VCA operates over such a

wide gain range, ideally the compensation should be optimized

for each gain. When the VCA is in high attenuation, there is

very little "loop gain," and the part needs to have high compen-

sation. On the other hand, at high gain, the same compensation

capacitor would overcompensate the part and roll off the high

frequency performance. Thus, the SSM2018T and SSM2118T

employ a patented adaptive compensation circuit. The compen-

sation capacitor is "Miller" connected between the base and col-

lector of an internal transistor. By changing the gain of this

transistor via the control voltage, the compensation is changed.

Increasing the compensation capacitor causes the frequency re-

sponse and slew rate to decrease, which will tend to cause high

frequency distortion to increase. For the basic VCA circuit,

47 pF was chosen as the optimal value. The OVCE circuit de-

scribed later uses a 220 pF capacitor. The reason for the in-

crease is to compensate for the extra phase shift from the

additional output amplifier used in the OVCE configuration.

The compensation capacitor can be adjusted over a practical

range from 47 pF to 220 pF, if desired. Below 47 pF, the parts

may oscillate, and above 220 pF the frequency response is sig-

nificantly degraded.

Control Section

As mentioned before, the control voltage on Pin 11 steers the

current through the gain core transistors to set the gain. The

output gain formula is as follows:

V

OUT

=

V

IN

◊

e

(≠aV

C

)

The exponential term arises from the standard Ebers-Moll

equation describing the relationship of a transistor's collector

current as a function of the base-emitter voltage:

I

C

=

I

S

◊

e

(V

BE

/V

T

)

.

The factor "a" is a function of not only V

T

but also the scaling

due to the resistor divider of the 200

and 1.8 k

resistors

shown in Figures 38 and 40. The resulting expression for "a" is

as follows: a = 1/(10

◊

V

T

) which is approximately equal to four

at room temperature. Substituting a = 4 in the above equation

results in a ≠28.8 mV/dB control law at room temperature.

The ≠28.8 mV/dB number is slightly different from the data

sheet specification of ≠30 mV/dB. The difference arises from

the temperature dependency of the control law. The term V

T

is known as the thermal voltage, and it has a direct dependency

Figure 40. SSM2118T Detailed Functional Diagram

REV. A

≠13≠

SSM2018T/SSM2118T

on temperature: V

T

= kT/q (k = Boltzmann's constant =

1.38E-23, q = electron charge = 1.6E-19, and T = absolute

temperature in Kelvin). This temperature dependency leads to

the ≠3500 ppm/

∞

C drift of the control law. It also means that

the control law changes as the part warms up. Thus, our speci-

fication for the control law states that the part has been powered

up for 60 seconds.

When the part is initially turned on, the temperature of the die

is still at the ambient temperature (25

∞

C for example), but the

power dissipation causes the die to warm up. With

±

15 V sup-

plies and a supply current of 11 mA, 330 mW is dissipated.

This number is multiplied by

JA

to determine the rise in the

die's temperature. In this case, the die increases from 25

∞

C to

approximately 50

∞

C. A 25

∞

C temperature change causes a

8.25% increase in the gain constant, resulting in a gain constant

of 30 mV/dB. The graph in Figure 31 shows how the gain con-

stant varies over the full temperature range.

Proper Operating Mode for the SSM2018T and SSM2118T

Both parts have the flexibility of operating in either Class A or

Class AB. This is accomplished by adjusting the amount of cur-

rent flowing in the gain core (I

M

in Figure 38). The traditional

trade-off between the two classes is that Class A tends to have

lower THD but higher noise than Class AB. However, by utiliz-

ing well matched gain core transistors, distortion compensation

circuitry, and laser trimming, the SSM2018T and SSM2118T

have excellent THD performance in Class AB. Thus, the parts

offer the best of both worlds in having the low noise of Class AB

with low THD.

Because the parts operate optimally in Class AB, the distortion

trim is performed for this class. To guarantee conformance to the

data sheet THD specifications, both the SSM2018T and SSM2118T

must be operated in Class AB. This does not mean that the parts

cannot be operated in Class A, but the optimal THD trim point

is different for the two classes. Using Class A operation results

in a shift of THD performance from a typical value of 0.006%

to 0.05% without trim. An external potentiometer could be

added to change the trim back to its optimal point as shown in

the OVCE application circuit, but this adds the expense and

time in adjusting a potentiometer.

The class of operation is set by selecting the proper value for R

B

shown in Figure 37. R

B

determines the current flowing into the

MODE input (Pin 12). For class AB operation with

±

15 V

supplies, R

B

should be 150 k

. This results in a current of 95

µ

A. For other supply voltages, adjust the value of R

B

such that

current remains at 95

µ

A. This current follows the formula:

I

MODE

=

(V

CC

≠ 0.7V )

R

B

The factor of 0.7 V arises from the fact that the dc bias on Pin

12 is a diode drop above ground.

Output Drive

The SSM2018T is buffered by an internal op amp to provide a

low impedance output. This output is capable of driving to

within 1.2 V of either rail at 1% distortion for a 100 k

load.

(Note: This 100 k

load is in parallel with the feedback resistor

of 18 k

, so the effective load is 15.3 k

.) For better than

0.01% distortion, the output should remain about 3.5 V away

from either rail as shown in Figure 3. As the graph of output

swing versus load resistance shows (Figure 10), to maintain less

than 1% distortion, the output current should be limited to

approximately

±

1.3 mA. If higher current drive is required,

then the output should be buffered with a high quality op amp

such as the OP176 or AD797.

The internal amplifiers are compensated for unity gain stability

and are capable of driving a capacitive load up to 4700 pF.

Larger capacitive loads should be isolated from the output of the

SSM2018T by the use of a 50

series resistor.

Upgrading SSM2018 Sockets

The SSM2018T easily replaces the SSM2018 in the basic VCA

configuration. The parts are pin for pin compatible allowing di-

rect replacement. At the same time, the trimming potentiom-

eters for symmetry and offset should be removed, as shown in

Figure 41. Upgrading to the SSM2018T immediately saves the

expense of the potentiometers and the time in production of

trimming for minimum distortion and control feedthrough.

18k

50pF

V+

V

OUT

47pF

NC

1µF

1k

3k

V≠

V+

1µF 18k

1µF 18k

R

B

: 150k

FOR CLASS AB

NC = NO CONNECT

R

B

V

CONTROL

V

IN+

V

IN≠

1

2

3

4

5

6

7

8

16

15

14

13

12

10

9

SSM2018T

11

470k

500k

100k

10M

OFFSET

TRIM

V+

V≠

SYMMETRY

TRIM

REMOVE FOR SSM2018T

Figure 41. Upgrading SSM2018 Sockets

If the SSM2018 is used in the OVCE or VCP configuration, the

SSM2018T can still directly replace it. However, the potenti-

ometers cannot necessarily be removed, as explained in the

OVCE and VCP sections.

Temperature Compensation of the Gain Constant

As explained above, the gain constant has a 3500 ppm/

∞

C tem-

perature drift due to the inherent nature of the control port.

Over the full temperature range of ≠40

∞

C to +85

∞

C, the drift

causes the gain to change by 7 dB if the part is in a gain of

±

20 dB. If the application requires that the gain constant be the

same over a wide temperature range, then external temperature

compensation should be employed. The simplest form of com-

pensation is a temperature compensating resistor (TCR), such

as the PT146 from Precision Resistor Co. These elements are

different from a standard thermistor in that they are linear over

temperature to better match the linear drift of the gain constant.

REV. A

≠14≠

SSM2018T/SSM2118T

such that full scale produces 80 dB of attenuation. The resistor

divider can be adjusted to provide other attenuation ranges. If a

parallel interface is needed, then the DAC8562 may be used, or

for a dual DAC, the AD8582.

0.1

µ

F

+15V

18k

V

IN

6

DAC8512

8

7

CS

CLR

2

1

0.1

µ

F

18k

50pF

47pF

V

OUT

150k

+15V

≠15V

0.1

µ

F

+5V

C

CON

1

µ

F

R6

825

R7

1k

0V

V

C

+2.24V

5

LD

3

SCLK

4

SDI

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SSM2018T

NC

NC

NC

NC

NC = NO CONNECT

Figure 44. 12-Bit DAC Controls the VCA Gain

Supply Considerations and Single Supply Operation

The SSM2018T and SSM2118T have a wide operating supply

range. Many of the graphs in this data sheet show the perfor-

mance of the part from

±

5 V to

±

18 V. These graphs offer typi-

cal performance specifications and are a good indication of the

parts capabilities. The minimum operating supply voltage is

±

4.5 V. Below this voltage, the parts are inoperable. Thus, to

account for supply variations, the recommended minimum sup-

ply is

±

5 V.

The circuits in the data sheet do not show supply decoupling for

simplicity; however, to ensure best performance, each supply

pin should be decoupled with a 0.1

µ

F ceramic (or other low re-

sistance and inductance type) capacitor as close to the package

as possible. This minimizes the chance of supply noise feeding

through the part and causing excessive noise in the audio fre-

quency range.

The SSM2018T and SSM2118T can be operated in single sup-

ply mode as long as the circuit is properly biased. Figure 45

shows the proper configuration, which includes an amplifier to

create a false ground node midway between the supplies. A

high quality, wide bandwidth audio amplifier such as the OP176

or AD797 should be used to ensure a very low impedance

ground over the full audio frequency range. The minimum op-

erating supply for the SSM2018 is

±

5 V, which gives a mini-

mum single supply of +10 V and ground. The performance of

the circuit with +10 V is identical to graphs that show operation

of the SSM2018T with

±

5 V supplies.

1µF

2k

V

C

(PIN 11)

SSM2018T OR SSM2118T

1k

*

3500ppm/

∞

C

1k

*

3500ppm/

∞

C

CONTROL

VOLTAGE

*PRECISION RESISTOR CO.

10601 75

TH

ST. NORTH

LARGO, FL 34647

(813) 541-5771

Figure 42. Two TCRs Compensate for Temperature Drift

of Gain Constant

+15V

≠15V

R3

10k

50pF

R4

1k

R5

9k

R1

10k

OP176

R2

10k

1k

*

3500ppm/

∞

C

V

C

(PIN 11)

SSM2018T OR SSM2118T

CONTROL

VOLTAGE

Figure 43. Current Source Allows Temperature Compen-

sation with One TCR

One of the resistors in the divider to the control port can be sub-

stituted with an appropriately chosen TCR to compensate the

SSM2018T or the SSM2118T as shown in Figure 42. Because

the resistor divider effectively cuts the temperature coefficient in

half, two TCRs must be used. The combined drift of the two is

7000 ppm/

∞

C, given an effective drift for to the control voltage

of ≠3500 ppm/

∞

C. Of course, a single TCR with the appropriate

coefficient can be used. The 3500 ppm parts were chosen be-

cause they are a standard item and do not need to be special

ordered.

In many applications, an op amp is used to drive the control

voltage. If this is the case, it may be more economical to use the

op amp and a single TCR for temperature compensation. The

op amp is configured as a Howland current source as shown in

Figure 43. The current then flows through a single TCR to

create the control voltage. Because the resistor divider is not

present, the temp coefficient is equivalent to the TCR's coef-

ficient. Using this technique, the drift was reduced from

≠3500 ppm/

∞

C to ≠150 ppm/

∞

C, which results in a total com-

pensated gain shift of 0.4 dB over the full temperature range at a

gain of

±

20 dB.

Digital Control of the Gain

A common method of controlling the gain of a VCA is to use a

digital-to-analog converter to set the control voltage. Figure 44

shows a 12-bit DAC, the DAC8512, controlling the SSM2018T

(or SSM2118T). The DAC8512 is a complete 12-bit converter

in an 8-pin package. It includes an on board reference and a

output amplifier to produce an output voltage from 0 V to

+4.095 V, which is 1 mV/bit. Since the voltage is always posi-

tive, this circuit only provides attenuation. The resistor divider

on the output of the DAC8512 is set to scale the output voltage

REV. A

≠15≠

SSM2018T/SSM2118T

V+

1

µ

F

R

B

18k

V+

18k

V

IN+

1

µ

F 18k

V

IN≠

47pF

1

µ

F

50pF

1k

V

CONTROL

3k

V

OUT

1

2

16

15

5

6

7

12

11

10

3

4

14

13

8

9

SSM2018T

V+

OP176

100k

100k

V+

10

µ

F

Figure 45. Single Supply Operation of SSM2018T

Operational Voltage Controlled Element

The SSM2018T has considerable flexibility beyond the basic

VCA circuit utilized throughout this data sheet. The name

"Operational Voltage Controlled Element" comes from the fact

that the part behaves much like an operational amplifier with a

second voltage controlled output. The symbol for the OVCE

connected as a unity gain follower/VCA is shown in Figure 46.

The voltage output labeled V

1≠G

is fed back to the inverting in-

put just as for an op amp's feedback. The V

G

output is ampli-

fied or attenuated depending upon the control voltage. Because

the OVCE works just like an op amp, the feedback could just as

easily have included resistors to add gain, or a filter network to

add frequency shaping. The full circuit for the OVCE is shown

in Figure 47. Notice that the amplifier whose output (Pin 16)

was originally connected to V

MINUS

is now the output for feed-

back. As mentioned before, because the SSM2018T is trimmed

for the basic VCA configuration, potentiometers are needed for

the OVCE configuration to ensure the best THD and control

feedthrough performance.

If a symmetry trim is to be performed, it should precede the

control feedthrough trim and be done as follows:

1. Apply a 1 kHz sine wave of +10 dBu to the input, with the

control voltage set for unity gain.

2. Adjust the symmetry trim potentiometer to minimize distor-

tion of the output signal.

Next the control feedthrough trim is done as follows:

1. Ground the input signal port and apply a 60 Hz sine wave

to the control port. The sine wave should have its high and

low peaks correspond to the highest gain to be used in the

application and 30 dB of attenuation, respectively. For ex-

ample, a range of +20 dB gain to 30 dB attenuation requires

that the sine wave amplitude ranges between ≠560 mV and

+840 mV on Pin 11.

2. Adjust the control feedthrough potentiometer to null the sig-

nal seen at the output.

V

IN

V

C

V

G

V

1≠G

Figure 46. OVCE Follower/VCA Connection

18k

50pF

470k

500k

V+

100k

10M

CONTROL

FEEDTHROUGH

TRIM

V+

V≠

V

1≠G

V

G

INPUTS

220pF

NC

V≠

1µF

1k

3k

V

CONTROL

R

B

: 30k

FOR CLASS A

150k

FOR CLASS AB

NC = NO CONNECT

SYMMETRY

TRIM

V+

R

B

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SSM2018T

18k

50pF

Figure 47. OVCE Application Circuit

REV. A

≠16≠

SSM2018T/SSM2118T

PRINTED IN U.S.A.

C1937≠5≠7/94

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Pin Plastic DIP (N-16) Package

PIN 1

0.280 (7.11)

0.240 (6.10)

9

16

1

8

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.100 (2.54)

BSC

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

0.840 (21.33)

0.745 (18.93)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

16-Pin SOIC (R-16) Package

PIN 1

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

1

16

9

8

0.0192 (0.49)

0.0138 (0.35)

0.0500 (1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.4133 (10.50)

0.3977 (10.00)

0.0118 (0.30)

0.0040 (0.10)

0.0500 (1.27)

0.0157 (0.40)

8

∞

0

∞

0.0291 (0.74)

0.0098 (0.25)

x 45

∞

0.0125 (0.32)

0.0091 (0.23)

Voltage Controlled Panner

An interesting circuit that is built with the OVCE building block

is a voltage controlled panner. Figure 48 shows the feedback

connection for the circuit. Notice that the average of both out-

puts is fed back to the input. Thus, the average must be equal

to the input voltage. When the control voltage is set for gain at

V

G

, this causes V

1-G

to attenuate (to keep the average the same).

On the other hand, when V

G

is attenuated, V

1-G

is amplified.

The result is that the control voltage causes the input to "pan"

from one output to the other. The following expressions show

how this circuit works mathematically:

V

G

=

2 K

◊

V

IN

and V

I ≠G

=

2 (1 ≠ K )

◊

V

IN

where K varies between 0 and 1 as the control voltage is

changed from full attenuation to full gain respectively. When

V

C

= 0, then K = 0.5 and V

G

= V

1-G

= V

IN

. Again, trimming is

required for best performance. Pin 9 should be grounded. This

is possible because the feedback is constant and the adaptive

network is not needed. The VCP is the only application shown

in this data sheet where Pin 9 is grounded.

V

IN

V

C

V

G

V

1≠G

18k

18k

Figure 48. Basic VCP Connection