þÿ

AIC1571

5-bit DAC, Synchronous PWM Power

Regulator with Dual Linear Controllers

Analog Integrations Corporation 4F, 9 Industry E. 9th Rd, Science-Based Industrial Park, Hsinchu, Taiwan

DS-1571-00 012102

TEL: 886-3-5772500

FAX: 886-3-5772510

www.analog.com.tw

1

n

FEATURES

l

Provides 3 Regulated Voltages for Microprocessor

Core, Clock and GTL Power.

l

Simple Voltage-Mode PWM Control.

l

Dual N-Channel MOSFET Synchronous Driver.

l

Operates from +3.3V, +5V and +12V Inputs.

l

Fast Transient Response.

l

Full 0% to 100% Duty Ratios.

l

±1.0% Output Voltage for VCORE and

±

2.0%

Output Voltage Reference for VCLK and VGTL.

l

TTL Compatible 5-bit Digital-to-Analog Core Output

Voltage Selection. Range from 1.3V to 3.5V.

0.1V Steps from 2.1V to 3.5V.

0.05V Steps from 1.3V to 2.05V.

l

Adjustable Current Limit without External Sense

Resistor.

l

Microprocessor Core Voltage Protection against

Shorted MOSFET.

l

Power Good Output Voltage Monitor.

l

Over-Voltage and Over-Current Fault Monitors.

l

200KHz Free-Running Oscillator Programmable up

to 350KHz.

n

APPLICATIONS

l

Full Motherboard Power Regulation for Computers.

l

Power Integrations for 3 Output Power System.

n

DESCRIPTION

The AIC1571 combines a synchronous voltage mode

controller with two linear controllers as well as the

monitoring and protection functions in this chip. The

PWM controller regulates the microprocessor core

voltage with a synchronous rectified buck converter.

One linear controller regulates power for the GTL

bus and the other linear controller provides power for

the clock driver circuit or memory (1.8V)

An integrated 5 bit D/A converter that adjusts the

core PWM output voltage from 2.1V to 3.5V in 0.1V

increments and from 1.3V to 2.05V in 0.05V incre-

ments. The linear regulator uses an internal driver

device to provide 2.5V±2.5%. The linear controller

drives with an external N-channel MOSEFET to pro-

vide 1.5V±2.5%.

This chip monitors all the output voltages. Power

Good signal is issued when the core voltage is

within ±10% of the DAC setting and the other levels

are above their under-voltage levels. Over-voltage

protection for the core output uses the lower N-

channel MOSFET to prevent output voltage above

115% of the DAC setting.

The PWM over-current function monitors the output

current by using the voltage drop across the upper

MOSFET's R

DS(on)

, eliminating the need for a current

sensing resistor

.

AIC1571

2

n

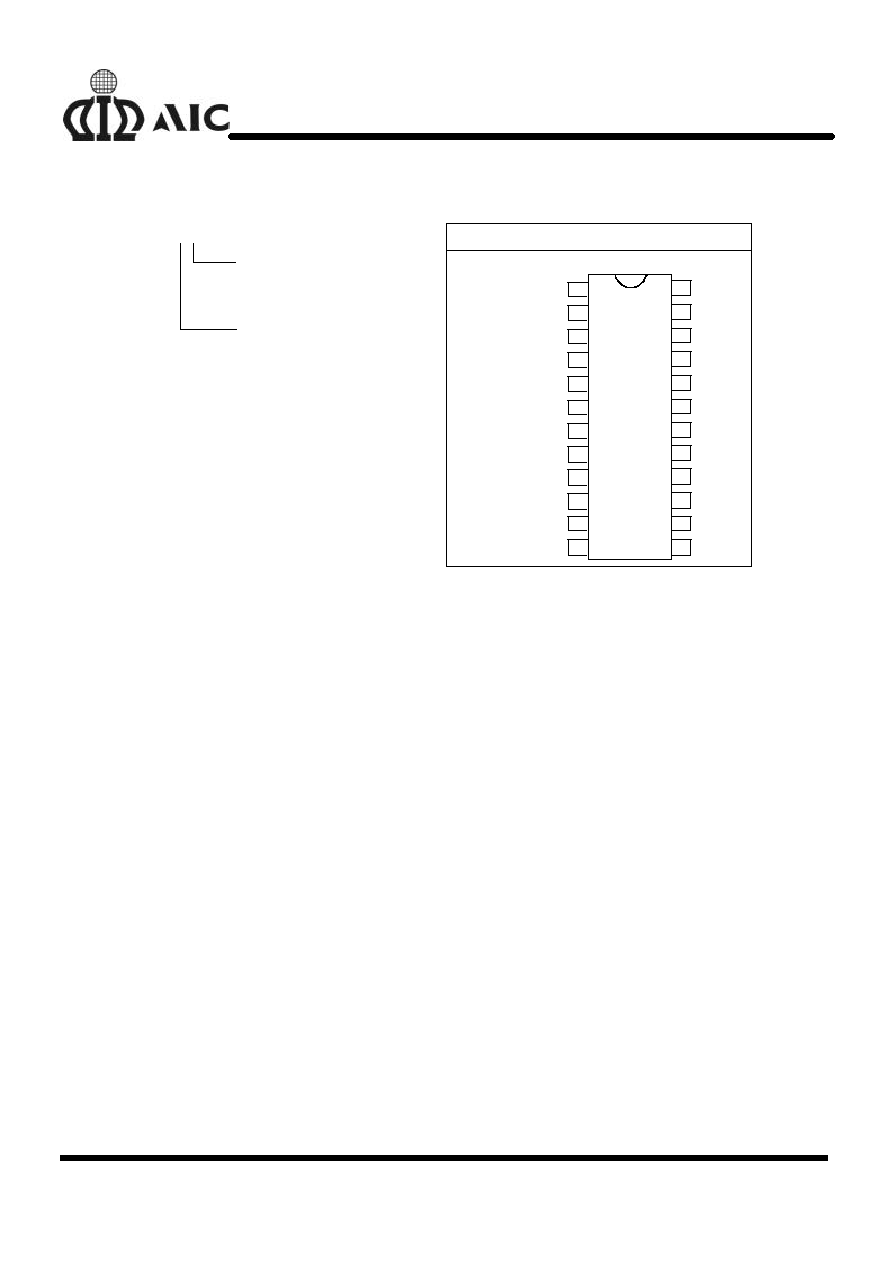

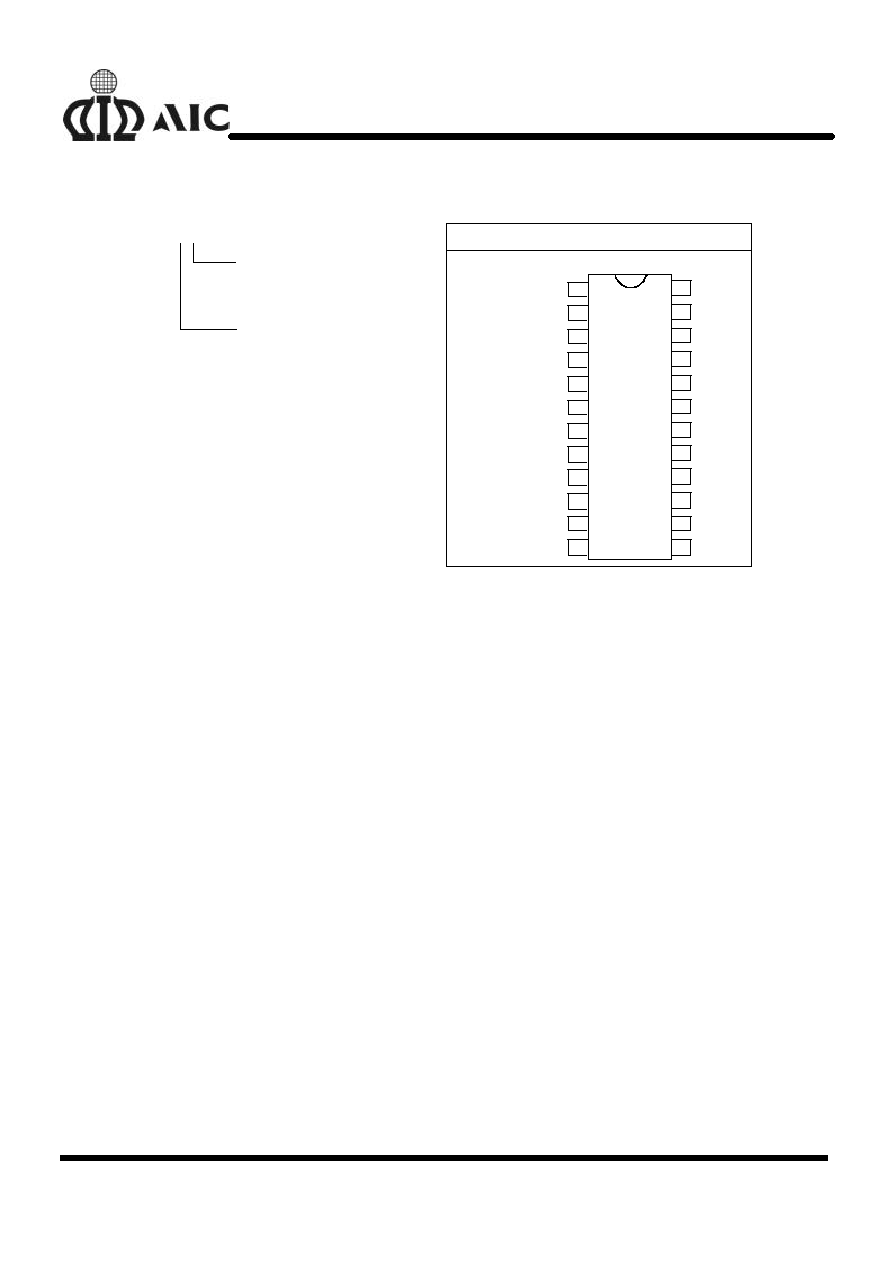

ORDERING INFORMATION

PIN CONFIGURATION

PACKING TYPE

TR: TAPE & REEL

TB: TUBE

PACKAGING TYPE

S: SMALL OUTLINE

AIC1571CXXX

Example: AIC1571CSTR

à

in SO-24 Package & Taping &

Reel Packing Type

SO-24

TOP VIEW

LGATE

UGATE

PHASE

VSEN

PGND

OCSET

16

15

FB1

GATE3

COMP1

FB3

24

22

23

21

20

19

17

18

14

13 GATE2

GND

1

3

4

2

5

7

6

8

9

10

VID0

VID4

VID3

VID2

VCC

VID1

RT

PGOOD

SS

FAULT

11

12

VIN2

FB2

n

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V

CC

.................. ... ... ... ... ........ ... ... ... ............ ..... ... ..................... +15V

PGOOD, FAULT and GATE Voltage

........ ... ........ ... ... ..... .... GND -0.3V to V

CC

+0.3V

Input, Output , or I/O Voltage

......... ...... ... ... ... ... ... ... ... ..... ... ............ GND -0.3V to 7V

Recommended Operating Conditions

Supply Voltage; VCC

... ... .................. ................... +12V±10%

Ambient temperature Range

... ... ..... ... ... ... ... ................. 0

°

C~70

°

C

Junction Temperature Range

... ... ......... ... ... .................. 0

°

C~100

°

C

Thermal Information

Thermal Resistance,

JA

SOIC package

... ... ... ... ... ... ... ... ... ... ... ... ... ..... ............... 100

°

C/W

SOIC package (with 3in

2

of copper)

... ...... ... ... .......... ......... 90

°

C/W

Maximum Junction Temperature (Plastic Package)

... ... ... ... ... ... ..... ... ...... 150

°

C

Maximum Storage Temperature Range

... ... ... ... ... ... ... ... ... ... ... .... -65

°

C ~ 150

°

C

Maximum Lead Temperature (Soldering 10 sec)

... ... ... ... ... ... ... ... ... ..... ... 300

°

C

n

TEST CIRCUIT

Refer to APPLICATION CIRCUIT.

AIC1571

3

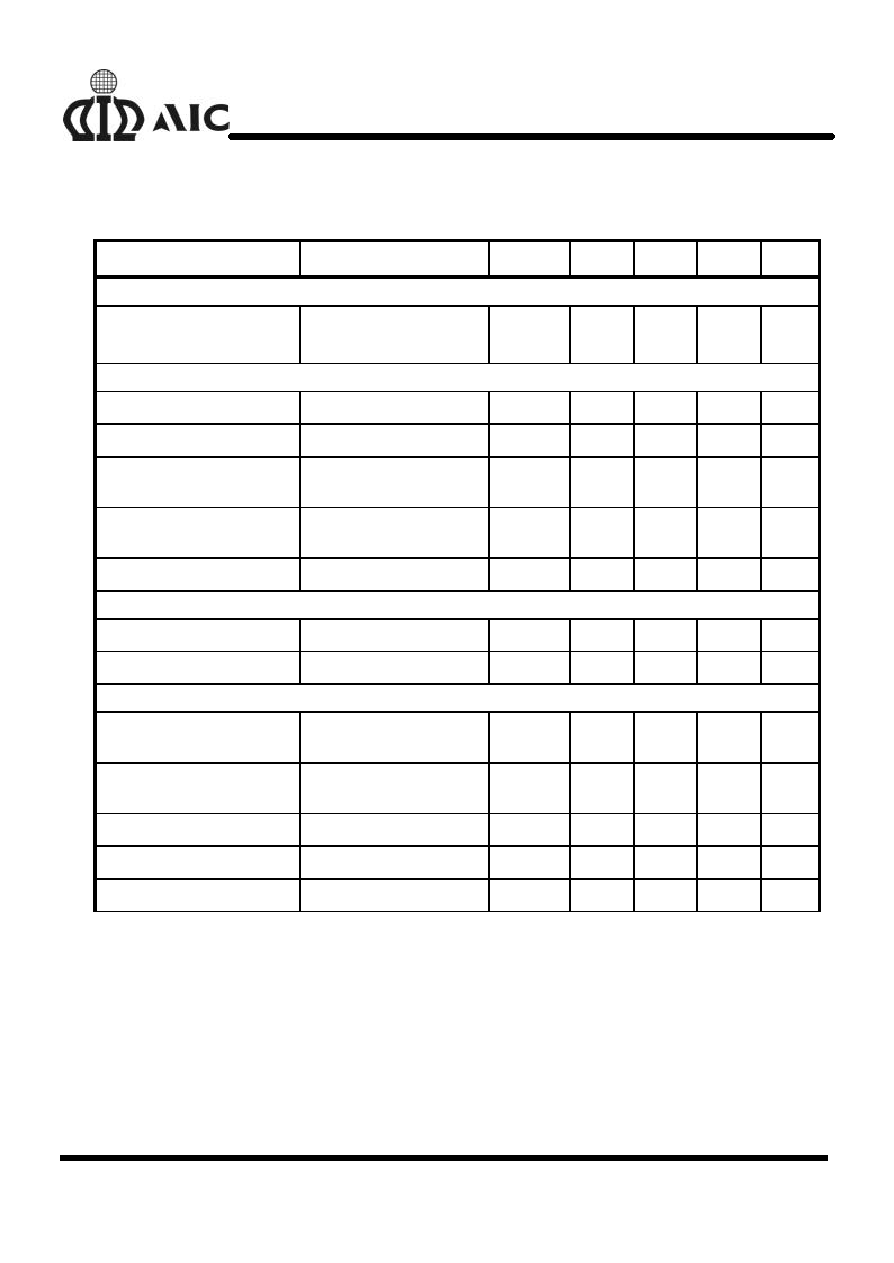

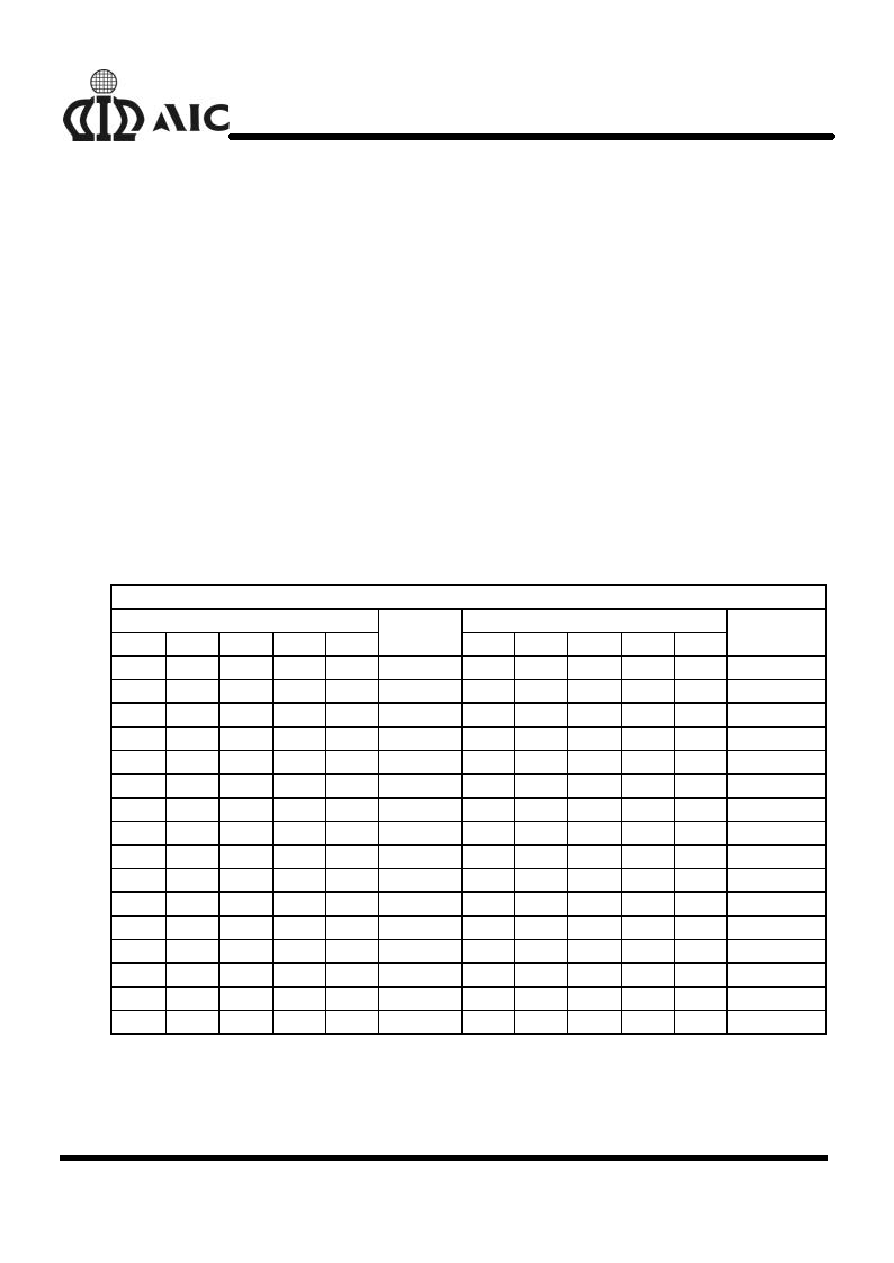

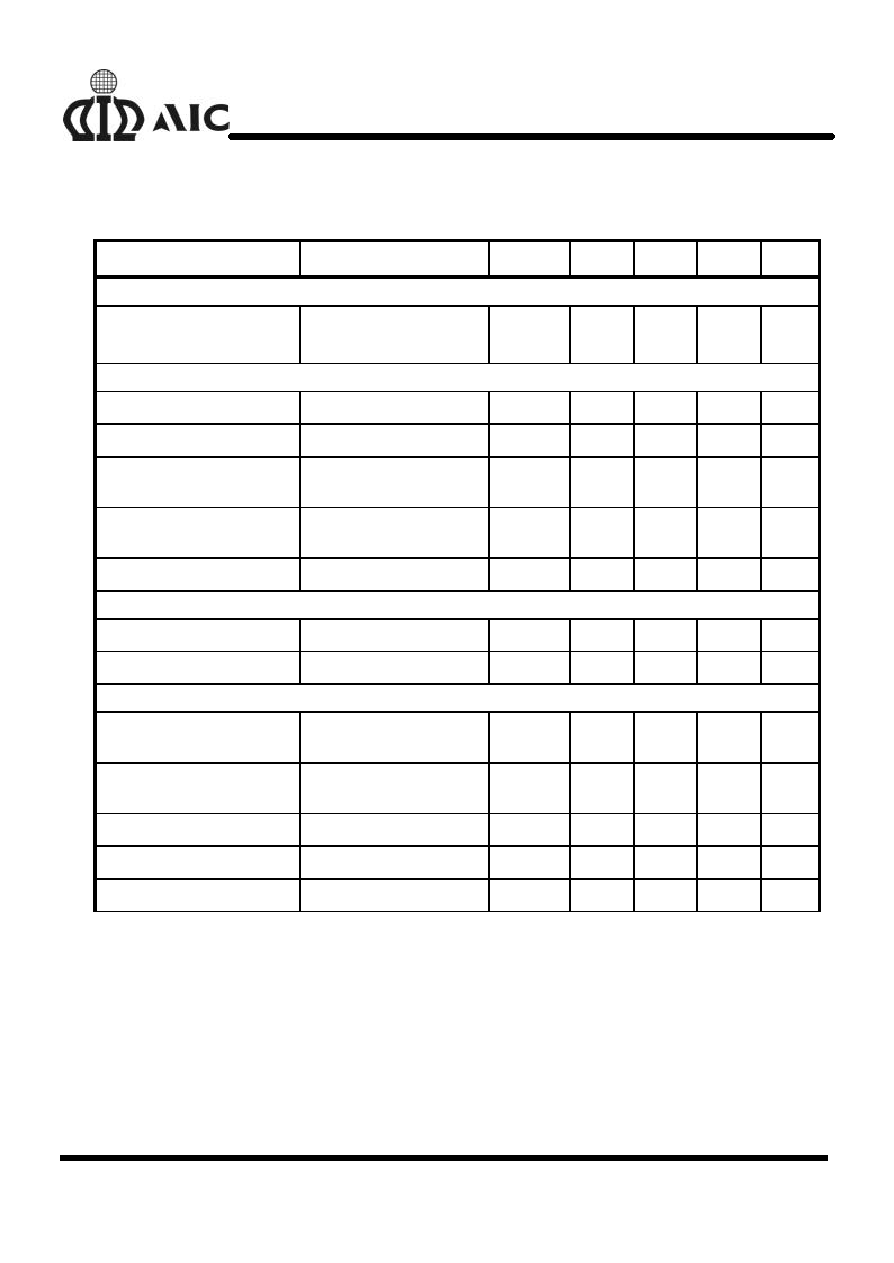

n

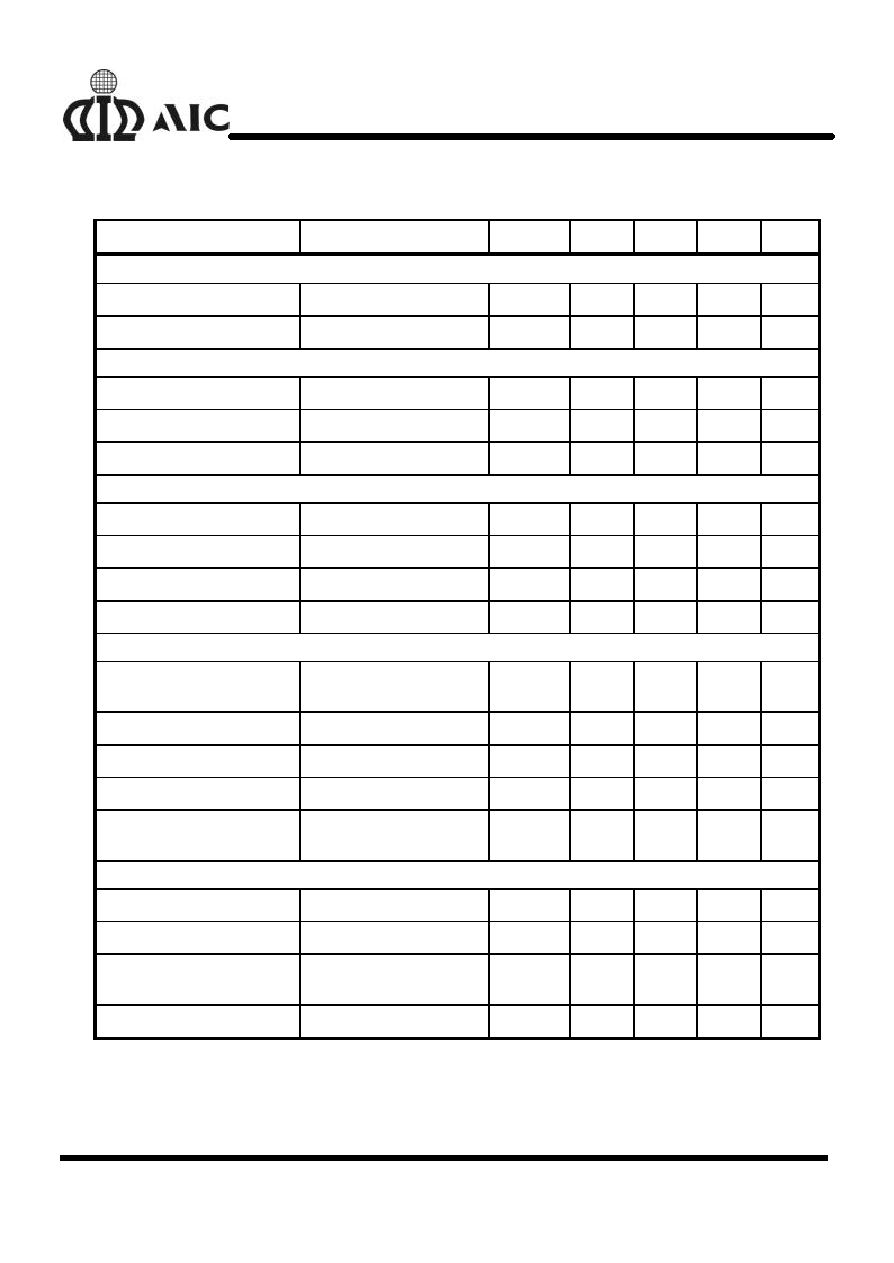

ELECTRICAL CHARACTERISTICS

(V

cc

=12V, T

J

=25

°

C, Unless otherwise

specified)

PARAMETER

TEST CONDITIONS

SYMBOL MIN.

TYP.

MAX.

UNIT

VCC SUPPLY CURRENT

Supply Current

UGATE, LGATE, GATE2

and GATE3 open

I

CC

1.8

5

mA

POWER ON RESET

Rising VCC Threshold

V

OCSET

=4.5V

VCC

THR

8.6

9.5

10.4

V

Falling VCC Threshold

V

OCSET

=4.5V

VCC

THF

8.2

9.2

10.2

V

Rising VIN2 Under-Voltage

Threshold

VIN2

THR

2.5

2.6

2.7

V

VIN2 Under-Voltage Hystere-

sis

VIN2

HYS

130

mV

Rising V

OCSET1

Threshold

V

OCSETH

1.3

V

OSCILLATOR

Free Running Frequency

RT=Open

F

170

200

230

KHz

Ramp. Amplitude

RT=open

V

OSC

1.3

V

P-P

REFERENCE AND DAC

DAC (VID0~VID4) Input Low

Voltage

VID

L

0.8

V

DAC (VID0~VID4) Input High

Voltage

VID

H

2

V

DACOUT Voltage Accuracy

VDAC=1.3V~3.5V

-1.0

+1.0

%

FB2 Reference Voltage

V

REF2

1.245

1.270

1.295

V

FB3 Reference Voltage

V

REF3

1.250

1.275

1.300

V

AIC1571

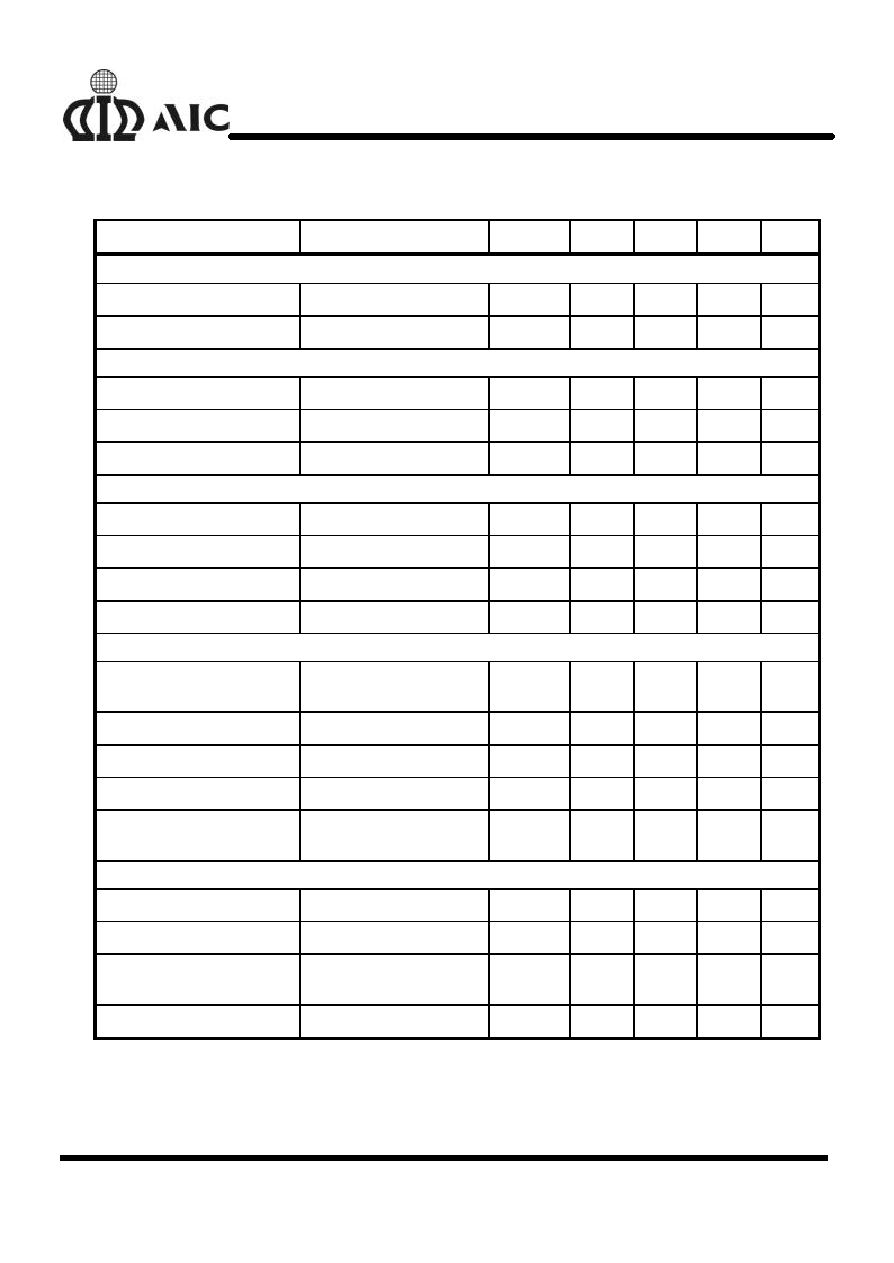

4

n

ELECTRICAL CHARACTERISTICS

(Continued)

PARAMETER

TEST CONDITIONS

SYMBOL

MIN.

TYP.

MAX.

UNIT

LINEAR CONTROLLER

Regulation

0 < I

GATE2/3

< 10mA

-2.5

+2.5

%

Under-Voltage Level

FB2/3 falling

FB2/3

UV

70

80

%

PWM CONTROLLER ERROR AMPLIFIER

DC GAIN

76

dB

Gain Bandwidth Product

GBWP

11

MHz

Slew Rate

COMP1=10pF

SR

6

V/

µ

S

PWM CONTROLLER GATE DRIVER

Upper Drive Source

VCC=12V, V

UGATE

=11V

R

UGH

5.2

6.5

Upper Drive Sink

VCC=12V, V

UGATE

=1V

R

UGL

3.3

5

Lower Drive Source

VCC=12V, V

LGATE

=11V

R

LGH

4.1

6

Lower Drive Sink

VCC=12V, V

LGATE

=1V

R

LGL

3

5

PROTECTION

V

OUT1

Voltage Over-Voltage

Trip

VSEN Rising

OVP

112

115

118

%

OCSET Current Source

V

OCSET

=4.5V

DC

I

OCSET

170

200

230

µ

A

FAULT Sourcing Current

V

FAULT

=10V

I

OVP

10

16

mA

Soft-Start Current

I

SS

11

µ

A

Chip Shutdown Soft Start

Threshold

1.0

V

POWER GOOD

V

OUT1

Upper Threshold

VSEN Rising

109

110.5

112

%

V

OUT1

Under-Voltage

VSEN Falling

90.5

92

93.5

%

V

OUT1

Hysteresis

(VSEN/DACOUT)

Upper and Lower Thresh-

old

3

%

P

GOOD

Voltage Low

I

PGOOD

=-4mA

V

PGOOD

0.5

V

AIC1571

5

n

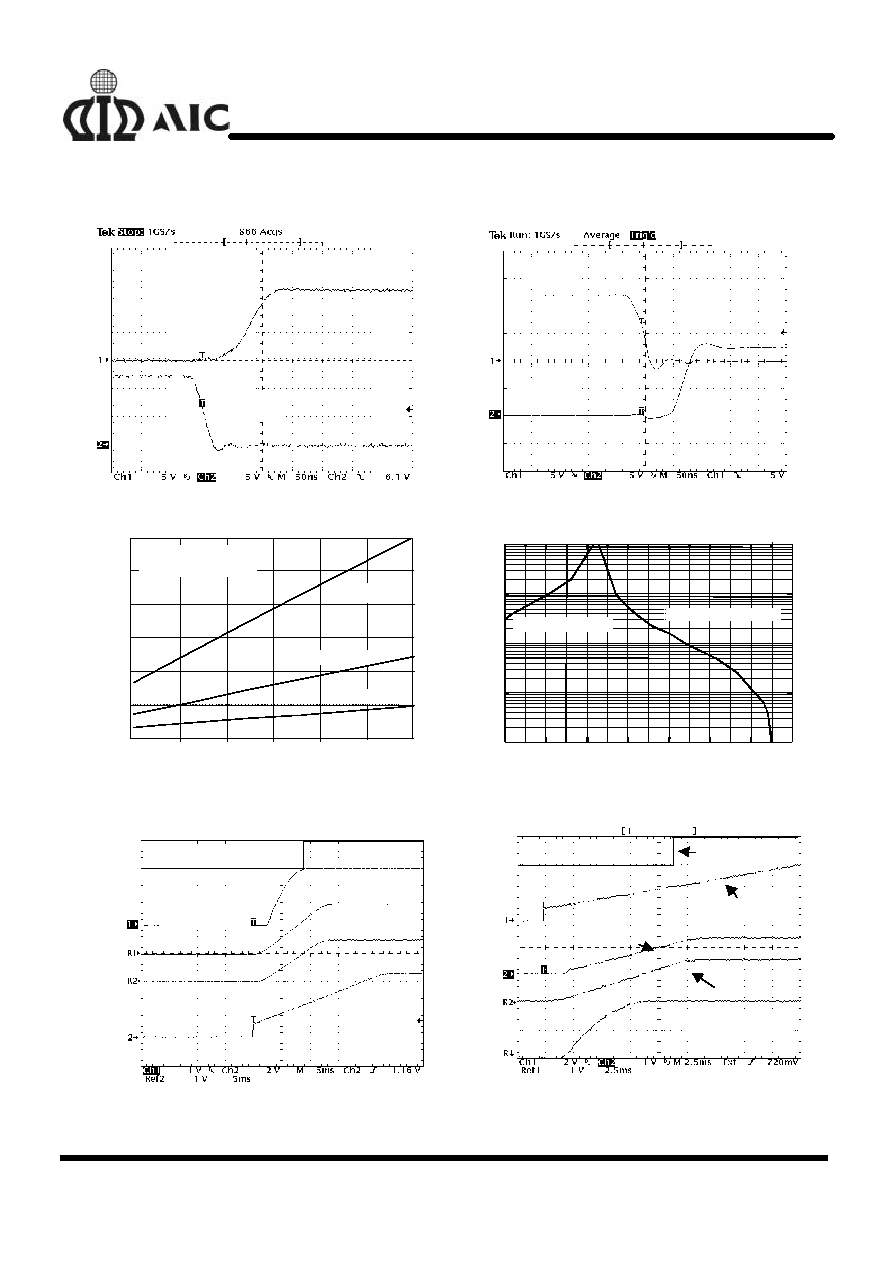

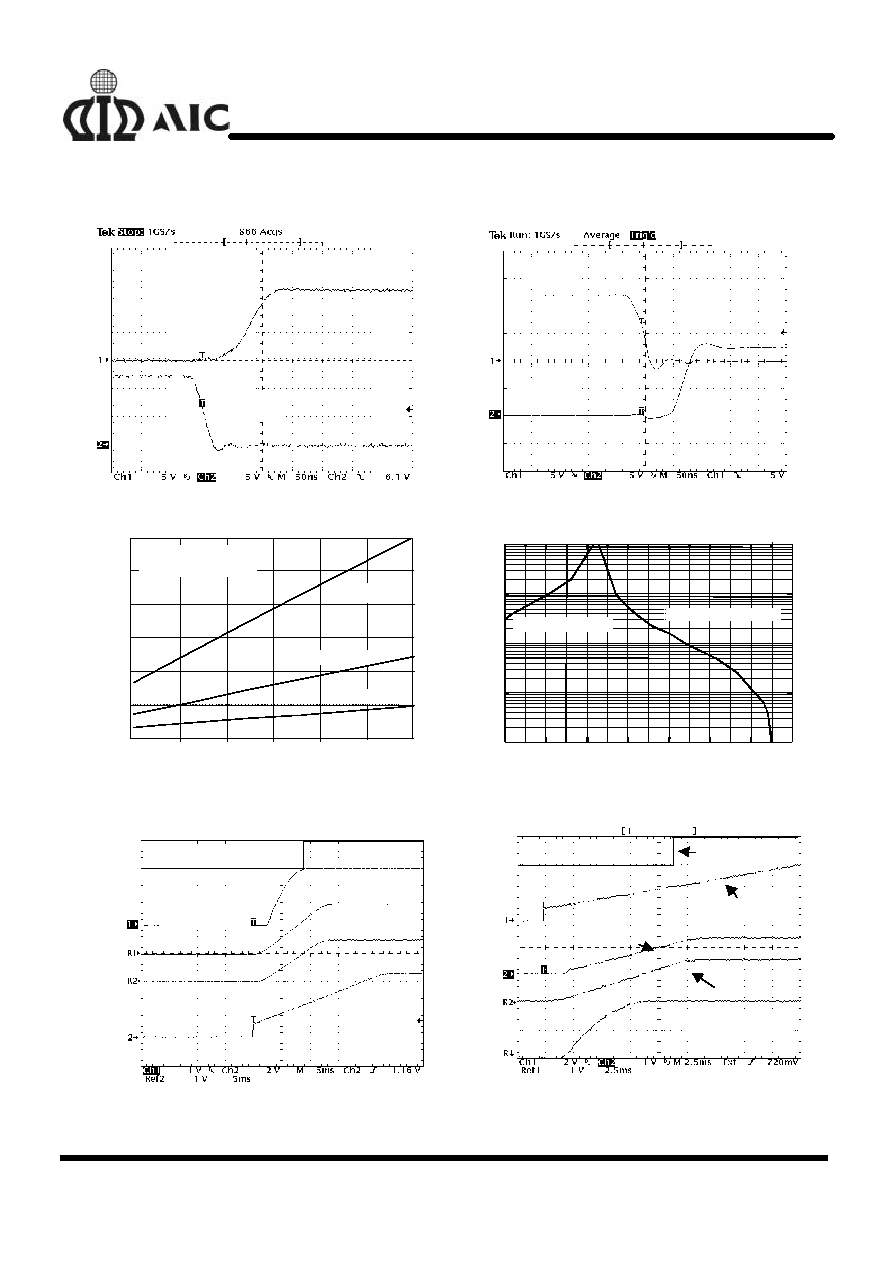

TYPICAL PERFORMANCE CHARACTERISTICS

U

GATE

L

GATE

U

GATE

L

GATE

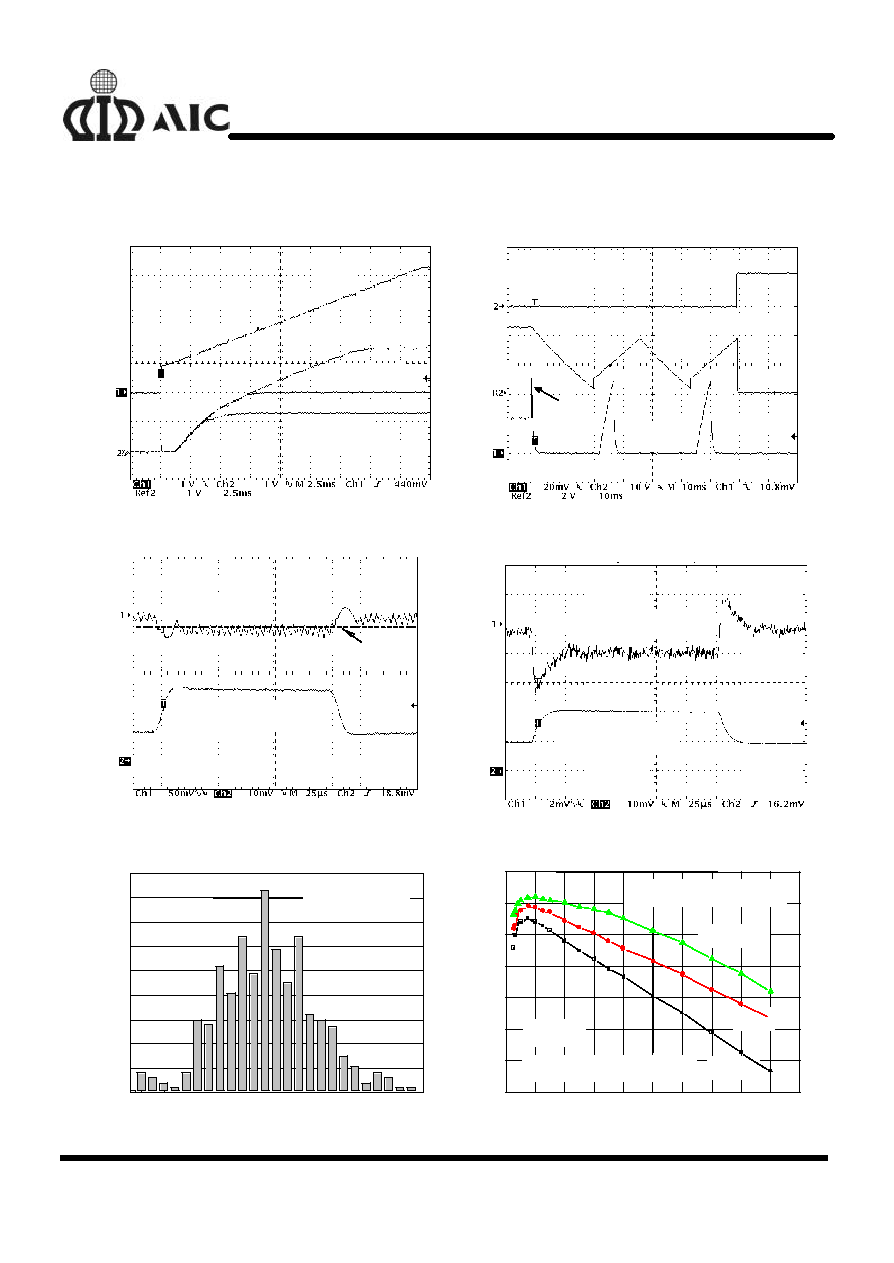

FIG.1 The gate drive waveforms

I

CC

(

mA)

Switching Frequency (KHz)

100

150

200

250

300

350

400

0

10

20

30

40

50

60

C

UGATE

=C

LGATE

=C

GATE

V

CC

=12V

C

GATE

=5000pF

C

GATE

=2000pF

C

GATE

=660pF

100

150

200

250

300

350

400

1

10

100

1000

10000

Resistance (k

)

Switching Frequency (KHz)

R

T

Pull Down to GND

R

T

Pull Up to +12V

450

FIG. 2 Bias Supply Current VS. Frequency FIG. 3 R

T

Resistance VS. Frequency

V

OUT2

(1V/div)

SS (2V/div)

V

OUT3

(1V/div)

V

OUT1

(1V/div)

PGOOD (5V/div)

SS (2V/div)

V

OUT1

(1V/div)

V

OUT3

SS (2V/div)

PGOOD (5V/div)

V

OUT1

(1V/div)

SS (2V/div)

V

OUT3

V

OUT2

(1V/div)

PGOOD (5V/div)

FIG.4-1 Circuit 1---Soft Start Interval

with 3 Outputs FIG.4-2 Circuit 2---Soft Start Interval

with 3

and PGOOD

Outputs and PGOOD

AIC1571

6

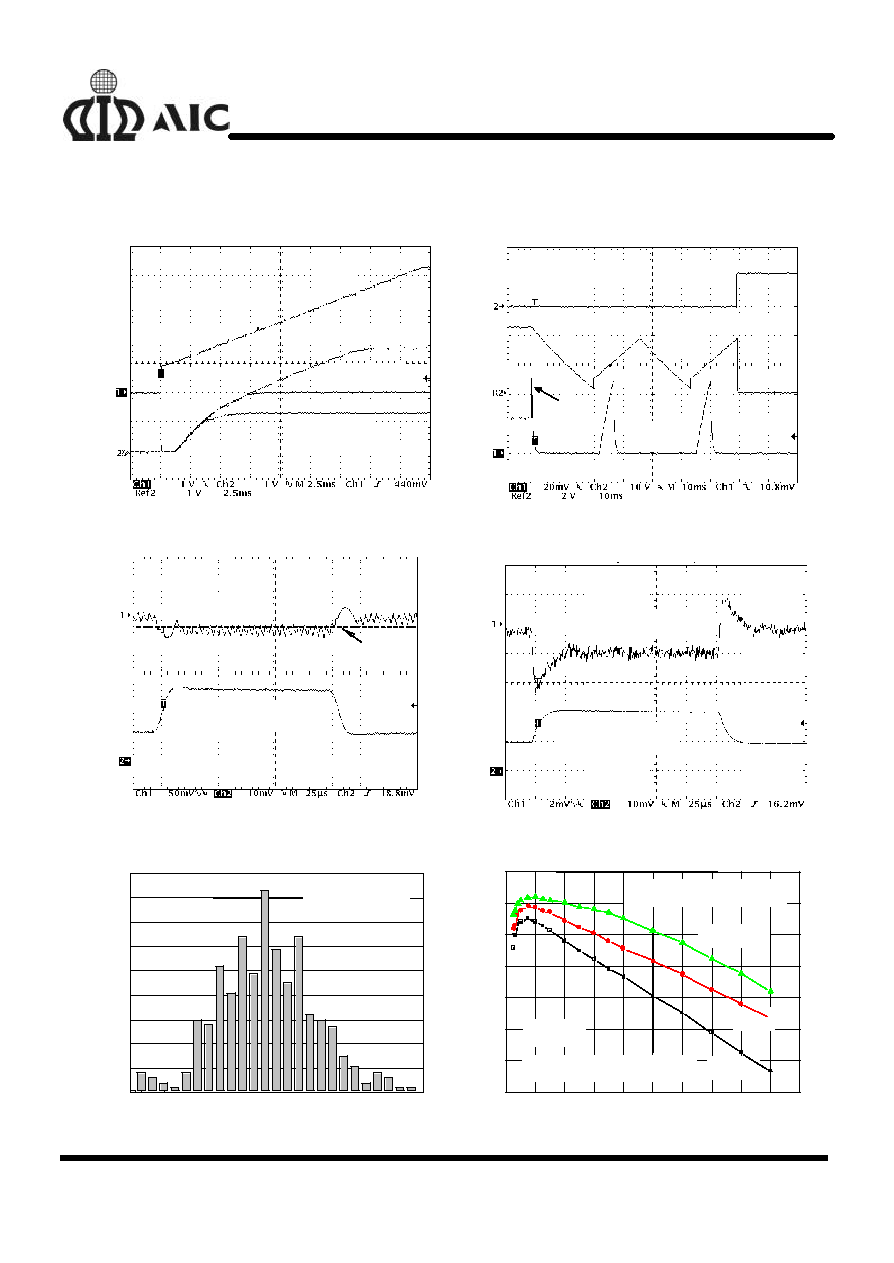

n

TYPICAL PERFORMANCE CHARACTERISTICS

(Continued)

VDAC=3.5V

VDAC=1.3V

VDAC=2V

SS

FAULT

SS

10A/div

Inductor Current

Over Load

Applied

FIG. 5 Soft Start Initiates PWM Output

FIG. 6 Over-Current Operation on Inductor

V

OUT1

5A to 12A Load Step

2.0V

DC

V

OUT3

(

2mV/div

)

1A to 2A Load Step

FIG. 7 Transient Response of PWM Output

FIG. 8 Transient Response of Linear Controller

-0.5 -0.4 -0.3 -0.2 -0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0

10

20

30

40

50

60

70

80

90

Number of Parts

DACOUT=2.0V

TA=25

°

C

0

2

4

6

8

10

12

14

16

18

20

65

70

75

80

85

90

95

100

Power MOSFET : CEB6030L

Vo=2.8V

Vo=2V

Vo=1.3V

V

IN

=5V

Switching Frequency = 200KHz

Efficiency (%)

FIG. 9 DACOUT Voltage Accuracy (%)

FIG.10 Efficiency vs. Load Current (A)

AIC1571

7

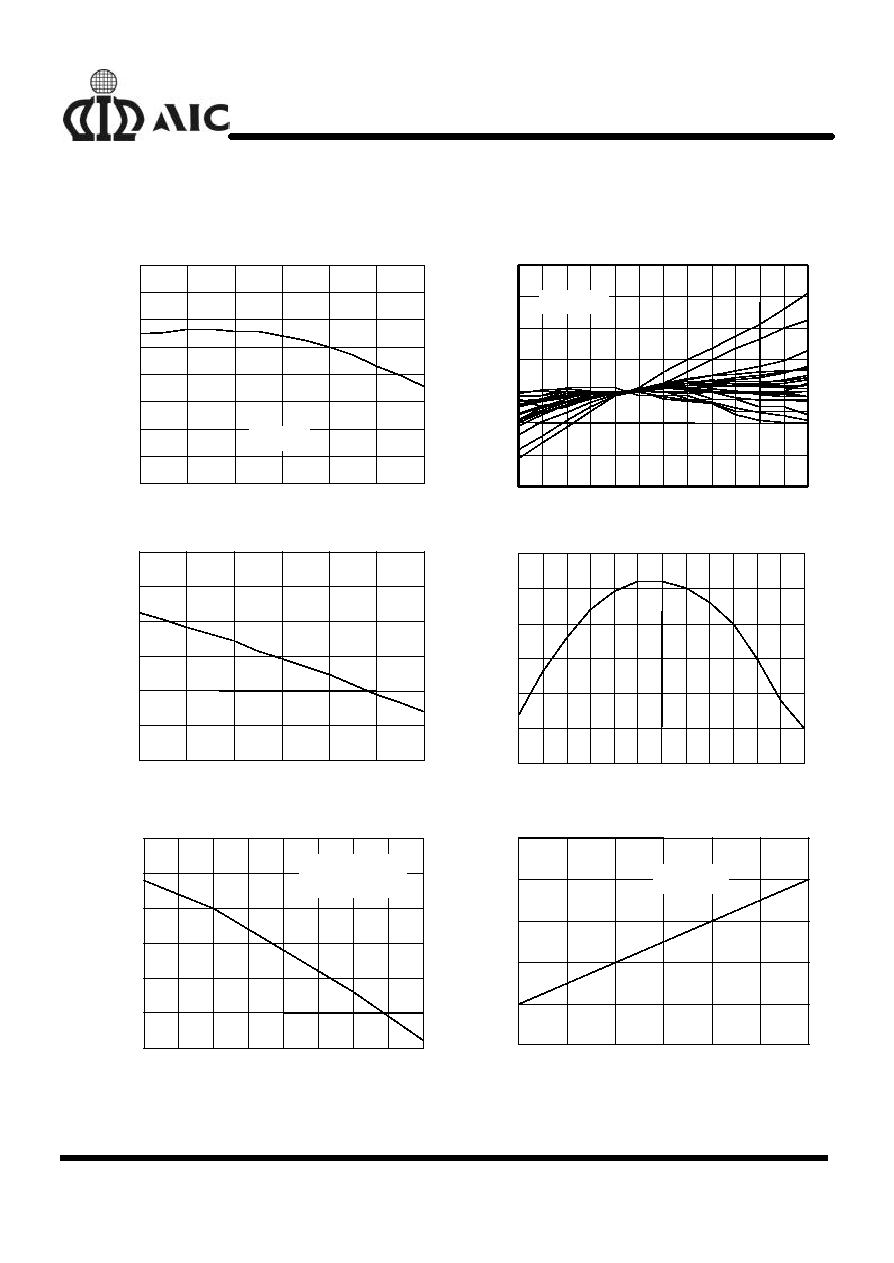

n

TYPICAL PERFORMANCE CHARACTERISTICS

(Continued)

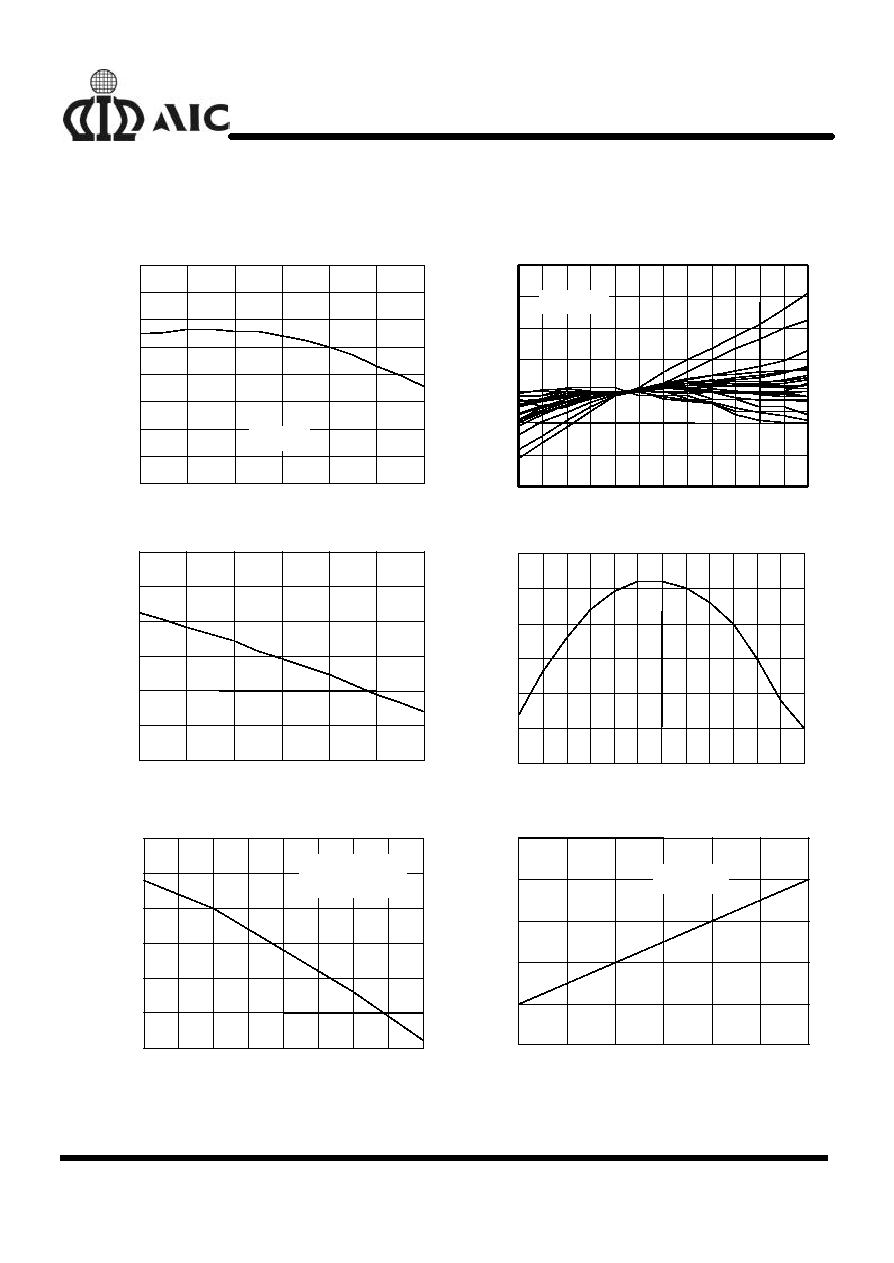

-20

0

20

40

60

80

100

180

185

190

195

200

205

210

215

220

RT=OPEN

Switching Frequency (

KHz)

DACOUT Voltage Drift (%)

-20 -10 0

10

20

30

40

50

60

70

80

90 100

0.0

0.2

0.4

0.6

0.8

DACOUT=2.0V

-0.6

-0.4

-0.2

FIG.11 Oscillator Frequency vs. Temperature (

°

C)

FIG.12 Temperature Drift of 24 Different Parts

-20

0

20

40

60

80

1

00

180

185

190

195

200

205

210

OCSET Current (

µ

A)

-20 -10

0

10

20

30

40

50

60

70

80

90

100

9.25

9.30

9.35

9.40

9.45

9.50

9.55

SS Charge Current (

uA)

FIG.13 OCSET Current vs .Temperature (

°

C)

FIG.14 SS Current vs. Temperature (

°

C)

10

11

12

13

14

15

16

17

18

-2.0

-1.5

-1.0

-0.5

0.0

0.5

1.0

DACOUT=2.0V

V

IN

=5V

NO LOAD

V

CORE

Drift Voltage (mV)

4.0

4.5

5.0

5.5

6.0

6.5

7.0

-0.2

-0.1

0.0

0.1

0.2

0.3

NO LOAD

Vcore Drift (mV)

FIG.15 Vcore Drift vs. VCC (V)

FIG.16 Vcore Drift vs. VIN (V)

AIC1571

8

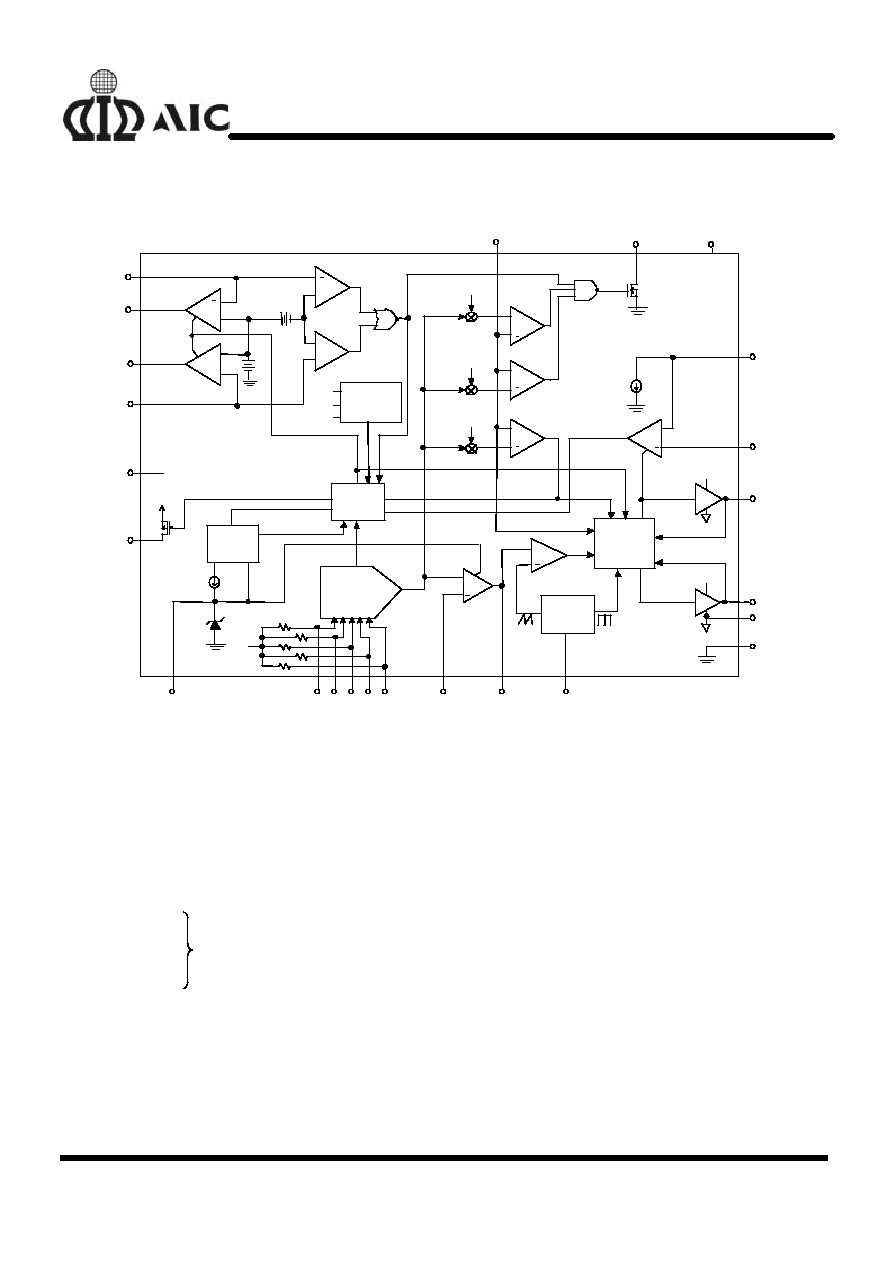

n

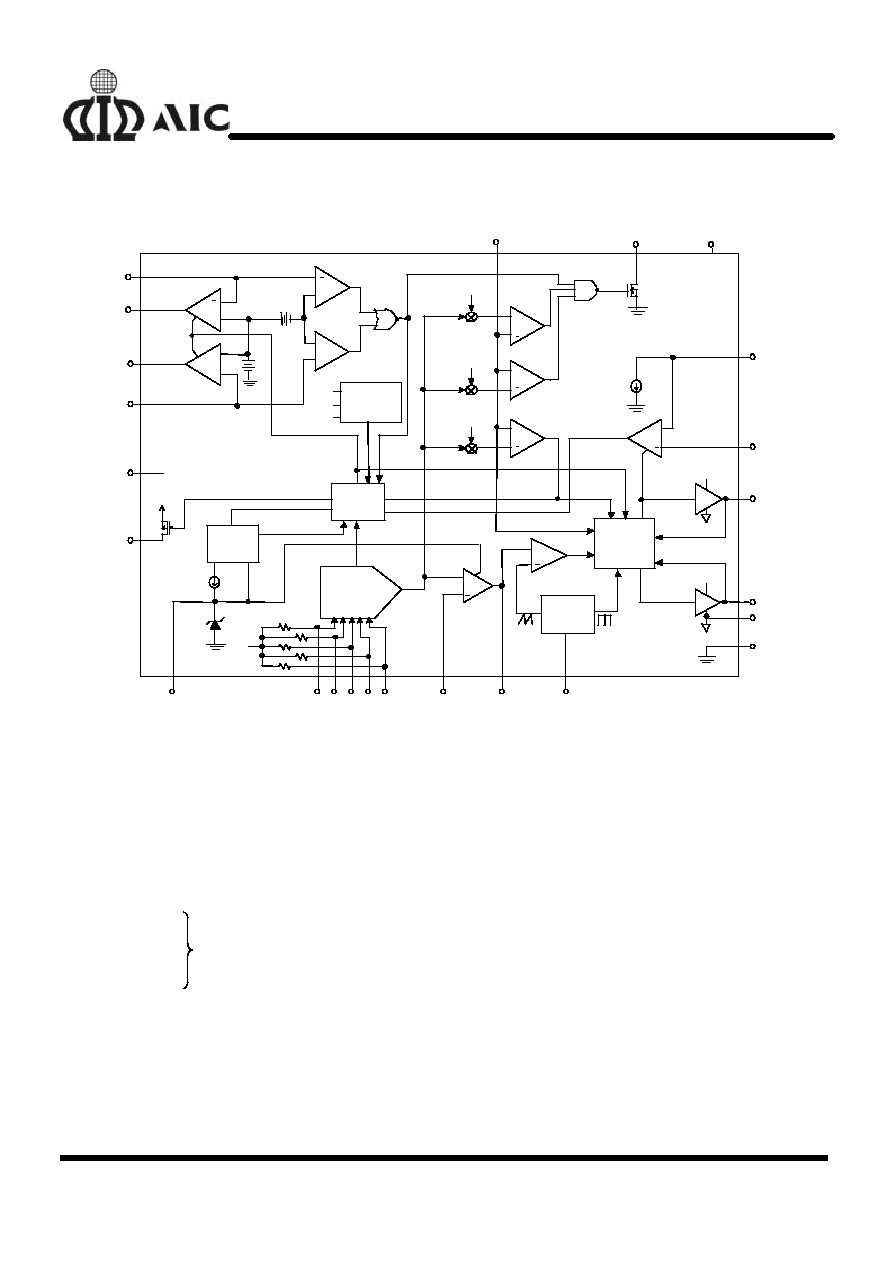

BLOCK DIAGRAM

5 BIT TTL D/A

CONVERTER

(DAC)

+

+

+

+

+

SS

110%

90%

115%

0.3V

1.26V

70K

FB3

FB2

GATE3

FAULT

VIN2

VID4

VID3

VID2

VID1

VID0

SOFT

START

10

µ

A

4V

70K

70K

70K

70K

5V

FB1

COMP1

RT

OCSET

PHASE

GND

PGND

LGATE

UGATE

200

µ

A

GATE CONTROL

VCC

PGOOD

VCC

VCC

OSCILLATOR

PWM COMP

OV

OC1

VSEN

ERROR

AMP

LUV

INHiBIT

VCC

OCSET

VIN2

POWER

ON RESET

OFF

VCC

FAULT

LOGIC &

LATCH

+

+

-

+

+

+

-

GATE2

n

PIN DESCRIPTIONS

Pin 1: VCC:

The chip power supply pin. It also

provides the gate bias charge for

all the MOSFETs controlled by

the IC. Recommended supply

voltage is 12V.

Pin 2:

VID4:

Pin 3: VID3:

Pin 4: VID2:

Pin 5: VID1:

Pin 6: VID0:

5bit DAC voltage select pin. TTL

inputs used to set the internal

voltage reference VDAC. When

left open, these pins are inter-

nally pulled up to 5V and provide

logic ones. The level of VDAC

sets the converter output voltage

as well as the PGOOD and OVP

thresholds.

Table 1 specifies the VDAC volt-

age for the 32 combinations of

DAC inputs.

Pin 7: PGOOD:

Power good indicator pin. PGOOD

is an open drain output. This pin is

pulled low when the converter out-

put is ±10% out of the VDAC ref-

erence voltage and the other out-

puts are below their under-voltage

thresholds. The PGOOD output is

open for VID codes that inhibit op-

eration. See Table 1.

Pin 8: FAULT:

This pin is low during normal op-

eration, but it is pulled to VCC in

the event of an over-voltage or over-

current condition.

AIC1571

9

Pin 9:

SS:

Soft-start pin. Connect a capaci-

tor from this pin to ground. This

capacitor, along with an internal

10

µ

A (typically) current source,

sets the soft-start interval of the

converter.

Pulling this pin low will shut down

the IC.

Pin 10: RT:

Frequency adjustment pin. Con-

necting a resistor (RT) from this

pin to GND, increasing the fre-

quency. Connecting a resistor

(RT) from this pin to VCC, de-

creasing the frequency by the

following figure (Fig.3).

Pin 11: FB2:

Connect this pin to a resistor di-

vider to set the linear controller

output voltage.

Pin 12: VIN2:

This pin is used to monitor the

3.3V supply. If, following a start-

up cycle, the voltage drops below

2.6V (typically), the chip shuts

down. A new soft-start cycle is

initiated upon return of the 3.3V

supply above the under-voltage

threshold.

Pin 13: GATE2: Linear Controller output drive pin.

This pin can drive either a Dar-

lington NPN transistor or a N-

channel MOSFET.

Pin 14: GND:

Signal GND for IC. All voltage

levels are measured with respect

to this pin.

Pin 15: GATE3: Linear Controller output drive pin.

This pin can drive either a Dar-

lington NPN transistor or a N-

channel MOSFET.

Pin 16: FB3:

Negative feedback pin for the

linear controller error amplifier

connect this pin to a resistor di-

vider to set the linear controller

output voltage.

Pin 17: COMP1: External compensation pin. This

pin is connected to error amplifier

output and PWM comparator. An

RC network is connected to FB1

in to compensate the voltage

control feedback loop of the con-

verter.

Pin 18: FB1:

The error amplifier inverting input

pin. the FB1 pin and COMP1 pin

are used to compensate the volt-

age-control feedback loop.

Pin 19: VSEN:

Converter output voltage sense

pin. Connect this pin to the con-

verter output. The PGOOD and

OVP comparator circuits use this

signal to report output voltage

status and for over-voltage protec-

tion function.

Pin 20: OCSET: Current limit sense pin. Connect

a resistor R

OCSET

from this pin to

the drain of the external high-side

N-MOSFET. R

OCSET

, an internal

200

µ

A current source (I

OCSET

),

and the upper N-MOSFET on-

resistance (R

DS(ON)

) set the over-

current trip point according to the

following equation:

I

I

R

R

PEAK

OCSET

OCSET

DS(ON)

=

×

Pin 21: PGND:

Driver power GND pin. PGND

should be connected to a low im-

pedance ground plane in close to

lower N-MOSFET source.

Pin 22: LGATE: Lower N-MOSFET gate drive pin.

Pin 23: PHASE: Over-current detection pin. Con-

nect the PHASE pin to source of

the external high-side N-

MOSFET. This pin detects the

voltage drop across the high-side

N-MOSFET R

DS(ON)

for over-

current protection.

Pin 24: UGATE: External high-side N-MOSFET

gate drive pin. Connect UGATE

to gate of the external high-side

N-MOSFET.

AIC1571

10

n

APPLICATIONS INFORMATION

The AIC1571 is designed for microprocessor

computer applications with 3.3V and 5V power,

and 12V bias input. This IC has one PWM con-

troller and two linear controllers. The PWM con-

troller is designed to regulate the microproces-

sor core voltage (V

OUT1

) by driving 2 MOSFETs

(Q1 and Q2) in a synchronous rectified buck

converter configuration. The core voltage is

regulated to a level programmed by the 5 bit D/A

converter. One integrated linear controller sup-

plies the 2.5V clock power (V

OUT2

). The other

linear controller drive an external MOSFET(Q3)

to supply the GTL bus power(V

OUT3

)

The Power-On Reset (POR) function continually

monitors the input supply voltage +12V at VCC

pin, the 5V input voltage at OCSET pin, and the

3.3V input at VIN2 pin. The POR function initi-

ates soft-start operation after all three input sup-

ply voltage exceed their POR thresholds.

Soft-Start

The POR function initiates the soft-start se-

quence. Initially, the voltage on SS pin rapidly

increases to approximate 1V. Then an internal

10µA current source charges an external ca-

pacitor (C

SS

) on the SS pin to 4V. As the SS pin

voltage slews from 1V to 4V, the PWM error

amplifier reference input (Non-inverting terminal)

and output (COMP1 pin) is clamped to a level

proportional to the SS pin voltage. As the SS pin

voltage slew from 1V to 4V, the output clamp

generates PHASE pulses of increasing width

that charge the output capacitors. Additionally

both linear regulator's reference inputs are

clamped to a voltage proportional to the SS pin

voltage. This method provides a controlled out-

put voltage smooth rise.

Fig.4 and Fig.5 show the soft-start sequence for

the typical application. The internal oscillator's

triangular waveform is compared to the clamped

error amplifier output voltage. As the SS pin volt-

age increases, the pulse width on PHASE pin

increases. The interval of increasing pulse width

continues until output reaches sufficient voltage

to transfer control to the input reference clamp.

Each linear output (VOUT2 and VOUT3) initially

follows a ramp. When each output reaches suf-

ficient voltage the input reference clamp slows

the rate of output voltage rise. The PGOOD sig-

nal toggles `high' when all output voltage levels

have exceeded their under-voltage levels.

Fault Protection

All three outputs are monitored and protected

against extreme overload. A sustained overload

on any output or over-voltage on PWM output

disable all converters and drive the FAULT pin to

VCC.

AIC1571

11

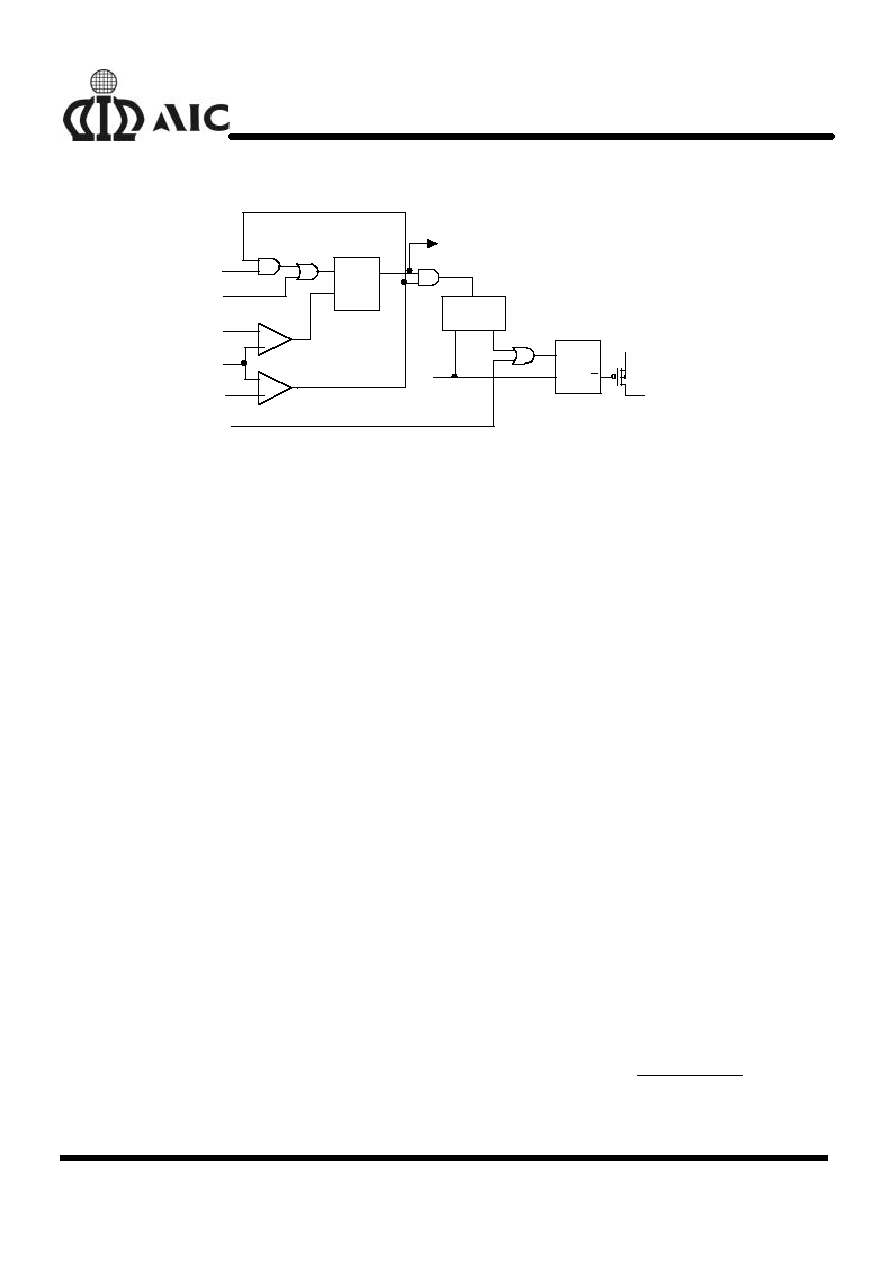

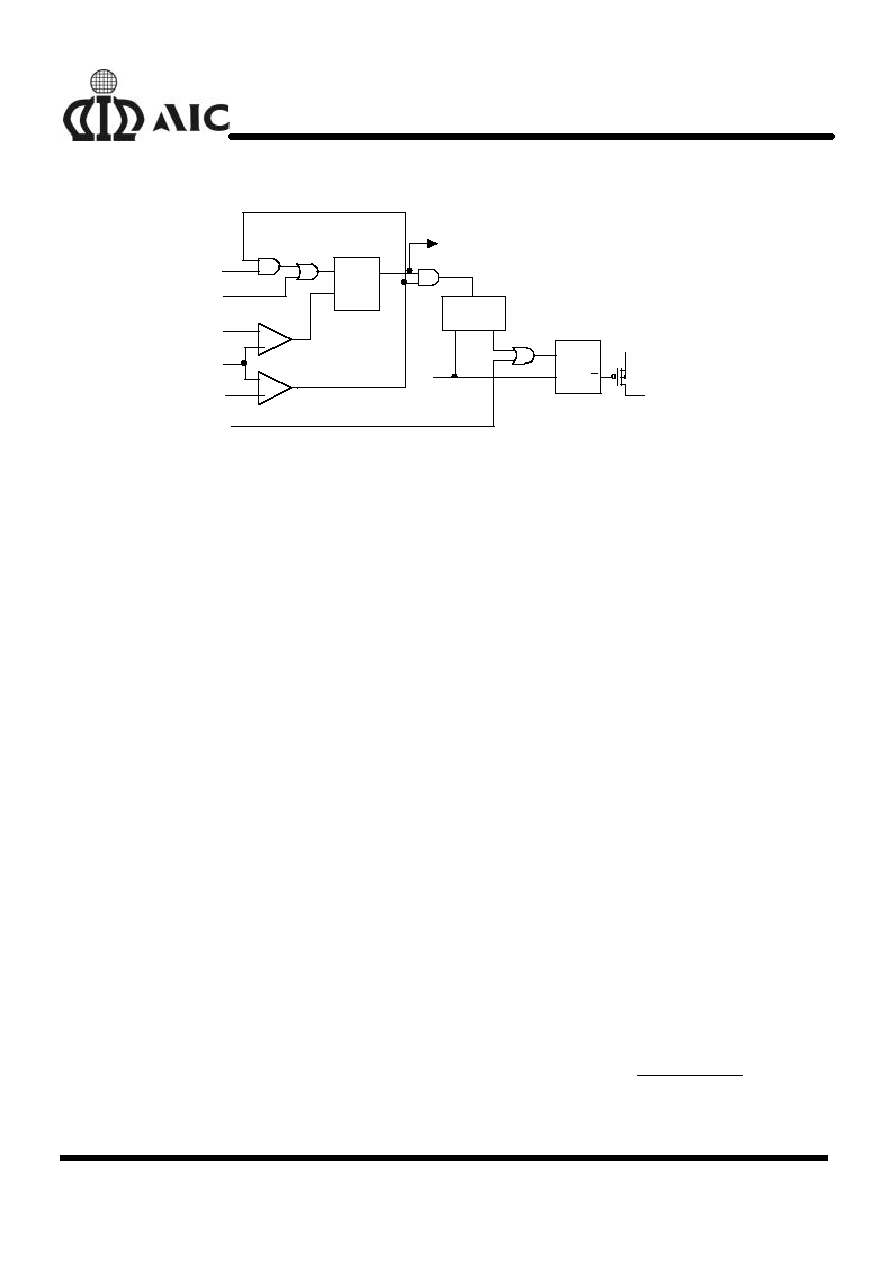

+

+

0.2V

OV

LATCH

OVER CURRENT

3.6V

SS

OC1

R

LUV

Q

S

FAULT

VCC

FAULT LATCH

POR

Q

R

S

R

S

COUNTER

INHIBIT

Fig. 17 Simplified Schematic of Fault Logic

A simplified schematic is shown in figure 17. An

over-voltage detected on VSEN immediately sets

the fault latch. A sequence of three over-current

fault signals also sets the fault latch. An under-

voltage event on either linear output (FB2 or FB3)

is ignored until the soft-start interval. Cycling the

bias input voltage (+12V) off then on reset the

counter and the fault latch.

Over-Voltage Protection

During operation, a short on the upper PWM

MOSFET (Q1) causes V

OUT1

to increase. When

the output exceed the over-voltage threshold of

115% of DACOUT, the FAULT pin is set to fault

latch and turns Q2 on as required in order to

regulate V

OUT1

to 115% of DACOUT. The fault

latch raises the FAULT pin close to VCC potential.

A separate over-voltage circuit provides protection

during the initial application of power. For voltage

on VCC pin below the power-on reset (and above

4V), should VSEN exceed 0.7V, the lower

MOSFET (Q2) is driven on as needed to regulate

V

OUT1

to 0.7V.

Over-Current Protection

All outputs are protected against excessive over-

current. The PWM controller uses upper

MOSFET's on-resistance, R

DS(ON)

to monitor the

current for protection against shorted outputs.

Both the linear regulator and controller monitor

FB2 and FB3 for under-voltage to protect against

excessive current.

When the voltage across Q1 (I

D

·

R

DS(ON)

) exceeds

the level (200

µ

A

·

R

OCSET

), this signal inhibit all

outputs. Discharge soft-start capacitor (Css) with

10

µ

A current sink, and increments the counter.

Css recharges and initiates a soft-start cycle

again until the counter increments to 3. This sets

the fault latch to disable all outputs. Fig. 6 illus-

trates the over-current protection until an over load

on OUT1.

Should excessive current cause FB2 or FB3 to fall

below the linear under-voltage threshold, the LUV

signal sets the over-current latch if Css is fully

charged. Cycling the bias input power off then on

reset the counter and the fault latch.

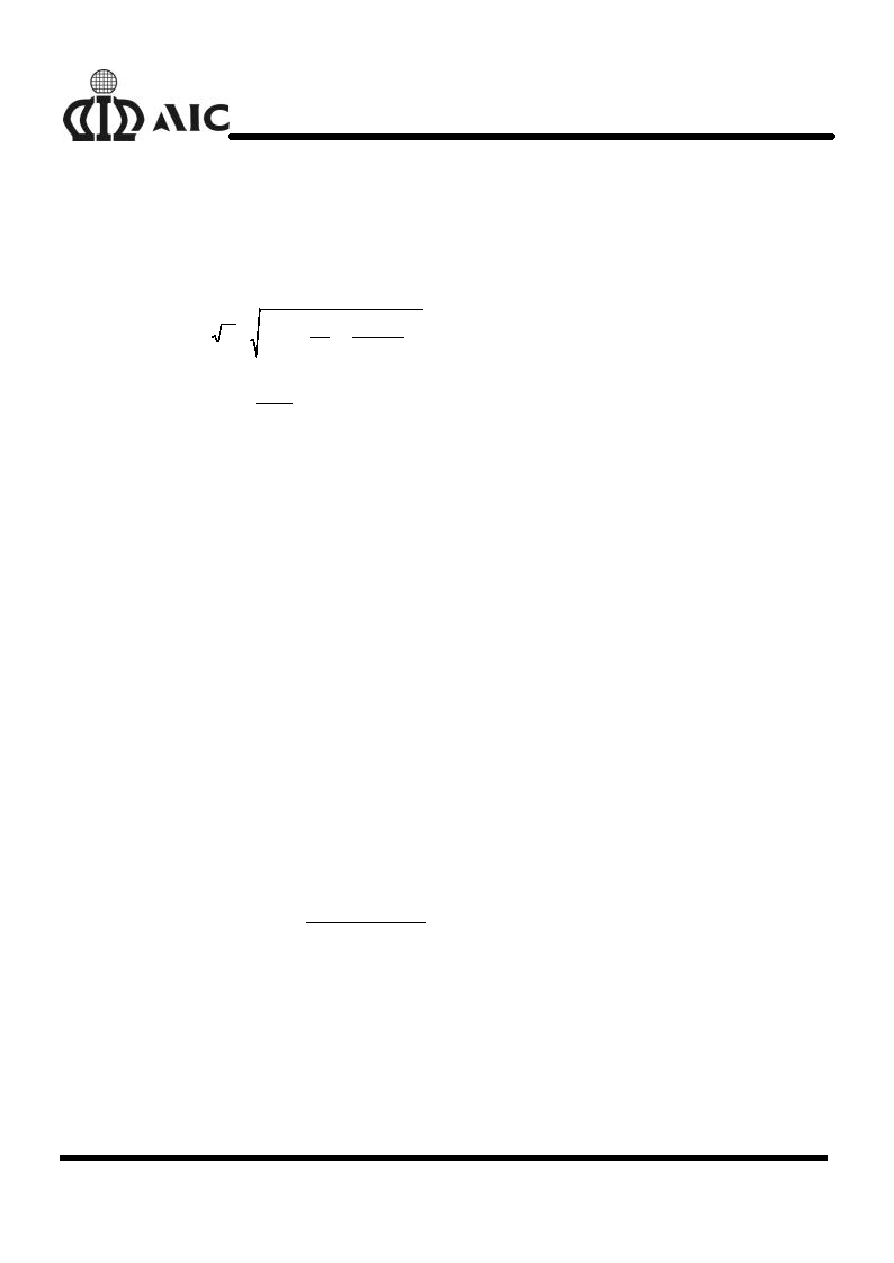

The over-current function for PWM controller will

trip at a peak inductor current (I

PEAK

) determined

by:

I

I

R

R

PEAK

OCSET

OCSET

DS(ON)

=

×

The OC trip point varies with MOSFET's tempera-

AIC1571

12

ture. To avoid over-current tripping in the normal

operating load range, determine the R

OCSET

resis-

tor from the equation above with:

1. The maximum R

DS(ON)

at the highest junction.

2. The minimum I

OCSE

T

from the specification ta-

ble.

3. Determine I

PEAK

> I

OUT(MAX)

+ (inductor ripple

current) /2.

PWM OUT1 Voltage Program

The output voltage of the PWM converter is pro-

grammed to discrete levels between 1.3V to 3.5V.

The VID pins program an internal voltage reference

(DACOUT) through a TTL compatible 5 bit digital

to analog converter. The VID pins can be left open

for a logic 1 input, because they are internally

pulled up to 5V by a 70k

resistor. Changing the

VID inputs during operation is not recommended.

All VID pin combinations resulting in an INHIBIT

disable the IC and the open collector at the

PGOOD pin.

Shutdown

Holding the SS pin low with an open drain or col-

lector signal turns off all three regulators.

The VID codes resulting in an INHIBIT as shown in

Table 1 also shut down the IC.

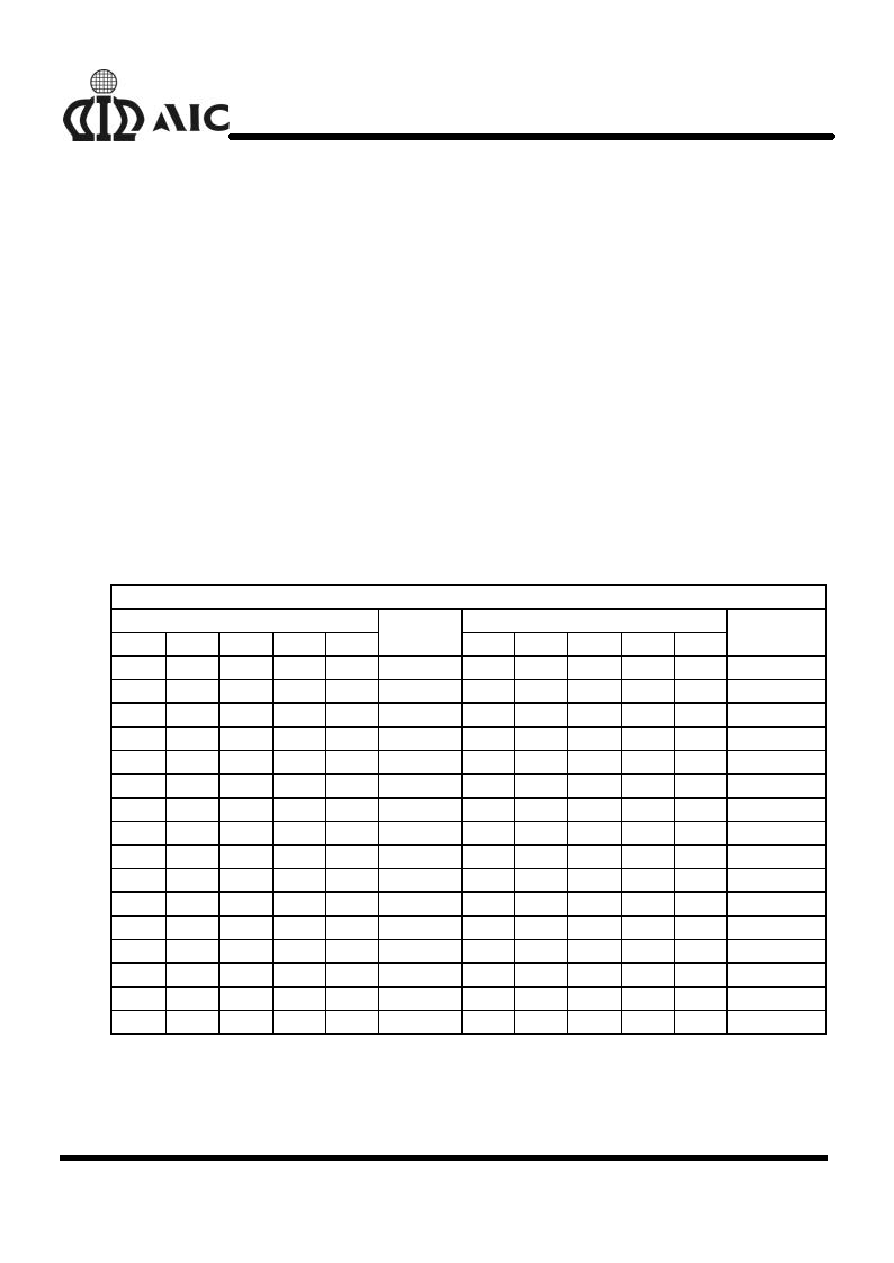

Table 1 V

OUT1

Voltage Program (0=connected to GND, 1=open or connected to 5V)

For all package version

PIN NAME

PIN NAME

VID4

VID3

VID2

VID1

VID0

DACOUT

VOLTAGE

VID4

VID3

VID2

VID1

VID0

DACOUT

VOLTAGE

0

1

1

1

1

1.30V

1

1

1

1

1

INHIBIT

0

1

1

1

0

1.35V

1

1

1

1

0

2.1 V

0

1

1

0

1

1.40V

1

1

1

0

1

2.2 V

0

1

1

0

0

1.45V

1

1

1

0

0

2.3 V

0

1

0

1

1

1.50V

1

1

0

1

1

2.4 V

0

1

0

1

0

1.55V

1

1

0

1

0

2.5 V

0

1

0

0

1

1.60V

1

1

0

0

1

2.6 V

0

1

0

0

0

1.65V

1

1

0

0

0

2.7 V

0

0

1

1

1

1.70V

1

0

1

1

1

2.8 V

0

0

1

1

0

1.75V

1

0

1

1

0

2.9 V

0

0

1

0

1

1.80 V

1

0

1

0

1

3.0 V

0

0

1

0

0

1.85 V

1

0

1

0

0

3.1 V

0

0

0

1

1

1.90 V

1

0

0

1

1

3.2 V

0

0

0

1

0

1.95 V

1

0

0

1

0

3.3 V

0

0

0

0

1

2.00 V

1

0

0

0

1

3.4 V

0

0

0

0

0

2.05 V

1

0

0

0

0

3.5 V

AIC1571

13

Layout Considerations

Any inductance in the switched current path

generates a large voltage spike during the

switching interval. The voltage spikes can de-

grade efficiency, radiate noise into the circuit,

and lead to device over-voltage stress. Careful

component selection and tight layout of critical

components, and short, wide metal trace mini-

mize the voltage spike.

1) A ground plane should be used. Locate the

input capacitors (C

IN

) close to the power

switches. Minimize the loop formed by C

IN

,

the upper MOSFET (Q1) and the lower

MOSFET (Q2) as possible. Connections

should be as wide as short as possible to

minimize loop inductance.

2) The connection between Q1, Q2 and output

inductor should be as wide as short as prac-

tical. Since this connection has fast voltage

transitions will easily induce EMI.

3) The output capacitor (C

OUT

) should be locat-

ed as close the load as possible. Because

minimize the transient load magnitude for

high slew rate requires low inductance and

resistance in circuit board

4) The AIC1571 is best placed over a quiet

ground plane area. The GND pin should be

connected to the groundside of the output

capacitors. Under no circumstances should

GND be returned to a ground inside the C

IN

,

Q1, Q2 loop. The GND and PGND pins

should be shorted right at the IC. This help

to minimize internal ground disturbances in

the IC and prevents differences in ground

potential from disrupting internal circuit op-

eration.

5) The wiring traces from the control IC to the

MOSFET gate and source should be sized

to carry 1A current. Locate C

OUT2

close to

the AIC1571 IC.

6) The Vcc pin should be decoupled directly to

GND by a 1uF ceramic capacitor, trace

lengths should be as short as possible.

+

+

+

V

OUT

C

OUT

Q1

+3.3V

IN

+5V

IN

L

OUT

GATE3

C

IN

Q2

C s s

SS

GATE2

PGND

LGATE

PHASE

UGATE

OCSET

VIN2

GND

VCC

+12V

+

+

Q3

V

OUT3

C

OUT3

Power Plane Layer

Circuit Plane Layer

Via

Connection

to

Ground

Plane

+

Q4

V

OUT2

C

OUT2

Fig. 18 Printed circuit board power planes and islands

AIC1571

14

A multi-layer printed circuit board is recom-

mended. Figure 18 shows the connections of

the critical components in the converter. The C

IN

and C

OUT

could each represent numerous physi-

cal capacitors. Dedicate one solid layer for a

ground plane and make all critical component

ground connections with vias to this layer.

PWM Output Capacitors

The load transient for the microprocessor core

requires high quality capacitors to supply the

high slew rate (di/dt) current demand.

The ESR (equivalent series resistance) and ESL

(equivalent series inductance) parameters rather

than actual capacitance determine the buck ca-

pacitor values. For a given transient load magni-

tude, the output voltage transient change due to

the output capacitor can be note by the following

equation:

V

ESR

I

ESL

I

T

OUT

OUT

OUT

=

×

+

×

, where

I

OUT

is transient load current step.

After the initial transient, the ESL dependent

term drops off. Because the strong relationship

between output capacitor ESR and output load

transient, the output capacitor is usually chosen

for ESR, not for capacitance value. A capacitor

with suitable ESR will usually have a larger ca-

pacitance value than is needed for energy stor-

age.

A common way to lower ESR and raise ripple

current capability is to parallel several capaci-

tors. In most case, multiple electrolytic capaci-

tors of small case size are better than a single

large case capacitor.

Output Inductor Selection

Inductor value and type should be chosen based

on output slew rate requirement, output ripple

requirement and expected peak current. Inductor

value is primarily controlled by the required cur-

rent response time. The AIC1571 will provide ei-

ther 0% or 100% duty cycle in response to a

load transient. The response time to a transient

is different for the application of load and remove

of load.

t

L

I

V

V

RISE

OUT

IN

OUT

=

×

-

,

t

=

L

I

V

FALL

OUT

OUT

×

.

Where

I

OUT

is transient load current step.

In a typical 5V input, 2V output application, a

3

µ

H inductor has a 1A/

µ

S rise time, resulting in

a 5

µ

S delay in responding to a 5A load current

step. To optimize performance, different combi-

nations of input and output voltage and expected

loads may require different inductor value. A

smaller value of inductor will improve the tran-

sient response at the expense of increase out-

put ripple voltage and inductor core saturation

rating.

Peak current in the inductor will be equal to the

maximum output load current plus half of induc-

tor ripple current. The ripple current is approxi-

mately equal to:

I

=

(V

V

) V

L V

RIPPLE

IN

OUT

OUT

IN

-

×

× ×

f

;

f = AIC1571 oscillator frequency.

The inductor must be able to withstand peak

current without saturation, and the copper resis-

tance in the winding should be kept as low as

possible to minimize resistive power loss

Input Capacitor Selection

Most of the input supply current is supplied by

the input bypass capacitor, the resulting RMS

current flow in the input capacitor will heat it up.

Use a mix of input bulk capacitors to control the

voltage overshoot across the upper MOSFET.

The ceramic capacitance for the high frequency

AIC1571

15

decoupling should be placed very close to the

upper MOSFET to suppress the voltage induced

in the parasitic circuit impedance. The buck ca-

pacitors to supply the RMS current is approxi-

mate equal to:

I

(1 D)

D

I

1

12

V

D

f L

RMS

2

OUT

IN

2

= -

×

×

+

×

×

×

, where

D

V

V

OUT

IN

=

The capacitor voltage rating should be at least

1.25 times greater than the maximum input volt-

age.

PWM MOSFET Selection

In high current PWM application, the MOSFET

power dissipation, package type and heatsink

are the dominant design factors. The conduction

loss is the only component of power dissipation

for the lower MOSFET, since it turns on into

near zero voltage. The upper MOSFET has con-

duction loss and switching loss. The gate char-

ge losses are proportional to the switching fre-

quency and are dissipated by the AIC1571.

However, the gate charge increases the switch-

ing interval, t

SW

which increase the upper MOS-

FET switching losses. Ensure that both MOS-

FETs are within their maximum junction tem-

perature at high ambient temperature by calcu-

lating the temperature rise according to package

thermal resistance specifications.

2

f

t

V

I

D

R

I

P

SW

IN

OUT

DS(ON)

2

OUT

UPPER

×

×

×

+

×

×

=

P

I

R

D)

LOWER

OUT

2

DS(ON)

=

×

× -

(1

The equations above do not model power loss

due to the reverse recovery of the lower

MOSFET's body diode.

The R

DS(ON)

is different for the two previous

equations even if the type devices is used for

both. This is because the gate drive applied to

the upper MOSFET is different than the lower

MOSFET. Logic level MOSFETs should be se-

lected based on on-resistance considerations,

R

DS(ON)

should be chosen base on input and

output voltage, allowable power dissipation and

maximum required output current. Power dissi-

pation should be calculated based primarily on

required efficiency or allowable thermal dissipa-

tion.

Rectifier Schottky diode is a clamp that prevent

the loss parasitic MOSFET body diode from

conducting during the dead time between the

turn off of the lower MOSFET and the turn on of

the upper MOSFET. The diode's rated reverse

breakdown voltage must be greater than twice

the maximum input voltage.

Linear Controller MOSFET Selection

The power dissipated in a linear regulator is :

)

V

(V

I

P

OUT

IN2

OUT

LINEAR

-

×

=

Select a package and heatsink that maintains

junction temperature below the maximum rating

while operation at the highest expected ambient

temperature.

Linear Output Capacitor

The output capacitors for the linear controller

provide dynamic load current. The linear con-

troller uses dominant pole compensation inte-

grated in the error amplifier and is insensitive to

output capacitor selection. C

OUT2

and C

OUT3

should be selected for transient load regulation.

AIC1571

16

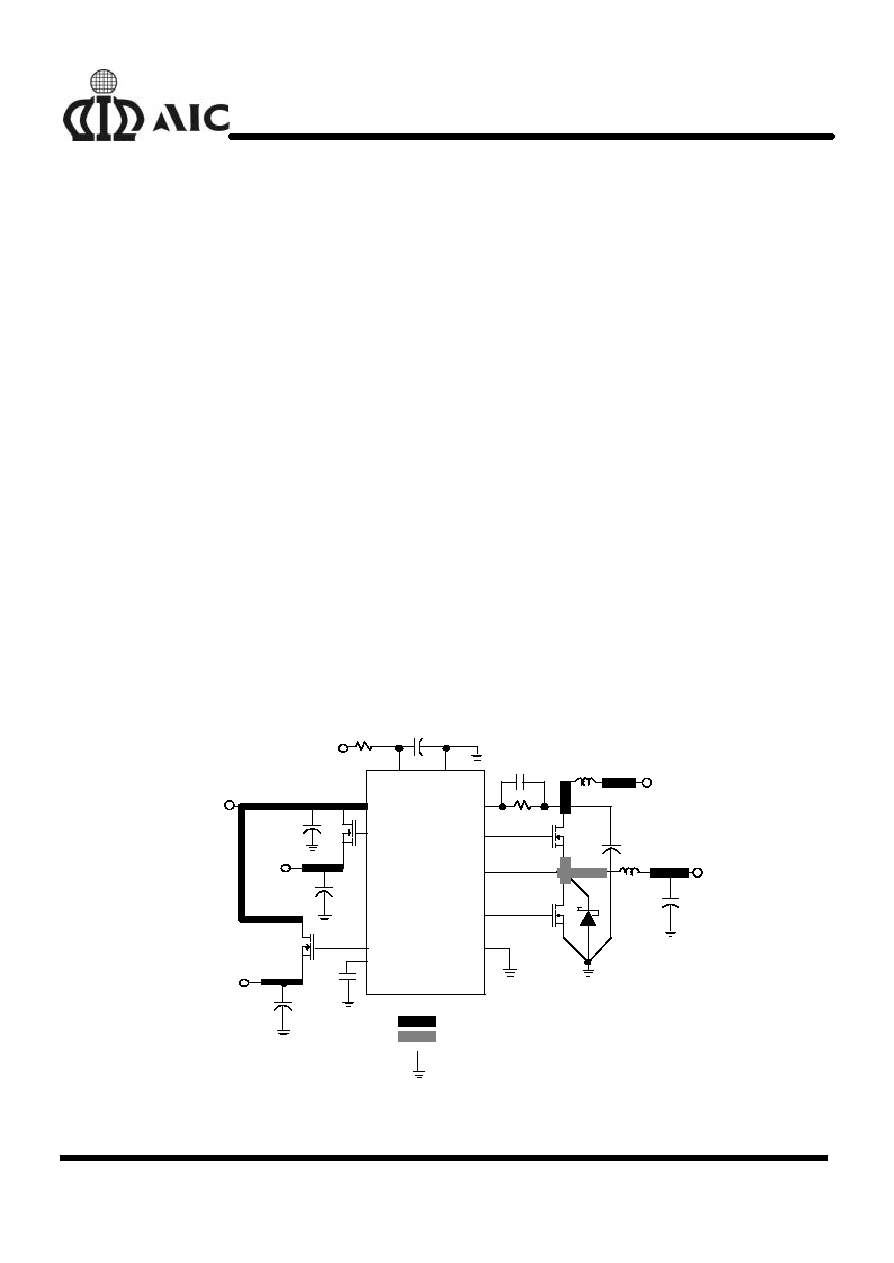

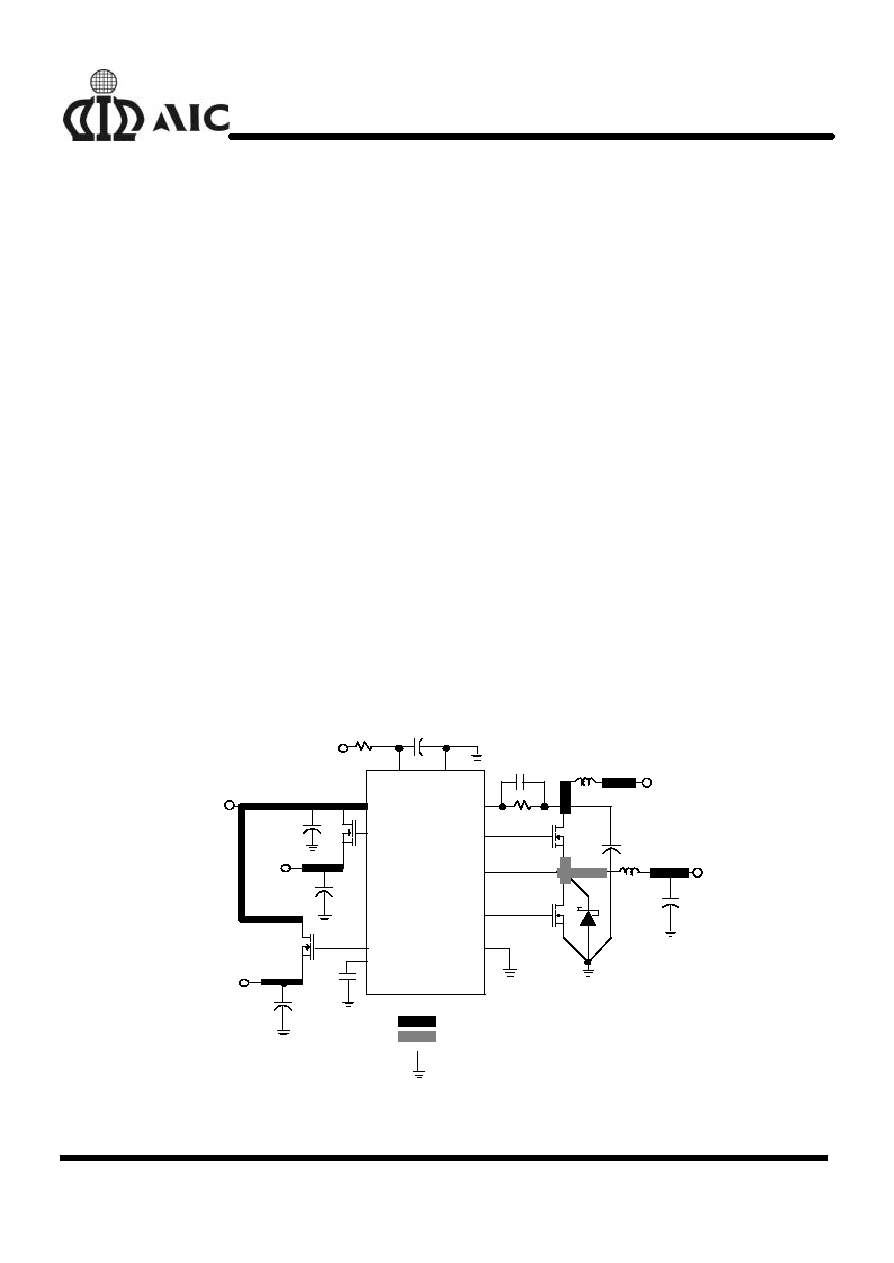

n

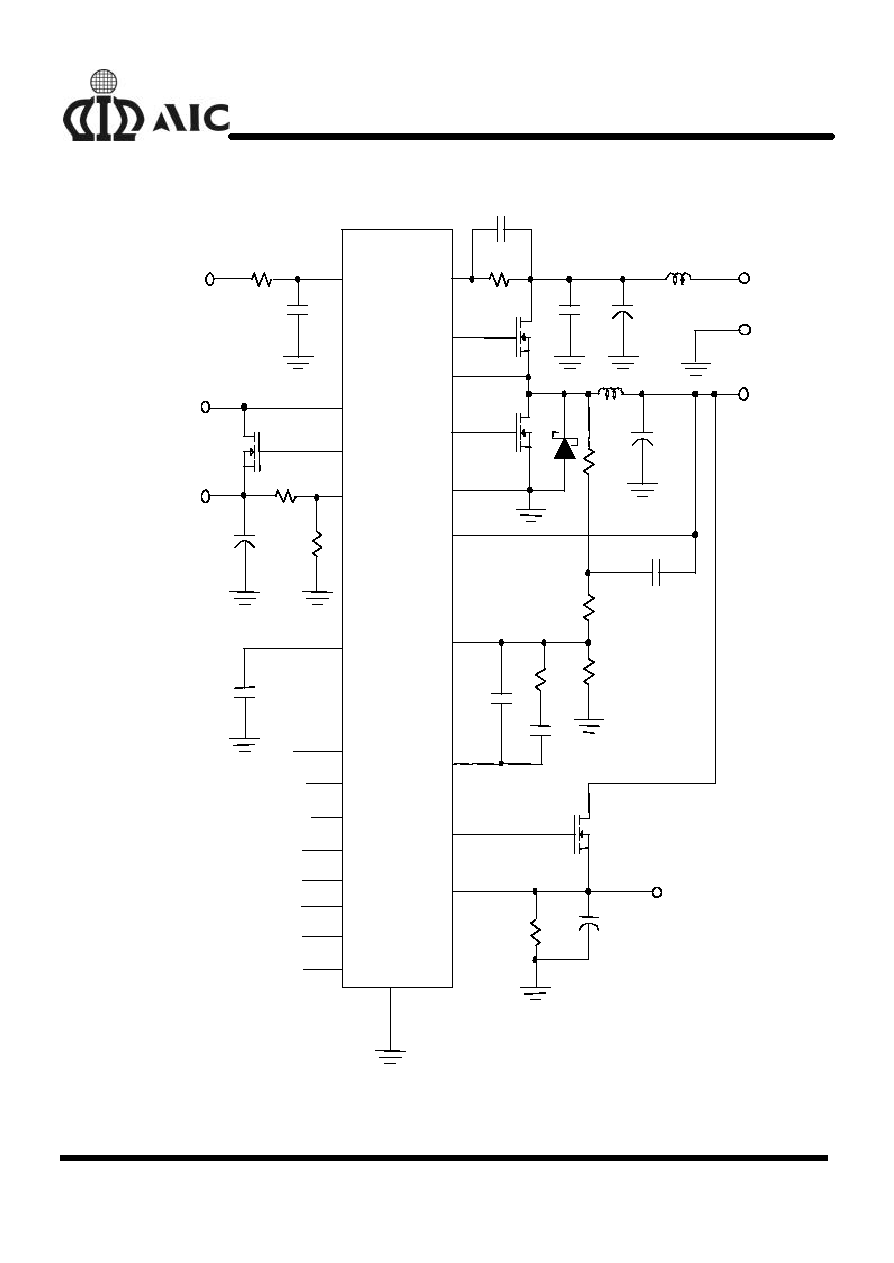

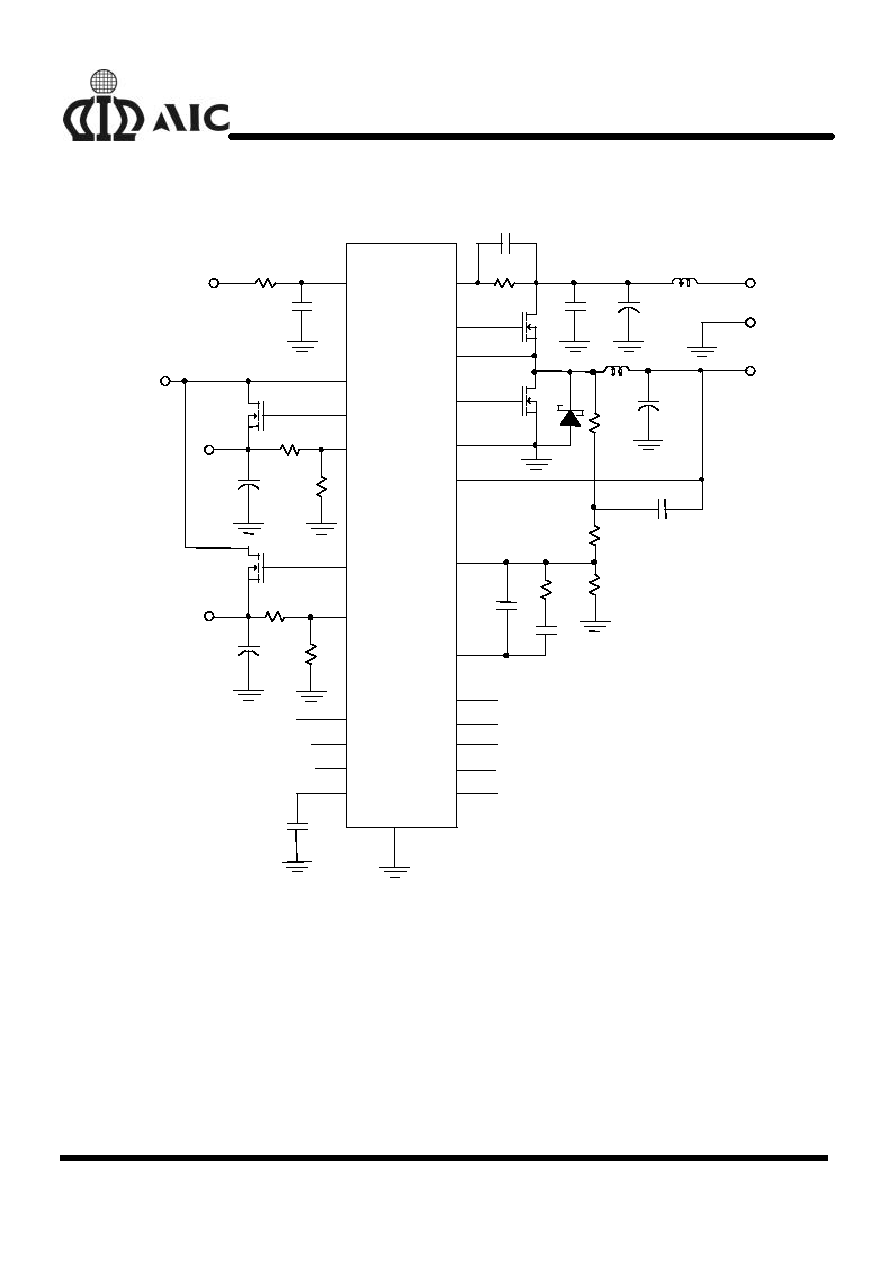

APPLICATION CIRCUIT

+

+

+

+

UGATE

PHASE

VIN2

LGATE

GATE3

PGND

FB3

VSEN

FB1

GATE2

FB2

COMP1

VID0

RT

VID1

FAULT

VID2

PGOOD

VID3

SS

VID4

4 x 1000

µ

F

C45-46

2

3

4

5

6

40nF

C48

9

8

10

7

11

13

Q4

20N03HL

VOUT2

C47-48

1.8V

10K

R12

R11

4.2K

2 x 1000

µ

F

+3.3V

IN

20N03HL

Q3

R12

R11

12

15

16

1.5V

V

OUT3

10K

1.87K

2.2

µ

F

GND

+5V

IN

VCC

+12V

IN

10

R15

C42

2.2nF

D5820

21

1

µ

H

L1

C1-C7

C15

1

µ

F

6 x 1000

µ

F

C18

1000pF

2.2K

R2

C16

Q2

Q1

C24-36

C40

19

C41

R10

0.68

µ

F

160K

10pF

5K

2.2K

732K

R9

R8

R4

L2

OCSET

7 x 1000

µ

F

3.5

µ

H

1

17

18

22

23

24

20

14

V

OUT1

Circuit 1 Motherboard Power application Circuit

AIC1571

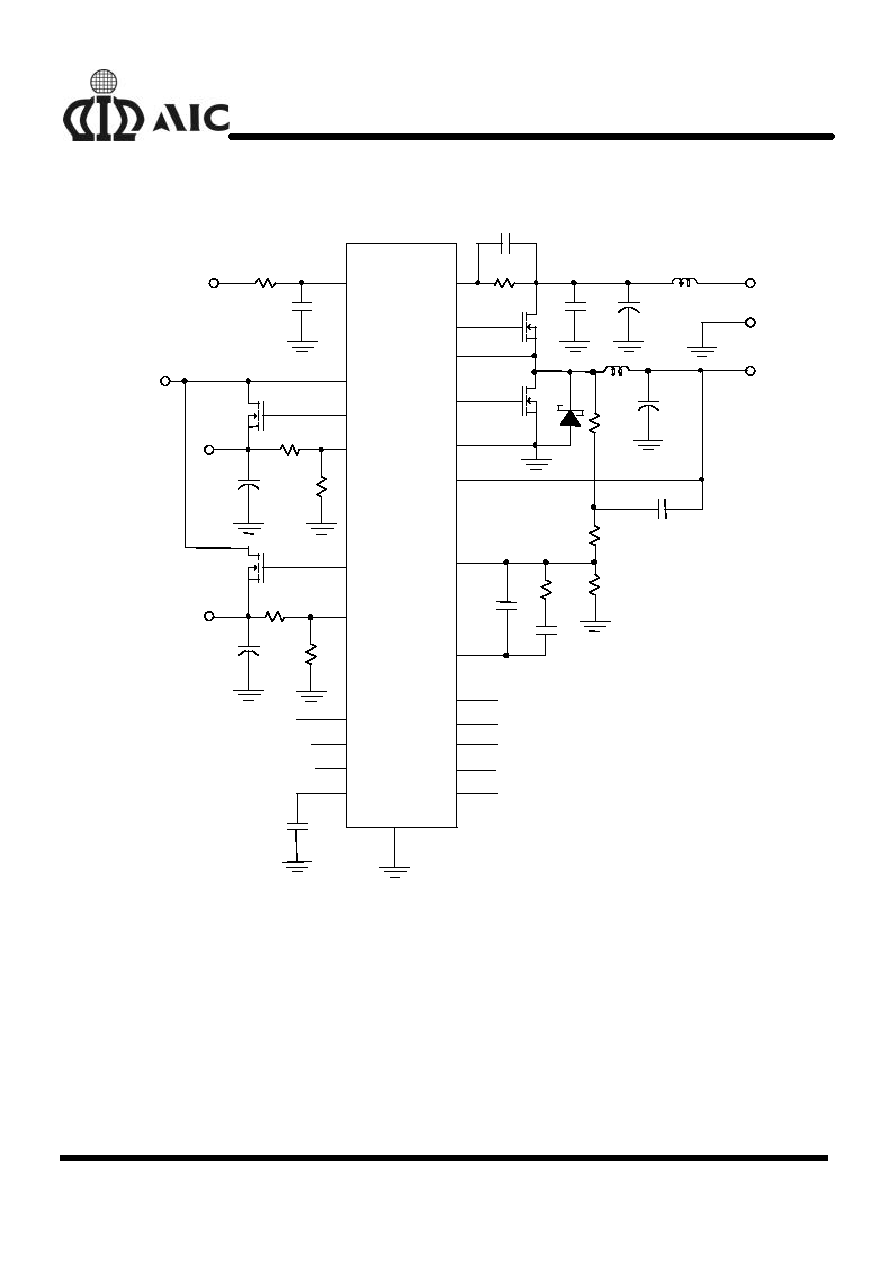

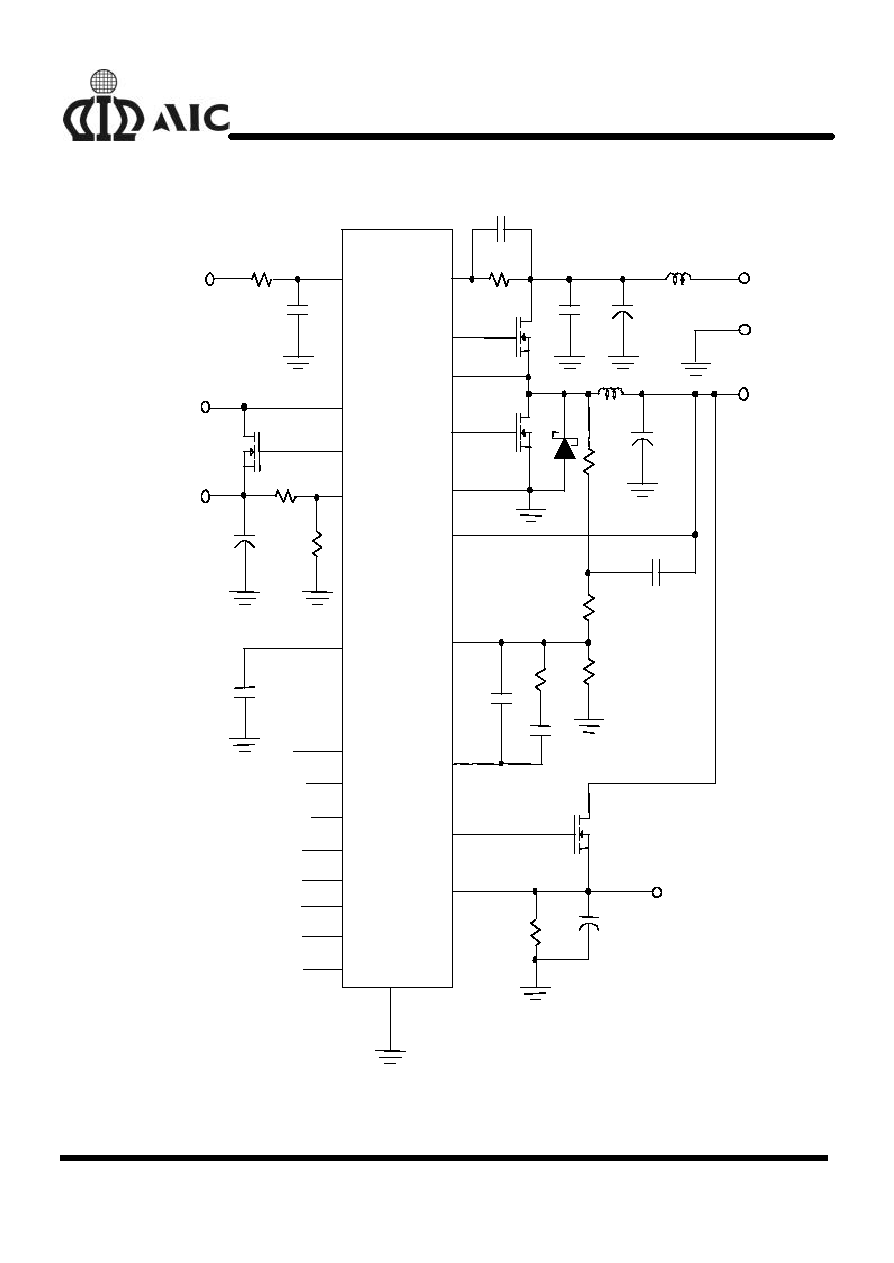

17

+

+

+

+

UGATE

PHASE

VIN2

LGATE

GATE3

PGND

FB3

VSEN

FB1

SS

RT

COMP

1

FAULT

PGOOD

GATE2

VID0

VID1

FB2

VID2

VID3

VID4

20N03H

L

C47

1000

µ

F

Q4

20N03HL

Q3

R14

10K

V

OUT2

1.27V

2.2

µ

F

2 x 1000

µ

F

11

13

40nF

C48

9

8

10

7

2

3

4

5

6

GND

+5V

IN

C43-46

VCC

+12V

IN

10

R15

C42

2.2nF

D5820

21

1

µ

H

L1

C1-C7

6 x1000

µ

F

C15

1

µ

F

C18

1000pF

2.2K

R2

C16

Q2

Q1

C24-36

7 x1000

µ

F

C40

19

C41

R10

R12

R11

0.68

µ

F

160K

10pF

5K

2.2K

732K

R9

R8

R4

L2

OCSET

3.5

µ

H

1

12

15

16

1.5V

VOUT3

+3.3V

IN

10K

1.87K

17

18

22

23

24

20

14

V

OUT1

Circuit 2 Power Integration for 3-Output Power System

AIC1571

18

n

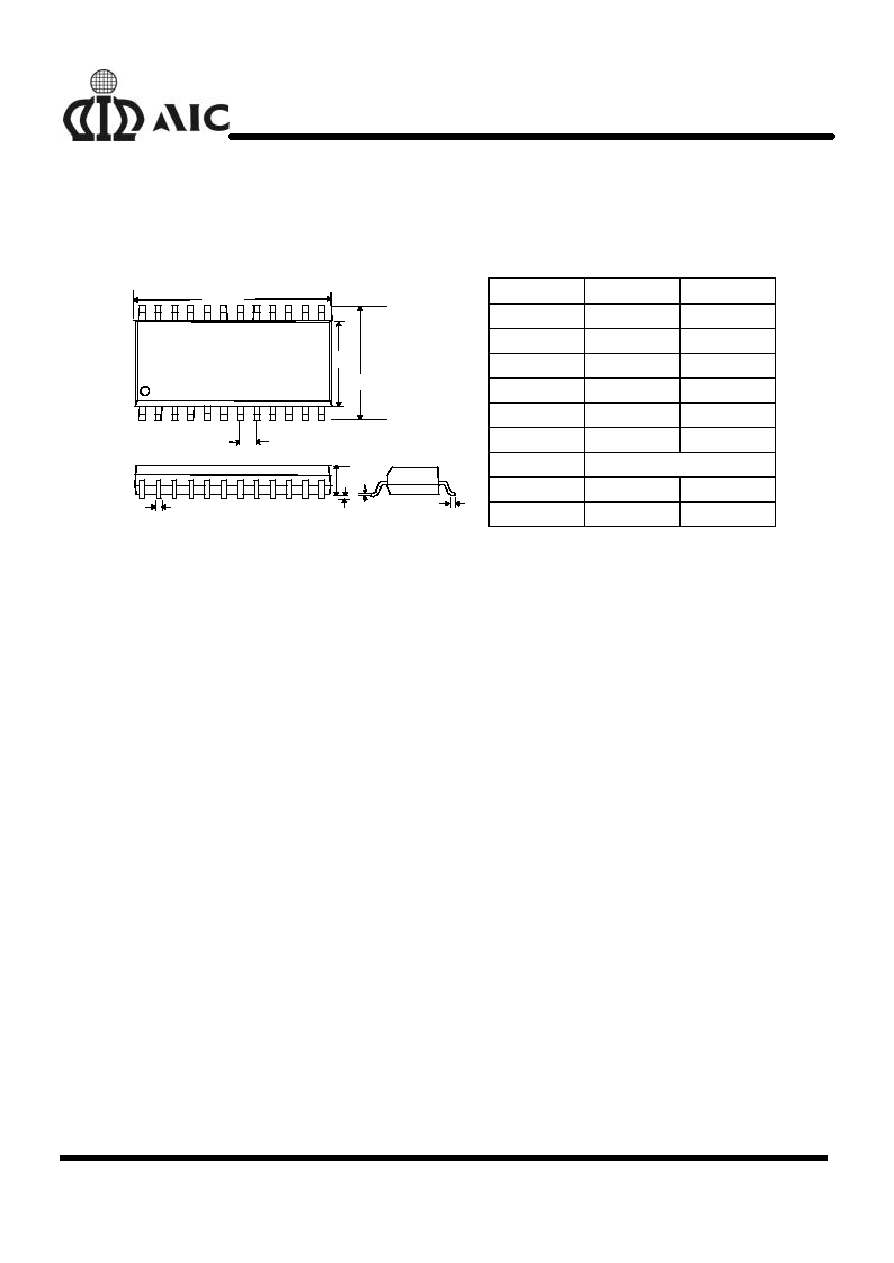

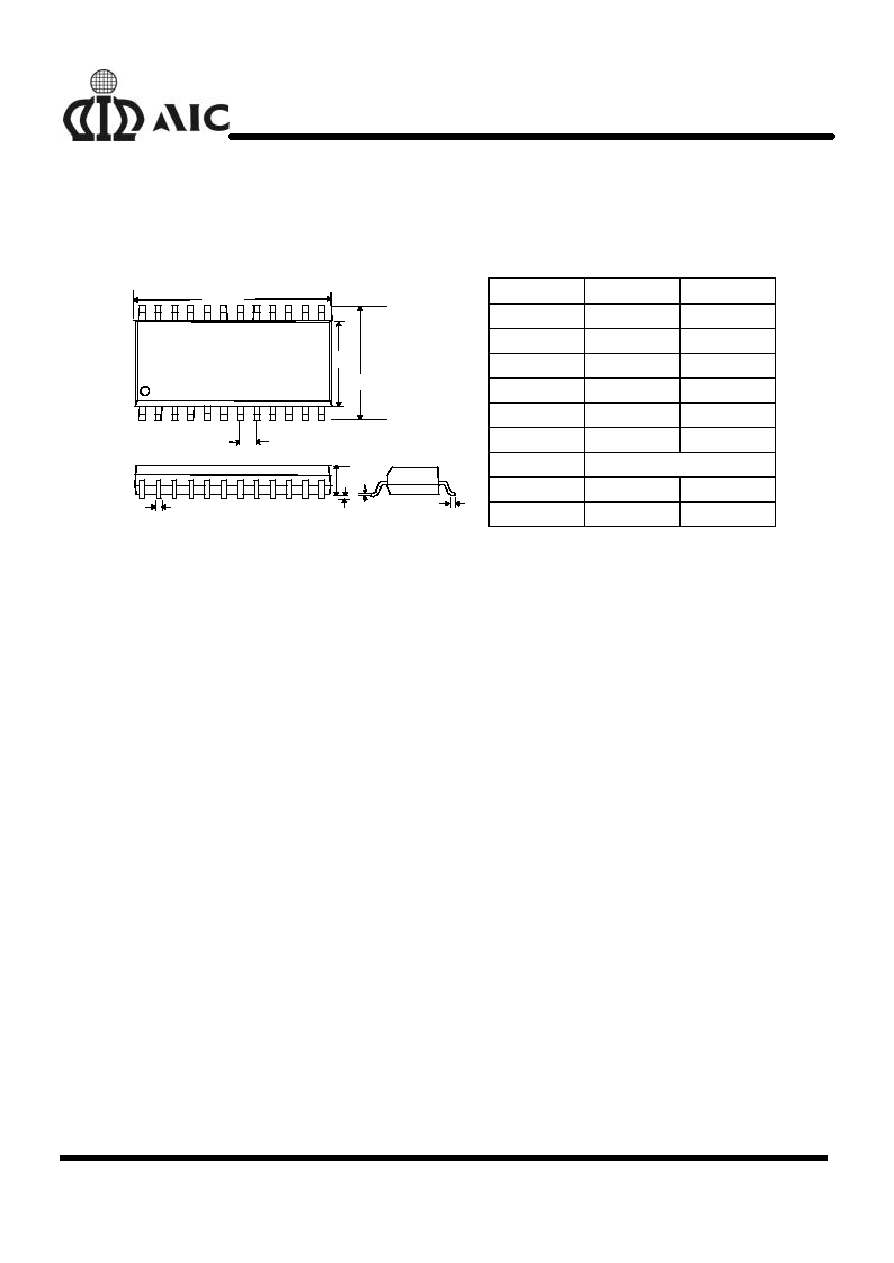

PHYSICAL DIMENSIONS

l

24 LEAD PLASTIC SO (300 mil) (unit: mm)

SYMBOL

MIN

MAX

A

2.35

2.65

A1

0.10

0.30

B

0.33

0.51

C

0.23

0.32

D

15.20

15.60

E

7.40

7.60

e

1.27(TYP)

H

10.00

10.65

e

B

D

A

A1 C

E

H

L

L

0.40

1.27