OVERVIEW

The CCB-26 is a low cost driver and

smart controller board suitable for

operating small stepper motors. It utilizes

bipolar power drivers with adjustable

currents of up to 0.85 amps (1.25 amps

with cooling) per phase. This all-in-one

package is designed for OEM applica-

tions using high volume production

linear actuators and rotary steppers. Built

in phase step sequences include 1/8, 1/4,

1/2, Full, and Wave drives.

The CCB-26 has an instruction set of

over 30 commands that include loop on

port, count delays, and set/clear ports. In

addition to 5 general-purpose ports, jog,

limit and home sensor inputs are also

available.

Other features include auxiliary step

pulse and direction inputs to allow

motion generation via external pulse

sources, with limit switch protection and

position counter tracking.

Application development is facilitated

with AMS' free software; featuring:

∑ Program Editor

∑ Syntax Checker Loader

∑ Microsoft "C" Source Code

∑ Pull-Down Menus

∑ Dumb Terminal Emulation

∑ Quick Basic Information Program

∑ Speed, Distance, Accel/Decel Plots

For evaluation and medium volume

production, a companion "mini-mother"

board simplifies product interface. The

dual axis board has an RS-232 interface,

expandable for multiple axes. The

communication, power and I.O. signal

connectors provide for real-world

interface.

PARTY LINE MODE

"Party Line" communication protocol

can be used in applications using a host

computer. This protocol greatly reduces

communication time and supports

between 1 and 60 axes of motion

connected in parallel from a single serial

port.

NON-VOLATILE MEMORY

2k bytes of non-volatile memory is

available to store user programs for

future execution. Any number of

programs may coexist, limited only by

the available memory space. Utilizing

this feature allows all parameters, such as

initial velocity, ramp and step mode to be

set as defaults then modified "on the fly"

during program execution.

TRIP POINT

The trip point is a programmable

position that allows predefined opera-

tions to be triggered when the motor

position matches the established trip

point position. During motion the

position counter is continuously updated

and compared to the programmed trip

position.

RESET

Upon hardware reset all parameters (set

by commands B,D,E,H,I,K,T,V) most

recently saved are downloaded into the

working registers of the controller. Both

Jog and Go inputs are then active.

During reset all outputs are off.

FEATURES

∑ Small in size

∑ 0.85 amp bipolar chopper drive

∑ Microstep to 1/8, 1/4, 1/2, Full step

∑ High torque full step mode

∑ Bi-directional ramping between speeds

∑ User I.O. ports

∑ Speeds to 25,000 steps per second

∑ Speed alterable "on the fly"

∑ Soft decelerate stop command & input

∑ Motion output signal

∑ Receive/send commands while moving

∑ Step register of over 16M steps

∑ Enable signal polarity (programmable)

∑ Special "Home" function at any step rate

∑ Read position counter while moving

∑ Limit and home switch inputs

∑ 2k non-volatile memory

∑ 9.6k / 470k Baud

∑ Programmable trip point

∑ Selectable "Party Line" serial mode

∑ Limit switch polarity (programmable)

∑ 16 way branch (on ports 1-3)

TERMINAL INTERFACE

By using a simple RS-232 buffer, motion

sequences can be programmed from a

standard terminal or host PC. Command

lines consist of an ASCII character

followed by a number. The input line

editor provides a user-friendly interface.

CCB-26

MICROSTEP DRIVER

WITH

INTELLIGENT

CONTROLLER

C

C

B

-

2

6

ADVANCED MICRO SYSTEMS, INC. reserves the right to make improvements and changes in specifications or prices at any time without prior notification. 9356

SUMMARY OF COMMANDS

ASCII Description

ESC

Abort/Terminate

A

Port Set/Increment/Read

B

Jog Speed/30: Slow, Fast

C

Restore, Clear Page

D

Divide Factor

E

Enable, Limit Sense

F

Find Home: Sense Speed

G

Go (Address/Branch), Trace

H

Select phase table

I

Initial Velocity-SPS

J

Jump To Address, Repetition

K

Ramp Slope

k

Trip Output Values

L

Loop On Port Condition

M

Constant Velocity-SPS

O

Set Origin

P

Program Mode

Q

Query Program

R

Relative Move

S

Store Parameters

T

Set Trip Point

V

Slew Velocity-SPS

W

Wait n Milliseconds

X

Examine Settings

Z

Read Position Once/Repeat

+

+ Step Command

-

- Step Command

\

Write To NV Memory

[

Read NV Memory

]

Query Hardware Status

^

Query Motion Status

@

Soft Stop

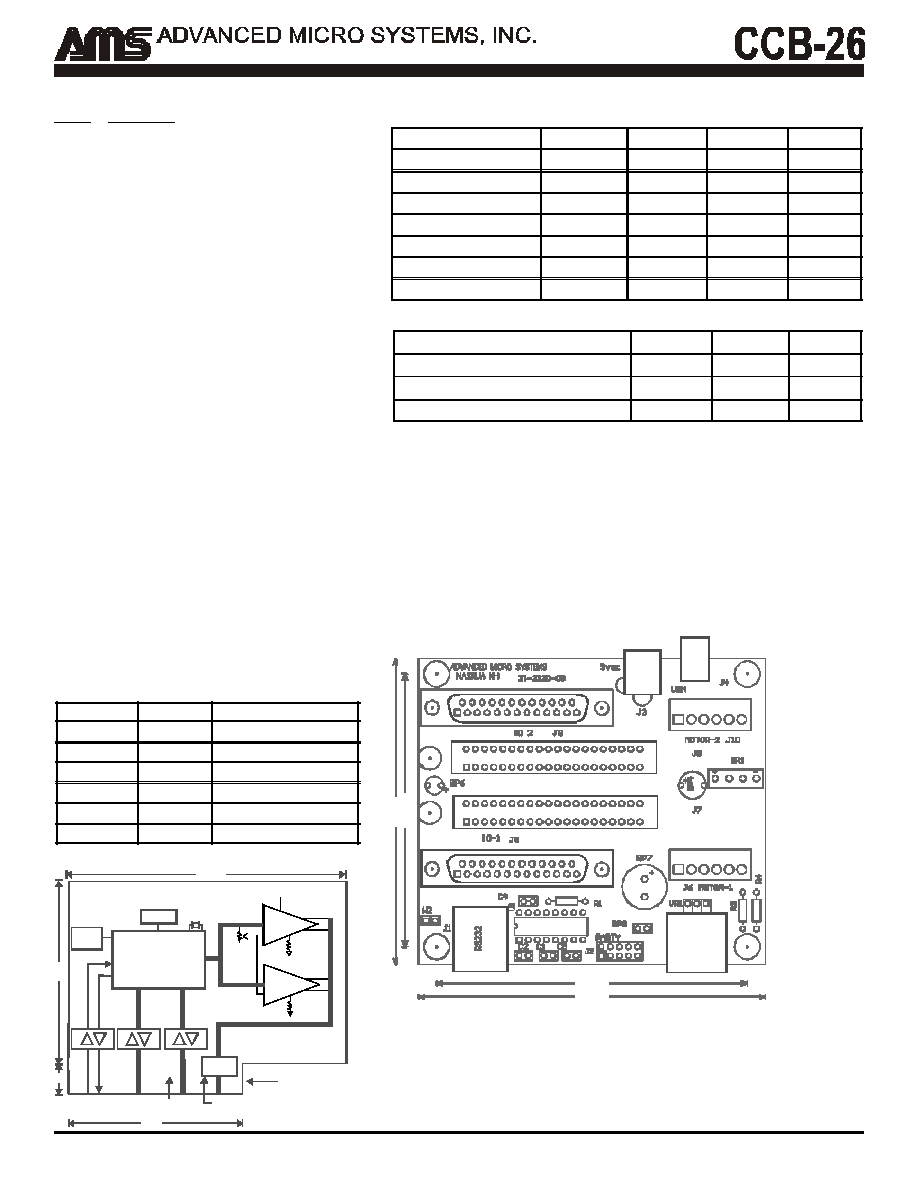

PROGRAMMABLE PHASE SEQUENCE

CCB-26 BLOCK DIAGRAM

ELECTRICAL SPECIFICATIONS

Logic D.C. Characteristics: (Vcc= 5V ±10%)

Drive Outputs @ 25 degrees C (Ambient)

2 AXIS MOTHER BOARD (MODEL DCMB)

The DCMB is an accessory to the CCB-26. It contains the interface for one or

two axis of motion control. The expansion connector provides the ability to

add more axis in a microprocessor based system.

∑ Two axis interface

∑ Expansion connector for multi-axis

∑ 1 amp, 5 volt regulator for additional load

∑ DB25 connector for input/output signals

∑ DC or 9-18 VAC input for low cost power

∑ Separate motor and power supply inputs

∑ RJ45 connector for RS-232 input

An RS-232 input converts standard serial voltages to TTL levels to drive up to 10

axis using Advanced Micro System's "Party Line" protocol. The open drain TXD

outputs from each axis are wire-or'd, providing a party line communication

method. Prior to operation each axis must be assigned a one character name that

is stored in the CCB-26 NV memory. Removing the "Party Line" jumper and

inserting one axis at a time facilitates name assignment.

2 Townsend West, Nashua, NH 03063-1277 603-882-1447 FAX 603-881-7600

Vmm

P1

CLAMP

CONTROL

ENABLE

5V SERIAL

VMM*

(POWER)

MOTOR

3.375

2.09

I/O

5V

POWER

RESET

NV MEM

SMC-26

5V/40ma

2

.

2

0

.

3

8

C U R R E N T

SENSE

DRIVER A

DRIVER B

3.40

3.80

3

.

0

0

3

.

3

7

Sequence

Steps/Rev Remark

1/8 Micro

1600

High resolution

1/4 Micro

800

Reduced resonance

1/2 Micro

400

Good speed

Full - Wave

200

One phase on

Half

400

High torque

Full

200

Highest torque

Description

Condition

Typ

Max

Unit

Icc: Supply current

Enabled

104

120

Ma

Icc: Supply current

Disabled

45

60.0

Ma

Vil: Input low voltage

-.05

0.85

Volts

IiI: Input low current

Vil=0.45V

-500.0

µa

Vih: Input high voltage

2.0

Vcc+0.55

Volts

Vol: Output low voltage

IoI=1.6ma

0.45

Volts

Voh: Output high voltage Ioh= -80µa

2.4

Volts

Description

Min

Max

Unit

Current per phase

0

0.85

Amps

Current per phase with cooling

1.25

Amps

Motor power supply (Vmm):

5

50

Volts