| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: AAT3680 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

1

BatteryManager

TM

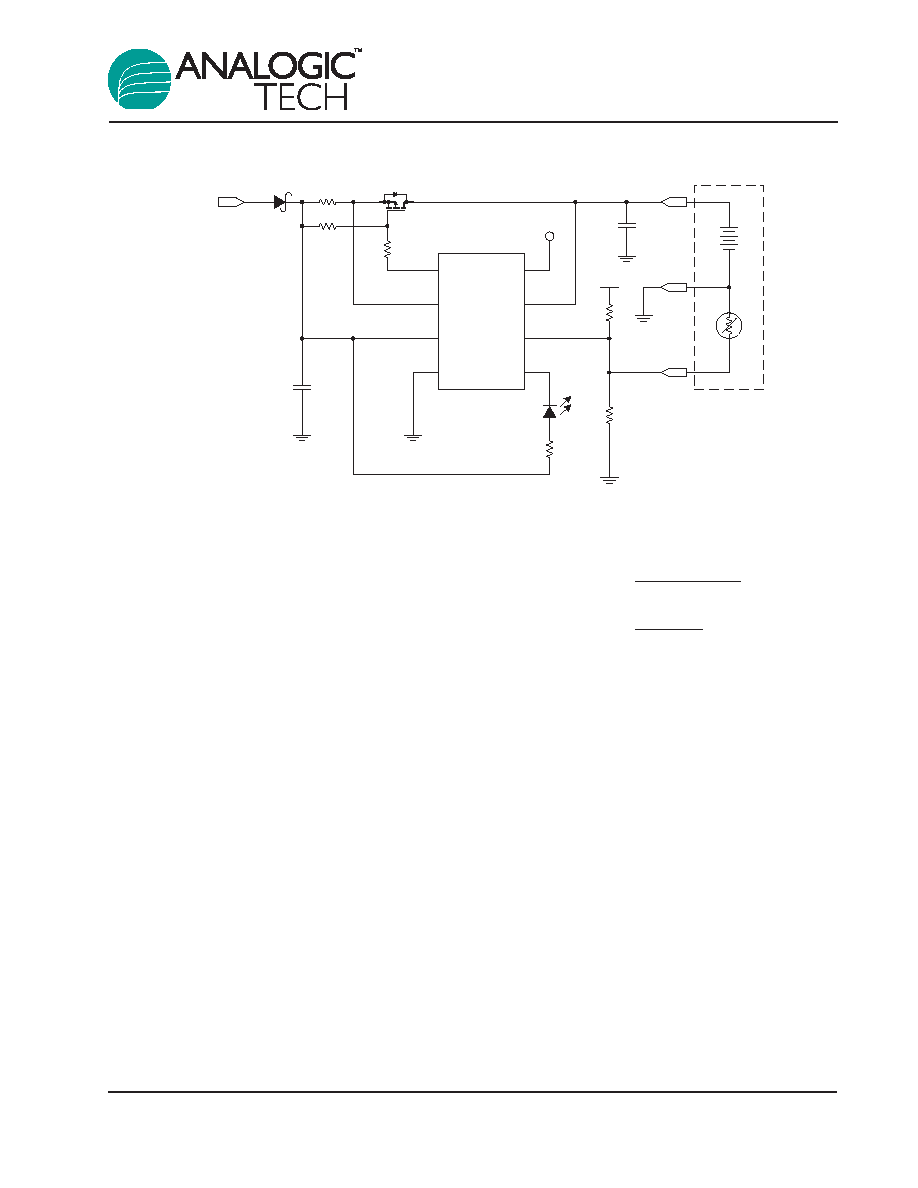

Typical Application

Q1

SMA

B34DLA

FZT968

AAT3680

C2

1

µ

F

C3

10

µ

F

R2

1k

R

SENSE

0.2

R1

1.9k

BATT+

BATT-

TEMP

RT1

RT2

VP

Battery

Pack

DRV

CSI

VP

VP

VSS

STAT

TS

BAT

T2X

LED1

General Description

The AAT3680 BatteryManager is a member of

AnalogicTech's Total Power Management ICTM

(TPMICTM) product family. This device is a lithium-

ion/polymer battery charge and management IC,

specifically designed for compact portable applica-

tions. The AAT3680 precisely regulates battery

charge voltage and charge current, and is capable

of two trickle charge current levels controlled by

one external pin. Battery charge temperature and

charge state are carefully monitored for fault con-

ditions. In the event of an over-current, short-cir-

cuit, or over-temperature failure, the device will

automatically shut down, protecting the charging

device and the battery under charge. A battery

charge state monitor output pin is provided to indi-

cate the battery charge status through a display

LED. The battery charge status output is a serial

interface which may also be read by a system

microcontroller.

The AAT3680 is available in a Pb-free, 8-pin MSOP

or 12-pin TSOPJW package, specified over the

-20∞C to +70∞C temperature range.

Features

∑

Input Voltage Range: 4.5V to 7V

∑

1% Accurate Preset Voltages: 4.1V, 4.2V

∑

Low Operation Current, Typically 0.5mA

∑

Programmable Charge Current

∑

Automatic Recharge Sequencing

∑

Battery Temperature Monitoring

∑

Deep Discharge Cell Conditioning

∑

Fast Trickle Charge Option with Thermal

Over-Ride

∑

Full Battery Charge Auto Turn-Off / Sleep Mode

∑

Over-Voltage, Over-Current, and Over-

Temperature Protection

∑

Power On Reset

∑

LED Charge Status Output or System

Microcontroller Serial Interface

∑

Temperature Range: -20∞C to +70∞C

∑

8-Pin MSOP or 12-Pin TSOPJW Package

Applications

∑

Cellular Phones

∑

Desktop Chargers

∑

Personal Digital Assistants (PDAs)

∑

USB Chargers

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

2

3680.2006.03.1.6

Pin Description

Pin Configuration

TSOPJW-12

MSOP-8

(Top View)

(Top View)

1

2

CSI

BAT

T2X

DRV

VP

TS

STAT

VSS

1

2

3

4

8

7

6

5

1

2

3

4

5

6

12

11

10

9

8

7

BAT

CSI

N/C

T2X

DRV

VSS

TS

VP

VP

VP

VP

STAT

Pin #

TSOPJW-12

MSOP-8

Symbol

Function

1

8

BAT

Battery voltage level sense input.

2

7

CSI

Current sense input.

3

N/A

N/C

Not connected.

4

6

T2X

2X battery trickle charge control input. Connect this pin to VSS to

double the battery trickle charge current. Leave this pin floating for

normal trickle charge current (10% of full charge current). To enter

microcontroller fast-read status, pull this pin high during power-up.

5

5

DRV

Battery charge control output.

6

4

VSS

Common ground connection.

7

3

STAT

Battery charge status output. Connect an LED in series with 2.2k

from STAT to VP to monitor battery charge state.

8, 9, 10, 11

1

VP

Power supply input pin.

12

2

TS

Battery temperature sense input.

Absolute Maximum Ratings

1

T

A

=25∞C, unless otherwise noted.

Thermal Information

3

Recommended Operating Conditions

Symbol

Description

Conditions

Min

Typ

Max

Units

V

P

Operation Input Voltage

4.5

7.0

V

I

DRV

DRV Pin Sink Current

40

mA

T

Ambient Temperature Range

-20

70

∞C

Symbol

Description

Value

Units

JA

Maximum Thermal Resistance

TSOPJW-12

120

∞C/W

MSOP-8

150

P

D

Maximum Power Dissipation

TSOPJW-12

1.0

W

MSOP-8

833

mW

Symbol

Description

Value

Units

V

P

V

P

Relative to V

SS

-0.3 to 7.5

V

V

CSI

CSI to GND

-0.3 to V

P

+ 0.3

V

V

T2X

T2X to GND

-0.3 to 5.5

V

V

BAT

BAT to GND

-0.3 to V

P

+ 0.3

V

T

J

Operating Junction Temperature Range

-40 to 150

∞C

ESD

ESD Rating

Note 2

kV

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

3

1. Stresses above those listed in Absolute Maximum Ratings may cause permanent damage to the device. Functional operation at condi-

tions other than the conditions specified is not implied. Only one Absolute Maximum Rating should be applied at any one time.

2. IC devices are inherently ESD sensitive; handling precautions required.

3. Mounted on an FR4 printed circuit board.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

4

3680.2006.03.1.6

Electrical Characteristics

V

IN

= 4.5V to 5.5V, T

A

= -20∞C to 70∞C, unless otherwise noted; typical values are at T

A

= 25∞C.

Symbol Description

Conditions

Min

Typ

Max Units

I

P

Operating Current

V

IN

= 5.5V, V

CH

= 4.1V, V

CH

= 4.2V

0.5

3

mA

I

SLEEP

Sleep Mode Current

V

IN

= 3.5V, V

CH

= 4.1V, V

CH

= 4.2V

2

6

µA

I

STAT(HI)

STAT High-Level Output

V

IN

= 5.5V

-1

+1

µA

Leakage Current

V

STAT(LOW)

STAT Low-Level Sink Current

V

IN

= 5.5V, I

SINK

= 5mA

0.3

0.6

V

I

SINK

DRV Pin Sink Current

V

IN

= 5.5V

20

mA

V

OL@DRV

DRV Pin Output Low

I

SINK

= 5mA, V

IN

= 5.5V

0.4

1.0

V

AAT3680-4.1

T

A

= 25∞C

4.075 4.100

4.125

V

CH

Output Charge Voltage

See Note 1

4.059 4.100

4.141

V

AAT3680-4.2

T

A

= 25∞C

4.175 4.200

4.225

See Note 1

4.158 4.200

4.242

V

CS

Charge Current Regulation

V

IN

= 5.5V, V

CH

= 4.1V, V

CH

= 4.2V

90

100

110

mV

AAT3680-4.1

2.94

3.0

3.06

V

MIN

Preconditioning Voltage Threshold

AAT3680-4.2

3.04

3.1

3.16

V

V

TRICKLE

Trickle-Charge Current Regulation

T2X Floating, V

CH

= 4.1V, V

CH

= 4.2V

10

mV

T

2X

Trickle Charge Current Gain

T2X = V

SS

1.8

V

TS1

Low-Temperature Threshold

V

IN

= 5.5V

29.1

30

30.9

% V

P

V

TS2

High-Temperature Threshold

V

IN

= 5.5V

58.2

60

61.8

% V

P

V

TERM

Charge Termination Threshold Voltage

4

12

24

mV

V

CH

= 4.1V

3.92

4.00

4.08

V

RCH

Battery Recharge Voltage Threshold

V

CH

= 4.2V

4.018

4.10

4.182

V

V

UVLO

Under-Voltage Lockout

V

IN

Rising, T

A

= 25∞C

3.5

4.0

4.5

V

V

OVP

Over-Voltage Protection Threshold

4.4

V

V

OCP

Over-Current Protection Threshold

200

% V

CS

1. The AAT3680 output charge voltage is specified over 0∞ to 50∞C ambient temperature; operation over -20∞C to +70∞C is guaranteed

by design.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

5

Functional Block Diagram

LED Signal

Generator

MUX

Microcontroller

Status Generator

Microcontroller

Read Enable

Charge Status

Logic Control

Power-On

Reset

CSI

VP

STAT

T2X

DRV

VSS

Under-

Voltage

Lock Out

Over-Current /

Short-Circuit

Protection

2x Trickle

Charge

Control

Loop Select

MUX Driver

BAT

TS

V

REF

Temperature Sense

Comparator

Voltage

Comparator

Current Loop

Error Amp

Voltage Loop

Error Amp

Functional Description

The AAT3680 is a linear charge controller designed

for single-cell lithium-ion/polymer batteries. It is a

full-featured battery management system IC with

multiple levels of integrated power savings, system

communication, and protection. Refer to the block

diagram (above) and flow chart (Figure 1) in this

section for details.

Cell Preconditioning

Before the start of charging, the AAT3680 checks

several conditions in order to maintain a safe charg-

ing environment. The input supply must be above

the minimum operating voltage, or under-voltage

lockout threshold (V

UVLO

), for the charging

sequence to begin. Also, the cell temperature, as

reported by a thermistor connected to the TS pin,

must be within the proper window for safe charging.

When these conditions have been met and a bat-

tery is connected to the BAT pin, the AAT3680

checks the state of the battery. If the cell voltage is

below V

MIN

, the AAT3680 begins preconditioning

the cell. This is performed by charging the cell with

10% of the programmed constant current. For

example, if the programmed charge current is

500mA, then the preconditioning mode (trickle

charge) current will be 50mA. Cell preconditioning

is a safety precaution for deeply discharged cells

and, furthermore, limits power dissipation in the

pass transistor when the voltage across the device

is largest. The AAT3680 features an optional T2X

mode, which allows faster trickle charging at

approximately two times the default rate. This

mode is selected by connecting the T2X pin to V

SS

.

If an over-temperature fault is triggered, the fast

trickle charge will be latched off, and the AAT3680

will continue at the default 10% charge current.

Constant Current Charging

Cell preconditioning continues until the voltage on

the BAT pin reaches V

MIN

. At this point, the

AAT3680 begins constant current charging (fast

charging). Current level for this mode is pro-

grammed using a current sense resistor R

SENSE

between the VP and CSI pins. The CSI pin moni-

tors the voltage across R

SENSE

to provide feedback

for the current control loop. The AAT3680 remains

in constant current charge mode until the battery

reaches the voltage regulation point, V

CH

.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

6

3680.2006.03.1.6

Constant Voltage Charging

When the battery voltage reaches V

CH

during con-

stant current mode, the AAT3680 transitions to con-

stant voltage mode. The regulation voltage is fac-

tory programmed: 4.1V and 4.2V are available to

support different anode materials in lithium-ion/poly-

mer cells. In constant voltage operation, the

AAT3680 monitors the cell voltage and terminates

the charging cycle when the voltage across R

SENSE

decreases to approximately 10mV.

Charge Cycle Termination, Recharge

Sequence

After the charge cycle is complete, the AAT3680

latches off the pass device and automatically enters

power-saving sleep mode. Either of two possible

conditions will bring the IC out of sleep mode: the

battery voltage at the BAT pin drops below V

RCH

(recharge threshold voltage) or the AAT3680 is reset

by cycling the input supply through the power-on

sequence. Falling below V

RCH

signals the IC that it

is time to initiate a new charge cycle.

Figure 1: AAT3680 Operational Flow Chart.

UVLO

Temperature Test

TS > V

TS1

TS < V

TS2

Power On Reset

Power On Reset

Preconditioning Test

Current Phase Test

V

CH

> V

BAT

V

MIN

> V

BAT

V

TERM

R

SENSE

< V

RCH

Voltage

Phase Test

V

P

> V

UVLO

Shut Down

Mode

Shutdown

Mode

Yes

No

Yes

Yes

Low Current

Conditioning

Charge

Low Current

Conditioning

Charge

(Trickle Charge)

Temperature

Fault

Temperature

Fault

No

No

Current

Charging

Mode

Current

Charging

Mode

Yes

Voltage

Charging

Mode

< I

BAT

No

Yes

No

Charge Complete

Latch Off

Charge Complete

Latch Off

Voltage

Charging

Mode

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

7

Sleep Mode

When the input supply is disconnected, the charger

automatically enters power-saving sleep mode. Only

consuming an ultra-low 2µA in sleep mode, the

AAT3680 minimizes battery drain when it is not

charging.This feature is particularly useful in applica-

tions where the input supply level may fall below the

battery charge or under-voltage lockout level. In such

cases, where the AAT3680 input voltage drops, the

device will enter sleep mode and automatically

resume charging once the input supply has recov-

ered from its fault condition. This makes the AAT3680

well suited for USB battery charger applications.

Charge Inhibit

The AAT3680 charging cycle is fully automatic;

however, it is possible to stop the device from

charging even when all conditions are met for

proper charging. Switching the TS pin to either VP

or VSS will force the AAT3680 to turn off the pass

device and wait for a voltage between the low- and

high-temperature voltage thresholds.

Resuming Charge and the V

RCH

Threshold

The AAT3680 will automatically resume charging

under most conditions when a battery charge cycle is

interrupted. Events such as an input supply interrup-

tion or under voltage, removal and replacement of the

battery under charge, or charging a partially drained

battery are all possible. The AAT3680 will monitor the

battery voltage and automatically resume charging in

the appropriate mode based upon the measured bat-

tery cell voltage. This feature is useful for systems

with an unstable input supply, which could be the

case when powering a charger from a USB bus sup-

ply. This feature is also beneficial for charging or

"topping off" partially discharged batteries.

The only restriction on resuming charge of a bat-

tery is that the battery cell voltage must be below

the battery recharge voltage threshold (V

RCH

)

specification. There is V

RCH

threshold hysteresis

built into the charge control system. This is done

to prevent the charger from erroneously turning on

and off once a battery charge cycle is complete.

For example, the AAT3680-4.2 has a typical V

RCH

threshold of 4.1V. A battery under charge is above

4.1V, but is still in the constant voltage mode because

it has not yet reached 4.2V to complete the charge

cycle. If the battery is removed and then placed back

on the charger, the charge cycle will not resume until

the battery voltage drops below the V

RCH

threshold.

In another case, a battery under charge is in the

constant current mode and the cell voltage is 3.7V

when the input supply is inadvertently removed

and then restored. The battery is below the V

RCH

threshold and the charge cycle will immediately

resume where it left off.

LED Display

Charge Status Output

The AAT3680 provides a battery charge status output

via the STAT pin. STAT is an open-drain serial data

output capable of displaying five distinct status func-

tions with one LED connected between the STAT pin

and VP. There are four periods which determine a

status word. Under default conditions, each output

period is one second long; thus, one status word will

take four seconds to display through an LED.

The five modes include:

1. Sleep/Charge Complete: The IC goes into

sleep mode when no battery is present -OR-

when the charge cycle is complete.

2. Fault: When an over-current (OC) condition is

detected by the current sense and control cir-

cuit -OR- when an over-voltage (OV) condition

is detected at the BAT pin -OR- when a battery

over-temperature fault is detected on the

TEMP pin.

3. Battery Conditioning: When the charge sys-

tem is in the 1X or 2X trickle charge mode.

4. Constant Current (CC) Mode: When the sys-

tem is in the constant current charge mode.

5. Constant Voltage (CV) Mode: When the sys-

tem is in the constant voltage charge mode.

An additional feature of the LED status display is

for a Battery Not Detected state. When the

AAT3680 senses there is no battery connected to

the BAT pin, the STAT output will turn the LED on

and off at a rate dependent on the size of the out-

put capacitor being used. The LED cycles on for

two periods then remains off for two periods. See

Figure 2.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

8

3680.2006.03.1.6

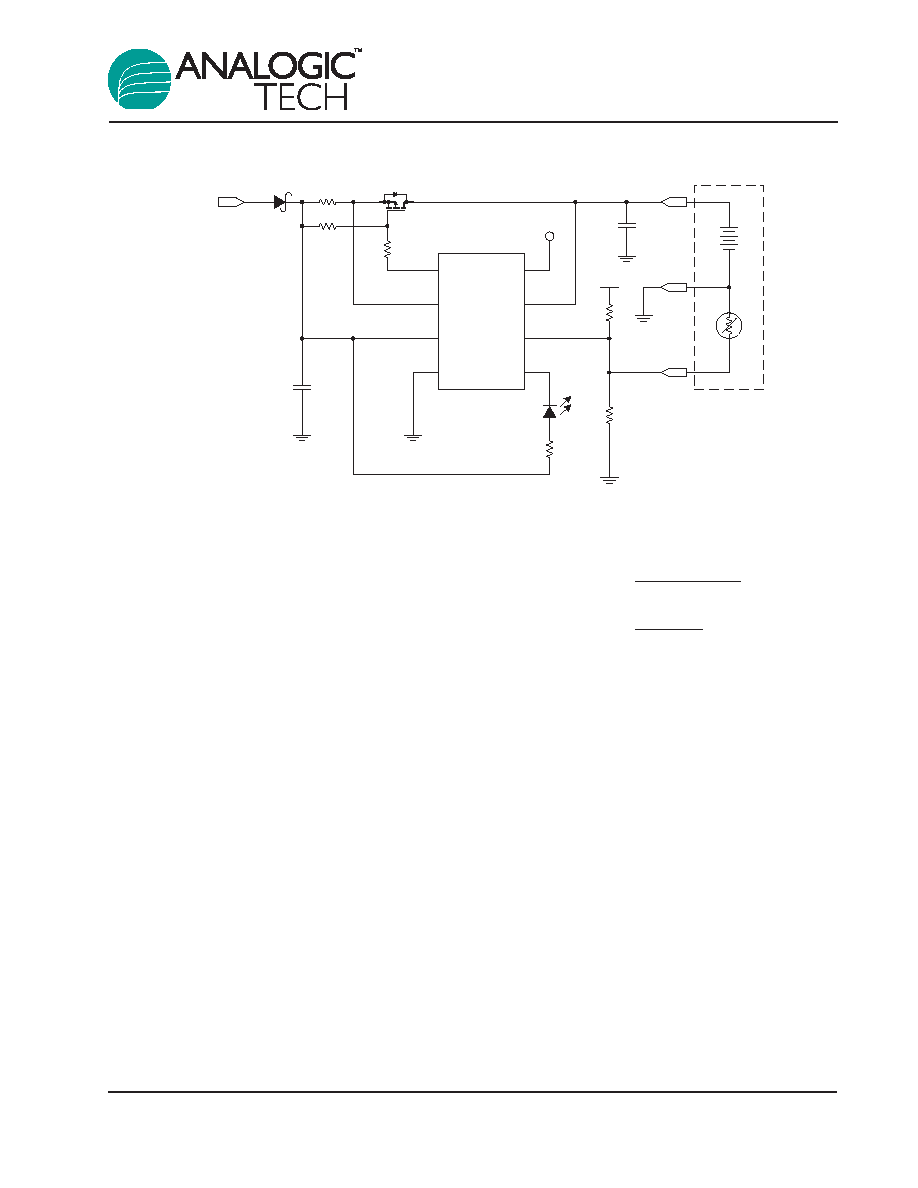

High-Speed Data Reporting

A high-speed data reporting application schematic

is shown in Figure 3. An optional system micro-

controller interface can be enabled by pulling up

the T2X pin to 4.5V to 5.5V during the power-up

sequence. The T2X pin should be pulled high with

the use of a 100k

resistor. If the input supply to

VP will not exceed 5.5V, then the T2X pin may be

tied directly to VP through a 100k

resistor. Since

this is a TTL-level circuit, it may not be pulled high-

er than 5.5V without risk of damage to the device.

When the high-speed data report feature is

enabled, the STAT output periods are sped up to

40µs, making the total status word 160µs in length

(see Figure 4).

An additional feature is the Output Status for

Battery Not Detected state. When the AAT3680

senses there is no battery connected to the BAT

pin, the STAT pin cycles for two periods, then

remains off for two periods.

When in high-speed data reporting, the AAT3680

will only trickle charge at the 2X trickle charge

level. This is because the TX2 pin is pulled high to

enable the high-speed data reporting.

A status display LED may not be connected to the

STAT pin when the high-speed data reporting is

being utilized. If both display modes are required,

the display LED must be switched out of the circuit

before the T2X pin is pulled high. Failing to do so

could cause problems with the high-speed switching

control circuits internal to the AAT3680.

Figure 3: High-Speed Data Reporting Application Schematic.

Q1

FZT788B

AAT3680

C2

10

µ

F

C1

4.7

µ

F

R2

100k

R

SENSE

0.2

R1

2.5k

BATT+

BATT-

TEMP

RT1

RT2

VP

VP

Battery

Pack

DRV

CSI

VP

VSS

STAT

TS

BAT

TX2

STAT

C3

0.1

µ

F

100k

Figure 2: LED Display Output.

Sleep / Charge Complete

Temp., OC, OV Fault

Battery Conditioning

Constant Current Mode

Constant Voltage Mode

off / off / off / off

on / on / off / off

on / on / on / on

on / off / off / off

on / on / on / off

Charge Status

Output Status

LED Display

on/off

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

on/off

on/off

on/off

Protection Circuitry

The AAT3680 is a highly integrated battery man-

agement system IC including several protection

features. In addition to battery temperature moni-

toring, the IC constantly monitors for over-current

and over-voltage conditions. If an over-current sit-

uation occurs, the AAT3680 latches off the pass

device to prevent damage to the battery or the sys-

tem, and enters shutdown mode until the over-cur-

rent event is terminated.

An over-voltage condition is defined as a condition

where the voltage on the BAT pin exceeds the

maximum battery charge voltage. If an over-volt-

age condition occurs, the IC turns off the pass

device until voltage on the BAT pin drops below the

maximum battery charge constant voltage thresh-

old. The AAT3680 will resume normal operation

after the over-current or over-voltage condition is

removed. During an over-current or over-voltage

event, the STAT will report a FAULT signal.

In the event of a battery over-temperature condi-

tion, the IC will turn off the pass device and report

a FAULT signal on the STAT pin. After the system

recovers from a temperature fault, the IC will

resume operation in the 1X trickle charge mode to

prevent damage to the system in the event a defec-

tive battery is placed under charge. Once the bat-

tery voltage rises above the trickle charge to con-

stant current charge threshold, the IC will resume

the constant current mode.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

9

Figure 4: Microcontroller Interface Logic Output.

Sleep / Charge Complete

Temp., OC, OV Fault

Battery Conditioning

Constant Current Mode

Constant Voltage Mode

HI / HI / HI / HI

LO / LO / HI / HI

LO / LO / LO / LO

LO / HI / HI / HI

LO / LO / LO / HI

Charge Status

Output Status

STAT Level

Figure 5: Typical Charge Profile.

Preconditioning

(Trickle Charge)

Phase

Constant Current

Phase

Constant Voltage

Phase

Output Charge

Voltage (V

CH

)

Preconditioning

Voltage Threshold

(V

MIN

)

Regulation

Current

(I

CHARGE(REG)

)

Trickle Charge

and Termination

Threshold

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

10

3680.2006.03.1.6

Applications Information

Choosing an External Pass Device

(PNP or PMOS)

The AAT3680 is designed to work with either a

PNP transistor or P-channel power MOSFET.

Selecting one or the other requires looking at the

design tradeoffs, including performance versus

cost issues. Refer to the following design guide for

selecting the proper device.

PNP Transistor

In this design example, we will use the following

conditions: V

P

= 5V (with 10% supply tolerance),

I

CHARGE(REG)

= 600mA, 4.2V single cell lithium-ion

pack. V

P

is the input voltage to the AAT3680, and

I

CHARGE(REG)

is the desired fast-charge current.

1. The first step is to determine the maximum

power dissipation (P

D

) in the pass transistor.

Worst case is when the input voltage is the high-

est and the battery voltage is the lowest during

fast-charge (this is referred to as V

MIN

, nominal-

ly 3.1V when the AAT3680-4.2 transitions from

trickle charge to constant current mode). In this

equation, V

CS

is the voltage across R

SENSE

.

2. The next step is to determine which size package

is needed to keep the junction temperature below

its rated value, T

J(MAX)

. Using this value and the

maximum ambient temperature inside the system

T

A(MAX)

, calculate the thermal resistance R

JA

required:

It is recommended to choose a package with a

lower R

JA

than the number calculated above. A

SOT223 package would be an acceptable choice,

as it has an R

JA

of 62.5∞C/W when mounted to a

PCB with adequately sized copper pad soldered

to the heat tab.

3. Choose a collector-emitter (V

CE

) voltage rating

greater than the input voltage. In this example,

V

P

is 5.0V, so a 15V device is acceptable.

4. Choose a transistor with a collector current rating

at least 50% greater than the programmed

I

CHARGE(REG)

value. In this example, we would

select a device with at least a 900mA rating.

5. Calculate the required current gain (

or h

FE

);

> 200:

where I

C(MAX)

is the collector current (which is the

same as I

CHARGE(REG)

), and I

B(MIN)

is the minimum

amount of base current drive shown in Electrical

Characteristics as I

SINK

. Important Note: The cur-

rent gain (

or h

FE

) can vary by a factor of three

over temperature and drops off significantly with

increased collector current. It is critical to select a

transistor with

, at full current and lowest temper-

ature, greater than the

MIN

calculated above.

In summary, select a PNP transistor with ratings

V

CE

15V, R

JA

80∞C/W, I

C

900mA,

MIN

30 in

a SOT223 (or better thermal) package.

P-Channel Power MOSFET

The following conditions apply to Figure 6, for use

with the AAT3680-4.2V version: V

P

= 5V (with 10%

supply tolerance), I

CHARGE(REG)

= 750mA, 0.4V

Schottky diode, 4.2V single cell lithium-ion battery

pack. V

P

is the input voltage to the AAT3680, and

I

CHARGE(REG)

is the desired fast-charge current.

MIN

I

C(MAX)

I

B(MIN)

=

=

= 30

0.60

0.02

R

JA

(T

J(MAX)

- T

A(MAX)

)

P

D

=

=

= 80∞C/W

(150

- 40)

1.38

P

D

= (V

P(MAX)

- V

CS

- V

MIN

)

I

CHARGE(REG)

= (5.5V - 0.1V - 3.1V)

600mA

= 1.38W

1. The first step is to determine the maximum power

dissipation (P

D

) in the pass transistor. Worst case

is when the input voltage is the highest and the

battery voltage is the lowest during fast-charge

(this is referred to as V

MIN

, nominally 3.1V when

the AAT3680-4.2 transitions from trickle charge to

constant current mode). In this equation, V

CS

is

the voltage across R

SENSE

, and V

D

is the voltage

across the reverse current blocking diode. Refer

to section below titled Schottky Diode for further

details. Omit the value for V

D

in the equation

below if the diode is not used.

2. The next step is to determine which size package

is needed to keep the junction temperature below

its rated value, T

J(MAX)

. Using this value, and the

maximum ambient temperature inside the system

T

A(MAX)

, calculate the thermal resistance R

JA

required:

It is recommended to choose a package with a

lower R

JA

than the number calculated above.

A SOT223 package would be an acceptable

choice, as it has an R

JA

of 62.5∞C/W when

mounted to a PCB with an adequately sized

copper pad soldered to the heat tab.

3. Choose a drain-source (V

DS

) voltage rating

greater than the input voltage. In this example,

V

P

is 5.0V, so a 12V device is acceptable.

4. Choose a MOSFET with a drain current rating at

least 50% greater than the programmed

I

CHARGE(REG)

value. In this example, we would

select a device with at least a 1.125A rating.

R

JA

(T

J(MAX)

- T

A(MAX)

)

P

D

=

=

= 79∞C/W

(150

- 40)

1.4

P

D

= (V

P(MAX)

- V

CS

- V

D

- V

MIN

)

I

CHARGE(REG)

= (5.5V - 0.1V - 0.4V - 3.1V)

750mA

= 1.4W

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

11

Figure 6: Typical Applications Schematic Using a P-Channel Power MOSFET with the AAT3680-4.2.

Q1

RFD10P03L

AAT3680

C2

10

µ

F

C1

4.7

µ

F

R2

1k

R

SENSE

0.2

R1

1k

R4

100k

BATT+

BATT-

TEMP

RT1

RT2

VP

Battery

Pack

DRV

CSI

VP

VP

VSS

STAT

TS

BAT

T2X

D1

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

12

3680.2006.03.1.6

5. Calculate the required threshold voltage to

deliver I

CHARGE(REG)

:

where V

GS

is the available gate-to-source voltage

provided by the AAT3680, V

CS

is the voltage

across the sense resistor, V

OL@DRV

is the rated

low voltage at the DRV pin, and V

P(MIN)

is the

worst case input voltage (assuming 10% toler-

ance on the 5V supply). Choose a MOSFET

device with sufficiently low V

GS(TH)

so the device

will conduct the desired I

CHARGE(REG)

.

6. Calculate the worst case maximum allowable

R

DS(ON)

at worst case V

GS

voltage:

Select a P-channel power MOSFET with R

DS(ON)

lower than 197m

at V

GS

= -4.3V.

In summary, select a P-channel MOSFET with ratings

V

DS

12V, R

JA

79∞C/W and R

DS(ON)

197m

at

V

GS

= -4.3V in a SOT223 (or better thermal) package.

Choosing a Sense Resistor

The charging rate recommended by lithium-

ion/polymer cell vendors is normally 1C, with a 2C

absolute maximum rating. Charging at the highest

recommended rate offers the advantage of short-

ened charging time without decreasing the battery

lifespan. This means that the suggested fast

charge rate for a 500mAH battery pack is 500mA.

The current sense resistor, R

SENSE

, programs the

charge current according to the following equation:

Where I

CHARGE(REG)

is the desired typical charge cur-

rent during constant current charge mode. V

P

-V

CSI

is the voltage across R

SENSE

, shown in the Electrical

Characteristic table as V

CS

. To program a nominal

500mA charge current during fast-charge, a 200m

value resistor should be selected. Calculate the

worst case power dissipated in the sense resistor

according to the following equation:

A 500mW LRC type sense resistor from IRC is

adequate for this purpose. Higher value sense

resistors can be used, decreasing the power dissi-

pated in the sense resistor and pass transistor.

The drawback of higher value sense resistors is

that the charge cycle time is increased, so tradeoffs

should be considered when optimizing the design.

Thermistor

The AAT3680 checks battery temperature before

starting the charge cycle, as well as during all

stages of charging. This is accomplished by mon-

itoring the voltage at the TS pin. Either a negative

temperature coefficient thermistor (NTC) or posi-

tive temperature coefficient thermistor (PTC) can

be used because the AAT3680 checks to see that

the voltage at TS is within a voltage window bound-

ed by V

TS1

and V

TS2

. Please see the equations

below for specifying resistors:

R

T1

and R

T2

for use with NTC Thermistor

5

R

TH

R

TC

3

(R

TC

- R

TH

)

5

R

TH

R

TC

(2

R

TC

) - (7

R

TH

)

R

T1

=

R

T2

=

P

(V

CS

)

2

R

SENSE

=

=

= 50mW

(0.1

)

2

0.2

R

SENSE

(V

P

- V

CSI

)

I

CHARGE(REG)

=

R

DS(ON)

(V

P(MIN)

- V

CS(MAX)

- V

BAT(MAX)

)

I

CHARGE(REG)

=

=

= 197m

(4.5V

- 0.11V - 4.242V)

0.75A

V

GS

= (V

CS

+ V

OL@DRV

) - V

P(MIN)

= (0.1V + 0.1V) - 4.5V

= - 4.3V

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

13

R

T1

and R

T2

for use with PTC Thermistor

Where R

TC

is the thermistor's cold temperature

resistance and R

TH

is the thermistor's hot tempera-

ture resistance. See thermistor specifications for

information. To ensure there is no dependence on

the input supply changes, connect the divider

between V

P

and V

SS

. Disabling the temperature-

monitoring function is achieved by applying a volt-

age between V

TS1

and V

TS2

on the TS pin.

Capacitor Selection

Input Capacitor

In general, it is good design practice to place a

decoupling capacitor between the V

P

and V

SS

pins.

An input capacitor in the range of 1µF to 10µF is rec-

ommended. If the source supply is unregulated, it

may be necessary to increase the capacitance to

keep the input voltage above the under-voltage lock-

out threshold.

If the AAT3680 is to be used in a system with an

external power supply source, such as a typical

AC-to-DC wall adapter, then a C

IN

capacitor in the

range of 10µF should be used. A larger input

capacitor in this application will minimize switching

or power bounce effects when the power supply is

"hot plugged" in.

Output Capacitor

The AAT3680 does not need an output capacitor

for stability of the device itself. However, a capaci-

tor connected between BAT and V

SS

will control the

output voltage when the AAT3680 is powered up

when no battery is connected. The AAT3680 can

become unstable if a high impedance load is

placed across the BAT pin to V

SS

. Such a case is

possible with aging lithium-ion/polymer battery

cells. As cells age through repeated charge and

discharge cycles, the internal impedance can rise

over time. A 10µF or larger output capacitor will

compensate for the adverse effects of a high-

impedance load and assure device stability over all

operating conditions.

Operation Under No-Load Conditions

Under no-load conditions, that is when the

AAT3680 is powered with no battery connected

between the BAT pin and V

SS

, the output capacitor

is charged up very quickly by the trickle charge

control circuit to the BAT pin until the output reach-

es the recharge threshold (V

RCH

). At this point, the

AAT3680 will drop into sleep mode. The output

capacitor will discharge slowly by the capacitor's

own internal leakage until the voltage seen at the

BAT pin drops below the V

RCH

threshold. This

100mV cycle will continue at approximately 3Hz

with a 0.1µF capacitor connected. A larger capaci-

tor value will produce a slower voltage cycle. This

operation mode can be observed by viewing the

STAT LED blinking on and off at the rate estab-

lished by the C

OUT

value.

For desktop charger applications, where it might

not be desirable to have a "charger ready" blinking

LED, a large C

OUT

capacitor in the range of 100µF

or more would prevent the operation of this mode.

Reverse Current Blocking Diode

Bipolar Circuit Application

When using the AAT3680 with a PNP transistor, a

reverse blocking diode is not required because

there is no current path from BAT to V

P

. However,

it is advisable to still place a blocking diode

between the bipolar transistor collector and the

BAT pin connection to the circuit output. In the

event where the input supply is interrupted or

removed during the constant current or constant

voltage phases of the charging cycle, the battery

under charge will discharge through the circuit

pass transistor, rendering it impossible to turn off.

If the circuit is unable to turn off, the reverse leak-

age will eventually discharge the battery. A block-

ing diode will prevent this undesirable effect.

MOSFET Circuit Application

A reverse blocking diode is generally required for

the circuit shown in Figure 6. For this application,

the blocking diode gives the system protection

from a shorted input, when the AAT3680 is used

5

R

TH

R

TC

3

(R

TC

- R

TH

)

5

R

TH

R

TC

(2

R

TH

) - (7

R

TC

)

R

T1

=

R

T2

=

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

14

3680.2006.03.1.6

with a P-channel MOSFET. If there is no other pro-

tection in the system, a shorted input could dis-

charge the battery through the body diode of the

pass MOSFET. If a reverse-blocking diode is

added to the system, a device should be chosen

which can withstand the maximum constant cur-

rent charge current at the maximum system ambi-

ent temperature.

Diode Selection

Typically, a Schottky diode is used in reverse current

blocking applications with the AAT3680. Other

lower cost rectifier type diodes may also be used if

sufficient input power supply headroom is available.

The blocking diode selection should based on mer-

its of the device forward voltage (V

F

), current rat-

ing, and input supply level versus the maximum

battery charge voltage and cost.

First, determine the minimum diode forward voltage

drop requirement. Refer to the following equation:

Where:

V

IN(MIN)

= Minimum input supply level

V

BAT(MAX)

=

Maximum battery charge voltage

required

V

F(TRAN)

= Pass transistor forward voltage drop

V

F(DIODE)

= Blocking diode forward voltage

Based on the maximum constant current charge

level set for the system, the next step is to deter-

mine the minimum current rating and power han-

dling capacity for the blocking diode. The constant-

current charge level itself will dictate what the mini-

mum current rating must be for a given blocking

diode. The minimum power handling capacity must

be calculated based on the constant current ampli-

tude and the diode forward voltage (V

F

):

Where:

P

D(MIN)

= Minimum power rating for a diode selection

V

F

= Diode forward voltage

I

CC

= Constant current charge level for the

system

Schottky Diodes

Schottky diodes are selected for this application

because they have a low forward voltage drop, typ-

ically between 0.3V and 0.4V. A lower V

F

permits

a lower voltage drop at the constant current charge

level set by the system; less power will be dissi-

pated in this element of the circuit. Schottky

diodes allow for lower power dissipation, smaller

component package sizes, and greater circuit lay-

out densities.

Rectifier Diodes

Any general-purpose rectifier diode can be used

with the AAT3680 application circuit in place of a

higher cost Schottky diode. The design trade-off is

that a rectifier diode has a high forward voltage

drop. V

F

for a typical silicon rectifier diode is in the

range of 0.7V. A higher V

F

will place an input sup-

ply voltage requirement for the battery charger sys-

tem. This will also require a higher power rated

diode since the voltage drop at the constant current

charge amplitude will be greater. Refer to the pre-

viously stated equations to calculate the minimum

V

IN

and diode P

D

for a given application.

PCB Layout

For the best results, it is recommended to physical-

ly place the battery pack as closely as possible to

the AAT3680's BAT pin. To minimize voltage drops

in the PCB, keep the high current carrying traces

adequately wide. For maximum power dissipation

in the pass transistor, it is critical to provide enough

copper to spread the heat. Refer to the AAT3680

demo board PCB layout in Figures 8, 9, and 10.

P

D(MIN)

V

F

I

CC

=

V

IN(MIN)

= V

BAT(MAX)

+ V

F(TRAN)

+ V

F(DIODE)

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

15

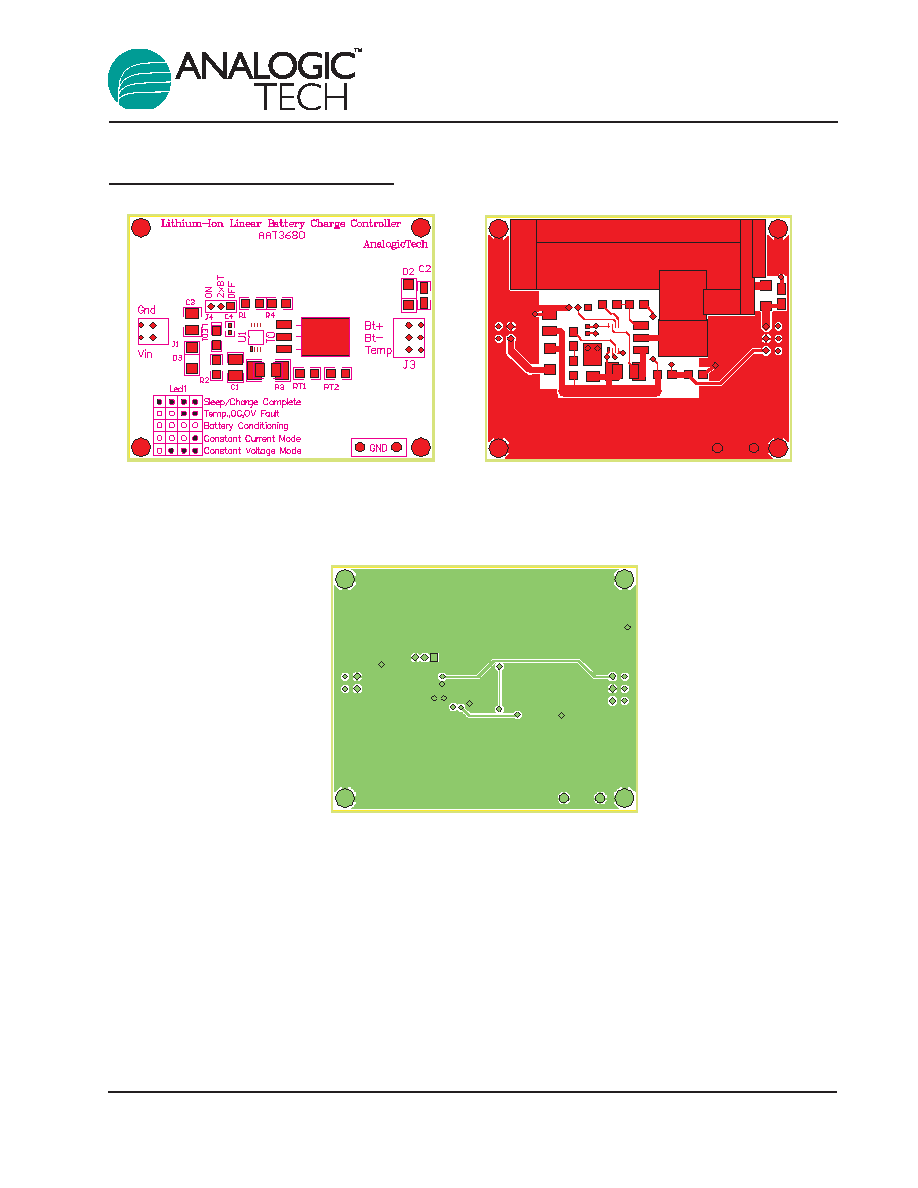

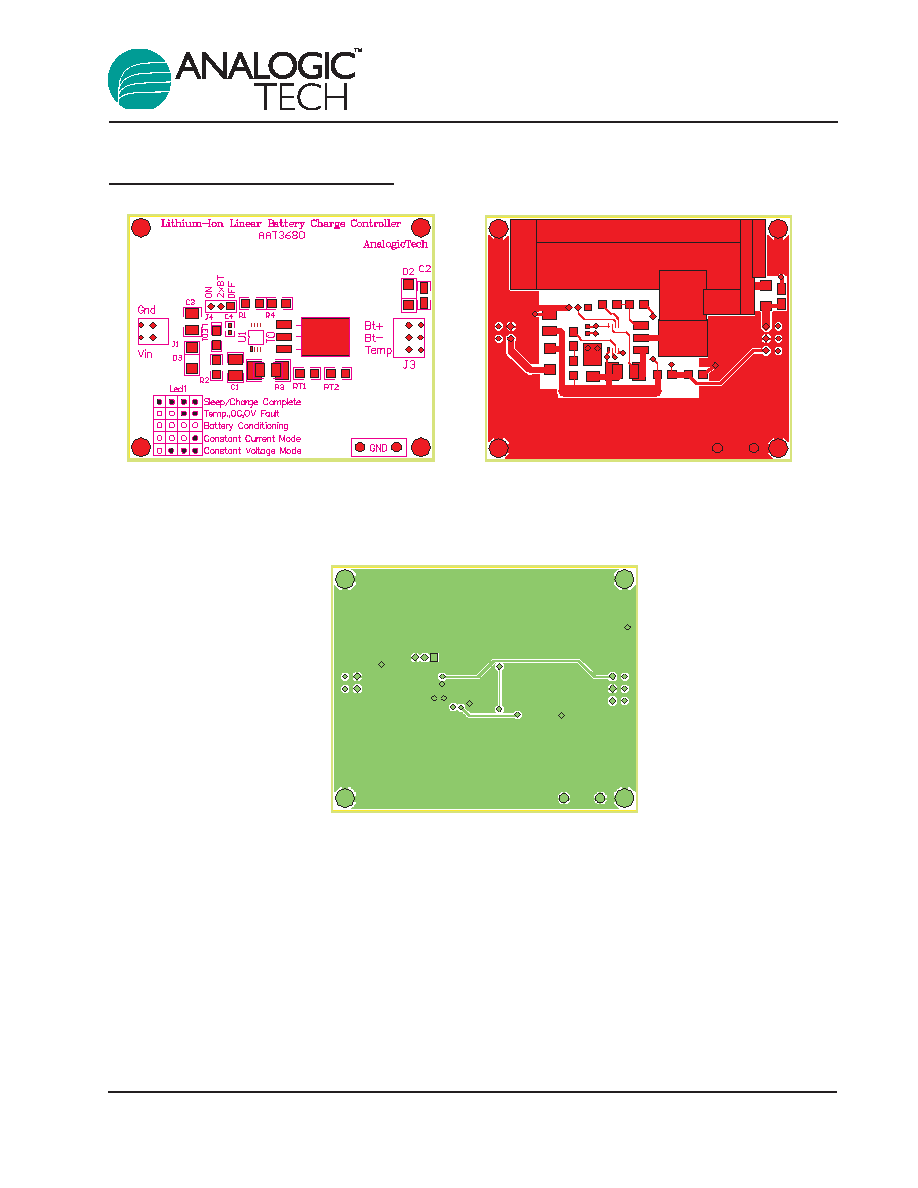

Evaluation Board Schematic

Figure 8: AAT3680 Demo Board Silk Screen /

Figure 9: AAT3680 Demo Board Component

Assembly Drawing.

Side Layout.

Figure 10: AAT3680 Demo Board

Solder Side Layout.

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

16

3680.2006.03.1.6

Evaluation Board Bill of Materials

PNP Transistor Example

P-Channel Power MOSFET Example

Designator

Part Type

Footprint

Manufacturer

Part Number

R3

0.2

, 0.5W

1206

IRC

LRC1206-01-R200F

R2

1k

, 5%

1206

Various

RT1

100k

, 5%

0805

Various

RT2

100k

, 5%

0805

Various

R1

1k

, 5%

0805

Various

C2

1µF

1206

MuRata

Header/SW1

2mm, 3 Pos

Sullins

PRPN031PAEN

Select with Starting Jumper

C1

10µF

1206

MuRata

GRM42-6X5R75K10

C3

10µF

1206

MuRata

GRM42-6X5R106K16

R4

100k

, 5%

0805

Various

U1

Li-Ion Charge Controller IC

MSOP-8

AnalogicTech

AAT3680IKS-4.2

D1

Green LED

1206

Various

D2

0.0

Jumper

D3

1.0A Schottky Diode

SMA

Diodes Inc.

B340LA

Q1

30V P-Ch MOSFET, 0.2

TO-252

Various

RFD10P03L

Designator

Part Type

Footprint

Manufacturer

Part Number

R3

0.2

, 0.5 Watt

1206

IRC

LRC1206-01-R200F

R2

1k

, 5%

1206

Various

RT1

100k

, 5%

0805

Various

RT2

100k

, 5%

0805

Various

R1

3.9k

, 5%

0805

Various

C2

1µF

1206

MuRata

Header/SW1

2mm, 3 Pos

Sullins

PRPN031PAEN

Select with Starting Jumper

C1

10µF

1206

MuRata

GRM42-6X5R75K10

C3

10µF

1206

MuRata

GRM42-6X5R106K16

R4

Not Populated

U1

Li-Ion Charge Controller IC

MSOP-8

AnalogicTech

AAT3680IKS-4.2-T1

D1

Green LED

1206

Various

D2

1.0A Schottky Diode

SMA

Diodes Inc.

B340LA

D3

0.0

Jumper

Q1

PNP Transistor

SOT223

Zetex

F2T968

Ordering Information

Package Information

MSOP-8

All dimensions in millimeters.

PIN 1

1.95 BSC

0.254 BSC

0.155

±

0.075

0.60

±

0.20

3.00

±

0.10

0.95

±

0.15

0.95 REF

0.85

±

0.10

3.00

±

0.10

10

∞

±

5

∞

4

∞

±

4

∞

0.65 BSC

0.30

±

0.08

0.075

±

0.075

4.90

±

0.10

GAUGE PLANE

All AnalogicTech products are offered in Pb-free packaging. The term "Pb-free" means

semiconductor products that are in compliance with current RoHS standards, including

the requirement that lead not exceed 0.1% by weight in homogeneous materials. For more

information, please visit our website at http://www.analogictech.com/pbfree.

Output Voltage

Package

Marking

1

Part Number (Tape and Reel)

2

MSOP-8

4.2V

ESXYY

AAT3680IKS-4.2-T1

TSOPJW-12

4.2V

ESXYY

AAT3680ITP-4.2-T1

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

3680.2006.03.1.6

17

1. XYY = assembly and date code.

2. Sample stock is generally held on all part numbers listed in BOLD.

TSOPJW-12

All dimensions in millimeters.

0.20 + 0.10

- 0.05

0.055

±

0.045

0.45

±

0.15

7

∞

NOM

4

∞ ±

4

∞

3.00

±

0.10

2.40

±

0.10

2.85

±

0.20

0.50 BSC 0.50 BSC 0.50 BSC 0.50 BSC 0.50 BSC

0.15

±

0.05

0.9625

±

0.0375

1.00

+ 0.10

-

0.065

0.04 REF

0.010

2.75

±

0.25

AAT3680

Lithium-Ion/Polymer

Linear Battery Charge Controller

18

3680.2006.03.1.6

Advanced Analogic Technologies, Inc.

830 E. Arques Avenue, Sunnyvale, CA 94085

Phone (408) 737-4600

Fax (408) 737-4611

© Advanced Analogic Technologies, Inc.

AnalogicTech cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in an AnalogicTech product. No circuit patent licenses, copyrights, mask work rights,

or other intellectual property rights are implied. AnalogicTech reserves the right to make changes to their products or specifications or to discontinue any product or service without notice.

Customers are advised to obtain the latest version of relevant information to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those pertaining to warranty, patent infringement, and limitation of liability. AnalogicTech

warrants performance of its semiconductor products to the specifications applicable at the time of sale in accordance with AnalogicTech's standard warranty. Testing and other quality con-

trol techniques are utilized to the extent AnalogicTech deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily performed.