APEX MICROTECHNOLOGY CORPORATION ∑ TELEPHONE (520) 690-8600 ∑ FAX (520) 888-3329 ∑ ORDERS (520) 690-8601 ∑ EMAIL prodlit@apexmicrotech.com

1

INTRODUCTION

This easy-to-use kit provides a platform for the evaluation of

linear power amplifiers circuits using the MP230FC/MP240FC

pin out. With ample bread boarding areas it is flexible enough

to analyze a multitude of standard or proprietary circuit con-

figurations. Critical connections for power supply bypassing

are pre-wired. Components not usually readily available in

engineering labs are provided. External connection to the evalu-

ation kit can be made via the terminal block and the banana

jacks at the edges of the circuit board. Additionally, an optional

BNC connector can be inserted into the hole at the edge of

the board and wired to the number 5 terminal pad.

BEFORE YOU GET STARTED

∑

All Apex amplifiers should be handled using proper ESD

precautions.

∑

Do not change connections while the circuit is powered.

∑

Initially set all power supplies to the minimum operating

voltage allowed in the device data sheet.

PARTS LIST

Ref Apex Part #

Descrip/Vendor

Qty

NA

HS28

Heat Sink

1

NA

HS26

Heat Sink

1

NA

MS11

Cage jack strip

2

BJ1-4

BJ1

Banana Jack/

4

Deltron 164-6218

NA

EVAL45

PC Board

1

NA

60SPG00004 Spacer Grommets/

4

Micro Plastics

C1-4

OX7R105KWN 1uF Cap/

4

Novacap 1825B105K201N

TS1 TS02 Terminal Strip 1

C5,6*

EC05

2200uF 100V/

2

United Chemi-Con

82DA222M100KC2D

C5,6*

EC03

680uF 200V/

2

United Chemi-Con

KMH200VN681M25MX40T2

RLIM*

CSR17

0.025 Ohm Resistor/

1

Isotek PBV-R025-1

RLIM*

CSR18

0.050 Ohm Resistor/

1

Isotek PBV-R050-1

RLIM*

CSR19

0.100 Ohm Resistor/

1

Isotek PBV-R100-1

Rs1-Rs4 NA

Separate purchase required 4

See text.

*Chosen per directions

FIGURE 1. EVAL45 Schematic

APEX MICROTECHNOLOGY CORPORATION ∑ 5980 NORTH SHANNON ROAD ∑ TUCSON, ARIZONA 85741 ∑ USA ∑ APPLICATIONS HOTLINE: 1 (800) 546-2739

2

EVALUATION KIT FOR

MP230FC/MP240FC PIN OUT

EK52

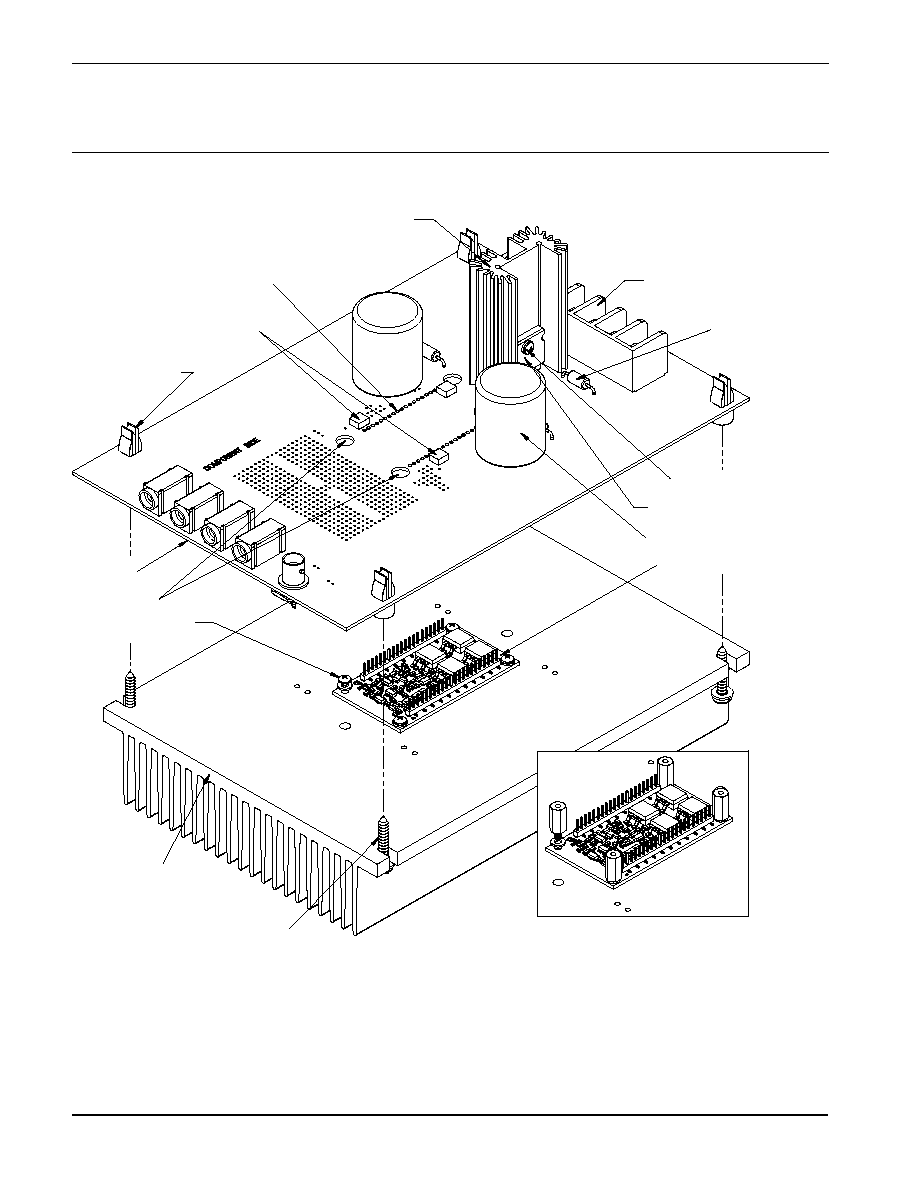

ASSEMBLY

During assembly refer to Figure 3 and the data sheet for the prod-

uct you are using, either the MP230FC or MP240FC.

1 Note that four balancing resistors, Rs1-Rs4, are required

for this evaluation kit and that these resistors are not sup-

plied. Each application will require different values and

so these resistors must be purchased by the user before

construction of the kit begins. See the recommendation in

the product data sheet as to the type of resistor needed

and a convenient source for purchasing the resistors.

Do not be tempted to operate the amplifier without these

resistors.

2. Note that each side of the circuit board is identified as

either the "Component Side" or "DUT Side."

3. Locate the two pre-loaded 30-position cage jack carrier

strips. Use wire cutters to cut off and discard 10 positions

from one of the carrier strips. From the "DUT Side " of the

PCB insert this carrier strip into the mounting holes for pins

1-20 of the amplifier and solder from the "Component Side"

of the PCB. Be sure that the cage jacks are fully seated

before soldering. Be careful that solder does not flow into

the cage jack.

4. In a similar manner to step 3 cut off 8 positions from the

remaining carrier strip, insert and solder into the mounting

holes for amplifier pins 21-42.

5. Pull out and discard each of the carriers.

6. Solder the surface mount capacitors at C1, C2, C3, and

C4 on the "Component Side" of the PCB.

7. Solder the surface mount balancing resistors that you

purchased separately at Rs1-Rs4 on the "Component

Side" of the PCB.

8. Mount the four horizontal banana jacks at locations BJ1-

4 and a BNC connector, if desired (not supplied), to the

PCB pad at location 5. Solder from the "DUT Side" of the

PCB.

9. Mount the terminal strip to the "Component Side" of the

PCB. Make sure the terminal strip is fully seated and solder

the pins from the "DUT Side" of the PCB. Be sure to fill

the mounting holes with solder.

10. Mount the electrolytic capacitors at C5 and C6 from the

"Component Side" of the PCB. Match the polarity markings

on the capacitor with the polarity markings on the PCB.

Use the correct voltage capacitors for the product you are

using: 100V capacitors for the MP230 and 200V capacitors

for the MP240. Be sure the capacitors have snapped into

the PCB and solder from the "DUT Side" of the PCB. Be

sure to fill the holes with solder.

11. Several low ohm value resistors are provided with this

evaluation kit: 0.025 ohm, 0.050 ohm and 0.100 ohm.

These are used to implement current limiting in the output

circuit. Select the value most appropriate for your applica-

tion. Refer to the product data sheet to determine which

resistor value you should use.

12. Mount the HS28 heat sink to the PCB and solder the

mounting tabs of the heat sink.

13. Apply a thin layer of thermal grease on the back of the

chosen current limiting sense resistor, insert the resistor

into the PCB and mount the resistor to the HS28 heat sink

using #4 screw and nut hardware (not supplied). Solder

the leads of the current limiting resistor from the "DUT

Side" of the board. Be sure to fill the mounting holes with

solder.

14. Mount other components and wiring as needed to com-

plete your application circuit using the pads and holes

provided.

15. From the "DUT side" of the PCB snap the spacer- grommets

into the holes at the four corners of the PCB. Notice that

the holes are slightly rectangular and match the spacer-

grommet's long and short sides to the holes in the PCB.

16. Apply a thin layer of thermal grease to the amplifier base.

Position the amplifier over the mounting holes in the HS26

heat sink. Firmly push the amplifier onto the heat sink

while slightly rotating the amplifier back and forth, ending

with the mounting holes of the amplifier over the mounting

holes in the heat sink.

17. Attach the amplifier to the heat sink with 4 4-40 X Ω" male-

female hex spacers (not supplied). These spacers serve

as alignment pins and aide in the assembly of the PCB to

the heat sink. Alternately, use 4-40 X º" machine screws

to mount the amplifier to the heat sink. Do not over-tighten

the spacers or screws as this provides no thermal benefit

and may break the hardware.

18. Place the PCB assembly onto the HS26 heat sink so that

the four hex spacers come through the aligning holes

near the four corners of the amplifier position in the PCB.

Carefully lower the PCB assembly until the pins of the

amplifier engage the cage jacks. Alternately, sight through

the aligning holes in the PCB and match-up the PCB to the

screws used to mount the amplifier. In either case be sure

the pins of the amplifier are engaged with the cage jacks

and then continue pushing the PCB assembly in the area

between the amplifier's pins until the 4 spacer grommets

at the four corners of the PCB touch the HS26 heat sink.

At this point you may need to push the PCB down slightly

in the area of the amplifier if the PCB is bowed.

19. Use #8 X 1" sheet metal screws (not provided) to mount

the PCB to the heat sink at the four spacer-grommets.

20. Hook up power and signals as necessary. The amplifier

is now ready for testing.