1

4728A≠CLOCK≠06/03

Features

∑

32-kHz Oscillator

∑

1.3 V to 1.8 V Operating-voltage Range

∑

180 nA Typical Current Consumption

∑

Voltage Regulator

∑

Integrated Capacitors, Mask Selectable

∑

Mask Options for Pad Designation, Motor Period and Motor Pulse Width

∑

Low Resistance Outputs for Bipolar Stepping Motor

∑

Motor Fast-test Function

Description

The e1217X is an integrated circuit in CMOS silicon gate technology for analog

watches. It consists of a 32-kHz oscillator, frequency dividers down to 1/64 Hz, output

pulse formers and push-pull motor drivers. Integrated capacitors are provided (select-

able mask option) for tuning of the crystal. Low current consumption and high

oscillator stability are enabled by an on-chip voltage regulator.

32-kHz

Standard Watch

CMOS IC

e1217X

3

e1217X

4728A≠CLOCK≠06/03

Functional Description

Voltage Regulator

An integrated voltage regulator provides the oscillator with a well-controlled negative

supply voltage V

REG

. This improves the stability of the oscillator and keeps current con-

sumption at a minimum.

Oscillator

The oscillator inverter with feedback resistor generates the 32768 Hz clock frequency. A

total capacitance of 24 pF is integrated. This can be selected for COSCOUT in 2 pF

increments via a mask option.

Frequency Divider

A 21-bit binary counter is provided, dividing the oscillator frequency down to 1/64 Hz.

The leading six stages are connected to V

DD

and V

REG

, while the remaining 15 stages

are connected to V

DD

and V

SS

.

Motor Drive Output

The e1217X contains two push-pull output buffers for driving bipolar stepping motors.

During a motor pulse, the n-channel device of one buffer and the p-channel device of

the other buffer are activated. The p-channel devices of both buffers are active (see Fig-

ure 3) between the two pulses.

Cycle time and pulse width can be chosen via a metal mask option (Table 1).

RESET

A debounced RESET input is provided. Connecting the RESET input to V

DD

resets the

12 low-order stages of the frequency divider, thus disabling further motor pulses. Motor

pulses, which are in progress when the reset function is applied, will be completed. After

releasing the RESET pad from V

DD

, the next motor pulse appears with a delay of one

half motor cycle on the drive output opposed to the former (Figure 4). Due to the

debounce circuitry on the RESET input, V

DD

must be applied for at least 31.2 ms. Dur-

ing RESET the input current is limited to 8 nA typically.

Test

A test frequency of 512 Hz is output to this pad which can be measured with a high

resistance probe (R

≥

10 M

W

, C

≥

20 pF). This signal can be used for testing and tuning

the oscillator. Connecting TEST to V

DD

for at least 4 ms changes the motor cycle time

from the selected value to the test cycle time (mask options), while the motor pulse

width remains unchanged (Figure 3).

This feature can be used to reduce the amount of time required for testing the mechani-

cal parts of the watch.

Table 1. Motor Options

Motor-cycle Parameters

Value

Cycle time T

M

2, 4, 6, 8, 10, 12, 20, 24, 30, 40, 60, 80, 120 s

Motor pulse width t

M

0.98 to 14.65 ms in increments of 0.98 ms

Motor test cycle time T

MT

250, 125, 62.5 ms

4

e1217X

4728A≠CLOCK≠06/03

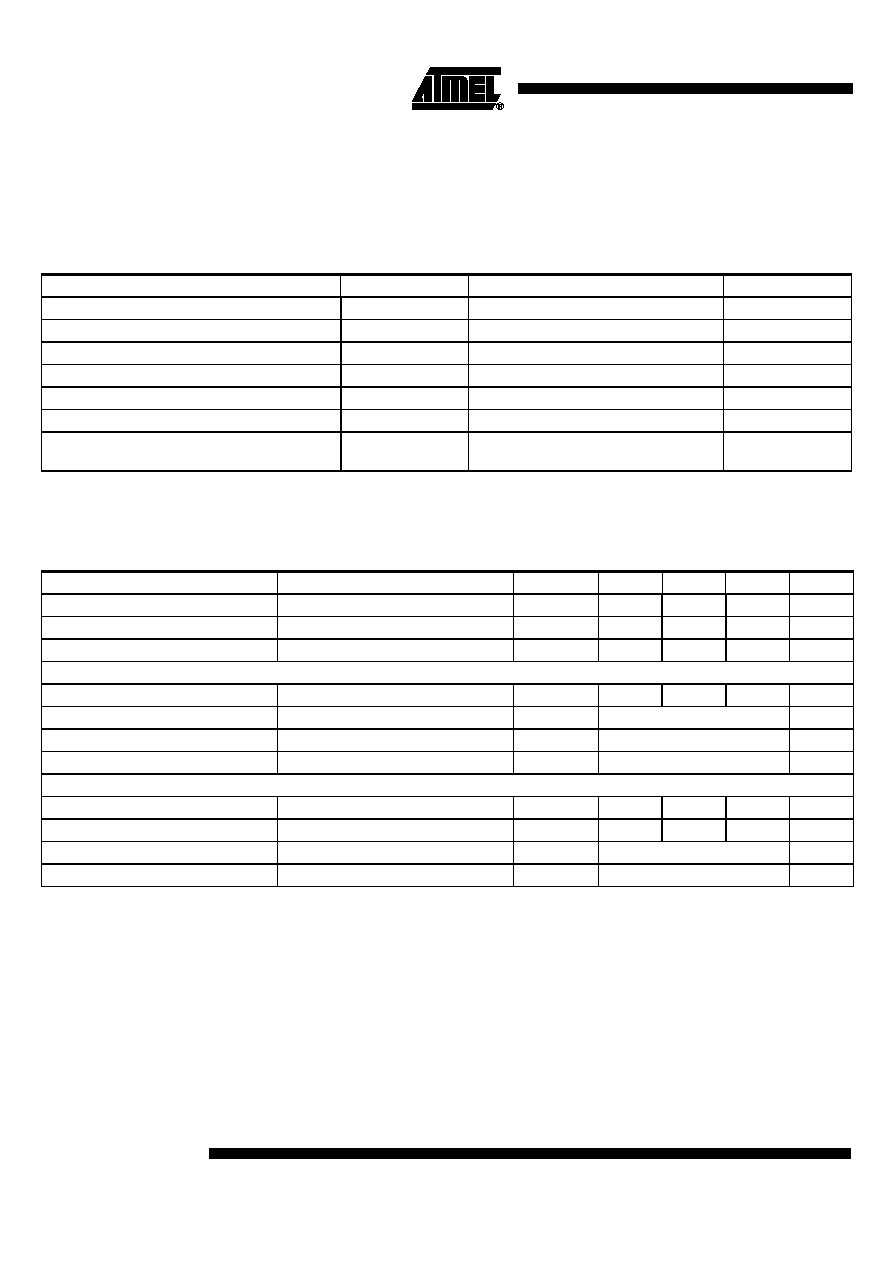

Absolute Maximum Ratings

Absolute maximum ratings define parameter limits which, if exceeded, may permanently change or damage the device.

All inputs and outputs on Atmel's circuits are protected against electrostatic discharges. However, precautions to minimize

the build-up of electrostatic charges during handling are recommended.

The circuit is protected against supply-voltage reversal for typically 5 minutes.

Parameters

Symbol

Value

Unit

Supply voltage

V

SS

-0.3 to +5

V

Input voltage range, all inputs

V

IN

(V

SS

- 0.3

V)

£

V

IN

£

(V

DD

+ 0.3 V)

V

Output short-circuit duration

indefinite

Power dissipation (DIL package)

P

tot

125

mW

Operating ambient temperature range

T

amb

-20 to +70

∞

C

Storage temperature range

T

stg

-40 to +125

∞

C

Lead temperature during soldering at 2 mm

distance, 10 s

T

sld

260

∞

C

Operating Characteristics

V

DD

= 0 V; V

SS

= -1.55 V; T

amb

= +25

∞

C; C

TR

= 15 pF, unless otherwise specified.

All voltage levels are measured with reference to V

DD

. Test crystal as specified below.

Parameters

Test Conditions

Symbol

Min.

Typ.

(1)

Max.

Unit

Operating voltage

Functional test (Figure 2)

V

SS

-1.3

-1.8

V

Operating current

C

oscout

= 16 pF, R

L

= R

I

SS

-180

-300

nA

RESET input current

RESET = V

DD

I

R

8

nA

Motor Outputs

Motor output current

R

L

= 2 k

W

, V

SS

= -1.55 V

I

M

±0.7

mA

Motor period

T

M

See Table 2

s

Motor pulse width

T

M

See Table 2

ms

Motor test period

T

MT

See Table 2

ms

Oscillator

Stability

D

V

SS

= 100 mV, C

TR

= 5 pF

D

f/f

0.1

ppm

Start-up voltage

Startup within 2 s

V

ST

-1.3

V

Integrated input capacitor

C

OSC IN

See Table 2

pF

Integrated output capacitor

C

OSCOUTmax

= 24 pF

C

OSC OUT

See Table 2

pF

Note:

1. Typical parameters represent the statistical mean values.

5

e1217X

4728A≠CLOCK≠06/03

Figure 2. Functional Test Circuit

Range of trimmer capacitance: C

TR

= 5 pF to 30 pF

Test Crystal

Specification

Additional Notes

1.

It is recommended to connect the quartz case to V

DD

(by conductive epoxy).

2.

Capacitive coupling of TEST to OSCIN must be minimized by appropriate layout

of the PCB to avoid disturbancing the oscillator.

TEST

OSCIN

OSCOUT

MOT2

MOT1

RESET

e1217X

V

SS

C

TR

R

L

1

2

3

4

8

7

6

5

V

DD

Frequency

f = 32,768 Hz

Series resistance

R

S

= 30 k

W

Static capacitance

C

0

= 1.5 pF

Dynamic capacitance

C

1

= 3 fF

Load capacitance

C

L

= 8 pF