| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: S3842 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

KSI-8006-003

1

S3842

Current Mode PWM Controller

Descriptions

The S3842, high performance current mode controller, Provides the necessary features to

off-line and DC-DC fixed frequency current control applications offering the designer a cost

effective solution with minimal external components. Internally protection circuity includes

built-in input and reference under-voltage lockout and current limiting with hysteresis.

Also other characteristics of internal circuit provide improved line regulation, enhanced load

response, trimmed oscillation for precise duty cycle control, a temperature compensated

reference, high gain error amplifier, current sensing comparator and totempole output

designed to source and sink high peak current from a capacitive load such as the gate of a

power MOSFET.

Features

∑ Optimized for off-line control ∑ Current mode operation to 500

∑ Low start up and operating current ∑ Under voltage lockout with 6V hysteresis

∑ Pulse by pulse current limiting

∑ Internally trimmed bandgap reference about 5V

∑ Enhanced load response characteristic ∑ Automatic feed forward compensation

Ordering

Information

Type NO. Marking Package Code

S3842 S3842 SOP-8

Outline Dimensions unit :

mm

S

S

e

e

m

m

i

i

c

c

o

o

n

n

d

d

u

u

c

c

t

t

o

o

r

r

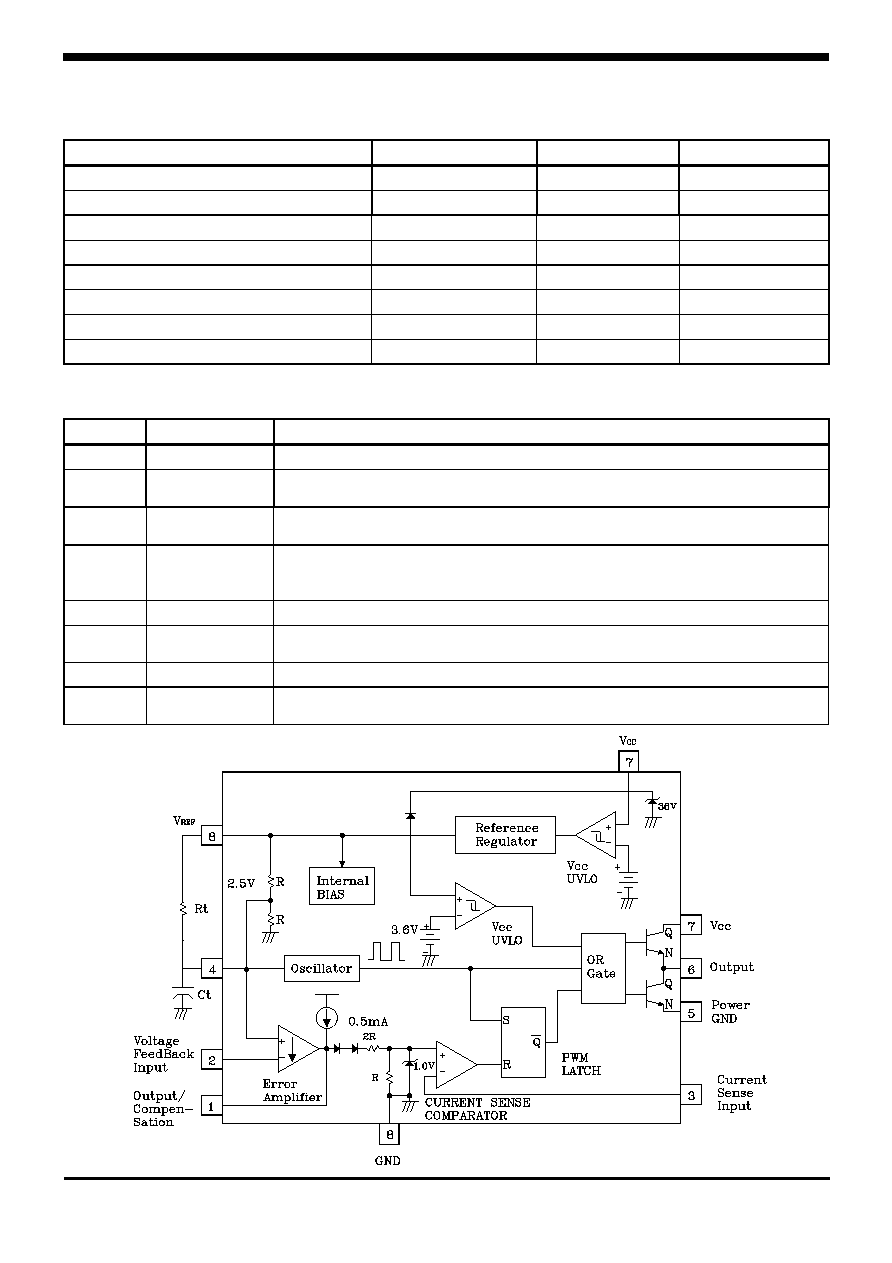

PIN Connections

1. Output / Compensation

2. Voltage feedback. Input

3. Current sense Input

4. Rt/Ct

5. GND

6. Output

7. Vcc

8. Vref

KSI-8006-003

2

S3842

Absolute Maximum Ratings

Ta=25

∞C

Characteristic Symbol

Ratings

Unit

Supply voltage

V

cc

30 V

Current Sense and V

fb

Input

V

IN

-0.3 to V

cc

V

Total Power Supply and Zener Current

I

CC

+ I

Z

30 mA

Output Sink of Source Current

I

o

1 A

Error AMP Output Sink Current

I

eo

10

mA

Operating Ambient Temperature

T

a

0 to 70

∞C

Storage Temperature Range

T

stg

-65 to 150

∞C

Power Dissipation at T

a

50∞C

P

d

1 W

note) All voltages are with respect to PIN5, and current are positive into the specified pin.

PIN Description

PIN NO

Function

Description

1

Compensation Error amplifier output and is made available for loop compensation.

2

Voltage

feedback

Inverting input of error amplifier, normally connected to the switching

power supply output through a resistor driver.

3 Current

sense

A voltage proportional to inductor current is connected to this input.

The PWM uses this information to terminate the output.

4 R

t

/C

t

The oscillator frequency and maximum output duty cycle are

programmed by connecting resistor R

t

to Vref and capacitor C

t

to

ground.

5

Ground

This pin is the combined control circuitry and power ground.

6 Output

This output directly drives the gate of a power MOSFET. Peak current

up to 1.0A are sourced and sinked by this pin.

7 V

CC

This pin is the positive supply of the control IC.

8 Vref

This is the reference output. it provides charging current for capacitor

C

t

through resistor R

t

.

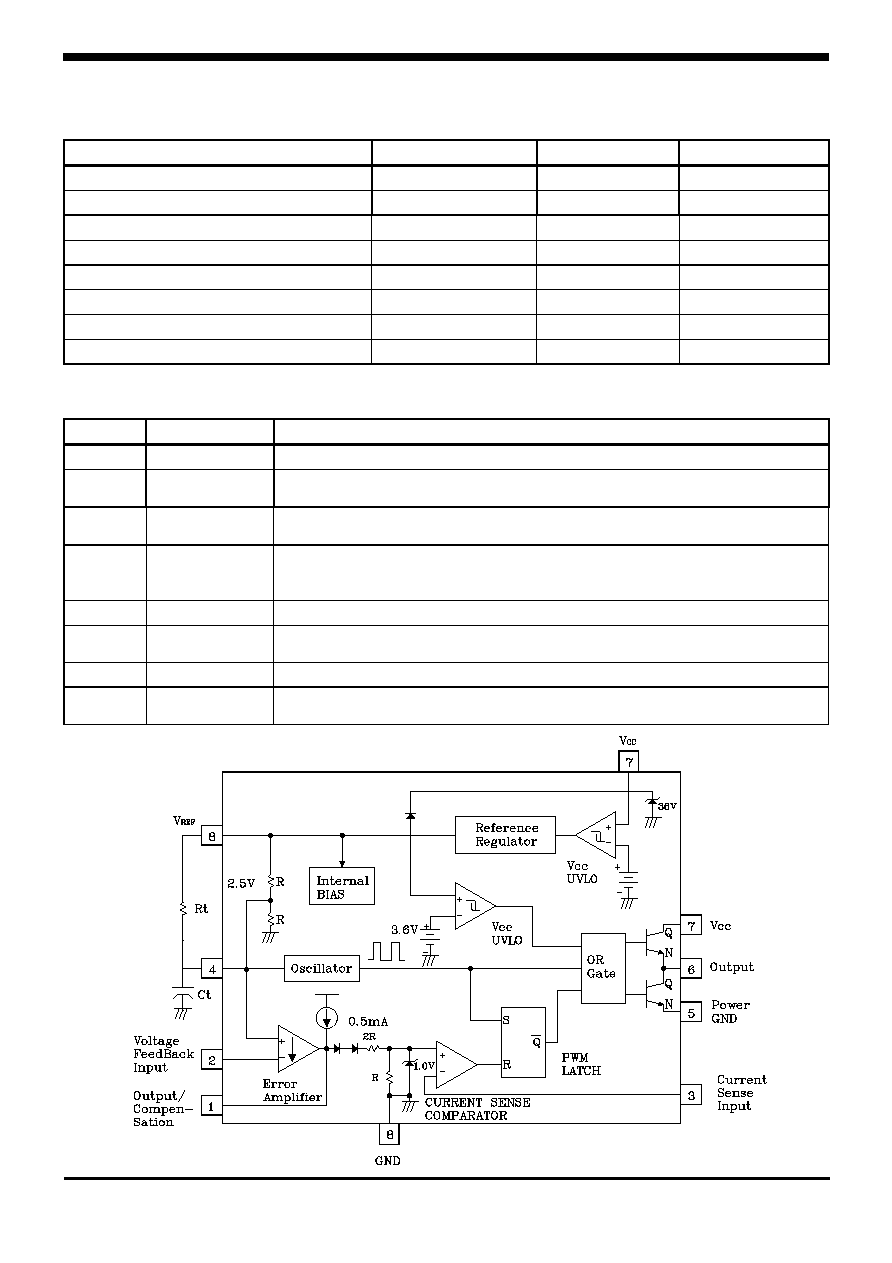

Block Diagram

KSI-8006-003

3

S3842

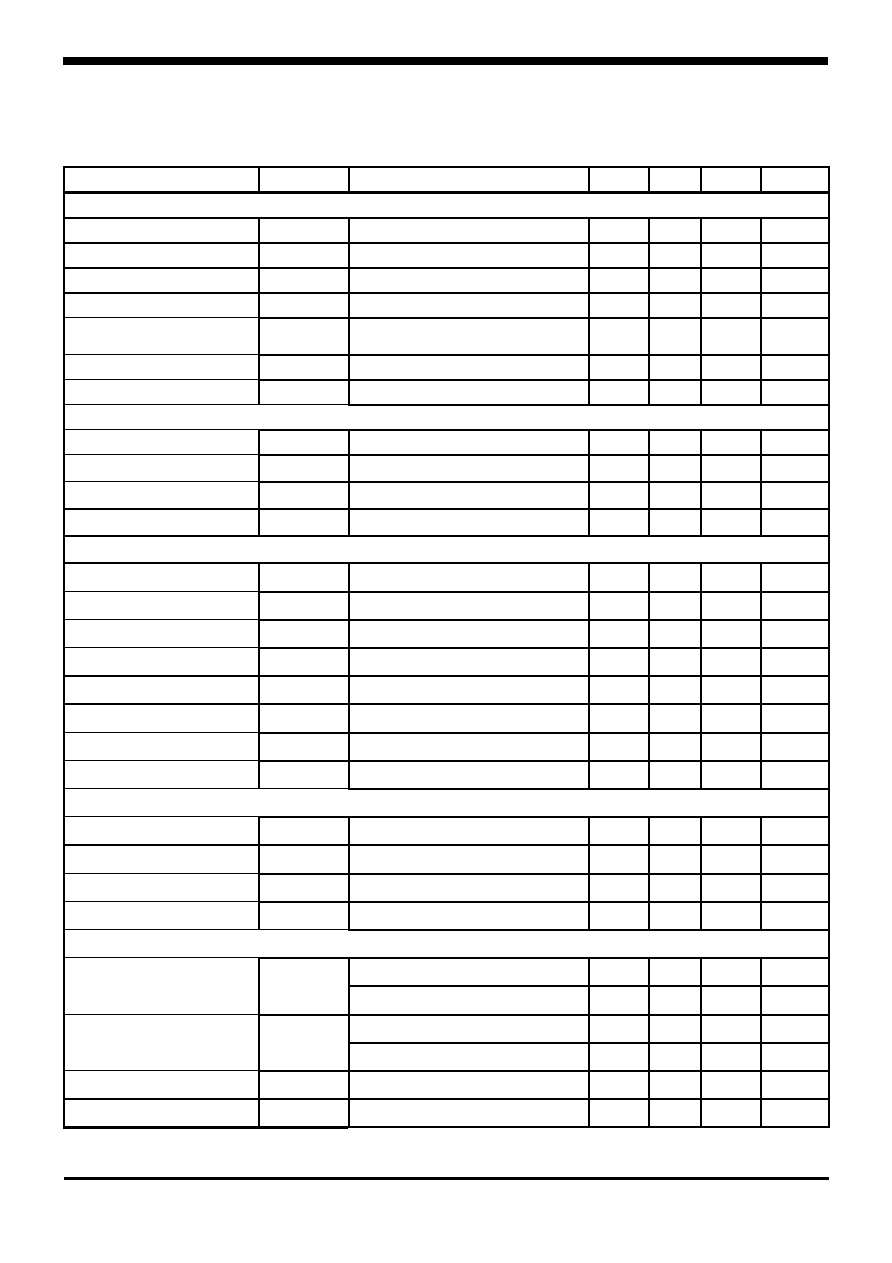

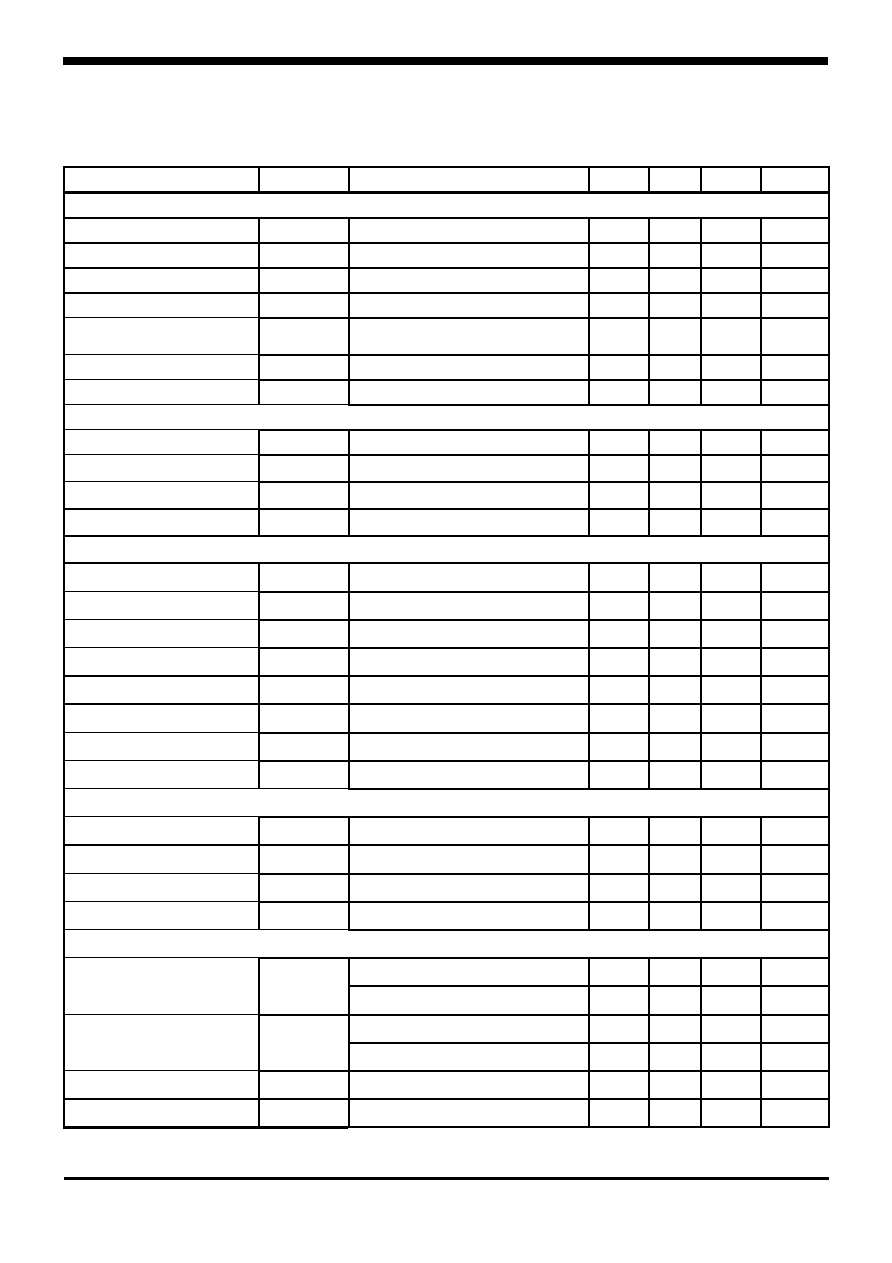

Electrical Characteristics

(Unless otherwise stated, these specifications apply for 0

Ta

70

∞C;

V

CC

=15V

(Note.4),

R

L

=10 , C

L

=3.3nF

)

Characteristic Symbol

Test

Condition Min.

Typ.

Max.

Unit

1. Reference Section

Output Voltage

Vref

Ta

=25

∞C,

I

O

=1mA

4.90 5.00 5.10

V

Line Regulation

Vref

12V V

CC

25V

- 6 20 mV

Load Regulation

Vref

1mA I

O

20mA

- 6 25 mV

Temperature Stability

V

T

/V

T

(Note 1)

-

0.2

0.4

mV/

∞C

Output Noise Voltage

V

n

10Hz f 10KHz,T

a

=25

∞C(Note

1)

- 50 - uV

Long Term Stability

S

T

a

=125

∞C, 1000Hrs (Note 1)

- 5 - mV

Output Short Circuit

I

SC

-

-30

-100

-180 mA

2. Oscillator Section

Initial Accuracy

f

SC

T

a

=25

∞C

47 52 57 KHz

Voltage Stability

f /V

12 V

a

25V

- 0.05 1.0 %

Temperature Stability

f /T

T

min

T

a

T

max

(Note 1)

- 5 - %

Amplitude V

4

V

PIN4

Peak to Peak

-

1.7

-

V

3. Error Amp Section

Input Voltage

V

2

V

PIN1

=2.5V

2.42 2.50 2.58

V

Input Bias Current

I

b

-

- -0.3

-2.0

Open Loop Voltage Gain

A

VO1

2V V

O

4V

65 90 -

Supply Voltage Rejection

SVR

12V V

a

25V

60 70 -

Output Sink Current

I

O

V

PIN2

=2.7V, V

PIN1

=1.1V 2

6

-

mA

Output Source Current

I

O

V

PIN2

=2.3V, V

PIN1

=5V -0.5

-0.8

-

mA

V

OUT

High V

ch

V

PIN2

=2.3V, R

L

=15 to Ground

5 6 - V

V

OUT

Low V

c1

V

PIN2

=2.7V, R

L

=15 Pin8

- 0.7 1.1 V

4. Current Sense Section

Gain G

V

(Note 2 & 3)

2.8

3.0

3.2

V/V

Maximum Input Signal

V

3

V

PIN 1

=5V (Note 2)

0.9

1.0

1.1

V

Supply Volt Rejection

SVR

12 V

a

25V (Note 2)

- 70 -

Input Bias Current

I

b

-

- -2

-10

5.Output Section

I

SINK

=20mA -

0.1

0.4

V

Output Low Level

V

Ol

I

SINK

=200mA -

1.5

2.2

V

I

SOURCE

=20mA 13.0

13.5

-

V

Output High Level

V

Oh

I

SOURCE

=200mA 12.0

13.5

-

V

Rise time

t

r

T

a

=25

∞C, Cl=1nF (Note 1)

- 50

150 ns

Fall time

t

f

T

a

=25

∞C, Cl=1nF (Note 1)

- 50

150 ns

KSI-8006-003

4

S3842

Electrical Characteristics(continued)

Characteristic Symbol

Test

Condition Min.

Typ.

Max.

Unit

6. Under-Voltage Lockout Section

Start Threshold

V

th

V

PIN7

where

V

PIN8

4.9V

14.5 16.0 17.5

V

Min. Operation Voltage

After Turn-On

V

CC(min)

V

PIN7

where

V

PIN8

1V

8.5 10.0 11.5 V

7. PWM Section

Maximum Duty Cycle

DC

max

-

93 97 100 ns

8. Total Standby Section

Start-Up Current

I

st

V

CC

= 15V before turn on

-

0.4

0.7

mA

Operating Supply Current

I

CC

V

PIN2

=

V

PIN3

=0V

- 11 20 mA

Zener Voltage

V

Z

I

CC

=25mA

- 36 - V

NOTE: 1.Thes parameters, although guaranteed.are not 100% tested in production

2.Parameter measured at trip piont of latch with V

pin2

= 0

3.Gain defined as : A =V

PIN1

/V

PIN3

; 0 V

PIN3

0.8V

4.Adjust V

CC

above the start threshold before setting at 15V

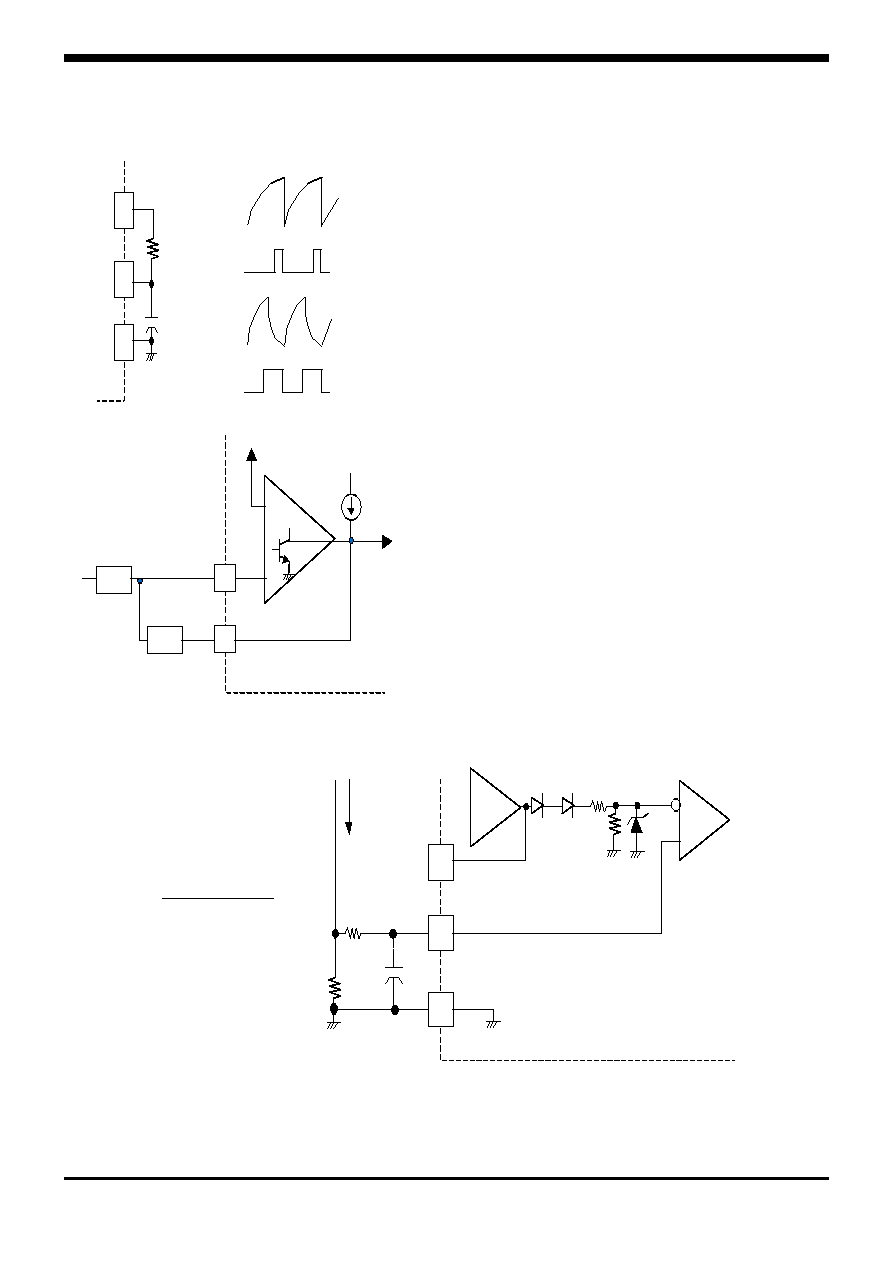

Information in Using IC

1. Under voltage Lockout

To prevent erratic output behavior which activating

the power switch with extraneous leakage currents,

during under voltage lockout. Output(pin6) should be

shunted to ground with a bleeder resister.

The Vcc comparator upper and lower threshold are

16V/10V. The large hysteresis and low start up

currents makes it ideally suited in off-line converter

application where efficient bootstrap start-up

techniques are required.

O N /O F F C O M M A N D

T O R E S E T O F I C

V c c

V o n - 1 6 V

V o f f - 1 0 V

7

V cc

Icc

<17mA

<1mA

10V

16V

KSI-8006-003

5

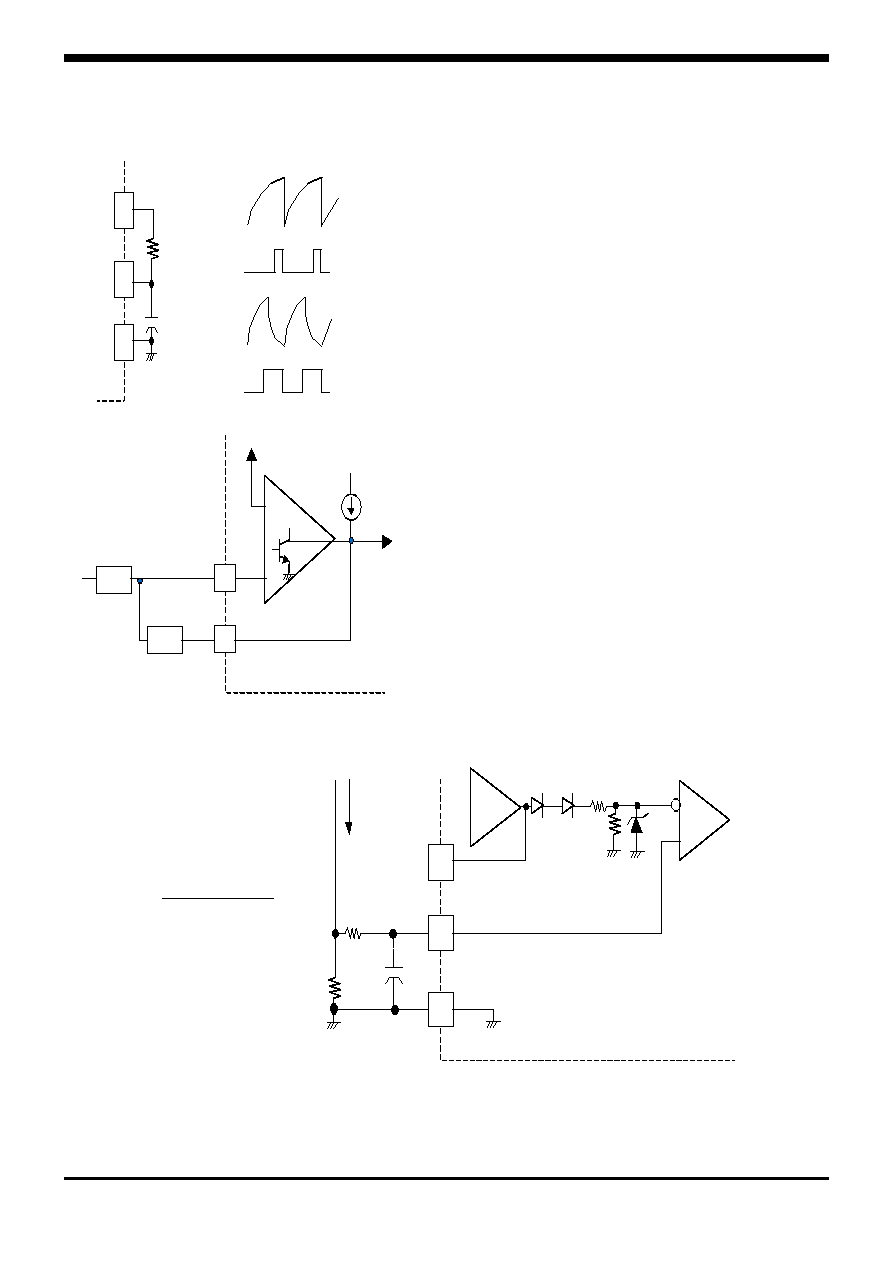

2. Oscillator Waveforms and Maximum Duty Cycle

The oscillator frequency is programmed by the values

selected for the timing components Rt and Ct. Ct is

charged from 5V, Vref, through resistor Rt

to

approximately 2.8V and discharged to 1.2V by an

internal current sink.

During the discharge of Ct, the oscillator generates an

internal blanking pulse and the center input NOR gate high.

This makes output to be in a low state and control the

amount of output dead time.

3. Error AMP Configuration

Error amp output(Pin1) is provided for external loop

Compensation and error amp can source or sink up to 0.5mA.

The non-inverting input is internally biased at 2.5V and is

not pinned out. The converter output voltage is typically

divided down and monitored by the inverting input(pin2).

4. Current Sense Circuit

A normal operating conditions occurs when the power supply output is overloaded or if output voltage to 1.0V

Therefore the maximum peak switch current is lpk(max)=1.0V/R

s

, and under the normal operating conditions the

peak inductor current controlled by the voltage at pin1.

S3842

8

Rt

Ct

4

5

LARGE Rt

SMALL Ct

SMALL Rt

LARGE Ct

Vpin4

INTERNAL

CLOCK

INTERNAL

CLOCK

Vpin4

COMP

ERROR

AMP

1

3

5

GND

CURRENT

SENSE

Rs

R

C

2R

R

IV

I

Ipeak =

R(V pin1 - 2V be)

3R x Rs

0.5mA

2

+

-

1

Zf

Zt

2.50V

V in

COMP

KSI-8006-003

6

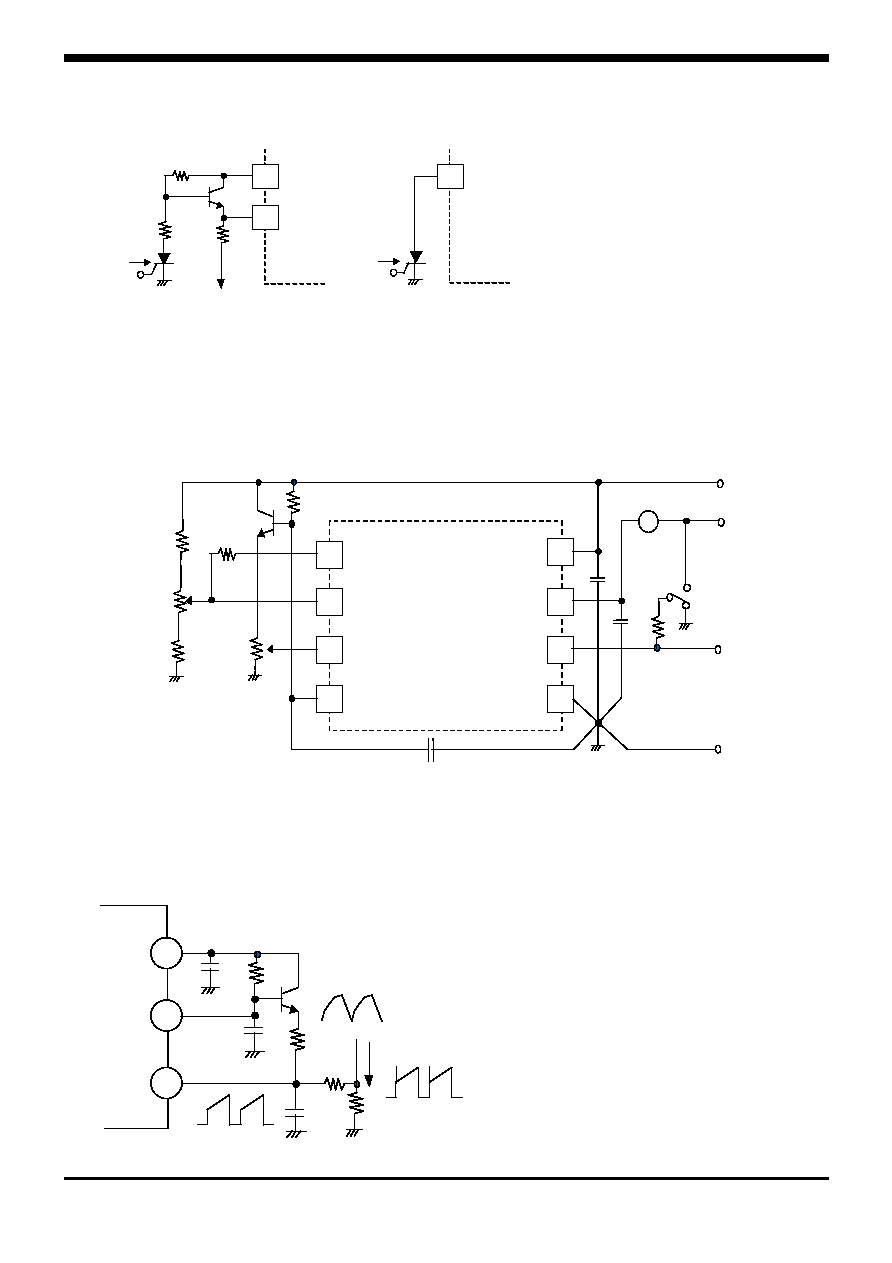

5. Shutdown Techniques

Shutdown of the S3842 can be

accomplished by two methods;

either raise pin3 above 1V or pull

pin1 below a voltage two diodes

drops above ground. Either causes

the output of the PWM method

comparator to be high (refer to

block diagram). The PWM latch is reset dominant so that the output will remain low until the next clock cycle after

the shutdown condition at pins 1 and/or 3 is removed. In one example, an externally latched shutdown may be

accomplished by adding an SCR which turn off, allowing the SCR to reset.

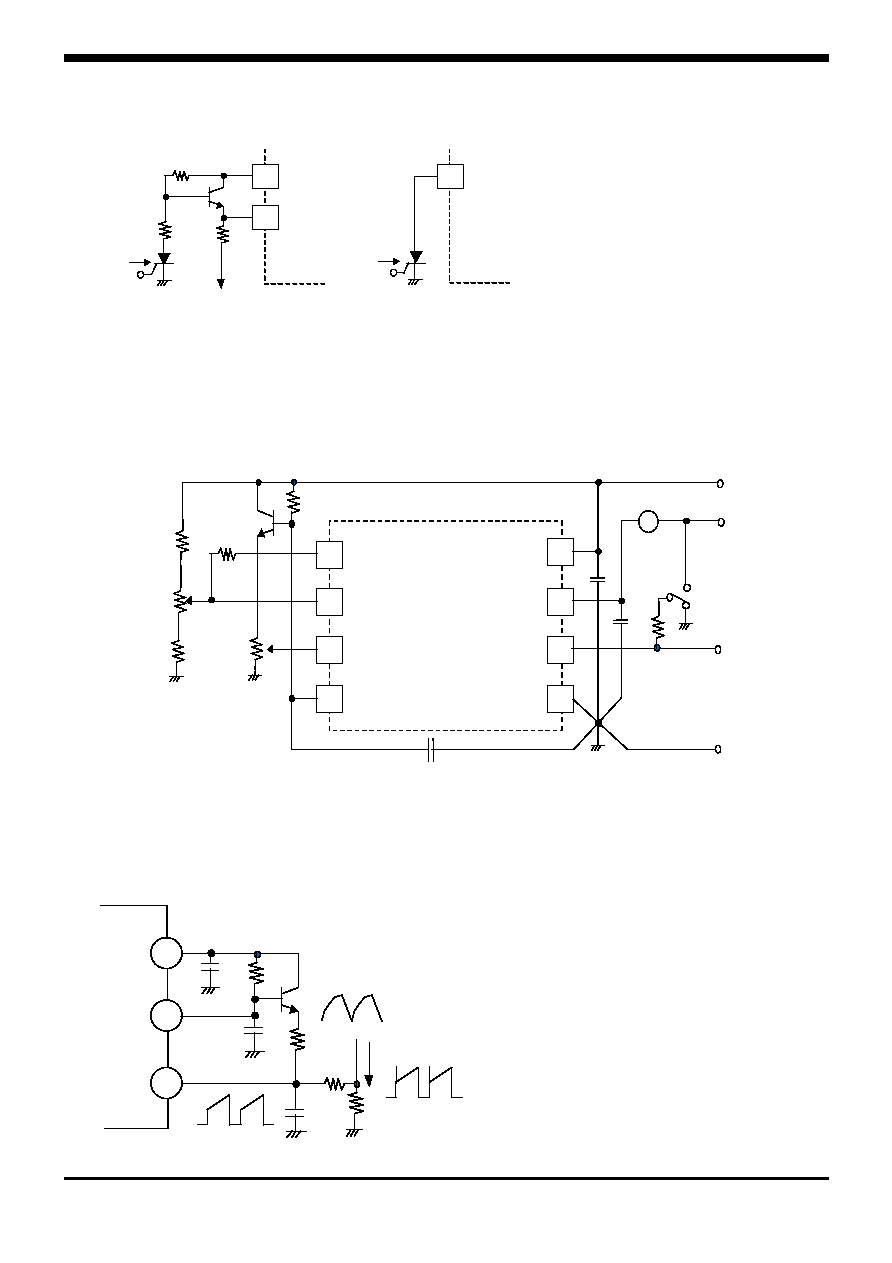

6. Open Loop Test

High peak currents associated with capacitive leads necessitate careful grounding techniques. Timing and bypass

capacitors should be connected close to Pin5 in a single point ground. The transistor and 5 potentiometer are

used to sample the oscillator waveform and apply an adjustable ramp to Pin3.

7. Slope Compensation

A fraction of the oscillator ramp can be resistively

summed with the current sense signal to provide

slope compensation for converters requiring duty

cycle over 50%. Note that capacitor C, forms a

filter with R

2

to suppress the leading edge switch

spikes.

8

4

3

I

S E N S E

R

T

/C

T

V

RE F

I

S E N S E

R

T

C

T

R

1

R

2

C

0.1u F

R

S E N S E

S3842

8

3

V

RE F

I

S E N S E

T O CUR R E NT

S E NS E R ES I S T O R

S HUT

DO W N

4.7K

4.7K

5.00

1

CO MP

S HUT

DO W N

I

SENSE

ADJUST

S3842

V

REF

1

GND

V

REF

I

SENSE

4.7K

COMP

2

3

4

8

7

6

5

Vcc

OUTPUT

GROUND

ERROR

AMP

ADJUST

2N2222

R

T

4.7K

1K

0.1uF

0.1uF

1K/1W

R

T

/C

T

Vin

Vcc

OUTPUT

100K

KSI-8006-003

7

S3842

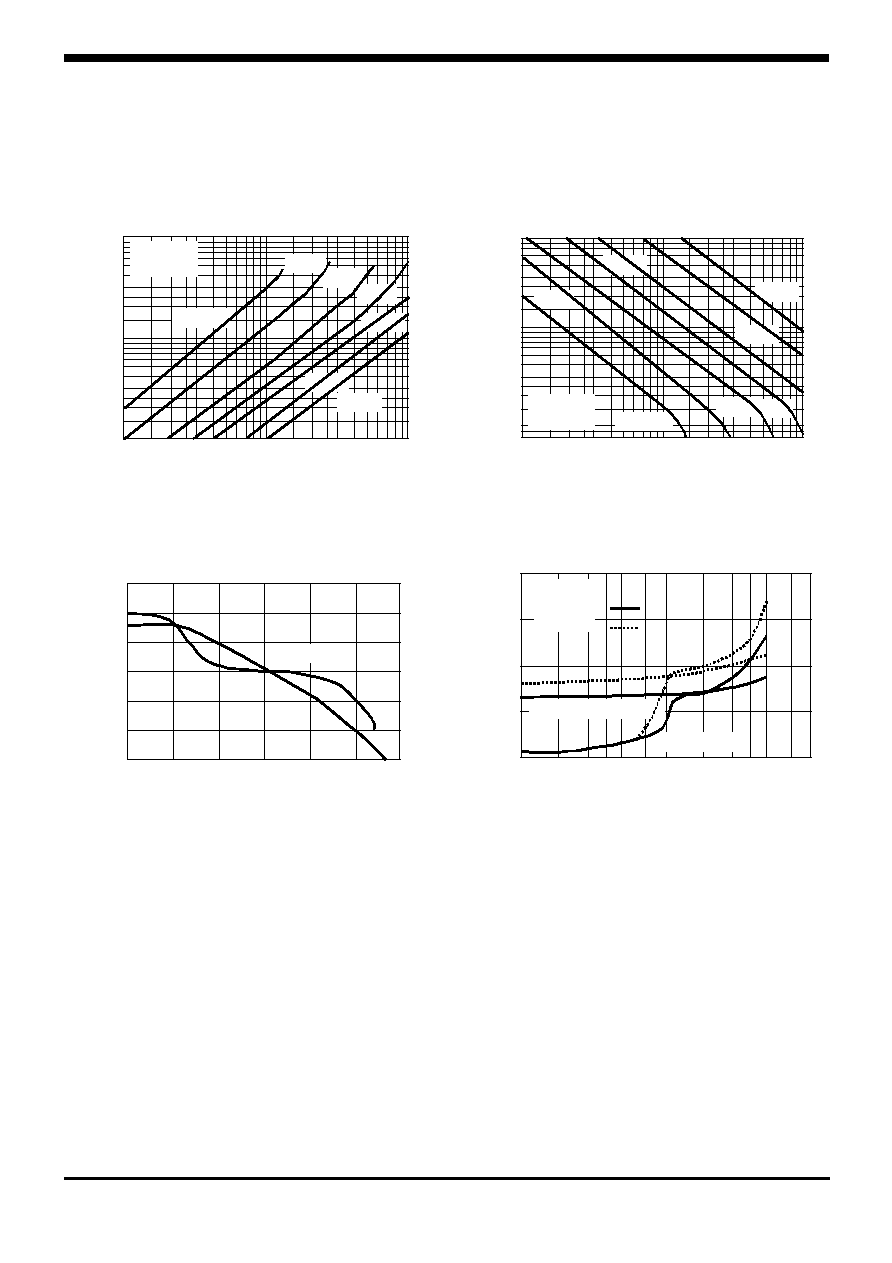

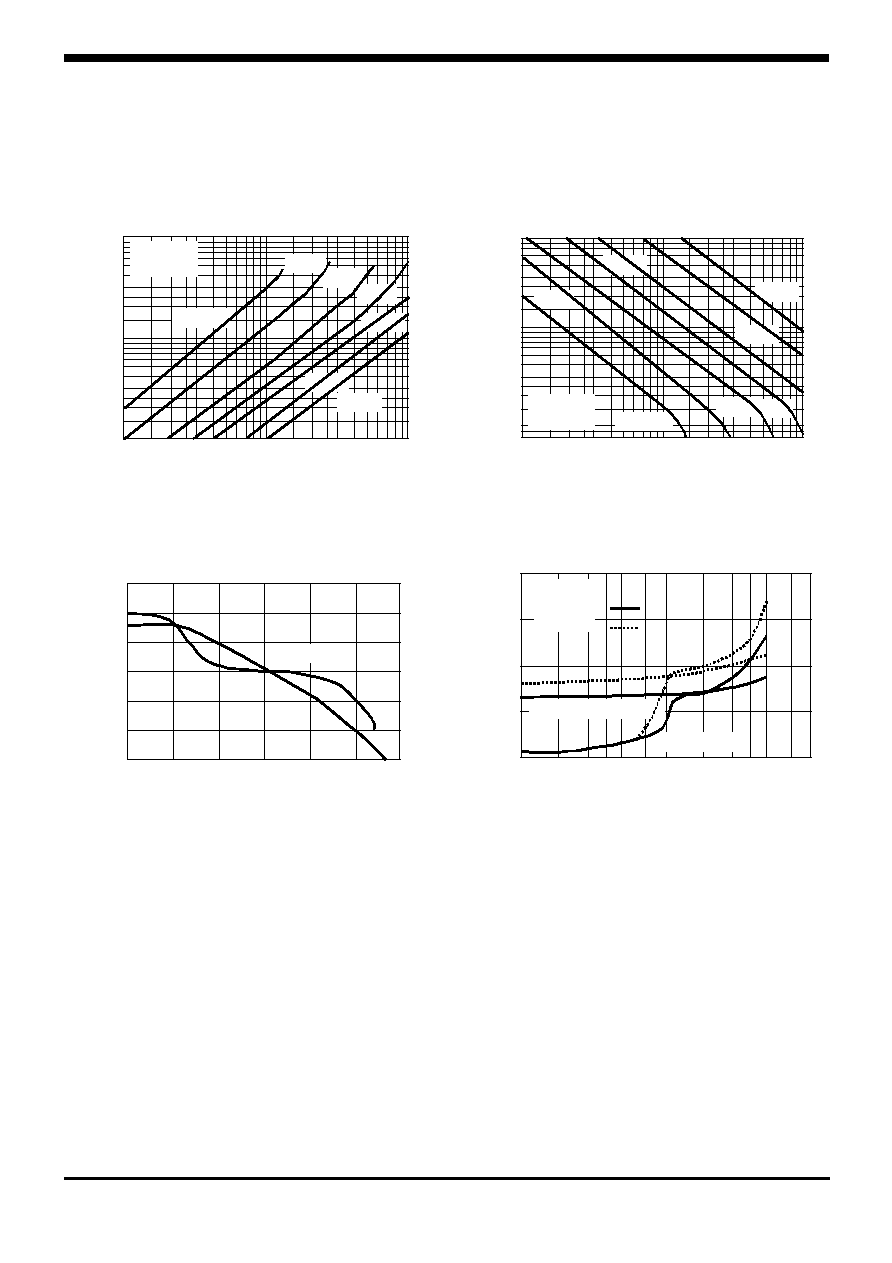

Electrical Characteristic Curves

%DT PERCENT OUTPUT DEAD-TIME

OUTPUT DEAD-TIME vs.

OSCILLATOR FREQUENCY

f

OSC

OS CILLATOR FREQUENCY (KHz )

1.0

2.0

5.0

10

100

50

20

10K

20K

50K

100K

200K

500K 1.0M

V c c =15V

Ta = 25

o

C

Ct =10n F

2.0n F

5.0n F

1.0n F

500pF

200pF

100pF

R

T

T

IM

IN

G

RESISTOR

(

K)

TIMING RESISTOR vs.

OSCILLATOR FREQUENCY

f

OSC

OS CILLATOR FREQUENCY (KHz )

0.8

2.0

5.0

8.0

80

50

20

10K

20K

50K

100K

200K

500K 1.0M

V c c =15V

Ta = 25

o

C

C

T

=10n F

2.0n F

5.0n F

1.0n F

500pF

200pF

100pF

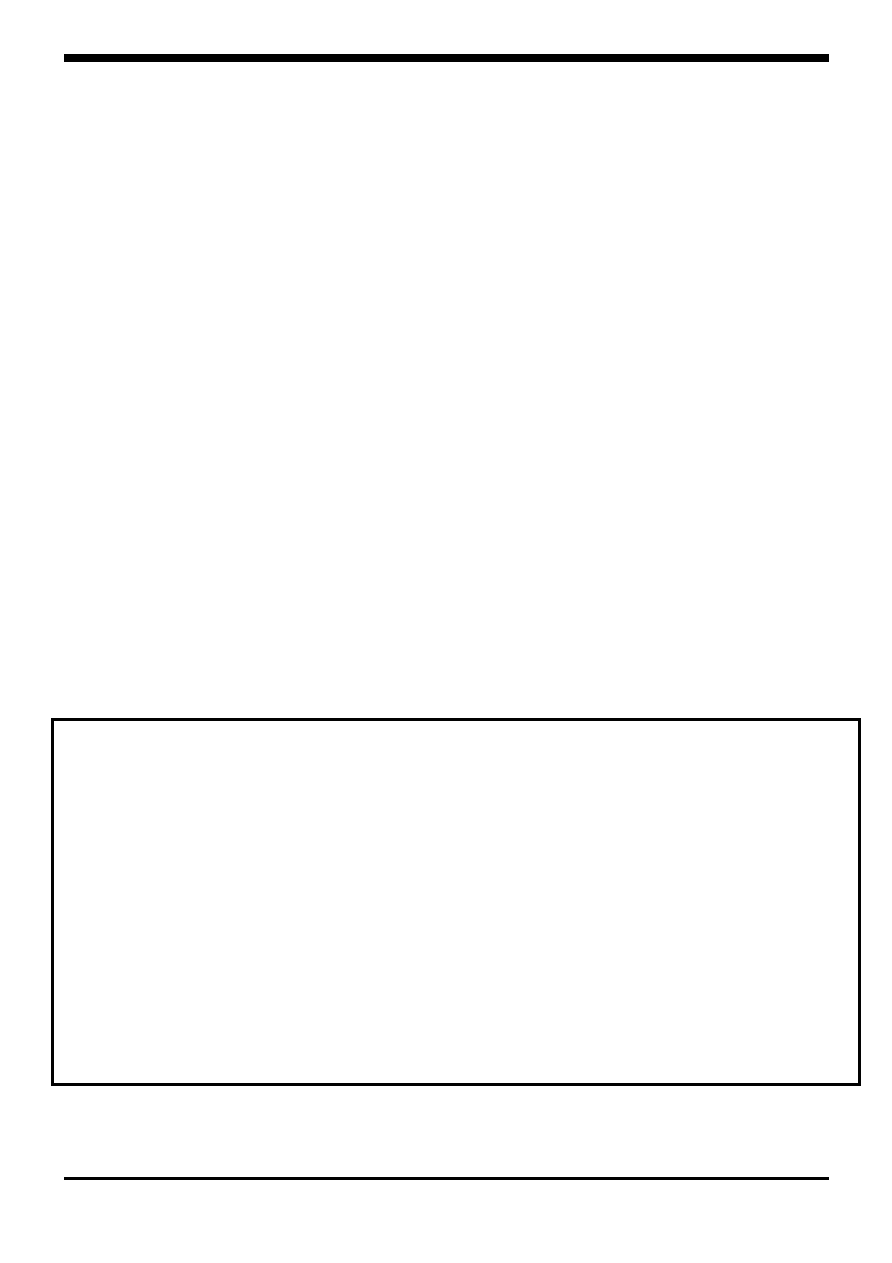

10

100

1K

10K

100K

1M

10M

FREQUENCY (Hz)

VOLTAGE GAIN (dB

)

20

40

60

80

0

Error Amplifier Open-Loop

Frequency Response

PHASE

(

o

)

-135

-90

-45

0

-180

AV

1

2

3

4

0

SA

TUR

A

TION VOLTA

GE (V)

Output Saturation Characteristics

OUTPUT CURRENT SOURCE OR SINK (A)

0.1

0.2

0.3 0.4 0.5 0.7

1

2

3

4

5

7

10

Vcc=15V

Ta = 25

o

C

Ta=-55

o

C

SINK SAT(VOL)

SOURCE SAT(Vcc-VOH)

KSI-8006-003

8

S3842

These AUK products are intended for usage in general electronic equipments(Office and

communication equipment, measuring equipment, domestic electrification, etc.).

Please make sure that you consult with us before you use these AUK products in equipm-

ents which require high quality and/or reliability, and in equipments which could have

major impact to the welfare of human life(atomic energy control, airplane, spaceship, traffic

signal, combustion central, all types of safety device, etc.).

AUK cannot accept liability to any damage which may occur in case these AUK products

were used in the mentioned equipments without prior consultation with AUK.