| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CM9130 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

1

CM9130

PRELIMINARY

Features

∑

2.9V to 6V input voltage range

∑

Powers display backlight and/or flash WLED

∑

Low external parts count, requires no inductor and

ballast resistors

∑

Low EMI and reflected ripple

∑

Adaptive charge pump ratio (1x or 1.5x) maximizes

efficiency at both high and low input voltages

∑

Precision regulation for each output with 2% cur-

rent matching at 20mA

∑

Programmable LED current via ISET pin

∑

Typical 500 KHz fixed switching frequency

∑

Supports up to 300mA, drives three LEDs regu-

lated to 50mA each

∑

Analog and PWM intensity control

∑

Less than 10µA shutdown current

∑

Over-current and over-temperature protection

∑

Undervoltage lockout

∑

Soft-start limits start-up inrush current

∑

TQFN-16 package

∑

Optional RoHS compliant lead free packaging

Applications

∑

Drives white LEDs for STN/TFT Color LCD back-

lighting

∑

Cell phones, PDAs

∑

Digital Still Cameras

∑

Flash for DSC

Product Description

The CM9130 is an adaptive fractional switched capaci-

tor (charge pump) regulator optimized for driving 3

white LEDs. Each LED's driver current is matched to

within 2% for uniform intensity. It supports an input volt-

age range of 2.9V to 6V, with undervoltage lockout. A

failure detection circuit prevents the loss of power when

one or more LEDs fail (short or open). Internal over-

temperature and over-current management provide

short circuit protection.

The CM9130 regulates up to 300mA of output current

to drive WLEDs, allowing up to 50mA per LED channel.

The maximum LED current is programmed with an

external resistor. The EN input allows for Analog and

PWM brightness control. The CM9130 can also be

used for a camera flash. In full shutdown mode, the

CM9130 draws only 10µA.

The CM9130 automatically selects the most efficient

charge pump ratio based on the operating voltage

requirement of the white LEDs. The proprietary design

architecture maintains high efficiency (> 80%), and at

low V

IN

provides longer battery life. With a high V

IN,

or

when the adapter is powered, it provides cool reliable

operation.

The CM9130 is available in a compact 16 lead TQFN

package. It can operate over the industrial temperature

range of -40∞C to 85∞C.

Typical Application

CM9130

VOUT

LED1

VIN

LED2

LED3

1.0uF

2.9V to 6.0V

1.0uF

1uF

C1P C1N

C2P C2N

ISET

GND

1uF

R

SET

EN

Enable

on

off

PhotonIC

TM

Three Output Driver for White LEDs

©

2006 California Micro Devices Corp. All rights reserved.

2

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

04/26/06

CM9130

PRELIMINARY

Ordering Information

Note 1: Parts are shipped in Tape & Reel form unless otherwise specified.

Specifications

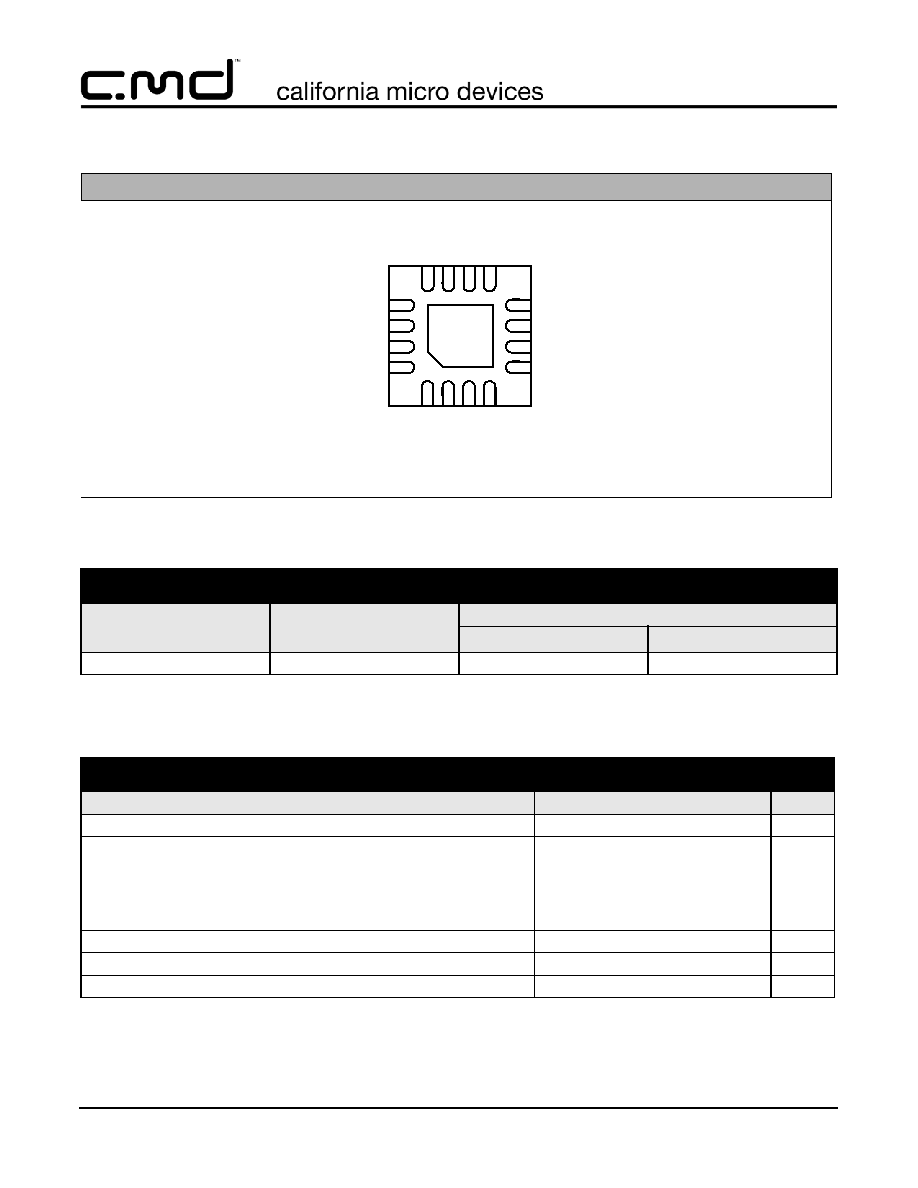

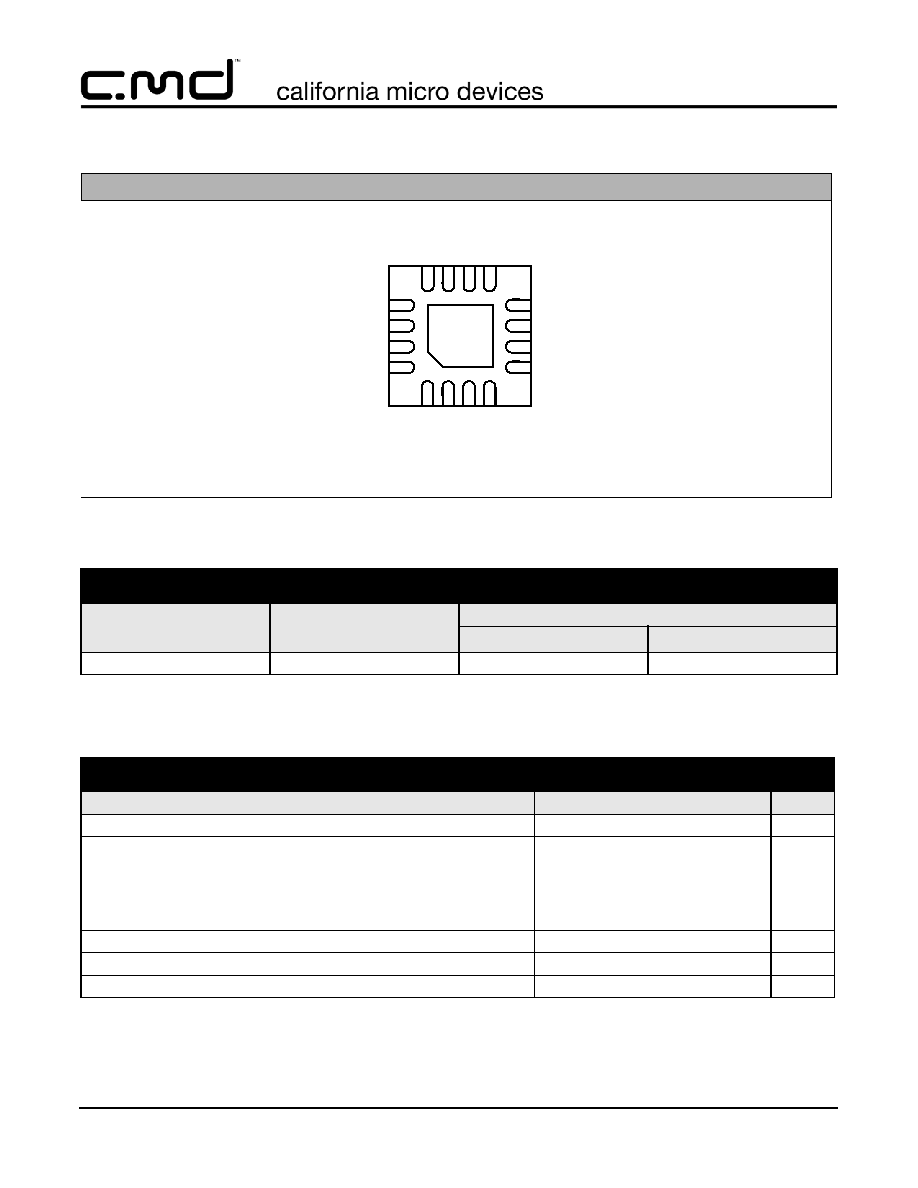

PACKAGE / PINOUT DIAGRAM

Bottom View

16-Lead TQFN Package

(4mm x 4mm)

ISET1

VIN

C1P

LED1

EN

GND

C1N

NC

LED

2

VO

U

T

LED

3

C2P

NC

NC

NC

C2N

4

3

2

1

9

10

11

12

5

6

7

8

16

15

14

13

TQFN16

4 X 4

Note: This drawing is not to scale.

PART NUMBERING INFORMATION

Leads

Package

Lead-free Finish

Ordering Part Number

1

Part Marking

16

TQFN

CM9130-01QE

ABSOLUTE MAXIMUM RATINGS

PARAMETER

RATING

UNITS

ESD Protection (HBM)

± 2

kV

Pin Voltages

V

IN

to GND

V

OUT

to GND

ISET, EN to GND

All other pins to GND

[GND - 0.3] to +6.0

[GND - 0.3] to +7.0

[GND - 0.3] to +5.0

[GND - 0.3] to +5.0

V

V

V

Storage Temperature Range

-65 to +150

∞C

Operating Temperature Range

-40 to +85

∞C

Lead Temperature (Soldering, 10s)

300

∞C

Package Pinout

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

3

CM9130

PRELIMINARY

ELECTRICAL OPERATING CHARACTERISTICS

V

IN

= 3.6V; All outputs are on. Typical values are at T

A

= 25∞C.

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

S

V

IN

Supply Voltage Range

2.9

6.0

V

V

UVLO

Undervoltage Lockout

All outputs are no load.

1.7

1.8

1.9

V

I

Q

Quiescent Current

1x mode

500

A

I

SD

Shutdown Supply Current

V

EN

< 0.4V

2

10

A

VOUT Charge Pump

V

OUT

Output Voltage

I

OUT

= 0mA to 120mA,

V

IN

= 3.0 to 5.5V

4.2

5.5

V

I

LED TOT

Total I

LED

Current

I

LED1

thru I

LED3

+photoflash

300

mA

ILED

Accuracy of ISET

V

IN

= 3.0V to 5.5V

1

%

Matching current between LED1

to LED3

V

IN

= 4.0V, I

LED 1,2,3

= 20mA

2

5

%

I

LED

per driver

Device total I

LED

< 150mA

50

mA

EN, ISET

V

IH

High Level Input Voltage

1.8

V

IL

Low Level Input Voltage

0.4

Protection

Over-current Limit

400

mA

Over-temperature Limit

135

∞C

Over-temperature Hysteresis

15

∞C

Specifications (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

4

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

04/26/06

CM9130

PRELIMINARY

100 mV/

div

Iin

Vout

Vin

20mA/

div

50mV/

div

1us/div

Typical Waveforms

Cin=C2=C3=Cout=1uF, Iout=120mA

1.5x mode

100 mV/

div

20mA/

div

50mV/

div

Iin

Vout

Vin

1us/div

1.0x mode

Typical Waveforms

Cin=C2=C3=Cout=1uF, Iout=120mA

LED Current vs. Vin

5

10

15

20

25

3.0

3.5

4.0

4.5

5.0

5.5

6.0

Input Voltage (V)

L

E

D Cu

rr

e

n

t

(

m

A

)

Iin

Vout

ENB

.5ms/div

Startup

Cin=C2=C3=Cout=1uF, Iout=120mA

2V/

div

200mA/

div

2V/

div

Iout=120mA

Iout=60mA

Iout=30mA

Source Current

25

50

75

100

125

150

175

200

3.0

3.5

4.0

4.5

5.0

5.5

6.0

Input Voltage (V)

I

n

p

u

t

Cu

rre

n

t

(

m

A)

Vled=3.2V

Charge Pump Efficiency

60

70

80

90

100

3.0

3.5

4.0

4.5

5.0

5.5

6.0

Input Voltage (V)

E

f

f

i

c

i

en

cy (

%

)

Vled=3.2V

Iout=30mA

Iout=60mA

Iout=120mA

Typical Performance Curves

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

5

CM9130

PRELIMINARY

Pin Descriptions

CM9130

VOUT

VIN

C1P

UVLO

OSC

500 KHz

Charge Pump x1, x1.5

C1N

C2P C2N

LED1

LED2

Current

Sinks

Bandgap

Mode Select

Failed LED

Condition

LED3

GND

EN

ISET

PIN DESCRIPTIONS

LEAD(s)

NAME

DESCRIPTION

1

LED1

Cathode of LED1 pin.

2

C1P

This pin is the plus side of charge pump bucket capacitor C1. Connect a 1.0

F

ceramic capacitor with a voltage rating of 10 V or greater between C1N and C1P.

3

VIN

Positive supply voltage input pin. This voltage should be between 2.9V and 6V.

This pin requires a 1.0

F or larger ceramic capacitor to ground.

4

ISET

Enable pin and Current set pin for drivers, active low.

To set the LED current, a resistor, R

SET

, is connected between this pin and ground.

The regulated LED current is 1000x the current flowing in R

SET

, and is

approximately:

If this resistor is tied to directly ground (and enable function not used) Logic Low=0,

otherwise subtract the voltage drop of the device that drives this pin low.

I

LED

0.66V

LogicLow

(

)

≠

R

SET

----------------------------------------------------- 1000

◊

=

Functional Block Diagram

©

2006 California Micro Devices Corp. All rights reserved.

6

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

04/26/06

CM9130

PRELIMINARY

Application Information

The CM9130 is a switched capacitor, charge pump

voltage converter ideally suited for driving white LEDs

to backlight LCD color displays in portable devices.

The CM9130 charge pump is the perfect driver for por-

table applications such as cellular phones, digital still

cameras, PDAs and any application where small

space, compact overall size, low system cost and mini-

mal EMI are critical.

The CM9130 requires only two external switched

(bucket) capacitors, plus an input and an output capac-

itor, providing for a compact, low profile design. In

many applications, these can all be conveniently the

same value of 1.0µF, available in a compact 0805 sur-

face mount package.

The adaptive conversion ratio selects the most efficient

operating mode. When V

IN

is higher than the needed

V

OUT

(V

LED

+V

CURRENT_SINK

), the 1x mode is set.

When the input voltage is below the LED forward volt-

age and a voltage boost is needed, the 1.5x mode is

automatically selected. The 1.5x mode uses a frac-

tional charge pump to convert the nominal Li-ion bat-

tery voltage (3.6V) by 1.5 times and regulates the LED

current to the low dropout current sources.

The current regulated sources maintain constant LED

drive in the presence of supply voltage fluctuations. All

LEDs are driven with the same current, even when they

have slightly different forward voltages. The individual

current sources sense the current through each LED

and match this current to less than 2% for uniform

brightness across the color LCD display.

The CM9130 drives up to three WLEDS. The maxi-

mum current programmed by R

SET

determines the

maximum intensity; the display can be further dimmed

by PWM control applied to its EN pin.

CM9130 Operation

When a voltage is applied to the VIN pin, the CM9130

initiates a softstart cycle, typically lasting 100 µS. Soft-

start limits the inrush current while the output capaci-

tors are charged. Following softstart, the CM9130 next

determines the best conversion ratio (1x or 1.5x).

5

NC

6

NC

7

NC

8

C2N

This pin is the minus side of charge pump bucket capacitor C2. Connect a 1.0

F

ceramic capacitor between C2N and C2P.

9

EN

PWM/Analog input pin. Can be used as second Enable pin, active high. Should tied

high when not used.

10

GND

Ground terminal pin.

11

C1N

This pin is the minus side of charge pump bucket capacitor C1. Connect a 1.0

F

ceramic capacitor between C1N and C1P.

12

NC

13

C2P

This pin is the plus side of charge pump bucket capacitor C2. Connect a 1.0

F

ceramic capacitor between C2N and C2P.

14

LED3

Cathode of LED3 pin.

15

VOUT

Charge pump output voltage pin, which connects to the anodes of all LEDs. A 1

F

capacitor to ground is recommended.

16

LED2

Cathode of LED2 pin.

PIN DESCRIPTIONS

Pin Descriptions (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

7

CM9130

PRELIMINARY

The 1.5x mode employs a fractional charge pump. The

charge pump uses two phases from the internal oscil-

lator to drive switches that are connected to the bucket

capacitors, C1 and C2, as shown in

Figure 1

In the first

switch position, the bucket capacitors are connected in

series and each are charged from V

IN

to a voltage of

V

IN

/2. The next phase changes the switch positions so

that C1 and C2 are in parallel, and places them on top

of VIN. The resulting voltage across C

OUT

is then

V

IN

+1/2V

IN

= 1.5 x V

IN

.

Figure 1. Switch Operation

The CM9130 has over-temperature and over-current

protection circuitry to limit device stress and failure dur-

ing short circuit conditions. An overcurrent condition

will limit the output current (approximately 400~600mA)

and will cause the output voltage to drop, until automat-

ically resetting after removal of the excessive current.

Over-temperature protection disables the IC when the

junction is about 135 ∞C, and automatically turns on the

IC when the junction temperature drops by approxi-

mately 15 ∞C.

Efficiency

A conventional charge pump with a fixed gain of 2x will

usually develop more voltage than is needed to drive

paralleled white LEDs from Li-Ion sources. This exces-

sive gain develops a higher internal voltage, reducing

system efficiency and increasing battery drain in porta-

ble devices. A fractional charge pump with a gain of

1.5x is better suited for driving white LEDs in these

applications.

The CM9130 charge pump automatically switches

between the two conversion gains, 1x and 1.5x, allow-

ing high efficiency levels over a wide operating input

voltage range. The 1x mode allows the voltage to pass

directly through to the output when sufficient input volt-

age is available. As the battery discharges to the point

where any one current source no longer has sufficient

voltage headroom to maintain a constant current regu-

lation, the 1.5x charge pump is enabled.

At nominal loads, the switching losses and quiescent

current are negligible. If these losses are ignored for

simplicity, the efficiency,

, for an ideal 1.5x charge

pump can be expressed as the output power divided by

the input power:

For an ideal 1.5x charge pump, I

IN

1.5 x I

OUT

, and the

efficiency may be expressed as;

Many charge pumps are fixed 2x designs. The ideal 2x

charge pump efficiency can be similarly expressed;

In 1x mode, when the input voltage is above the output

voltage, the ideal efficiency is simply V

OUT

/V

IN

.

Charge C1 and C2 to Ω VIN each

VIN

C1

C2

Ω VIN

VOUT

Ω VIN

Transfer Ω VIN charge to top of VIN

VIN

C1

C2

Ω VIN

Ω VIN

C

OUT

VOUT

C

OUT

P

LED

P

IN

-------------

=

IN

SINK

_

CURRENT

LED

IN

OUT

OUT

IN

OUT

OUT

IN

LED

SINK

_

CURRENT

LED

OUT

V

5

.

1

V

9

.

3

,

V

9

.

3

)

V

V

(

For

V

5

.

1

V

I

5

.

1

V

I

)

V

(

P

P

)

V

V

(

V

◊

=

+

◊

=

◊

◊

◊

+

=

P

OUT

P

IN

-------------

3.9V

2.0 V

IN

◊

-----------------------

Application Information (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

8

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

04/26/06

CM9130

PRELIMINARY

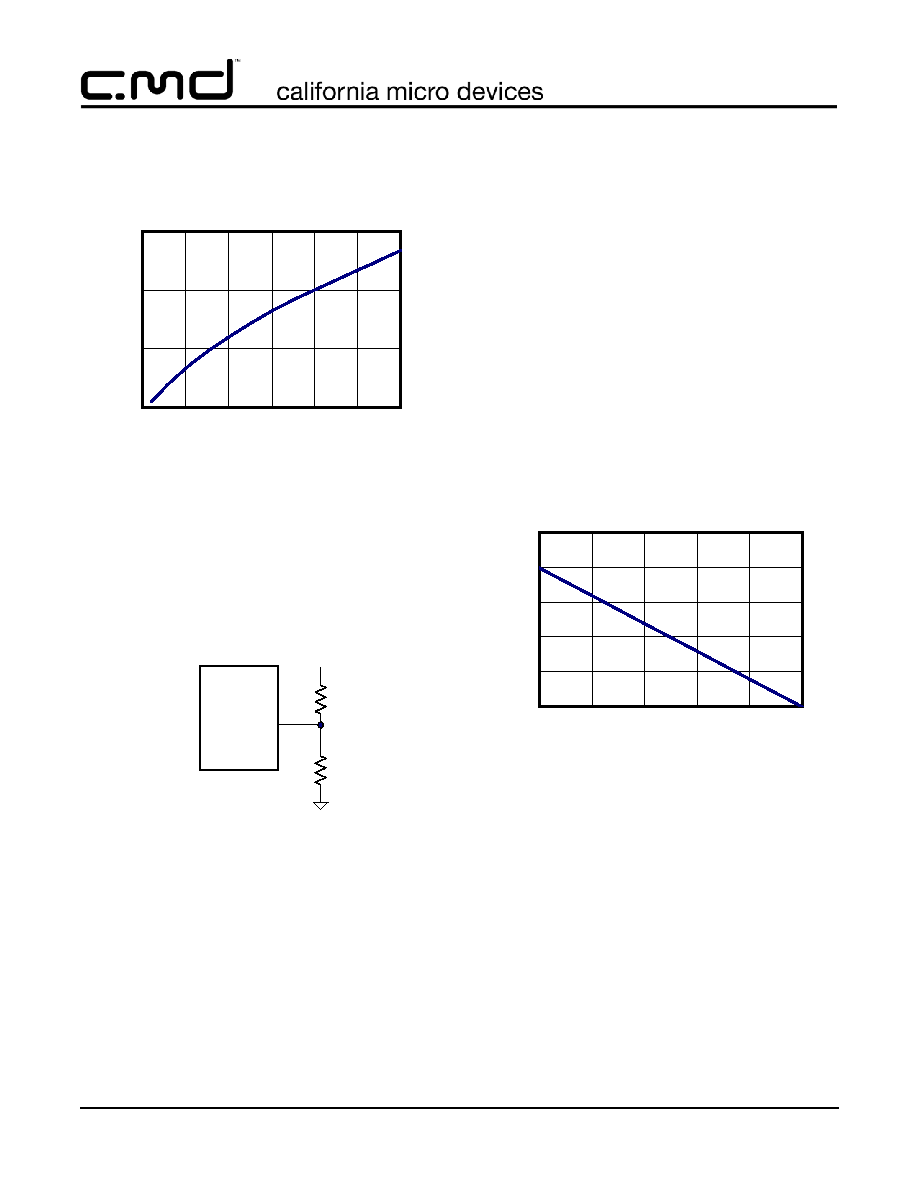

The typical conversion efficiency plots for these modes,

with some losses, are shown in

Figure 2

.

Figure 2. Ideal charge pump efficiency

As can be seen, the CM9130, with 1x and 1.5x modes,

has better efficiency in this application than a fixed 2x

charge pump. At low battery voltages, the higher effi-

ciency of the CM9130 charge pump's 1,5x gain

reduces the battery drain. At higher input voltages, typ-

ically seen when the system is running off an AC

adapter, the CM9130, operating the 1x mode, has bet-

ter efficiency than single mode 1.5x or 2x charge

pumps, lowering the power dissipation for cooler circuit

operation and long life.

While the charge pump efficiency is easily determined,

the system efficiency is more difficult due to the current

source outputs, which complicate measuring the output

power. The forward voltage of the white LEDs will vary,

and the constant current sources will adjust to maintain

the current. When comparing systems, it is best to

compare the input current for a specified LED drive

current.

The 1x mode has better efficiency than the 1.5x mode.

Selecting LEDs with low forward voltage (V

LED

)

increases the time spent in the 1x mode as the battery

discharges, extending the operating time.

Failed LED Detection

If a LED is shorted, the CM9130 will continue to oper-

ate and drive the remaining LEDs at the programmed

current. If a LED opens, the other LEDs will still be reg-

ulated at the programmed current.

LED Current Set (ISET)

An external resistor programs a reference current, set-

ting the maximum driver current. This resistor must be

tied to a good analog ground. If it is pulled to ground

through a switch, for example, from the host controller

output, the voltage drop across that switch should not

exceed 10 mV.

The voltage at the ISET pin is provided by a .66V band-

gap reference. The LED current is approximately

1000x the current set by the R

SET

resistor, according to

the following formula:

Logic Low is the voltage on device driving this pin to

ground. If the resistor is tied to ground directly, Logic

low = 0. For 20mA LED current, R

SET

= 33k. When this

pin is driven high or open, the device will enter a sleep

mode with V

OUT

=4.5V and, with no load, I

QUIESCENT

=

500

A.

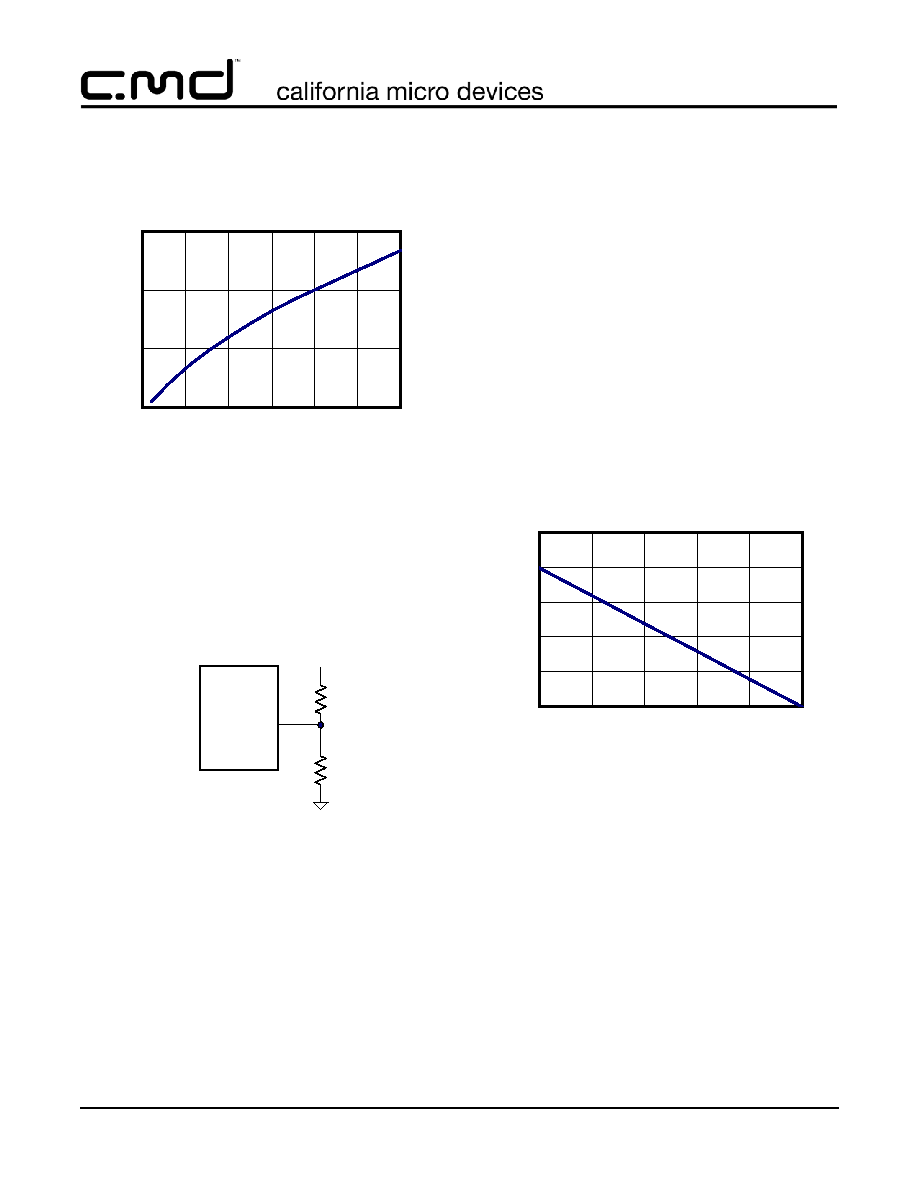

Analog Control of Display Intensity

Typically, portable devices control the backlight display

intensity in response to ambient light conditions, or

lower the intensity after a short standby interval to con-

verse battery charge. The luminous intensity of white

LEDs is proportional to the amount of forward current

through them, but the color wavelength emitted is also

dependent upon the forward current. In applications

where color shift is not critical, brightness can be con-

trolled by adjusting the diode's current. A typical white

LED Intensity vs. forward current curve is shown in

Figure 3

.

30

45

60

75

90

3.0

3.5

4.0

4.5

5.0

5.5

6.0

Input Voltage (V)

E

f

f

i

ci

e

n

cy (

%

)

VLED=3.5V

2X

1X-1.5X

dual mode

1.5X

1X

R

SET

0.66V

LogicLow

(

)

≠

I

LED

----------------------------------------------------- 1000

◊

=

Application Information (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

9

CM9130

PRELIMINARY

Figure 3. Typical Luminous Intensity vs.

LED Current

The Iset pins of the CM9130 can be used to connect

an analog DC signal for analog dimming of the white

LEDs, as shown in

Figure 4

This requires an additional

resistor, R, and a DC source voltage, Vc.

Figure 4. Analog LED current adjust

A control voltage, V

C

, applied to the resistor divider will

decrease the current for all LEDs. The maximum LED

current occurs with 0V on V

C

, which is set by R

P

is the

parallel combination of R and R

SET

.

Choose the maximum control voltage, V

C

, which sets

zero LED current, and then determine the resistor ratio.

The resistors can be determined from the equations

below.

For example, a V

C

max of 2.5V and a maximum current

setting of 20mA, R=125k, R

SET

=44.8k.

Figure 5

shows

the control curve.

Figure 5. LED Current Control Curve

The circuit in

Figure 6

is an example of logic dimming

control, which changes the LED forward current in dis-

crete steps. The NMOS source is an open drain (or

open collector if bipolar) device, either the output of a

host controller, or a discrete device. Open drain, or

open collector devices sink current in their active, low

voltage state (logic 0), and are high impedance in their

high voltage, non-active state (logic 1). The open drain

must not be pulled high with an external resistor, but

instead connected only to the current setting resistors.

The parallel combination of R and R

SET

determine the

full intensity current. When the drain goes high, R

SET

determines the lower intensity current.

Relative Luminous Intensity

0.0

0.5

1.0

1.5

0.0

5.0

10.0

15.0

20.0

25.0

30.0

Forward Current (mA)

N

o

r

m

al

i

z

ed

t

o

20m

A

CM9130

ISET

V

C

R

R

SET

R

P

0.66V

I

LED

max

----------------------- 1000

◊

=

Ratio

0.66V

Vc 0.66

≠

V

--------------------------

=

R

R Ratio

◊

(

) Rp

+

Ratio

-------------------------------------------

=

Rset

Ratio R

◊

=

LED Current vs. Vc

0

5

10

15

20

25

0.0

0.5

1.0

1.5

2.0

2.5

Control Voltage, Vc

LED

C

u

r

r

e

nt

(

m

A

)

Application Information (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

10

CM9130

PRELIMINARY

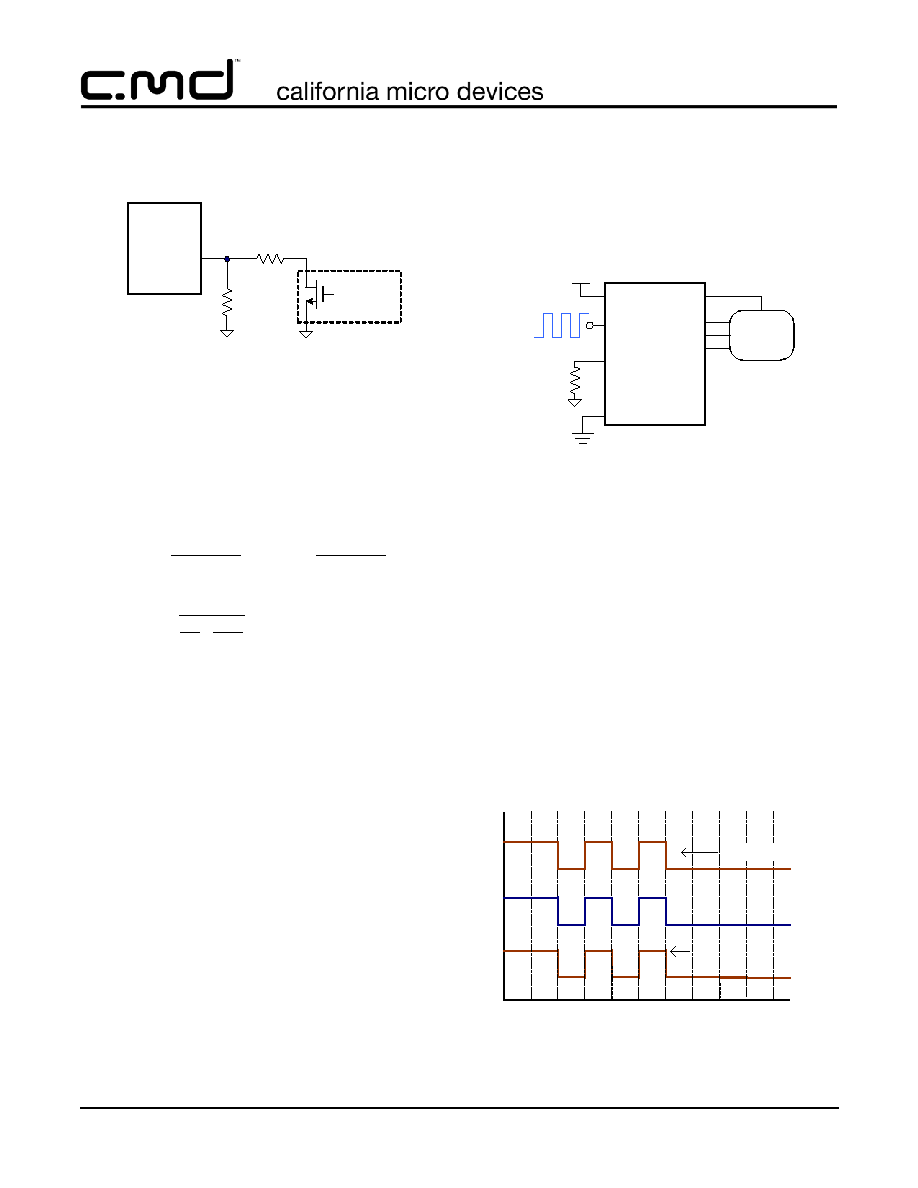

Figure 6. Logic Signal Dimming

For example, to reduce the luminosity intensity by half,

using the LED curve from

Figure 3

, the current setting

needs to be changed from 20

-

mA to about 8

-

mA. The

values in

Figure 6

will accomplish this, are where

obtained using the following equations;

Additional parallel resistors can be added in the same

way.

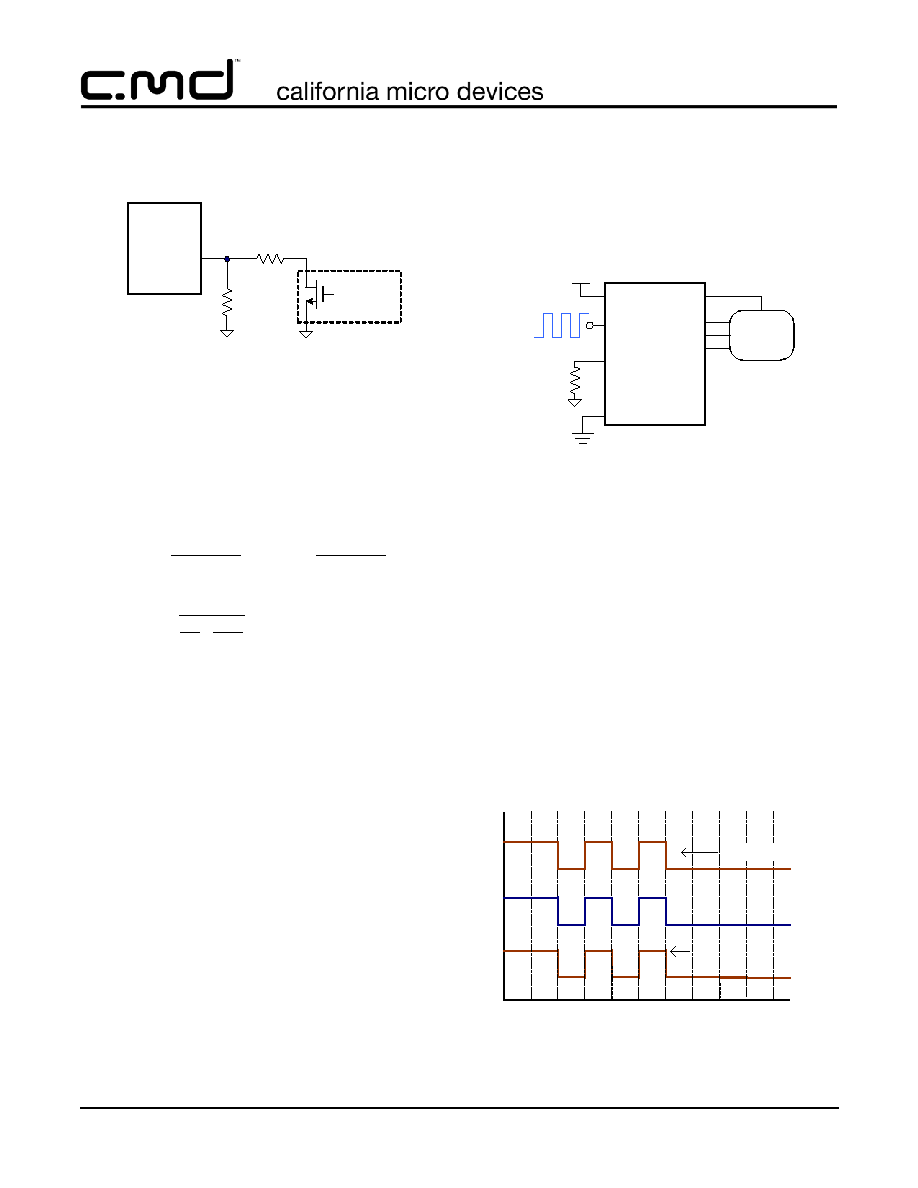

PWM Control of Display Intensity

Typically, portable devices control the backlight display

intensity in response to ambient light conditions, or

lower the intensity after a short standby interval to con-

verse battery charge. The CM9130 allows the output to

lower the LED brightness by applying a pulsing (PWM)

signal to EN, as shown in

Figure 7

. The waveforms are

shown in

Figure 8

.

The white in white LEDs is typically bichromatic, pro-

duced by a blue or UV LED that excites yellow phos-

phors. The two colors combine and the human eye

sees these them as white light. The forward current of

the LED influences the chromaticity, with higher LED

current increasing the blue content of the color.

Using a PWM signal allows the LEDs to be dimmed

without substantially shifting their color balance due to

chromaticity shifts related to changing white LED for-

ward current. The PWM signal causes the LEDs to

operate either at the full ISET current, or at zero cur-

rent. Only the time averaged current changes. Above a

minimum frequency, the human eye will perceive the

change in duty cycle as a change in brightness.

Figure 7. PWM applied to EN

The recommended frequency is between 100 Hz and

200 Hz, with a duty cycle greater than 20%. If a fre-

quency of less then 100 Hz is used, flicker might be

seen in the LEDs. The frequency should also be

greater than the refresh rate of the TFT display. Higher

frequencies will cause a loss of brightness control lin-

earity. In addition, higher frequency can cause chroma-

ticity shifts because the fixed rise and fall times of the

PWM signal will shift the forward current.

The PWM signal will cause the average LED current to

be reduced. The average current is determined by the

PWM duty cycle, which can vary from 0% to 100%.

Decreased Duty Cycle will linearly lower LED bright-

ness, 0% Duty Cycle will turn off the display LEDs.

Figure 8. PWM Signal Dimming

CM9130

ISET

R

R

SET

82.5k

55k

Open Drain

Controller

Output

Rset

1

Rp

1

1

R

(min)

I

1000

*

V

66

.

Rset

(max)

I

1000

*

V

66

.

Rp

LED

LED

-

=

=

=

CM9130

VOUT

LED1

VIN

LED2

LED3

V

BATT

Display

EN

GND

R

SET

ISET

PWM

on

off

I

LED (1,2,3)

VOUT

I

SET

EN

PWM signal

Application Information (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

04/26/06

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

11

CM9130

PRELIMINARY

CM9130 Design Examples

Cell Phone

Some mobile phone LCD displays (both STN and mini-

TFT) use white LEDs for backlighting. Light guides are

used to distribute the light uniformly behind the LCD. A

typical application is shown in

Figure 9

. The display's

intensity can be lowered by a PWM signal applied to

the EN pin, as determined by ambient light conditions.

Figure 9. Display Backlight

Camera Flash

The CM9130 can support a camera flash in digital still

cameras as well as in camera equipped smart phones

and PDAs. In this case the flash LEDs are supplied 3 x

50

-

mA = 150

-

mA. See

Figure 10

.

Figure 10. Flash Application

Capacitor Selection

For proper performance, use surface-mount, low ESR

ceramic capacitors for all four positions. X7R or X5R

ceramic dielectric provides good stability over the oper-

ating temperature and voltage range,

The capacitance and ESR of the external bucket

capacitors will directly affect the output impedance and

efficiency of the converter. A ceramic 1

F capacitor is

recommended.

Reflected input ripple depends on the impedance of

the V

IN

source, such as the PCB traces and the Li-ion

battery, which have elevated impedance at higher fre-

quencies. The input capacitor located near the con-

verter input reduces this source impedance and ripple.

Any ESR from the capacitor will result in steps and

spikes in the ripple waveform, and possibly produce

EMI. Much of the ripple voltage is due to moving cur-

rent charge in and out of the capacitor and the capaci-

tor's impedance at the charge pump frequency. If ripple

voltage or current on the battery bus is an application

issue, add a small input inductor between the battery

and the capacitor, or just increase the capacitor.

For a given output current, increasing the output

capacitance reduces output ripple in the 1.5x mode.

Increasing the output capacitor will also increase star-

tup current and time. In most LED applications, high

frequency output ripple is not a concern because it will

not cause intensity variations that are visible to the

human eye.

Layout Guide

The charge pump is rapidly charging and discharging

the external capacitors, so external traces to the

capacitors should be made wide and short to minimize

inductance and high frequency ringing. The four

capacitors should be located as close as practical to

the charge pump, particularly C1 and C2, which have

the highest dv/dt. Use a solid ground plane, and con-

nect the ground side of C

IN

, C

OUT

and the package

GND as close as practical.

CM9130

VOUT

LED1

VIN

LED2

LED3

EN

V

BATT

Display

MENU

GND

R

SET

ISET

CM9130

VOUT

LED1

VIN

LED2

LED3

GND

R

SET

V

BATT

WLED

Flash

EN

ISET

Flash

Application Information (cont'd)

©

2006 California Micro Devices Corp. All rights reserved.

12

490 N. McCarthy Blvd., Milpitas, CA 95035-5112

l

Tel: 408.263.3214

l

Fax: 408.263.7846

l

www.cmd.com

04/26/06

CM9130

PRELIMINARY

TQFN-16 Mechanical Specifications

The CM9130 is supplied in a 16-lead, 4.0mm x 4.0mm

TQFN package. Dimensions are presented below.

For complete information on the TQFN16, see the Cal-

ifornia Micro Devices TQFN Package Information doc-

ument.

* This is an approximate number which may vary.

Package Dimensions for 16-Lead TQFN

PACKAGE DIMENSIONS

Package

TQFN-16 (4x4)

Leads

16

Dim.

Millimeters

Inches

Min

Nom

Max

Min

Nom

Max

A

0.80

0.84

0.031

0.033

A1

0.00

0.04

0.00

0.002

A3

0.20 REF

.008

b

0.25

0.33

0.010

0.013

D

4.0 BSC

0.157

D1

1.95 REF

0.077

D2

2.05

2.15

0.081

0.085

E

4.0 BSC

0.157

E1

1.95 REF

0.077

E2

2.05

2.15

0.081

0.085

e

0.65 TYP.

0.026

L

0.55

0.65

0.022

0.026

# per

tube

xx

pieces*

# per

tape and

reel

xxxx pieces

Controlling dimension: millimeters

A3 A1

0.10 C

0.08 C

A

SIDE VIEW

Mechanical Package Diagrams

D

E

0.15 C

0.15 C

BOTTOM VIEW

TOP VIEW

e

b

L

0.10

C A B

M

16X

D2

E2

DAP SIZE

1.8 X 1.8

E1

D1

Pin 1 Marking

Mechanical Details