| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CMI8800 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

cmi

Capella Microsystems Inc.

3777 Stevens Creek Blvd., Suite 320

Santa Clara, CA 95051-7364 U.S.A

Tel: (408) 260-3400

FAX: (408) 248-3416

Copyright © Capella Microsystems 1999 1

CONFIDENTIAL

CMI8800 Single/Three Phase

Spindle Motor Controller/Driver IC

For DVD/CD-ROM

PRELIMINARY DATA SHEET

Revision 3.0

07/09/99

This preliminary data sheet indicates that this product is still in the design cycle. All specifications

are based on design goals only. Capella Microsystems Inc. assumes no responsibility for the use of this

product.

Capella Microsystems Inc. reserves the right to make changes in specifications or discontinue

this product at any time without notice. Please contact Capella Microsystems Inc. for possible updates

before starting a design.

Capella Microsystems Inc. products are not designed for use in life support applications. Any

parties who use these products in such applications do so at their own risk and agree to fully indemnify

Capella Microsystems Inc. for any damages resulting from such improper usage or sale.

cmi

3777 Stevens Creek Blvd., Suite 320

Santa Clara, CA 95051-7364 U.S.A

Tel: (408) 260-3400

FAX: (408) 248-3416

Copyright © Capella Microsystems 1999 2

CONFIDENTIAL

GENERAL DESCRIPTION

The CMI8800 is a spindle motor

controller/ driver IC designed for DVD/CD-ROM

and Video CD (VCD) applications. This chip can

be used to control/drive single phase spindle

motors (see Page 20, Figure 17 for the

CMI8800 Application example) as well as

conventional three phase spindle motors. It

contains all of the necessary functional blocks

such as the hall bias generator, hall amplifier,

current limit amplifier, thermal shutdown, anti-

reverse protection, short brake, H-bridge power

driver and other functional blocks required for

motor controller/driver ICs (see Page 4, Figure 2

for the CMI8800 Simplified Block Diagram).

FEATURES

Brushless DC motor controller/driver IC

dedicated for DVD/CD-ROM and Video-CD

(VCD) spindle motor applications

Can drive both single phase spindle motors

as well as conventional three phase spindle

motors

Built-in hall bias generator and hall

amplifiers for easy interface with hall sensor

devices

Built-in sleep or start/stop mode to put the

chip and motor into sleep mode for power

saving

Built-in current limit amplifier to limit the

maximum allowed current into the motor

coil

Built-in thermal shutdown for overheat

protection

Built-in torque control to setup the motor's

torque according to the control voltage

applied to the EC and ECR pins

Built-in anti-reverse protection circuitry to

prevent the motor from going into the

opposite (reverse) rotation direction in the

constant linear velocity (CLV) operating

mode (used when the rotation speed is

decreased from the inner track to the outer

track)

Built-in frequency generator (FG) output as

well as rotation detect (FR) output circuitry

Built-in short brake circuitry to short all of

the motor coils and stop the motor quickly

Compatible with 3.3V digital signal

processor (DSP) interface

APPLICATIONS

DVD-DRIVES

CD-DRIVES

Absolute Maximum Ratings

(Ta = 25

∞

∞

C)

Description

Symbol

Value

Unit

Power Supply for Internal Core

VCCI

7

V

Power Supply for Motor Driver

VCCM1/VCCM2

16

V

Maximum Power Dissipation

Pd

1700*

mW

Storage Temperature

Tstg

-55 ~ 150

∞

C

Operating Temperature

Topr

-20 ~ 75

∞

C

Maximum Output Current

Iout

1300

mA

Hall Bias Current

IHB

50

mA

* 13.6mW/

∞

C Derating for Operating Temperature > 25

∞

C

(see Page 19, Figure 16 for the Derating Curve)

Recommended Power Supply Range

Description

Symbol

Value

Unit

Power Supply for Internal Core

VCCI

4.25 ~ 5.5

V

Power Supply for Motor Driver

VCCM1/VCCM2

3.0 ~ 15

V

cmi

3777 Stevens Creek Blvd., Suite 320

Santa Clara, CA 95051-7364 U.S.A

Tel: (408) 260-3400

FAX: (408) 248-3416

Copyright © Capella Microsystems 1999 3

CONFIDENTIAL

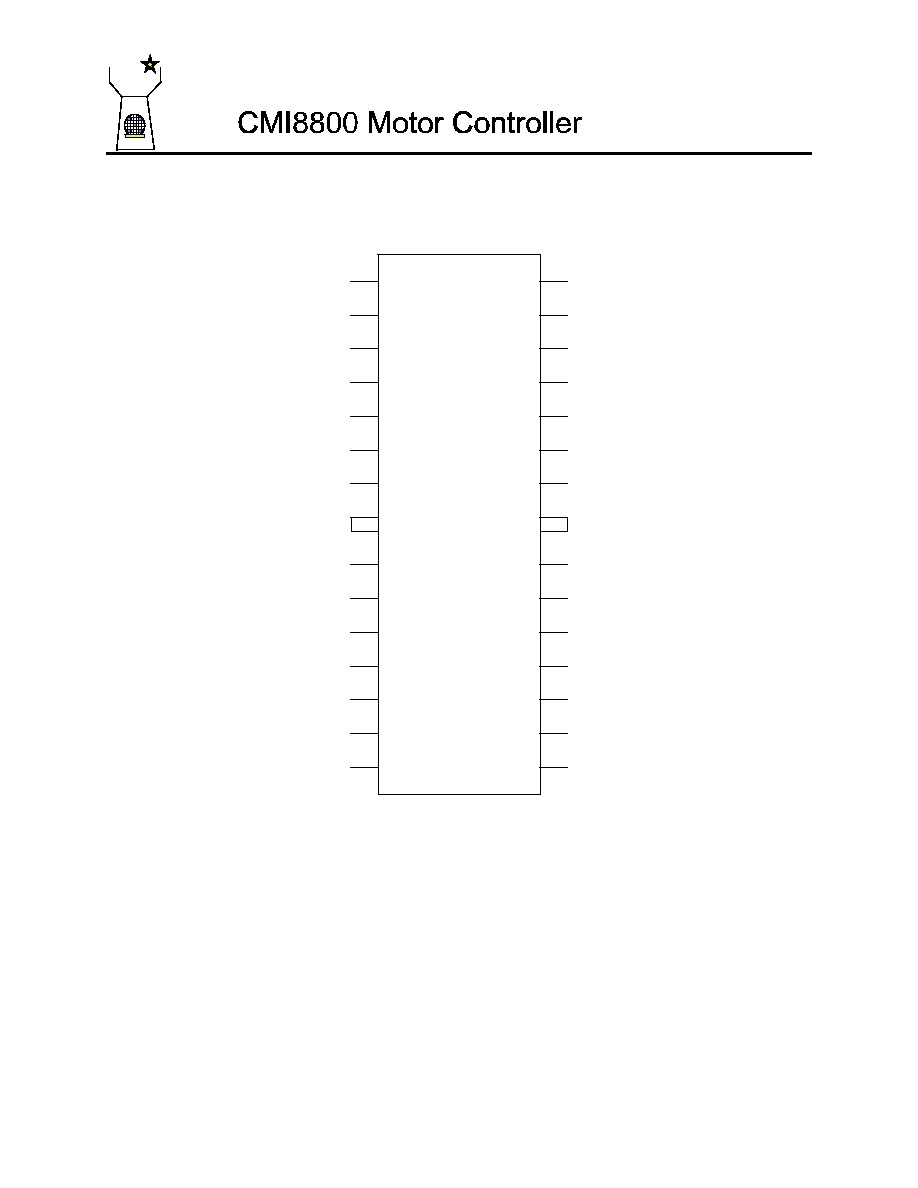

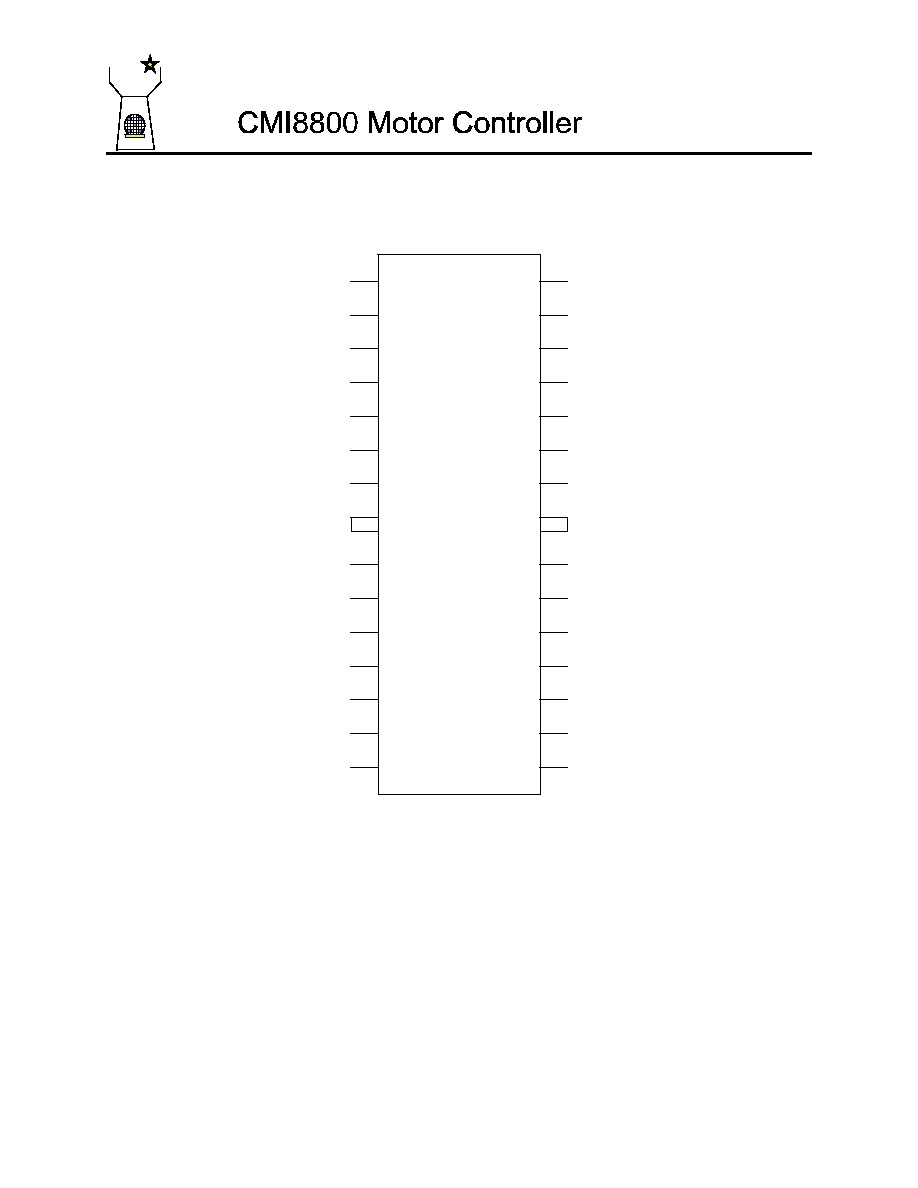

CMI8800

1

2

28

27

3

4

26

25

5

24

6

7

23

22

8

9

21

20

10

11

19

18

12

17

13

14

16

15

LDIN

RNF

W

VCCM1

LDOT

VCCM2

V

VCCI

N.C.

FG

N.C.

PS~

U

EC

FIN

FIN

GND

ECR

H1+

FR

H1-

1P/3P~

H2+

SB

H2-

CNF

H3+

BR

H3-

VH

Figure 1: CMI8800 Pin Assignment

cmi

3777 Stevens Creek Blvd., Suite 320

Santa Clara, CA 95051-7364 U.S.A

Tel: (408) 260-3400

FAX: (408) 248-3416

Copyright © Capella Microsystems 1999 4

CONFIDENTIAL

13

14

H3+

H3-

21

20

18

17

16

15

ECR

FR

SB

CNF

BR

VH

Hall Bias

Generator

H3+

H3-

MUX

In case of

Single Phase

11

12

H2+

H2-

Hall

Amp

8

9

10

GND

H1+

H1-

Hall

Amp

Hall

Amp

Hysteresis

Comp

H1+

H1-

H3+

H3-

Hysteresis

Comp

H2+

H2-

28

27

26

25

24

23

22

RNF

VCCM1

VCCM2

VCCI

FG

PS~

EC

Torque

Limit

VCCI

VCCI

CLK

Q~

D

Q

R

Communication

Control Logic

1

2

3

4

7

LDIN

W

LDOT

V

U

19

1P/3P~

Logic

Thermal

Shutdown

Torque

Sense Amp

Current

Limit Amp

+

-

Analog

Mux

A0

S

B1

+

-

Single Phase Motor -

Signal Processing

Circuitry

H-Bridge

Power

Driver

1P/3P~

Figure 2: CMI8800 Simplified Block Diagram

cmi

3777 Stevens Creek Blvd., Suite 320

Santa Clara, CA 95051-7364 U.S.A

Tel: (408) 260-3400

FAX: (408) 248-3416

Copyright © Capella Microsystems 1999 5

CONFIDENTIAL

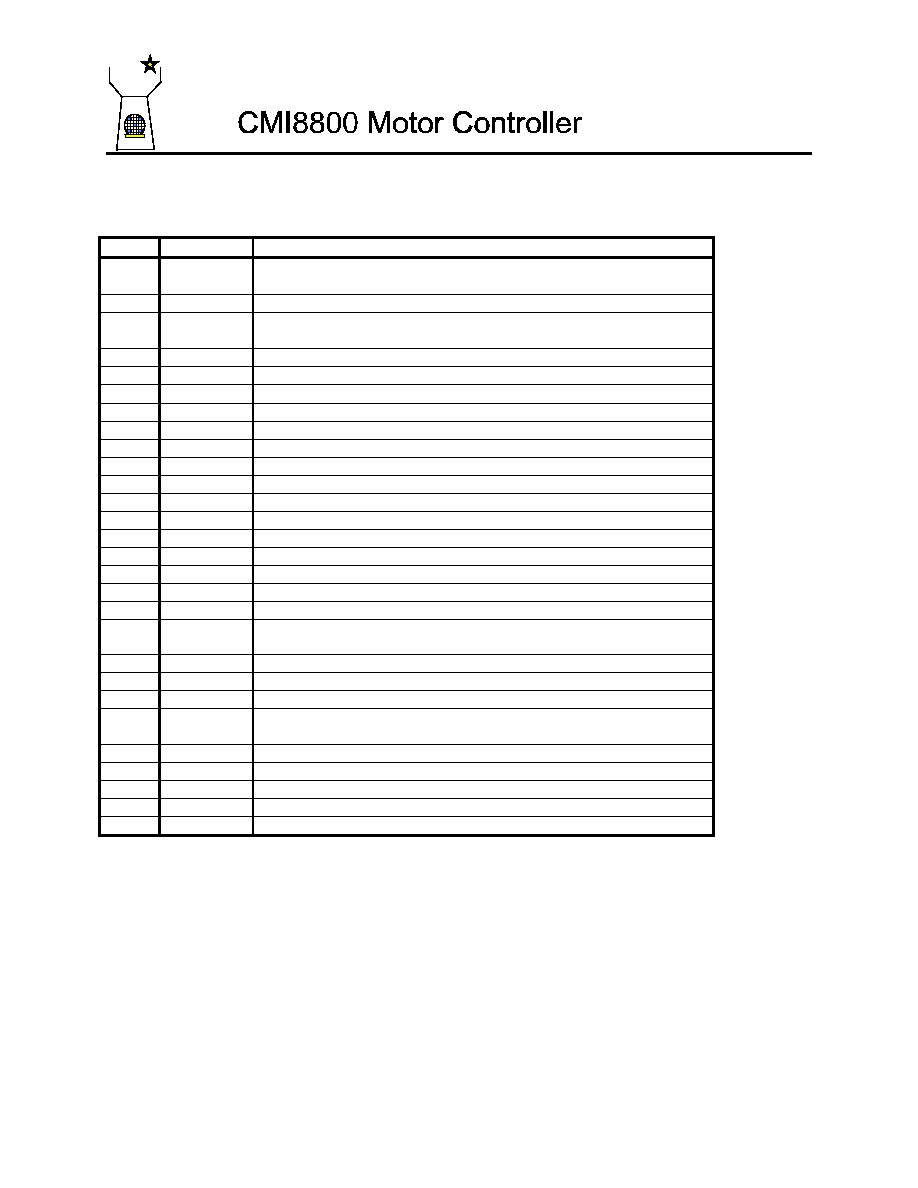

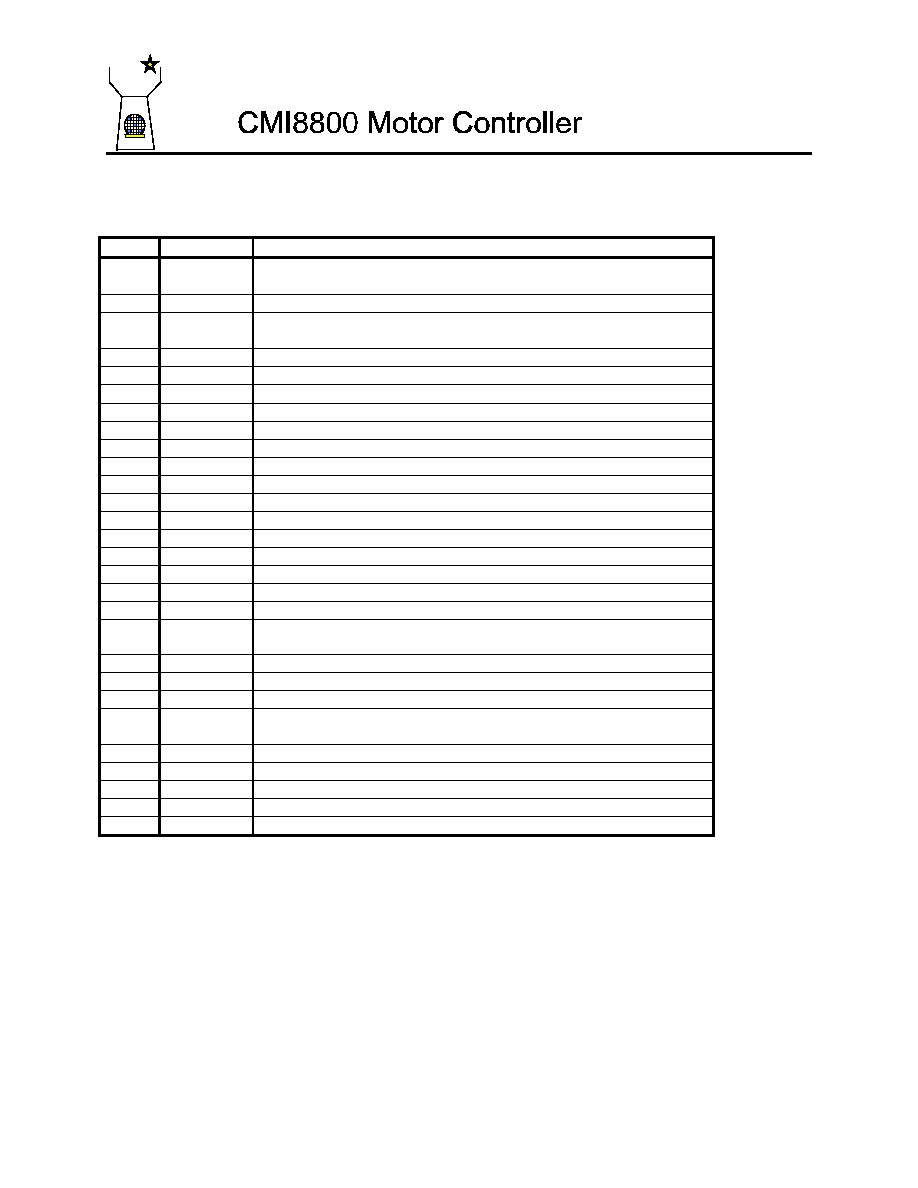

Pin Description

Pin #

Pin Name

Pin Description

1

LDIN

Input for the External Lead Network (for Single Phase Motor)

This Pin is left open for three phase motor applications

2

W

H-Bridge Power Driver Output (W)

3

LDOT

Output of External Lead Network (for Single Phase Motor)

This pin must be left open for three phase motor applications

4

V

H-Bridge Power Driver Output (V), NC for Single Phase Mode

5

NC

No Connection [This pin must be left open]

6

NC

No Connection [This pin must be left open]

7

U

H-Bridge Power Driver Output (U)

8

GND

Common Ground

9

H1+

Hall Amplifier #1 Positive Input

10

H1-

Hall Amplifier #1 Negative Input

11

H2+

Hall Amplifier #2 Positive Input

12

H2-

Hall Amplifier #2 Negative Input

13

H3+

Hall Amplifier #3 Positive Input

14

H3-

Hall Amplifier #3 Negative Input

15

VH

Hall Bias Generator Output (Open Collector Output)

16

BR

Brake Mode Control, High = Break Mode

17

CNF

Charge Pump Capacitor Between this Pin and Ground

18

SB

Short Brake Control Pin, High = Short Brake Mode

19

1P/3P~

Single Phase (1P)/Three Phase (3P) Control Pin

High = Single Phase. Default = Three Phase = Low

20

FR

Rotation Detection Pin

21

ECR

Reference Voltage to Torque Sense Amplifier

22

EC

Torque Control Input Terminal

23

PS~

Power Save or Sleep Mode Control

(Logic Low: Power Save or Sleeping Mode)

24

FG

FG Signal Output Pin

25

VCCI

5V Power Supply for Internal Core Circuitry

26

VCCM2

12V Power Supply for H-Bridge Motor (Power) Driver

27

VCCM1

12V Power Supply for Internal Core Circuitry

28

RNF

Motor Current Sense Resistor

Note: FIN

ý

ý

GND