CAT28C257

1

CAT28C257

256K-Bit CMOS PARALLEL EEPROM

FEATURES

s

Fast read access times: 120/150 ns

s

Low power CMOS dissipation:

Active: 25 mA max.

Standby: 150

µ

A max.

s

Simple write operation:

On-chip address and data latches

Self-timed write cycle with auto-clear

s

Fast write cycle time:

5ms max

s

CMOS and TTL compatible I/O

s

Automatic page write operation:

1 to 128 Bytes in 5ms

Page load timer

s

End of write detection:

Toggle bit

DATA

DATA

DATA

DATA

DATA

polling

s

Hardware and software write protection

s

100,000 Program/erase cycles

s

100 Year data retention

s

Commercial, industrial and automotive

temperature ranges

DESCRIPTION

The CAT28C257 is a fast, low power, 5V-only CMOS

Parallel EEPROM organized as 32K x 8-bits. It requires a

simple interface for in-system programming. On-chip

address and data latches, self-timed write cycle with auto-

clear and V

CC

power up/down write protection eliminate

additional timing and protection hardware.

DATA

Polling

and Toggle status bits signal the start and end of the self-

timed write cycle. Additionally, the CAT28C257 features

hardware and software write protection.

The CAT28C257 is manufactured using Catalyst's

advanced CMOS floating gate technology. It is designed

to endure 100,000 program/erase cycles and has a data

retention of 100 years. The device is available in JEDEC

approved 28-pin DIP or 32-pin PLCC packages.

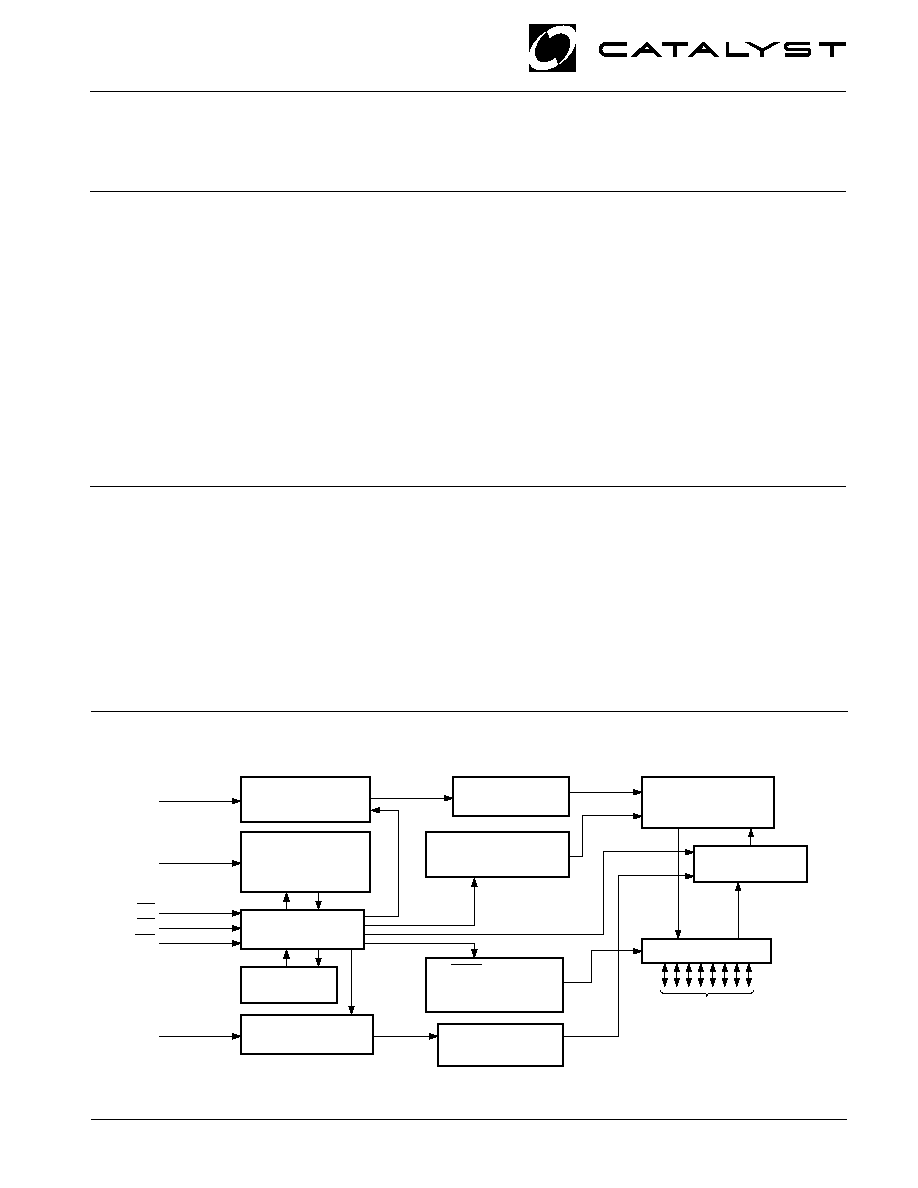

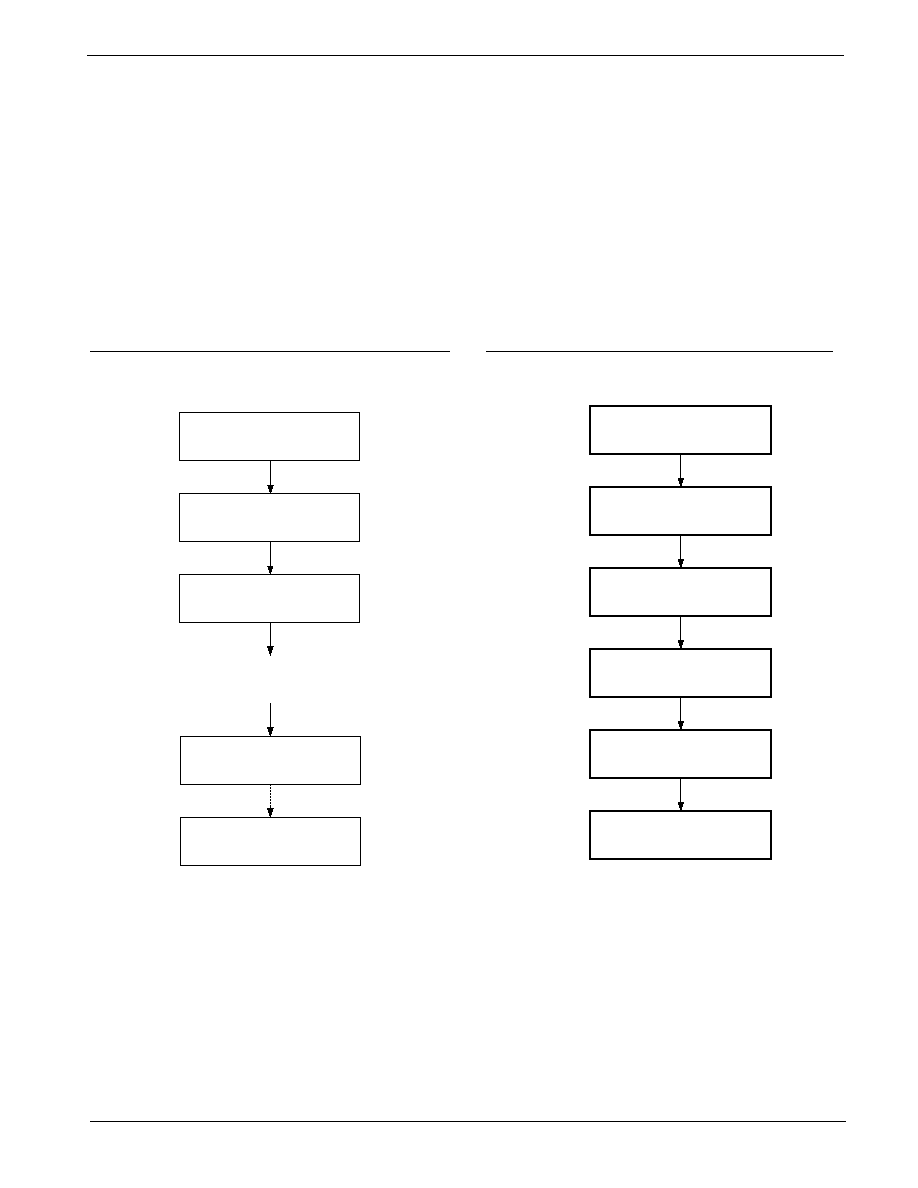

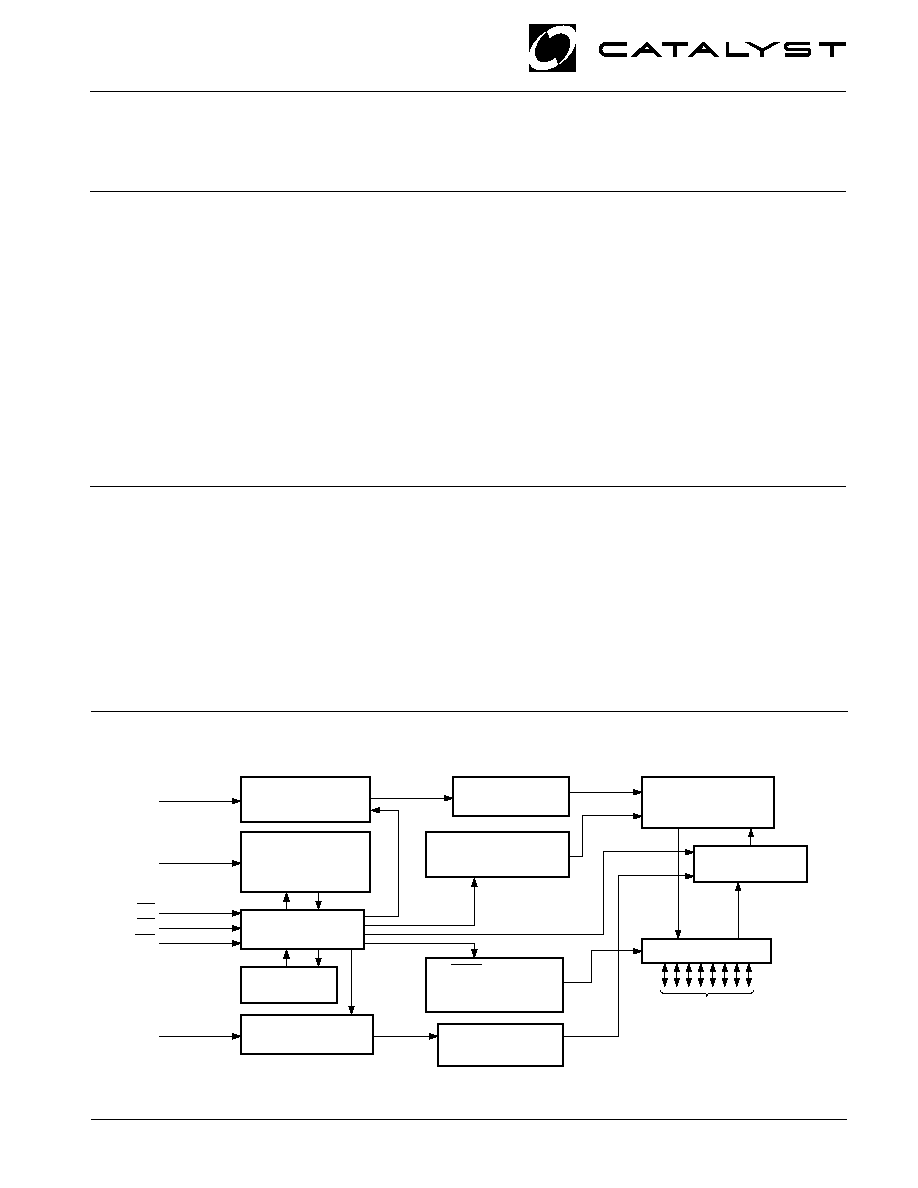

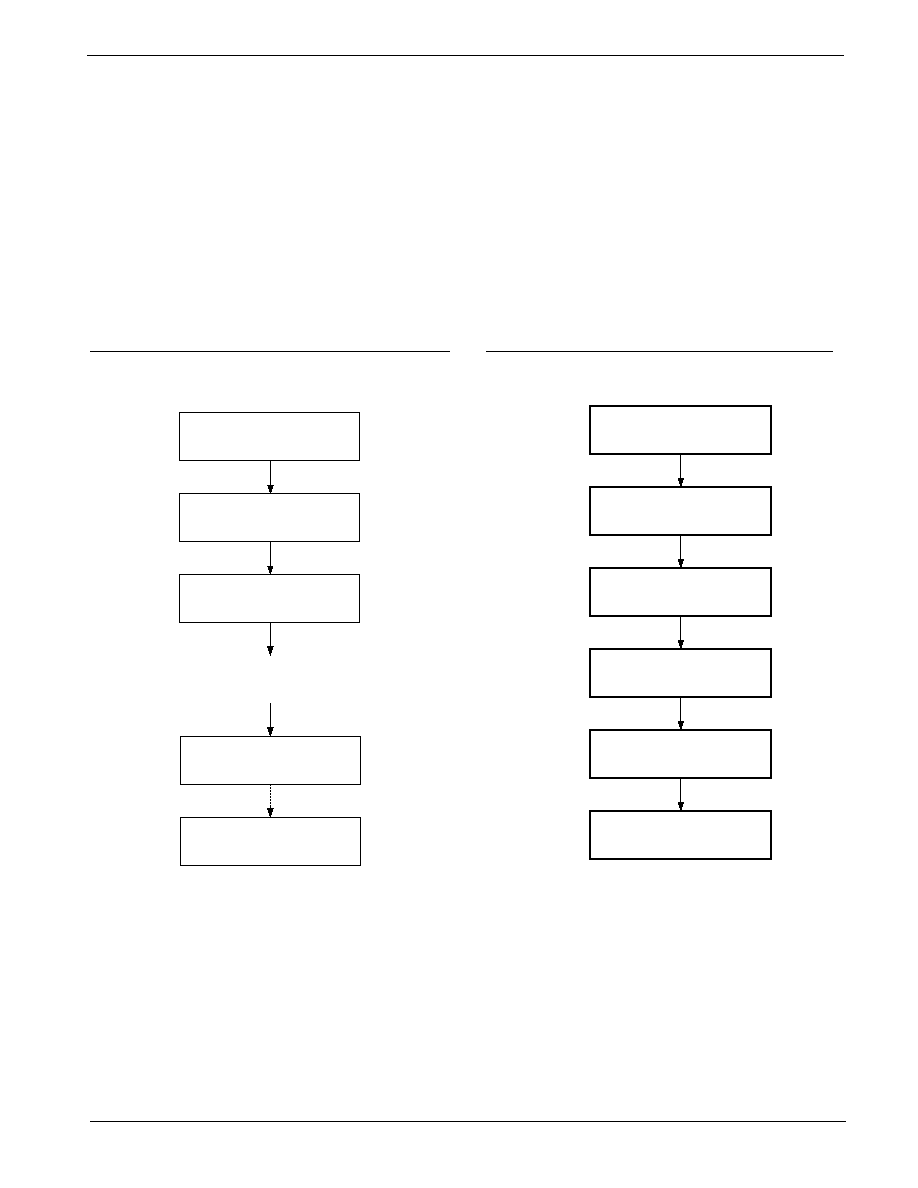

BLOCK DIAGRAM

5096 FHD F02

© 2002 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

ADDR. BUFFER

& LATCHES

ADDR. BUFFER

& LATCHES

INADVERTENT

WRITE

PROTECTION

CONTROL

LOGIC

TIMER

ROW

DECODER

COLUMN

DECODER

HIGH VOLTAGE

GENERATOR

A7A14

CE

OE

WE

A0A6

I/O0I/O7

I/O BUFFERS

32,768 x 8

E

2

PROM

ARRAY

128 BYTE PAGE

REGISTER

VCC

DATA POLLING

AND

TOGGLE BIT

Doc. No. 1015, Rev. B

CAT28C257

2

Doc. No. 1015, Rev. B

5096 FHD F01

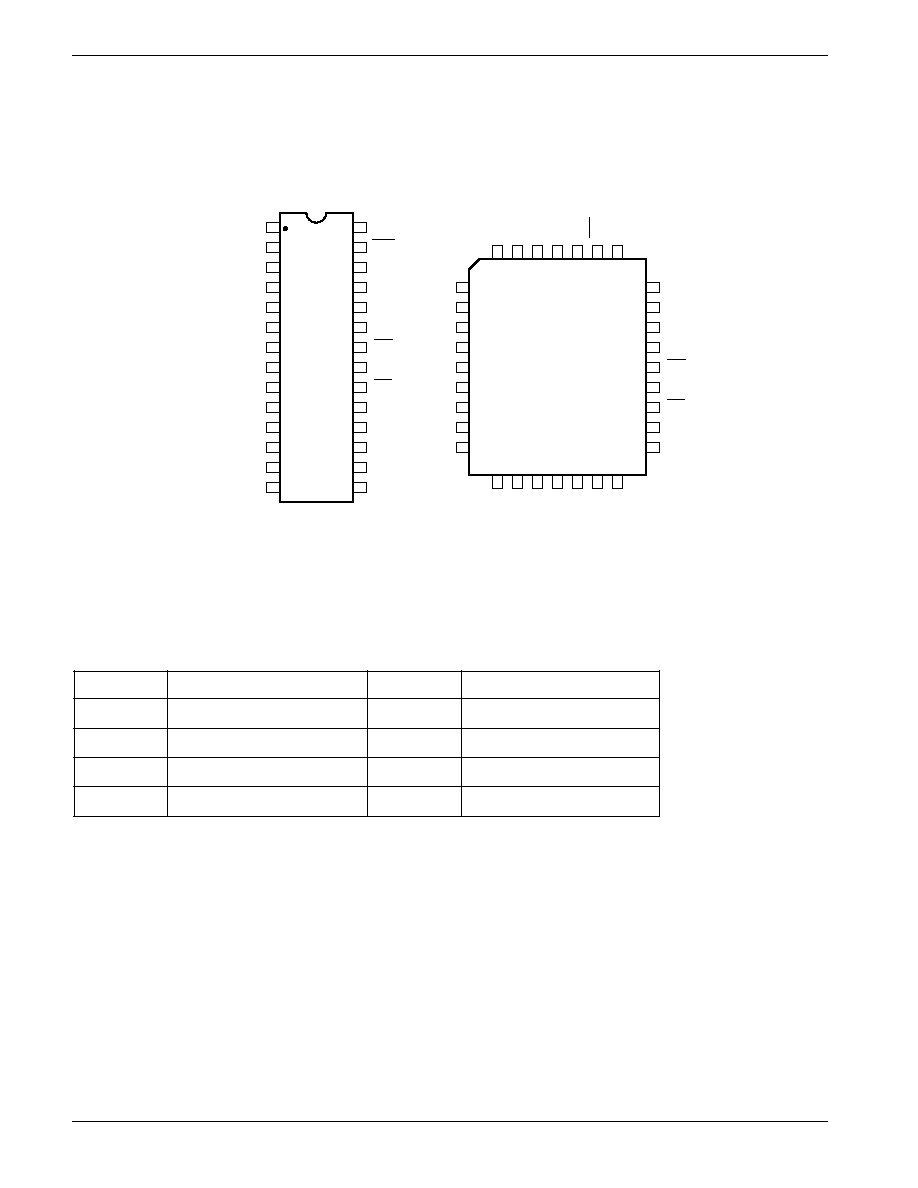

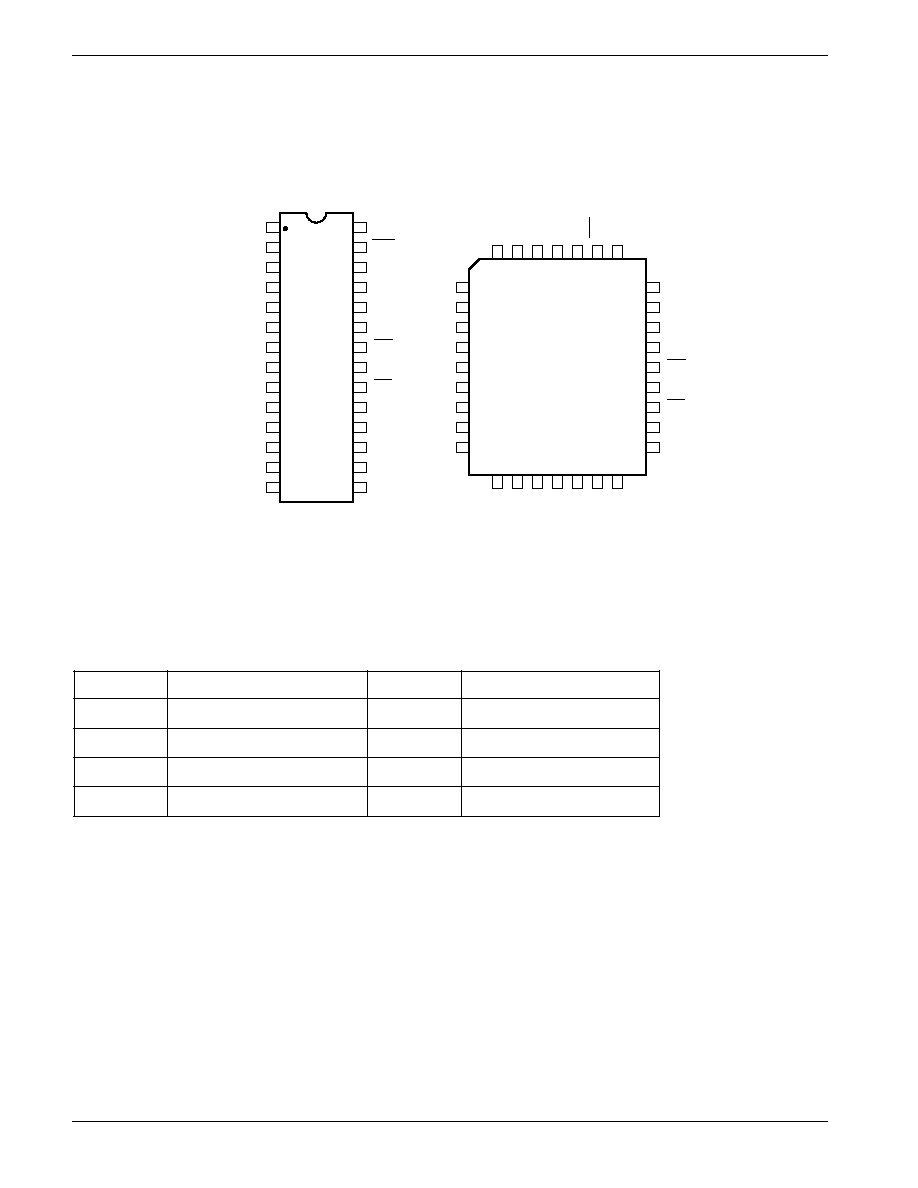

PIN CONFIGURATION

PLCC Package (N)

DIP Package (P)

I/O2

VSS

I/O6

I/O5

13

14

20

19

18

17

9

10

11

12

24

23

22

21

A1

A0

I/O0

I/O1

OE

A10

CE

I/O7

A5

A4

A3

A2

5

6

7

8

1

2

3

4

A14

A12

A7

A6

A9

A11

28

27

26

25

VCC

WE

A13

A8

A6

A5

A4

A3

5

6

7

8

A2

A1

A0

NC

9

10

11

12

I/O0

13

A8

A9

A11

NC

29

28

27

26

OE

A10

CE

25

24

23

22

I/O7

21

I/O

1

I/O

2

V

SS

NC

I/O

3

I/O

4

I/O

5

14 15 16 17 18 19 20

4

3

2

1 32 31 30

A

7

A

12

A

14

NC

V

CC

WE

A

13

I/O4

I/O3

16

15

I/O6

PIN FUNCTIONS

Pin Name

Function

A

0

A

14

Address Inputs

I/O

0

I/O

7

Data Inputs/Outputs

CE

Chip Enable

OE

Output Enable

Pin Name

Function

WE

Write Enable

V

CC

5V Supply

V

SS

Ground

NC

No Connect

CAT28C257

3

Doc. No. 1015, Rev. B

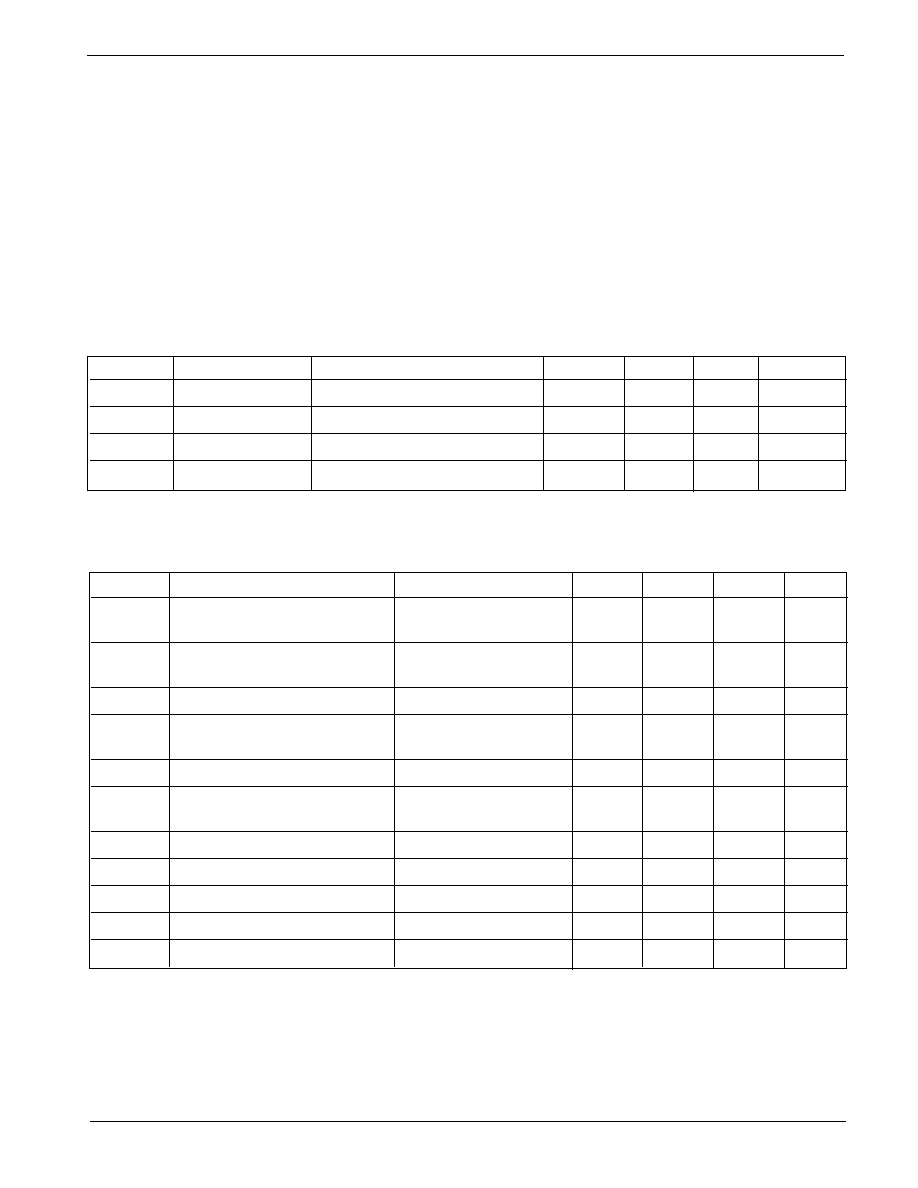

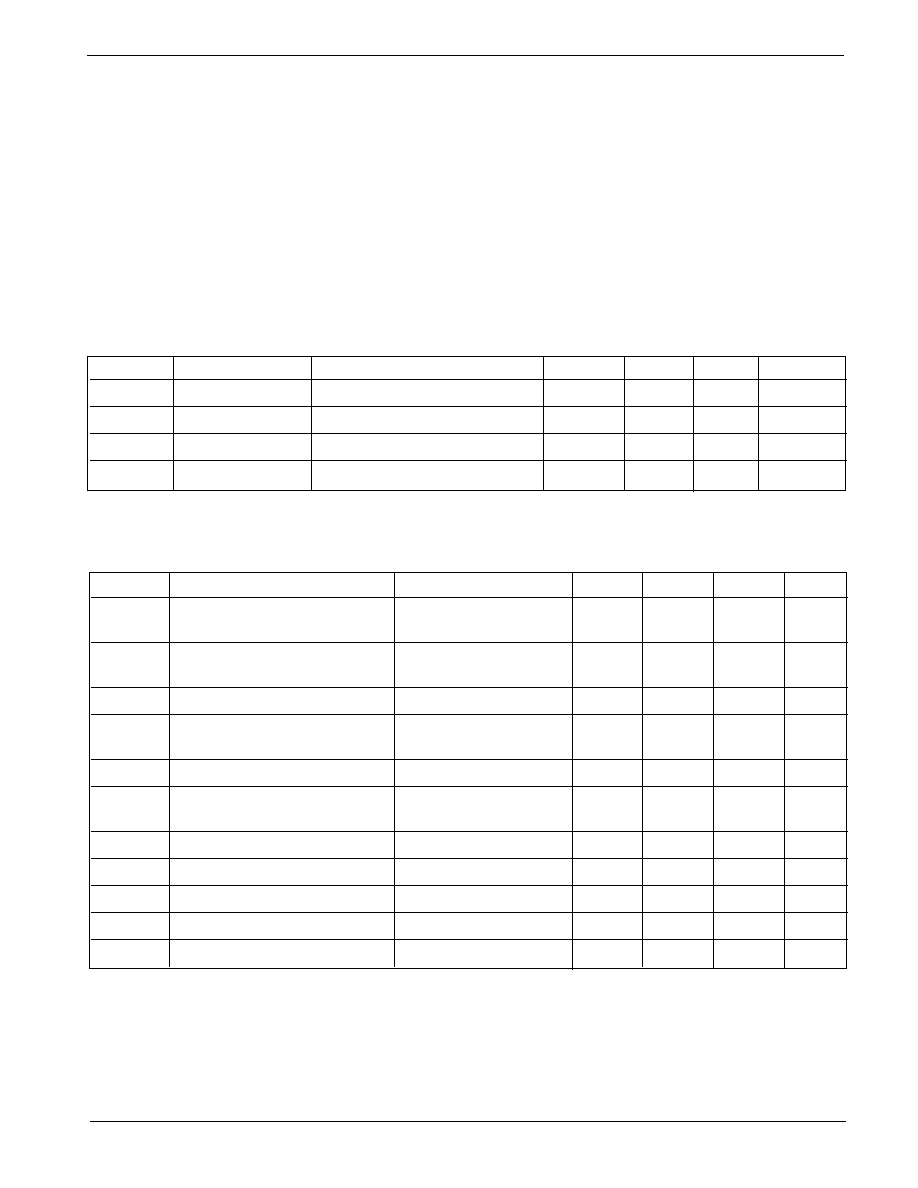

D.C. OPERATING CHARACTERISTICS

V

CC

= 5V

±

10%, unless otherwise specified.

Symbol

Parameter

Test Conditions

Min

Typ

Max

Units

I

CC

V

CC

Current (Operating, TTL)

CE

=

OE

= V

IL

, f=6MH

z

30

mA

All I/O's Open

I

CCC

(5)

V

CC

Current (Operating, CMOS)

CE

=

OE

= V

ILC

, f=6MH

z

25

mA

All I/O's Open

I

SB

V

CC

Current (Standby, TTL)

CE

= V

IH

, All I/O's Open

1

mA

I

SBC

(6)

V

CC

Current (Standby, CMOS)

CE

= V

IHC

,

150

µ

A

All I/O's Open

I

LI

Input Leakage Current

V

IN

= GND to V

CC

10

10

µ

A

I

LO

Output Leakage Current

V

OUT

= GND to V

CC

,

10

10

µ

A

CE = V

IH

V

IH

(6)

High Level Input Voltage

2

V

CC

+0.3

V

V

IL

(5)

Low Level Input Voltage

0.3

0.8

V

V

OH

High Level Output Voltage

I

OH

= 400

µ

A

2.4

V

V

OL

Low Level Output Voltage

I

OL

= 2.1mA

0.4

V

V

WI

Write Inhibit Voltage

3.5

V

*COMMENT

Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device.

These are stress ratings only, and functional operation

of the device at these or any other conditions outside of

those listed in the operational sections of this specifica-

tion is not implied. Exposure to any absolute maximum

rating for extended periods may affect device perfor-

mance and reliability.

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias .................. -55

°

C to +125

°

C

Storage Temperature ........................ -65

°

C to +150

°

C

Voltage on Any Pin with

Respect to Ground

(2)

............ -2.0V to +V

CC

+ 2.0V

V

CC

with Respect to Ground ................ -2.0V to +7.0V

Package Power Dissipation

Capability (Ta = 25

°

C) ................................... 1.0W

Lead Soldering Temperature (10 secs) ............ 300

°

C

Output Short Circuit Current

(3)

........................ 100 mA

RELIABILITY CHARACTERISTICS

Symbol

Parameter

Test Method

Min

Typ

Max

Units

N

END

(1)

Endurance

MIL-STD-883, Test Method 1033 10

4

or 10

5

Cycles/Byte

T

DR

(1)

Data Retention

MIL-STD-883, Test Method 1008

100

Years

V

ZAP

(1)

ESD Susceptibility

MIL-STD-883, Test Method 3015

2000

Volts

I

LTH

(1)(4)

Latch-Up

JEDEC Standard 17

100

mA

Note:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

(2) The minimum DC input voltage is 0.5V. During transitions, inputs may undershoot to 2.0V for periods of less than 20 ns. Maximum DC

voltage on output pins is V

CC

+0.5V, which may overshoot to V

CC

+2.0V for periods of less than 20 ns.

(3) Output shorted for no more than one second. No more than one output shorted at a time.

(4) Latch-up protection is provided for stresses up to 100mA on address and data pins from 1V to V

CC

+1V.

(5) V

ILC

= 0.3V to +0.3V.

(6) V

IHC

= V

CC

0.3V to V

CC

+0.3V.

CAT28C257

4

Doc. No. 1015, Rev. B

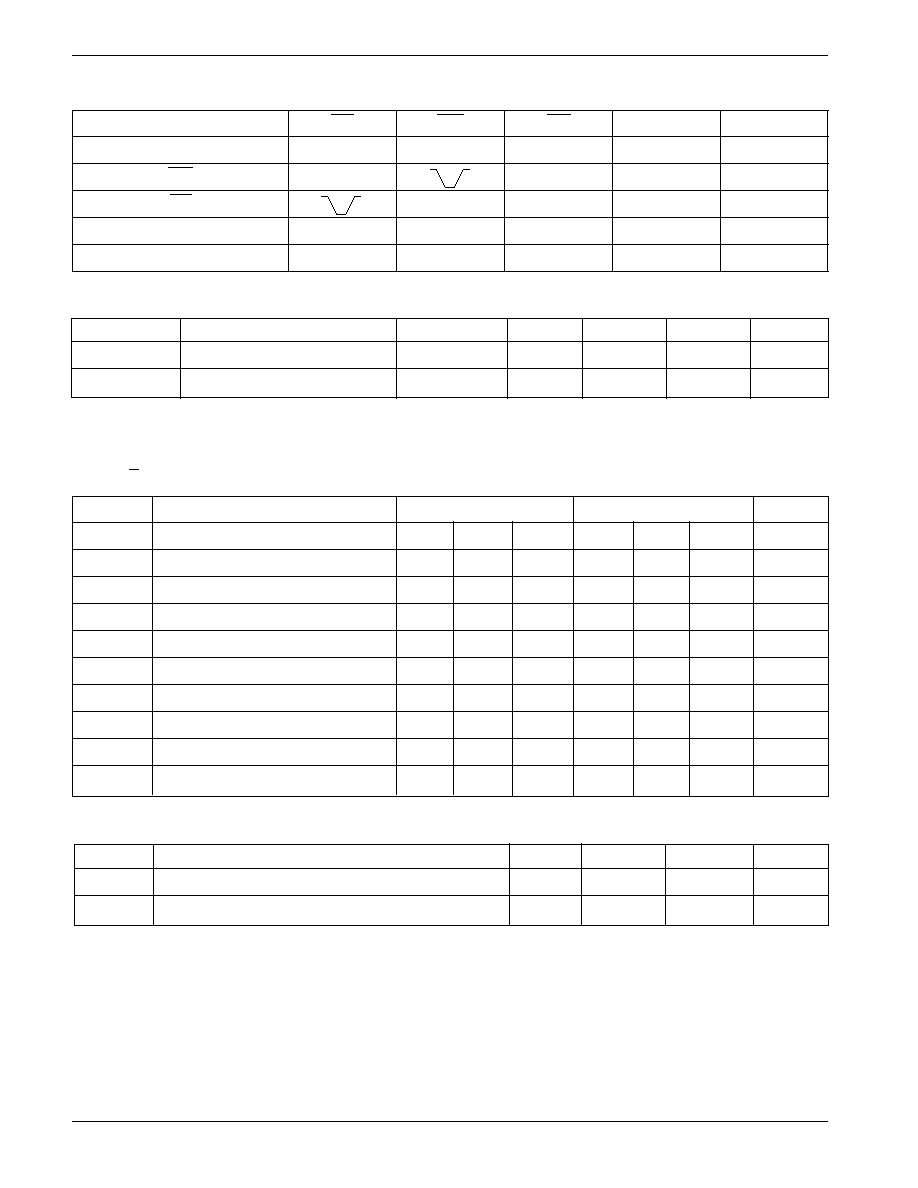

CAPACITANCE T

A

= 25

°

C, f = 1.0 MHz, V

CC

= 5V

Symbol

Test

Conditions

Min

Typ

Max

Units

C

I/O

(1)

Input/Output Capacitance

V

I/O

= 0V

10

pF

C

IN

(1)

Input Capacitance

V

IN

= 0V

6

pF

MODE SELECTION

Mode

CE

WE

OE

I/O

Power

Read

L

H

L

D

OUT

ACTIVE

Byte Write (WE Controlled)

L

H

D

IN

ACTIVE

Byte Write (CE Controlled)

L

H

D

IN

ACTIVE

Standby, and Write Inhibit

H

X

X

High-Z

STANDBY

Read and Write Inhibit

X

H

H

High-Z

ACTIVE

Note:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

(2) Output floating (High-Z) is defined as the state when the external data line is no longer driven by the output buffer.

28C257-12

28C257-15

Symbol

Parameter

Min

Typ

Max

Min

Typ

Max

Units

t

RC

Read Cycle Time

120

150

ns

t

CE

CE

Access Time

120

150

ns

t

AA

Address Access Time

120

150

ns

t

OE

OE

Access Time

50

70

ns

t

LZ

(1)

CE

Low to Active Output

0

0

ns

t

OLZ

(1)

OE

Low to Active Output

0

0

ns

t

HZ

(1)(2)

CE

High to High-Z Output

50

50

ns

t

OHZ

(1)(2)

OE

High to High-Z Output

50

50

ns

t

OH

(1)

Output Hold from Address Change

0

0

ns

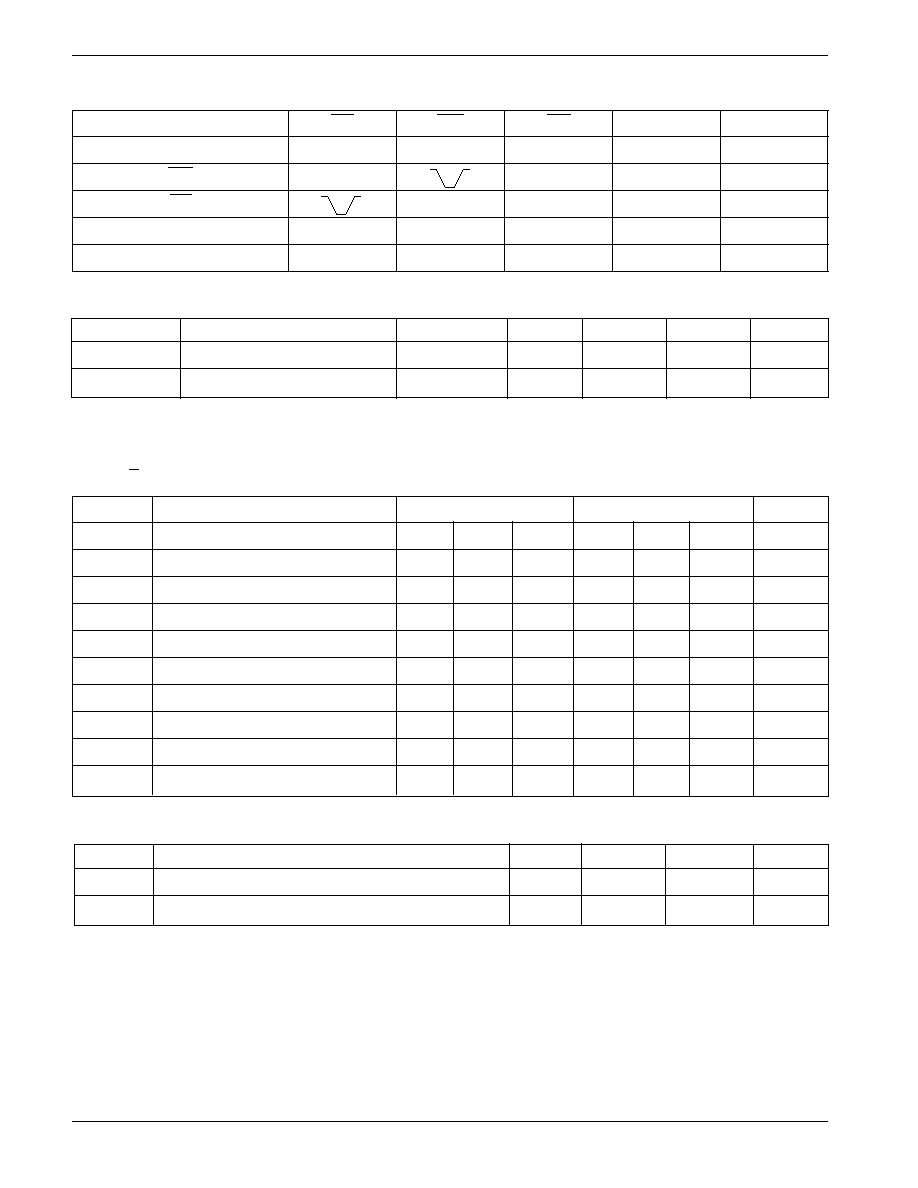

A.C. CHARACTERISTICS, Read Cycle

V

CC

=5V + 10%, Unless otherwise specified

Symbol

Parameter

Min

Typ

Max

Units

t

PUR

Power-Up to Read

100

µ

s

t

PUW

Power-Up to Write

5

10

ms

Power-Up Timing

CAT28C257

5

Doc. No. 1015, Rev. B

Note:

(1)

This parameter is tested initially and after a design or process change that affects the parameter.

(2)

Input rise and fall times (10% and 90%) < 10 ns.

(3)

A write pulse of less than 20ns duration will not initiate a write cycle.

(4)

A timer of duration t

BLC

max. begins with every LOW to HIGH transition of WE. If allowed to time out, a page or byte write will begin;

however a transition from HIGH to LOW within t

BLC

max. stops the timer.

5096 FHD F04

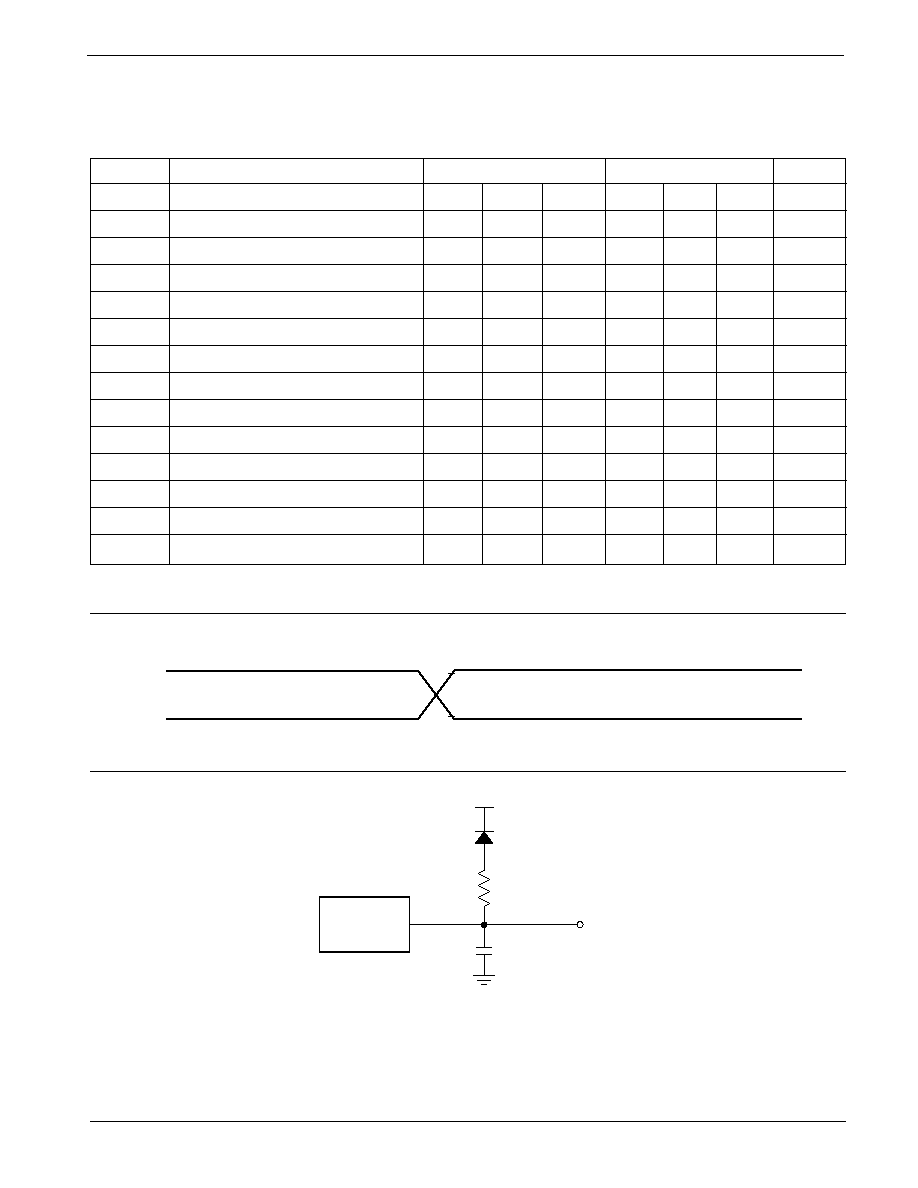

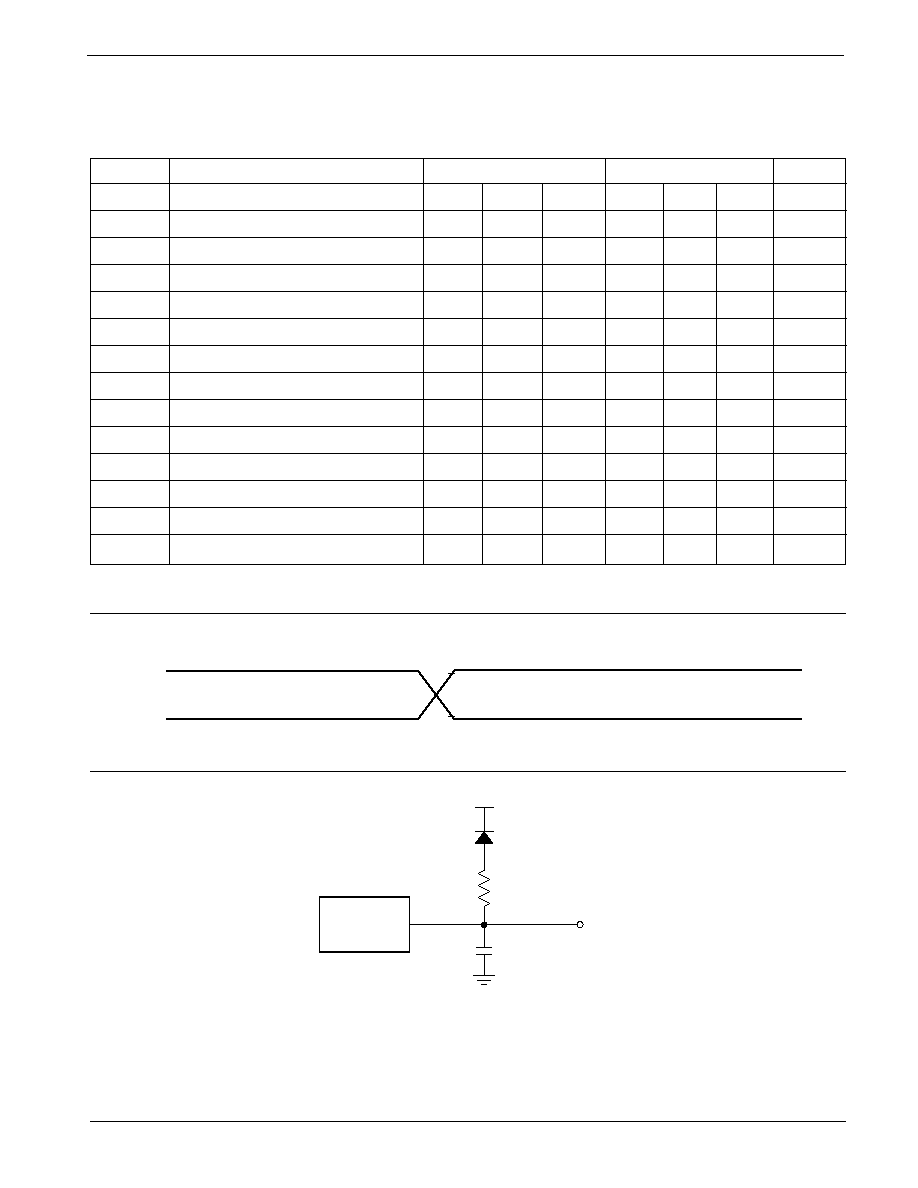

Figure 1. A.C. Testing Input/Output Waveform(2)

1.3V

DEVICE

UNDER

TEST

1N914

3.3K

CL = 100 pF

OUT

CL INCLUDES JIG CAPACITANCE

Figure 2. A.C. Testing Load Circuit (example)

INPUT PULSE LEVELS

REFERENCE POINTS

2.0 V

0.8 V

2.4 V

0.45 V

5096 FHD F03

A.C. CHARACTERISTICS, Write Cycle

V

CC

=5V

±

10%, unless otherwise specified

28C257-12

28C257-15

Symbol

Parameter

Min

Typ

Max

Min

Typ

Max

Units

t

WC

Write Cycle Time

5

5

ms

t

AS

Address Setup Time

0

0

ns

t

AH

Address Hold Time

50

50

ns

t

CS

CE

Setup Time

0

0

ns

t

CH

CE

Hold Time

0

0

ns

t

CW

(3)

CE

Pulse Time

100

100

ns

t

OES

OE

Setup Time

0

0

ns

t

OEH

OE

Hold Time

0

0

ns

t

WP

(3)

WE

Pulse Width

100

100

ns

t

DS

Data Setup Time

50

50

ns

t

DH

Data Hold Time

0

0

ns

t

INIT

(1)

Write Inhibit Period After Power-up

5

10

5

10

ms

t

BLC

(1)(4)

Byte Load Cycle Time

0.1

100

0.1

100

µ

s

CAT28C257

6

Doc. No. 1015, Rev. B

ADDRESS

CE

OE

WE

tRC

DATA OUT

DATA VALID

DATA VALID

tCE

tOE

tOH

tAA

tOHZ

tHZ

VIH

HIGH-Z

tLZ

tOLZ

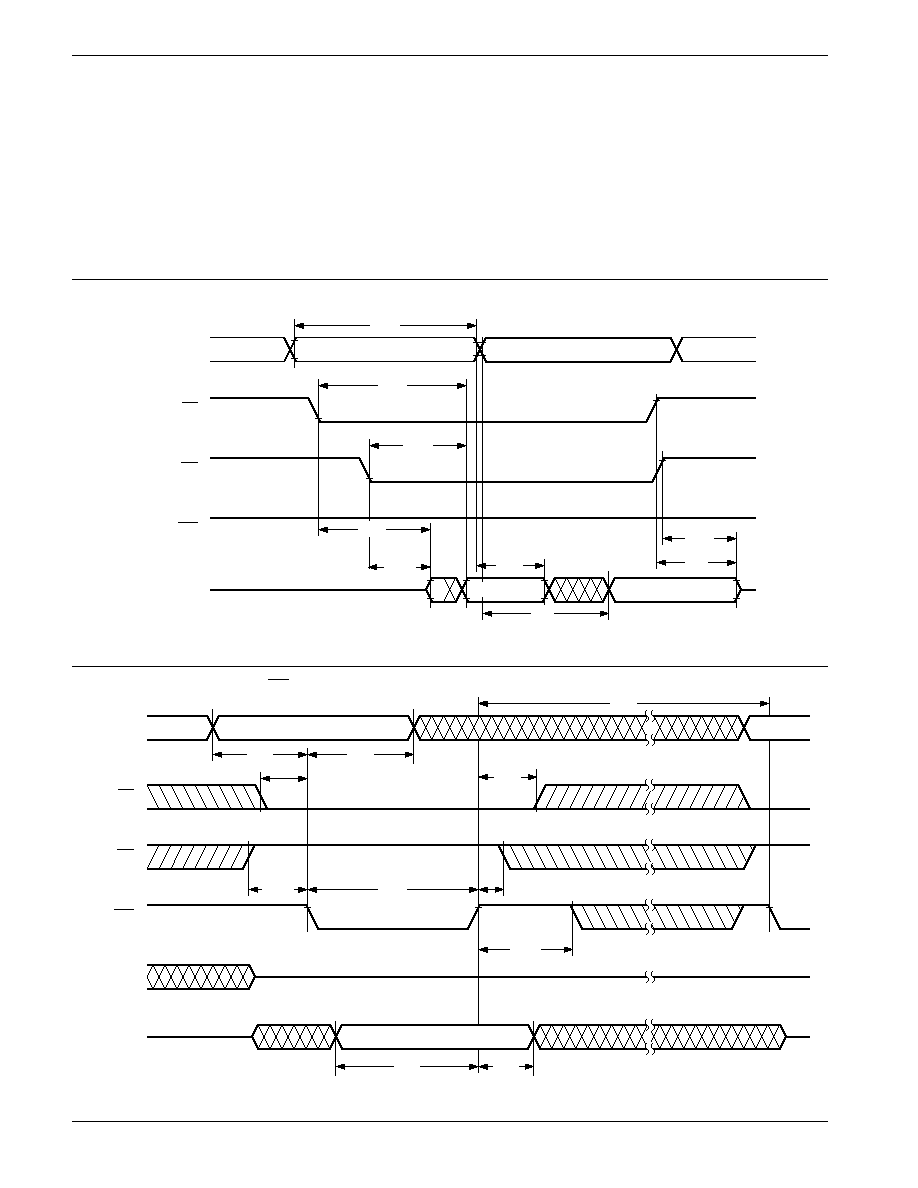

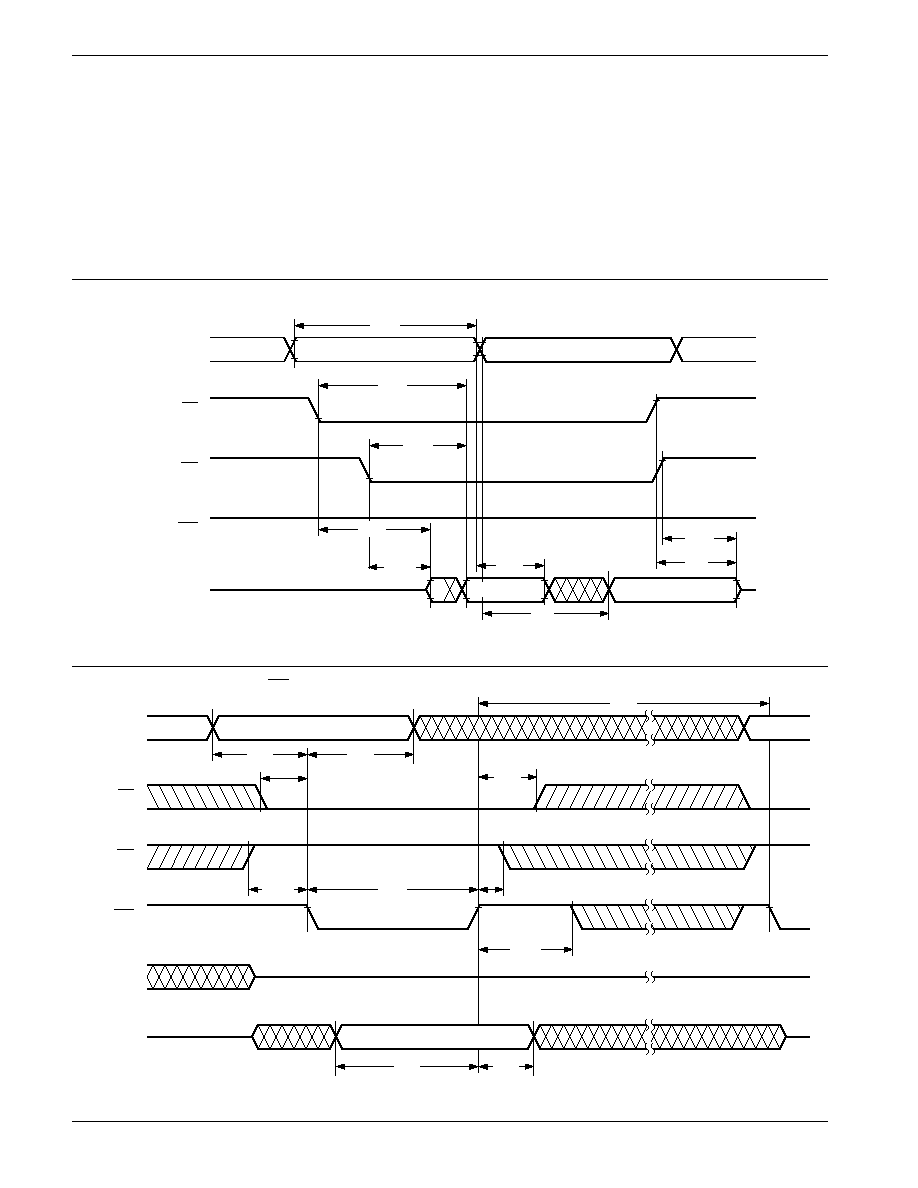

DEVICE OPERATION

Read

Data stored in the CAT28C257 is transferred to the data

bus when

WE

is held high, and both

OE

and

CE

are

held low. The data bus is set to a high impedance state

when either

CE

or

OE

goes high. This 2-line control

architecture can be used to eliminate bus contention in

a system environment.

Byte Write

A write cycle is executed when both

CE

and

WE

are low,

and

OE

is high. Write cycles can be initiated using either

WE

or

CE

, with the address input being latched on the

falling edge of

WE

or

CE

, whichever occurs last. Data,

conversely, is latched on the rising edge of

WE

or

CE

,

whichever occurs first. Once initiated, a byte write cycle

automatically erases the addressed byte and the new

data is written within 5 ms.

Figure 3. Read Cycle

Figure 4. Byte Write Cycle [WE Controlled]

ADDRESS

CE

OE

WE

DATA OUT

tAS

DATA IN

DATA VALID

HIGH-Z

tCS

tAH

tCH

tWC

tOEH

tBLC

tDH

tDS

tOES

tWP

5096 FHD F06

28C257 F06

CAT28C257

7

Doc. No. 1015, Rev. B

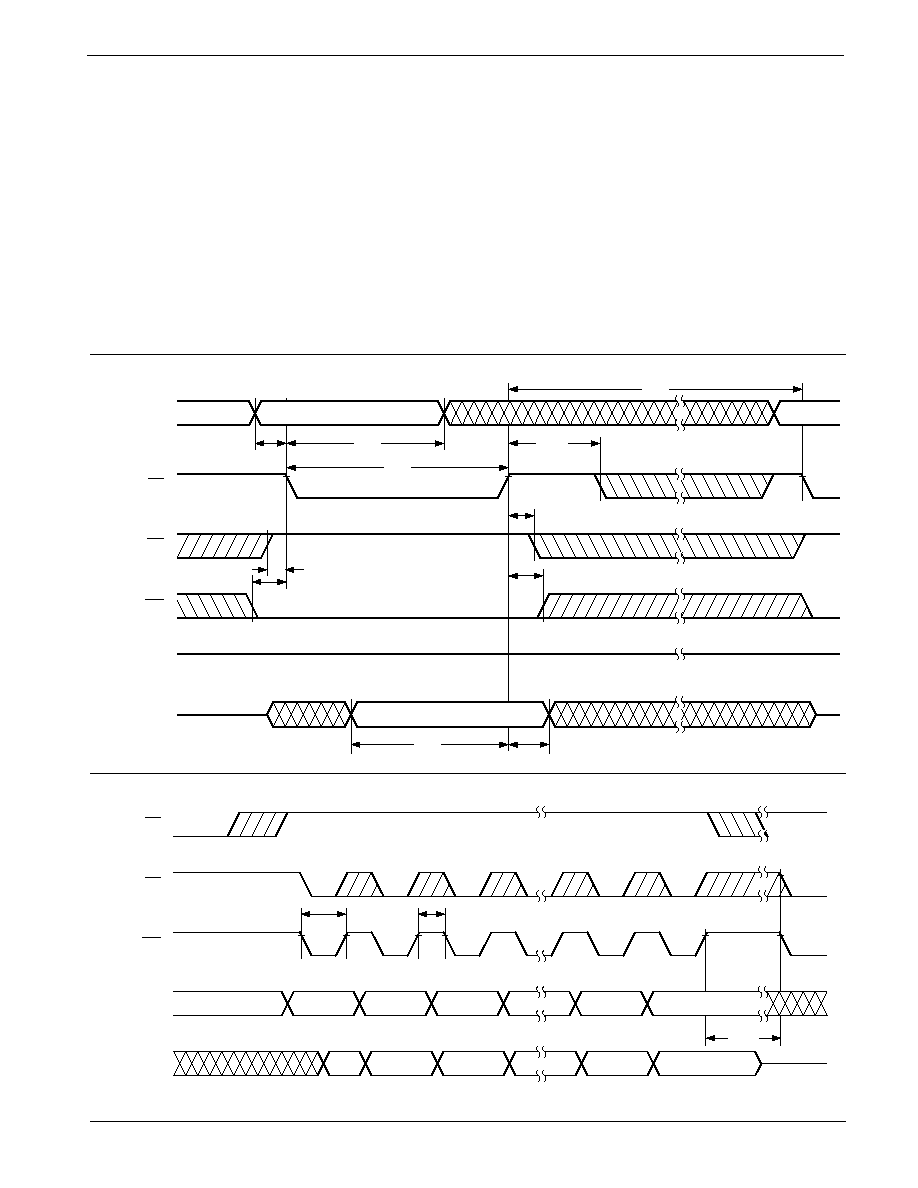

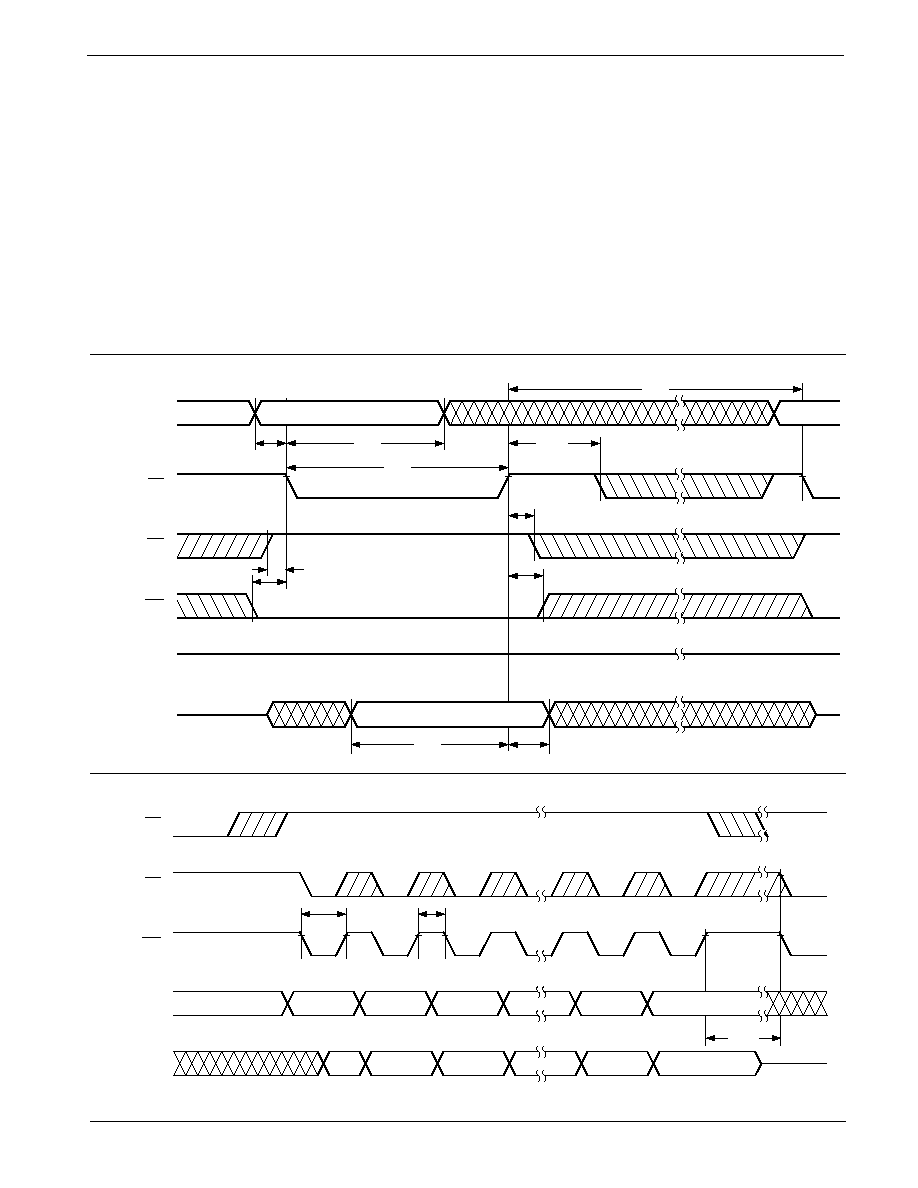

Page Write

The page write mode of the CAT28C257 (essentially an

extended BYTE WRITE mode) allows from 1 to 128

bytes of data to be programmed within a single E

2

PROM

write cycle. This effectively reduces the byte-write time

by a factor of 128.

Following an initial WRITE operation (

WE

pulsed low, for

t

WP

, and then high) the page write mode can begin by

issuing sequential

WE

pulses, which load the address

and data bytes into a128 byte temporary buffer. The

page address where data is to be written, specified by

bits A

7

to A

14

, is latched on the last falling edge of

WE

.

Each byte within the page is defined by address bits A

0

to A

6

(which can be loaded in any order) during the first

and subsequent write cycles. Each successive byte load

cycle must begin within t

BLC MAX

of the falling edge of the

preceding

WE

pulse. There is no page write window

limitation as long as

WE

is pulsed low within t

BLC MAX

.

Upon completion of the page write sequence,

WE

must

stay high a minimum of t

BLC MAX

for the internal automatic

program cycle to commence. This programming cycle

consists of an erase cycle, which erases any data that

existed in each addressed cell, and a write cycle, which

writes new data back into the cell. A page write will only

write data to the locations that were addressed and will

not rewrite the entire page.

Figure 5. Byte Write Cycle [

CE

CE

CE

CE

CE

Controlled]

5096 FHD F07

Figure 6. Page Mode Write Cycle

OE

CE

WE

ADDRESS

I/O

tWP

tBLC

BYTE 0

BYTE 1

BYTE 2

BYTE n

BYTE n+1

BYTE n+2

LAST BYTE

tWC

5096 FHD F10

ADDRESS

CE

OE

WE

DATA OUT

tAS

DATA IN

DATA VALID

HIGH-Z

tAH

tWC

tOEH

tDH

tDS

tOES

tBLC

tCH

tCS

tCW

CAT28C257

8

Doc. No. 1015, Rev. B

WE

CE

OE

I/O6

tOEH

tOE

tOES

tWC

(1)

(1)

ADDRESS

CE

WE

OE

I/O7

DIN = X

DOUT = X

DOUT = X

tOE

tOEH

tWC

tOES

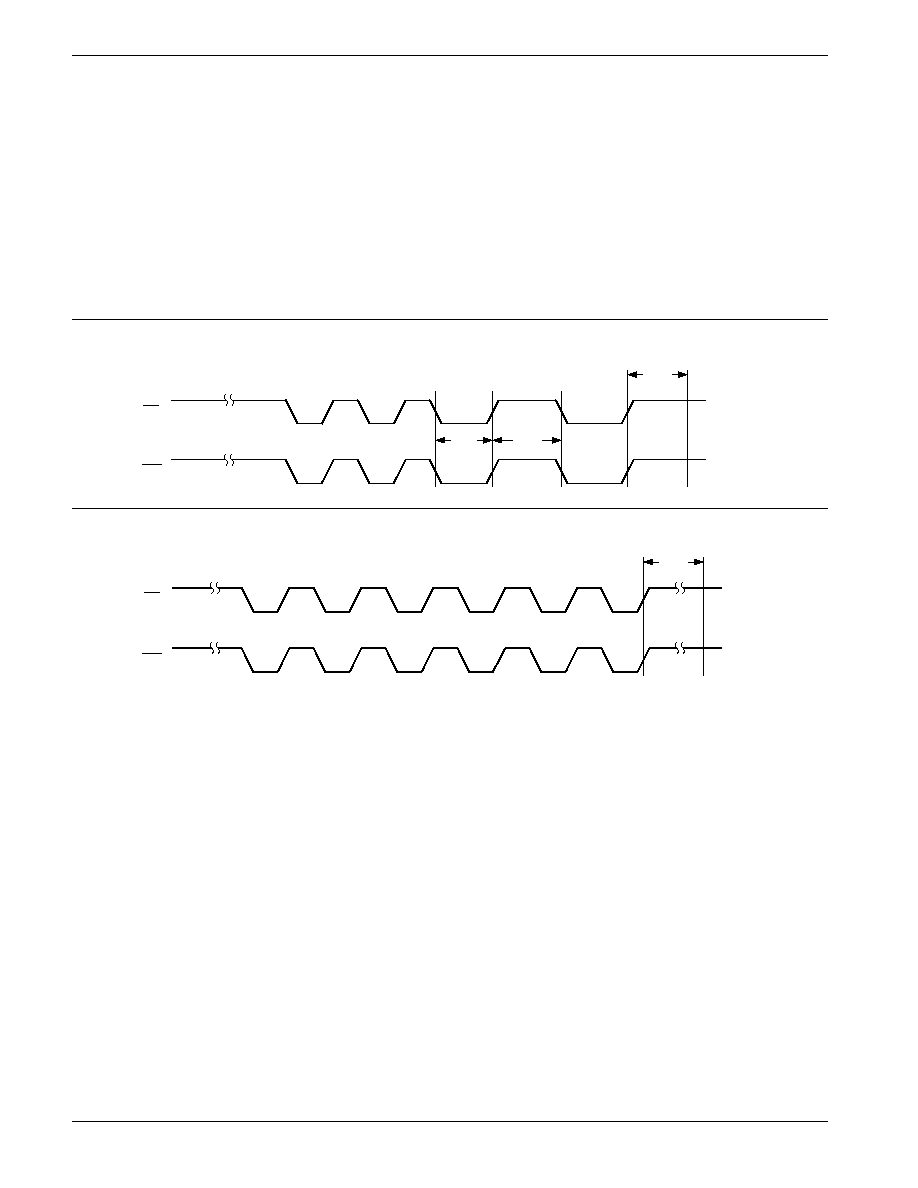

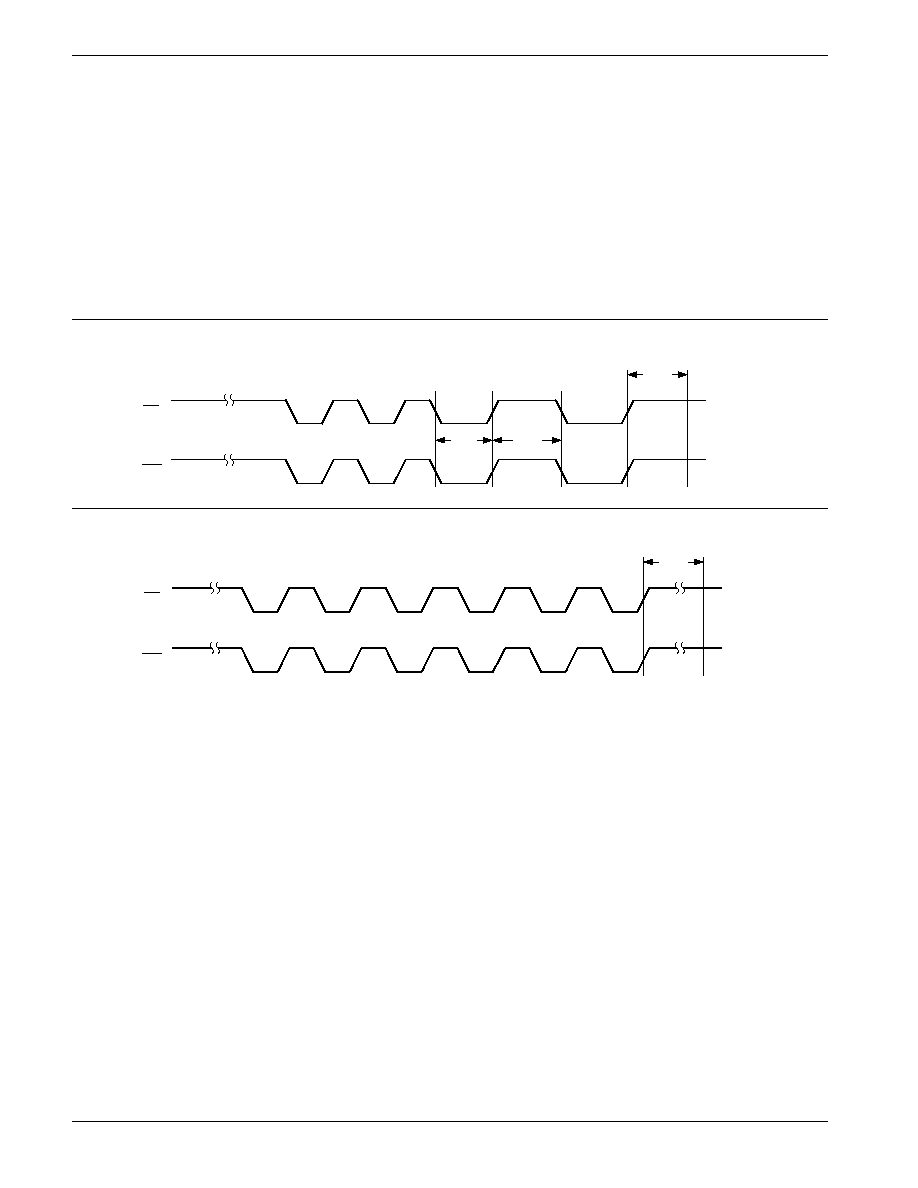

DATA Polling

DATA polling is provided to indicate the completion of

write cycle. Once a byte write or page write cycle is

initiated, attempting to read the last byte written will

output the complement of that data on I/O

7

(I/O

0

I/O

6

are indeterminate) until the programming cycle is

complete. Upon completion of the self-timed write cycle,

all I/O's will output true data during a read cycle.

Toggle Bit

In addition to the DATA Polling feature of the CAT28C257,

the device offers an additional method for determining

the completion of a write cycle. While a write cycle is in

progress, reading data from the device will result in I/O

6

toggling between one and zero. However, once the write

is complete, I/O

6

stops toggling and valid data can be

read from the device.

Figure 7. DATA Polling

28C257 F10

Figure 8. Toggle Bit

28C257 F11

Note:

(1)

Beginning and ending state of I/O

6

is indeterminate.

CAT28C257

9

Doc. No. 1015, Rev. B

Note:

(1)

Write protection is activated at this point whether or not any more writes are completed. Writing to addresses must occur within t

BLC

Max., after SDP activation.

HARDWARE DATA PROTECTION

The following is a list of hardware data protection features

that are incorporated into the CAT28C257.

(1) V

CC

sense provides for write protection when V

CC

falls below 3.5V min.

(2) A power on delay mechanism, t

INIT

(see AC

characteristics), provides a 5 to 10 ms delay before

a write sequence, after V

CC

has reached 3.5V min.

(3) Write inhibit is activated by holding any one of

OE

low,

CE

high or

WE

high.

(4) Noise pulses of less than 20 ns on the

WE

or

CE

inputs will not result in a write cycle.

SOFTWARE DATA PROTECTION

The CAT28C257 features a software controlled data

protection scheme which, once enabled, requires a data

algorithm to be issued to the device before a write can be

performed. The device is shipped from Catalyst with the

software protection NOT ENABLED (the CAT28C257 is

in the standard operating mode).

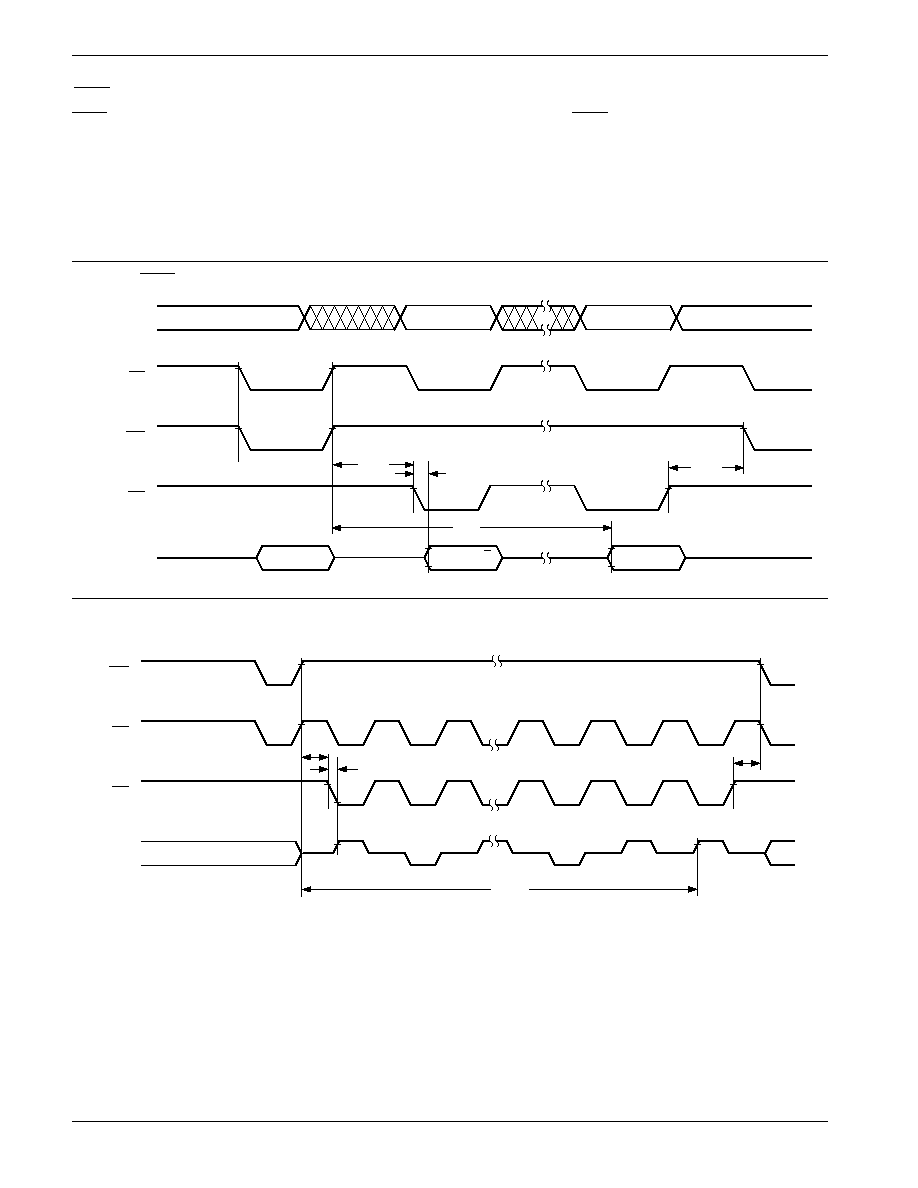

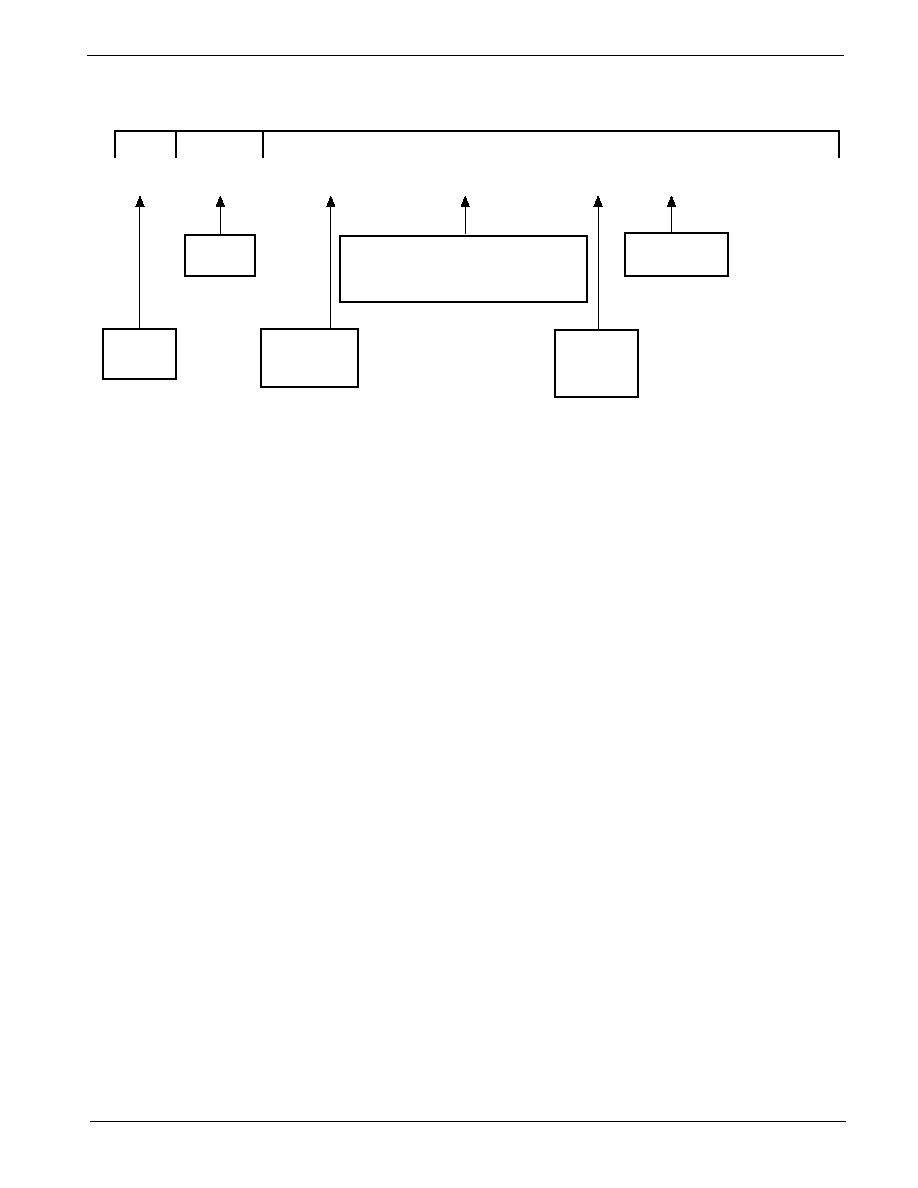

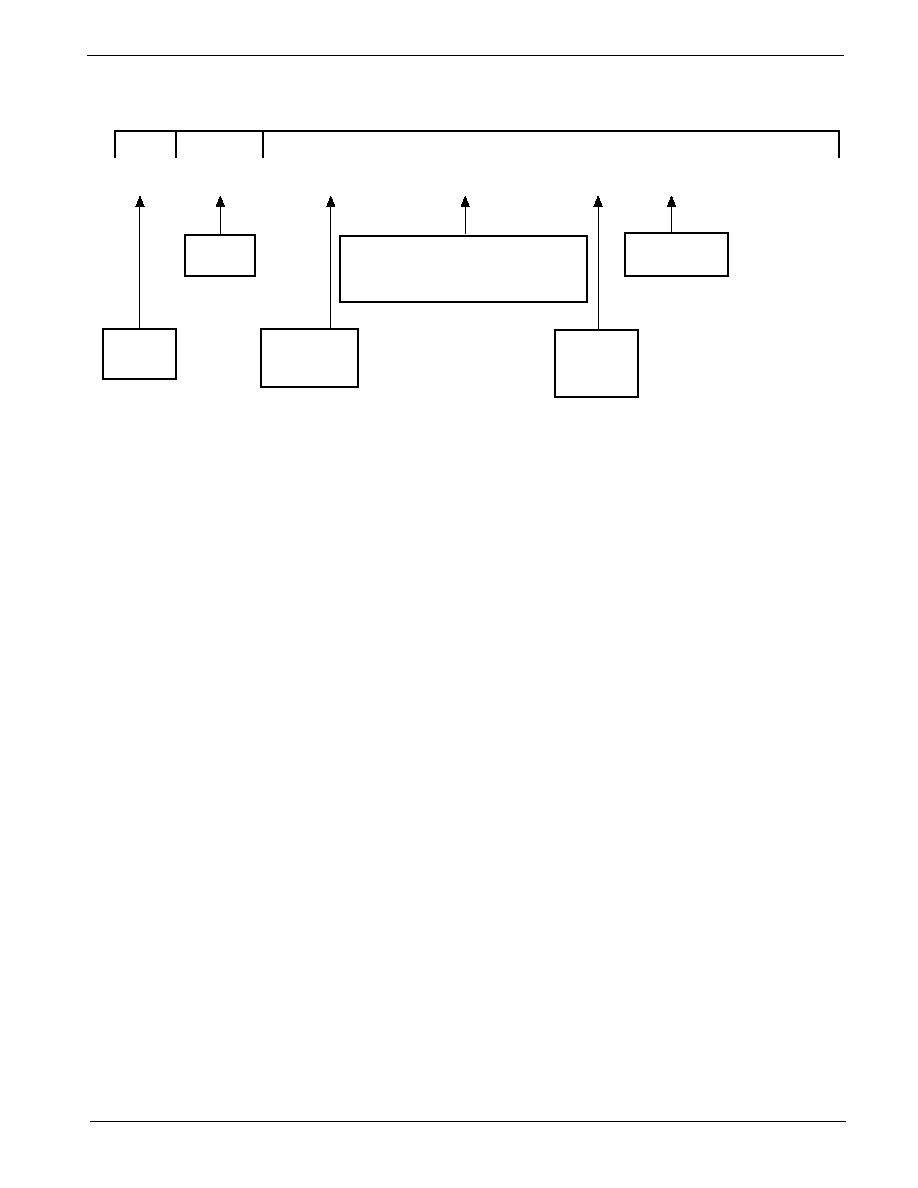

Figure 9. Write Sequence for Activating Software

Data Protection

Figure 10. Write Sequence for Deactivating

Software Data Protection

5096 FHD F08

5096 FHD F09

SOFTWARE DATA

PROTECTION ACTIVATED

(12)

WRITE DATA:

XX

WRITE LAST BYTE

TO

LAST ADDRESS

TO ANY ADDRESS

WRITE DATA:

AA

ADDRESS:

5555

WRITE DATA:

55

ADDRESS:

2AAA

WRITE DATA:

A0

ADDRESS:

5555

(1)

WRITE DATA:

AA

ADDRESS:

5555

WRITE DATA:

55

ADDRESS:

2AAA

WRITE DATA:

80

ADDRESS:

5555

WRITE DATA:

AA

ADDRESS:

5555

WRITE DATA:

55

ADDRESS:

2AAA

W R I T E DATA :

20

ADDRESS:

5555

CAT28C257

10

Doc. No. 1015, Rev. B

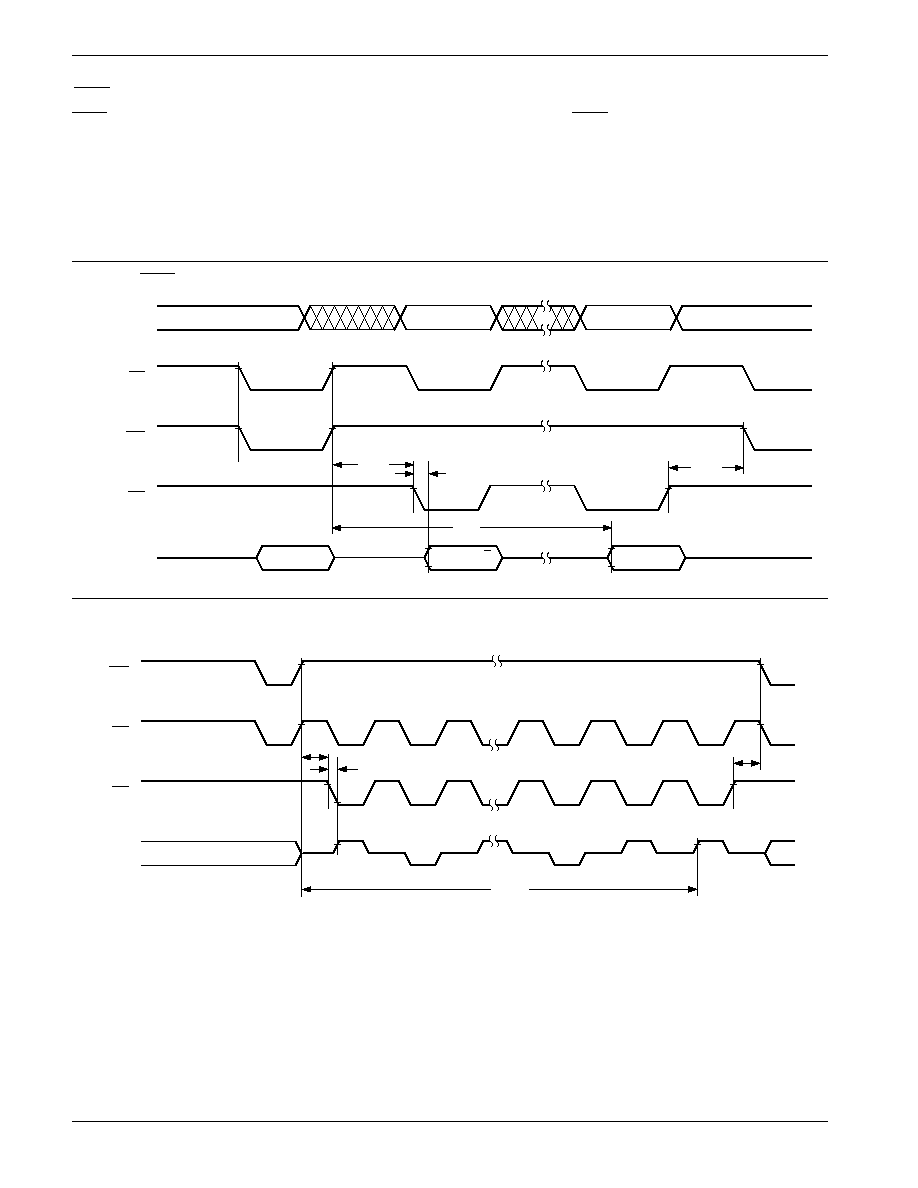

To activate the software data protection, the device must

be sent three write commands to specific addresses with

specific data (Figure 9). This sequence of commands

(along with subsequent writes) must adhere to the page

write timing specifications (Figure 11). Once this is done,

all subsequent byte or page writes to the device must be

preceded by this same set of write commands. The data

protection mechanism is activated until a deactivate

sequence is issued regardless of power on/off transitions.

This gives the user added inadvertent write protection

on power-up in addition to the hardware protection

provided.

To allow the user the ability to program the device with

an E

2

PROM programmer (or for testing purposes) there

is a software command sequence for deactivating the

data protection. The six step algorithm (Figure 10) will

reset the internal protection circuitry, and the device will

return to standard operating mode (Figure 12 provides

reset timing). After the sixth byte of this reset sequence

has been issued, standard byte or page writing can

commence.

Figure 11. Software Data Protection Timing

5096 FHD F13

CE

WE

tWP

AA

5555

55

2AAA

A0

5555

DATA

ADDRESS

tBLC

tWC

BYTE OR

PAGE

WRITES

ENABLED

Figure 12. Resetting Software Data Protection Timing

CE

WE

AA

5555

55

2AAA

DATA

ADDRESS

tWC

80

5555

AA

5555

55

2AAA

20

5555

SDP

RESET

DEVICE

UNPROTECTED

5096 FHD F14

CAT28C257

11

Doc. No. 1015, Rev. B

ORDERING INFORMATION

Notes:

(1)

The device used in the above example is a CAT28C257NI-90T (100,000 Cycle Endurance, PLCC, Industrial temperature, 200 ns

Access Time, Tape & Reel).

28C257 F17a

Speed

12: 120ns

15: 150ns

Prefix

Device #

Suffix

28C257

Product

Number

CAT

Optional

Company

ID

N

I

T

Tape & Reel

T: 500/Reel

Package

P: PDIP

N: PLCC

-90

Temperature Range

Blank = Commercial (0°C to +70°C)

I = Industrial (-40°C to +85°C)

A = Automotive (-40° to +105°C)*

* -40°C to +125°C is available upon request

Catalyst Semiconductor, Inc.

Corporate Headquarters

1250 Borregas Avenue

Sunnyvale, CA 94089

Phone: 408.542.1000

Fax: 408.542.1200

www.catalyst-semiconductor.com

Copyrights, Trademarks and Patents

Trademarks and registered trademarks of Catalyst Semiconductor include each of the following:

DPP TM

AE

2

TM

Catalyst Semiconductor has been issued U.S. and foreign patents and has patent applications pending that protect its products. For a complete list of patents

issued to Catalyst Semiconductor contact the Company's corporate office at 408.542.1000.

CATALYST SEMICONDUCTOR MAKES NO WARRANTY, REPRESENTATION OR GUARANTEE, EXPRESS OR IMPLIED, REGARDING THE SUITABILITY OF ITS

PRODUCTS FOR ANY PARTICULAR PURPOSE, NOR THAT THE USE OF ITS PRODUCTS WILL NOT INFRINGE ITS INTELLECTUAL PROPERTY RIGHTS OR THE

RIGHTS OF THIRD PARTIES WITH RESPECT TO ANY PARTICULAR USE OR APPLICATION AND SPECIFICALLY DISCLAIMS ANY AND ALL LIABILITY ARISING

OUT OF ANY SUCH USE OR APPLICATION, INCLUDING BUT NOT LIMITED TO, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Catalyst Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other application in which the failure of the Catalyst Semiconductor product could create a

situation where personal injury or death may occur.

Catalyst Semiconductor reserves the right to make changes to or discontinue any product or service described herein without notice. Products with data sheets

labeled "Advance Information" or "Preliminary" and other products described herein may not be in production or offered for sale.

Catalyst Semiconductor advises customers to obtain the current version of the relevant product information before placing orders. Circuit diagrams illustrate

typical semiconductor applications and may not be complete.

Publication #:

1015

Revison:

B

Issue date:

5/2/02

Type:

Final