| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CS51311 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Features

s

Synchronous Switching

Regulator Controller for

CPU V

CORE

s

Dual N-Channel MOSFET

Synchronous Buck Design

s

V

2

TM

Control Topology

s

200ns Transient Loop

Response

s

5-bit DAC with 1.2% Tolerance

s

Hiccup Mode Overcurrent

Protection

s

40ns Gate Rise and Fall Times

(3.3nF load)

s

65ns Adaptive FET

Non-overlap Time

s

Adaptive Voltage Positioning

s

Power-Good Output Monitors

Regulator Output

s

V

CC

Monitor Provides Under

Voltage Lockout

s

Enable Through use of the

COMP pin

Package Options

CS51311

Synchronous CPU Buck Controller

for 12V and 5V Applications

CS51311

Description

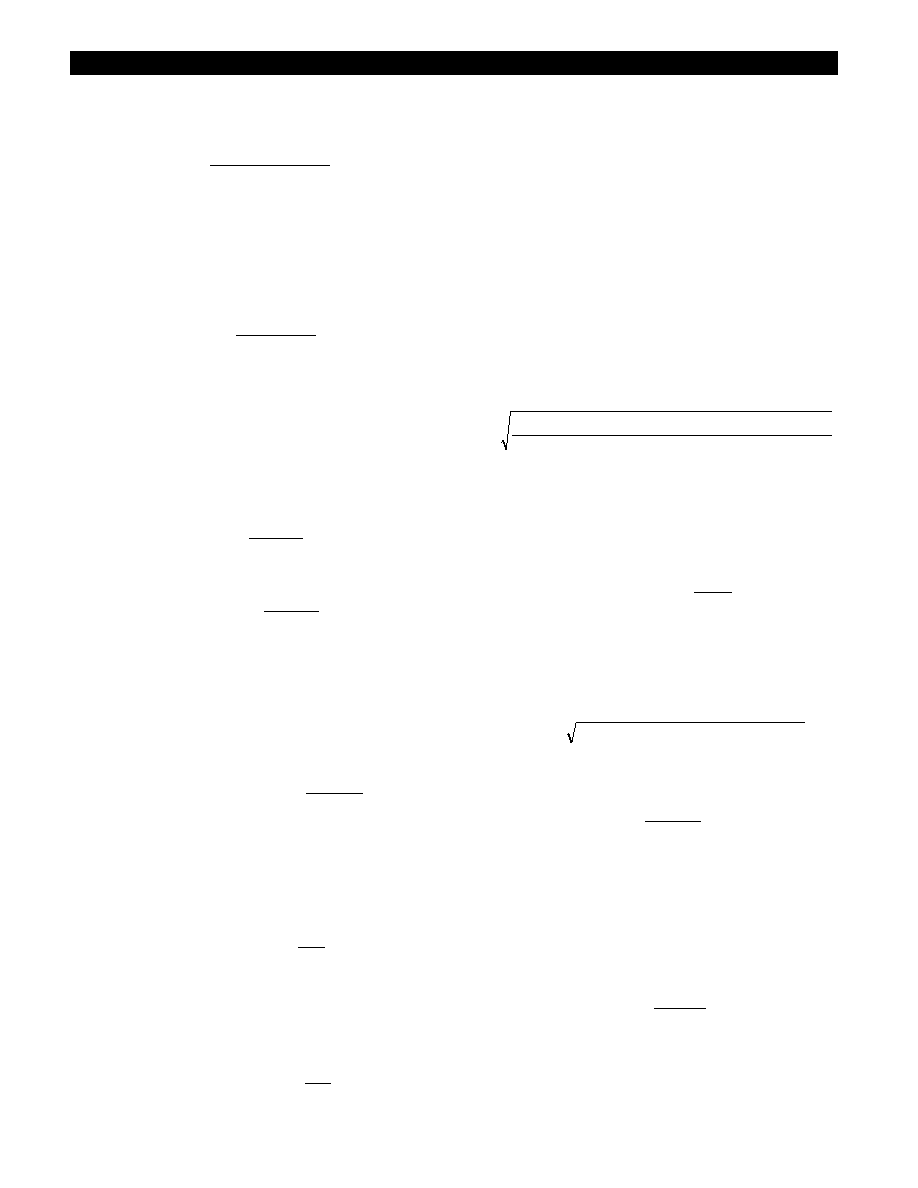

Application Diagram

V

OUT

VID0

VID1

VID2

VID3

V

CC

VID4

V

FB

COMP

C

OFF

PWRGD

Gnd

GATE(L)

GATE(H)

1

14 Lead SO Narrow

1

Pentium is a registered trademark of Intel Corporation.

A Company

Æ

V

2

is a trademark of Switch Power, Inc.

Rev. 3/11/99

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

The CS51311 is a synchronous dual

NFET Buck Regulator Controller. It is

designed to power the core logic of

the latest high performance CPUs. It

uses the V

2

TM

control method to

achieve the fastest possible transient

response and best overall regulation.

It incorporates many additional fea-

tures required to ensure the proper

operation and protection of the CPU

and Power system. The CS51311 pro-

vides the industry's most highly inte-

grated solution, minimizing external

component count, total solution size,

and cost.

The CS51311 is specifically designed

to power Intel's Pentium

Æ

II processor

and includes the following features:

5-bit DAC with 1.2% tolerance,

Power-Good output, over-current

hiccup mode protection, V

CC

monitor,

soft start, adaptive voltage position-

ing, adaptive FET non-overlap time,

and remote sense. The CS51311 will

operate over an 8.4V to 14V range

and is available in 14 lead narrow

body surface mount package.

680pF

GATE(H)

GATE(L)

V

FB

V

OUT

10K

1200

µ

F/10V

x3

3.3m

1.2

µ

H

FS70VSJ-03

FS70VSJ-03

510

0.1

µ

F

510

1200

µ

F/10V

x5

V

CC(CORE)

2.0V@19A

+5V

+12V

VID0

VID1

VID2

VID3

VID4

PWRGD

C

OFF

Gnd

V

CC

COMP

PWRGD

0.01

µ

F

1

µ

F

100

0.1

µ

F

2

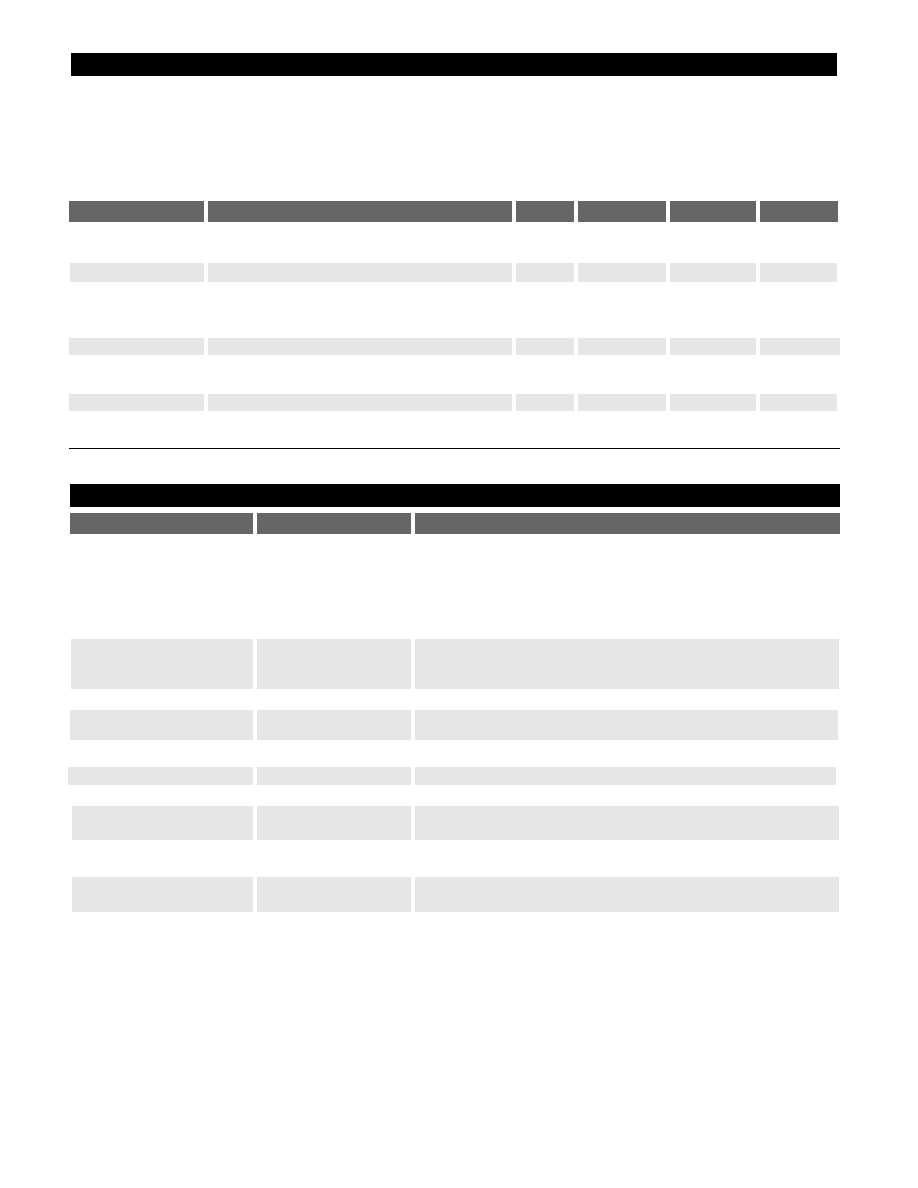

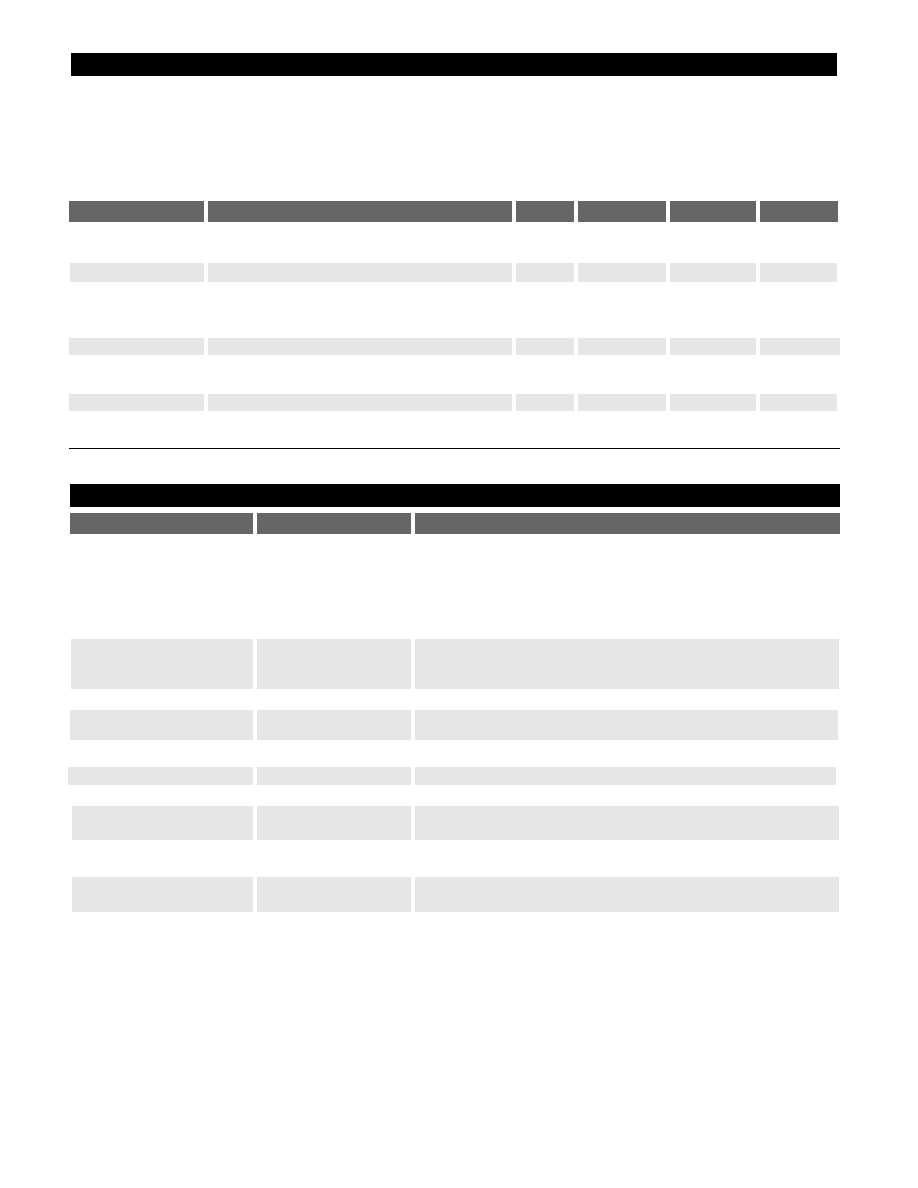

Package Pin Description

PACKAGE PIN #

PIN SYMBOL

FUNCTION

Absolute Maximum Ratings

Pin Symbol

Pin Name

V

MAX

V

MIN

I

SOURCE

I

SINK

CS51311

Operating Junction Temperature, T

J

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150∞C

Lead Temperature Soldering

Reflow (SMD styles only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 sec. max above 183∞C, 230∞C peak

Storage Temperature Range, T

S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65∞ to 150∞C

ESD Susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2kV

V

CC

IC Power Input

16V

-0.3V

N/A

1.5 APeak

200mA DC

COMP

Compensation Pin

6V

-0.3V

1mA

5mA

V

FB

, V

OUT

, V

ID0-4

Voltage Feedback Input, Output

6V

-0.3V

1mA

1mA

Voltage Sense Pin, Voltage

ID DAC Inputs

C

OFF

Off-Time Pin

6V

-0.3V

1mA

50mA

GATE(H), GATE(L) High-Side, Low-Side FET Drivers

16V

-0.3V DC

1.5APeak

1.5A Peak

200mA DC

200mA DC

PWRGD

Power-Good Output

6V

-0.3V

1mA

30mA

Gnd

Ground

0V

0V

1.5A Peak

N/A

200mA DC

1,2,3,4,5

V

IDO

≠ V

ID4

Voltage ID DAC inputs. These pins are internally pulled up to

5.65V if left open. V

ID4

selects the DAC range. When V

ID4

is

high (logic one), the Error Amp reference range is 2.125V to

3.525V with 100mV increments. When V

ID4

is low (logic zero),

the Error amp reference voltage is 1.325V to 2.075V with 50mV

increments.

6

V

FB

Error amp inverting input, PWM comparator non-inverting

input, current limit comparator non-inverting input, PWRGD

comparator input.

7

V

OUT

Current limit comparator inverting input.

8

V

CC

Input power supply pin for the internal circuitry.

Decouple with filter capacitor to Gnd.

9

GATE(H)

High side switch FET driver pin .

10

Gnd

Ground pin.

11

GATE(L)

Low side synchronous FET driver pin.

12

PWRGD

Power-Good Output. Open collector output drives low when

V

FB

is out of regulation.

13

C

OFF

Off-Time Capacitor Pin. A capacitor from this pin to Gnd sets

the off time for the regulator

14

COMP

Error amp output. PWM comparator inverting input.

A capacitor on this pin provides error amp compensation.

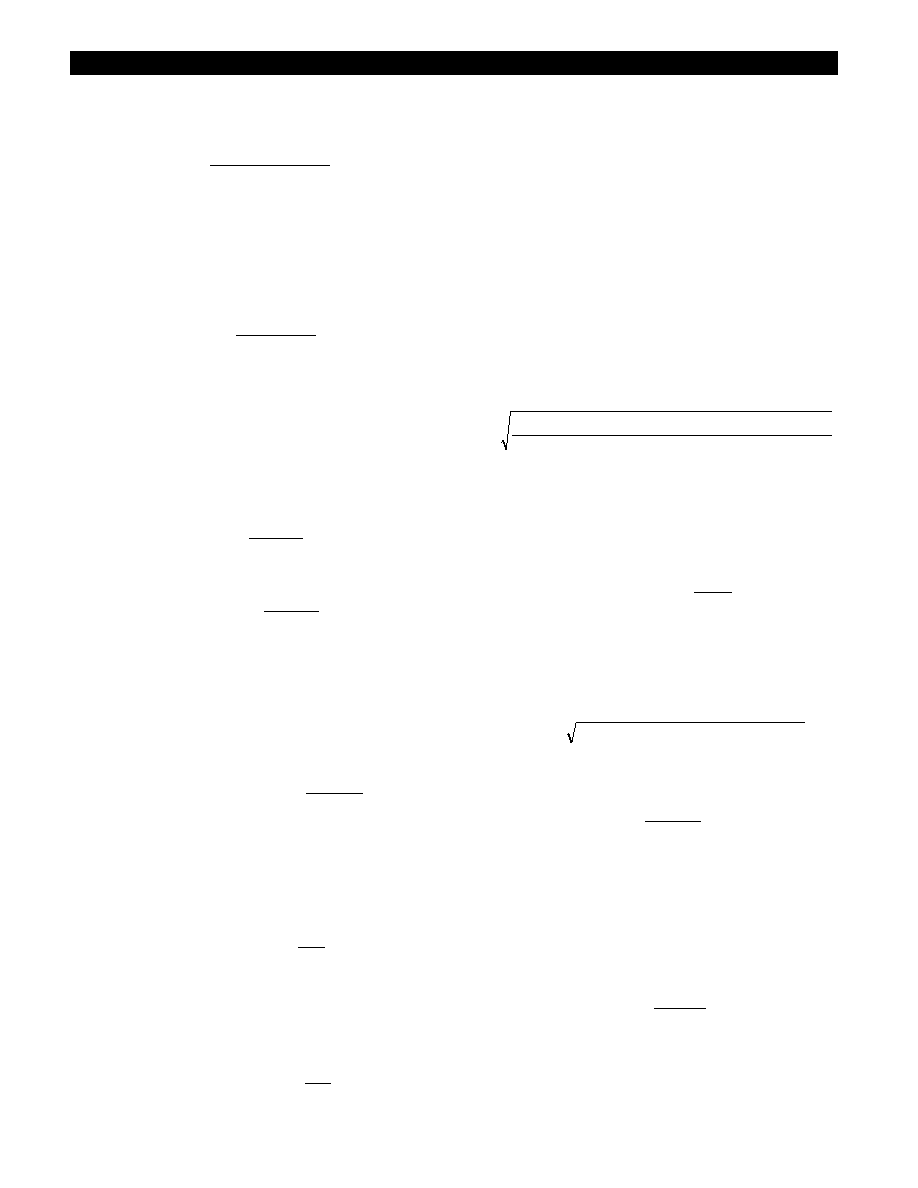

Electrical Characteristics: 0∞C < T

A

< 70∞C; 0∞C < T

J

< 125∞C; 9V < V

CC

< 14V;

2.0V DAC Code (V

ID4

= V

ID3

=V

ID2

= V

ID1

= 0, V

ID0

= 1), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 390pF; Unless otherwise stated.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

3

CS51311

75∞C T

J

125∞C

25∞C T

J

75∞C

V

ID4

V

ID3

V

ID2

V

ID1

V

ID0

MIN

TYP

MAX

± TOL

MIN

TYP

MAX

± TOL

UNIT

1

0

0

0

0

3.483

3.525

3.567

1.2%

3.455

3.525

3.596

2.0%

V

1

0

0

0

1

3.384

3.425

3.466

1.2%

3.357

3.425

3.494

2.0%

V

1

0

0

1

0

3.285

3.325

3.365

1.2%

3.259

3.325

3.392

2.0%

V

1

0

0

1

1

3.186

3.225

3.264

1.2%

3.161

3.225

3.290

2.0%

V

1

0

1

0

0

3.087

3.125

3.163

1.2%

3.063

3.125

3.188

2.0%

V

1

0

1

0

1

2.989

3.025

3.061

1.2%

2.965

3.025

3.086

2.0%

V

1

0

1

1

0

2.890

2.925

2.960

1.2%

2.875

2.925

2.975

1.7%

V

1

0

1

1

1

2.791

2.825

2.859

1.2%

2.777

2.825

2.873

1.7%

V

1

1

0

0

0

2.692

2.725

2.758

1.2%

2.679

2.725

2.771

1.7%

V

1

1

0

0

1

2.594

2.625

2.657

1.2%

2.580

2.625

2.670

1.7%

V

1

1

0

1

0

2.495

2.525

2.555

1.2%

2.482

2.525

2.568

1.7%

V

1

1

0

1

1

2.396

2.425

2.454

1.2%

2.389

2.425

2.461

1.5%

V

1

1

1

0

0

2.297

2.325

2.353

1.2%

2.290

2.325

2.360

1.5%

V

1

1

1

0

1

2.198

2.225

2.252

1.2%

2.192

2.225

2.258

1.5%

V

1

1

1

1

0

2.099

2.125

2.151

1.2%

2.093

2.125

2.157

1.5%

V

0

0

0

0

0

2.050

2.075

2.100

1.2%

2.044

2.075

2.106

1.5%

V

0

0

0

0

1

2.001

2.025

2.049

1.2%

1.995

2.025

2.055

1.5%

V

0

0

0

1

0

1.953

1.975

1.997

1.1%

1.945

1.975

2.005

1.5%

V

0

0

0

1

1

1.904

1.925

1.946

1.1%

1.896

1.925

1.954

1.5%

V

0

0

1

0

0

1.854

1.875

1.896

1.1%

1.847

1.875

1.903

1.5%

V

0

0

1

0

1

1.805

1.825

1.845

1.1%

1.798

1.825

1.852

1.5%

V

0

0

1

1

0

1.755

1.775

1.795

1.1%

1.748

1.775

1.802

1.5%

V

0

0

1

1

1

1.706

1.725

1.744

1.1%

1.699

1.725

1.751

1.5%

V

0

1

0

0

0

1.656

1.675

1.694

1.1%

1.650

1.675

1.700

1.5%

V

0

1

0

0

1

1.607

1.625

1.643

1.1%

1.601

1.625

1.649

1.5%

V

0

1

0

1

0

1.558

1.575

1.593

1.1%

1.551

1.575

1.599

1.5%

V

0

1

0

1

1

1.508

1.525

1.542

1.1%

1.502

1.525

1.548

1.5%

V

0

1

1

0

0

1.459

1.475

1.491

1.1%

1.453

1.475

1.497

1.5%

V

0

1

1

0

1

1.409

1.425

1.441

1.1%

1.404

1.425

1.446

1.5%

V

0

1

1

1

0

1.360

1.375

1.390

1.1%

1.354

1.375

1.396

1.5%

V

0

1

1

1

1

1.310

1.325

1.340

1.1%

1.305

1.325

1.345

1.5%

V

1

1

1

1

1

1.225

1.250

1.275

2.0%

1.225

1.250

1.275

2.0%

V

s

Voltage Identification DAC

Measure V

FB

= V

COMP

, V

CC

= 12V (Note 1)

s

Error Amplifier

V

FB

Bias Current

0.2V V

FB

3.5V

-7.0

0.1

7.0

µA

COMP Source Current

V

COMP

= 1.2V to 3.6V; V

FB

= 1.9 V

15

30

60

µA

COMP Sink Current

V

COMP

=1.2V; V

FB

= 2.1V;

30

60

120

µA

Open Loop Gain

C

COMP

= 0.1µF

80

dB

Unity Gain Bandwidth

C

COMP

= 0.1µF

50

kHz

PSRR @ 1kHz

C

COMP

= 0.1µF

70

dB

Transconductance

32

mmho

Output Impedance

0.5

M

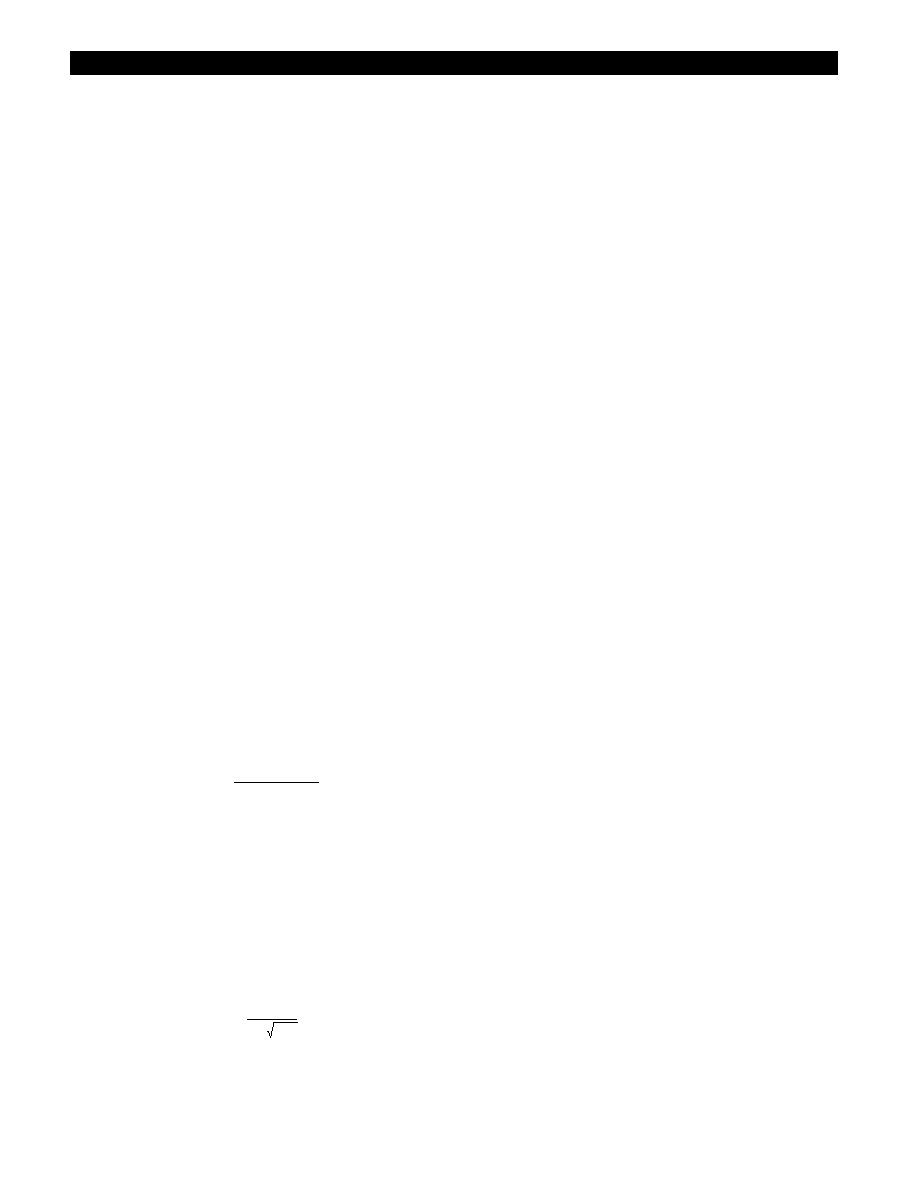

Electrical Characteristics: 0∞C < T

A

< 70∞C; 0∞C < T

J

< 125∞C; 9V < V

CC

< 14V;

2.0V DAC Code (V

ID4

= V

ID3

=V

ID2

= V

ID1

= 0, V

ID0

= 1), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 390pF; Unless otherwise stated.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

4

CS51311

Line Regulation

9V V

CC

14V

0.01

%/V

Input Threshold

V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

1.00

1.25

2.40

V

Input Pull-up Resistance

V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

25

50

100

k

Pull-up Voltage

5.48

5.65

5.82

V

s

GATE(H) and GATE(L)

High Voltage at 100mA

Measure V

CC

≠GATE(L)/(H)

1.2

2.1

V

Low Voltage at 100mA

Measure GATE(L)/(H)

1.0

1.5

V

Rise Time

1.6V < GATE(H)/(L) < (V

CC

≠ 2.5V)

40

80

ns

Fall Time

(V

CC

≠ 2.5V) > GATE(L)/(H) > 1.6V

40

80

ns

GATE(H) to GATE(L) Delay

GATE(H) < 2V, GATE(L) > 2V

30

65

110

ns

V

CC

= 12V

GATE(L) to GATE(H) Delay

GATE(L) < 2V, GATE(H) > 2V

30

65

110

ns

V

CC

= 12V

GATE pull-down

Resistance to Gnd (Note 2)

20

50

115

k

s

Overcurrent Protection

OVC Comparator Offset Voltage

0V V

OUT

3.5V

77

86

101

mV

Discharge Threshold Voltage

0.2

0.25

0.3

V

V

OUT

Bias Current

0.2V V

OUT

3.5V

-7.0

0.1

7.0

µA

OVC Latch Discharge Current

V

COMP

= 1V

100

800

2500

µA

s

PWM Comparator

PWM Comparator Offset Voltage

0V V

FB

3.5V

0.99

1.10

1.23

V

Transient Response

V

FB

= 0 to 3.5V

200

300

ns

s

C

OFF

Off-Time

1.0

1.6

2.3

µs

Charge Current

V

COFF

= 1.5V

550

µA

Discharge Current

V

COFF

= 1.5V

25

mA

s

Power-Good Output

PWRGD Sink Current

V

FB

= 1.7V, V

PWRGD

= 1V

0.5

4

15

mA

PWRGD Upper Threshold

% of nominal DAC code

5

8.5

12

%

PWRGD Lower Threshold

% of nominal DAC code

-12

-8.5

-5

%

PWRGD Output Low Voltage

V

FB

= 1.7V, I

PWRGD

= 500µA

0.2

0.3

V

CS51311

5

Electrical Characteristics: 0∞C < T

A

< 70∞C; 0∞C < T

J

< 125∞C; 9V < V

CC

< 14V;

2.0V DAC Code (V

ID4

= V

ID3

=V

ID2

= V

ID1

= 0, V

ID0

= 1), C

GATE(H)

= C

GATE(L)

= 3.3nF, C

OFF

= 390pF; Unless otherwise stated.

+

-

+

-

+

-

V

FB

COMP

C

OFF

OFF

TIME

PWM COMP

DISCHARGE

COMP

+

-

V

OUT

V

ID0

V

ID1

V

ID2

V

ID3

V

ID4

DAC

+

-

+

-

+

-

1.1V

EA

CURRENT LIMIT

+

-

86mV

0.25V

FAULT

LATCH

R

S

Q

PWRGD

Gnd

GATE(L)

GATE(H)

V

CC

UVLO

NONOVERLAP

LOGIC

+

-

Block Diagram

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

s

General Electrical Specifications

V

CC

Monitor Start Threshold

7.9

8.4

8.9

V

V

CC

Monitor Stop Threshold

7.6

8.1

8.6

V

Hysteresis

Start - Stop

0.15

0.30

0.60

V

V

CC

Supply Current

No Load on GATE(H), GATE(L)

12

20

mA

Note 1: The IC power dissipation in a typical application with V

CC

= 12V, switching frequency f

SW

= 250kHz, 50nc

MOSFETs and R

JA

= 115∞C/W yields an operating junction temperature rise of approximately 52∞C, and a junction tem-

perature of 77∞C with an ambient temperature of 25∞C.

Note 2: Guaranteed by design, not 100% tested in production.

CS51311

6

Reference

Voltage

+

C

≠

E

+

≠

Ramp Signal

Output

Voltage

Feedback

Error

Signal

GATE(H)

GATE(L)

Error

Amplifier

COMP

PWM

Comparator

V

FB

Figure 6: V

2

TM

Control Diagram

Typical Performance Characteristics

150

125

100

75

50

25

0

0

2000

4000

6000

8000

10000

12000

14000

16000

Falltime (ns)

Load Capacitance (pF)

V

CC

= 12V

T

A

= 25

∞

C

0.10

0.05

0

-

0.05

-

0.10

-

0.15

-

0.20

1.325 1.375 1.425 1.475 1.525 1.575 1.625 1.675 1.725 1.775 1.825 1.875 1.925 1.975 2.025 2.075

DAC Output Voltage Setting (V)

Output Error (%)

V

CC

= 12V

T

A

= 25

∞

C

V

ID4

= 0

Figure 4: Percent Output Error vs. DAC Output

Voltage Setting, V

ID4

= 0.

Figure 1: Gate(H) and Gate(L) Falltime vs. Load Capacitance.

Figure 2: Gate(H) and Gate(L) Risetime vs. Load Capacitance.

Figure 5: Percent Output Error vs. DAC Output

Voltage Setting, V

ID4

= 1.

150

125

100

75

50

25

0

0

2000

4000

6000

8000

10000

12000

14000

16000

Risetime (ns)

Load Capacitance (pF)

V

CC

= 12V

T

A

= 25

∞

C

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

-

0.05

-

0.10

-

0.15

-

0.20

-

0.25

Output Error (%)

2.125 2.225 2.325 2.425 2.525 2.625 2.725 2.825 2.925 3.025 3.125 3.225 3.335 3.425 3.525

DAC Output Voltage Setting (V)

V

CC

= 12V

T

A

= 25

∞

C

V

ID4

= 1

0.10

0.05

0

-

0.05

-

0.10

-

0.15

0

20

40

60

80

100

120

Junction Temperature (

∞

C)

DAC Output V

oltage

Deviation (%)

V

CC

= 12V

Figure 3: DAC Output Voltage vs. Temperature,

DAC Code = 00001.

Application Information

V

2

TM

Control Method

The V

2

TM

method of control uses a ramp signal that is gen-

erated by the ESR of the output capacitors. This ramp is

proportional to the AC current through the main inductor

and is offset by the value of the DC output voltage. This

control scheme inherently compensates for variation in

either line or load conditions, since the ramp signal is gen-

erated from the output voltage itself. This control scheme

differs from traditional techniques such as voltage mode,

which generates an artificial ramp, and current mode,

which generates a ramp from inductor current.

The V

2

TM

control method is illustrated in Figure 6. The out-

put voltage is used to generate both the error signal and

the ramp signal. Since the ramp signal is simply the output

Theory Of Operation

Application Information: continued

CS51311

voltage, it is affected by any change in the output regard-

less of the origin of that change. The ramp signal also con-

tains the DC portion of the output voltage, which allows

the control circuit to drive the main switch to 0% or 100%

duty cycle as required.

A change in line voltage changes the current ramp in the

inductor, affecting the ramp signal, which causes the V

2

TM

control scheme to compensate the duty cycle. Since the

change in inductor current modifies the ramp signal, as in

current mode control, the V

2

TM

control scheme has the same

advantages in line transient response.

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined

only by the comparator response time and the transition

speed of the main switch. The reaction time to an output

load step has no relation to the crossover frequency of the

error signal loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal loop.

The main purpose of this "slow" feedback loop is to pro-

vide DC accuracy. Noise immunity is significantly

improved, since the error amplifier bandwidth can be rolled

off at a low frequency. Enhanced noise immunity improves

remote sensing of the output voltage, since the noise associ-

ated with long feedback traces can be effectively filtered.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to compen-

sate for a deviation in either line or load voltage. This

change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation.

A current mode controller maintains fixed error signal

under deviation in the line voltage, since the slope of the

ramp signal changes, but still relies on a change in the error

signal for a deviation in load. The V

2

TM

method of control

maintains a fixed error signal for both line and load varia-

tion, since the ramp signal is affected by both line and load.

Constant Off-Time

To minimize transient response, the CS51311 uses a

Constant Off-Time method to control the rate of output

pulses. During normal operation, the Off-Time of the high

side switch is terminated after a fixed period, set by the

C

OFF

capacitor. Every time the V

FB

pin exceeds the COMP

pin voltage an Off-Time is initiated. To maintain regula-

tion, the V

2

TM

Control Loop varies switch On-Time. The

PWM comparator monitors the output voltage ramp, and

terminates the switch On-Time.

Constant Off-Time provides a number of advantages.

Switch duty Cycle can be adjusted from 0 to 100% on a

pulse-by pulse basis when responding to transient condi-

tions. Both 0% and 100% Duty Cycle operation can be

maintained for extended periods of time in response to

Load or Line transients.

Programmable Output

The CS51311 is designed to provide two methods for pro-

gramming the output voltage of the power supply. A five

bit on board digital to analog converter (DAC) is used to

program the output voltage within two different ranges.

The first range is 2.125V to 3.525V in 100mV steps, the sec-

ond is 1.325V to 2.075V in 50mV steps, depending on the

digital input code. If all five bits are left open, the CS51311

enters adjust mode. In adjust mode, the designer can

choose any output voltage by using resistor divider feed-

back to the V

FB

pin, as in traditional controllers. The

CS51311 is specifically designed to meet or exceed Intel's

Pentium

Æ

II specifications.

Error Amplifier

An inherent benefit of the V

2

TM

control topology is that

there is no large bandwidth requirement on the error

amplifier design. The reaction time to an output load step

has no relation to the crossover frequency, since transient

response is handled by the ramp signal loop. The main

purpose of this"slow"feedback loop is to provide DC accu-

racy. Noise immunity is significantly improved, since the

error amplifier bandwidth can be rolled off at a low fre-

quency. Enhanced noise immunity improves remote sens-

ing of the output voltage, since the noise associated with

long feedback traces can be effectively filtered. The COMP

pin is the output of the error amplifier and a capacitor to

Gnd compensates the error amplifier loop. Additionally,

through the built-in offset on the PWM Comparator non-

inverting input, the COMP pin provides the hiccup timing

for the Over-Current Protection, the soft start function that

minimizes inrush currents during regulator power-up and

switcher output enable.

Startup

The CS51311 provides a controlled startup of regulator

output voltage and features Programmable Soft Start

implemented through the Error Amp and external

Compensation Capacitor. This feature, combined with

overcurrent protection, prevents stress to the regulator

power components and overshoot of the output voltage

during startup.

As Power is applied to the regulator, the CS51311

Undervoltage Lockout circuit (UVL) monitors the ICs sup-

ply voltage (V

CC

) which is typically connected to the +12V

output of the AC-DC power supply. The UVL circuit pre-

vents the NFET gates from being activated until V

CC

exceeds the 8.4V (typ) threshold. Hysteresis of 300mV (typ)

is provided for noise immunity. The Error Amp Capacitor

connected to the COMP pin is charged by a 30µA current

source. This capacitor must be charged to 1.1V (typ) so that

it exceeds the PWM comparator's offset before the V

2

TM

PWM control loop permits switching to occur.

When V

CC

has exceeded 8.4V and COMP has charged to

1.1V, the upper Gate driver (GATE(H)) is activated, turn-

ing on the upper FET. This causes current to flow through

the output inductor and into the output capacitors and

load according to the following equation:

I = (V

IN

≠ V

OUT

) ◊

GATE(H) and the upper NFET remain on and inductor cur-

rent ramps up until the initial pulse is terminated by either

the PWM control loop or the overcurrent protection. This

initial surge of in-rush current minimizes startup time, but

avoids overstressing of the regulator's power components.

The PWM comparator will terminate the initial pulse if the

T

L

7

CS51311

8

Application Information: continued

regulator output exceeds the voltage on the COMP pin

plus the 1.1V PWM comparator offset prior to the drop

across the current sense resistor exceeding the current limit

threshold. In this case, the PWM control loop has achieved

regulation and the initial pulse is then followed by a con-

stant off time as programmed by the C

OFF

capacitor. The

COMP capacitor will continue to slowly charge and the

regulator output voltage will follow it, less the 1.1V PWM

offset, until it achieves the voltage programmed by the

DAC's VID input. The Error Amp will then source or sink

current to the COMP cap as required to maintain the cor-

rect regulator DC output voltage. Since the rate of increase

of the COMP pin voltage is typically set much slower than

the regulator's slew capability, inrush current, output volt-

age, and duty cycle all gradually increase from zero. (See

Figures 7, 8, and 9).

Figure 7: Normal Startup (2ms/div).

Channel 1 - Regulator Output Voltage (1V/div)

Channel 2 - COMP Pin (1V/div)

Channel 3 - V

CC

(10V/div)

Channel 4 - Regulator Input Voltage (5V/div)

Figure 8: Normal Startup showing initial pulse followed by Soft Start

(20µs/div).

Channel 1 - Regulator Output Voltage (1V/div)

Channel 2 ≠ Inductor Switching Node (5V/div)

Channel 3 - V

CC

(10V/div)

Channel 4 - Regulator Input Voltage (5V/div)

Figure 9: Pulse-by-Pulse Regulation during Soft Start (2µs/div).

Channel 1 - Regulator Output Voltage (1V/div)

Channel 2 ≠ Inductor Switching Node (5V/div)

Channel 3 - V

CC

(10V/div)

Channel 4 - Regulator Input Voltage (5V/div)

If the voltage across the Current Sense resistor generates a

voltage difference between the V

FB

and V

OUT

pins that

exceeds the OVC Comparator Offset Voltage (86mV typi-

cal), the Fault latch is set. This causes the COMP pin to be

quickly discharged, turning off GATE(H) and the upper

NFET since the voltage on the COMP pin is now less than

the 1.1V PWM comparator offset. The Fault latch is reset

when the voltage on the COMP decreases below the

Discharge threshold voltage (0.25V typical). The COMP

capacitor will again begin to charge, and when it exceeds

the 1.1V PWM comparator offset, the regulator output will

Soft Start normally (see Figure 10).

Because the start-up circuit depends on the current sense

function, a current sense resistor should always be used.

Figure 10: Startup with COMP pre-charged to 2V (2ms/div).

Channel 1 - Regulator Output Voltage (1V/div)

Channel 2 - COMP Pin (1V/div)

Channel 3 - V

CC

(10V/div)

Channel 4 - Regulator Input Voltage (5V/div)

Soft Start @

COMP > 1.1V

OCP @

V

CC

> 8.4V

Duty Cycle = V

OUT

/ V

IN

0.27V / 3.54V = 7%

5.2%

Start-up @

V

CC

> 8.4V

Initial Pulse until V

OUT

> COMP + PWM Offset

Start-up @

V

CC

> 8.4V

Application Information: continued

233

CS51311

When driving large capacitive loads, the COMP must

charge slowly enough to avoid tripping the CS51311 over-

current protection. The following equation can be used to

ensure unconditional startup:

<

where

I

CHG

= COMP Source Current (30µA typical);

C

COMP

= COMP Capacitor value (0.1µF typical);

I

LIM

= Current Limit Threshold;

I

LOAD

= Load Current during startup;

C

OUT

= Total Output Capacitance.

Normal Operation

During Normal operation, Switch Off-Time is constant and

set by the C

OFF

capacitor. Switch On-Time is adjusted by

the V

2

TM

Control loop to maintain regulation. This results in

changes in regulator switching frequency, duty cycle, and

output ripple in response to changes in load and line.

Output voltage ripple will be determined by inductor rip-

ple current and the ESR of the output capacitors

Transient Response

The CS51311 V

2

TM

Control Loop's 200ns reaction time pro-

vides unprecedented transient response to changes in

input voltage or output current. Pulse-by-pulse adjustment

of duty cycle is provided to quickly ramp the inductor cur-

rent to the required level. Since the inductor current cannot

be changed instantaneously, regulation is maintained by

the output capacitor(s) during the time required to slew the

inductor current.

Overall load transient response is further improved

through a feature called "Adaptive Voltage Positioning".

This technique pre-positions the output capacitors voltage

to reduce total output voltage excursions during changes

in load.

Holding tolerance to 1% allows the error amplifiers refer-

ence voltage to be targeted +25mV high without compro-

mising DC accuracy. A "Droop Resistor", implemented

through a PC board trace, connects the Error Amps feed-

back pin (V

FB

) to the output capacitors and load and carries

the output current. With no load, there is no DC drop

across this resistor, producing an output voltage tracking

the Error amps, including the +25mV offset. When the full

load current is delivered, a 50mV drop is developed across

this resistor. This results in output voltage being offset -

25mV low.

The result of Adaptive Voltage Positioning is that addition-

al margin is provided for a load transient before reaching

the output voltage specification limits. When load current

suddenly increases from its minimum level, the output

capacitor is pre-positioned +25mV. Conversely, when load

current suddenly decreases from its maximum level, the

output capacitor is pre-positioned -25mV. For best

Transient Response, a combination of a number of high fre-

quency and bulk output capacitors are usually used.

Slope Compensation

The V

2

TM

control method uses a ramp signal, generated by

the ESR of the output capacitors, that is proportional to the

ripple current through the inductor. To maintain regulation,

the V

2

TM

control loop monitors this ramp signal, through the

PWM comparator, and terminates the switch on-time.

The stringent load transient requirements of modern

microprocessors require the output capacitors to have very

low ESR. The resulting shallow slope presented to the

PWM comparator, due to the very low ESR, can lead to

pulse width jitter and variation caused by both random or

synchronous noise.

Adding slope compensation to the control loop, avoids

erratic operation of the PWM circuit, particularly at lower

duty cycles and higher frequencies, where there is not

enough ramp signal, and provides a more stable switch-

point.

The scheme that prevents that switching noise prematurely

triggers the PWM circuit consists of adding a positive volt-

age slope to the output of the Error Amplifier (COMP pin)

during an off-time cycle.

The circuit that implements this function is shown in

Figure 11.

Figure 11: Small RC filter provides the proper voltage ramp at the

beginning of each on-time cycle.

The ramp waveform is generated through a small RC filter

that provides the proper voltage ramp at the beginning of

each on-time cycle. The resistors R1 and R2 in the circuit of

Figure 11 form a voltage divider from the GATE(L) output,

superimposing a small artificial ramp on the output of the

error amplifier. It is important that the series combination

R1/R2 is high enough in resistance not to load down and

negatively affect the slew rate on the GATE(L) pin.

Over-Current Protection

A loss-less hiccup mode current limit protection feature is

provided, requiring only the COMP capacitor to imple-

ment. The CS51311 provides overcurrent protection by

sensing the current through a "Droop" resistor, using an

internal current sense comparator. The comparator com-

pares the voltage drop through the "Droop" resistor to an

internal reference voltage of 86mV (typical).

If the voltage drop across the "Droop" resistor exceeds this

threshold, the current sense comparator allows the fault

Protection and Monitoring Features

C

COMP

R

1

To Synchronous FET

C

1

R

2

14

11

COMP

GATE(L)

CS51311

I

LIM

- I

LOAD

C

OUT

I

CHG

C

COMP

CS51311

10

Application Information: continued

latch to be set. This causes the regulator to stop switching.

During this overcurrent condition, the CS51311 stays off

for the time it takes the COMP pin capacitor to discharge

to its lower 0.25V threshold. As soon as the COMP pin

reaches 0.25V, the Fault latch is reset (no overcurrent con-

dition present) and the COMP pin is charged with a 30µA

current source to a voltage 1.1V greater than the V

FB

volt-

age. Only at this point the regulator attempts to restart nor-

mally by delivering short gate pulses to both FETS. The

CS51311 will operate initially with a duty cycle whose val-

ue depends on how low the V

FB

voltage was during the

overcurrent condition (whether hiccup mode was due to

excessive current or hard short). This protection scheme

minimizes thermal stress to the regulator components,

input power supply, and PC board traces, as the overcur-

rent condition persists. Upon removal of the overload, the

fault latch is cleared, allowing normal operation to resume.

Overvoltage Protection

Overvoltage protection (OVP) is provided as result of the

normal operation of the V

2

TM

control topology and requires

no additional external components. The control loop

responds to an overvoltage condition within 200ns, caus-

ing the top MOSFET to shut off, disconnecting the regula-

tor from its input voltage. This results in a "crowbar"

action to clamp the output voltage and prevents damage to

the load. The regulator will remain in this state until the

overvoltage condition ceases or the input voltage is pulled

low. The bottom FET and board trace must be properly

designed to implement the OVP function.

Power-Good Circuit

The Power-Good pin (pin 12) is an open-collector signal

consistent with TTL DC specifications. It is externally

pulled up, and is pulled low (below 0.3V) when the regula-

tor output voltage typically exceeds ± 8.5% of the nominal

output voltage. Maximum output voltage deviation before

Power-Good is pulled low is ± 12%.

Output Enable

On/off control of the regulator outputs can be implement-

ed by pulling the COMP pins low. It is required to pull the

COMP pins below the 1.1V PWM comparator offset volt-

age in order to disable switching on the GATE drivers.

Step 1: Definition of the design specifications

In computer motherboard applications the input voltage

comes from the "silver box" power supply. 5V ± 5% is

used for conversion to output voltage, and 12V ± 5% is

used for the external NFET gate voltage and circuit bias.

The CPU V

CC(CORE)

tolerance can be affected by any or all

of the following reasons:

1) buck regulator output voltage setpoint accuracy;

2) output voltage change due to discharging or charging of

the bulk decoupling capacitors during a load current tran-

sient;

3) output voltage change due to the ESR and ESL of the

bulk and high frequency decoupling capacitors, circuit

traces, and vias;

4) output voltage ripple and noise.

Budgeting the tolerance is left up to the designer who must

take into account all of the above effects and provide a

V

CC(CORE)

that will meet the specified tolerance at the

CPU's inputs.

The designer must also ensure that the regulator compo-

nent junction temperatures are kept within the manufac-

turer's specified ratings at full load and maximum ambient

temperature. As computer motherboards become increas-

ingly complex, regulator size also becomes important, as

there is less space available for the CPU power supply.

Step 2: Selection of the Output Capacitors

These components must be selected and placed carefully to

yield optimal results. Capacitors should be chosen to pro-

vide acceptable ripple on the regulator output voltage. Key

specifications for output capacitors are their ESR

(Equivalent Series Resistance), and ESL (Equivalent Series

Inductance). For best transient response, a combination of

low value/high frequency and bulk capacitors placed close

to the load will be required.

In order to determine the number of output capacitors the

maximum voltage transient allowed during load transi-

tions has to be specified. The output capacitors must hold

the output voltage within these limits since the inductor

current can not change with the required slew rate. The

output capacitors must therefore have a very low ESL and

ESR.

The voltage change during the load current transient is:

V

OUT

= I

OUT

◊

(

+ ESR +

)

,

where

I

OUT

/ t = load current slew rate;

I

OUT

= load transient;

t = load transient duration time;

ESL = Maximum allowable ESL including capacitors,

circuit traces, and vias;

ESR = Maximum allowable ESR including capacitors

and circuit traces;

t

TR

= output voltage transient response time.

The designer has to independently assign values for the

change in output voltage due to ESR, ESL, and output

capacitor discharging or charging. Empirical data indicates

that most of the output voltage change (droop or spike

depending on the load current transition) results from the

total output capacitor ESR.

The maximum allowable ESR can then be determined

according to the formula

ESR

MAX

=

,

where V

ESR

= change in output voltage due to ESR

(assigned by the designer).

Once the maximum allowable ESR is determined, the num-

ber of output capacitors can be found by using the formula

V

ESR

I

OUT

t

TR

C

OUT

ESL

t

CS51311-based V

CC(CORE)

Buck Regulator Design Procedure

Application Information: continued

CS51311

11

Number of capacitors =

,

where

ESR

CAP

= maximum ESR per capacitor (specified in

manufacturer's data sheet);

ESR

MAX

= maximum allowable ESR.

The actual output voltage deviation due to ESR can then be

verified and compared to the value assigned by the design-

er:

V

ESR

= I

OUT

◊ ESR

MAX

Similarly, the maximum allowable ESL is calculated from

the following formula:

ESL

MAX

=

,

where

I/T = load current slew rate (as high as 20A/µs);

V

ESL

= change in output voltage due to ESL.

The actual maximum allowable ESL can be determined by

using the equation:

ESL

MAX

=

,

where ESL

CAP

= maximum ESL per capacitor (it is estimat-

ed that a 10 ◊ 12mm Aluminum Electrolytic capacitor has

approximately 4nH of package inductance).

The actual output voltage deviation due to the actual maxi-

mum ESL can then be verified:

V

ESL

=

.

The designer now must determine the change in output

voltage due to output capacitor discharge during the tran-

sient:

V

CAP

=

,

where

t

TR

= the output voltage transient response time

(assigned by the designer);

V

CAP

= output voltage deviation due to output capaci-

tor discharge;

I = Load step.

The total change in output voltage as a result of a load cur-

rent transient can be verified by the following formula:

V

OUT

= V

ESR

+ V

ESL

+ V

CAP

Step 3: Selection of the Duty Cycle,

Switching Frequency, Switch On-Time (T

ON

)

and Switch Off-Time (T

OFF

)

The duty cycle of a buck converter (including parasitic

losses) is given by the formula:

Duty Cycle = D =

,

where

V

OUT

= buck regulator output voltage;

V

HFET

= high side FET voltage drop due to R

DS(ON)

;

V

L

= output inductor voltage drop due to inductor wire

DC resistance;

V

DROOP

= droop (current sense) resistor voltage drop;

V

IN

= buck regulator input voltage;

V

LFET

= low side FET voltage drop due to R

DS(ON)

.

Step3a: Calculation of Switch On-Time

The switch On-Time (time during which the switching

MOSFET in a synchronous buck topology is conducting) is

determined by:

T

ON

= ,

where F

SW

= regulator switching frequency selected by the

designer.

Higher operating frequencies allow the use of smaller

inductor and capacitor values. Nevertheless, it is common

to select lower frequency operation because a higher fre-

quency results in lower efficiency due to MOSFET gate

charge losses. Additionally, the use of smaller inductors at

higher frequencies results in higher ripple current, higher

output voltage ripple, and lower efficiency at light load

currents.

Step 3b: Calculation of Switch Off-Time

The switch Off-Time (time during which the switching

MOSFET is not conducting) can be determined by:

T

OFF

=

- T

ON

,

The C

OFF

capacitor value has to be selected in order to set

the Off-Time, T

OFF

, above:

C

OFF

= ,

where

3980 is a characteristic factor of the CS51311;

D = Duty Cycle.

Step 4: Selection of the Output Inductor

The inductor should be selected based on its inductance,

current capability, and DC resistance. Increasing the induc-

tor value will decrease output voltage ripple, but degrade

transient response. There are many factors to consider in

selecting the inductor including cost, efficiency, EMI and

ease of manufacture. The inductor must be able to handle

the peak current at the switching frequency without satu-

rating, and the copper resistance in the winding should be

kept as low as possible to minimize resistive power loss.

There are a variety of materials and types of magnetic

cores that could be used for this application. Among them

are ferrites, molypermalloy cores (MPP), amorphous and

powdered iron cores. Powdered iron cores are very com-

monly used. Powdered iron cores are very suitable due to

Period ◊ (1 - D)

3980

1

F

SW

Duty Cycle

F

SW

V

OUT

+ (V

HFET

+ V

L

+ V

DROOP

)

V

IN

+ V

LFET

- V

HFET

- V

L

I ◊ t

TR

C

OUT

ESL

MAX

◊ I

t

ESL

CAP

Number of output capacitors

V

ESL

◊ t

I

ESR

CAP

ESR

MAX

Application Information: continued

CS51311

12

their high saturation flux density and have low loss at high

frequencies, a distributed gap and exhibit very low EMI.

The inductor value can be determined by:

L =

,

where

V

IN

= input voltage;

V

OUT

= output voltage;

t

TR

= output voltage transient response time (assigned

by the designer);

I = load transient.

The inductor ripple current can then be determined:

I

L

= ,

where

I

L

= inductor ripple current;

V

OUT

= output voltage;

T

OFF

= switch Off-Time;

L = inductor value.

The designer can now verify if the number of output

capacitors from step 2 will provide an acceptable output

voltage ripple (1% of output voltage is common). The for-

mula below is used:

I

L

= ,

Rearranging we have:

ESR

MAX

= ,

where

ESR

MAX

= maximum allowable ESR;

V

OUT

= 1% ◊ V

OUT

= maximum allowable output volt-

age ripple ( budgeted by the designer );

I

L

= inductor ripple current;

V

OUT

= output voltage.

The number of output capacitors is determined by:

Number of capacitors =

,

where ESR

CAP

= maximum ESR per capacitor (specified in

manufacturer's data sheet).

The designer must also verify that the inductor value

yields reasonable inductor peak and valley currents (the

inductor current is a triangular waveform):

I

L(PEAK)

= I

OUT

+

,

where

I

L(PEAK)

= inductor peak current;

I

OUT

= load current;

I

L

= inductor ripple current.

I

L(VALLEY)

= I

OUT

-

,

where I

L(VALLEY)

= inductor valley current.

Given the requirements of an application such as a buck

converter, it is found that a toroid powdered iron core is

quite suitable due to its low cost, low core losses at the

switching frequency, and low EMI.

Step 5: Selection of the Input Capacitors

These components must be selected and placed carefully to

yield optimal results. Capacitors should be chosen to pro-

vide acceptable ripple on the input supply lines. A key

specification for input capacitors is their ripple current rat-

ing. The input capacitor should also be able to handle the

input RMS current I

IN(RMS)

.

The combination of the input capacitors C

IN

discharges

during the on-time.

The input capacitor discharge current is given by:

I

CINDIS(RMS)

=

,

where

I

CINDIS(RMS)

= input capacitor discharge current;

I

L(PEAK)

= inductor peak current;

I

L(VALLEY)

= inductor valley current.

C

IN

charges during the off-time, the average current

through the capacitor over one switching cycle is zero:

I

CIN(CH)

= I

CIN(DIS)

◊

,

where

I

CIN(CH)

= input capacitor charge current;

I

CIN(DIS)

= input capacitor discharge current;

D = Duty Cycle.

The total Input RMS current is:

I

CIN(RMS)

= (I

CIN(DIS)

2

◊ D) + (I

CIN(CH)

2

◊ (1 - D))

The number of input capacitors required is then deter-

mined by:

N

CIN

= ,

where

N

CIN

= number of input capacitors;

I

CIN(RMS)

= total input RMS current;

I

RIPPLE

= input capacitor ripple current rating (specified

in manufacturer's data sheets).

The total input capacitor ESR needs to be determined in

order to calculate the power dissipation of the input capac-

itors:

ESR

CIN

= ,

where

ESR

CIN

= total input capacitor ESR;

ESR

CAP

= maximum ESR per capacitor (specified in

manufacturer's data sheets);

N

CIN

= number of input capacitors.

ESR

CAP

N

CIN

I

CIN(RMS)

I

RIPPLE

D

1 - D

(I

L(PEAK)

2

+ (I

L(PEAK)

◊ I

L(VALLEY)

) + I

L(VALLEY)

2

◊ D

3

I

L

2

I

L

2

ESR

CAP

ESR

MAX

V

OUT

I

L

V

OUT

ESR

MAX

V

OUT

◊ T

OFF

L

(V

IN

- V

OUT

) ◊ t

TR

Once the total ESR of the input capacitors is known, the

input capacitor ripple voltage can be determined using the

formula:

V

CIN(RMS)

= I

CIN(RMS)

◊ ESR

CIN

,

where

V

CIN(RMS)

= input capacitor RMS voltage;

I

CIN(RMS)

= total input RMS current;

ESR

CIN

= total input capacitor ESR.

The designer must determine the input capacitor power

loss in order to ensure there isn't excessive power dissipa-

tion through these components. The following formula is

used:

P

CIN(RMS)

= I

CIN(RMS)

2

◊ ESR

CIN

where

P

CIN(RMS)

= input capacitor RMS power dissipation;

I

CIN(RMS)

= total input RMS current;

ESR

CIN

= total input capacitor ESR.

Step 6: Selection of the Input Inductor

A CPU switching regulator, such as the one in a buck

topology, must not disturb the primary +5V supply. One

method of achieving this is by using an input inductor and

a bypass capacitor. The input inductor isolates the +5V

supply from the noise generated in the switching portion

of the microprocessor buck regulator and also limits the

inrush current into the input capacitors upon power up.

The inductor's limiting effect on the input current slew rate

becomes increasingly beneficial during load transients. The

worst case is when the CPU load changes from no load to

full load (load step), a condition under which the highest

voltage change across the input capacitors is also seen by

the input inductor. The inductor successfully blocks the

ripple current while placing the transient current require-

ments on the input bypass capacitor bank, which has to

initially support the sudden load change.

The minimum inductance value for the input inductor is

therefore:

L

IN

= ,

where

L

IN

= input inductor value;

V = voltage seen by the input inductor during a full

load swing;

(dI/dt)

MAX

= maximum allowable input current slew

rate (0.1A/µs for a PentiumÆ II power supply).

The designer must select the LC filter pole frequency so

that at least 40dB attenuation is obtained at the regulator

switching frequency. The LC filter is a double-pole net-

work with a slope of -2, a roll-off rate of ≠40dB/dec, and a

corner frequency:

f

C

= ,

where

L = input inductor;

C = input capacitor(s).

Step 7: Selection of the Switching FET

FET Basics

The use of the MOSFET as a power switch is propelled by

two reasons: 1) Its very high input impedance; and 2) Its very

fast switching times. The electrical characteristics of a MOS-

FET are considered to be those of a perfect switch. Control

and drive circuitry power is therefore reduced. Because the

input impedance is so high, it is voltage driven. The input

of the MOSFET acts as if it were a small capacitor, which

the driving circuit must charge at turn on. The lower the

drive impedance, the higher the rate of rise of V

GS

, and the

faster the turn- on time. Power dissipation in the switching

MOSFET consists of 1) conduction losses, 2) leakage losses,

3) turn-on switching losses, 4) turn-off switching losses,

and 5) gate-transitions losses. The latter three losses are

proportional to frequency. For the conducting power dissi-

pation rms values of current and resistance are used for

true power calculations. The fast switching speed of the

MOSFET makes it indispensable for high-frequency power

supply applications. Not only are switching power losses

minimized, but also the maximum usable switching fre-

quency is considerably higher. Switching time is indepen-

dent of temperature. Also, at higher frequencies, the use of

smaller and lighter components (transformer, filter choke,

filter capacitor) reduces overall component cost while

using less space for more efficient packaging at lower

weight.

The MOSFET has purely capacitive input impedance. No

DC current is required. It is important to keep in mind the

drain current of the FET has a negative temperature coeffi-

cient. Increase in temperature causes higher on-resistance

and greater leakage current. For switching circuits, V

DS(ON)

should be low to minimize power dissipation at a given I

D

,

and V

GS

should be high to accomplish this. MOSFET

switching times are determined by device capacitance,

stray capacitance, and the impedance of the gate drive cir-

cuit. Thus the gate driving circuit must have high momen-

tary peak current sourcing and sinking capability for

switching the MOSFET. The input capacitance, output

capacitance and reverse-transfer capacitance also increase

with increased device current rating.

Two considerations complicate the task of estimating

switching times. First, since the magnitude of the input

capacitance, C

ISS

, varies with V

DS

, the RC time constant

determined by the gate-drive impedance and C

ISS

changes

during the switching cycle. Consequently, computation of

the rise time of the gate voltage by using a specific gate-

drive impedance and input capacitance yields only a rough

estimate. The second consideration is the effect of the

"Miller" capacitance, C

RSS

, which is referred to as C

DG

in

the following discussion. For example, when a device is on,

V

DS(ON)

is fairly small and V

GS

is about 12V. C

DG

is

charged to V

DS(ON)

- V

GS

, which is a negative potential if

the drain is considered the positive electrode. When the

drain is "off", C

DG

is charged to quite a different potential.

In this case the voltage across C

DG

is a positive value since

the potential from gate-to-source is near zero volts and V

DS

is essentially the drain supply voltage. During turn-on and

turn-off, these large swings in gate-to-drain voltage tax the

current sourcing and sinking capabilities of the gate drive.

In addition to charging and discharging C

GS

, the gate drive

must also supply the displacement current required by

1

2 LC

V

(dI/dt)

MAX

Application Information: continued

CS51311

13

Application Information: continued

CS51311

14

C

DG

(I

GATE

= C

dg

dV

dg

/dt). Unless the gate-drive

impedance is very low, the V

GS

waveform commonly

plateaus during rapid changes in the drain-to-source volt-

age.

The most important aspect of FET performance is the Static

Drain-To-Source On-Resistance (R

DS(ON)

), which effects

regulator efficiency and FET thermal management require-

ments. The On-Resistance determines the amount of cur-

rent a FET can handle without excessive power dissipation

that may cause overheating and potentially catastrophic

failure. As the drain current rises, especially above the con-

tinuous rating, the On-Resistance also increases. Its posi-

tive temperature coefficient is between +0.6%/C and

+0.85%/C. The higher the On-Resistance the larger the

conduction loss is. Additionally, the FET gate charge

should be low in order to minimize switching losses and

reduce power dissipation.

Both logic level and standard FETs can be used. The refer-

ence designs derive gate drive from the 12V supply, which

is generally available in most computer systems and uti-

lizes logic level FETs.

Voltage applied to the FET gates depends on the applica-

tion circuit used. Both upper and lower gate driver outputs

are specified to drive to within 1.5V of ground when in the

low state and to within 2V of their respective bias supplies

when in the high state. In practice, the FET gates will be

driven rail-to-rail due to overshoot caused by the capaci-

tive load they present to the controller IC.

Step 7a - Selection of the switching (upper) FET

The designer must ensure that the total power dissipation

in the FET switch does not cause the power component's

junction temperature to exceed 150∞C.

The maximum RMS current through the switch can be

determined by the following formula:

I

RMS(H)

=

,

where

I

RMS(H)

= maximum switching MOSFET RMS current;

I

L(PEAK)

= inductor peak current;

I

L(VALLEY)

= inductor valley current;

D = Duty Cycle.

Once the RMS current through the switch is known, the

switching MOSFET conduction losses can be calculated:

P

RMS(H)

= I

RMS(H)

2

◊ R

DS(ON)

where

P

RMS(H)

= switching MOSFET conduction losses;

I

RMS(H)

= maximum switching MOSFET RMS current;

R

DS(ON)

= FET drain-to-source on-resistance

The upper MOSFET switching losses are caused during

MOSFET switch-on and switch-off and can be determined

by using the following formula:

P

SWH

= P

SWH(ON)

+ P

SWH(OFF)

= ,

where

P

SWH(ON)

= upper MOSFET switch-on losses;

P

SWH(OFF)

= upper MOSFET switch-off losses;

V

IN

= input voltage;

I

OUT

= load current;

t

RISE

= MOSFET rise time (from FET manufacturer's

switching characteristics performance curve);

t

FALL

= MOSFET fall time (from FET manufacturer's

switching characteristics performance curve);

T = 1/F

SW

= period.

The total power dissipation in the switching MOSFET can

then be calculated as:

P

HFET(TOTAL)

= P

RMSH

+ P

SWH(ON)

+ P

SWH(OFF)

,

where

P

HFET(TOTAL)

= total switching (upper) MOSFET losses;

P

RMSH

= upper MOSFET switch conduction Losses;

P

SWH(ON)

= upper MOSFET switch-on losses;

P

SWH(OFF)

= upper MOSFET switch-off losses.

Once the total power dissipation in the switching FET is

known, the maximum FET switch junction temperature

can be calculated:

T

J

= T

A

+ [P

HFET(TOTAL)

◊ R

JA

],

where

T

J

= FET junction temperature;

T

A

= ambient temperature;

P

HFET(TOTAL)

= total switching (upper) FET losses;

R

JA

= upper FET junction-to-ambient thermal resistance

Step 7b: Selection of the synchronous (lower) FET

The switch conduction losses for the lower FET can be cal-

culated as follows:

P

RMSL

= I

RMS

2

◊ R

DS(ON)

= [I

OUT

◊ (1 - D)]

2

◊ R

DS(ON)

,

where

P

RMSL

= lower MOSFET conduction losses;

I

OUT

= load current;

D = Duty Cycle;

R

DS(ON)

= lower FET drain-to-source on-resistance.

The synchronous MOSFET has no switching losses, except

for losses in the internal body diode, because it turns on

into near zero voltage conditions. The MOSFET body

diode will conduct during the non-overlap time and the

resulting power dissipation (neglecting reverse recovery

losses) can be calculated as follows:

P

SWL

= V

SD

◊ I

LOAD

◊ non-overlap time ◊ F

SW

,

where

P

SWL

= lower FET switching losses;

V

SD

= lower FET source-to-drain voltage;

I

LOAD

= load current

Non-overlap time = GATE(L)-to-GATE(H) or GATE(H)-

to-GATE(L) delay (from CS51311 data sheet Electrical

V

IN

◊ I

OUT

◊ (t

RISE

+ t

FALL

)

6T

(I

L(PEAK)

2

+ (I

L(PEAK)

◊ I

L(VALLEY)

) + I

L(VALLEY)

2

◊ D

3

Application Information: continued

CS51311

15

Characteristics section);

F

SW

= switching frequency.

The total power dissipation in the synchronous (lower)

MOSFET can then be calculated as:

P

LFET(TOTAL)

= P

RMSL

+ P

SWL

,

where

P

LFET(TOTAL)

= Synchronous (lower) FET total losses;

P

RMSL

= Switch Conduction Losses;

P

SWL

= Switching losses.

Once the total power dissipation in the synchronous FET is

known the maximum FET switch junction temperature can

be calculated:

T

J

= T

A

+ [P

LFET(TOTAL)

◊ R

JA

],

where

T

J

= MOSFET junction temperature;

T

A

= ambient temperature;

P

LFET(TOTAL)

= total synchronous (lower) FET losses;

R

JA

= lower FET junction-to-ambient thermal resistance.

Step 8: Control IC Power Dissipation

The power dissipation of the IC varies with the MOSFETs

used, V

CC

, and the CS51311 operating frequency. The aver-

age MOSFET gate charge current typically dominates the

control IC power dissipation.

The IC power dissipation is determined by the formula:

P

CONTROLIC

= I

CC

V

CC

+ P

GATE(H)

+ P

GATE(L)

,

where

P

CONTROLIC

= control IC power dissipation;

I

CC

= IC quiescent supply current;

V

CC

= IC supply voltage;

P

GATE(H)

= upper MOSFET gate driver (IC) losses;

P

GATE(L)

= lower MOSFET gate driver (IC) losses.

The upper (switching) MOSFET gate driver (IC) losses are:

P

GATE(H)

= Q

GATE(H)

◊ F

SW

◊ V

GATE(H)

,

where

P

GATE(H)

= upper MOSFET gate driver (IC) losses;

Q

GATE(H)

= total upper MOSFET gate charge;

F

SW

= switching frequency;

V

GATE(H)

= upper MOSFET gate voltage.

The lower (synchronous) MOSFET gate driver (IC) losses

are:

P

GATE(L)

= Q

GATE(L)

◊ F

SW

◊ V

GATE(L)

,

where

P

GATE(L)

= lower MOSFET gate driver (IC) losses;

Q

GATE(L)

= total lower MOSFET gate charge;

F

SW

= switching frequency;

V

GATE(L)

= lower MOSFET gate voltage.

The junction temperature of the control IC is primarily a

function of the PCB layout, since most of the heat is

removed through the traces connected to the pins of the IC.

Step 9: Slope Compensation

Voltage regulators for today's advanced processors are

expected to meet very stringent load transient require-

ments. One of the key factors in achieving tight dynamic

voltage regulation is low ESR at the CPU input supply

pins. Low ESR at the regulator output results in low output

voltage ripple. The consequence is, however, that there's

very little voltage ramp at the control IC feedback pin (V

FB

)

and regulator sensitivity to noise and loop instability are

two undesirable effects that can surface. The performance

of the CS51311-based CPU V

CC(CORE)

regulator is

improved when a fixed amount of slope compensation is

added to the output of the PWM Error Amplifier (COMP

pin) during the regulator Off-Time. Referring to Figure 11,

the amount of voltage ramp at the COMP pin is dependent

on the gate voltage of the lower (synchronous) FET and the

value of resistor divider formed by R1and R2.

V

SLOPECOMP

= V

GATE(L)

◊

(

)

◊ (1 - e ),

where

V

SLOPECOMP

= amount of slope added;

V

GATE(L)

= lower MOSFET gate voltage;

R1, R2 = voltage divider resistors;

t = t

OFF

(switch off-time);

= RC constant determined by C1 and the parallel com-

bination of R1, R2 (Figure 11), neglecting the low driver

output impedance

The artificial voltage ramp created by the slope compensa-

tion scheme results in improved control loop stability pro-

vided that the RC filter time constant is smaller than the

off-time cycle duration (time during which the lower MOS-

FET is conducting).

Step 10: Selection of Current Limit Filter Components

The current limit filter is implemented by a 0.1µF ceramic

capacitor across and two 510 resistors in series with the

V

FB

and V

OUT

current limit comparator input pins. They

provide a time constant = RC = 100µs, which enables the

circuit to filter out noise and be immune to false triggering,

caused by sudden and fast load changes. These load tran-

sients can have slew rates as high as 20A/µs.

Adaptive voltage positioning is used to help keep the out-

put voltage within specification during load transients. To

implement adaptive voltage positioning a "Droop

Resistor" must be connected between the output inductor

and output capacitors and load. This resistor carries the

full load current and should be chosen so that both DC and

AC tolerance limits are met. An embedded PC trace resis-

tor has the distinct advantage of near zero cost implemen-

tation. However, this droop resistor can vary due to three

reasons: 1) the sheet resistivity variation caused by varia-

tion in the thickness of the PCB layer; 2) the mismatch of

L/W; and 3) temperature variation.

1) Sheet Resistivity

For one ounce copper, the thickness variation is typically

"Droop" Resistor for Adaptive Voltage Positioning

and Current Limit

-t

R2

R1 + R2

CS51311

16

Application Information: continued

1.26 mil to 1.48 mil. Therefore the error due to sheet resis-

tivity is:

= ±8%.

2) Mismatch due to L/W

The variation in L/W is governed by variations due to the

PCB manufacturing process. The error due to L/W mis-

match is typically 1%.

3) Thermal Considerations

Due to I

2

◊ R power losses the surface temperature of the

droop resistor will increase causing the resistance to

increase. Also, the ambient temperature variation will con-

tribute to the increase of the resistance, according to the

formula:

R = R

20

[1+

20

(-20)],

where

R

20

= resistance at 20∞C;

=

;

T= operating temperature;

R = desired droop resistor value.

For temperature T = 50∞C, the % R change = 12%.

Droop Resistor Tolerance

Tolerance due to sheet resistivity variation

±8%

Tolerance due to L/W error

1%

Tolerance due to temperature variation

12%

Total tolerance for droop resistor

21%

In order to determine the droop resistor value the nominal

voltage drop across it at full load has to be calculated. This

voltage drop has to be such that the output voltage at full

load is above the minimum DC tolerance spec:

V

DROOP(TYP)

= .

Example: for a 450MHz Pentium

Æ

II, the DC accuracy spec

is 1.93 < V

CC(CORE)

< 2.07V, and the AC accuracy spec is

1.9V < V

CC(CORE)

< 2.1V. The CS51311 DAC output voltage

is +2.001V < V

DAC

< +2.049V. In order not to exceed the

DC accuracy spec, the voltage drop developed across the

resistor must be calculated as follows:

V

DROOP(TYP)

=

=

= 71mV.

With the CS51311 DAC accuracy being 1%, the internal

error amplifier's reference voltage is trimmed so that the

output voltage will be 25mV high at no load. With no load,

there is no DC drop across the resistor, producing an out-

put voltage tracking the error amplifier output voltage,

including the offset. When the full load current is deliv-

ered, a drop of -50mV is developed across the resistor.

Therefore, the regulator output is pre-positioned at 25mV

above the nominal output voltage before a load turn-on.

The total voltage drop due to a load step is V-25mV and

the deviation from the nominal output voltage is 25mV

smaller than it would be if there was no droop resistor.

Similarly at full load the regulator output is pre-positioned

at 25mV below the nominal voltage before a load turn-off.

the total voltage increase due to a load turn-off is V-25mV

and the deviation from the nominal output voltage is

25mV smaller than it would be if there was no droop resis-

tor. This is because the output capacitors are pre-charged

to a value that is either 25mV above the nominal output

voltage before a load turn-on or, 25mV below the nominal

output voltage before a load turn-off .

Obviously, the larger the voltage drop across the droop

resistor (the larger the resistance), the worse the DC and

load regulation, but the better the AC transient response.

Current Limit

The current limit setpoint has to be higher than the normal

full load current. Attention has to be paid to the current

rating of the external power components as these are the

first to fail during an overload condition. The MOSFET

continuous and pulsed drain current rating at a given case

temperature has to be accounted for when setting the cur-

rent limit trip point.

Temperature curves on MOSFET manufacturers' data

sheets allow the designer to determine the MOSFET drain

current at a particular V

GS

and T

J

(junction temperature).

This, in turn, will assist the designer to set a proper current

limit, without causing device breakdown during an over-

load condition.

Let's assume the full CPU load is 16A. The internal current

sense comparator current limit voltage limits are: 77mV <

V

TH

< 101mV. Also, there is a 21% total variation in R

SENSE

as discussed in the previous section.

We compute the value of the current sensing element

(embedded PCB trace) for the minimum current limit set-

point:

R

SENSE(MIN)

= R

SENSE(TYP)

◊ 0.79,

R

SENSE(MAX)

= R

SENSE(TYP)

◊ 1.21,

R

SENSE(MAX)

= =

= 4.8m.

We select,

R

SENSE(TYP)

= 3.3m.

We calculate the range of load currents that will cause the

internal current sense comparator to detect an overload

condition.

Nominal Current Limit Setpoint

From the overcurrent detection data in the electrical char-

acteristics table:

V

TH(TYP)

= 86mV,

77mV

16A

V

TH(MIN)

I

CL(MIN)

+2.001V-1.93V

1.21

[V

DAC(MIN)

-V

DC (MIN)

]

1+R

DROOP(TOLERANCE)

V

DAC(MIN)

-V

DC(MIN)

1+R

DROOP(TOLERANCE)

0.00393

∞C

1.48 - 1.26

1.37

Application Information: continued

CS51311

17

I

CL(NOM)