| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CPC7583xC | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

DS-CPC7583 - R3.0

www.clare.com

1

Features

∑

Small 20 pin or 28 pin SOIC or 28 pin

micro-leadframe (MLP) package

∑

MLP version provides 65% PCB area reduction over

4

th

generation EMRs

∑

Monolithic IC reliability

∑

Low, matched, R

ON

∑

Eliminates the need for zero-cross switching

∑

Flexible switch timing for transition from ringing

mode to talk mode.

∑

Clean, bounce-free switching

∑

SLIC tertiary protection via integrated current

limiting, voltage clamping and thermal shutdown

∑

5 V operation with power consumption < 10.5 mW

∑

Intelligent battery monitor

∑

Logic-level inputs, no external drive circuitry required

∑

SOIC versions pin-compatible with Legerity

7583/8583 family

Applications

∑

Central office (CO)

∑

Digital Loop Carrier (DLC)

∑

PBX Systems

∑

Digitally Added Main Line (DAML)

∑

Hybrid Fiber Coax (HFC)

∑

Fiber in the Loop (FITL)

∑

Pair Gain System

∑

Channel Banks

Description

The CPC7583 is a monolithic 10-pole line card access

switch in a 20 or 28 pin SOIC or a 28 pin MLP

package. It provides the necessary functions to

replace three 2-Form-C electromechanical relays on

analog line cards and combined voice and data line

cards found in central office, access, and PBX

equipment. The device contains solid state switches

for tip and ring line break, ringing injection/ringing

return, and test access. The CPC7583 requires only a

+5 V supply and offers break-before-make or

make-before-break switch operation using simple

logic-level input control.

Ordering Information

Specify CPC7583Zx for 20 pin SOIC package,

CPC7583Bx for 28 pin SOIC package, or CPC7583Mx

for MLP package in tubes. Add -TR to the part number

for tape and reel packaging.

Part Number

Description

CPC7583xA

With protection SCR

CPC7583xB

Without protection SCR

CPC7583xC

With extra logic state and protection SCR

CPC7583xD

With extra logic state but without protection

SCR

CPC7583

T

LINE

R

LINE

T

BAT

V

DD

R

BAT

D

GND

V

BAT

F

GND

V

REF

IN

TESTIN

IN

RINGING

IN

TESTOUT

T

SD

LATCH

7

10

8

5

22

6

12

13

14

28

1

24

20

19

23

17

16

15

18

L

A

T

C

H

Switch

Control

Logic

SCR

and

Trip

Circuit

+5 Vdc

SLIC

Secondary

Protection

X

X

X

X

X

X

X

X

X

SW5

SW7

SW6

SW2

SW4

SW10

SW8

T

TESTIN

(T

)

CHANTEST

T

TESTOUT

(T

)

DROPTEST

R

TESTOUT

(R

)

DROPTEST

R

TESTIN

(R

)

CHANTEST

T

RING

SW3

SW9

SW1

300

(min.)

RINGING

V

BAT

X

Tip

Ring

NOTE: Pin assignments are for 28 pin device.

CPC7583

Line Card Access Switch

CPC7583

2

www.clare.com

R3.0

1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Package Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Pinout Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Absolute Maximum Ratings (at 25∞ C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Electrical Characteristics, TA = -40∞ C to +85∞ C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.1 Power Supply Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.2 Break Switches, SW1 and SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.3 Ringing Return Switch, SW3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.4 Ringing Switch, SW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.5 TEST

OUT

Switches, SW5 and SW6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.6 Ringing Test Return Switch, SW7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.7 Ringing Test Switch, SW8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.8 TEST

In

Switches, SW9 and SW10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Additional Electrical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Protection Circuitry Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Truth Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7.1 Truth Table for CPC7583xA and CPC7583xB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7.2 Truth Table for CPC7583xC and CPC7583xD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Switch Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Make-Before-Break Operation (Ringing to Talk Transition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 Break-Before-Make Operation (Ringing to Talk Transition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Alternate Break-Before-Make Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Data Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 T

SD

Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6 Ringing Switch Zero-Cross Current Turn Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.8 Battery Voltage Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9 Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.1 Diode Bridge/SCR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.2 Current Limiting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Temperature Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.11 External Protection Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Manufacturing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Moisture Reflow Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.2 Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 CPC7583Z - 20 Pin SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 CPC7583B - 28 Pin SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.3 CPC7583M - 28 Pin MLP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.4 CPC7583Z - Tape and Reel Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.5 CPC7583B - Tape and Reel Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.6 CPC7583M - Tape and Reel Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CPC7583

R3.0

www.clare.com

3

1. Specifications

1.1 Package Pinout

1.2 Pinout Description

CPC7583B &

CPC7583M

T

BAT

F

GND

D

GND

T

TESTin

IN

TESTin

R

T

TESTout

IN

TESTout

R

TESTout

T

LINE

T

RINGING

V

DD

T

NC

NC

NC

NC

NC

NC

NC

NC

NC

SD

V

BAT

R

BAT

TESTin

R

LINE

R

RINGING

LATCH

IN

RINGING

27

26

25

24

23

22

21

20

19

18

17

16

15

28

1

3

4

5

6

7

8

2

9

10

11

12

13

14

CPC7583Z

IN

TESTIN

R

TESTIN

IN

TESTOUT

R

TESTOUT

V

BAT

R

BAT

R

LINE

R

RINGING

LATCH

IN

RINGING

20

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

8

9

10

T

BAT

F

GND

D

GND

T

TESTIN

T

LINE

V

DD

T

SD

NC

T

TESTOUT

T

RINGING

20

Pin

28

Pin

Name

Description

1

1

F

GND

Fault ground

2

NC

No connection

3

NC

No connection

4

NC

No connection

2

5

T

TESTin

Connect to TEST

IN

bus tip lead

3

6

T

BAT

Connect to tip on SLIC side

4

7

T

LINE

Connect to tip on line side

5

8

T

RINGING

Connect to ringing generator return

9

NC

Not connected

6

10

T

TESTout

Connect to TEST

OUT

bus tip lead

7

11

NC

No connection

8

12

V

DD

+5 V supply

9

13

T

SD

Temperature shutdown pin. Bi-directional

I/O with internal pullup to V

DD

. Output

function indicates status of thermal

shutdown circuitry. Input function can be

used to set the `all off' mode using an

open-drain type output.

10 14

D

GND

Digital ground

11 15

IN

TESTout

Logic-level switch control input

12 16 IN

RINGING

Logic-level switch control input

13 17

IN

TESTin

Logic-level switch control input

14 18

LATCH

Data latch control, active high, transparent

low

15 19

R

TESTout

Connect to TEST

OUT

bus ring lead

16 20

R

RINGING

Connect to ringing generator current

limiting resistor

21

NC

No connection

17 22

R

LINE

Connect to ring on the line side

18 23

R

BAT

Connect to ring on the SLIC side

19 24

R

TESTin

Connect to TEST

IN

bus ring lead

25

NC

No connection

26

NC

No connection

27

NC

No connection

20 28

V

BAT

Battery voltage supply. Must be capable of

sourcing the trigger current for proper

operation of the SCR.

CPC7583

4

www.clare.com

R3.0

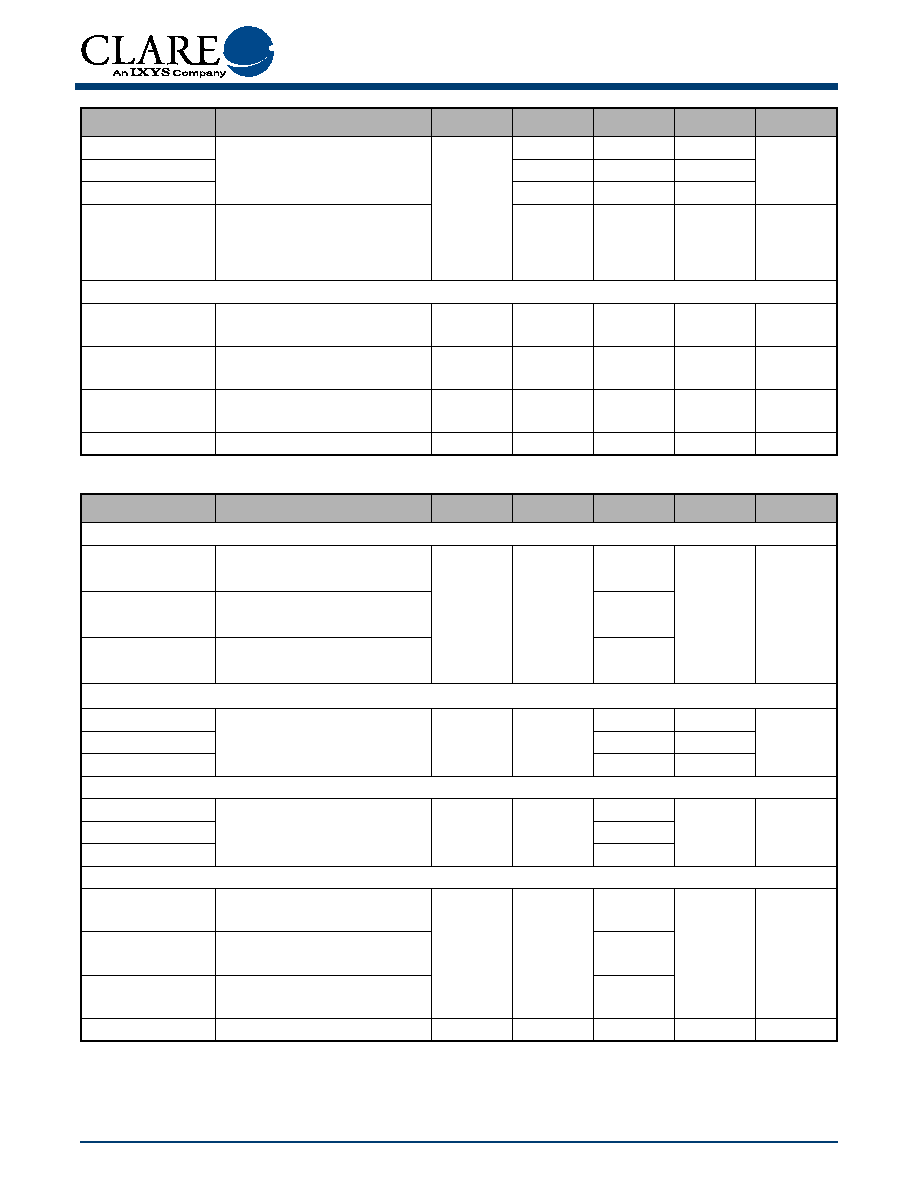

1.3 Absolute Maximum Ratings (at 25∞ C)

1.4 Electrical Characteristics, T

A

= -40∞ C to +85∞ C

Unless otherwise specified, minimum and maximum

values are production testing requirements. Typical

values are characteristic of the device and are the

result of engineering evaluations. Typical values are

provided for information purposes only and are not

part of the testing requirements. V

DD

= 5V

dc

Absolute maximum ratings are stress ratings. Stresses in

excess of these ratings can cause permanent damage to

the device. Functional operation of the device at conditions

beyond those indicated in the operational sections of this

data sheet is not implied.

1.4.1 Power Supply Specifications

1.4.2 Break Switches, SW1 and SW2

Parameter

Minimum Maximum

Unit

Operating temperature

-40

+110

∞C

Storage temperature

-40

+150

∞C

Operating relative humidity

5

95

%

Pin soldering temperature

(10 seconds max)

-

+260

∞C

+5 V power supply(V

DD

)

-0.3

7

V

Battery Supply

-

-85

V

D

GND

to F

GND

separation

-5

+5

V

Logic input voltage

-0.3

V

DD

+0.3

V

Logic input to switch output

isolation

-

330

V

Switch open contact

isolation (SW1, SW2, SW3,

SW5, SW6, SW7, SW9,

SW10)

-

330

V

Switch open contact

isolation (SW4)

-

465

V

Switch open contact

isolation (SW8)

-

235

V

Supply

Minimum Typical Maximum

Unit

V

DD

+4.5

+5.0

+5.5

V

V

BAT

1

-19

-

-72

V

1

V

BAT

is used only for internal protection circuitry. If V

BAT

rises above

-10 V, the device will enter the all-off state and will remain in the all-off state

until the battery drops below -15 V.

ESD Rating (Human Body Model)

1000 V

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -320 V to gnd

V

SW

(differential) = +260 V to -60 V

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(differential) = -330 V to gnd

V

SW

(differential) = +270 V to -60 V

0.3

-40∞ C

V

SW

(differential) = -310 V to gnd

V

SW

(differential) = +250 V to -60 V

0.1

R

ON

+25∞ C

I

SW

(on) = ±10 mA, ±40 mA,

R

BAT

and T

BAT

= -2 V

R

ON

-

14.5

-

+85∞ C

20.5

28

-40∞ C

10.5

-

R

ON

match

Per on-resistance test condition of SW1

& SW2

R

ON

0.15

0.8

CPC7583

R3.0

www.clare.com

5

1.4.3 Ringing Return Switch, SW3

DC current limit

+25∞ C

V

SW

(on) = ±10 V

I

SW

-

225

-

mA

+85∞ C

80

150

-40∞ C

-

400

425

Dynamic current limit

(t = <0.5

µs)

Break switches on, ringing switches off,

apply ±1 kV 10/1000

µs pulse, with

appropriate protection in place.

-

2.5

-

A

Logic input to switch output isolation

+25∞ C

V

SW

(T

LINE

, R

LINE

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(T

LINE

, R

LINE

) = ±330 V, logic

inputs = gnd

-

0.3

-40∞ C

V

SW

(T

LINE

, R

LINE

) = ±310 V, logic

inputs = gnd

-

0.1

dv/dt sensitivity

-

-

-

200

-

V/

µs

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -320 V to gnd

V

SW

(differential) = +260 V to -60 V

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(differential) = -330 V to gnd

V

SW

(differential) = +270 V to -60 V

0.3

-40∞ C

V

SW

(differential) = -310 V to gnd

V

SW

(differential) = +250 V to -60 V

0.1

R

ON

+25∞ C

I

SW

(on) = ±0 mA, ±10 mA

R

ON

-

60

-

+85∞ C

85

110

-40∞ C

45

-

DC current limit

+25∞ C

V

SW

(on) = ± 10 V

I

SW

-

120

-

mA

+85∞ C

70

85

-40∞ C

-

210

Dynamic current limit

(t = <0.5

µs)

Break switches off, ringing switches on,

apply ±1 kV 10/1000

µs pulse, with

appropriate protection in place.

2.5

A

Logic input to switch output isolation

+25∞ C

V

SW

(T

RING

, T

LINE

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(T

RING

, T

LINE

) = ±330 V, logic

inputs = gnd

0.3

-40∞ C

V

SW

(T

RING

, T

LINE

) = ±310 V, logic

inputs = gnd

0.1

dv/dt sensitivity

-

-

-

200

-

V/

µs

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

CPC7583

6

www.clare.com

R3.0

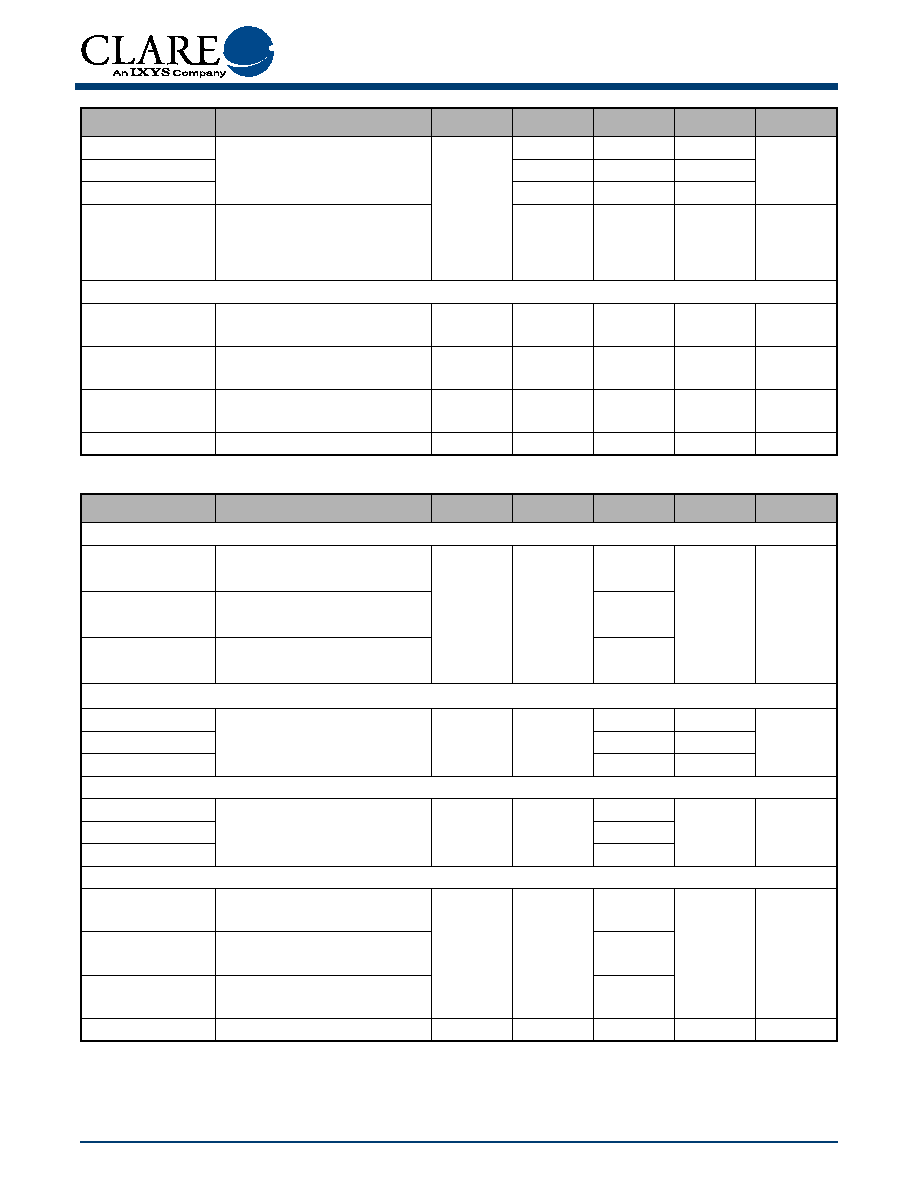

1.4.4 Ringing Switch, SW4

1.4.5 TEST

OUT

Switches, SW5 and SW6

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -255 V to +210 V

V

SW

(differential) = +255 V to -210 V

I

SW

-

0.05

1

µA

+85∞ C

V

SW

(differential) = -270 V to +210 V

V

SW

(differential) = +270 V to -210 V

0.1

1

-40∞ C

V

SW

(differential) = -245 V to +210 V

V

SW

(differential) = +245 V to -210 V

0.05

1

On Voltage

I

SW

(on) = ± 1 mA

-

1.5

3

V

Ringing generator

current to ground during

ringing

Inputs set for ringing mode

I

RINGING

0.1

0.25

mA

On steady-state current* Inputs set for ringing mode

I

SW

-

150

mA

Surge current*

-

-

-

2

A

Release current

-

I

RINGING

450

-

µA

R

ON

I

SW

(on) = ±70 mA, ±80 mA

R

ON

10

15

Logic input to switch output isolation

+25∞ C

V

SW

(R

RING

, R

LINE

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(R

RING

, R

LINE

) = ±330 V, logic

inputs = gnd

0.3

-40∞ C

V

SW

(R

RING

, R

LINE

) = ±310 V, logic

inputs = gnd

0.1

dv/dt sensitivity

-

-

200

-

V/

µs

*Secondary protection and ringing source current limiting must prevent exceeding this parameter.

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -320 V to gnd

V

SW

(differential) = +260 V to -60 V

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(differential) = -330 V to gnd

V

SW

(differential) = +260 V to -60 V

0.3

-40∞ C

V

SW

(differential) = -310 V to gnd

V

SW

(differential) = +250 V to -60 V

0.1

R

ON

+25∞ C

I

SW

(on) = ±10 mA, ±40 mA

R

ON

-

35

-

+85∞ C

50

70

-40∞ C

26

-

DC current limit

CPC7583

R3.0

www.clare.com

7

1.4.6 Ringing Test Return Switch, SW7

+25∞ C

V

SW

(on) = ±10 V

I

SW

-

140

-

mA

+85∞ C

80

100

-

-40∞ C

-

210

250

Dynamic current limit

(t = <0.5

µs)

Break switches in on state, ringing

switches off, apply ±1 kV at

10/1000

µs pulse, with appropriate

secondary protection in place.

-

2.5

-

A

Logic input to switch output isolation

+25∞ C

V

SW

(T

TESTout

, T

LINE

, R

TESTout

, R

LINE

)

= ±320 V, logic inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(T

TESTout

, T

LINE

, R

TESTout

, R

LINE

)

= ±330 V, logic inputs = gnd

I

SW

-

0.3

1

µA

-40∞ C

V

SW

(T

TESTout

, T

LINE

, R

TESTout

, R

LINE

)

= ±310 V, logic inputs = gnd

I

SW

-

0.1

1

µA

dv/dt sensitivity

-

-

200

-

V/

µs

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -320 V to gnd

V

SW

(differential) = +260 to -60 V

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(differential) = -330 V to gnd

V

SW

(differential) = +270 V to -60 V

0.3

-40∞ C

V

SW

(differential) = -310 V to gnd

V

SW

(differential) = +250 V to -60 V

0.1

R

ON

+25∞ C

I

SW

(on) = ±10 mA, ±40 mA

R

ON

-

60

-

+85∞ C

85

100

-40∞ C

45

-

DC current limit

+25∞ C

V

SW

(on) = ±10 V

I

SW

70

120

-

mA

+85∞ C

80

-40∞ C

210

Logic input to switch output isolation

+25∞ C

V

SW

(T

RING

, T

TESTin

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(T

RING

, T

TESTin

) = ±330 V, logic

inputs = gnd

0.3

-40∞ C

V

SW

(T

RING

, T

TESTin

) = ±310 V, logic

inputs = gnd

0.1

dv/dt sensitivity

-

-

200

-

V/

µs

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

CPC7583

8

www.clare.com

R3.0

1.4.7 Ringing Test Switch, SW8

1.4.8 TEST

In

Switches, SW9 and SW10

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -60 V to +175 V

I

SW

-

0.05

1

µA

+85∞ C

0.1

-40∞ C

0.05

On Voltage

I

SW(ON)

= ±1 mA

-

0.75

1.5

V

R

ON

I

SW(ON)

= ±70 mA, ±80 mA

R

ON

35

-

Release Current

-

-

450

-

µA

Logic input to switch output isolation

+25∞ C

V

SW

(R

RING

, R

TESTin

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(R

RING

, R

TESTin

) = ±330 V, logic

inputs = gnd

0.3

-40∞ C

V

SW

(R

RING

, R

TESTin

) = ±310 V, logic

inputs = gnd

0.1

dv/dt sensitivity

-

-

200

-

V/

µs

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Off-state leakage current

+25∞ C

V

SW

(differential) = -320 V to gnd

V

SW

(differential) = -60 V to +260 V

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(differential) = -330 V to gnd

V

SW

(differential) = -60 V to +270 V

0.3

-40∞ C

V

SW

(differential) = -310 V to gnd

V

SW

(differential) = -60 V to +250 V

0.1

R

ON

+25∞ C

I

SW

(on) = ±10 mA, ±40 mA

R

ON

-

35

-

+85∞ C

50

70

-40∞ C

26

-

DC current limit

+25∞ C

V

SW

(on) = ±10 V

I

SW

-

160

-

mA

+85∞ C

80

110

-

-40∞ C

-

210

250

Logic input to switch output isolation

+25∞ C

V

SW

(T

TESTin

, R

TESTin

) = ±320 V, logic

inputs = gnd

I

SW

-

0.1

1

µA

+85∞ C

V

SW

(T

TESTin

, R

TESTin

) = ±330 V, logic

inputs = gnd

0.3

-40∞ C

V

SW

(T

TESTin

, R

TESTin

) = ±310 V, logic

inputs = gnd

0.1

dv/dt sensitivity

-

-

200

-

V/

µs

CPC7583

R3.0

www.clare.com

9

1.5 Additional Electrical Characteristics

Parameter

Test Conditions

Symbol

Minimum

Typical

Maximum

Unit

Digital input characteristics

Input low voltage

-

V

IL

-

-

1.5

V

Input high voltage

-

V

IH

3.5

-

-

Input leakage current

(high)

V

DD

= 5.5 V, V

BAT

= -75 V, V

IH

= 5 V

I

IH

-

0.1

1

µA

Input leakage current

(low)

V

DD

= 5.5 V, V

BAT

= -75 V, V

IL

= 0 V

I

IL

-

0.1

1

Power requirements

Power consumption in

talk and all-off states

V

DD

= 5 V, V

BAT

= -48 V, measure I

DD

and I

BAT

P

-

4.7

10.5

mW

Power consumption in

all other states

V

DD

= 5 V, V

BAT

= -48 V, measure I

DD

and I

BAT

P

5.2

10.5

V

DD

current in talk and

all-off states

V

DD

= 5 V, V

BAT

= -48 V

I

DD

-

0.9

2.0

mA

V

DD

current in all other

states

I

DD

-

1.0

2.0

V

BAT

current in any state V

DD

= 5V, V

BAT

= -48 V

I

BAT

-

4

10

µA

Temperature Shutdown Requirements (temperature shutdown flag is active low)

Shutdown activation

temperature

Not production tested - guarenteed by

design and Quality Control sampling

audits.

T

SD_on

110

125

150

∞C

Shutdown circuit

hysteresis

T

SD_off

10

-

25

∞C

CPC7583

10

www.clare.com

R3.0

1.6 Protection Circuitry Electrical Specifications

1.7 Truth Tables

1.7.1 Truth Table for CPC7583xA and CPC7583xB

Parameter

Conditions

Symbol

Minimum

Typical

Maximum

Unit

Parameters Related to the Diodes in the Diode Bridge

Voltage drop at

continuous current

(50/60 Hz)

Apply ± dc current limit of break

switches

Forward

Voltage

-

2.8

3.5

V

Voltage drop at surge

current

Apply ± dynamic current limit of break

switches

Forward

Voltage

-

5

-

Parameters Related to the Protection SCR (when equipped)

Surge current

-

-

-

-

*

A

Trigger current (+25∞ C)

I

TRIG

60

-

mA

Trigger current (+85∞ C)

I

TRIG

35

-

Hold current (+25∞ C)

I

HOLD

110

-

Hold current (+85∞ C)

I

HOLD

60

70

-

Gate trigger voltage

I

GATE

= I

TRIGGER

ß

V

TBAT

or

V

RBAT

V

BAT

-4

-

V

BAT

-2

V

Reverse leakage current V

BAT

= -48 V

I

VBAT

-

-

1.0

µA

On-state voltage

0.5 A, t = 0.5

µs

V

TBAT

or

V

RBAT

-3

-

V

2.0 A, t = 0.5

µs

-5

-

V

*Passes GR1089 and ITU-T K.20 with appropriate secondary protection in place.

ß

V

BAT

must be capable of sourcing I

TRIGGER

for the internal SCR to activate.

State

IN

RINGING

IN

TESTIN

IN

TESTOUT

Latch

T

SD

TEST

IN

Switches

Break

Switches

Ringing

Test

Switches

Ringing

Switches

TEST

OUT

Switches

Talk

0

0

0

0

1 or

Floating

1

Off

On

Off

Off

Off

TESTout

0

0

1

Off

Off

Off

Off

On

TESTin

0

1

0

On

Off

Off

Off

Off

Simultaneous

TESTin and

TESTout

0

1

1

On

Off

Off

Off

On

Ringing

1

0

0

Off

Off

Off

On

Off

Ringing

Generator

Test

1

1

0

Off

Off

On

Off

Off

Latched

X

X

X

1

Unchanged Unchanged Unchanged Unchanged Unchanged

All Off

1

0

1

0

Off

Off

Off

Off

Off

1

1

1

0

Off

Off

Off

Off

Off

X

X

X

X

0

2

Off

Off

Off

Off

Off

1

If T

SD

is tied high, thermal shutdown is disabled. If T

SD

is left floating, the thermal shutdown mechanism functions normally.

2

Forcing T

SD

to ground overrides the logic input pins and forces an all off state.

CPC7583

R3.0

www.clare.com

11

1.7.2 Truth Table for CPC7583xC and CPC7583xD

State

IN

RINGING

IN

TESTIN

IN

TESTOUT

Latch

T

SD

TEST

IN

Switches

Break

Switches

Ringing

Test

Switches

Ringing

Switches

TEST

OUT

Switches

Talk

0

0

0

0

1 or

Floating

1

Off

On

Off

Off

Off

TESTout

0

0

1

Off

Off

Off

Off

On

TESTin

0

1

0

On

Off

Off

Off

Off

Simultaneous

TESTin and

TESTout

0

1

1

On

Off

Off

Off

On

Ringing

1

0

0

Off

Off

Off

On

Off

Ringing

Generator

Test

1

1

0

Off

Off

On

Off

Off

Simultaneous

TESTout and

Ringing

Generator

Test

1

1

1

Off

Off

On

Off

On

Latched

X

X

X

1

Unchanged Unchanged Unchanged Unchanged Unchanged

All Off

1

0

1

0

Off

Off

Off

Off

Off

X

X

X

X

0

2

Off

Off

Off

Off

Off

1

If T

SD

is tied high, thermal shutdown is disabled. If T

SD

is left floating, the thermal shutdown mechanism functions normally.

2

Forcing T

SD

to ground overrides the logic input pins and forces an all off state.

CPC7583

12

www.clare.com

R3.0

2. Functional Description

2.1 Introduction

The CPC7583 has the following states:

∑

Talk. Loop break switches SW1, and SW2 closed, all

other switches open.

∑

Ringing. Ringing switches SW3, SW4 closed, all

other switches open.

∑

TESTout. Testout switches SW5, SW6 closed, all

other switches open.

∑

Ringing generator test. SW7, SW8 closed, all

other switches open.

∑

TESTin. Testin switches SW9 and SW10 closed.

∑

Simultaneous TESTin and TESTout. SW9, SW10,

SW5, and SW6 closed, all other switches open.

∑

Simultaneous test out and ringing generator

test. SW5, SW6, SW7, and SW8 closed, all other

switches open (only on the xC and xD versions).

∑

All Off. All switches open.

See

"Truth Tables" on page 10

for more information.

The CPC7583 offers break-before-make and

make-before-break switching from the ringing state to

the talk state with simple logic level input control.

Solid-state switch construction means no impulse

noise is generated when switching during ringing

cadence or ring trip, eliminating the need for external

zero-cross switching circuitry. State-control is via

logic-level input so no additional driver circuitry is

required. The linear line break switches SW1 and

SW2 have exceptionally low R

ON

and excellent

matching characteristics. The ringing switch SW4 has

a minimum open contact breakdown voltage of 465 V.

This is sufficiently high, with proper protection, to

prevent breakdown in the presence of a transient fault

condition (i.e., passing the transient on to the ringing

generator).

Integrated into the CPC7583 is an over voltage

clamping circuit, active current limiting, and a thermal

shutdown mechanism to provide protection to the

SLIC device during a fault condition. Positive and

negative surges are reduced by the current limiting

circuitry and hazardous potentials are diverted to

ground via diodes and the integrated SCR.

Power-cross potentials are also reduced by the current

limiting and thermal shutdown circuits.

To protect the CPC7583 from an overvoltage fault

condition, the use of a secondary protector is required.

The secondary protector must limit the voltage seen at

the T

LINE

and R

LINE

terminals to a level below the

maximum breakdown voltage of the switches. To

minimize the stress on the solid-state contacts, use of

a foldback or crowbar type secondary protector is

recommended. With proper selection of the secondary

protector, a line card using the CPC7583 will meet all

relevant ITU, LSSGR, TIA/EIA and IEC protection

requirements.

The CPC7583 operates from a +5 V supply only. This

gives the device extremely low idle and active power

consumption and allows use with virtually any range of

battery voltage. The battery voltage is also used by the

CPC7583 as a reference for the integrated protection

circuit. In the event of a loss of battery voltage, the

CPC7583 enters the all-off state.

2.2 Switch Logic

The CPC7583 provides, when switching from the

ringing state to the talk state, the ability to control the

release timing of the ringing switches SW3 and SW4

relative to the state of the loop break switches SW1

and SW2 using simple logic-level input. This is

referred to as a make-before-break or

break-before-make operation. When the line break

switch contacts (SW1 and SW2) are closed (or made)

before the ringing access switch contacts (SW3 and

SW4) are opened (broken), this is referred to

make-before-break operation. Break-before-make

operation occurs when the ringing access contacts

(SW3 and SW4) are opened (broken) before the line

break switch contacts (SW1 and SW2) are closed

(made). With the CPC7583, the make-before-break

and break-before-make operations can easily be

selected by applying the proper sequence of logic

inputs to IN

TESTout

, IN

RINGING

, and IN

TESTin

.

The logic sequences for either mode of operation are

given in

"Make-Before-Break Operation (Ringing to Talk

Transition)" on page 13

and

"Break-Before-Make Operation

(Ringing to Talk Transition)" on page 13

. Logic states and

explanations are given in

"Truth Tables" on page 10

.

Break-before-make operation can also be achieved

using the T

SD

pin as an input. In

"Break-Before-Make

Operation (Ringing to Talk Transition)" on page 13

, lines 2

and 3, it is possible to induce the switches to the all-off

state by grounding T

SD

instead of applying input to the

logic pins. This has the effect of overriding the logic

inputs and forcing the device to the all-off state. For

CPC7583

R3.0

www.clare.com

13

20 Hz ringing hold this input state for 25 ms. During

this hold period, toggle the inputs from the ringing

state to the talk state. After the 25 ms, release T

SD

to

return switch control to the input pins IN

TESTout

,

IN

RINGING

, IN

TESTin

and the latch control pin.

2.2.1 Make-Before-Break Operation (Ringing to Talk Transition)

2.2.2 Break-Before-Make Operation (Ringing to Talk Transition)

2.3 Alternate Break-Before-Make Operation

Note that break-before-make operation can also be

achieved using T

SD

as an input. In lines 2 and 3 of the

table

"Break-Before-Make Operation (Ringing to Talk

Transition)" on page 13

, instead of using the logic input

pins to force the all-off state, force T

SD

to ground. This

overrides the logic inputs and also forces the all off

state. Hold this state for one-half of the ringing cycle.

During this T

SD

forced all-off state, change the inputs

from the power ringing state (IN

RING

= 1, IN

TESTIN

= 0,

IN

TESTOUT

= 0) to the talk state (IN

RING

= 0,

IN

TESTIN

= 0, IN

TESTOUT

= 0). After the hold period,

release T

SD

to return switch control to the input pins

which will set the talk state.

2.4 Data Latch

The CPC7583 has an integrated data latch. The latch

operation is controlled by logic-level input at the

LATCH pin. The data input of the latch are the input

pins, while the output of the data latch is an internal

node used for state control. When the LATCH control

pin is at logic 0, the data latch is transparent and data

control signals flow directly through to state control. A

change in input will be reflected in a change is switch

state. When the LATCH control pin is at logic 1, the

data latch is active and a change in input control will

not affect switch state. The switches will remain in the

position they were in when the LATCH changed from

State

IN

RINGING

IN

TESTIN

IN

TESTOUT

Latch

T

SD

Timing

Break

Switches

1 and 2

Ring

Return

Switch 3

Ring

Access

Switch 4

All Other

Test

Switches

Ringing

1

0

0

0

Floating

-

Off

On

On

Off

Make-bef

ore-break

0

0

0

Floating

SW4 waiting for next

zero-current crossing to turn

off. Maximum time is one-half

of ringing. In this transition

state, current that is limited to

the dc break switch current

limit value will be sourced

from the ring node of the

SLIC.

On

Off

On

Off

Talk

0

0

0

Floating

Zero-cross current has

occurred

On

Off

Off

Off

State

IN

RINGING

IN

TESTIN

IN

TESTOUT

Latch

T

SD

Timing

Break

Switches

1 and 2

Ring

Return

Switch 3

Ring

Access

Switch 4

All Other

Test

Switches

Ringing

1

0

0

0

Floating

-

Off

On

On

Off

All off

1

0

1

Floating

Hold this state for one-half of

ringing cycle. SW4 waiting for

zero current to turn off.

Off

Off

On

Off

All off

1

0

1

Floating

Zero current has occurred.

SW4 has opened

Off

Off

Off

Off

Talk

0

0

0

Floating

Release break switches

On

Off

Off

Off

CPC7583

14

www.clare.com

R3.0

logic 0 to logic 1 and will not respond to changes in

input as long as the latch is at logic 1. The T

SD

input is

not tied to the data latch. Therefore, T

SD

is not

affected by the LATCH input and the T

SD

input will

override state control.

2.5 T

SD

Behavior

Setting T

SD

to +5 V allows switch control using the

logic inputs. This setting, however, also disables the

thermal shutdown circuit and is therefore not

recommended. When using logic controls via the input

pins, T

SD

should be allowed to float. As a result, the

two recommended states when using T

SD

as a control

are 0, which forces the device to an all-off state, or

float, which allows logic inputs to remain active. This

requires the use of an open collector type buffer.

2.6 Ringing Switch Zero-Cross Current Turn Off

After the application of a logic input to turn SW4 off,

the ringing switch is designed to delay the change in

state until the next zero-crossing. Once on, the switch

requires a zero-current cross to turn off, and therefore

should not be used to switch a pure DC signal. The

switch will remain in the on state no matter the logic

input until the next zero crossing. These switching

characteristics will reduce and possibly eliminate

overall system impulse noise normally associated with

ringing switches. See Clare application note

AN-144,

Impulse Noise Benefits of Line Card Access Switches

for

more information. The attributes of ringing switch SW4

may make it possible to eliminate the need for a

zero-cross switching scheme. A minimum impedance

of 300

in series with the ringing generator is

recommended.

2.7 Power Supplies

Both a +5 V supply and battery voltage are connected

to the CPC7583. Switch state control is powered

exclusively by the +5 V supply. As a result, the

CPC7583 exhibits extremely low power consumption

during both active and idle states.

The battery voltage is not used for switch control but

rather as a supply for the integrated secondary

protection circuitry. The integrated SCR is designed to

trigger when the voltage at T

BAT

or R

BAT

drops 2 to

4 V below the applied voltage on the V

BAT

pin. This

trigger prevents a fault induced overvoltage event at

the T

BAT

or R

BAT

nodes.

2.8 Battery Voltage Monitor

The CPC7583 also uses the V

BAT

voltage to monitor

battery voltage. If battery voltage is lost, the CPC7583

immediately enters the all-off state. It remains in this

state until the battery voltage is restored. The device

also enters the all-off state if the battery voltage rises

above ≠10 V and remains in the all-off state until the

battery voltage drops below ≠15 V. This battery

monitor feature draws a small current from the battery

(less than 1

µA typical) and will add slightly to the

device's overall power dissipation.

2.9 Protection

2.9.1 Diode Bridge/SCR

The CPC7583 uses a combination of current limited

break switches, a diode bridge/SCR clamping circuit,

and a thermal shutdown mechanism to protect the

SLIC device or other associated circuitry from damage

during line transient events such as lightning. During a

positive transient condition, the fault current is

conducted through the diode bridge to ground via

F

GND

. Voltage is clamped to a diode drop above

ground. During a negative transient of 2 to 4 V more

negative than the voltage source at V

BAT

, the SCR

conducts and faults are shunted to F

GND

via the SCR

or the diode bridge.

In order for the SCR to crowbar or foldback, the on

voltage (see

"Protection Circuitry Electrical

Specifications" on page 10

) of the SCR must be less

negative than the V

BAT

voltage. If the V

BAT

voltage is

less negative than the SCR on state voltage, or if the

V

BAT

supply is unable to source the trigger current, the

SCR will not crowbar.

For power induction or power-cross fault conditions,

the positive cycle of the transient is clamped to a diode

drop above ground and the fault current directed to

ground. The negative cycle of the transient will cause

the SCR to conduct when the voltage exceeds the

battery reference voltage by two to four volts, steering

the current to ground.

2.9.2 Current Limiting function

If a lightning strike transient occurs when the device is

in the talk state, the current is passed along the line to

the integrated protection circuitry and restricted by the

dynamic current limit response of the active switches.

During the talk state when a 1000V 10/1000

µS pulse

(GR-1089-CORE lightning) is applied to the line

though a properly clamped external protector, the

current into T

LINE

or R

LINE

will be a pulse with a typical

magnitude of 2.5 A and a duration of less than 0.5

µs.

CPC7583

R3.0

www.clare.com

15

If a power-cross fault occurs with the device in the talk

state, the current is passed though break switches

SW1 and SW2 on to the integrated protection circuit

and is limited by the dynamic DC current limit

response of the two break switches. The DC current

limit, specified over temperature, is between 80 mA

and 425 mA, and the circuitry has a negative

temperature coefficient. As a result, if the device is

subjected to extended heating due to power cross

fault, the measured current at T

LINE

or R

LINE

will

decrease as the device temperature increases. If the

device temperature rises sufficiently, the temperature

shutdown mechanism will activate and the device will

default to the all-off state.

2.10 Temperature Shutdown

The thermal shutdown mechanism will activate when

the device temperature reaches a minimum of 110∞ C,

placing the device in the all-off state regardless of

logic input. During thermal shutdown mode, the

voltage out of the T

SD

pin will read 0 V. Normal output

of T

SD

is V

DD

.

If presented with a short duration transient such as a

lightning event, the thermal shutdown feature will

typically not activate. But in an extended power-cross

transient, the device temperature will rise and the

thermal shutdown will activate forcing the switches to

the all-off state. At this point the current measured into

T

LINE

or R

LINE

will drop to zero. Once the device

enters thermal shutdown it will remain in the all-off

state until the temperature of the device drops below

the deactivation level of the thermal shutdown circuit.

This will permit the device to return to normal

operation. If the transient has not passed, current will

flow up to the value allowed by the dynamic DC

current limiting of the switches and heating will begin

again, reactivating the thermal shutdown mechanism.

This cycle of entering and exiting the thermal

shutdown mode will continue as long as the fault

condition persists. If the magnitude of the fault

condition is great enough, the external secondary

protector could activate and shunt all current to

ground.

2.11 External Protection Elements

The CPC7583 requires only over-voltage secondary

protection on the loop side of the device. The

integrated protection feature described above negates

the need for additional protection on the SLIC side.

The secondary protector must limit voltage transients

to levels that do not exceed the breakdown voltage or

input-output isolation barrier of the CPC7583. A

foldback or crowbar type protector is recommended to

minimize stresses on the CPC7583.

Consult Clare's application note, AN-100, "

Designing

Surge and Power Fault Protection Circuits for Solid

State Subscriber Line Interfaces

" for equations related

to the specifications of external secondary protectors,

fused resistors and PTCs.

CPC7583

16

www.clare.com

R3.0

3. Manufacturing Information

3.1 Soldering

3.1.1 Moisture Reflow Sensitivity

Clare has characterized the moisture reflow sensitivity

of LCAS products using IPC/JEDEC standard

J-STD-020A. Moisture uptake from atmospheric

humidity occurs by diffusion. During the solder reflow

process, in which the component is attached to the

PCB, the whole body of the component is exposed to

high process temperatures. The combination of

moisture uptake and high reflow soldering

temperatures may lead to moisture induced

delamination and cracking of the component. To

prevent this, this component must be handled in

accordance with IPC/JEDEC standard J-STD-020A

per the labelled moisture sensitivity level (MSL),

level 1 for the SOIC packages, and level 3 for the MLP

package.

3.1.2 Reflow Profile

The maximum ramp rates, dwell times, and

temperatures of the assembly reflow profile should not

exceed those specified in IPC standard IPC-9502,

table 2. Soldering processes are limited to 220 ∞C

component body temperature.

3.2 Washing

Clare does not recommend ultrasonic cleaning of

LCAS parts.

3.3 Mechanical Dimensions

3.3.1 CPC7583Z - 20 Pin SOIC Package

DIMENSIONS

MM

(INCHES)

0.40 MIN - 1.27 MAX

(0.016 MIN - 0.050 MAX)

0.25 MIN - 0.75 MAX X 45∞

(0.010 MIN - 0.029 MAX X 45∞)

0.23 MIN - 0.32 MAX

(0.009 MIN - 0.013 MAX)

0∞-8∞

PIN 1

PIN 20

10.00 MIN - 10.65 MAX

MAX)

(0.394 MIN - 0.419

7.40 MIN - 7.60 MAX

MAX)

(0.291 MIN - 0.299

0.10 MIN - 0.30 MAX

(0.004 MIN - 0.012 MAX)

0.33 MIN - 0.51 MAX

(0.013 MIN - 0.020 MAX)

1.27 TYP

(0.050 TYP)

0.508 MAX - 0.762 MAX

MAX)

(0.020 MIN - 0.030

12.60 MIN - 13.00 MAX

MAX)

(0.496 MIN - 0.512

2.35 MIN - 2.65 MAX

(0.093 MIN - 0.104 MAX)

CPC7583

R3.0

www.clare.com

17

3.3.2 CPC7583B - 28 Pin SOIC Package

3.3.3 CPC7583M - 28 Pin MLP Package

NOTE: For optimum solder joint size, MLP package

printed-circuit board pads should extend no more than

.05 mm past the chip post on the short sides, and no

more than .025 mm past the chip posts on the long

sides.

As the metallic pad on the bottom of the MLP package

is connected to the substrate of the die, Clare

recommends that no printed circuit board to traces

cross this area to maintain minimum creepage and

clearance values.

DIMENSIONS

MM

(INCHES)

7.391 MIN/7.595 MAX

(0.291 MIN/0.299 MAX)

10.109 MIN/10.516 MAX

(0.398 MIN/0.414 MAX)

17.983 MIN/18.085 MAX

(0.708 MIN/0.712 MAX)

1.270 TYP

(0.050 TYP)

PIN 28

PIN 1

0.508 MIN/1.016 MAX)

(0.020 MIN/0.040 MAX)

0.2311 MIN/0.3175 MAX

(0.0091 MIN/0.0125MAX)

0.254 MIN/0.737 MAX X 45∞

(0.010 MIN/0.029 MAX X 45∞)

2.235 MIN/2.438 MAX

(0.088 MIN/0.096 MAX)

0.366 MIN/0.467 MAX TYP

(0.014 MIN/0.018 MAX TYP)

2.438 MIN/2.642 MAX

(0.096 MIN/0.104 MAX)

0.660±0.102

(0.026±0.004)

0.37

(0.0146)

Pin 1

TOP VIEW

SIDE VIEW

Seating Plane

Dimensions in mm (inches)

Dimensions and tolerances conform to ANSI Y14.5M-1994

11.0

(0.4334)

7.0

(0.2758)

0.9 ± 0.1

(0.0355 ±0.0039)

0.02 ±0.03

(0.0008 ±0.0012)

0.2

(0.0079)

Bottom side

metallic pad

0.75

(0.0295)

0.33 -0.05 +0.07

(0.0130 -0.0020 +0.0028)

0.55 ± 0.05

(0.0217

0.0020)

±

0.60

(0.0236)

0.70

(0.0276)

0.18

(0.0071)

0.18

(0.0071)

0.61

(0.0240)

BOTTOM VIEW

5.0±0.05

(0.1970±0.0020)

7.5 ± 0.05

(0.2955 ± 0.0020)

3.3.4 CPC7583Z - Tape and Reel Dimensions

3.3.5 CPC7583B - Tape and Reel Dimensions

3.3.6 CPC7583M - Tape and Reel Dimensions

Top Cover

Tape Thickness

0.102 MAX

(0.004 MAX)

330.2 DIA.

(13.00 DIA)

Embossed Carrier

Embossment

K0=3.20 0.15

(0.13 0.01)

+

+

K1=2.60 0.15

(0.10 0.01)

+

+

P=12.00

(0.47)

A0=10.75 0.15

(0.42 0.01)

+

+

B0=13.40 0.15

(0.53 0.01)

+

+

W=24.00 0.3

(0.94 0.01)

+

+

A0=10.75

(0.42)

B0=18.50

(0.73)

W=24.00±0.03

(0.94±.001)

K1=2.60

(0.10)

K0=3.20

(0.13)

P=12.00

(0.47)

Top Cover

Tape Thickness

0.102 MAX

(0.004 MAX)

330.2 DIA.

(13.00 DIA)

Embossed Carrier

Embossment

Top Cover

Tape Thickness

0.102 MAX

(0.004 MAX)

330.2 DIA.

(13.00 DIA)

Embossed Carrier

Embossment

K0=1.35

(0.05)

P=12.00

(0.47)

A0=7.35

(0.29)

B0=11.35

(0.45)

W=24.00 0.3

(0.94 0.01)

+

+

For additional information please visit

www.clare.com

Clare, Inc. makes no representations or warranties with respect to the accuracy or completeness of the contents of this publication and reserves the right to make

changes to specifications and product descriptions at any time without notice. Neither circuit patent licenses or indemnity are expressed or implied. Except as set

forth in Clare's Standard Terms and Conditions of Sale, Clare, Inc. assumes no liability whatsoever, and disclaims any express or implied warranty relating to its

products, including, but not limited to, the implied warranty of merchantability, fitness for a particular purpose, or infringement of any intellectual property right.

The products described in this document are not designed, intended, authorized, or warranted for use as components in systems intended for surgical implant into

the body, or in other applications intended to support or sustain life, or where malfunction of Clare's product may result in direct physical harm, injury, or death to a

person or severe property or environmental damage. Clare, Inc. reserves the right to discontinue or make changes to its products at any time without notice.

Specification: DS-CPC7583 - R3.0

© Copyright 2003, Clare, Inc.

All rights reserved. Printed in USA.

5/30/2003