G

∑

SiC

Æ

Technology

SuperBrightTM LEDs

CXXX-CB290-S0100

Features Applications

∑ High Performance

≠ 2.0mW (460nm) Deep Blue

≠ 2.0mW (470nm) Blue

≠ 1.5mW (505nm) Signal Green

≠ 1.0mW (527nm) Green

∑ Sorted to Wavelength and Power Bins

∑ Single Wire Bond Structure

∑ Class II ESD Rating

∑ Outdoor LED Video Displays

∑ White LEDs

∑ Automotive Dashboard Lighting

∑ Cellular Phone Backlighting

∑ Audio Product Display Lighting

∑ Entertainment and Amusement

Description

Cree's CBTM series of SuperBrightTM LEDs combine highly efficient InGaN materials with Cree's

proprietary SiC substrate to deliver excellent price performance for high intensity blue and green LEDs.

These LED chips have an industry-standard vertical chip structure, which requires only a single wire bond

connection. Sorted Die Kits provide die sheets conveniently sorted into wavelength and radiant flux bins.

Cree's CB series chips are tested for conformity to optical and electrical specifications and the ability to

withstand 1000V ESD. These LEDs are useful in a broad range of applications such as outdoor and

indoor full motion LED video signs, transportation signaling and white LEDs, yet can also be used in high

volume applications such as LCD backlighting. Cree's CB series chips are compatible with most radial

and SMT LED assembly processes.

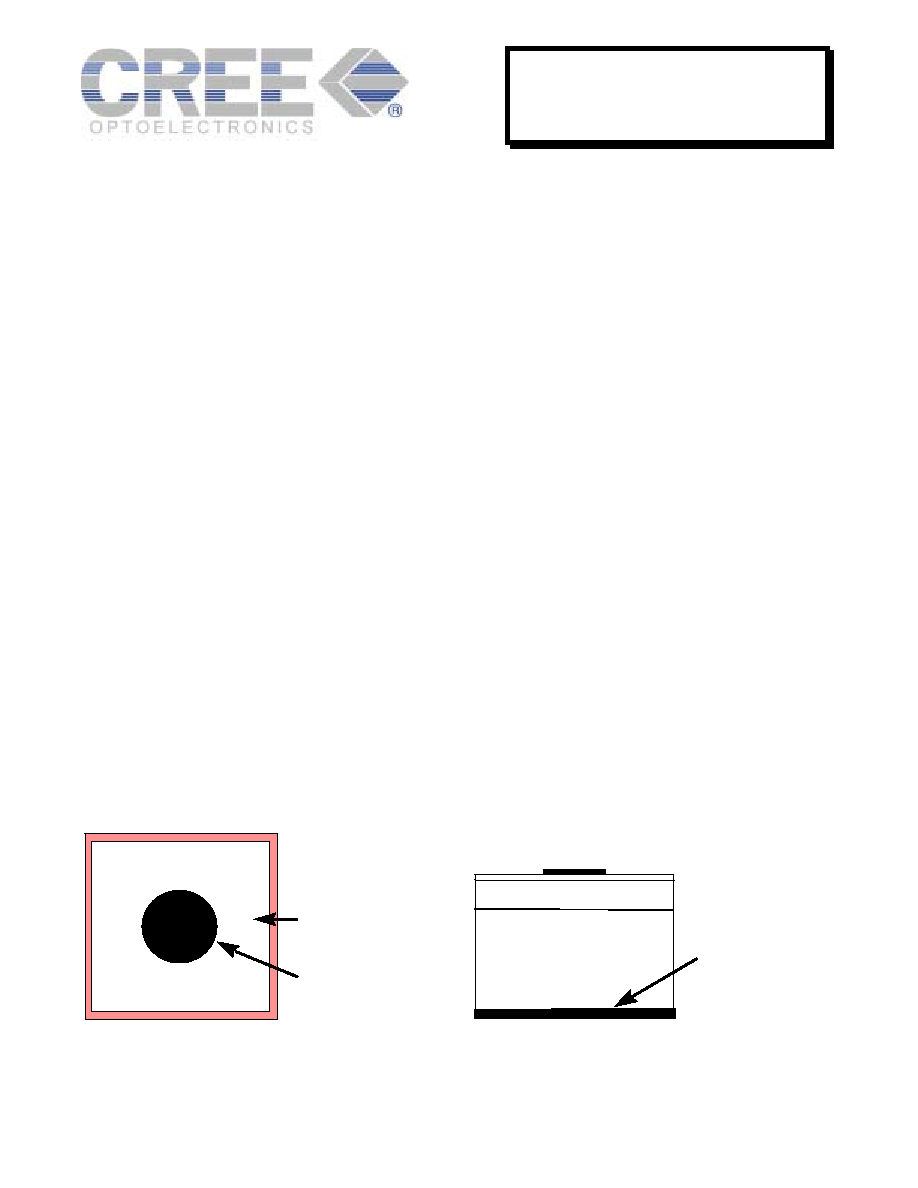

CXXX-CB290-S0100 Chip Diagram

Topside View

G

∑

SiCÆ LED Chip

300 x 300 µm

Mesa (junction)

240 x 240 µm

Gold Bond Pad

120 µm Diameter

Anode (+)

Die Cross Section

h = 250 µm

Backside

Metallization

Cathode (-)

InGaN

SiC Substrate

CPR3U Rev. I

© 1998-2003 Cree, Inc. All Rights Reserved.

G

∑

SiC

Æ

Technology

SuperBrightTM LEDs

CXXX-CB290-S0100

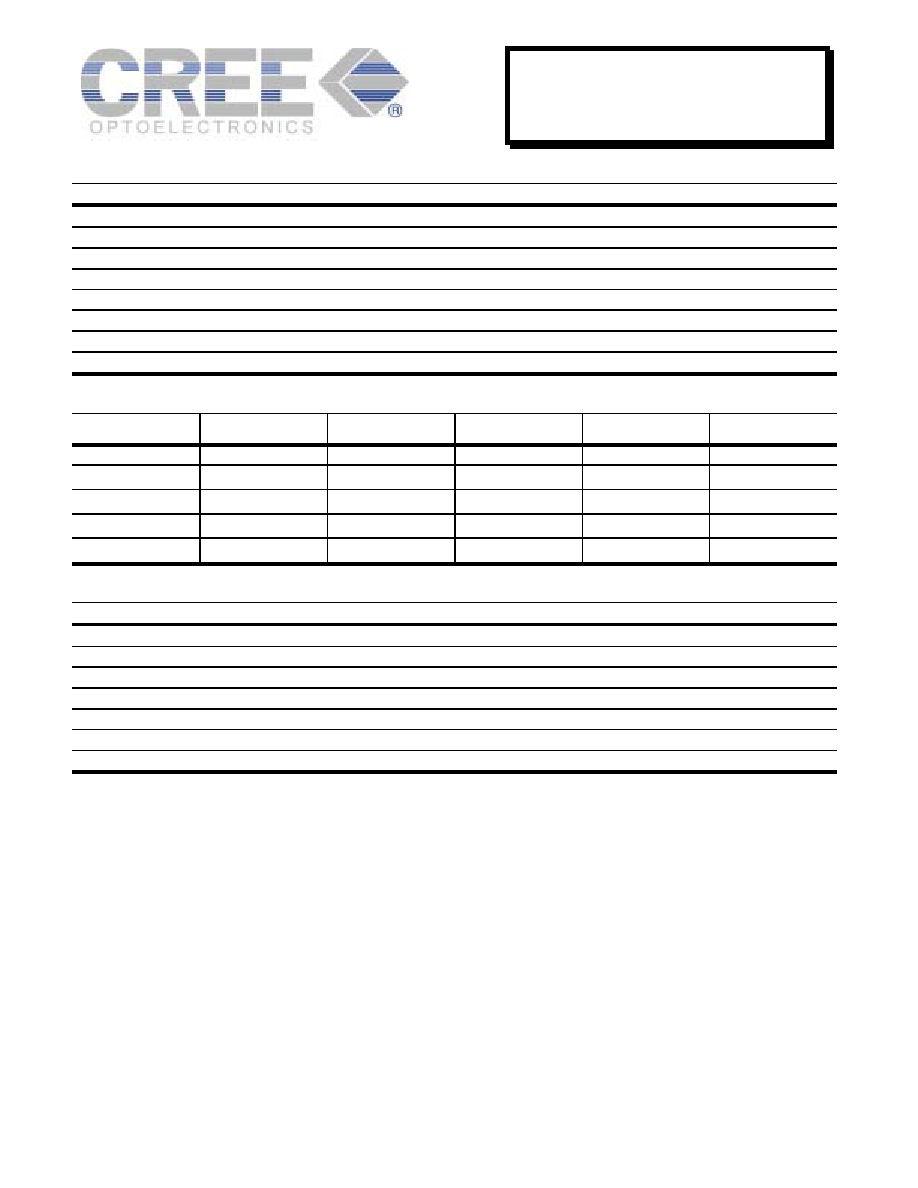

Maximum Ratings at T

A

= 25∞C

Notes 1&3

CXXX-CB290-S0100

DC Forward Current

30 mA

Peak Forward Current (1/10 duty cycle @ 1kHz)

100 mA

LED Junction Temperature

125∞C

Reverse Voltage

5 V

Operating Temperature Range

-20∞C to +80∞C

Storage Temperature Range

-30∞C to +100∞C

Electrostatic Discharge Threshold (HBM)

Note 2

1000

V

Electrostatic Discharge Classification (MIL-STD-883E)

Note 2

Class

2

Typical Electrical/Optical Characteristics at T

A

= 25∞C, If = 20mA

Note 3

Part Number

Forward Voltage

(V

f,

V)

Reverse Current

[I(Vr=5V), µA]

Peak Wavelength

(

p,

nm)

Halfwidth

(

D,

nm)

Optical Rise Time

(

, ns)

Typ

Max

Max Typ Typ Typ

C460CB290-S0100

3.3 3.7

10

458

26

30

C470CB290-S0100

3.3 3.7

10

468

26

30

C505CB290-S0100

3.3 3.7

10

502

30

30

C525CB290-S0100

3.3 3.7

10

523

36

30

Mechanical Specifications

CXXX-CB290-S0100

Description Dimension

Tolerance

P-N Junction Area (µm)

240 x 240

± 25

Bottom Area (µm)

300 x 300

± 25

Chip Thickness (µm)

250

± 25

Au Bond Pad Diameter (µm)

120

± 20

Au Bond Pad Thickness (µm)

1.2

± 0.5

Back Contact Metal Width (µm)

19.8

-5,+10

Notes:

1) Maximum ratings are package dependent. The above ratings were determined using a T-1 3/4 package (with Hysol OS4000 epoxy) for characterization.

Ratings for other packages may differ. The forward currents (DC and Peak) are not limited by the die but by the effect of the LED junction temperature on

the package. The junction temperature limit of 125∞C is a limit of the T-1 3/4 package; junction temperature should be characterized in a specific package to

determine limitations. Assembly processing temperature must not exceed 325∞C (< 5 seconds).

2) Product resistance to electrostatic discharge (ESD) according to the HBM is measured by simulating ESD using a rapid avalanche energy test (RAET). The

RAET procedures are designed to approximate the maximum ESD ratings shown. The RAET procedure is performed on each die. The ESD classification

of Class II is based on sample testing according to MIL-STD 883E.

3) All Products conform to the listed minimum and maximum specifications for electrical and optical characteristics, when assembled and operated at 20 mA

within the maximum ratings shown above. Efficiency decreases at higher currents. Typical values given are within the range of average values expected by

the manufacturer in large quantities and are provided for information only. All measurements were made using lamps in T-1 3/4 packages (with Hysol

OS4000 epoxy). Dominant wavelength measurements taken using Illuminance E.

4) Specifications are subject to change without notice.

CPR3U Rev. I

© 1998-2003 Cree, Inc. All Rights Reserved.

G

∑

SiC

Æ

Technology

SuperBrightTM LEDs

CXXX-CB290-S0100

Standard Bins:

All LED chips are sorted onto die sheets according to the bins shown below.

460CB290-0103

460CB290-0104

C460CB290-S0100

460CB290-0101

460CB290-0102

470CB290-0102

470CB290-0104

C470CB290-S0100

470CB290-0101

470CB290-0103

505CB290-0103

505CB290-0104

C505CB290-S0100

505CB290-0101

505CB290-0102

C527CB290-S0100

527CB290-0104

527CB290-0105

527CB290-0106

527CB290-0101

527CB290-0102

527CB290-0103

6.0mW

460nm

4.0mW

Sorted Die Kits may contain any or all

bins shown to the left.

465nm

2.0mW

2.0mW

455nm

1.5mW

5.5mW

4.0mW

3.5mW

465nm

3.4mW

2.5mW

520nm

525nm

530nm

500nm

505nm

1.0mW

1.7mW

535nm

470nm

475nm

510nm

CPR3U Rev. I

© 1998-2003 Cree, Inc. All Rights Reserved.

CPR3U Rev. I

© 1998-2003 Cree, Inc. All Rights Reserved.

G

∑

SiC

Æ

Technology

SuperBrightTM LEDs

CXXX-CB290-S0100

Characteristic Curves

Relative Intensity vs Forward Current - All Products

0.0

20.0

40.0

60.0

80.0

100.0

120.0

140.0

0

5

10

15

20

25

30

If (mA)

%

Wavelength Shift vs Forward Current - All Products

-4.0

-2.0

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

0

5

10

15

20

25

30

If (mA)

S

h

i

ft (nm)

527nm

505nm

470nm

Forward Current vs Forward Voltage - All Products

0

5

10

15

20

25

30

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Vf (V)

If (mA

)

Relative Intensity vs Wavelength - All Products

0%

20%

40%

60%

80%

100%

Wavelength (nm)

Re

la

tiv

e

Inte

ns

ity

(%)

500

5