PAGE 1 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

RS062R-XXXX-X2N Resistor Network

1. Scope

This specification applies to 0.

6mm x 0.

8mm size resistor ne

twork (4P2R) with

2 isolated

resistor for use in electronic equipment.

2. Type Designation

RS062R -- XXXX --

X 2 N

(1)

(2)

(3) (4) (5)

Where (1) Series No:

0.6mm x 0.8mm Size & 4 Pins 2 Resistors

(2) Nominal resistance value :

For example ≠

56R0 = 56

1001 = 1k

(3) Resistance tolerance:

J = ± 5.0%

(4) Outline type:

2 = Flat type

(5) N = Sn plating (Lead free, RoHS compliant)

3. Electrical Specifications

Table 1. :

Power Rating*

31mW/each element

Resistance Values

10 to 1M in E-24 series

Resistance Tolerance

± 5.0% (J)

T.C.R.

(Temperature Coefficient of Resistance)

± 200ppm/

Operating Temperature Range

-55 to 125

Maximum Operating Voltage**

12.5V

PAGE 2 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Note: *Package Power Temperature Derating Curve

AMBIENT TEMPERATURE(

)

0

-55

70

125

R

A

T

E

D

L

O

A

D

(

%

)

100

Figure 1.Power Temperature Derating Cure

Note: **Resistors shall have a rated DC or AC(rms.) continuous operating voltage corresponding

to the power rating, as calculated from the following formula

Where V

: Rated voltage (V)

P

: Rated power (W)

R

P

V

◊

=

R

: Nominal resistance ()

If the voltage so obtained exceeds the maximum operating voltage, this maximum voltage shall

be the rated voltage.

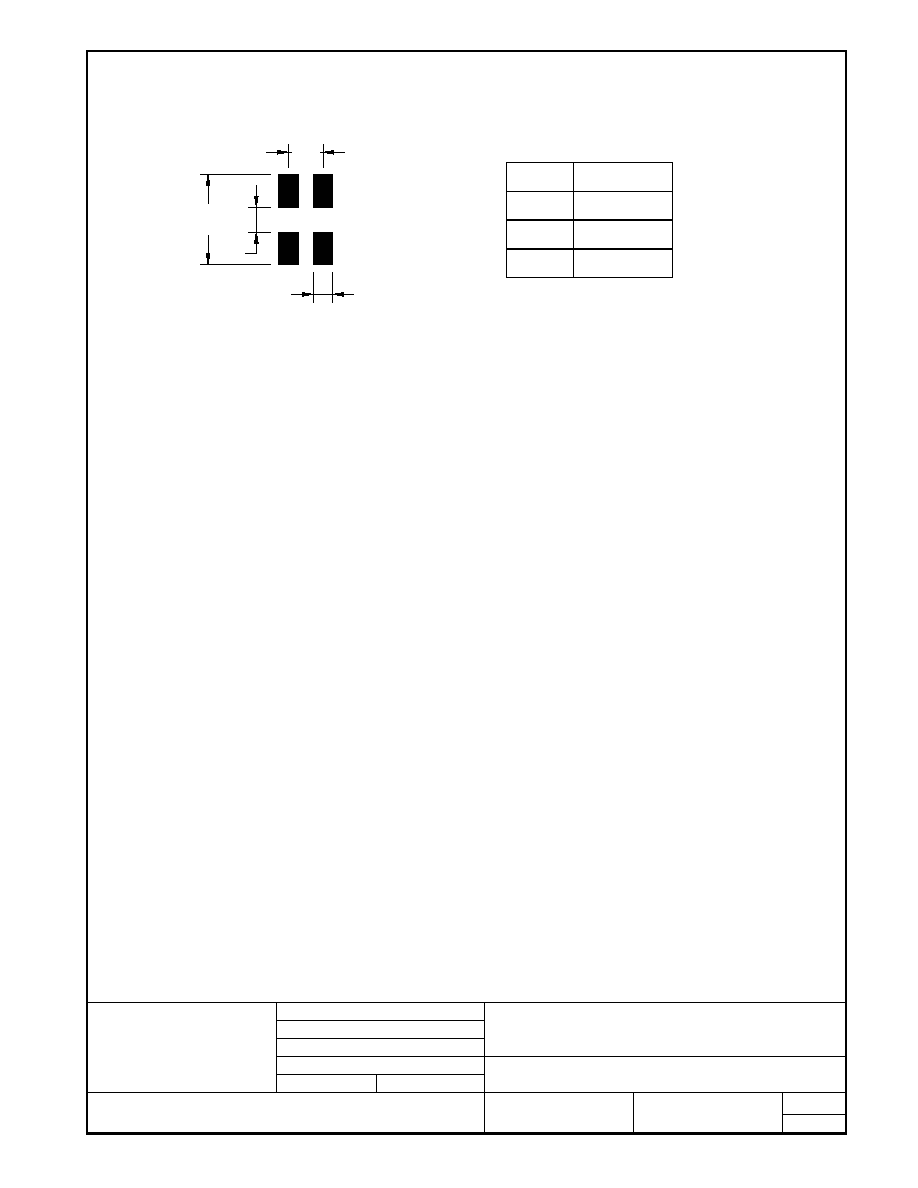

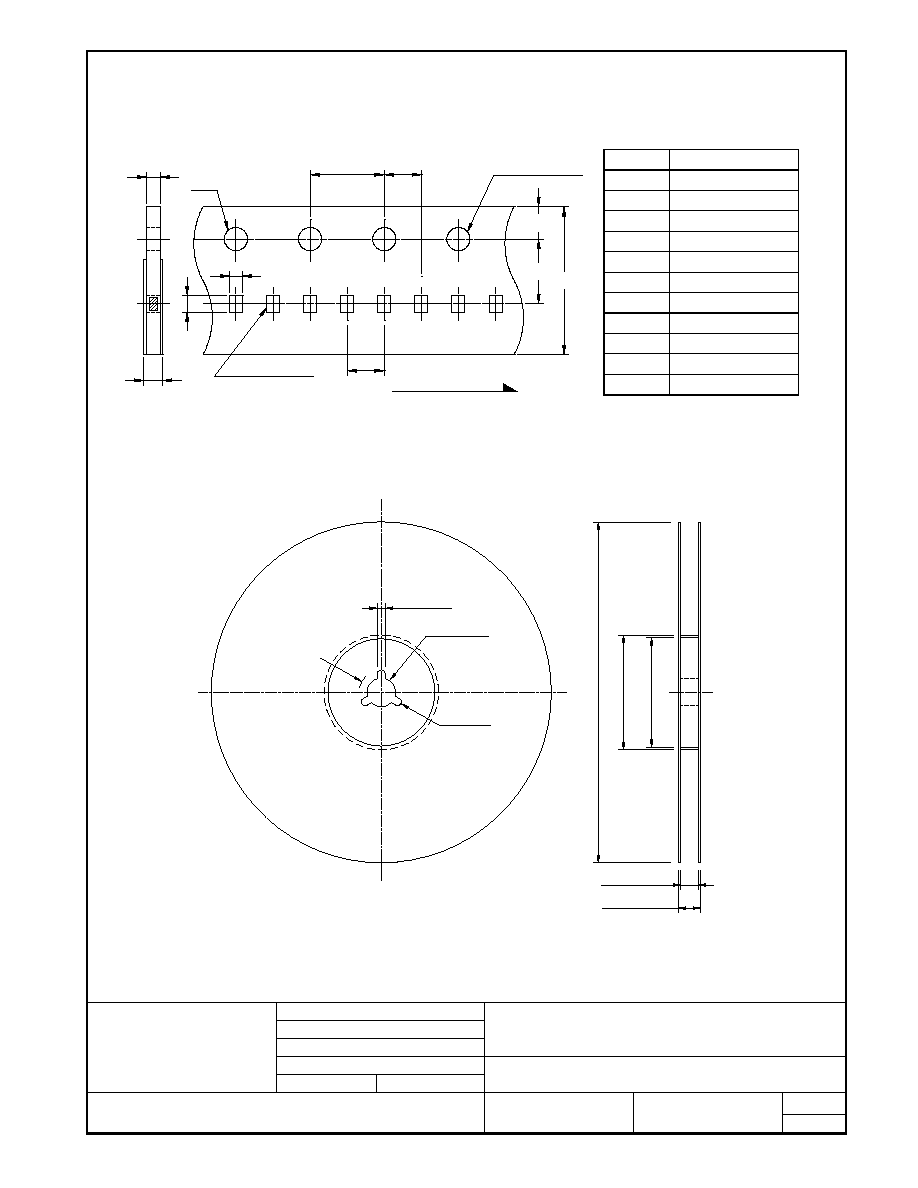

4. Outline dimensions and marking

A1

L

P

W

C

D

T

5. Schematics

L

0.80 ± 0.10

P

0.50 typical

W

0.60 ± 0.10

C

0.15 ± 0.10

A1

0.30 ± 0.10

D

0.15 ± 0.10

T

0.35 ± 0.10

Unit: mm

R1

R2

R1=R2

PAGE 3 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Figure 2 : Measurment Setup

Substrate Side

(R=0.5 mm)

Over coat Film

Measurement Point A

Pressure Rod

Substrate

(Metal)

Measurement Point B

Metal Block

Sample Electrode

Insulation Plate

B

A

Spring

Voltage Supply

6. Life test

6-1 Electrical

Item

Specification and Requirement

Test Method

Short Time Overload R: ±(2.0%+ 0.1)

Without damage by flashover, spark,

arcing, burning or breakdown

(1) Applied voltage :

2.5 x rated voltage or

2 x maximum operating voltage

which ever is less

(2) Test time : 5 seconds

Insulation Resistance Over 100 M on Overcoat layer face up

Over 1,000 M on Substrate side face up

(1) Setup as figure 2

(2) Test voltage : 100 V

DC

(3) Test time :

60 + 10 / -0 seconds

Voltage Proof

R: ±(1.0%+ 0.05)

Without damage by flashover, spark,

arcing, burning or breakdown

(1) Setup as figure 2

(2) Test voltage : 100 V

AC

(rms.)

(3) Test time:

60 +10 / -0 seconds

PAGE 4 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

6-2 Mechanical

Item

Specification and Requirement

Test Method

Solderability

The surface of terminal immersed

shall be minimum of 95% covered

with a new coating of solder

Solder bath :

After immersing in flux, dip in

245±5

molten solder bath for

2±0.5 seconds

Resistance to Solder

Heat

R:

±(1.0%+ 0.05)

Without distinct deformation in

appearance

(1) Pre-heat : 100~110

for 30 seconds

(2) Immersed at solder bath

of 270±5

for 10

±1 seconds

(3) Measuring resistance

1 hour after test

Vibration

R:

±(0.5%+ 0.05)

Without mechanical damage such as

break

(1) Vibration frequency :

( 10Hz to 55Hz to10Hz ) in 60

seconds as a period

(2) Vibration time :

period cycled for 2 hours in each

of 3 mutual perpendicular

directions

(3) Amplitude : 1.5mm

Shock

R:

±(0.25%+ 0.05)

Without mechanical damage such as

break

(1) Peak value : 490N

(2) Duration of pulse : 11ms

(3) 3 times in each positive

and negative direction of

3 mutual perpendicular

directions

Bending Test

R:

±(1.0%+ 0.05)

Without mechanical damage such as

break

Bending value : 3 mm for

30±1 seconds

PAGE 5 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

6-3 Endurance

Item

Specification and Requirement

Test Method

Rapid change of

Temperature

R:

±(1.0%+ 0.05)

Without distinct damage in

appearance

(1) Repeat 5 cycle as follow :

(-55±3

,30minutes)

(Room

temperature, 2~3 minutes)

(+125±2

,30minutes)

(Room temperature, 2~3

minutes)

(2) Measuring resistance

1 hour after test

Moisture with Load

R:

±(3.0%+ 0.1)

Without distinct damage in

appearance

Marking should be legible

(1) Environment condition :

40±2

,90~95

% RH

(2) Applied Voltage :

Rated voltage

(3) Test period : (1.5 hour ON)

(0.5 hour OFF) cycled for

total 1,000 + 48 / - 0 hours

(4) Measuring resistance

1 hour after test

Load Life

R:

±(3.0%+ 0.1)

Without distinct damage in appearance

(1) Test temperature :

70±2

(2) Applied Voltage : rated voltage

(3) Test period : (1.5 hour ON)

(0.5 hour OFF) cycled for

total 1,000 + 48 / - 0 hours

(4) Measuring resistance

1 hour after test

Low Temperature

Store

R:

±(3.0%+ 0.1)

Without distinct damage in appearance

(1) Store temperature :

-55±3 for total

1,000 + 48 / - 0 hours

(2) Measuring resistance

1 hour after test

High Temperature

Store

R:

±(3.0%+ 0.1)

Without distinct damage in appearance

(1) Store temperature :

+125±2

for total

1,000 + 48 / - 0 hours

(2) Measuring resistance

1 hour after test

PAGE 6 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

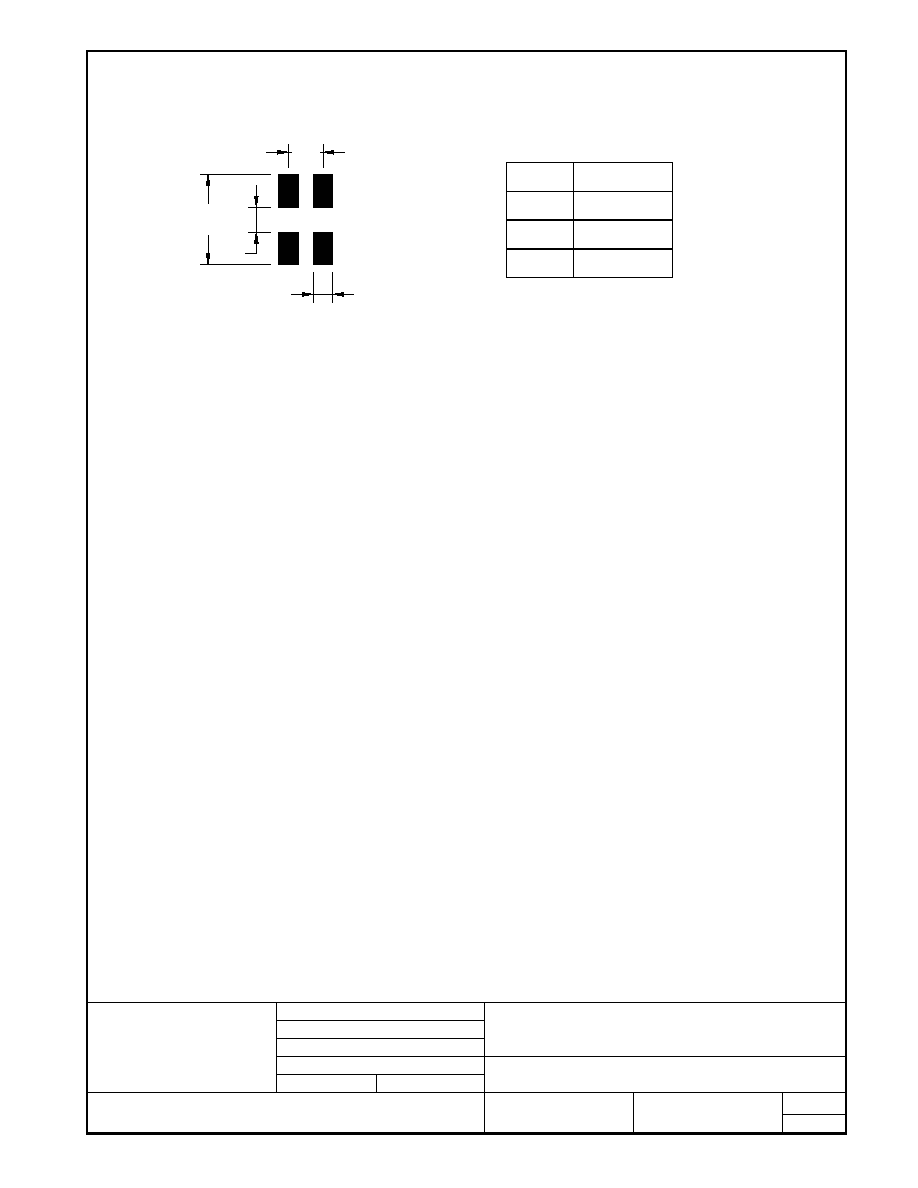

7. Recommend Land Pattern Dimensions

A

0.30

B

0.30

P

0.50

C

0.9

Unit : mm

C

B

P

A

PAGE 7 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

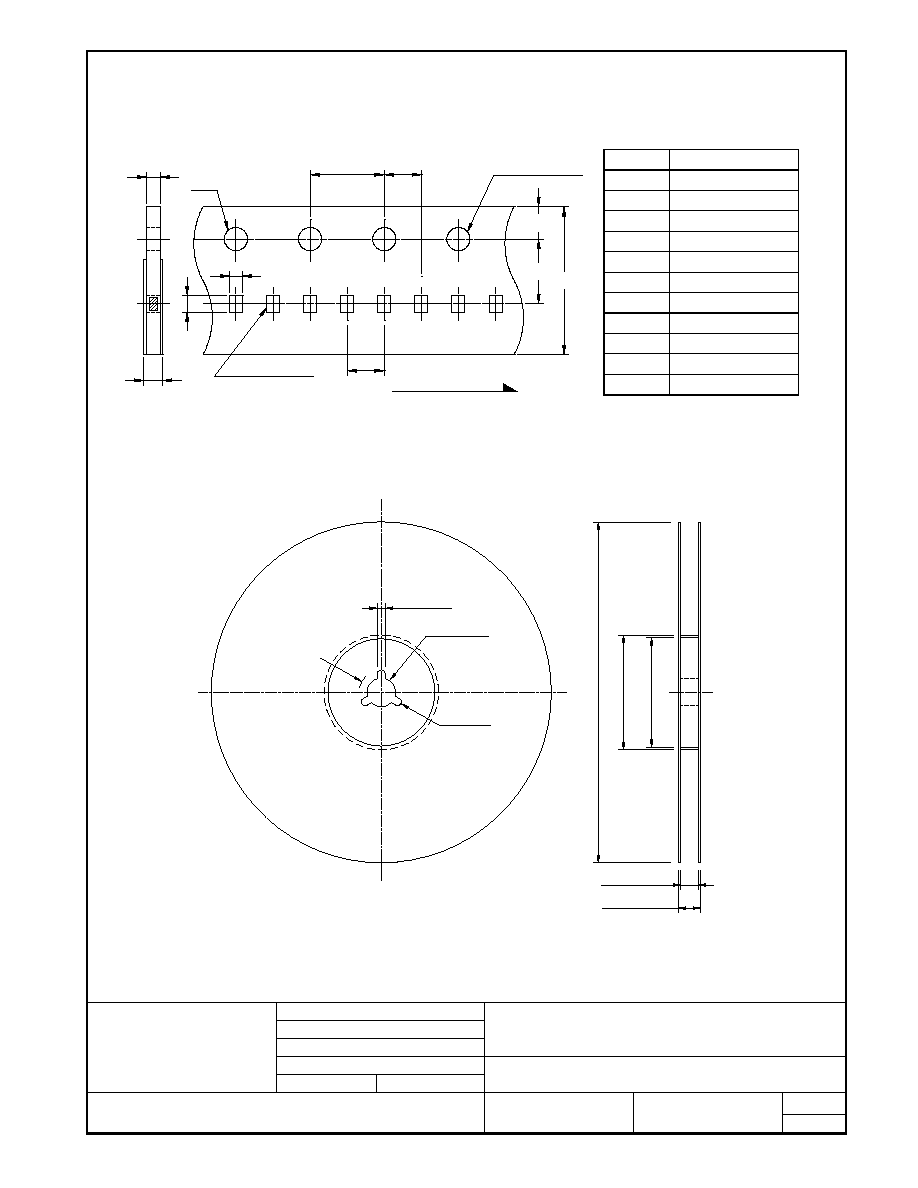

8. Packaging

8-1 Dimensions

8-1-1 Tape packaging dimensions

8-1-2 Reel dimensions

2.0 ± 0.5

13.0 ± 0.5

20min.

9.0 ± 0.3

Unit : mm

1

7

8

±

2

.

0

6

0

.

0

±

2

.

0

5

6

.

0

±

2

.

0

11.4 ± 1.0

Code

Dimensions (mm)

A

0.70 ± 0.10

B

0.90 ± 0.10

W

8.0 ± 0.3

C

1.75 ± 0.1

D

3.5 ± 0.05

P0

4.0 ± 0.1

P1

2.0 ± 0.05

P2

2.0 ± 0.05

T

0.5 ± 0.1

t

0.43 ± 0.05

D0

1.5

+0.1

-

0.0

Sprocket hole

W

t

P0

P2

D0

Carrier cavity

T

A

B

P1

Pulling direction

D

C

PAGE 8 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

8-2 Peel force of top cover tape

The peel speed shall be about 300 mm/minute

The peel force of top cover tape shall be between 0.1 to 0.7 N

8-3 Numbers of taping

10,000 pieces/reel

8-4 Label marking

The following items shall be marked on the production and shipping

Label on the reel.

8-4-1 Production Label

(1) Part No.

(2) Description

(3) Quantity

(4) Taping No.

8-4-2 Shipping Label

(1) *Customer's name

(2) *Customer's part No.

(3) Manufacturer's part No.

(4) Manufacturer's name

(5) Manufacturer's country

*Note : Item (1) and (2) are listed by request

165 ~ 180∞

Top Cover Tape

0.1~0.7 N

PAGE 9 OF 9

TITLE :

The Engineering Spec. For RS062R-XXXX-X2N

DOCUMENT

NO.

CYNP-5X-001

PAGE

REV.

A0

UNLESS OTHERWISE SPECIFIED

TOLERANCES ON

X =

±

X.X =

±

X.XX =

±

ANGLES

± HOLE DIA. ±

SCALE

X

UNIT

X

APPROVED BY

DRAWN BY

2005-10-04

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

9. Care note

9-1 Care note for storage

(1) Resistor network shall be stored in a room where temperature and humidity must be controlled.

(temperature 5 to 35

, humidity 45 to 85% RH) However, a humidity keep it low, as it is

possible.

(2) Resistor network shall be stored as direct sunshine doesn't hit on it.

(3) Resistor network shall be stored with no moisture, dust, a material that will make solderability

inferior, and a harmful gas (Chloridation hydrogen, sulfurous acid gas, and sulfuration

hydrogen)

9-2 Care note for operating and handling

(1) It is necessary to protect the edge and protection coat of resistors from mechanical stress.

(2) Handle with care when printing circuit board (PCB) is divided or fixed on support body,

because bending of printing circuit board (PCB) mounting will make mechanical stress for

resistors.

(3) Resistors shall be used with in rated range shown in specification. Especially, if voltage more

than specified value will be loaded to resistor, there is a case it will make damage for machine

because of temperature rise depending on generating of heat, and increase resistance value or

breaks.

(4) In case that resistor is loaded a rated voltage, it is necessary to confirms temperature of a

resistor and to reduce a load power according to load reduction curve, because a temperature

rise of a resistor depends on influence of heat from mounting density and neighboring element.

(5) Observe Limiting element voltage and maximum overload voltage specified in each

specification

(6) If there is possibility that a large voltage (pulse voltage, shock voltage) charge to resistor, it is

necessary that operating condition shall be set up before use.