CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 1 OF 11

1/4W 1220 LOW RESISTNACE CHIP RESISTOR

1. Scope

This specification applies to 2.0mm x 1.25mm size 1/4W, fixed metal film chip resistors rectangular

type for use in electronic equipment.

2. Type Designation

RL1220

- -

N

(1) (2)

(3)

(4)

(5)

Where (1)

Series

No.

(2) Temperature coefficient of resistanceT.C.R.

(3) Resistance value: refer to paragraph 4-1

For example--

Three digits of number ( 0.1

R)

R10 = 0.1

1R0 = 1.0

Four digits of numberR

< 0.1

R022 = 0.022

The "R" shall be used as a decimal point.

(4) Resistance tolerance: refer to paragraph 4-1.

(5) N = Sn plating (Lead free , RoHS compliant)

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 2 OF 11

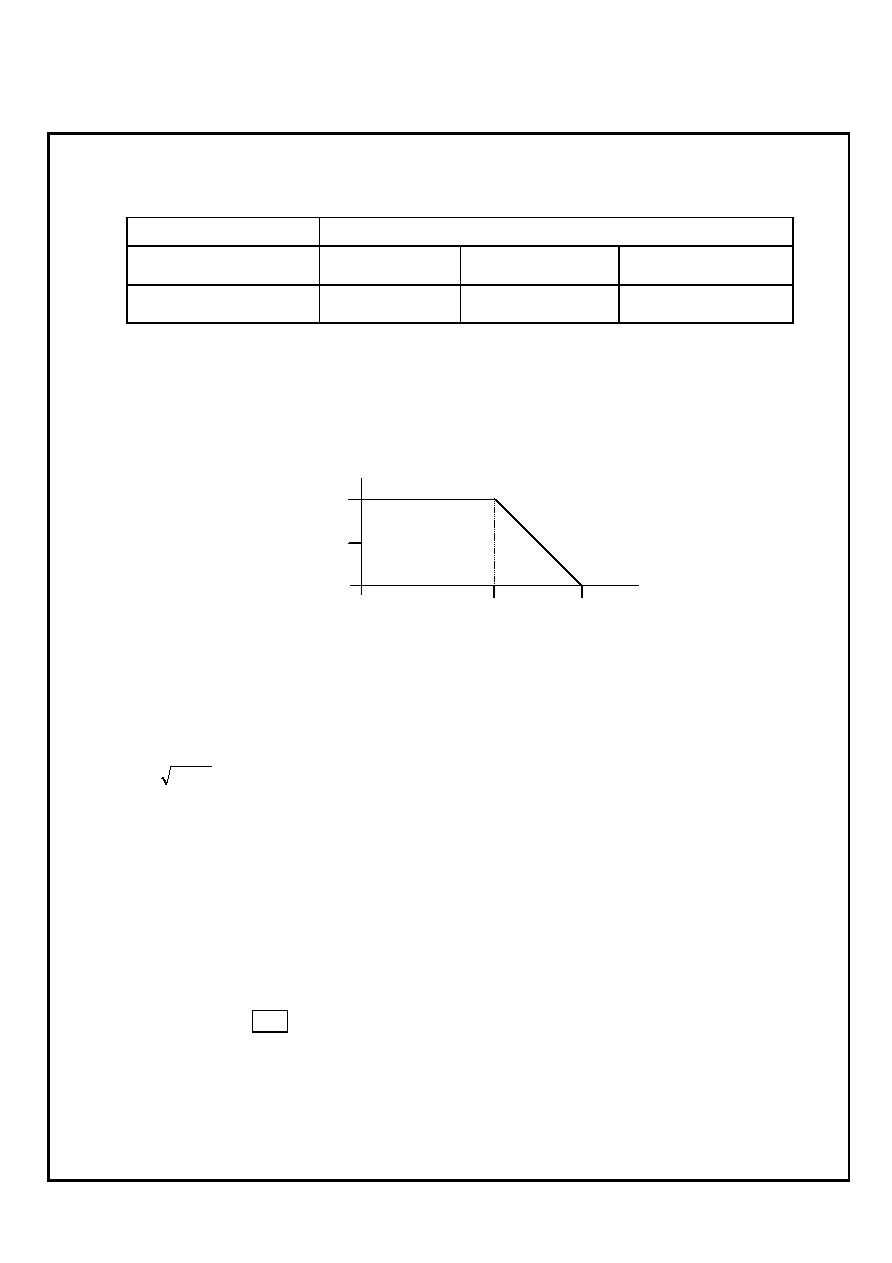

3. Construction and Physical Dimensions

Figure 1-1. Double sides structure (

< 0.082 )

Figure 1-2. Single side structure (

0.082 )

Dimensions (mm)

Code

Letter

Double sides

Structure

Single side

Structure

L

2.00

± 0.20

2.00

± 0.20

W

1.25

± 0.20

1.25

± 0.20

t 0.40

+0.15

-0.10

0.40

± 0.10

a

0.40

± 0.20

0.40

± 0.20

b

0.40

± 0.20

0.40

± 0.20

Note :

Resistive clement

Nickel alloy film

Electrode plating

Sn 100% ( Lead free)

Protective coat

Epoxy Resin coating

Substrate Alumina

ceramic

mass : Double sides structure 5mg (ref.)

Single side structure 4mg (ref.)

b

b

t

L

a

W

a

b

b

t

a

W

a

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 3 OF 11

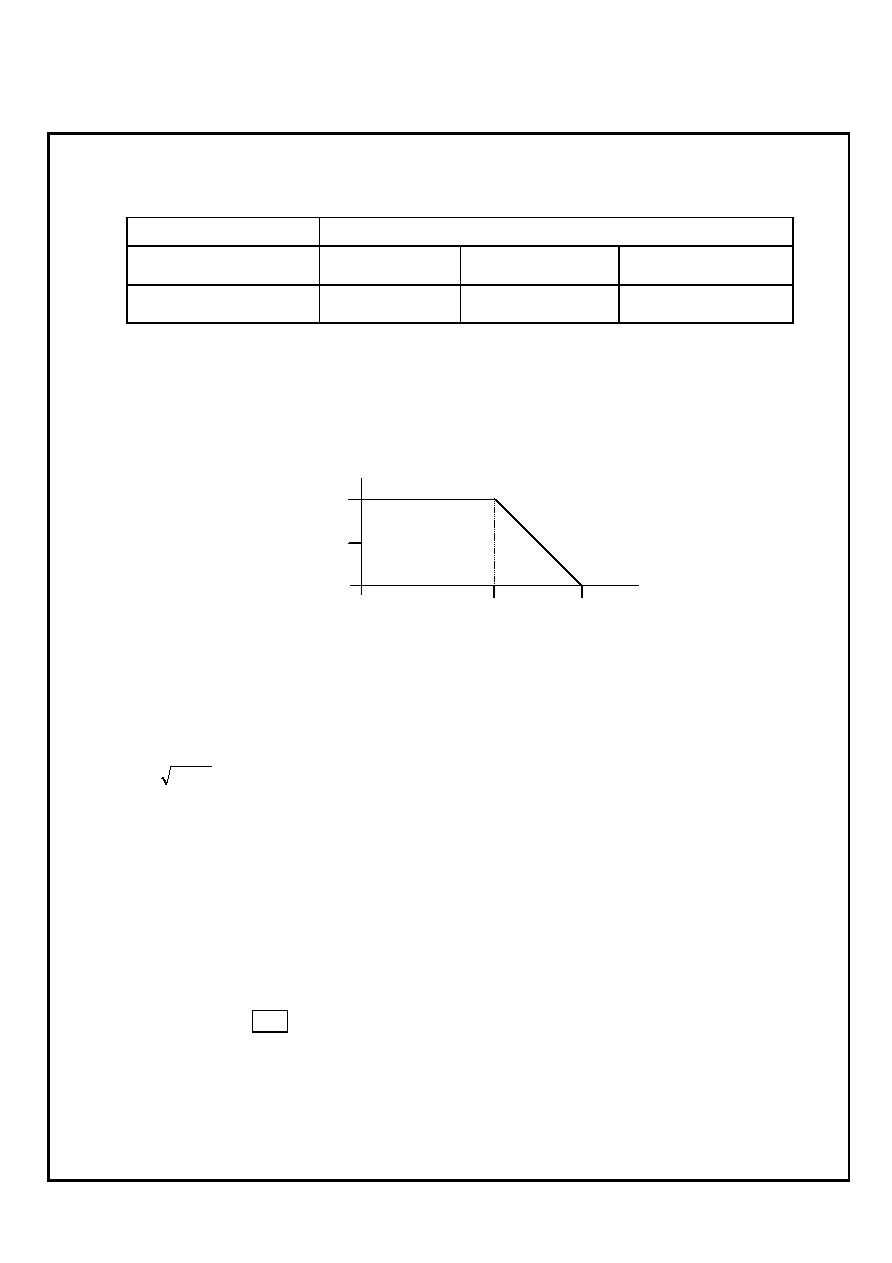

4. Ratings

4-1 Specification

Power Rating*

1/4 W

Resistance Value

10m

18m 22m82m 0.110

Resistance Tolerance

± 5%(J)

± 2%(G) , ± 5%(J)

± 1%(F) , ± 2%(G)

Note*:

Power Rating is based on continuous full load operation at rated ambient temperature of 70.

For resistors operated at ambient temperature in excess of 70, the maximum load shall be

derated in accordance with the following curve.

Figure 2 Derating Curve

4-2 Rated Voltage

The rated voltage shall be determined by the following expression.

R

P

V

◊

=

Where VRated voltage (V)

RNominal resistance value (

)

PRated dissipation (W)

4-3 Operating and Storage Temperature Range

-55 to +125

5. Marking

A rated resistance shall be marked on the protective coat with three digit of number.

Example ≠ ≠ 0.22

R22

But, there is no marking in the rated resistance under 0.1

-55

0

70

125

100

50

%

Rated

dissipation

ratio

Ambient temperature

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 4 OF 11

6. Characteristics

6-1 Electrical

6-1-1 Resistance

Resistance value shall be within the tolerance specified in paragraph 4-1

Refer to IEC 60115-1 Sub-clause 4.5.

6-1-2 Temperature Coefficient of Resistance

Not exceed the temperature coefficient of resistance specified in paragraph 4-1

Room temperature

Room temperature + 100

Refer to IEC 60115-1 Sub-clause 4.13.

6-1-3 Short Time Overload

Resistance Change :

± (0.5%)

Without significant damage by flashover (spark ,arching),burning or breakdown etc.

Test voltage : 2.5 times the rated voltage.

Duration : 5 seconds

Refer to IEC 60115-1 Sub-clause 4.13.

6-1-4 Insulation Resistance

(1) Between Electrode and Protection Film

100M

or over

(2) Between Electrode and Substrate

1,000M

or over

R0.5

Substrate

Protection Film

Pressure Rod

Measurement Point A

(Metal)

Test Sample

Spring

Insulation Prate

Metal Block

Measurement Point B

The resistor shall be cramped in the metal block and tested , as shown below.

Test voltage : 100V

DC

for 1 minute

Refer to IEC 60115-1 Sub-clause 4.6.

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 5 OF 11

6-1-5 Voltage Proof

Resistance Change :

± (0.5%)

Without damage by flashover, fire or breakdown, as shown below.

The resistor shall be tested as shown in paragraph 4-1-4

The voltage : 100V

AC

(rms.) for 1 minute

Refer to IEC 60115-1 Sub-clause 4.7.

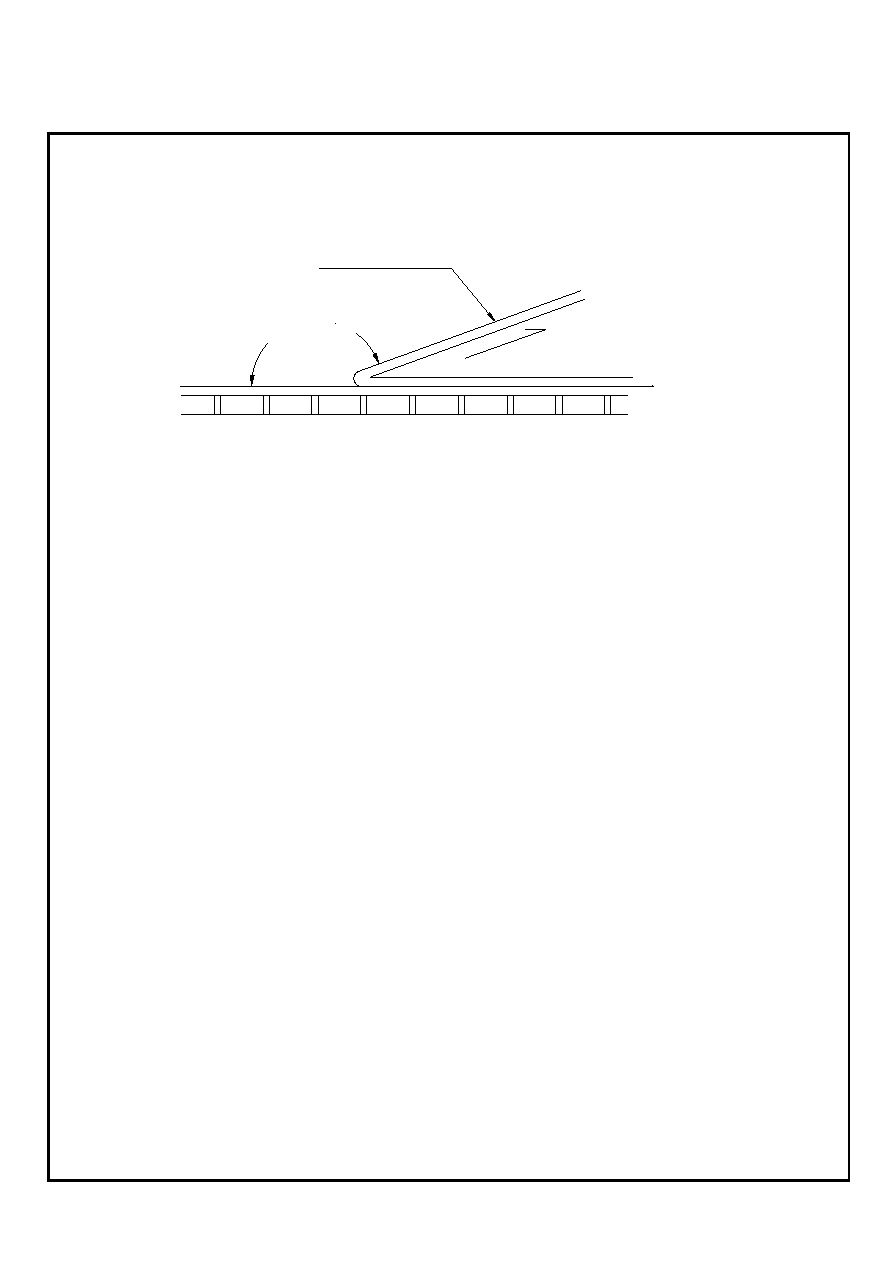

6-2 Mechanical

6-2-1 Terminal Strength

Resistance Change : ±(0.5%)

Without mechanical damage such as breaks.

Electrical characteristics shall be satisfied.

If there are electrodes on both surfaces, it shall satisfy the above specifications on whichever

surface may be fixated.

Bending Amplitude : 3 mm 30 seconds

Refer to IEC 60115-1 Sub-clause 4.33.

45

45

Solder

Supports

Within ± 2mm

Test PC Board

Sample

Pr

e

s

s

u

r

e

Press Jig

Refer to EIAJ RC-2530

Unit : mm

R230

Am

pl

it

ude

3 mm

20

50

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 6 OF 11

6-2-2 Body Strength

Resistance Change : ±(0.5%)

Without mechanical damage such as breaks.

A load of 10N using a R0.5 pressure rod shall be applied to the center in the direction of

the arrow and held for 10 seconds.

6-2-3 Solderability

A new uniform coating of solder shall cover minimum of 95% of the surface being immersed.

Temperature of solder : 245

± 5

Immersion duration : 2

± 0.5 seconds

Refer to IEC 60115-1 Sub-clause 4.17.

6-2-4 Resistance to Soldering Heat

Resistance Change :

± (0.5%)

Electrical characteristics shall be satisfied.

Without distinct deformation in appearance.

(1) Solder bath method

Pre-heat : 100 to 110 30 seconds

Temperature : 270

± 5 10 ± 1seconds

(2) Reflow Soldering method

Peak temperature : 260

± 5 10 seconds or less

Temperature : 220

± 5 60 seconds max.

The heating apparatus shall be the upper-heated oven and temperature shall be

the board surface temperature.

(3) Soldering iron method

Bit temperature : 350

± 5 3 ± 1/0 seconds

The resistor shall be stored at standard atmospheric conditions for 1 hour, after

which the measurements shall be made.

Refer to IEC 60115-1 Sub-clause 4.18.

R0.5

1/2L

L

Resistor

Pressure rod

Unit : mm

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 7 OF 11

6-2-5 Resistance to Solvent

Without mechanical damage and distinct damage in appearance.

Immersion cleaning

At normal temperature 300 seconds in Isopropyl Alcohol.

Refer to IEC 60115-1 Sub-clause 4.29.

6-3 Endurance

6-3-1 Rapid Change of Temperature

Resistance Change :

± (0.5%)

Without distinct damage

Resistance shall be subjected to 5 cycles of the temperature cycle as following :

-55

± 2, 30 minutes room temperature, 2 3 minutes

+125 ± 2, 30 minutes room temperature, 2 3 minutes

Refer to IEC 60115-1 Sub-clause 4.19.

6-3-2 Dump Heat with Load

Resistance Change :

± (1.0%)

Without distinct damage

60

± 2 with relative humidity of 90 to 95%

DC rated voltage for 1.5 hours on 0.5 hour off

1,000 + 48 / - 0 hours

6-3-3 Endurance at 70

Resistance Change :

± (1.0%)

Without distinct damage

70

± 2

DC rated voltage for 1.5 hours on 0.5 hour off

1,000 + 48 / -0 hours

Refer to IEC 60115-1 Sub-clause 4.25.

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 8 OF 11

Mounting of the test sample onto the test board shall be either of following methods.

(1) Mounting by solder dipping

Epoxy based glue shall be applied in the middle of two lands of the test board. The

resistor shall be mounted in such a way that the electrodes of resistors will be evenly

placed in the land area and then adhesive resin shall be cured. After applying the Resin

Flux with 25 weight % Methyl Alcohol, the board shall be soldered by dipping into a

molten solder bath with 260

± 5 for 3 to 5 seconds

(2) Mounting by Reflow soldering

Solder paste with approximate 200m thickness shall be applied to the land of test board.

The resistor shall be mounted in such way that the electrodes of resistors will be evenly

placed in the land area and then shall be soldered under the circumstance that the surface

temperature of the board shall be raised 245

± 5(peak) for 5 to 10 seconds in an

upper-heater oven.

Test board A

Material : Glass Fabric Epoxy Resin ( Refer to JIS C 6484 )

Board thickness : 1.6mm

Copper foil thickness : 0.035mm

Solder Resist Coating

40

4.0

100

(3.0)

1.2

1.65

Land

Unit : mm

4.5

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 9 OF 11

Test Board B

Material : Glass Fabric Epoxy Resin ( Refer to JIS C 6484 )

Board thickness : 1.6mm

Copper foil thickness : 0.035mm

Solder Resist Coating

2.4

0.4

6.

94

4

27

.0

8.5

18

.5

1

1.32

58.5

(5.08 x 9 = 45.72)

4.46

5.

3

5.08

1.22

Unit : mm

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 10 OF 11

7. Packaging

7-1 Dimensions

7-1-1 Tape packaging dimensions

7-1-2 Reel Dimensions

0.75 ± 0.05

0.8 ± 0.1

2.0 ± 0.05

A

B = 2.4 ± 0.2

A = 1.65 ± 0.2

CHIP

1.5

+

0.1

-

0.0

B

4.0 ± 0.1

4.0 ± 0.1

Unit : mm

8.0 ± 0.3

3.5 ± 0.05

1.75 ± 0.1

Pull

Cavity

Label

13 ± 0.2

21 ± 0.8

13 ± 1.4

9 ± 0.3

50

180

+0

-3

R1

2 ± 0.5

105

Unit : mm

60

+1 -0

CYNTEC CO., LTD.

DOCUMENT : RLA00000N

REVISION : A2

PAGE : 11 OF 11

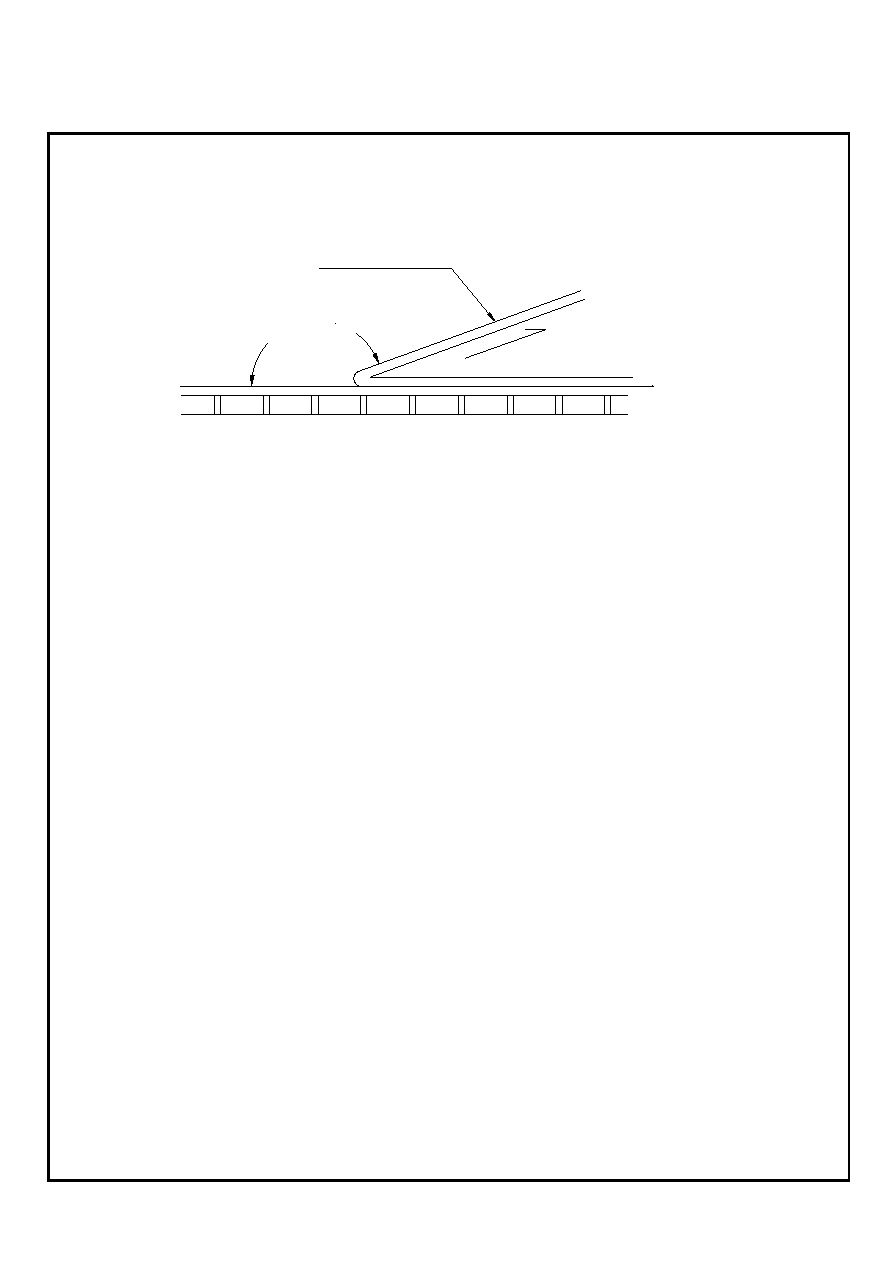

7-2 Peel force of top cover tape

The peel speed shall be about 300 mm/min.

The peel force of top cover tape shall be between 0.1 to 0.7 N.

7-2 Numbers of taping

5,000 pieces/reel

7-3 Label marking

The following items shall be marked on single of the reel.

(1) Type designation .

(2) Quantity

(3) Manufacturing date code

(4) Manufacturer's name

(5) The country of origin

(6) Shipping number

(7) Identification showing lead free products.

7-4 Note

Manufactured by our joint company. ( Susumu Co., Ltd. )

165 ~ 180∞

Top Cover Tape

0.1~0.7 N