CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 1 OF 6

(3)

(2)

(1)

(4)

L

a

a

(Bottom View)

R100

W

t

1W 3264L TYPE Low Resistance Chip Resistor

1. Scope

This specification applies to 3.2mm x 6.4mm size 1W, fixed metal film chip resistors rectangular

type for use in electronic equipment.

2. Type Designation

RL3264

L - - N

(1)

(2)

(3)

(4) (5)

Where

(1) Series No.

(2) L = L Type

(3) Resistance value :

For example - -

R100 = 100m

2R70 = 2.7

The " R " shall be used as a decimal point.

(4) Resistance tolerance: refer to paragraph 4-1.

(5) N = Sn plating (Lead free ,RoHS compliant)

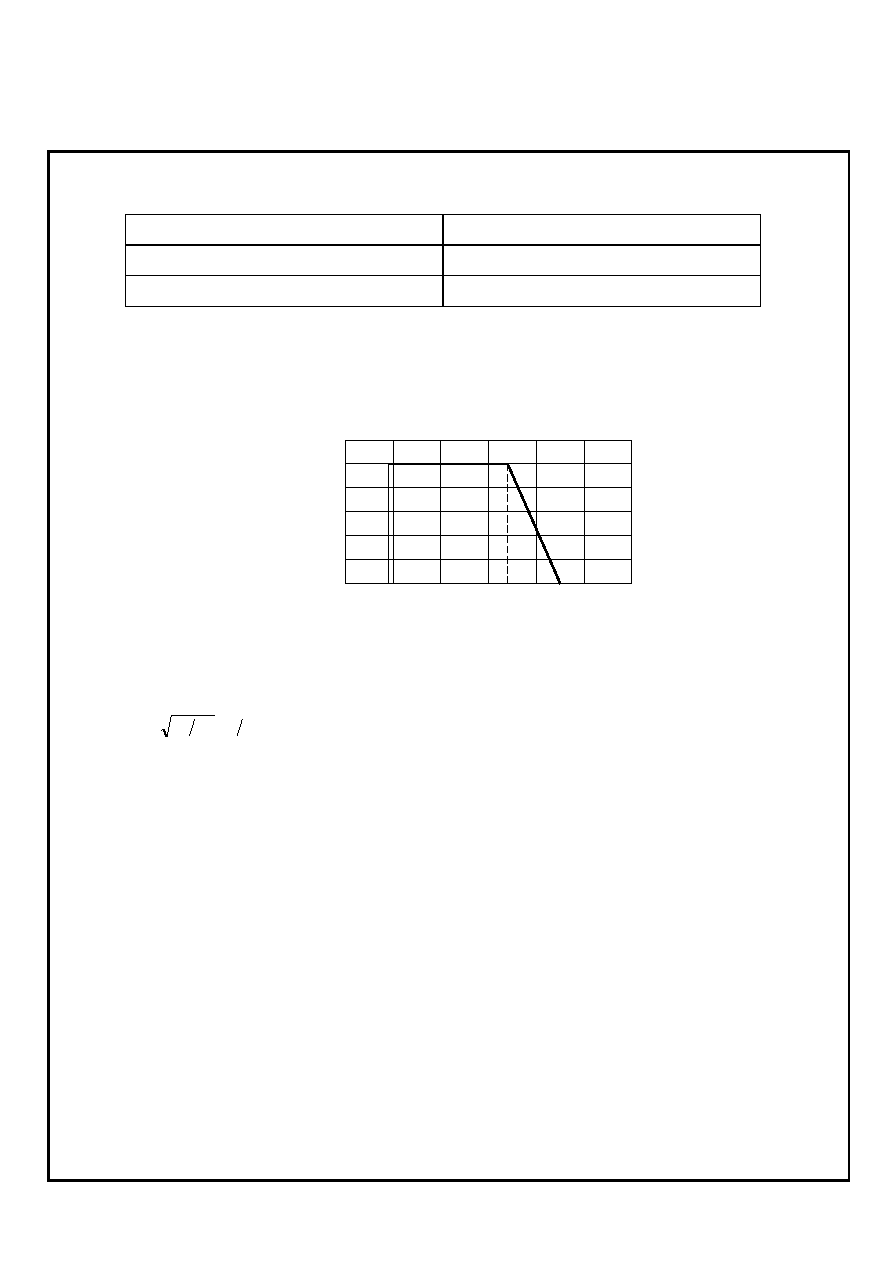

3. Outline Designation

(1) Substrate

Alumina 96%

(2) Resistor

Ni-alloy

(3) Terminals

Sn (on Cu )

(4) Protection coat

Heat resistive epoxy resin

(5) Marking

Epoxy resin

Dimensions (mm)

Code Letter

3264L

L

6.4

±

0.20

W

3.2

±

0.20

a

2.0

±

0.15

t

0.5

±

0.15

Figure 1. Construction and Dimensions

CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 2 OF 6

4. Ratings

4-1 Specification

Power Ratings *

1.0 W

Resistance Value

0.1

~ 2.7

Resistance Tolerance

±

1% ( F )

±

2% ( G )

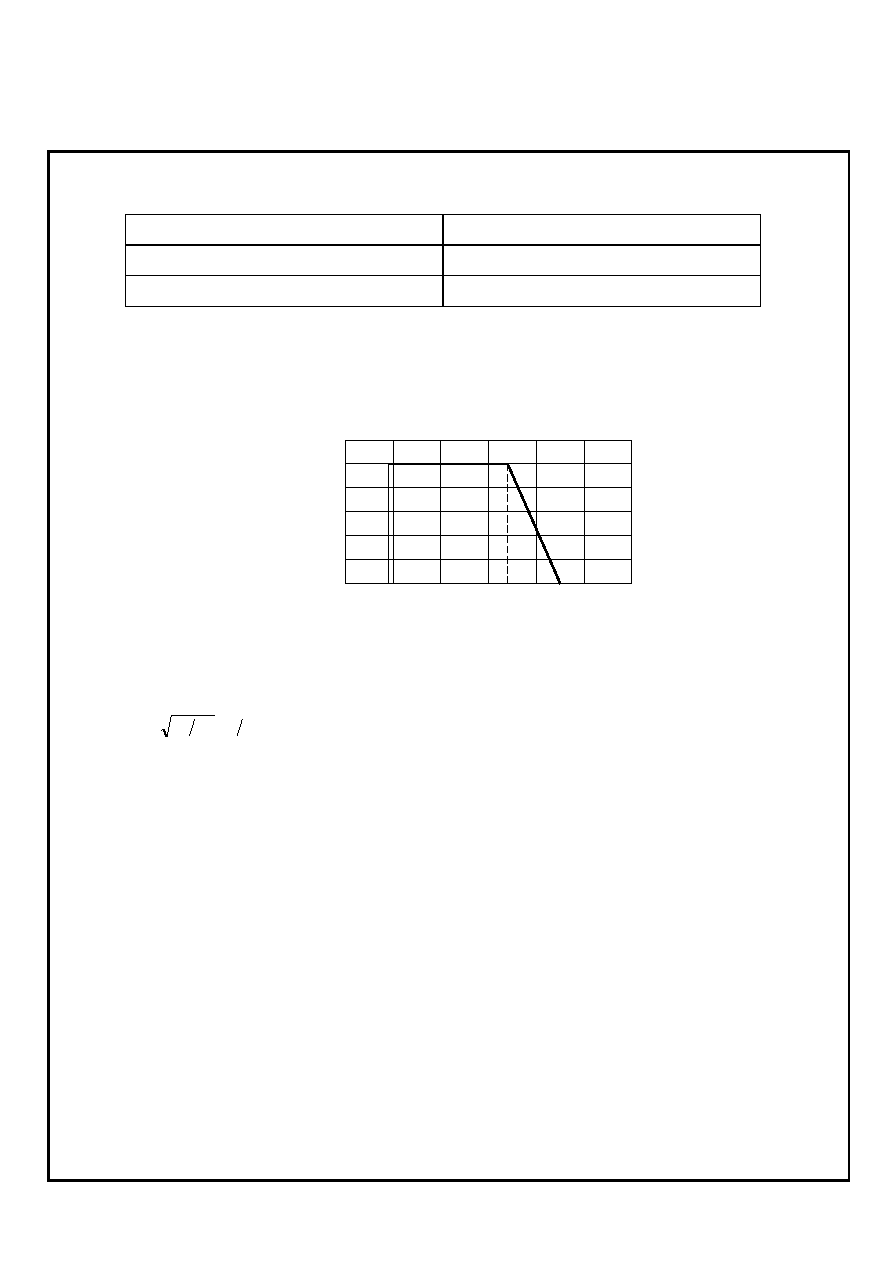

Note * :

Power ratings is based on continuous full load operation at rated ambient temperature of 70.

For resistors operated at ambient temperature in excess of 70, the maximum load shall be

derated in accordance with the following curve.

Figure 2.Power Temperature Derating Cure

4-2 Maximum over current

[ ]

ms

A

R

P

I

10

=

Where

I : maximum current 45A

P : 64W (100m

~ 470m

)

32W (560m

~ 2.7

)

R : Nominal resistance value (

)

Interval 60 seconds minimum

If maximum current so obtained exceed than 45A , use 45A as maximum current.

4-3 Operation and Storage Temperature Range

-55 to +125

0

70

100

125

-55

AMBIENT TEMPERATURE( )

RATED LOAD(%)

CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 3 OF 6

5. Schematic Diagram. Measurement Point

V

I

R100

Current terminal

Voltage terminal

Measurement Point

Schtemtic Diagram

6. Life test

6-1 Electrical

6-2-1 Short Time Overload

Resistance Change :

±

( 0.5% + 0.0005

)

Without significant damage by flashover ( spark, arching ), burning or

breakdown etc.

Test voltage : 2.5 times the rated voltage.

Duration : 5 seconds

6-2 Mechanical

6-2-1 Solderability

A new uniform coating of solder shall cover minimum of 90% of the surface

being immersed.

Temperature of solder : 245

±

5

Immersion duration : 3

±

0.5 seconds

6-2-2 Resistance to Soldering Heat

Resistance change :

±

( 0.5% + 0.0005

)

Electrical characteristics shall be satisfied.

Without distinct deformation in appearance

Dipped into solder for 10

±

1 seconds at 270

±

5

CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 4 OF 6

6-2-3 Substrate bending

Resistance change :

±

( 0.5% + 0.0005

)

Without mechanical damage such as breaks.

Electrical characteristics shall be satisfied.

Glass-Epoxy bard t = 1.6mm

Bending value : 2mm

Between the fulcrums : 90mm

6-3 Endurance

6-3-1 Rapid change of temperature

Resistance change :

±

( 0.5% + 0.0005

)

Without distinct damage.

Perform 5 cycles as follows :

-40 for 30minutes room temperature for 3 minutes

+125 for 30minutes room temperature for 3 minutes

6-3-2 Endurance at 70

Resistance change :

±

( 0.5% + 0.0005

)

Without distinct damage.

Rated voltage for 1.5 hours followed by a pause 0.5 hour at a

temperature of 70

±

3.

Cycle shall be repeated for 1,000 hours.

6-3-3 Dump heat with load

Resistance change :

±

( 0.5% + 0.0005

)

The marking shall be legible.

60

±

2 with relative humidity of 90% to 95%.

D.C. rated voltage for 1.5 hours ON 30 minutes OFF.

Cycle shall be repeated for 1,000 hours.

CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 5 OF 6

7. Packaging

7-1 Dimensions

7-1-1 Tape packaging dimensions

7-1-2 Reel dimensions

80

±

1

13.5 ± 1

2.0 ± 0.5

13 ± 0.3

18.4 max.

225

±

1

Unit : mm

3.43 ± 0.2

0.3 max.

Cavity

1.5 max.

6.63 ± 0.2

Feed forward hole

1.75 ± 0.1

2.0 ± 0.05

4.0 ± 0.1

Unit : mm

5.5 ± 0.05

12.0 ± 0.3

4.0 ± 0.1

-0.0

+0.1

1.5

CYNTEC CO., LTD.

DOCUMENT : RLWL0000N

REVISION : A0

PAGE : 6 OF 6

7-2 Peel Strength of Top Cover Tape

The peel speed shall be about 300mm/minute

The peel force of top cover tape shall between 0.1 to 0.7N

7-3 Number of Taping

5,000 pieces / reel

7-4 Label marking

The following items shall be marked on the reel.

(1) Part number

(2) Quantity per reel

(3) Manufacturing month code

(4) Manufacturer

(5) Inspection number (Lot number)

165 ~ 180∞

Top Cover Tape

Carrier tape

0.1 ~ 0.7N