CYNTEC CO., LTD.

DOCUMENT : RLN530000N

REVISION : A0

PAGE : 1 OF 9

1/4W 1632 LOW RESISTNACE CHIP RESISTOR

1. Scope

This specification applies to 1.6mm x 3.2mm size 1/4W, fixed metal film low resistance value chip

resistors rectangular type.

2. Type Designation

RL

T 1632 - 3 - - N

(1)

(2)

(3)

(4) (5)

Where

(1) Size No.

(2) Power ranting :

3 = 1/4W

(3) Resistance value: refer to paragraph 4-1

For example--

Four digits of number

R100 = 0.1

1R00 = 1.0

The "R" shall be used as a decimal point.

(4) Resistance tolerance: refer to paragraph 4-1.

(5) N = Sn plating ( Lead free , RoHS compliant)

3. Outline Dimensions

Figure 1.

b

b

t

L

a

W

a

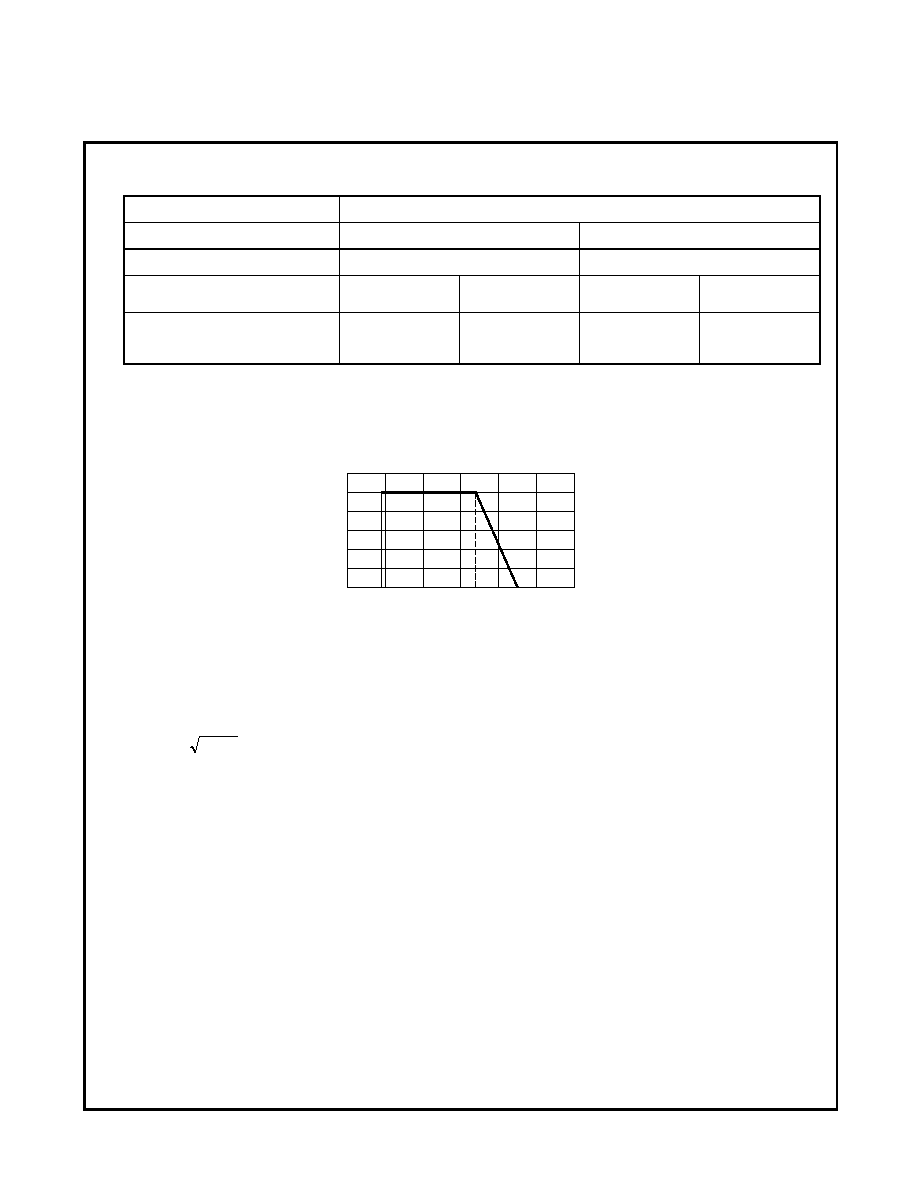

Dimension (mm)

Code

Letter

1632

L

3.20

+0.05

-0.2

W

1.60

+0.05

- 0.15

t

0.60 ± 0.10

a

0.50 ± 0.25

b

0.50 ± 0.30

CYNTEC CO., LTD.

DOCUMENT : RLN530000N

REVISION : A0

PAGE : 2 OF 9

4. Ratings

4-1 Specification

Power Rating*

1/4 W

Resistance Values

E24 & E96 series

E24 series

Resistance Tolerance

± 1%(F)

± 2%(G) , ± 5%(J)

Resistance Range

0.1 ~ < 0.2

0.2 ~ < 10

0.1 ~ < 0.2

0.2 ~ < 10

Temperature Coefficient of

Resistance ( ppm/ )

± 200

± 100

± 200

± 100

Note*:

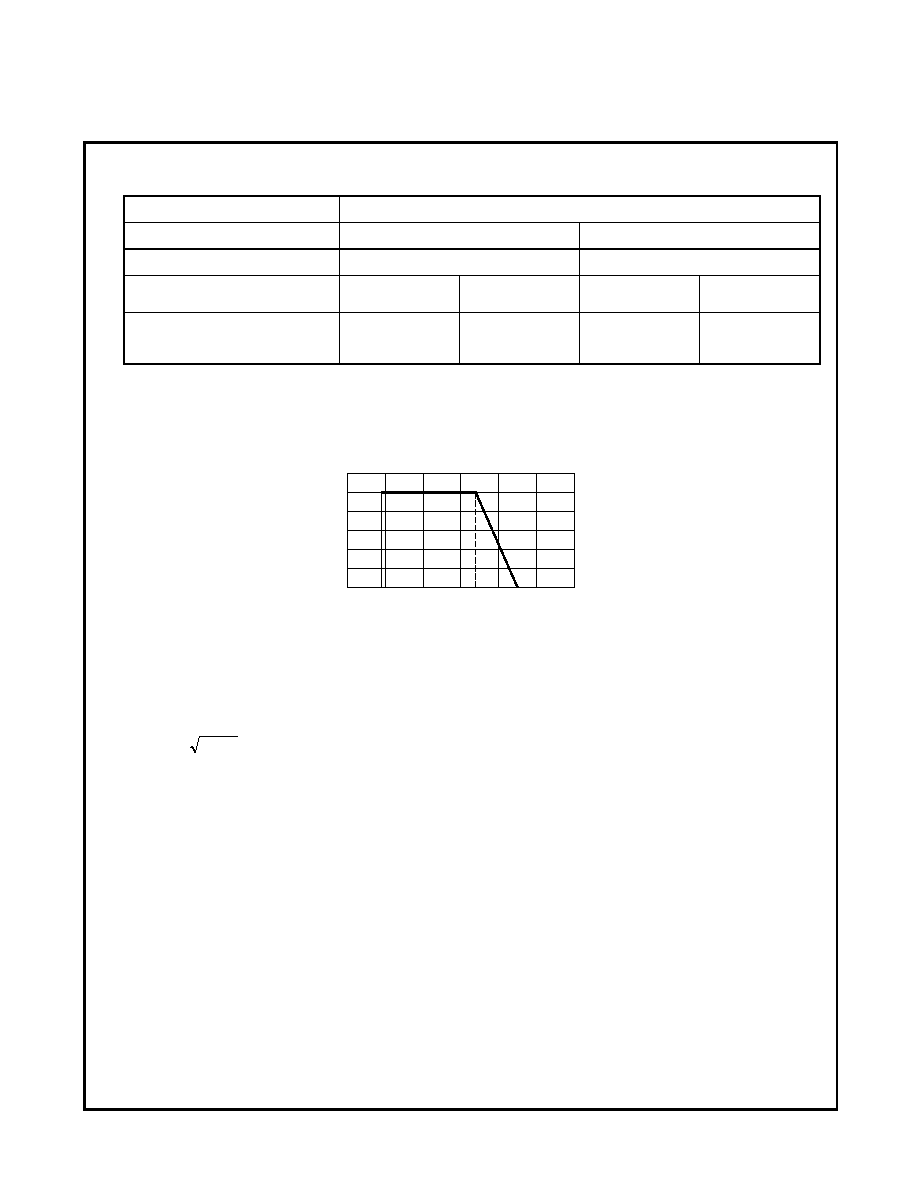

Power Rating is based on continuous full load operation at rated ambient temperature of 70.

For resistors operated at ambient temperature in excess of 70, the maximum load shall be

derated in accordance with the following curve.

Figure 2 Derating Curve

4-2 Rated Voltage

The rated voltage shall be determined by the following expression.

R

P

V

◊

=

Where VRated voltage (V)

RNominal resistance value ()

PRated dissipation (W)

4-3 Operating and Storage Temperature Range

-55 to +125

R

A

T

E

D

L

O

A

D

(

%

)

AMBIENT TEMPERATURE(

)

0

-55

70

125

100

CYNTEC CO., LTD.

DOCUMENT : RLN530000N

REVISION : A0

PAGE : 3 OF 9

5. Marking

Each resistor is marked with a 3-digit or 4-digits code on the protective coating to designate the

nominal resistance value.

(1) 0.1 R < 10 , Marking by 3 or 4 digits

Ex) E-24 0.47R 4 7 , 4.74 R 7 ,

E-96 4.994 R 9 9

(2) R < 0.1 , Marking by 4 digits

Ex) E-24 0.075R 0 7 5

6. Characteristics

6-1 Electrical

6-1-1 Resistance

Resistance value shall be within the tolerance specified in paragraph 4-1

Refer to IEC 60115-1 Sub-clause 4.5.

6-1-2 Temperature Coefficient of Resistance

Not exceed the temperature coefficient of resistance specified in paragraph 4-1

Room temperature Room temperature + 100

Refer to IEC 60115-1 Sub-clause 4.13.

6-1-3 Short Time Overload

Resistance Change : ± (2.0% + 0.01)

Without significant damage by flashover (spark ,arching),burning or breakdown etc.

Test voltage : 2.5 times the rated voltage.

Duration : 2 seconds

Refer to IEC 60115-1 Sub-clause 4.13.

CYNTEC CO., LTD.

DOCUMENT : RLN530000N

REVISION : A0

PAGE : 4 OF 9

R0.5

Substrate

Protection Film

Pressure Rod

Measurement Point A

(Metal)

Test Sample

Spring

Insulation Prate

Metal Block

Measurement Point B

6-1-4 Insulation Resistance

(1) Between Electrode and Protection Film

100M or over

(2) Between Electrode and Substrate

1,000M or over

The resistor shall be cramped in the metal block and tested , as shown below.

Test voltage : 100V

DC

± 15V

DC

Test time : 1 minute

Refer to IEC 60115-1 Sub-clause 4.6.

6-1-5 Voltage Proof

Resistance Change : ± (2.0% + 0.01)

Without damage by flashover, fire or breakdown, as shown below.

The resistor shall be tested as shown in paragraph 4-1

The voltage : 400V

AC

(rms.) for 1 minute

Refer to IEC 60115-1 Sub-clause 4.7.

CYNTEC CO., LTD.

DOCUMENT : RLN530000N

REVISION : A0

PAGE : 5 OF 9

R0.5

1/2L

L

Resistor

Pressure rod

Unit : mm

6-2 Mechanical

6-2-1 Terminal Strength

Resistance Change : ± (1.0% + 0.01)

Without mechanical damage such as breaks.

Electrical characteristics shall be satisfied.

If there are electrodes on both surfaces, it shall satisfy the above specifications on whichever

surface may be fixated.

Bending Amplitude : 3 mm

Holding time : 10 ± 1seconds

Refer to IEC 60115-1 Sub-clause 4.33.

6-2-2 Body Strength

Resistance Change : ±(1.0% + 0.01)

Without mechanical damage such as breaks.

A load of 5N using a R0.5 pressure rod shall be applied to the center in the direction of

the arrow and held for 10 seconds.

45

45

Solder

Supports

Within ± 2mm

Test PC Board

Sample

P

r

e

s

s

u

r

e

Press Jig

Refer to EIAJ RC-2530

Unit : mm

R230

A

m

p

l

i

t

u

d

e

3

m

m

20

50