128-Macrocell MAX

Æ

EPLD

CY7C342B

USE ULTRA37000

TM

FOR

ALL NEW DESIGNS

Cypress Semiconductor Corporation

∑

3901 North First Street

∑

San Jose

,

CA 95134

∑

408-943-2600

Document #: 38-03014 Rev. *B

Revised April 22, 2004

Features

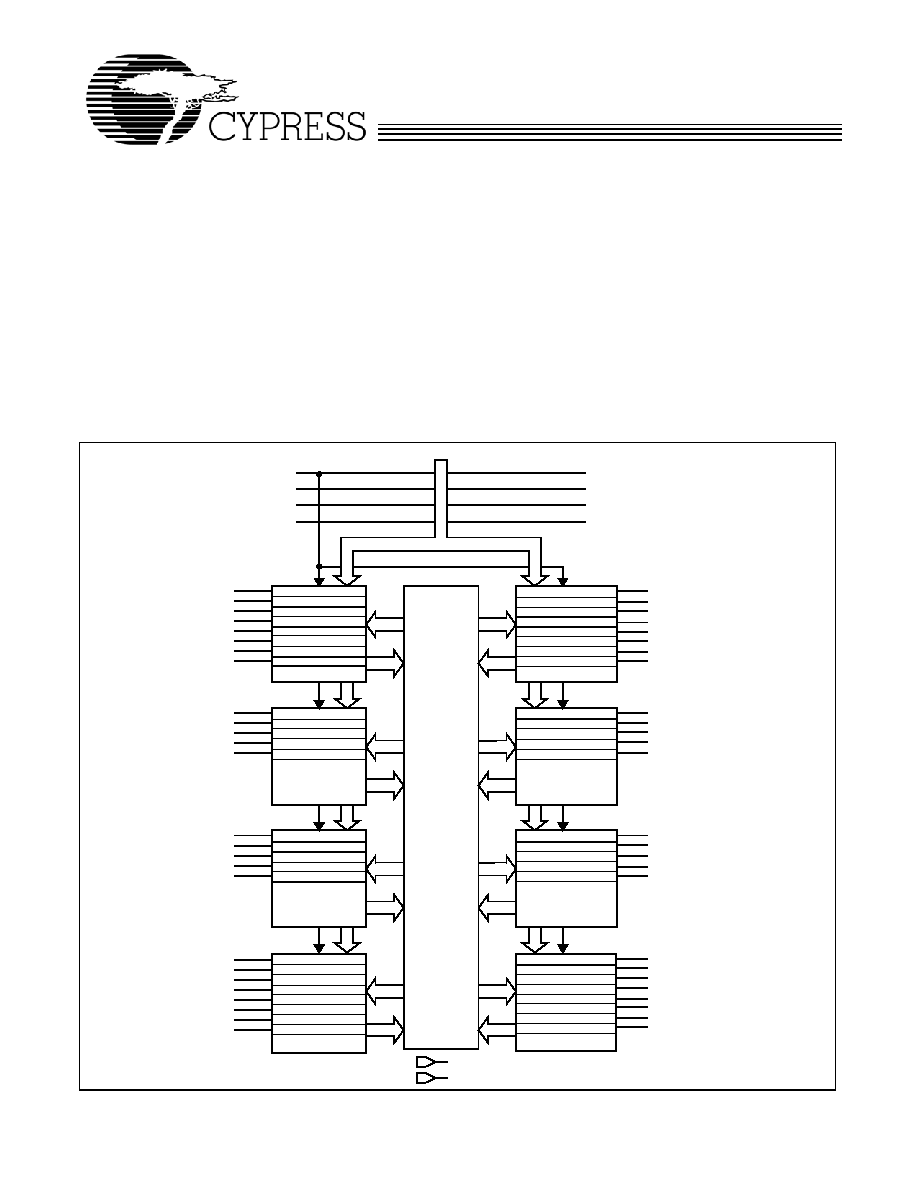

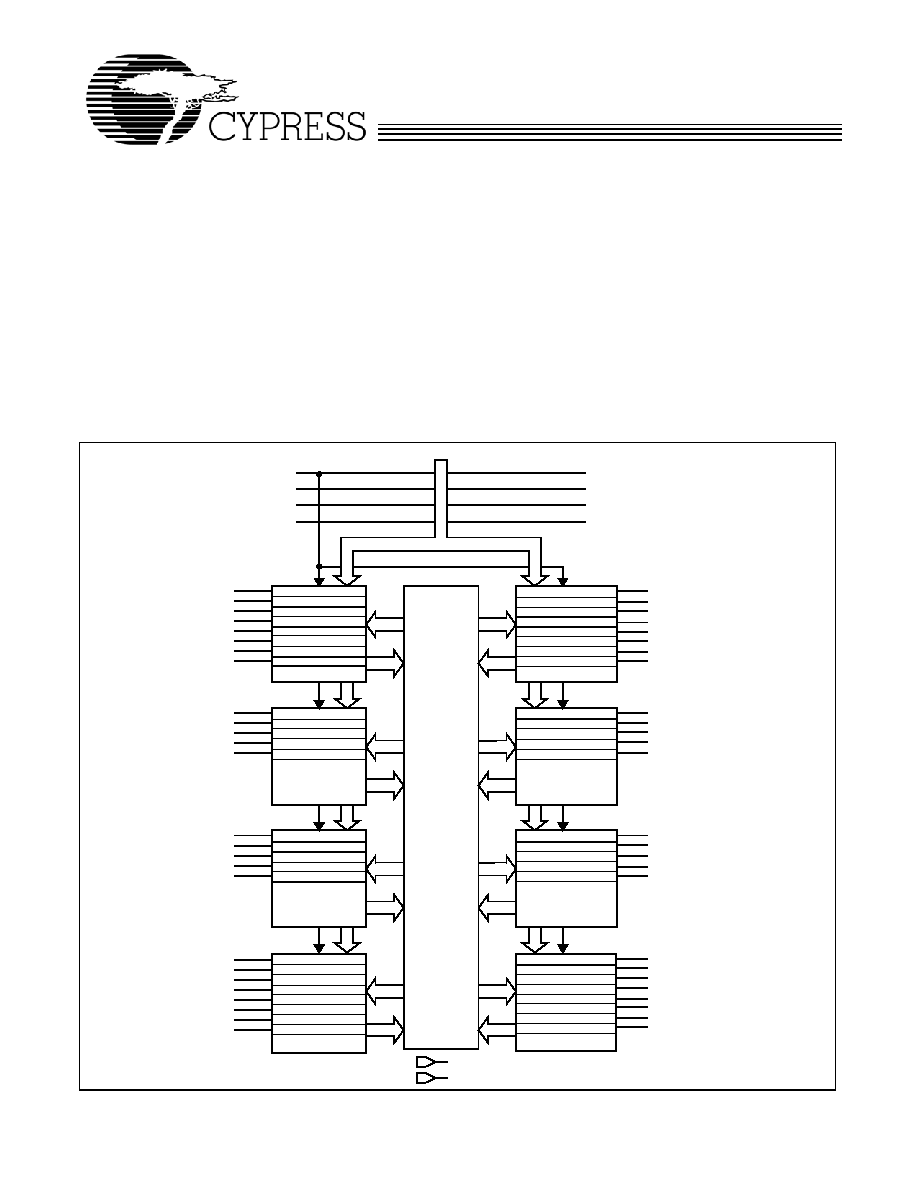

∑ 128 macrocells in eight logic array blocks (LABs)

∑ Eight dedicated inputs, 52 bidirectional I/O pins

∑ Programmable interconnect array

∑ Advanced 0.65-micron CMOS technology to increase

performance

∑ Available in 68-pin HLCC, PLCC, and PGA packages

Functional Description

The CY7C342B is an Erasable Programmable Logic Device

(EPLD) in which CMOS EPROM cells are used to configure

logic functions within the device. The MAX

Æ

architecture is

100% user-configurable, allowing the device to accommodate

a variety of independent logic functions.

The 128 macrocells in the CY7C342B are divided into eight

LABs, 16 per LAB. There are 256 expander product terms, 32

per LAB, to be used and shared by the macrocells within each

LAB.

Each LAB is interconnected with a programmable interconnect

array, allowing all signals to be routed throughout the chip.

The speed and density of the CY7C342B allows it to be used in a

wide range of applications, from replacement of large amounts of

7400-series TTL logic, to complex controllers and multifunction

chips. With greater than 25 times the functionality of 20-pin PLDs,

the CY7C342B allows the replacement of over 50 TTL devices.

By replacing large amounts of logic, the CY7C342B reduces board

space, part count, and increases system reliability.

MACROCELL 101

MACROCELL 100

MACROCELL 99

MACROCELL 98

MACROCELL 97

Logic Block Diagram

MACROCELL 85

MACROCELL 84

MACROCELL 83

MACROCELL 82

MACROCELL 81

MACROCELL 33

MACROCELL 34

MACROCELL 35

MACROCELL 36

MACROCELL 37

MACROCELL 17

MACROCELL 18

MACROCELL 19

MACROCELL 20

MACROCELL 21

MACROCELL 1

MACROCELL 2

MACROCELL 3

MACROCELL 4

MACROCELL 5

MACROCELL 6

MACROCELL 7

MACROCELL 8

MACROCELL 121≠128

MACROCELL 102≠112

MACROCELL 86≠96

MACROCELL 38≠48

MACROCELL 22≠32

MACROCELL 9≠16

SYSTEM CLOCK

P

I

A

INPUT

(A7) 68

INPUT

(A8) 66

INPUT

(L6) 36

INPUT

(K6) 35

(B8) 65

(A9) 64

(B9) 63

(A10) 62

(B10) 61

(B11) 60

(C11) 59

(C10) 58

(D11) 57

(D10) 56

(E11) 55

(F11) 53

(F10) 52

(G11) 51

(H11) 49

(H10) 48

(J11) 47

(J10) 46

(K11) 45

(K10) 44

(L10) 43

(L9) 42

(K9) 41

(L8) 40

(K8) 39

(L7) 38

4 (A5)

5 (B4)

6 (A4)

7 (B3)

8 (A3)

9 (A2)

10 (B2)

11 (B1)

12 (C2)

13 (C1)

14 (D2)

15 (D1)

17 (E1)

18 (F2)

19 (F1)

21 (G1)

22 (H2)

23 (H1)

24 (J2)

25 (J1)

26 (K1)

27 (K2)

28 (L2)

29 (K3)

30 (L3)

31 (K4)

LAB H

LAB G

LAB F

LAB E

LAB A

LAB B

LAB C

LAB D

3, 20, 37, 54 (B5, G2, K7, E10)

16, 33, 50, 67 (E2, K5, G10, B7)

V

CC

GND

() ≠ PERTAIN TO 68-PIN PGA PACKAGE

1 (B6)

INPUT/CLK

2 (A6)

INPUT

32 (L4)

INPUT

34 (L5)

INPUT

MACROCELL 120

MACROCELL 119

MACROCELL 118

MACROCELL 117

MACROCELL 116

MACROCELL 115

MACROCELL 114

MACROCELL 113

MACROCELL 73≠80

MACROCELL 72

MACROCELL 71

MACROCELL 70

MACROCELL 69

MACROCELL 68

MACROCELL 67

MACROCELL 66

MACROCELL 65

MACROCELL 57≠64

MACROCELL 49

MACROCELL 50

MACROCELL 51

MACROCELL 52

MACROCELL 53

MACROCELL 54

MACROCELL 55

MACROCELL 56

CY7C342B

USE ULTRA37000

TM

FOR

ALL NEW DESIGNS

Document #: 38-03014 Rev. *B

Page 2 of 14

Selection Guide

7C342B-15

7C342B-20

7C342B-25

7C342B-30

7C342B-35

Unit

Maximum Access Time

15

20

25

30

35

ns

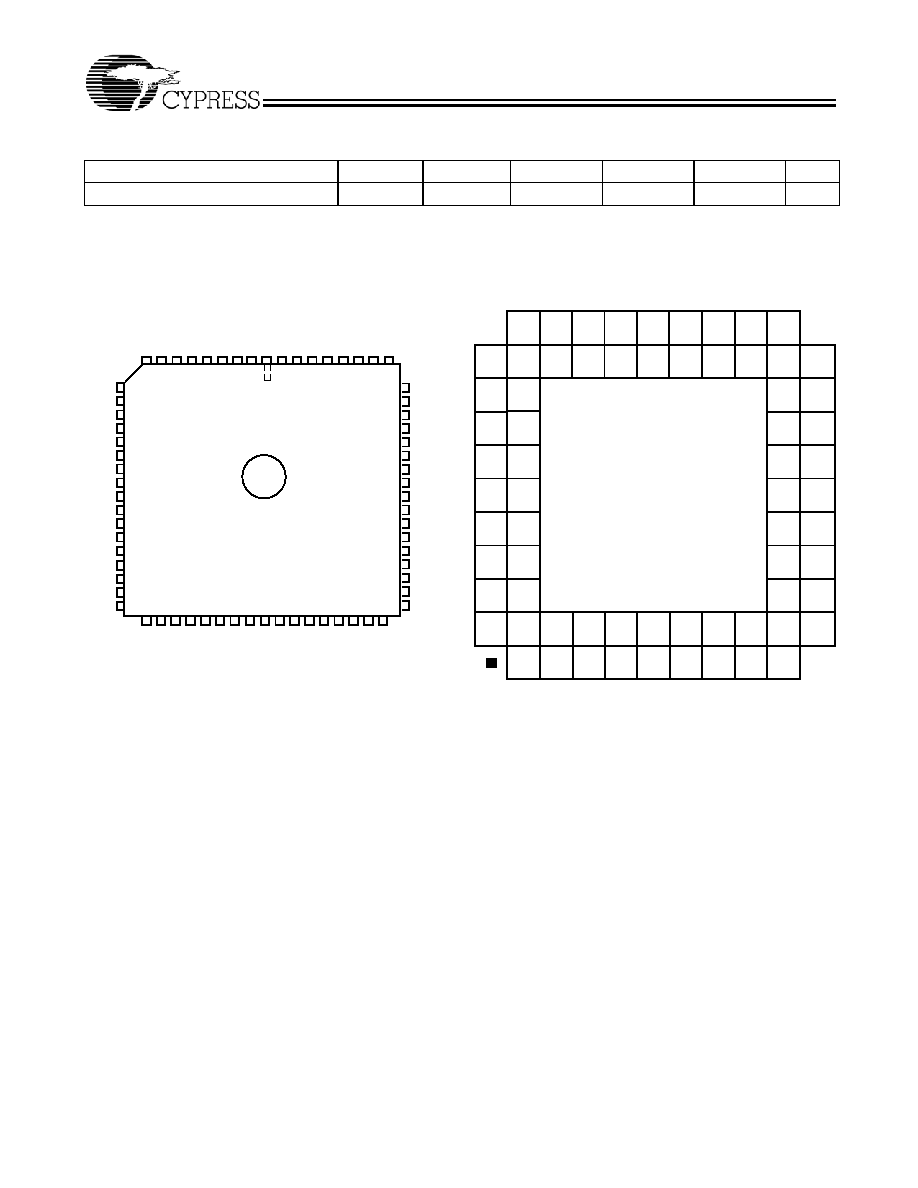

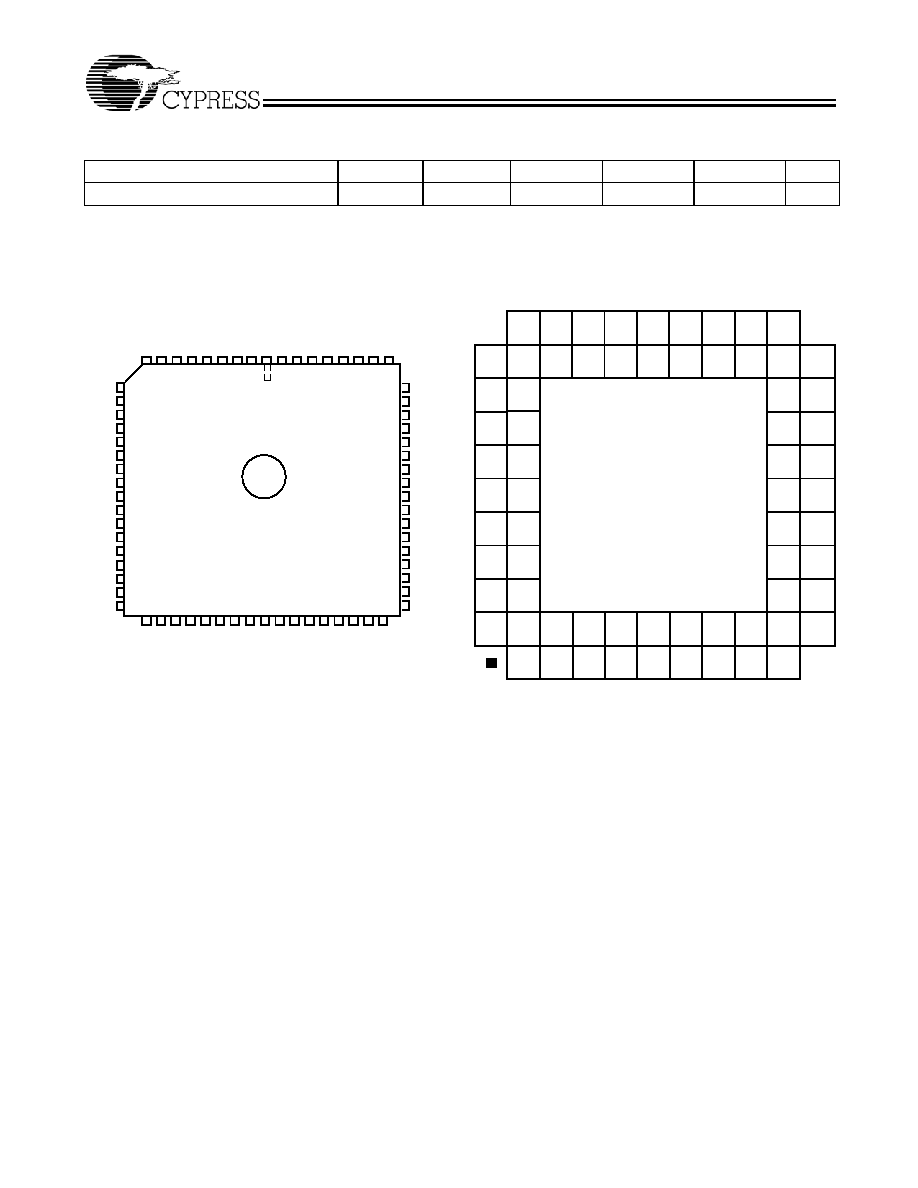

Pin Configurations

I/O

Top View

HLCC, PLCC

7 6

4

5

3

11

12

10

9 8

43

42

44

45

46

21

22

24

23

25

13

14

41

40

2

1

26 27

18

19

17

16

15

20

28 29

31

30

32 33

36

35

37 38 39

34

52

51

49

50

48

47

V

CC

53

54

55

60

58

59

57

56

66 65

63

64

62

68 67

61

I/O

INPUT

INPUT/CLK

INPUT

GND

INPUT

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O

V

CC

V

CC

INPUT

INPUT

GND

INPUT

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

INPUT

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O

V

CC

I/O

I/O

I/O

I/O

I/O

V

CC

I/O

INPUT/

CLK

INPUT

GND

I/O

I/O

I/O

I/O

V

CC

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

V

CC

INPUT

INPUT

GND

INPUT

I/O

INPUT

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

V

CC

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O

I/O

PGA

Bottom View

I/O

INPUT INPUT

I/O

I/O

I/O

I/O

I/O

I/O

L

K

J

H

G

F

E

D

C

B

A

1

2

3

4

5

6

7

8

9

10

11

7C342B

7C342B

CY7C342B

USE ULTRA37000

TM

FOR

ALL NEW DESIGNS

Document #: 38-03014 Rev. *B

Page 3 of 14

Logic Array Blocks

There are eight logic array blocks in the CY7C342B. Each LAB

consists of a macrocell array containing 16 macrocells, an

expander product term array containing 32 expanders, and an

I/O block. The LAB is fed by the programmable interconnect

array and the dedicated input bus. All macrocell feedbacks go

to the macrocell array, the expander array, and the program-

mable interconnect array. Expanders feed themselves and the

macrocell array. All I/O feedbacks go to the programmable

interconnect array so that they may be accessed by macro-

cells in other LABs as well as the macrocells in the LAB in

which they are situated.

Externally, the CY7C342B provides eight dedicated inputs,

one of which may be used as a system clock. There are 52 I/O

pins that may be individually configured for input, output, or

bidirectional data flow.

Programmable Interconnect Array

The Programmable Interconnect Array (PIA) solves inter-

connect limitations by routing only the signals needed by each

logic array block. The inputs to the PIA are the outputs of every

macrocell within the device and the I/O pin feedback of every

pin on the device.

Unlike masked or programmable gate arrays, which induce

variable delay dependent on routing, the PIA has a fixed delay.

This eliminates undesired skews among logic signals that may

cause glitches in internal or external logic. The fixed delay,

regardless of programmable interconnect array configuration,

simplifies design by assuring that internal signal skews or

races are avoided. The result is ease of design implemen-

tation, often in a signal pass, without the multiple internal logic

placement and routing iterations required for a programmable

gate array to achieve design timing objectives.

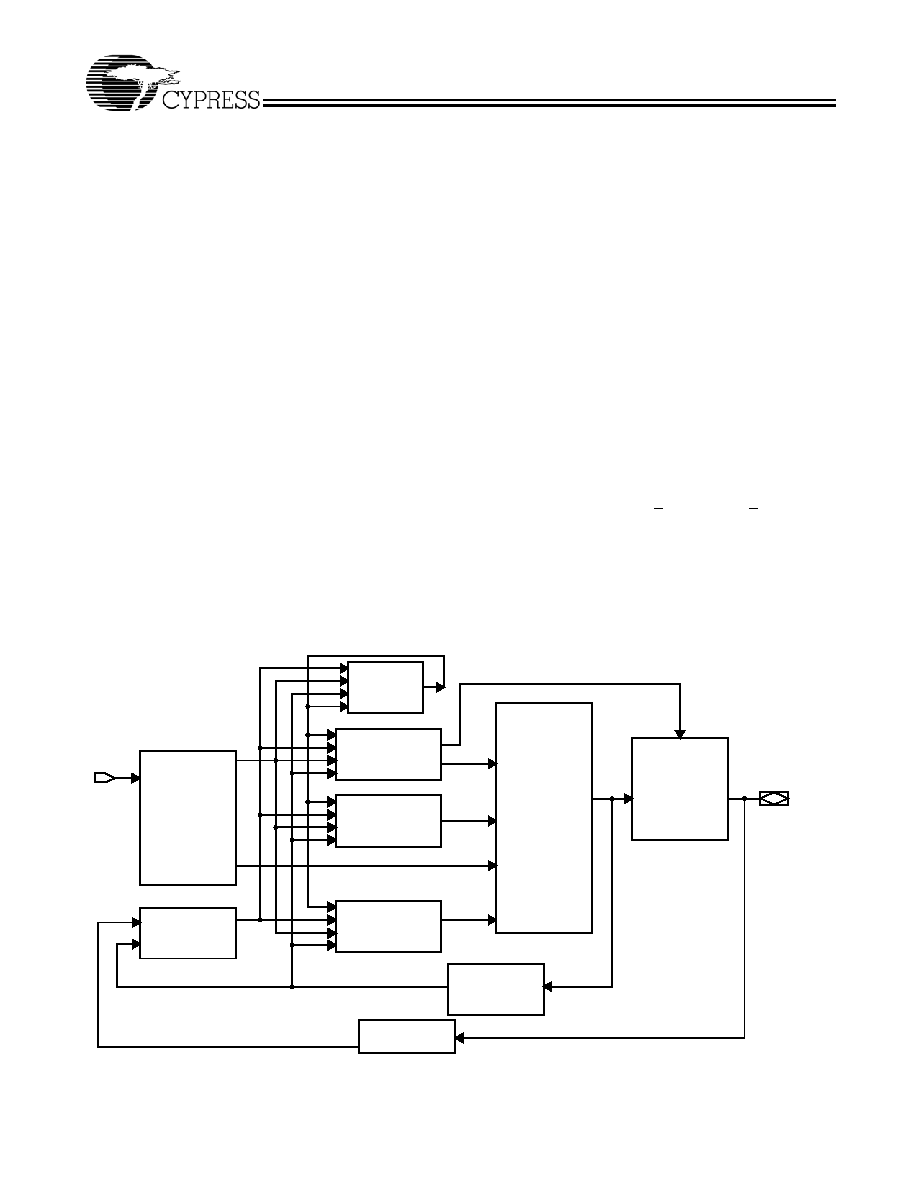

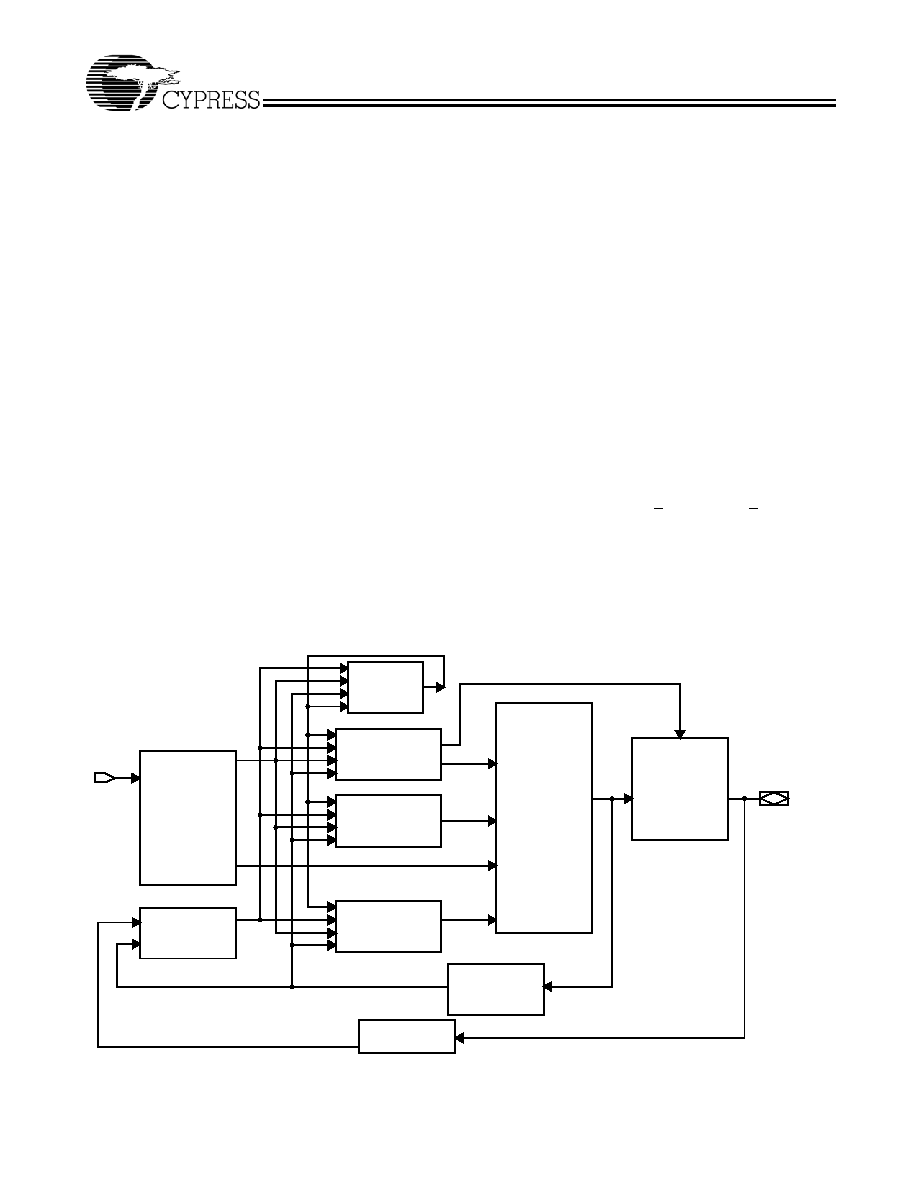

Timing Delays

Timing delays within the CY7C342B may be easily determined

using Warp

Æ

, Warp ProfessionalTM, or Warp EnterpriseTM

software by the model shown in Figure 1. The CY7C342B has

fixed internal delays, allowing the user to determine the

worst-case timing delays for any design.

Design Recommendations

Operation of the devices described herein with conditions

above those listed under "Maximum Ratings" may cause

permanent damage to the device. This is a stress rating only

and functional operation of the device at these or any other

conditions above those indicated in the operational sections of

this datasheet is not implied. Exposure to absolute maximum

ratings conditions for extended periods of time may affect

device reliability. The CY7C342B contains circuitry to protect

device pins from high static voltages or electric fields, but

normal precautions should be taken to avoid application of any

voltage higher than the maximum rated voltages.

For proper operation, input and output pins must be

constrained to the range GND < (V

IN

or V

OUT

) < V

CC

. Unused

inputs must always be tied to an appropriate logic level

(either V

CC

or GND). Each set of V

CC

and GND pins must

be connected together directly at the device. Power supply

decoupling capacitors of at least 0.2

µ

F must be connected

between V

CC

and GND. For the most effective decoupling,

each V

CC

pin should be separately decoupled to GND

directly at the device. Decoupling capacitors should have

good frequency response, such as monolithic ceramic types

have.

LOGIC ARRAY

CONTROL DELAY

t

LAC

EXPANDER

DELAY

t

EXP

CLOCK

DELAY

t

IC

t

RD

t

COMB

t

LATCH

INPUT

DELAY

t

IN

REGISTER

OUTPUT

DELAY

t

OD

t

XZ

t

ZX

LOGIC ARRAY

DELAY

t

LAD

FEEDBACK

DELAY

t

FD

OUTPUT

INPUT

SYSTEM CLOCK DELAY t

ICS

t

RH

t

RSU

t

PRE

t

CLR

PIA

DELAY

t

PIA

I/O DELAY

t

IO

Figure 1. CY7C342B Internal Timing Model

CY7C342B

USE ULTRA37000

TM

FOR

ALL NEW DESIGNS

Document #: 38-03014 Rev. *B

Page 4 of 14

Design Security

The CY7C342B contains a programmable design security

feature that controls the access to the data programmed into

the device. If this programmable feature is used, a proprietary

design implemented in the device cannot be copied or

retrieved. This enables a high level of design control to be

obtained since programmed data within EPROM cells is

invisible. The bit that controls this function, along with all other

program data, may be reset simply by erasing the entire

device.

The CY7C342B is fully functionally tested and guaranteed

through complete testing of each programmable EPROM bit

and all internal logic elements thus ensuring 100%

programming yield.

The erasable nature of these devices allows test programs to

be used and erased during early stages of the production flow.

The devices also contain on-board logic test circuitry to allow

verification of function and AC specification once encapsu-

lated in non-windowed packages.

Timing Considerations

Unless otherwise stated, propagation delays do not include

expanders. When using expanders, add the maximum

expander delay t

EXP

to the overall delay. Similarly, there is an

additional t

PIA

delay for an input from an I/O pin when

compared to a signal from straight input pin.

When calculating synchronous frequencies, use t

SU

if all

inputs are on dedicated input pins. When expander logic is

used in the data path, add the appropriate maximum expander

delay, t

EXP

to t

S1

. Determine which of 1/(t

WH

+ t

WL

), 1/t

CO1

,

or 1/(t

EXP

+ t

S1

) is the lowest frequency. The lowest of these

frequencies is the maximum data path frequency for the

synchronous configuration.

When calculating external asynchronous frequencies, use

t

AS1

if all inputs are on the dedicated input pins.

When expander logic is used in the data path, add the appro-

priate maximum expander delay, t

EXP

to t

AS1

. Determine

which of 1/(t

AWH

+ t

AWL

), 1/t

ACO1

, or 1/(t

EXP

+ t

AS1

) is the

lowest frequency. The lowest of these frequencies is the

maximum data path frequency for the asynchronous config-

uration.

The parameter t

OH

indicates the system compatibility of this

device when driving other synchronous logic with positive

input hold times, which is controlled by the same

synchronous clock. If t

OH

is greater than the minimum

required input hold time of the subsequent synchronous

logic, then the devices are guaranteed to function properly

with a common synchronous clock under worst-case

environmental and supply voltage conditions.

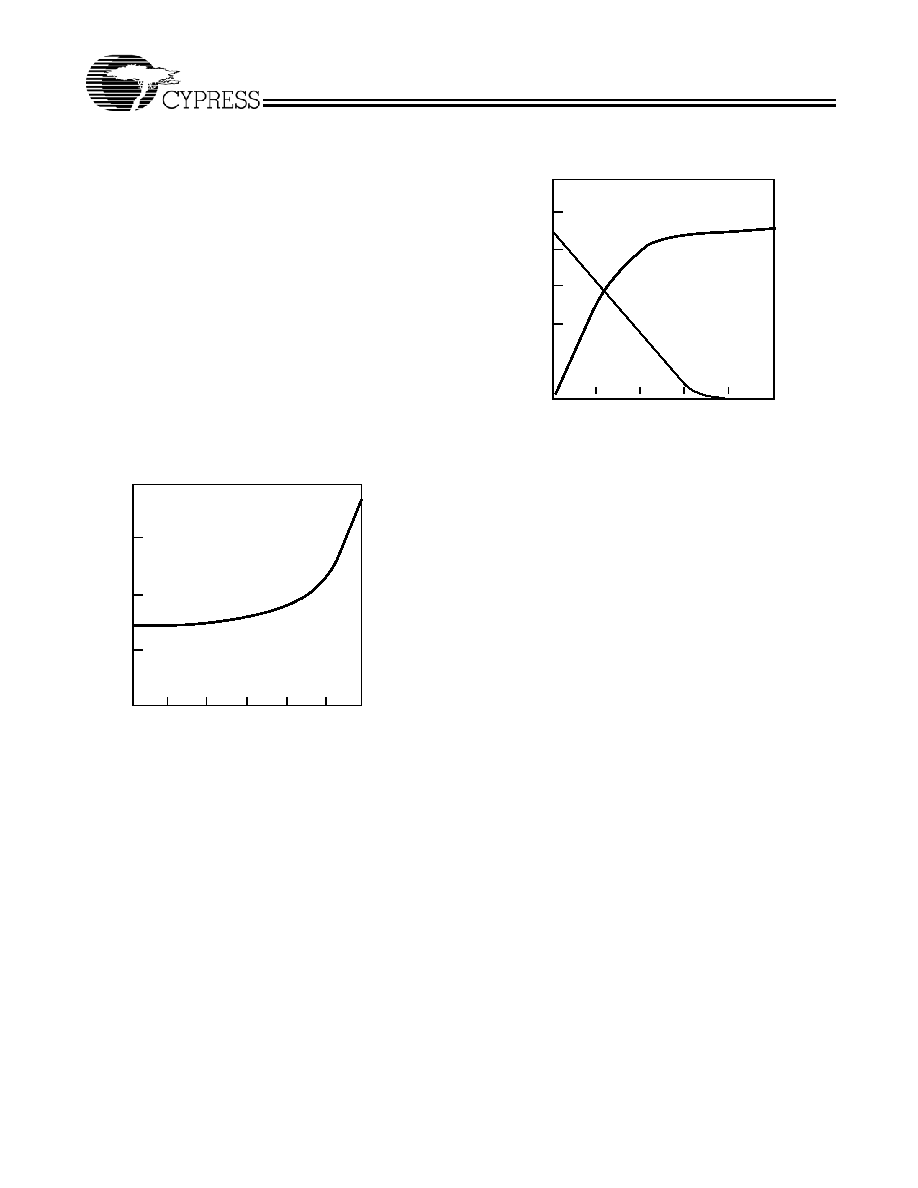

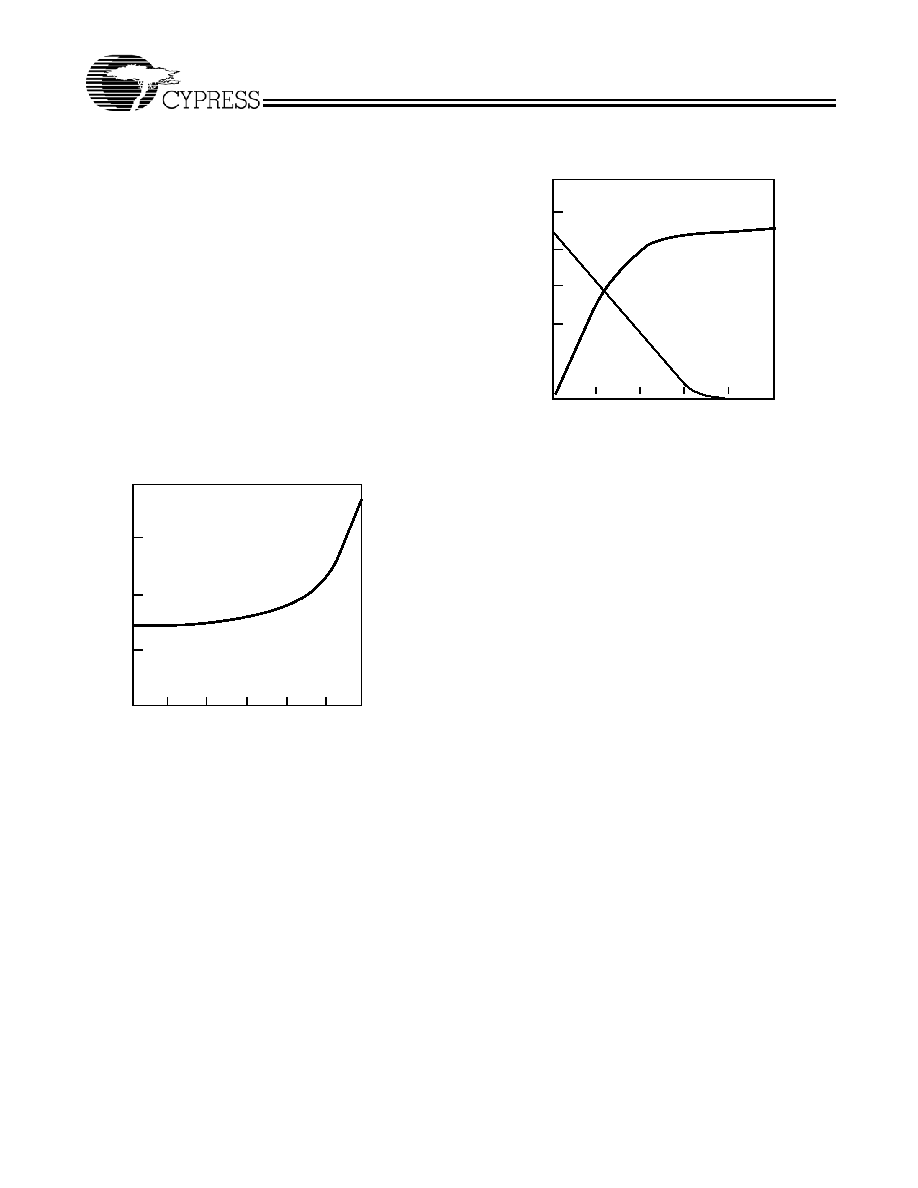

Typical I

CC

vs. f

MAX

400

300

200

100

1 kHz

10 kHz

100 kHz 1 MHz

I

CC

MAXIMUM FREQUENCY

10 MHz

0

50 MHz

100 Hz

ACTIVE (mA

)

T

y

p.

V

CC

= 5.0V

Room Temp.

Output Drive Current

0

1

2

3

4

I OU

TPUT

CURR

EN

T (

m

A)

TYPICAL

V

O

OUTPUT VOLTAGE (V)

250

200

150

100

50

5

O

I

OH

I

OL

V

CC

= 5.0V

Room Temp.

CY7C342B

USE ULTRA37000

TM

FOR

ALL NEW DESIGNS

Document #: 38-03014 Rev. *B

Page 5 of 14

Maximum Ratings

(Above which the useful life may be impaired. For user guide-

lines, not tested.)

Storage Temperature ................................ ≠65

∞

C to +135

∞

C

Ambient Temperature with

Power Applied............................................ ≠65

∞

C to +135

∞

C

Maximum Junction Temperature

(under bias)..................................................................150

∞

C

Supply Voltage to Ground Potential ............≠2.0V to +7.0V

[1]

DC Output Current per Pin

[1]

................... ≠25 mA to +25 mA

DC Input Voltage

[1]

.........................................≠2.0V to +7.0V

Operating Range

Range

Ambient Temperature

V

CC

Commercial

0

∞

C to +70

∞

C

5V

±

5%

Industrial

≠40

∞

C to +85

∞

C

5V

±

10%

Electrical Characteristics

Over the Operating Range

Parameter

Description

Test Conditions

Min.

Max.

Unit

V

CC

Supply Voltage

Maximum V

CC

rise time is 10 ms

4.75(4.5)

5.25(5.5)

V

V

OH

Output HIGH Voltage

I

OH

= ≠4 mA DC

[2]

2.4

V

V

OL

Output LOW Voltage

I

OL

= 8 mA DC

[2]

0.45

V

V

IH

Input HIGH Voltage

2.0

V

CC

+ 0.3

V

V

IL

Input LOW Voltage

≠0.3

0.8

V

I

IX

Input Current

V

I

= V

CC

or ground

≠10

+10

µ

A

I

OZ

Output Leakage Current

V

O

= V

CC

or ground

≠40

+40

µ

A

t

R

Recommended Input Rise Time

100

ns

t

F

Recommended Input Fall Time

100

ns

Capacitance

Parameter

Description

Test Conditions

Max.

Unit

C

IN

Input Capacitance

V

IN

= 0V, f = 1.0 MHz

10

pF

C

OUT

Output Capacitance

V

OUT

= 0V, f = 1.0 MHz

20

pF

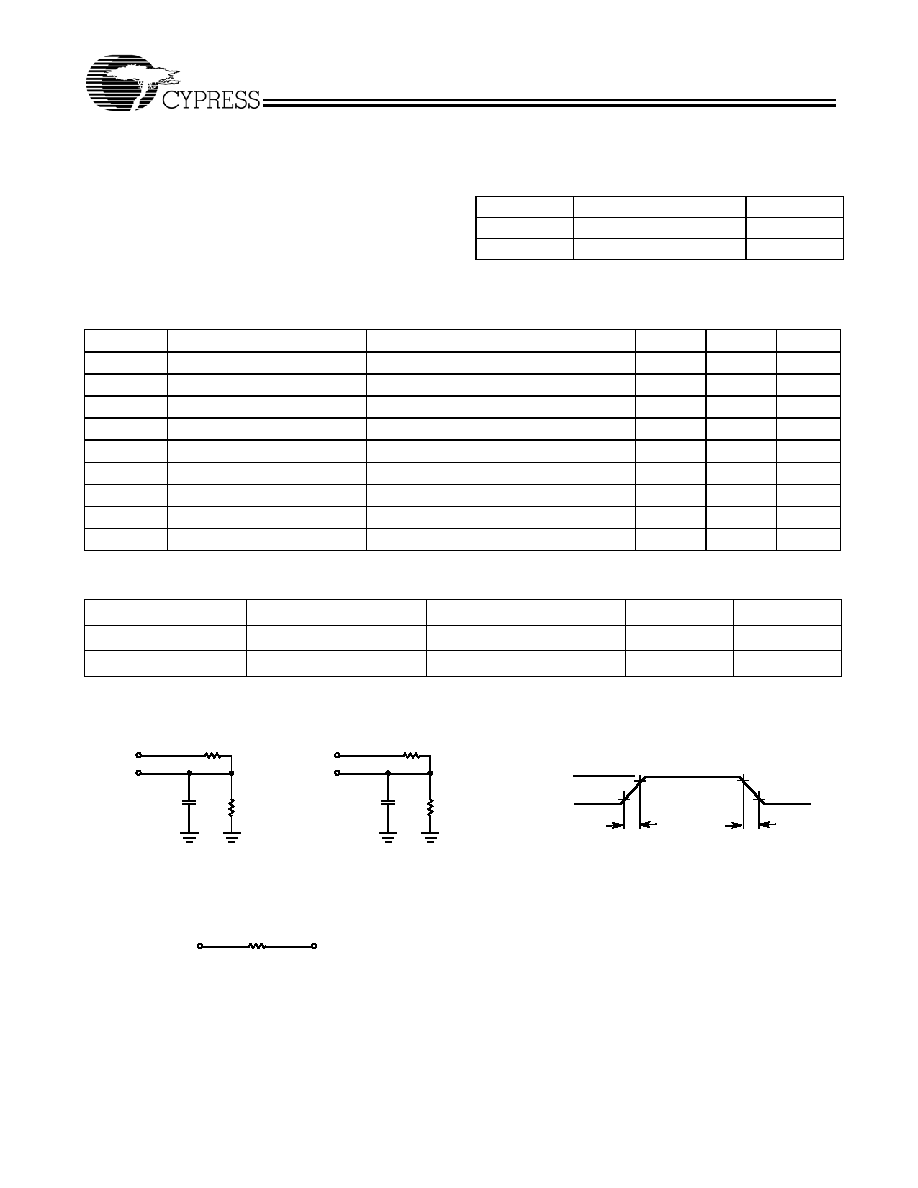

AC Test Loads and Waveforms

Notes:

1. Minimum DC input is ≠0.3V. During transactions, input may undershoot to ≠2.0V or overshoot to 7.0V for input currents less then 100 mA and periods shorter

than 20 ns.

2. The I

OH

parameter refers to high-level TTL output current; the I

OL

parameter refers to low-level TTL output current.

3.0V

5V

OUTPUT

R1 464

R2

250

50 pF

INCLUDING

JIG AND

SCOPE

GND

90%

10%

90%

10%

6 ns

6 ns

5V

OUTPUT

R1 464

R2

250

5 pF

INCLUDING

JIG AND

SCOPE

(a)

(b)

OUTPUT

1.75V

Equivalent to:

TH… VENIN EQUIVALENT (commercial/military)

ALL INPUT PULSES

163