1 04-02-052D

Commercial/Industrial

PA7536 PEEL ArrayTM

Programmable Electrically Erasable Logic Array

Versatile Logic Array Architecture

- 12 I/Os, 14 inputs, 36 registers/latches

- Up to 36 logic cell output functions

- PLA structure with true product-term sharing

- Logic functions and registers can be I/O-buried

Ideal for Combinatorial, Synchronous and

Asynchronous Logic Applications

- Integration of multiple PLDs and random logic

- Buried counters, complex state-machines

- Comparators, decoders, multiplexers and

other wide-gate functions

High-Speed Commercial and Industrial Versions

- As fast as 9ns/15ns (tpdi/tpdx), 83.3MHz (f

MAX

)

- Industrial grade available for 4.5 to 5.5V V

CC

and

-40 to +85 ∞C temperatures

CMOS Electrically Erasable Technology

- Reprogrammable in 28-pin DIP, SOIC and PLCC

packages

Flexible Logic Cell

- Up to 3 output functions per logic cell

- D,T and JK registers with special features

- Independent or global clocks, resets, presets,

clock polarity and output enables

- Sum-of-products logic for output enables

Development and Programmer Support

- ICT WinPLACE Development Software

- Fitters for ABEL, CUPL and other software

- Programming support by popular third-party

programmer

General Description

The PA7536 is a member of the Programmable Electrically

Erasable Logic (PEELTM) Array family based on ICT's

CMOS EEPROM technology. PEELTM Arrays free

designers from the limitations of ordinary PLDs by

providing the architectural flexibility and speed needed for

today's programmable logic designs. The PA7536 offers

versatile logic array architecture with 12 I/O pins, 14 input

pins and 36 registers/latches (12 buried logic cells, 12

Input registers/latches and 12 buried registers/latches). Its

logic array implements 50 sum-of-products logic functions

that share 64 product terms. The PA7536's logic and I/O

cells (LCCs, IOCs) are extremely flexible offering up to

three output functions per cell (a total of 36 for all 12 logic

cells). Cells are configurable as D, T, and JK registers with

independent or global clocks, resets, presets, clock

polarity, and other special features, making the PA7536

suitable for a variety of combinatorial, synchronous and

asynchronous logic applications. The PA7536 offers pin

compatibility and super-set functionality to popular 28-pin

PLDs, such as the 26V12. Thus, designs that exceed the

architectures of such devices can be expanded upon. The

PA7536 supports speeds as fast as 9ns/15ns (tpdi/tpdx)

and 83.3MHz (f

MAX

) and moderate power consumption

60mA (45mA typical). Packaging includes 28-pin DIP,

SOIC, and PLCC (see Figure 1). Development and

programming support for the PA7536 is provided by ICT

and popular third-party development tool manufacturers.

Figure 1. Pin Configuration

08-16-001A

D IP

I/C LK1

1

I

2

I

3

I

4

I

5

I

6

VC C

7

I

8

I

9

I

10

I

11

I

12

I/O

24

I/O

23

I/O

22

G N D

21

I/O

20

I/O

19

I/O

18

I/O

17

I/O

16

I/O

15

I

13

I

14

I/C LK2

28

I/O

27

I/O

26

I/O

25

1

I/C LK1

2

I

3

I

4

I

5

I

6

I

7

VC C

8

I

9

I

10

I

11

I

12

I

24

I/O

23

I/O

22

I/O

21

G N D

20

I/O

19

I/O

18

I/O

17

I/O

16

I/O

15

I/O

S O IC /TS S O P

13

I

14

I

28

I/C LK2

27

I/O

26

I/O

25

I/O

P L C C

25

I/O

24

I/O

23

I/O

22

I/O

21

G N D

20

I/O

19

I/O

4

I

3

I

2

I

1

I/

C

L

K

1

28

I/

C

L

K

2

27

I/

O

26

I/

O

5

I

6

I

7

VC C

8

I

9

I

10

I

11

I

12

I

13

I

14

I

15

I/

O

16

I/

O

17

I/

O

18

I/

O

Figure 2. Block Diagram

In pu t

Cells

(IN C )

1 2 In p ut P in s

2 Inp u t/

G lo ba l C lock Pins

G lo ba l

C e lls

2

1 2

I/O

C e lls

(IO C )

L og ic

C o ntro l

C e lls

(L C C )

1 2

1 2

1 2

1 2

A

B

C

D

7 6 (3 8 X 2)

A rra y In pu ts

true a n d

com ple m e n t

Buried

logic

2 su m te rm s

3 pro d uc t te rm s

for G lo b al C e lls

12 Lo gic C ontro l Cells

u p to 3 o u tp u t fu nction s p er c ell

(3 6 to tal o utp ut func tio n s po s sible)

L og ic fun ctio ns

to I/O ce lls

1 2 I/O Pins

4 8 s um te rm s

(fo ur p er LC C )

L og ic

Array

0 8-1 6-0 02 A

P A7536

I

I

I

I

I

VC C

I

I

I

I

I/O

I/O

I/O

I/O

I/O

I/O

G ND

I/CL K2

I/CL K1

I

I

I/O

I/O

I/O

G lo ba l Ce lls

In p ut C ells

I/O Ce lls

I

I/O

I/O

I/O

L og ic Co ntro l C e lls

2 04-02-052D

Commercial/Industrial

Inside the Logic Array

The heart of the PEELTM Array architecture is based on a

logic array structure similar to that of a PLA (programmable

AND, programmable OR). The logic array implements all

logic functions and provides interconnection and control of

the cells. Depending on the PEELTM Array selected, a

range of 38 to 62 inputs is available into the array from the

I/O cells, inputs cells and input/global-clock pins.

All inputs provide both true and complement signals, which

can be programmed to any product term in the array. The

number of product-terms among PEELTM Arrays ranges

from 67 to 125. All product terms (with the exception of

certain ones fed to the global cells) can be programmably

connected to any of the sum-terms of the logic control cells

(four sum-terms per logic control cell). Product-terms and

sum-terms are also routed to the global cells for control

purposes. Figure 3 shows a detailed view of the logic

array structure.

From

IO C ells

(IO C ,IN C ,

I/C LK)

From

Logic

C ontrol

C ells

(LC C )

To

G lobal

C ells

38 Array Inputs

67 Product T erm s

To

Logic C ontrol

C ells

(LC C )

50 Sum Term s

P A 75 36 L ogic A rray

0 8-1 6 -0 0 3A

Figure 3 PA7536 Logic Array

True Product-Term Sharing

The PEELTM logic array provides several advantages over

common PLD logic arrays. First, it allows for true product-

term sharing, not simply product-term steering, as

commonly found in other CPLDs. Product term sharing

ensures that product-terms are used where they are

needed and not left unutilized or duplicated. Secondly, the

sum-of-products functions provided to the logic cells can

be used for clocks, resets, presets and output enables

instead of just simple product-term control.

The PEELTM logic array can also implement logic functions

with many product terms within a single-level delay. For

example a 16-bit comparator needs 32 shared product

terms to implement 16 exclusive-OR functions. The

PEELTM logic array easily handles this in a single level

delay. Other PLDs/CPLDs either run out of product-terms

or require expanders or additional logic levels that often

slow performance and skew timing.

Logic Control Cell (LCC)

Logic Control Cells (LCC) are used to allocate and control

the logic functions created in the logic array. Each LCC has

four primary inputs and three outputs. The inputs to each

LCC are complete sum-of-product logic functions from the

array, which can be used to implement combinatorial and

sequential logic functions, and to control LCC registers and

I/O cell output enables.

A

B

C

D

R E G

D ,T,J

K

R

P

Q

M U X

System Clock

Preset

Reset

O n/O ff

RegType

From G lobal C ell

M U X

M U X

To

Array

To

I/O

Cell

From

Array

08 -16-0 04A

Figure 4. Logic Control Cell Block Diagram

As shown in Figure 4, the LCC is made up of three signal

routing multiplexers and a versatile register with

synchronous or asynchronous D, T, or JK registers

(clocked-SR registers, which are a subset of JK, are also

possible). See Figure 5. EEPROM memory cells are used

for programming the desired configuration. Four sum-of-

product logic functions (SUM terms A, B, C and D) are fed

into each LCC from the logic array. Each SUM term can be

selectively used for multiple functions as listed below.

3 04-02-052D

Commercial/Industrial

Sum-A = D, T, J or Sum-A

Sum-B = Preset, K or Sum-B

Sum-C = Reset, Clock, Sum-C

Sum-D = Clock, Output Enable, Sum-D

D

R

P

Q

D R e g is te r

Q = D a fte r clo cke d

B e st fo r sto ra g e , sim p le co u n te rs,

sh ifte rs a n d sta te m a ch in e s w ith

fe w h o ld (lo o p ) co n d itio n s.

T

R

P

Q

T R e g is te r

Q to g g le s w h e n T = 1

Q h o ld s w h e n T = 0

B e st fo r w id e b in a ry co u n te rs (sa ve s

p ro d u ct te rm s) a n d sta te m a ch in e s

w ith m a n y h o ld (lo o p ) co n d ition s.

J K R e g is te r

Q to g g le s w h e n J/K = 1 /1

Q h o ld s w h e n J/K = 0 /0

Q = 1 w h e n J/K = 1 /0

Q = 0 w h e n J/K = 0 /1

C o m b in e s fe a tu re s o f b o th D a n d T

re g iste rs.

J

R

P

Q

K

0 8 -1 6 -0 0 5 A

Figure 5. LCC Register Types

SUM-A can serve as the D, T, or J input of the register or a

combinatorial path. SUM-B can serve as the K input, or the

preset to the register, or a combinatorial path. SUM-C can

be the clock, the reset to the register, or a combinatorial

path. SUM-D can be the clock to the register, the output

enable for the connected I/O cell, or an internal feedback

node. Note that the sums controlling clocks, resets, presets

and output enables are complete sum-of-product functions,

not just product terms as with most other PLDs. This also

means that any input or I/O pin can be used as a clock or

other control function.

Several signals from the global cell are provided primarily

for synchronous (global) register control. The global cell

signals are routed to all LCCs. These signals include a

high-speed clock of positive or negative polarity, global

preset and reset, and a special register-type control that

selectively allows dynamic switching of register type. This

last feature is especially useful for saving product terms

when implementing loadable counters and state machines

by dynamically switching from D-type registers to load and

T-type registers to count (see Figure 11).

Multiple Outputs Per Logic Cell

An important feature of the logic control cell is its capability

to have multiple output functions per cell, each operating

independently. As shown in Figure 4, two of the three

outputs can select the Q output from the register or the

Sum A, B or C combinatorial paths. Thus, one LCC output

can be registered, one output can be combinatorial and the

third, an output enable or an additional buried logic

function. The multi-function PEELTM Array logic cells are

equivalent to two or three macrocells of other PLDs, which

have only one output per cell. They also allow registers to

be truly buried from I/O pins without limiting them to input-

only (see Figure 8 and Figure 9).

I/O C ell (IO C )

Input C ell (INC )

R EG /

L atch

Q

M UX

Input

T o

A rray

Input C ell C lock

F rom G lobal C ell

M UX

F rom

Logic

C ontrol

C ell

A ,B ,C

or

Q

M UX

M UX

1 0

D

I/O P in

M UX

T o

A rray

R EG /

L atch

Q

Input C ell C lock

F rom G lobal C ell

Input

Input

0 8-1 6 -00 6 A

Figure 6. I/O Cell Block Diagram

IO C /IN C R e g is te r

Q = D a fte r risin g e d g e o f clock

h o ld s u n til n e xt risin g e dg e

IO C /IN C L a tc h

Q = L w h e n clo ck is h ig h

h o ld s va lu e w h e n clo ck is lo w

L

Q

D

Q

0 8 -1 6 -0 0 7 A

Figure 7. IOC Register Configurations

4 04-02-052D

Commercial/Industrial

Input Cells (INC)

Input cells (INC) are included on dedicated input pins. The

block diagram of the INC is shown in Figure 6. Each INC

consists of a multiplexer and a register/transparent latch,

which can be clocked from various sources selected by the

global cell. The register is rising edge clocked. The latch is

transparent when the clock is high and latched on the

clock's failing edge. The register/latch can also be

bypassed for a non registered input.

I/O Cell (IOC)

All PEELTM Arrays have I/O cells (IOC) as shown above in

Figure 6. Inputs to the IOCs can be fed from any of the

LCCs in the array. Each IOC consists of routing and control

multiplexers, an input register/transparent latch, a three-

state buffer and an output polarity control. The register/

latch can be clocked from a variety of sources determined

by the global cell. It can also be bypassed for a non-

registered input. A feature of the 7536 IOC is the use of

SUM-D as a feed-back to the array when the I/O pin is a

dedicated output. This allows for additional buried registers

and logic paths. (See Figure 8 & Figure 9).

I/O w ith

independe nt

output ena ble

I/O

Q

D

Input w ith optional

register/latch

A

B

C

D

1

2

O E

D

Q

0 8 -1 6 -0 08 A

Figure 8. LCC & IOC With Two Outputs

A

B

C

D

O utput

1

2

3

B uried register or

logic paths

Q

D

D

Q

08 -16-009A

Figure 9. LCC & IOC With Three Outputs

Global Cells

The global cells, shown in Figure 10, are used to direct

global clock signals and/or control terms to the LCCs, IOCs

and INCs. The global cells allow a clock to be selected

from the CLK1 pin, CLK2 pin, or a product term from the

logic array (PCLK). They also provide polarity control for

IOC clocks enabling rising or falling clock edges for input

registers/latches. Note that each individual LCC clock has

its own polarity control. The global cell includes sum-of-

products control terms for global reset and preset, and a

fast product term control for LCC register-type, used to

save product terms for loadable counters and state

machines (see Figure 11). The PA7536 provides two

global cells that divide the LCC and IOCs into two groups,

A and B. Half of the LCCs and IOCs use global cell A, half

use global cell B. This means, for instance, two high-speed

global clocks can be used among the LCCs.

G lobal C ell: LC C & IO C

M U X

M U X

C L K 1

C L K 2

P CL K

R e g -Typ e

P re se t

R e se t

L C C R e se ts

L C C P re se ts

L C C R e g -T yp e

IO C C lo cks

L C C C lo cks

G lobal C ell: IN C

M U X

C L K 1

C L K 2

P CL K

IN C C lo cks

G ro u p A & B

0 8-1 6 -0 1 0 A

Figure 10. Global Cells

R e g is te r T yp e C h a n g e F e a tu re

G lo b a l C e ll ca n d yn a m ica lly cha n g e u se r-

se le cte d L C C re g iste rs fro m D to T o r fro m D

to JK . T h is sa v e s p ro d u ct te rm s fo r lo a d a b le

co u n te rs o r sta te m a ch in e s. U se a s D re g is te r

to lo a d , u se a s T o r JK to co u nt. T im in g a llo w s

d yn a m ic o p era tio n .

T

R

P

Q

D

R

P

Q

R e g-T yp e fro m G lo b al C e ll

E x a m p le :

P ro d u ct te rm s fo r 1 0 b it lo a d ab le b in a ry co u n ter

D u se s 5 7 p ro d u ct te rm s (4 7 co u n t, 1 0 lo a d )

T u se s 3 0 p ro d u ct te rm s (1 0 co u n t, 2 0 lo a d )

D /T u se s 2 0 p ro d u ct te rm s (1 0 co u n t, 1 0 lo a d )

0 8 -1 6 -01 1 A

Figure 11. Register Type Change Feature

5 04-02-052D

Commercial/Industrial

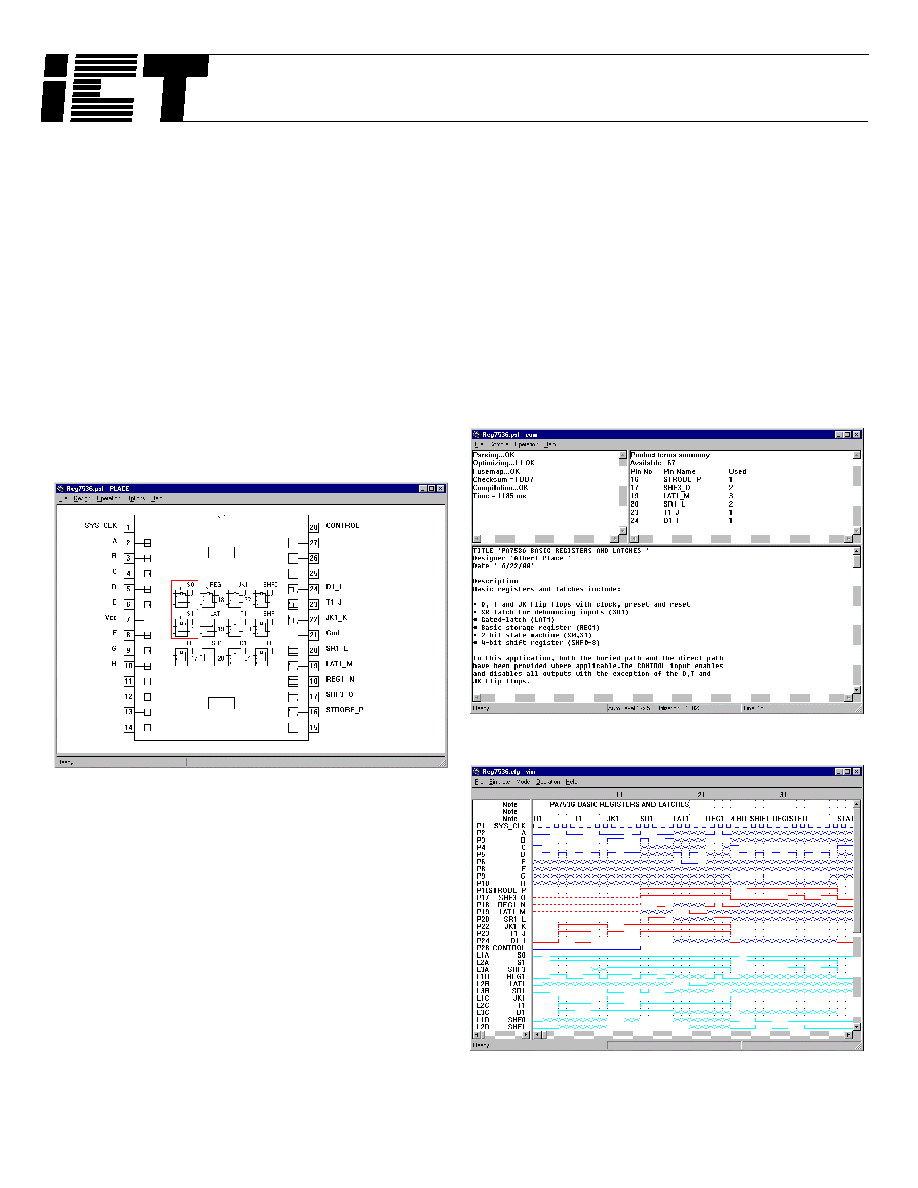

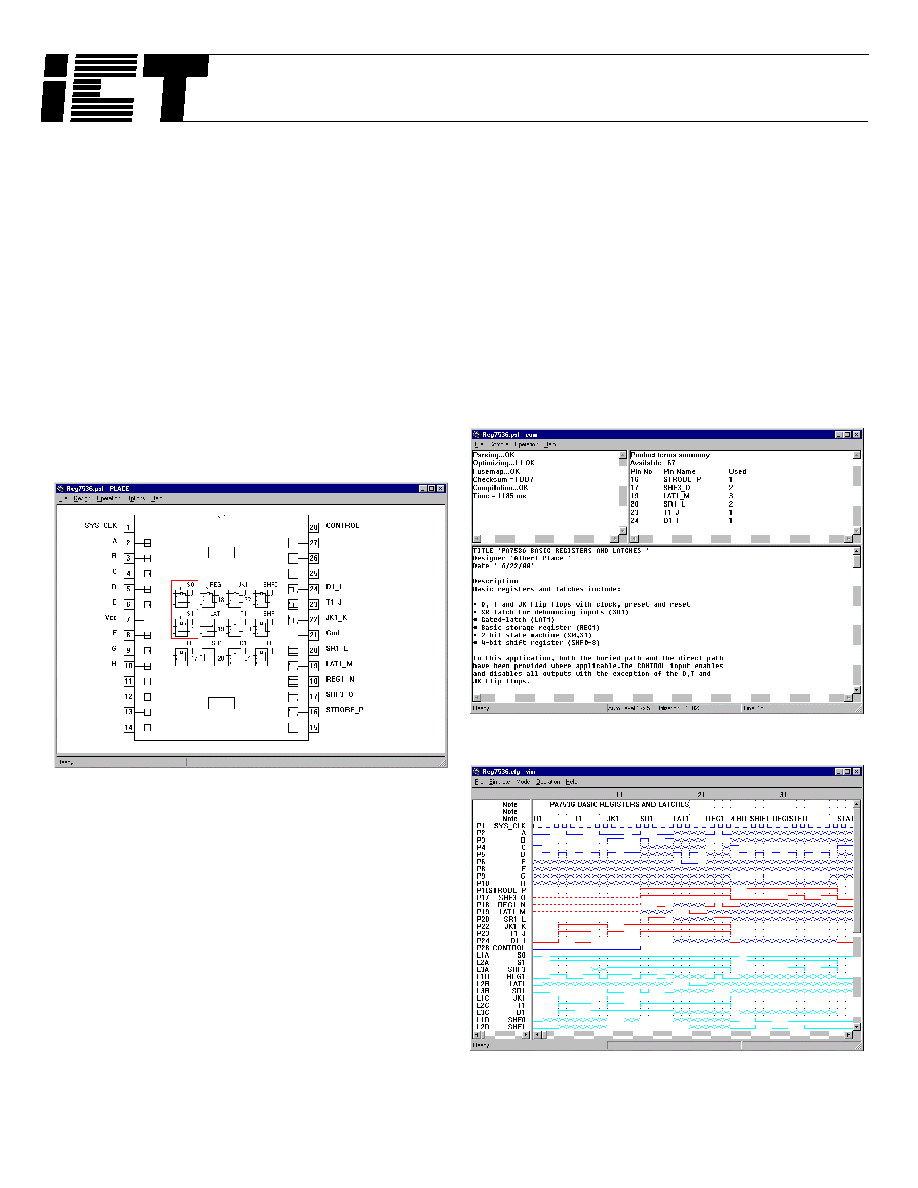

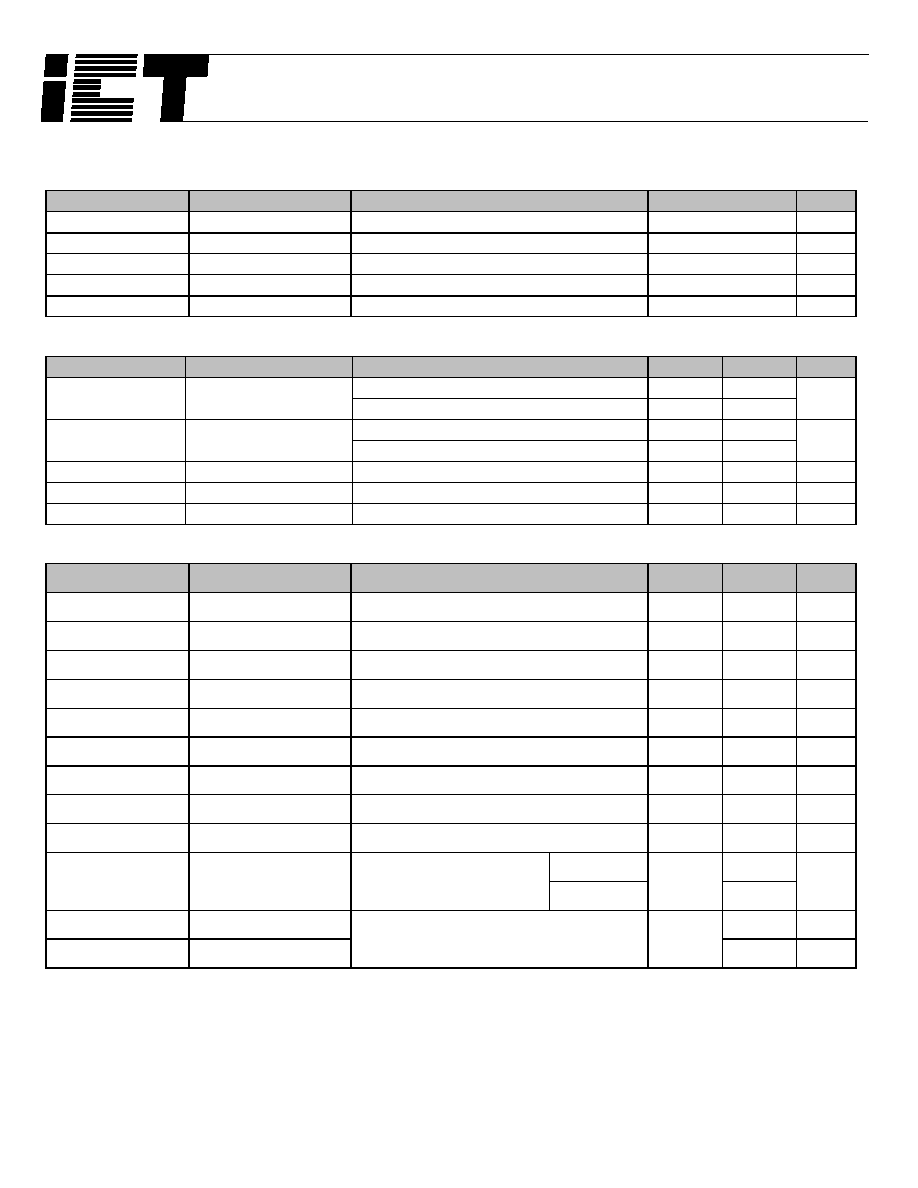

PEELTM Array Development Support

Development support for PEELTM Arrays is provided by

ICT and manufacturers of popular development tools. ICT

offers the powerful WinPLACE Development Software (free

to qualified PLD designers). The WinPLACE software

includes an architectural editor, logic compiler, waveform

simulator, documentation utility and a programmer

interface. The WinPLACE editor graphically illustrates and

controls the PEELTM Array's architecture, making the

overall design easy to understand, while allowing the

effectiveness of boolean logic equations, state machine

design and truth table entry. The WinPLACE compiler

performs logic transformation and reduction, making it

possible to specify equations in almost any fashion and fit

the most logic possible in every design. WinPLACE also

provides a multi-level logic simulator allowing external and

internal signals to be simulated and analyzed via a

waveform display.(See Figure 12, Figure 13 and Figure 14)

Figure 12 - WinPLACE Architectural Editor for

PA7536

PEELTM Array development is also supported by popular

development tools, such as ABEL and CUPL, via ICT's

PEELTM Array fitters. A special smart translator utility adds

the capability to directly convert JEDEC files for other

devices into equivalent JEDEC files for pin-compatible

PEELTM Arrays.

Programming

PEELTM Arrays are EE-reprogrammable in all package

types, plastic-DIP, PLCC, SOIC and TSSOP. This makes

them an ideal development vehicle for the lab. EE-

reprogrammability is also useful for production, allowing

unexpected changes to be made quickly and without

waste. Programming of PEELTM Arrays is supported by

popular third party programmers.

Design Security and Signature Word

The PEELTM Arrays provide a special EEPROM security bit

that prevents unauthorized reading or copying of designs.

Once set, the programmed bits of the PEELTM Arrays

cannot be accessed until the entire chip has been

electrically erased. Another programming feature,

signature word, allows a user-definable code to be

programmed into the PEELTM Array. The code can be read

back even after the security bit has been set. The signature

word can be used to identify the pattern programmed in the

device or to record the design revision.

Figure 13 - WinPLACE LCC and IOC screen

Figure 14 - WinPLACE simulator screen

6 04-02-052D

Commercial/Industrial

Table 1. Absolute Maximum Ratings

Symbol

Parameter

Conditions

Ratings

Unit

V

CC

Supply Voltage

Relative to Ground

-0.5 to + 7.0

V

V

I

, V

O

Voltage Applied to Any Pin

Relative to Ground

1

-0.5

to

V

CC

+ 0.6

V

I

O

Output Current

Per pin (I

OL

, I

OH

) ±25

mA

T

ST

Storage Temperature

-65 to + 150

∞C

T

LT

Lead Temperature

Soldering 10 seconds

+300

∞C

Table 2. Operating Ranges

Symbol

Parameter

Conditions

Min

Max

Unit

Commercial 4.75

5.25

V

CC

Supply

Voltage

Industrial 4.5

5.5

V

Commercial 0

+70

T

A

Ambient

Temperature

Industrial -40

+85

∞C

T

R

Clock Rise Time

See Note 2

20

ns

T

F

Clock Fall Time

See Note 2

20

ns

T

RVCC

V

CC

Rise Time

See Note 2

250

ms

Table 3. D.C. Electrical Characteristics

Over the Operating Range

Symbol

Parameter

Conditions

Min

Max

Unit

V

OH

Output HIGH Voltage - TTL

V

CC

= Min, I

OH

= -4.0mA

2.4

V

V

OHC

Output HIGH Voltage -

CMOS

V

CC

= Min, I

OH

= -10µA

V

CC

- 0.3

V

V

OL

Output LOW Voltage - TTL

V

CC

= Min, I

OL

= 16mA

0.5

V

V

OLC

Output LOW Voltage -

CMOS

V

CC

= Min, I

OL

= -10µA

0.15

V

V

IH

Input HIGH Level

2.0

V

CC

+ 0.3

V

V

IL

Input

LOW

Level

-0.3

0.8

V

I

IL

Input Leakage Current

V

CC

= Max, GND

'

IN

'

CC

±10

µA

I

OZ

Output Leakage Current

I/O = High-Z, GND

'

O

'

CC

±10

µA

I

SC

Output Short Circuit

Current

4

V

CC

= 5V, V

O

= 0.5V, TA= 25∞C -30

-120

mA

-15

60

I

CC

11

V

CC

Current

V

IN

= 0V or V

CC

3,11

f = 25MHz

All outputs disabled

4

I-15

45 (typ.)

19

70

mA

C

IN

7

Input Capacitance

5

6 pF

C

OUT

7

Output

Capacitance

5

T

A

= 25∞C, V

CC

= 5.0V @ f = 1 MHz

12 pF

7 04-02-052D

Commercial/Industrial

Table 4. A.C Electrical Characteristics Combinatorial

Over the Operating Range

-15/I-15

Unit

Symbol

Parameter

6,12

Min

Max

t

PDI

Propagation delay Internal (t

AL

+ t

LC

)

9

ns

t

PDX

Propagation delay External (t

IA

+ t

AL

+t

LC

+ t

LO

)

15

ns

t

IA

Input or I/O pin to array input

2

ns

t

AL

Array input to LCC

8

ns

t

LC

LCC input to LCC output

10

1

ns

t

LO

LCC output to output pin

4

ns

t

OD

, t

OE

Output Disable, Enable from LCC output

7

4

ns

t

OX

Output Disable, Enable from input pin

7

15

ns

This device has been designed and tested for the recommended operating conditions. Proper operation outside of these

levels is not guaranteed. Exposure to absolute maximum ratings may cause permanent damage.

Figure 15. Combinatorial Timing - Waveforms and Block Diagram

8 04-02-052D

Commercial/Industrial

Table 5. A.C. Electrical Characteristics Sequential

-15/I-15

Unit

Symbol

Parameter

6,1

Min

Max

t

SCI

Internal set-up to system clock

8

- LCC

14

(t

AL

+ t

SK

+ t

LC

- t

CK

)

5

ns

t

SCX

Input

16

(EXT.) set-up to system clock, - LCC (t

IA

+ t

SCI

)

7

ns

t

COI

System-clock to Array Int. - LCC/IOC/INC

14

(t

CK

+t

LC

)

7

ns

t

COX

System-clock to Output Ext. - LCC (t

COI

+ t

LO

)

11

ns

t

HX

Input hold time from system clock - LCC

0

ns

t

SK

LCC Input set-up to async. clock

13

- LCC

2

ns

t

AK

Clock at LCC or IOC - LCC output

1

ns

t

HK

LCC input hold time from system clock - LCC

4

ns

t

SI

Input set-up to system clock - IOC/INC

14

(t

SK

- t

CK

)

0

ns

t

HI

Input hold time from system clock - IOC/INC (t

SK

- t

CK

)

4

ns

t

PK

Array input to IOC PCLK clock

6

ns

t

SPI

Input set-up to PCLK clock

17

- IOC/INC (t

SK

-t

PK

-t

IA

)

0

ns

t

HPI

Input hold from PCLK clock

17

- IOC/INC (t

PK

+t

IA

-t

SK

)

6

ns

t

SD

Input set-up to system clock - IOC/INC Sum-D

15

(

tIA

+ t

AL

+ t

LC

+ t

SK

- t

CK

)

7

ns

t

HD

Input hold time from system clock - IOC Sum-D

0

ns

t

SDP

Input set-up to PCLK clock

(

tIA

+ t

AL

+ t

LC

+ t

SK

≠ t

pK

) - IOC Sum-D

7

ns

tHDP

Input hold time from PCLK clock - IOC Sum-D

0

ns

t

CK

System-clock delay to LCC/IOC/INC

6

ns

t

CW

System-clock low or high pulse width

6

ns

f

MAX1

Max. system-clock frequency Int/Int 1/(t

SCI

+ t

COI

)

83.3

MHz

f

MAX2

Max. system-clock frequency Ext/Int 1/(t

SCX

+ t

COI

)

71.4

MHz

f

MAX3

Max. system-clock frequency Int/Ext 1/(t

SCI

+ t

COX

)

62.5

MHz

f

MAX4

Max. system-clock frequency Ext/Ext 1/(t

SCX

+ t

COX

)

55.5

MHz

f

TGL

Max. system-clock toggle frequency 1/(t

CW

+ t

CW

)

9

83.3

MHz

t

PR

LCC presents/reset to LCC output

1

ns

t

ST

Input to Global Cell present/reset (t

IA

+ t

AL

+ t

PR

)

11

ns

t

AW

Asynch. preset/reset pulse width

8

ns

t

RT

Input to LCC Reg-Type (RT)

7

ns

t

RTV

LCC Reg-Type to LCC output register change

1

ns

t

RTC

Input to Global Cell register-type change (t

RT

+ t

RTV

)

8 ns

t

RW

Asynch. Reg-Type pulse width

10

ns

t

RESET

Power-on reset time for registers in clear state

2

5

µs

9 04-02-052D

Commercial/Industrial

Figure 16. Sequential Timing ≠ Waveforms and Block Diagram

Notes

1. Minimum DC input is -0.5V, however inputs may under-shoot to -2.0V

for periods less than 20ns.

2.Test points for Clock and V

CC

in t

R

,t

F

,t

CL

,t

CH

, and t

RESET

are referenced at

10% and 90% levels.

3. I/O pins are 0V or V

CC

.

4. Test one output at a time for a duration of less than 1 sec.

5. Capacitances are tested on a sample basis.

6. Test conditions assume: signal transition times of 5ns or less from the

10% and 90% points, timing reference levels of 1.5V (unless

otherwise specified).

7. t

OE

is measured from input transition to V

REF

±0.1V (See test loads at

end of Section 6 for V

REF

value). t

OD

is measured from input transition

to V

OH

-0.1V or V

OL

+0.1V.

8. "System-clock" refers to pin 1 or pin 28 high speed clocks.

9. For T or JK registers in toggle (divide by 2) operation only.

10. For combinatorial and async-clock to LCC output delay.

11. ICC for a typical application: This parameter is tested with the device

programmed as a 10-bit D-type counter.

12. Test loads are specified in Section 5 of the Data Book.

13. "Async. Clock" refers to the clock from the Sum term (OR gate).

14. The "LCC" term indicates that the timing parameter is applied to the

LCC register. The "IOC" term indicates that the timing parameter is

applied to the IOC register. The "LCC/IOC" term indicates that the

timing parameter is applied to both the LCC and IOC registers. The

"LCC/IOC/INC" term indicates that the timing parameter is applied to

the LCC,IOC, and INC registers.

15. This refers to the Sum-D gate routed to the IOC register for an

additional buried register.

16. The term "input" without any reference to another term refers to an

(external) input pin.

17. The parameter t

SPI

indicates that the PCLK signal to the IOC register

is always slower than the data from the pin or input by the absolute

value of (t

SK

-t

PK

-t

IA

). This means that no set-up time for the data

from the pin or input is required, i.e. the external data and clock can

be sent to the device simultaneously. Additionally, the data from the

pin must remain stable for t

HPI

time, i.e. to wait for the PCLK signal to

arrive at the IOC register.

18. Typical (typ) ICC is measured at T

A

= 25

∞

C, freq = 25MHZ, V

CC

=

5V

10 04-02-052D

Commercial/Industrial

Table 6. Ordering Information

Part Number

Speed

Temperature

Package

PA7536P-15 C

PA7536PI-15

9/15ns

I

P28

PA7536J-15 C

PA7536JI-15

9/15ns

I

J28

PA7536S-15

C

PA7536SI-15

9/15ns

I

S28

PA7536T-15

C

PA7536TI-15

9/15ns

I

T28

Figure 17. Part Number

D evice S uffix

P A 7 5 3 6 J -1 5

P a c k a g e

P = P lastic 600m il D IP

S = S O IC

J = P lastic (J) Leaded C hip C arrier (P LC C )

T = T S S O P

S p e e d

-15 = 9ns /15ns tpd/tpdx

T e m p e ra tu re R a n g e

(B lank ) = C om m ercial 0 to 70 ∞ C

I = Industrial -40 to +85 ∞ C

0 8 -1 6 -0 1 7 A

Corporate Office

2123 Ringwood Avenue

San Jose, CA 95131

TEL (408) 434-0678

FAX (408) 432-0815

Email:

sales&marketing@ictpld.com

Website:

http://www.ictpld.com

©2000 Integrated Circuit Technology Corp.

ICT reserves the right to make changes in specifications at any time and without notice. The information furnished by ICT

in this publication is believed to be accurate and reliable. However, no responsibility is assumed by ICT for its use nor for

any infringements of patents or other rights of third parties resulting from its use. No license is granted under any patents

or patent rights of ICT. ICT's products are not authorized for use as critical components in life support devices or systems.

Marks bearing

©

or TM are registered trademarks and trademarks of Integrated Circuit Technology Corp.