| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MAS281 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

MAS281

1/55

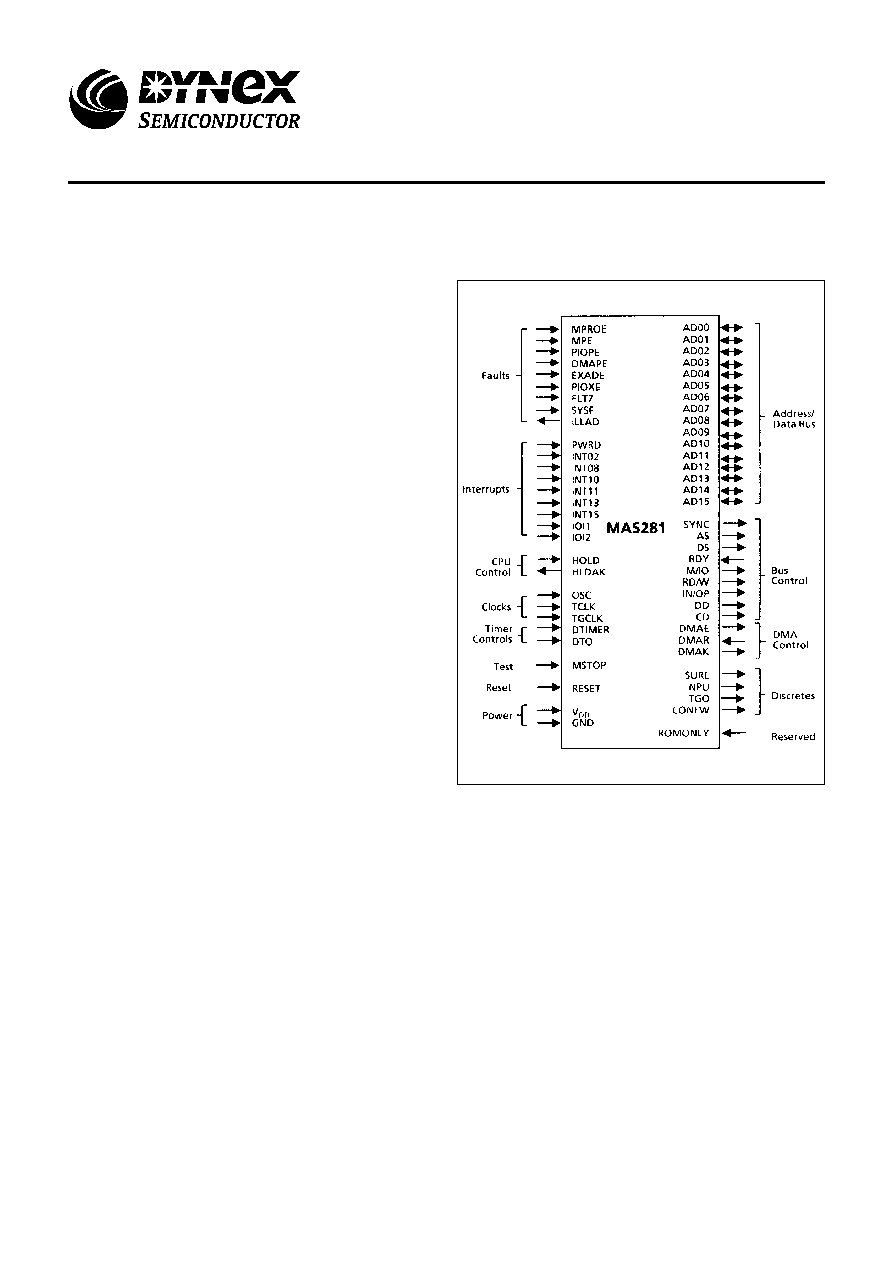

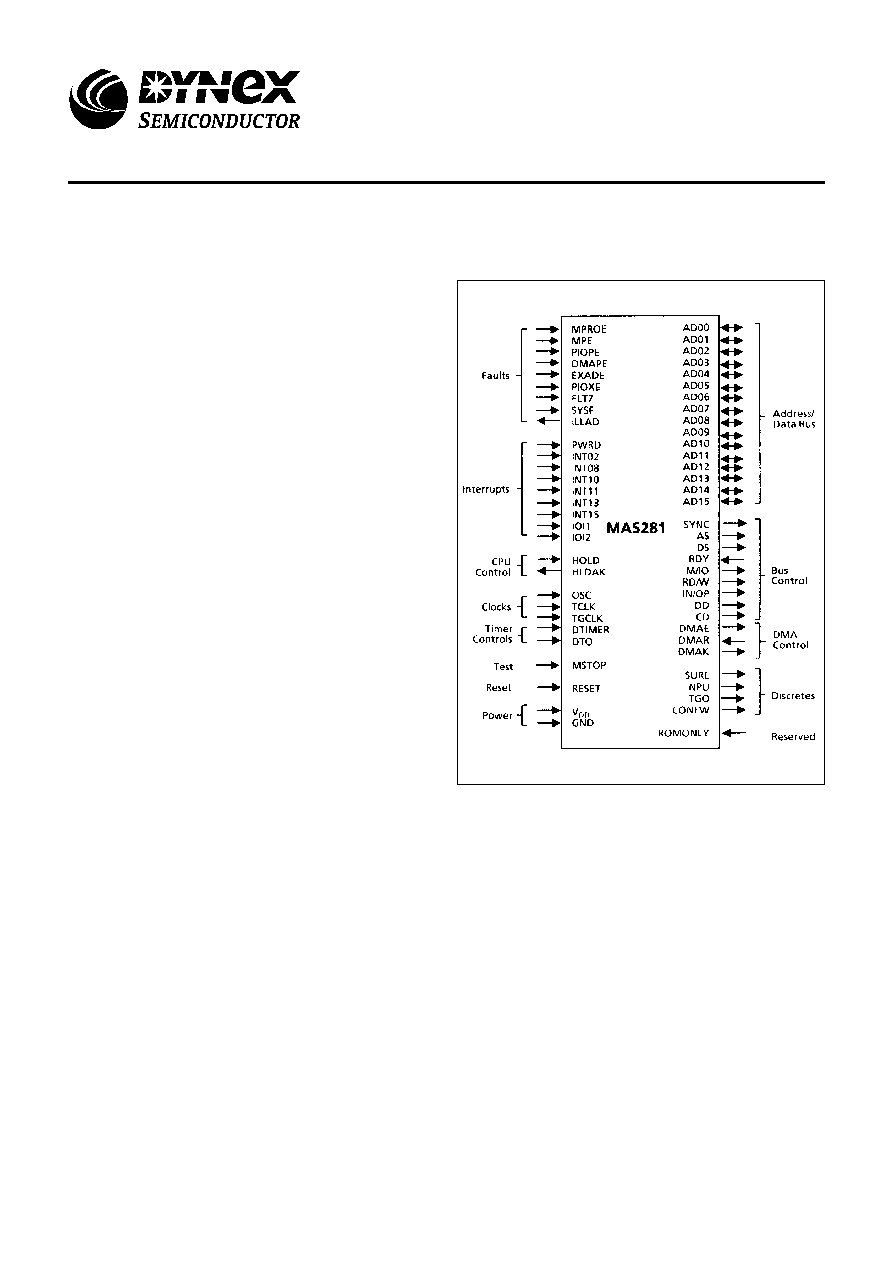

The MAS281 Microprocessor is a MIL-STD-1750A (Notice

1), 16-bit Central Processing Unit (CPU). It consists of three

CMOS/SOS large-scale integration (LSI) chips: the MA17501

Execution Unit (EU), the MA17502 Control Unit (CU), and the

MA17503 Interrupt Unit (IU). These three units can be

mounted on, and interconnected within a 64-pin ceramic

substrate. The microprocessor is also available as a 3-chip set

without the ceramic substrate (see ordering information on

page 55).

The MAS281 is optimised for real-time l/O and arithmetic

intensive operations. Key performance-enhancing features

include a parallel multiplier/accumulator, 32-bit barrel shifter,

instruction pre-fetch queue, and multiport register file.

Additional features include a comprehensive Built-ln-Test

(BIT), interval timers A and B, trigger-go counter, and Start-Up

ROM interface.

In accordance with MIL-STD-1750A, the MAS281

supports a 64K-word address space. An optional BMA31751

Memory Management Unit/Block Protect Unit (MMU(BPU))

chip may be added externally to expand this address space to

1M-words or add a 1K-word memory block protection

capability,

The MAS281 is offered in several screening grades which

are described in this document. For availability of speed

grades, please contact Dynex Semiconductor.

BLOCK DIAGRAM

FEATURES

s

MIL-STD-1750A 16-Bit Microprocessor

s

Full Performance over Military Temperature Range

(-55

∞

C to + 125

∞

C)

s

Radiation Hard CMOS/SOS Technology

s

Performance Optimised Architecture

- Parallel Multiplier/Accumulator

- 32-bit Barrel Shifter

- Instruction Pre-Fetch

- Multi-Port Register File

s

Implements MlL-STD-1750AOptions

- Timers A and B

- Trigger-Go Counter

- Start-Up ROM Interface

s

64 K-word Address Space Expandable to 1 M-word with

Optional MMU

MAS281

MIL-STD-1750A Microprocessor

Replaces June 1999 version, DS3563-4.0

DS3563-5.0 January 2000

MAS281

2/55

1.0 ARCHITECTURE

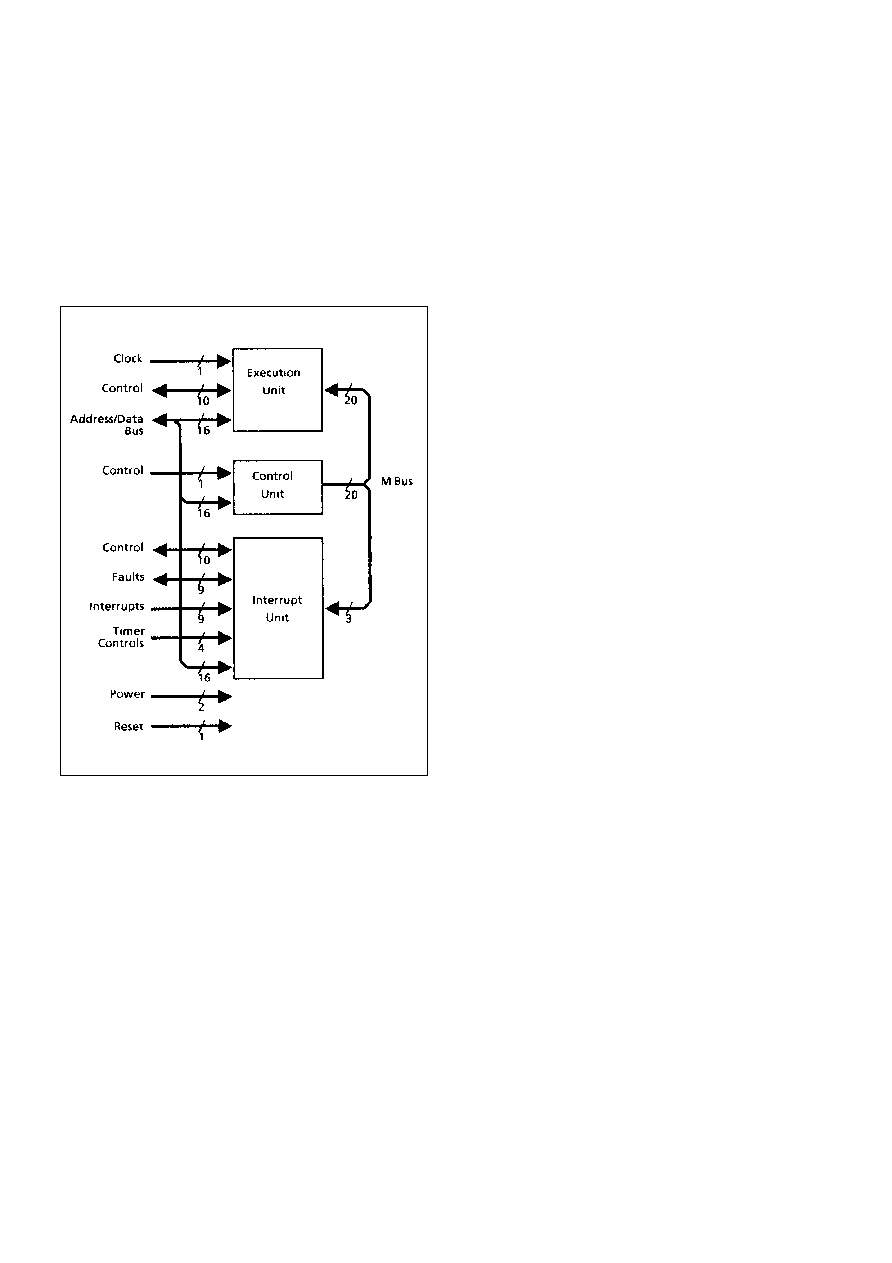

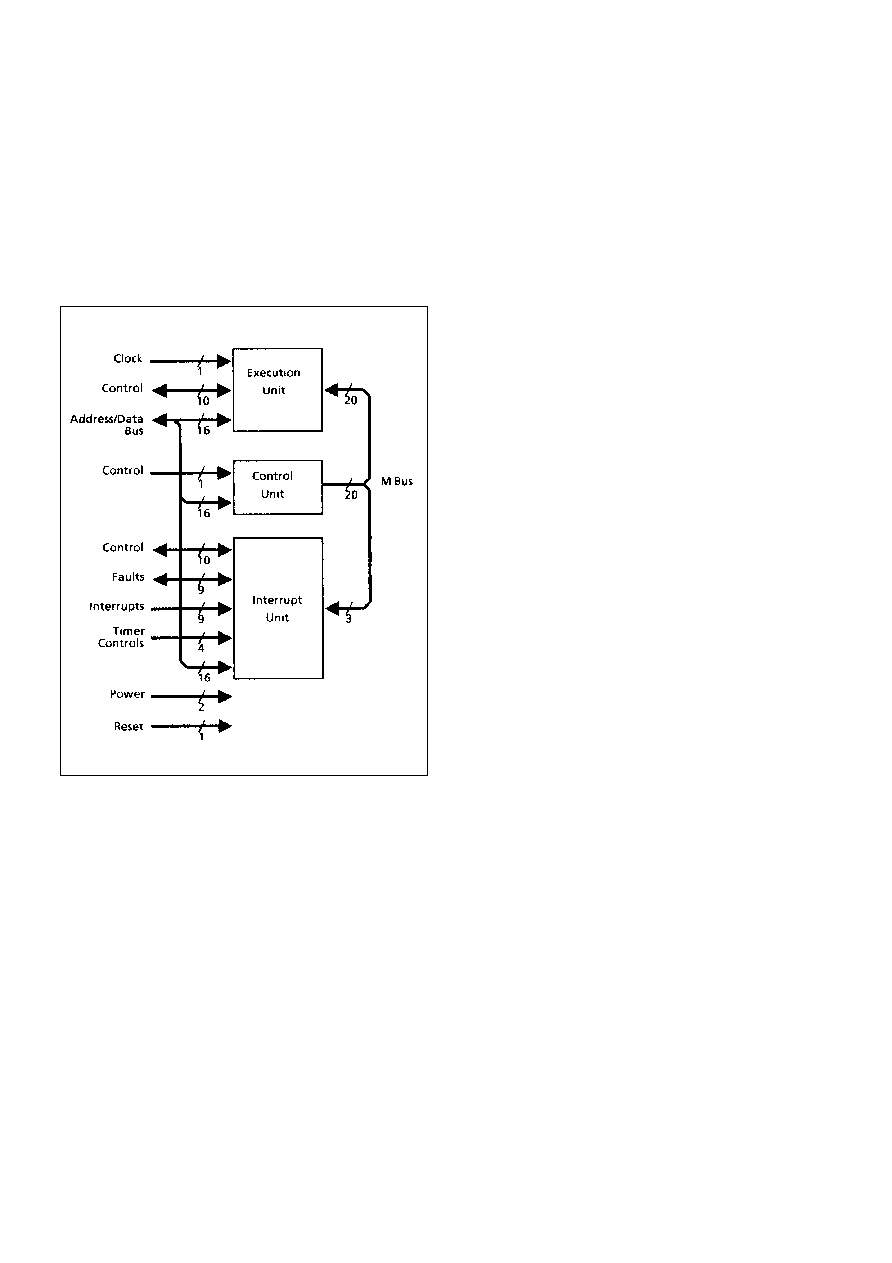

The MAS281 Microprocessor is a high performance

implementation of the MIL-STD-1750A (Notice 1) instruction

set architecture. It consists of three custom CMOS/SOS Large

Scale Integration chips referred to as the Execution Unit,

Control Unit, and Interrupt Unit - mounted on, and

interconnected within, a 64-pin, dual in-line ceramic substrate.

Figure 1 depicts the interconnection of these chips via the

substrate while Figure 2 depicts the architectural details within

each chip.

The MAS281 architecture has been optimised for both real

time l/O and arithmetic intensive operations. Two key features

of this architecture which contribute to the overall high

performance of the MAS281 are; a barrel shifter and a parallel

multiplier/accumulator. These subsystems allow the MAS281

to perform multi-bit shifts, multiplications, divisions, and

normalisations in a fraction of the clock cycles required on

machines not having such resources. This is especially true of

floating-point operations, in which the MAS281 excels. Such

operations constitute 16% of the Digital Avionics Instruction

Set (DAIS) mix and a generally much higher percentage of

many signal processing algorithms, therefore having a

significant impact on system performance.

In accordance with MIL-STD-1750A, the MAS281 can

access a 64K-word address space. With the addition of an

external MA31751 chip configured as a Memory Management

Unit (MMU), this address space may be expanded to a full

1Mword. Furthermore, this configuration provides write and

access lock and key protection down to 4K-word blocks. By

also configuring the MA31751 as a Block Protect Unit (BPU),

write protection may be extended down to 1K-word blocks. For

those applications not requiring adherence to the address

space requirements of MIL-STD-1750A, the MAS281 may be

optionally configured with up to 1Mword each of instruction

and operand space.

In addition to implementing all of the required features of

MIL-STD-1750A, the MAS281 also incorporates a number of

optional features. Interval timers A and B as well as a trigger-

go counter are provided. Most specified XIO commands are

decoded directly on the module and an additional set of

commands, associated with MMU and BPU operations, are

directly decoded on the MA31751 chip. Those commands not

directly decoded are output for decoding by external logic in

accordance with the XIO and VIO protocols of MIL-STD-

1750A.

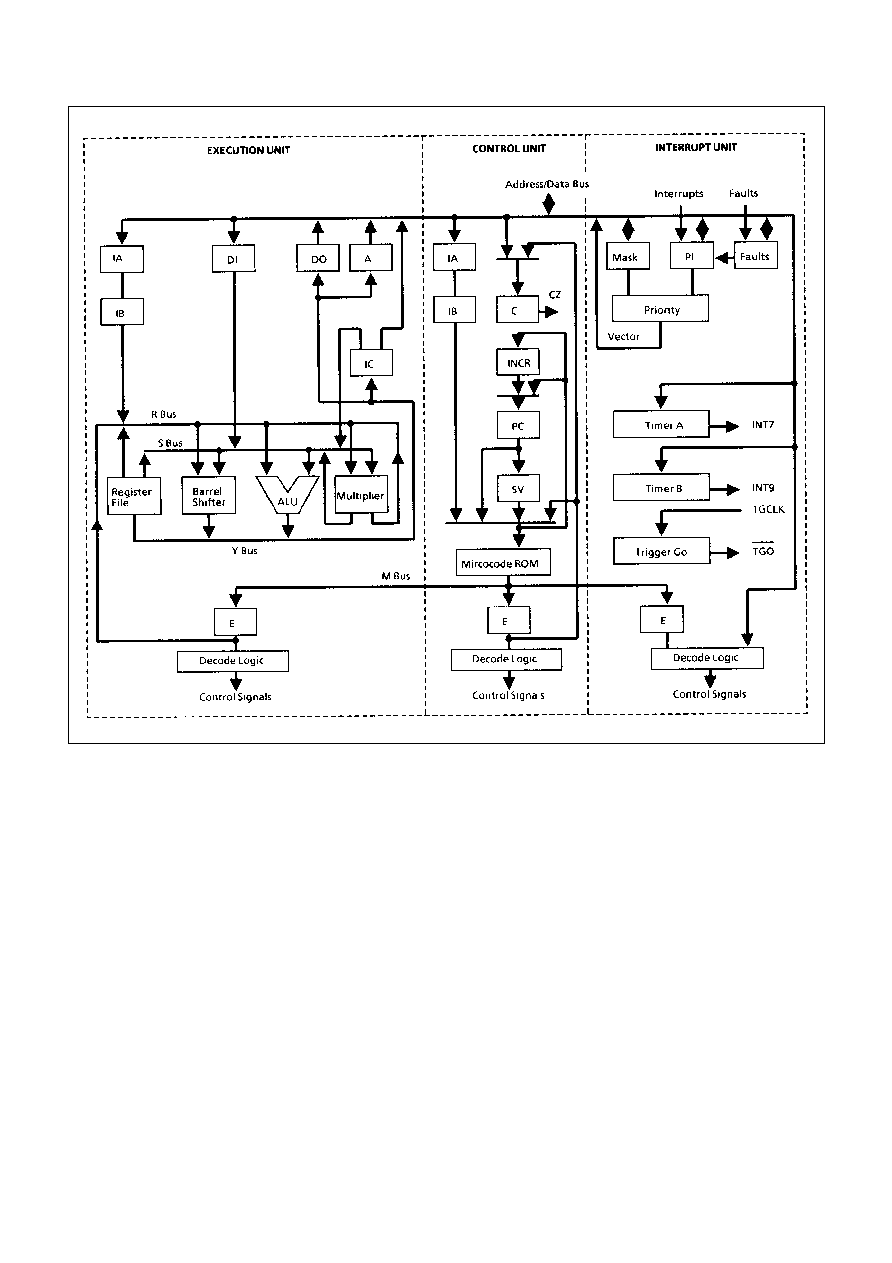

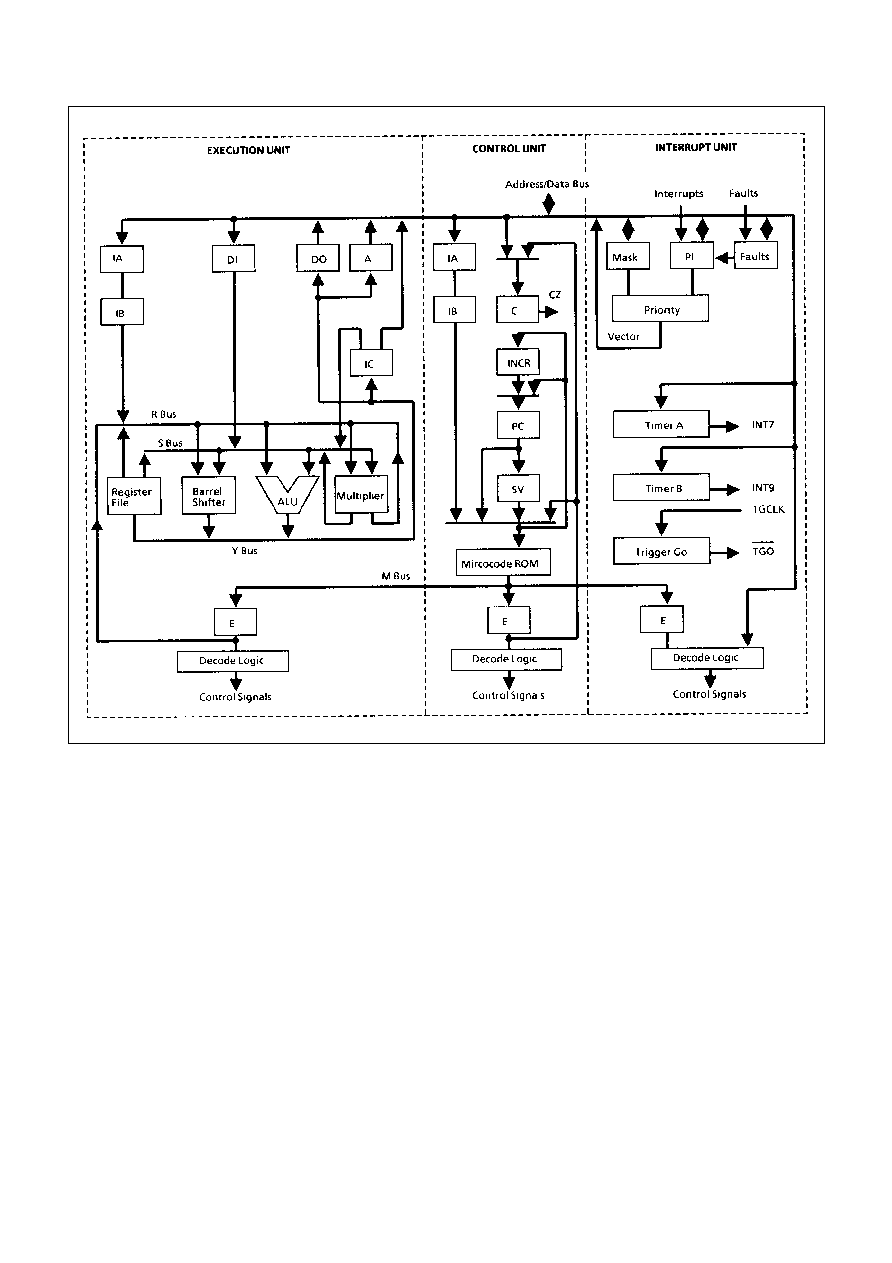

1.1 EXECUTION UNIT (EU)

The EU provides the computational resources for the

MAS281. Key features include: (1) a three-bus (R, S, and Y)

data path consisting of an arithmetic/logic unit (ALU), three-

port register file, barrel shifter, parallel multiplier/accumulator,

and status register; (2) instruction fetch registers IC, IA, and IB;

(3) operand transfer registers A, Dl, and DO; (4) a state

sequencer; and (5) microinstruction decode logic. A brief

description of these features follows:

1.1.1 ARITHMETIC/LOGIC UNIT (ALU)

A full function 16-bit ALU is used to perform arithmetic and

logic operations on one or two 16-bit operands in a single

machine cycle. The ALU supports 16-bit fixed-point single-

precision, 32-bit fixed-point double-precision, 32-bit floating-

point, and 48-bit floating-point extended precision data in two's

complement form. The ALU generates several machine flags

which reflect the outcome of its operations. These flags are

stored in the condition status (CS) field of the status register.

1.1.2 THREE PORT REGISTER FILE

A 24-word by 16-bit wide register file is used to store

operands, addresses, base pointers, stack pointers, indexes,

and temporary values. Registers R0 through R15 are general

purpose and user accessible in accordance with MIL-STD-

1750A; remaining registers are accessible only by microcode.

Wrap-around concatenation of R0 through R15 allows 32- and

48-bit operands to be stored. The three-port architecture

allows two 16-bit operands to be read and a third 16-bit

operand to be written simultaneously.

Figure 1: MAS281 Microprocessor Block Diagram

MAS281

3/55

Figure 2: MAS281 Architecture

1.1.3 PARALLEL MULTIPLIER/ACCUMULATOR

This multiplies a 24-bit multiplicand by a 4-bit multiplier and

accumulates the product in a single machine cycle. Only four

iterations through the multiplier are required to complete a 16-

bit by 16-bit multiply.

1.1.4 BARREL SHIFTER

This shifter is a 32-bit input, 16-bit output right-shift

network. The barrel shifter allows multibit shifts to be

accomplished in a single machine cycle and is used by the

microcode for all shift, rotate, and normalise operations.

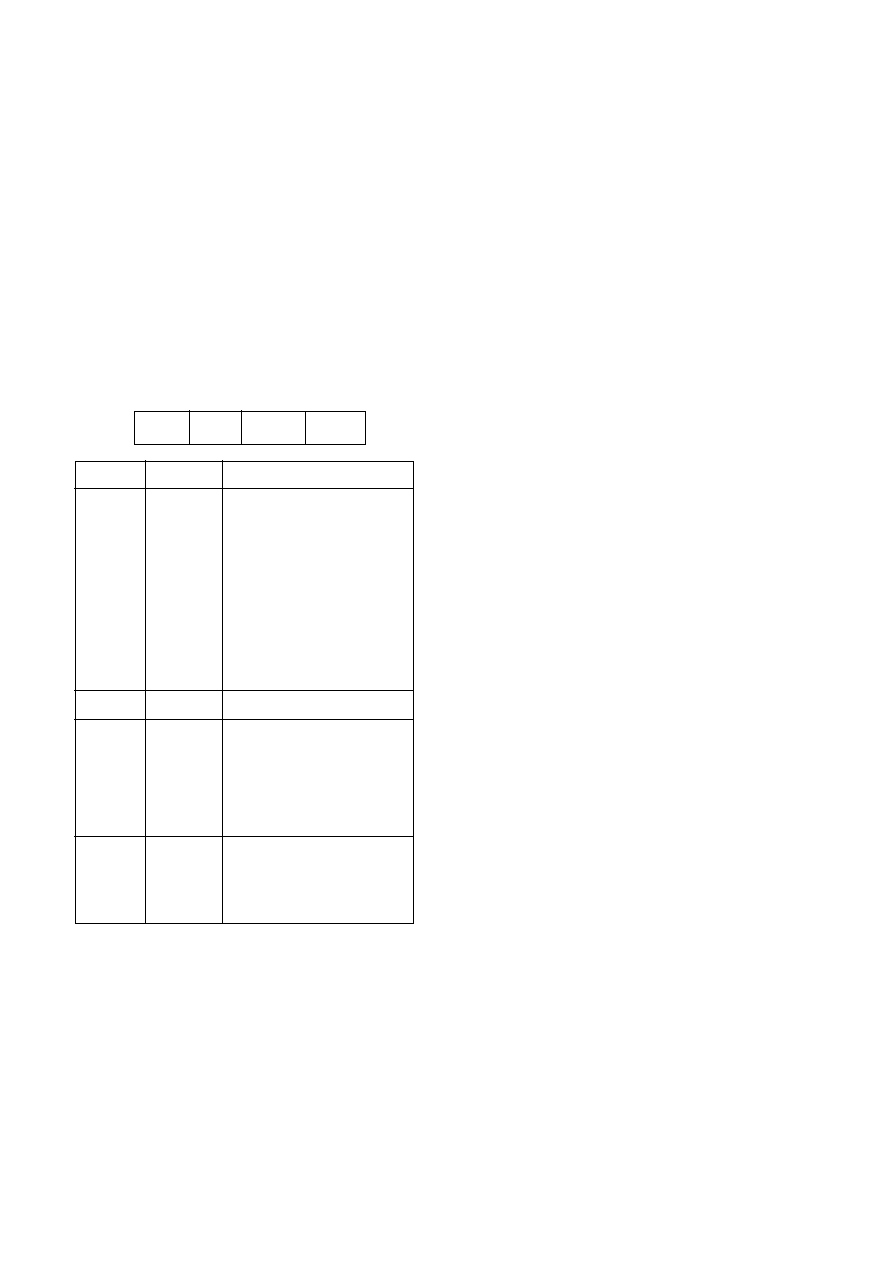

1.1.5 STATUS REGISTER

This 16-bit register holds the condition status (CS) bits C,

P, Z, and N; the 4-bit address state (AS) field; and the 4bit

processor state (PS) field. The CS bits are updated after each

logical, shift, and arithmetic operation performed by the ALU.

The CU interrogates these bits during conditional

operations to determine which course of action to follow. The

AS field is used during expanded memory access to define the

page register set to be used for instruction and operand

memory references. The PS field is used during memory

protect operations to define the access key used for memory

accesses. The PS field is also used during execution of

privileged instructions. PS must be zero for such operations to

be legal. Figure 3 depicts the status register format

1.1.6 STATE SEQUENCER

The EU utilises a state machine, clocked by the system

oscillator, to generate processor timing and control signals.

These signals constitute the lowest level of control available

within the module, and provide the framework for basic

operations, such as selecting the next microinstruction to be

executed, sequencing bus control signals to effect a memory

transfer, or performing an operation within the ALU. Each

complete pass through the state machine corresponds to one

such operation and constitutes a machine cycle.

MAS281

4/55

1.1.7 OPERAND TRANSFER REGISTERS

The Address (A), Data In (Dl), and Data Out (DO) registers

serve to buffer transfers between the data path and the

Address/Data (AD) bus. These registers are used under

microcode control and are not directly accessible by software.

A description of the use of these registers during memory and

l/O operations is provided in section 3.0.

1.1.8 INSTRUCTION FETCH REGISTERS

The Instruction Counter (IC), Instruction A (IA), and

Instruction B (IB) registers allow sequential instruction fetches

to be performed without the assistance of the ALU. The IC

register, which holds a 16-bit address and points to the next

instruction to be fetched, is loaded indirectly via reset, jump, or

branch operations. Once loaded, it uses a dedicated counter to

sequence from one instruction to the next. IA and IB serve as

an instruction pipeline with IA storing the next instruction to be

executed. Dl also plays a role by storing any immediate

operands. Use of these registers during instruction fetches is

described in section 3.0.

1.1.9 MICROCODE CONTROL LOGIC

All EU operations are performed under microcode control.

As depicted in Figure 2, microinstructions are provided by the

CU over the M bus, buffered by the Execution (E) register, and

decoded to generate various control signals.

1.2 CONTROL UNIT (CU)

The CU provides microprogrammed control of all MAS281

operations. It features a microsequencer, a microcode storage

ROM, and an instruction mapping ROM. A brief description of

these features follows:

1.2.1 MICROSEQUENCER

This 12-bit wide microcode address generator controls all

microcode ROM accesses. The microsequencer features a

program counter (PC) which points to the next sequential

microinstruction, a program counter save register (SV) to save

return addresses for microsubroutines, address increment

logic (INCR), instruction pipeline registers (IA and IB), a next

address multiplexer, a loop counter (C), and various

miscellaneous systems.

The microsequencer controls the execution of each

MILSTD-1750A, or macro, instruction by stepping through its

corresponding microcode sequence. If the macroinstruction is

a conditional, the CS bits of the status word will be interrogated

to determine the necessary course of action. At the completion

of each macroinstruction, the microsequencer checks to see if

a Hold request or an interrupt is pending. If so, the

microsequencer will branch to the appropriate microinstruction

sequence. If not, the microsequencer begins sequencing the

next macroinstruction.

Note that the microsequencer is itself under the control of

the EU state sequencer. Each processor machine cycle

corresponds to the execution of a single microinstruction.

A machine cycle requires five or more oscillator cycles

with the exact number determined by the type of operation

being performed. Internal processor operations, excluding

internally decoded XIO commands, require either five or six

oscillator cycles, the former associated with sequential

microcode execution and the latter with microcode branches.

Internally decoded XIO commands require a minimum of six

oscillator cycles to complete. External processor operations

require a minimum of five oscillator cycles to complete.

The internal ready signal is generated by the IU whenever

an internally decoded XIO command is detected An external

ready interface is provided which allows external machine

cycles to be extended when interfacing with slow devices. The

external ready signal is provided by external logic and must be

asserted in order to conclude the machine cycle.

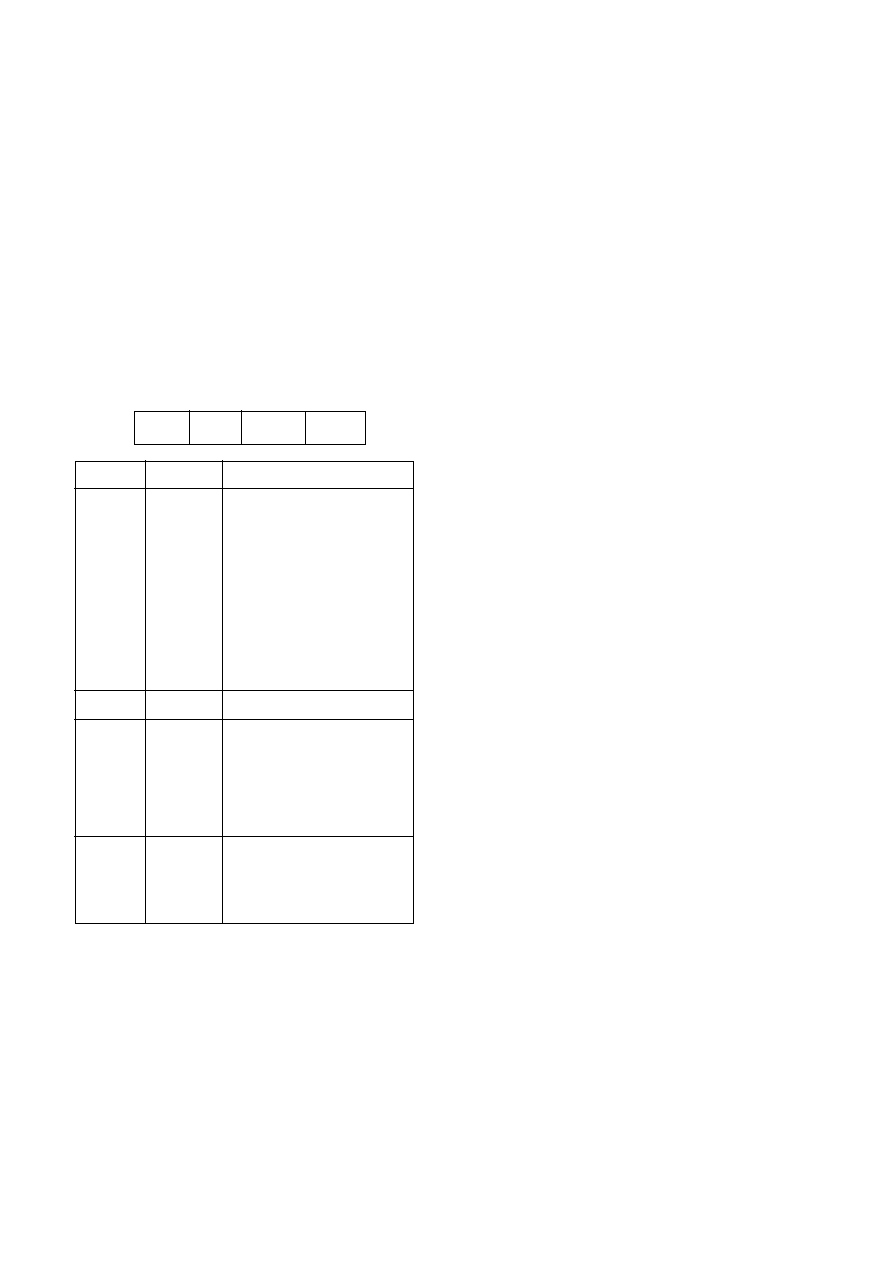

Field

Bits

Description

CS

CONDITION STATUS:

0

C-

Carry from an

addition or no borrow from

a subtraction

1

P-

Result >0

2

Z-

Result = 0

3

N-

Result<0

R

4 - 7

RESERVED

PS

8 - 11

PROCESSOR STATE:

(a)- Memory access key

code

(b)- Privileged instruction

enable

AS

12 - 15

ADDRESS STATE:

Page register sets for

expanded memory

addressing

Figure 3: Status Word Format

CS

R

PS

AS

3 4

7 8

11 12

15

0

MAS281

5/55

or more faults in FT will cause a level 1 (machine error)

interrupt request. Once a fault is set in FT, it may only be

cleared via an XIO command.

1.3.5 TIMERS A AND B

These are two 16-bit software controllable timers. Timer A

is clocked by the TCLK input while Timer B is clocked by the

internally generated TCLK/10. Timers A and B will generate

interrupt levels 7 and 9, respectively, when their maximum

counts of 65,536 are reached.

1.3.6 TRIGGER-GO COUNTER

This 16-bit counter is clocked by the TGCLK input, is

enabled during system initialisation, and may be reset but not

stopped by software action. It is stopped, however, upon

overflow or by assertion of the DTIMERN input. Upon overflow,

the TGON discrete output goes low and stays low until the

counter is reset by software. This counter is typically used as a

system "watchdog" timer.

1.3.7 XIO COMMAND DECODE LOGIC

This logic decodes all internally supported XlO commands

and generates the control signals necessary to carry out the

commanded action. An internal ready signal is generated upon

command detection and is used by the EU state sequencer as

previously discussed. Table 7b in Section 4.0 identifies the XlO

commands which are internally supported by the MAS281.

1.3.8 MICROCODE CONTROL LOGIC

Decode logic, which translates microcode received from

the CU into control signals, is used both by the MAS281 and by

the external system.

2.0 INTERFACE SIGNALS

2.1 PIN ASSIGNMENTS

Figure 4 defines the pin assignment for the MAS281

module. See section 10.0 for full packaging and pin

assignment information.

All signals - with the exception of power, ground and

ROMONLYN - are TTL compatible. In addition, each function

is provided with Electrostatic Discharge (ESD) protection

circuitry. Figure 5 depicts a typical system implementation

using many of these signals. Throughout this data sheet,

active low signals are denoted either by placing a bar over the

signal name, or by following the signal name with an "N" suffix,

e.g., DDN. If a signal has a dual function, both function names

will be used separated by a "/". The function name to the left of

the "/" will be active high while the function to the right will be

active low, again with an "N" suffix, e g., RD/WN.

1.2.2 MICROCODE ROM

This is a 2k- (2048) word by 40-bits/word ROM which

stores the microinstructions that implement the MIL-STD-

1750A instruction set. The address of the next microinstruction

to be accessed is generated by the microsequencer. The

accessed microinstruction is output to the M-bus and

broadcast to the EU and IU. In addition to the microinstruction

sequences corresponding to the MIL-STD-1750A instructions,

the microcode ROM also stores sequences for performing

initialisation, interrupt response, Hold response, instruction

prefetch, built-intest (BIT), and BlFs.

1.2.3 INSTRUCTION MAPPING ROM

This is a 512-word by 8-bits/word ROM which is used

during microcode branches.

1.3 INTERRUPT UNIT (IU)

The IU incorporates a pending interrupt register, a mask

register, a priority encoder, a fault register, two interval timers

(A and B), a trigger-go counter, XIO command decode logic,

and microcode control logic. A brief description of these

features follows:

1.3.1 PENDING INTERRUPT REGISTER (PL)

This 16-bit register is used to capture and hold interrupts

until they can be processed by software. Pl supports three

dedicated external, six user-definable external, and seven

dedicated internal interrupts. Interrupts are captured at the

beginning of each machine cycle and are stored using a logic 1

to represent a pending interrupt. Anti-repeat logic is provided

to prevent multiple captures of the same interrupt.

1.3.2 MASK REGISTER (MK)

This 16-bit register is used to store the interrupt mask.

Interrupts are masked by ANDing each mask bit with its

corresponding Pl register bit. Interrupts which are masked will

be captured in the Pl register but will not be acted on until

unmasked. Interrupt level 0 can not be masked. A logic 0 in a

given bit position indicates that the corresponding bit in the Pl

register will be masked.

1.3.3 PRIORITY ENCODER

This encoder generates an interrupt request to the CU

whenever one or more unmasked interrupts are pending and

enabled in the Pl and encodes the highest priority unmasked

pending interrupt as a 4-bit vector. This vector is read by the

EU over the AD bus during interrupt servicing in order to create

the interrupt Linkage and Service pointers.

1.3.4 FAULT REGISTER

This 16-bit register is used to capture and hold both internal

and user implemented external faults. Faults are captured at

the beginning of each machine cycle and are stored using

positive logic, i e, a logic "1" represents a fault. Setting any one