| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: V61558P | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

EM MICROELECTRONIC--MARIN SA

V6155

1

Extremely Accurate Power Surveillance,

Software Monitoring and Sleep Mode Detection

Features

n

Can-bus sleep mode detector

n

Standby mode, maximum current 50 mA

n

Reset output guaranteed for V

DD

voltage

down to 1.2 V

n

Comparator for voltage monitoring,voltage reference

1.275 V

n

±

1.2% voltage reference accuracy at +25

∞

C

n

±

2.5% voltage reference accuracy from

-

40 to +85

∞

C (3 to 5.5 V)

n

Programmable reset voltage monitoring

n

Programmable power-on reset (POR) delay

n

Watchdog with programmable time windows

guarantees a minimum time and a maximum time

between software clearing of the watchdog

n

Time base accuracy ± 10

%

n

System enable output offers added security

n

TTL / CMOS compatible

n

-40 to +85 ∞C temperature range

n

On request extended temperature range,

-

40 to +125

∞

C

n

DIP8 and SO8 packages

Description

The V6155 offers a high level of integration by voltage

monitoring and software monitoring in an 8 lead

package. A comparator monitors the voltage applied at

the V

IN

input comparing it with an internal 1.275 V

reference. The power-on reset function is initialized after

V

IN

reaches 1.275 V and takes the reset output inactive

after T

POR

depending of external resistance. The reset

output goes active low when the V

IN

voltage is less than

1.275 V. The RES and EN outputs are guaranteed to be

in a correct state for a supply voltage as low as 1.2 V.

The watchdog function monitors software cycle time and

execution. If software clears the watchdog too quickly

(incorrect cycle time) or too slowly (incorrect execution),

it will cause the system to be reset. The system enable

output prevents critical control functions being activated

until software has successfully cleared the watchdog

three times. Such a security could be used to prevent

motor controls being energized on repeated resets of a

faulty system. If the microcontroller does not work that

means no signal on the TCL input the V6155 goes in a

standby mode (CAN-bus sleep detector).

Applications

n

Automotive systems

n

Cellular telephones

n

Security systems

n

Battery powered products

n

High efficiency linear power supplies

n

Industrial electronics

Typical Operating Configuration

Pin Assignment

R

V

SS

EN

TCL

V

IN

V

DD

Fig. 1

100 nF

V6155

RES

GND

DIP8 / SO8

V

DD

R

TCL

RES

EN

Fig. 2

V6155

V

SS

V

IN

NC

V6155

2

Absolute Maximum Ratings

Parameter

Symbol Conditions

Maximum voltage at V

DD

Minimum voltage at V

DD

Max. voltage at any signal pin

Min. voltage at any signal pin

Storage temperature

Electrostatic discharge max. to

MIL-STD-883C method 3015

Max. soldering conditions

V

DDmax

V

DDmin

V

MAX

V

MIN

T

STO

V

Smax

T

Smax

V

SS

+ 8 V

V

SS

-

0.3 V

V

DD

+ 0.3 V

V

SS

-

0.3 V

-65 to+150 ∞C

1000 V

250 ∞C x 10 s

Table 1

Stresses above these listed maximum ratings may cause

permanent damage to the device. Exposure beyond

specified operating conditions may affect device

reliability or cause malfunction.

Handling Procedures

This device has built-in protection against high static

voltages or electric fields; however, anti-static

precautions should be taken as for any other CMOS

component. Unless otherwise specified, proper opera-

tion can only occur when all terminal voltages are kept

within the supply voltage range. Unused inputs must

always be tied to a defined logic voltage level.

Operating Conditions

Parameter

Symbol Min. Typ. Max. Units

s

Operating temperature

1)

Supply voltage

2)

& guaranteed

3)

Comparator input

voltage

RC-oscillator

programming

T

A

V

DD

V

DD

V

IN

R

-40

1.2

1.2

0

10

+125

7.0

V

DD

1000

∞C

V

V

V

k

Table 2

1)

The maximum operating temperature is confirmed by

sampling at initial device qualification. In production, all

devices are tested at +85

∞

C. On request devices tested

at +125

∞

C can be supplied.

2)

A 100 nF decoupling capacitor is required on the

supply voltage V

DD

for stability.

3)

RES must be pulled up externally to V

DD

even if it is

unused. (Note: RES and EN are used as inputs by EM test.)

Electrical Characteristics

3

V

DD

5.5 V, C = 100 nF, T

A

= -40 to +85

∞

C, unless otherwise specified

Parameter

Symbol

Test Conditions

Min.

Typ.

Max.

Units

Supply current in standby mode

(switched to R

INT

)

Supply current

and

Output Low Voltage

Output High Voltage

and V

IN

Input Low Level

Input High Level

Leakage current input

V

IN

input resistance

Comparator reference

1)

Comparator hysteresis

1)

I

SS

I

SS

V

OL

V

OL

V

OL

V

OL

V

OH

V

OH

V

OH

V

IL

V

IH

I

LI

R

VIN

V

REF

V

REF

V

REF

V

HY

R

EXT

= don't care, TCL = V

DD

V

IN

= V

DD

R

EXT

= 100 k

, I/Ps at V

DD

V

DD

= 4.5 V, I

OL

= 20 mA

V

DD

= 4.5 V, I

OL

= 8 mA

V

DD

= 2.0 V, I

OL

= 4 mA

V

DD

= 1.2 V, I

OL

= 0.5 mA

V

DD

= 4.5 V, I

OH

=

-

1mA

V

DD

= 2.0 V, I

OH

=

-

100

µ

A

V

DD

= 1.2 V, I

OH

=

-

30

µ

A

V

SS

V

TCL

V

DD

T

A

= +25

∞

C

T

A

=

-

40 to +125

∞

C

3.5

1.8

1.0

V

SS

2.0

1.25

1.24

1.22

34

55

0.4

0.2

0.2

0.05

4.1

1.9

1.1

0.05

100

1.275

2

50

100

0.4

0.4

0.2

0.8

V

DD

1

1.30

1.31

1.31

µ

A

µ

A

V

V

V

V

V

V

V

V

V

µ

A

M

V

V

V

mV

Table3

1)

The comparator reference is the power-down reset threshold. The power-on reset threshold equals the comparator

reference voltage plus the comparator hysteresis (see Fig. 6).

RES

EN

EN

TCL

TCL

TCL

TCL

RES EN

V6155

3

I

SS

Standby versus Temperature at V

DD

= 5.5 V

Timing Characteristics

V

DD

= 5.0 V

±

3

%

, C = 100 nF, T

A

=

-

40 to

+

85

∞

C, unless otherwise specified

Parameter

Symbol

Test Conditions

Min.

Typ.

Max.

Units

Propagation delays:

to Output Pins

V

IN

sensitivity

Logic Transition Times on all Output Pins

Power-on Reset delay

Watchdog Time

Open Window Percentage

Closed Window Time

Open Window Time

Watchdog Reset Pulse

T

CL

Input Pulse Width

Reset Pulse when switched to R internal

Watchdog Reset Pulse with R internal (R

I

)

T

DIDO

T

SEN

T

TR

T

POR

T

WD

OWP

T

CW

T

CW

T

OW

T

OW

T

WDR

T

WDR

T

TCL

T

RI

T

RIR

Load 10 k

, 50 pF

R

EXT

= 110 k

,

±

1%

R

EXT

= 110 k

,

±

1%

R

EXT

= 110 k

,

±

1%

R

EXT

= 110 k

,

±

1%

R

EXT

= 110 k

,

±

1%

1

90

90

72

36

150

0.3

250

5

30

100

100

±

0.2 T

WD

0.8 T

WD

80

0.4 T

WD

40

T

WD

/ 40

2.5

0.9

T

RI

/320

500

20

100

110

110

88

44

2.3

ns

µ

s

ns

ms

ms

ms

ms

ms

ns

s

s

Table 4

T

RI

versus Temperature at V

DD

= 5 V

TCL

32

34

28

30

I

SS

[

µ

A]

-

40

+25

T

A

[

∞

C]

Fig. 3

36

38

40

+85

+125

T

RI

[s]

-

40

+25

T

A

[

∞

C]

Fig. 4

2.5

+85

+125

2.0

1.5

1.0

0.5

0

V6155

4

Timing Waveforms

Watchdog Timeout Period

Voltage Monitoring

Timer Reaction

T

WD

= T

POR

T

CW

≠ closed window

T

OW

≠ open window

Watchdog

timer reset

Condition:

R

EXT

= 100 k

-

OWP

-

20%

+ OWP

+ 20%

80

100

120

Fig. 5

t [ms]

V

IN

Conditions:

V

DD

3 V

Fig. 6

RES

No timeout

T

POR

V

REF

V

HY

T

SEN

T

SEN

T

SEN

T

SEN

T

POR

T

TCL

Fig. 7

- Watchdog timer reset

Conditions: V

IN

>

V

REF

after power-up sequence

TCL

RES

EN

3 correct TCL services

EN goes active low

1

2

3

Timeout

T

CW

+T

OW

T

CW

+T

OW

T

CW

T

CW

+T

OW

T

CW

T

OW

T

WDR

T

CW

+T

OW

T

CW

+T

OW

T

RI

T

RIR

T

WDR

After 3 reset pulse periods

switch to R internal

After one edge (falling or rising)

on input

switch to R input

TCL

V6155

5

Combined Voltage and Timer Reaction

Block Diagram

Fig. 8

T

CW

+T

OW

T

POR

=T

WD

T

OW

T

CW

Condition:

V

OUTPUT

3 V

TCL

TCL

RES

EN

too early

3 correct TCL service

EN goes active low

- Watchdog timer reset

1

2

3

V

IN

V

REF

T

RI

T

RIR

After 3 reset pulse periods

switch to R internal

RES

EN

TCL

Fig. 9

V

REF

R

V

IN

Open drain

output RES

Current

Controlled

Oscillator

Voltage

Reference

Enable

Logic

Timer

Reset

Control

-

+

Comparator

Switch

Controller

R

1

1 M

V6155

6

Pin Description

Pin Name

Function

1

2

3

4

5

6

7

8

V

SS

NC

V

DD

R

V

IN

Push-pull active low enable output

Open drain active low reset output.

must be pulled up to V

DD

even if unused

Watchdog timer clear input signal

GND terminal

No connection

Voltage supply

R

EXT

input for RC oscillator tuning

Voltage comparator input

Table 5

Functional Description

V

IN

Monitoring

The power-on reset and the power-down reset are

generated as a response to the external voltage level on

the V

IN

input. The external voltage level is typically

obtained from a voltage divider as shown in Fig. 10. The

user uses an external voltage divider to set the desired

threshold level for power-on reset and power-down reset

in his system. The internal comparator reference

voltage is typically 1.275 V.

At power-up the reset output (RES)

is held low (see Fig.

6). When V

IN

becomes greater than V

REF

, the RES output

is held low for an additional power-on reset (POR) delay

which is equal to the watchdog time T

WD

(typically 100

ms with an external resistor of 110 kW connected at R

pin). The POR delay prevents repeated toggling of RES

even if V

IN

and the INPUT voltage drops out and

recovers. The POR delay allows the microprocessor's

crystal oscillator time to start and stabilize and ensures

correct recognition of the reset signal to the

microprocessor.

The RES output goes active low generating the power-

down reset whenever V

IN

falls below V

REF

. The sensitivity

or reaction time of the internal comparator to the voltage

level on V

IN

is typically 5 ms.

Timer Programming

The on-chip oscillator needs an external resistor R

EXT

connected between the R pin and V

SS

(see Fig. 10). It

allows the user to

adjust the power-on reset (POR)

delay, watchdog time T

WD

and with this also the closed

and open time windows as well as the watchdog reset

pulse width (T

WD

/40).

With R

EXT

= 110 kW, the typical values are:

- Power-on reset delay: T

POR

is 100 ms

- Watchdog time:

T

WD

is 100 ms

- Closed window:

T

CW

is 80 ms

- Open window:

T

OW

is 40 ms

- Watchdog reset:

T

WDR

is 2.5 ms

Note the current consumption increases as the fre-

quency increases.

Watchdog Timeout Period Description

The watchdog timeout period is divided into two parts, a

"closed" window and an "open" window (see

Fig. 5) and

is

defined by two parameters, T

WD

and the Open Window

Percentage (OWP).

The closed window starts just after the watchdog timer

resets and is defined by T

CW

= T

WD

-

OWP(T

WD

).

The open window starts after the closed time window

finishes and lasts till T

WD

+ OWP(T

WD

). The open window

time is defined by T

OW

= 2 x OWP(T

WD

).

For example if T

WD

= 100 ms (actual value) and OWP =

±

20% this means the closed window lasts during first

the 80 ms (T

CW

= 80 ms = 100 ms

-

0.2 (100 ms)) and

the open window the next 40 ms (T

OW

= 2 x 0.2 (100 ms)

= 40 ms). The watchdog can be serviced between 80

ms and 120 ms after the timer reset. However as the

time base is

±

10% accurate, software must use the

following calculation for servicing signal TCL during the

open window:

Related to curves (Fig. 11 to Fig. 21), especially Fig. 20

and Fig. 21, the relation between T

WD

and R

EXT

could

easely be defined. Let us take an example describing

the variations due to production and temperature:

1. Choice, T

WD

= 26 ms.

2. Related to Fig. 21, the coefficient (T

WD

to R

EXT

) is 1.025

where R

EXT

is in kW and T

WD

in ms.

3. R

EXT

(typ.) = 26 x 1.025 = 26.7 kW.

4. 26 ms at +25

∞

C

a)

(26 - 10% = 23.4 ms) (26 + 10% = 28.6 ms)

a)

b)

(23.4 - 5% = 22.2 ms) (28.6 + 5% = 30.0 ms)

b)

min.: (30.0 - 20% = 24.0 ms) max.: (22.2 + 20% = 26.7 ms)

Typical TCL period of

(24.0 + 26.7) / 2 = 25.4 ms

The ratio between T

WD

= 26 ms and the (TCL period)

= 25.4 ms is 0.975.

Then the relation over the production and the full

temperature range is, TCL period = 0.975 x T

WD

or TCL period = , as typical value.

a) While PRODUCTION value unknown for the custo-

mer when R

EXT

π 110 kW.

b)

While operating TEMPERATURE range

-40 ∞C

T

A

+85 ∞C.

5. If you fixed a TCL period = 26 ms

Þ R

EXT

= = 27.3 kW

If during your production the T

WD

time can be

measured at T

A

= +25 ∞C and the mC can adjust

the

TCL period, then

the TCL period range will be much

larger for the full operating temperature.

EN

RES

RES

TCL

0.975 x R

EXT

1.025

26 x 1.025

0.975

V6155

7

Timer Clearing and RES Action

The watchdog circuit monitors the activity of the

processor. If the user's software does not send a pulse

to the TCL input within the programmed open window

timeout period, a short watchdog RES pulse is

generated which is equal to T

WD

/40 = 2.5 ms typically

(see Fig. 7).

With the open window constraint, new security is added

to conventional watchdogs by monitoring both software

cycle time and execution. Should software clear the

watchdog too quickly (incorrect cycle time) or too slowly

(incorrect execution) it will cause the system to be reset.

If the software is stuck in a loop which includes the

routine to clear the watchdog, then a conventional

watchdog will not reset even though the software is

malfunctioning; the V6155 will generate a system reset

because the watchdog is cleared too quickly.

If no TCL pulse is applied before the closed and open

windows expire, RES will start to generate square waves

of period (T

CW

+ T

OW

+ T

WDR

). The watchdog will remain

in this state until the next TCL falling edge appears

during an open window, or until a fresh power-up

sequence. The system enable output, EN, can be used

to prevent critical control

functions being activated in the

event of the system going into this failure mode (see

section "Enable - EN Output").

The RES output must be pulled up to V

DD

even if the

output is not used by the system (see Fig. 10).

Combined Voltage and Timer Action

The combination of voltage and timer actions is

illustrated by the sequence of events shown in Fig. 8. On

power-up, when the voltage at V

IN

reaches V

REF

, the

power-on reset, POR, delay is initialized and holds RES

active for the time of the POR delay. A TCL pulse will

have no effect until this power-on reset delay is

completed. After the POR delay has elapsed, RES goes

inactive and the watchdog timer starts acting. If no TCL

pulse occurs, RES goes active low for a short time T

WDR

after each closed and open window period. A TCL pulse

coming during the open window clears the watchdog

timer. When the TCL pulse occurs too early (during the

closed window), RES goes active and a new timeout

sequence starts. A voltage drop below the V

REF

level for

longer than

typically 5 ms, overrides the timer and

immediately forces RES active and EN inactive. Any

further TCL pulse has no effect until the next power-up

sequence has completed.

Enable -

- EN Output

The system enable output, EN, is inactive always when

RES is active and remains inactive after a RES pulse

until the watchdog is serviced correctly 3 consecutive

times (i.e. the TCL pulse must come in the open

window). After three consecutive services of the

watchdog

with TCL during the open window, the EN

goes active low.

A malfunctioning system would be repeatedly reset by

the watchdog. In a conventional system critical motor

controls could be energized each time reset goes

inactive (time allowed for the system to restart) and in

this way the electrical motors driven by the system could

function out of control. The V6155 prevents the above

failure mode by using the EN output to disable the motor

controls until software has successfully cleared the

watchdog three times (i.e. the system has correctly

restarted after a reset condition).

CAN-Bus Sleep Mode Detector

If the microcontroller is in standby mode that means it

does not have any pulses on the TCL input. After 3 reset

pulse periods (T

CW

+ T

OW

+T

WDR

) on the RES output, the

V6155 switches on an internal resistor of 1 M

, and it

will have a reset pulse of typically 3 ms every 1 second

on the RES output. When a TCL edge (rising or falling)

appears on the TCL input or the power supply goes

down and up, the V6155 switches to the R input.

Typical Application

R

V

SS

EN

TCL

V

IN

V

DD

GND

Fig. 10

100 nF

V6155

RES

RES

EN Motor

Controls

Address

Decoder

100 k

100 k

R1

R2

µ

P

Supply voltage

V6155

8

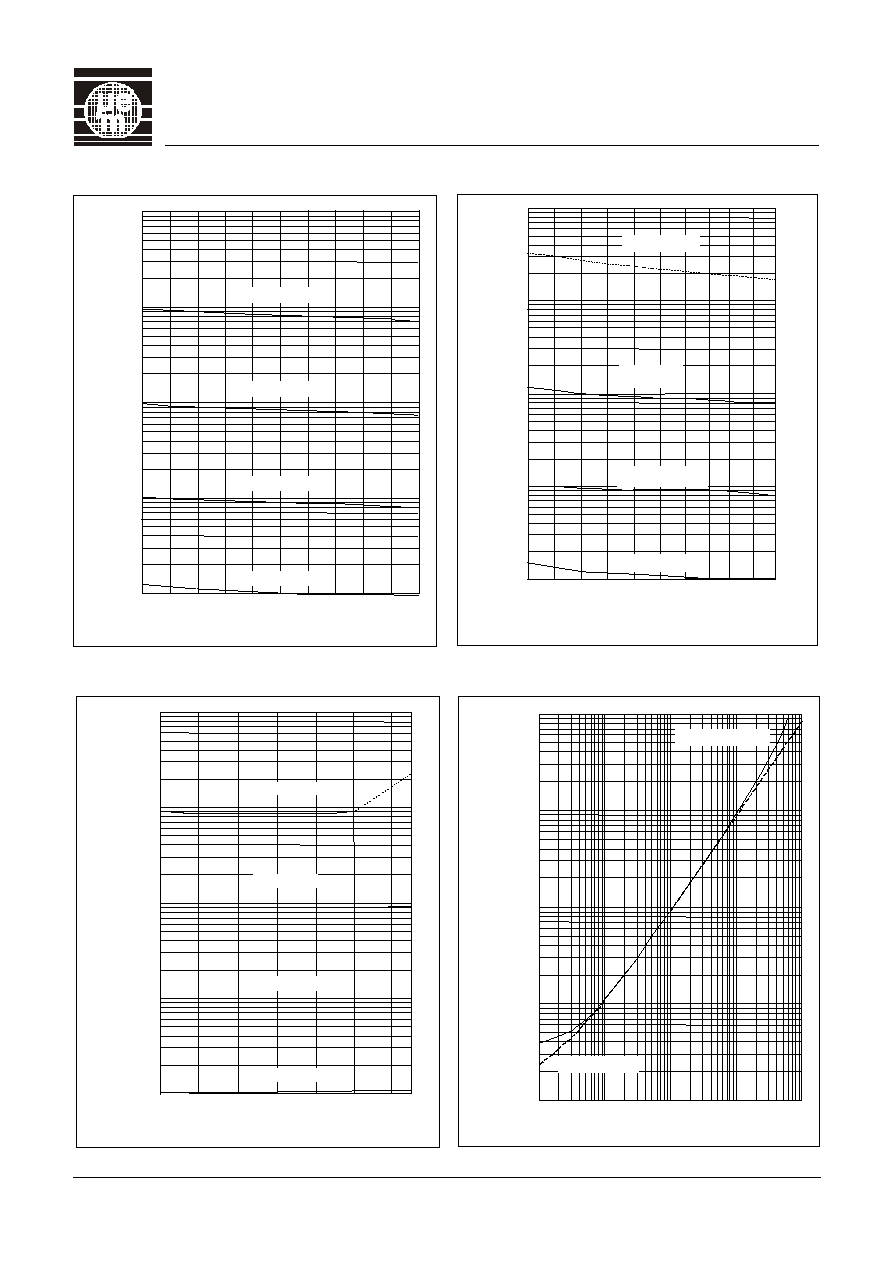

V

REF

versus V

DD

at T

A

=

--

40

∞∞

C,

++

25

∞∞

C,

++

85

∞∞

C

V

REF

versus Temperature at V

DD

= 3 V, 5 V and 8 V

V

REF

versus V

DD

at T

A

= -40 ∞C, +25 ∞C, +85 ∞C

V

REF

versus Temperature at V

DD

= 3 V, 5 V and 8 V

2.0

V

REF

[V]

1.5

2.5

3.5

4.5

5.5

6.5

7.5

V

DD

[V]

Fig. 11

T

A

= -40

∞

C

T

A

= +25

∞

C

T

A

= +85

∞

C

0.8

1.8

1.6

1.4

1.2

1.0

0.6

0.4

0.2

0.0

1.50

V

REF

[V]

-50 -25

0 +25 +50

T

A

[

∞

C]

Fig. 13

1.45

1.40

1.35

1.30

1.25

1.20

1.15

1.10

1.05

1.00

+125

+100

+75

V

DD

= 8 V

V

DD

= 5 V and 3 V

1.290

V

REF

[V]

1

2

3

4

5

6

7

V

DD

[V]

Fig. 12

T

A

= -40

∞

C

T

A

= +25

∞

C

T

A

= +85

∞

C

1.285

1.280

1.275

1.270

1.265

1.260

8

1.280

V

REF

[V]

-50 -25

T

A

[

∞

C]

Fig. 14

1.275

1.270

1.265

1.260

1.255

1.250

1.245

0 +25 +50 +75 +100 +125

V

DD

= 5 V

V

DD

= 8 V

V

DD

= 3 V

V6155

9

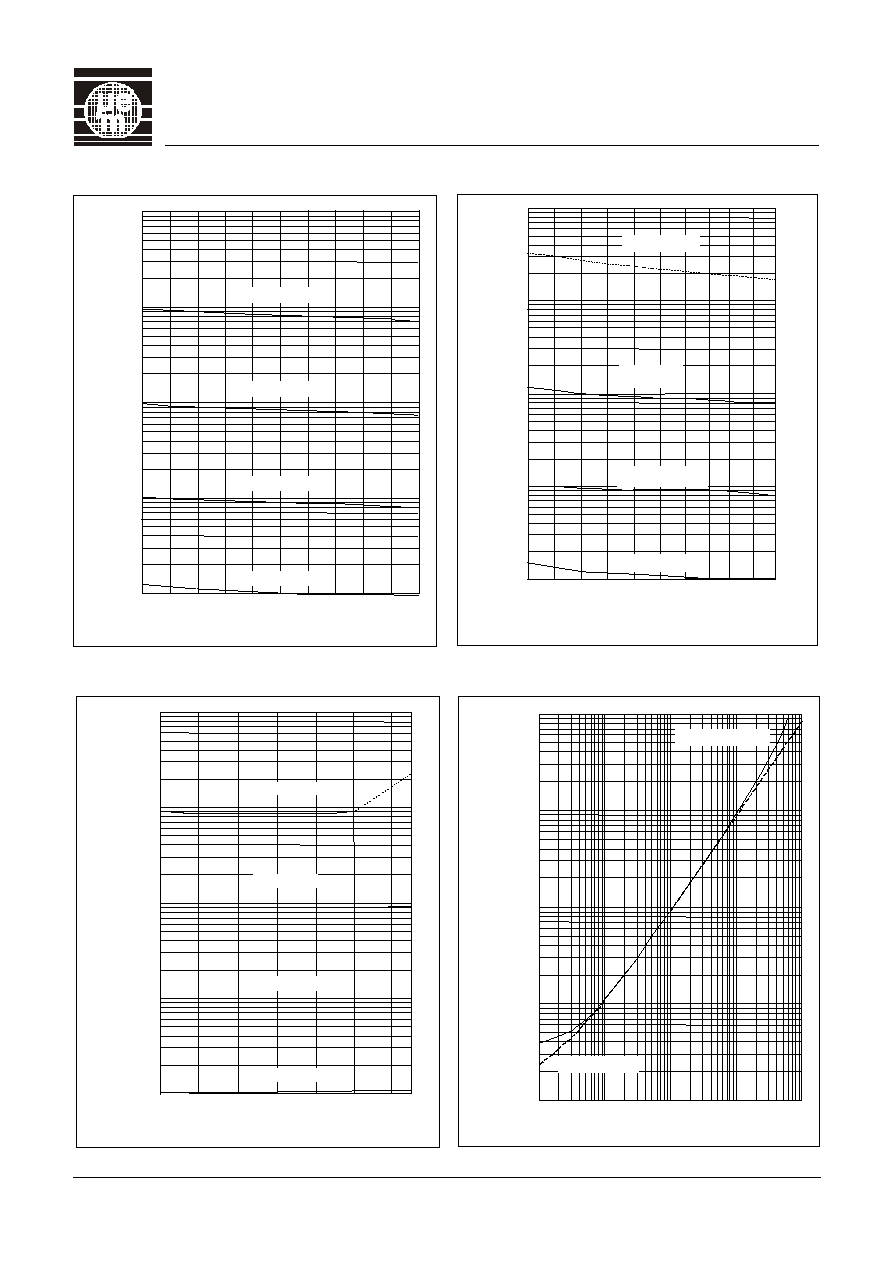

T

WD

versus Supply Voltage at T

A

++

85

∞∞

C

T

WD

versus V

DD

at T

A

= +125

∞∞

C

T

WD

versus Temperature at V

DD

= 5 V

T

WD

versus R at V

DD

= 5 V

100000

10000

1000

100

10

3

5

7

V

DD

[V]

Fig. 15

T

WD

[ms]

4

6

8

R = 10 M

R = 1 M

R = 100 k

R = 10 k

100000

10000

1000

100

10

-40

+10

T

A

[

∞

C]

Fig. 17

T

WD

[ms]

-15

+35

R = 10 M

R = 1 M

R = 100 k

R = 10 k

+60 +85 +110

T

WD

[ms]

10000

1000

100

1

10

100

1000 10'000

R [k

]

Fig. 18

10

1

T

A

+85

∞

C

T

A

= +125

∞

C

10000

0

1000

0

1000

100

10

3

5

7

V

OUTPUT

[V]

Fig. 16

T

WD

[ms]

4

6

8

R = 10 M

R = 1 M

R = 100 k

R = 10 k

V6155

10

T

WD

versus R at V

DD

= 5 V

10'000

1000

100

1

10

100

1000

10'000

R [k

]

Fig. 19

T

WD

[ms]

10

1

T

A

+85

∞

C

T

A

= +125

∞

C

V6155

11

T

WD

Coefficient versus R

EXT

at T

A

=

++

25

∞∞

C

R

EXT

Coefficient versus T

WD

at T

A

=

++

25

∞∞

C

1.06

1.04

1.02

1.00

0.98

0.96

0.94

0.92

0.90

0.88

0.86

T

WD

Coefficient

10

1000

100

R

EXT

[k

]

Fig. 20

1.10

1.08

Fig. 21

1.16

1.14

1.12

1.10

1.08

1.06

1.04

1.02

1.00

0.98

0.96

0.94

0.92

0.90

R

EXT

Coefficient

10

100

1000

T

WD

[ms]

V6155

12

Ordering Information

The V6155 is available in the following packages:

Type

Package

V6155 8P

DIP8

V6155 8S

SO8

When ordering please specify complete part number.

© 2000 EM Microelectronic-Marin SA, 10/00, Rev. C/311

EM Microelectronic-Marin SA cannot assume any responsibility for use of any circuitry described other than entirely

embodied in an EM Microelectronic-Marin SA product. EM Microelectronic-Marin SA reserves the right to change the

circuitry and specifications without notice at any time. You are strongly urged to ensure that the information given

has not been superseded by a more up-to-date version.

EM Microelectronic-Marin SA, CH - 2074 Marin, Switzerland, Tel. (+41) 32 - 755 51 11, Fax (+41) 32 - 755 54 03