Product Profile 2005

www.epcos.com

PhaseMod PFC Modules

for Low-Voltage Power Factor Correction

just everywhere ...

Active everywhere

Passive electronic components are found in every electrical and electronic product ≠

from automotive and industrial electronics through information and communications

to consumer electronics. These key components are needed to store electrical

energy, select frequencies, and protect against overvoltage and overcurrent. With a

portfolio of 40,000 different products and a global presence, we are market leader in

Europe and number two worldwide among manufacturers of passive electronic

components.

EPCOS AG

2

Welcome to the World

of Passive Electronic Components

Preview

For many years, power factor correction (PFC) has been used in applications such as

industry and energy supply for buildings to improve the quality of electric power and

make it more efficient. A major commercial benefit is the saving of energy costs. But

power factor correction also helps to decrease the current load in transmission

networks and distribution grids. By reducing the currents, net losses are lowered,

electric power is saved and CO

2

emission reduced. The voltage also becomes more

stable due to lower current losses, i.e. voltage drops are decreased.

This product profile is addressed to end customers, panel builders, distribution

companies and power utilities in the low-voltage power distribution sector.

Power factor correction reduces the apparent current, decreases ohmic losses,

lowers the primary power consumption and reduces costs. EPCOS is worldwide

market leader in low-voltage power factor correction.

3

EPCOS AG

PhaseMod PFC Modules

for Low-Voltage Power Factor Correction

4

EPCOS AG

General

Important Notes

The following applies to all products named in this

publication:

1. Some parts of this publication contain statements

about the suitability of our products for certain

areas of application. These statements are based on

our knowledge of typical requirements that are often

placed on our products in the areas of application con-

cerned. We nevertheless expressly point out that such

statements cannot be regarded as binding state-

ments about the suitability of our products for a

particular customer application. As a rule, EPCOS is

either unfamiliar with individual customer applications

or less familiar with them than the customers them-

selves. For these reasons, it is always ultimately in-

cumbent on the customer to check and decide

whether an EPCOS product with the properties de-

scribed in the product specification is suitable for use

in a particular customer application.

2. We also point out that in individual cases, a mal-

function of passive electronic components or

failure before the end of their usual service life can-

not be completely ruled out in the current state of

the art, even if they are operated as specified. In

customer applications requiring a very high level of

operational safety and especially in customer applica-

tions in which the malfunction or failure of a passive

electronic component could endanger human life or

health (e.g. in accident prevention or life-saving sys-

tems), it must therefore be ensured by means of suit-

able design of the customer application or other action

taken by the customer (e.g. installation of protective

circuitry or redundancy) that no injury or damage is

sustained by third parties in the event of malfunction or

failure of a passive electronic component.

3. The warnings, cautions and product-specific notes

must be observed.

4. In order to satisfy certain technical requirements, some

of the products described in this publication may

contain substances subject to restrictions in cer-

tain jurisdictions (e.g. because they are classed

as "hazardous"). Useful information on this will be

found in our Material Data Sheets on the Internet

(www.epcos.com/material). Should you have any more

detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Conse-

quently, the products described in this publication

may change from time to time. The same is true of

the corresponding product specifications. Please

check therefore to what extent product descriptions

and specifications contained in this publication are still

applicable before or when you place an order.

We also reserve the right to discontinue production

and delivery of products. Consequently, we cannot

guarantee that all products named in this publication

will always be available.

6. Unless otherwise agreed in individual contracts, all

orders are subject to the current version of the

"General Terms of Delivery for Products and

Services in the Electrical Industry" published by

the German Electrical and Electronics Industry

Association (ZVEI).

7. The trade names EPCOS, CeraDiode, CSSP, SIMID,

PhaseCap, PhaseMod, SIFI, SIKOREL, SilverCap,

SIOV, SIP5D, SIP5K, TOPcap, UltraCap, WindCap are

trademarks registered or pending in Europe and in

other countries. Further information will be found on

the Internet at www.epcos.com/trademarks.

EPCOS AG

5

General

PhaseMod PFC Modules

General

Awareness of the necessity of pow-

er quality is increasing, and power

factor correction (PFC) will be imple-

mented on a growing scale in future.

Enhancing power quality ≠ im-

provement of power factor ≠ saves

costs and ensures a fast return on

investment. In power distribution, in

low- and medium-voltage networks,

PFC focuses on the power flow

(cos

) and the optimization of volt-

age stability by generating reactive

power to improve voltage quality

and reliability at distribution level.

Installing a automatic power factor

correction system provides a com-

fortable and at the actual demand

adapted solution.

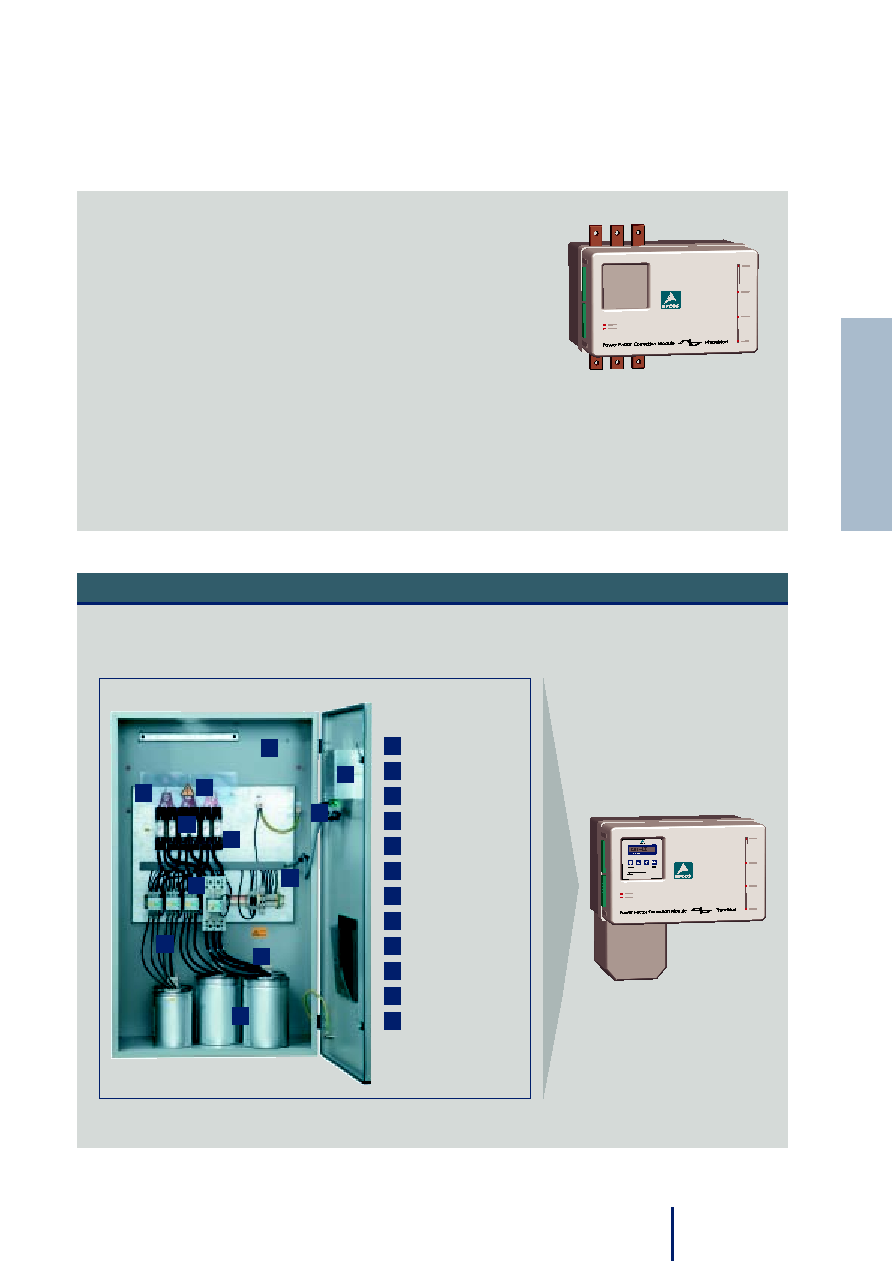

The innovative PhaseMod series

represents a totally new approach in

terms of integrated automatic power

factor correction systems (EPCOS-

patented). It will replace the tradi-

tional technology of discrete switch

gears consisting of a bunch of

components such as capacitors,

copper bus bars, contactors and

fuses almost randomly chosen and

assembled onto a mounting plate

and interconnected with cables.

The forward integrated PhaseMod

family provides all the functions of

carefully selected and optimally co-

ordinated key components includ-

ing the necessary interconnections.

It improves the power quality whilst

at the same time extending the ca-

pacitors useful life by using contac-

tors with damping resistors.

Forward integration

Forwar

d integration

Cabinet

Bus bar

Mounting plate

HRC fuse sockets

HRC fuses

Mounting rail

Control cabling

PFC controller

Discharge resistors

Contactors

Cabling

Capacitors

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

12

11

10

Please read the important notes, cautions and warnings!

Traditional

New