Document Outline

- Deckblatt_large_size_607.pdf

Aluminum electrolytic capacitors

For automotive applications,

large size,150 ∞C / 2000 h

Series/Type:

B41607

Date: July 2005

© EPCOS AG 2005. Reproduction, publication and dissemination of this data sheet, enclosures hereto and the

information contained therein without EPCOS' prior express consent is prohibited.

1

EPCOS AG

Please read the important notes, cautions and warnings.

Large size

Aluminum electrolytic capacitors

Introduction

The B41605 and B41607 series were

designed for applications with strin-

gent demands for power and current

carrying capacity at ambient temper-

atures ranging up to 150 ∞C. Tinned

copper leads of 1.2 mm diameter, al-

so allowing determination of the poles

because of the different lead length,

can be either welded or soldered.

To stand up the specified vibrational

stability in an automobile, EPCOS

developed a special process for these

models, in the meantime patented,

that fixes the capacitor winding so re-

liably by a sophisticated corrugation

configuration that vibrational stability

up to 40 g can be specified even for

these large-sized models.

40 g corrugation profile

Aluminum case

Winding

KAL0982-9-E

Insulating sleeve

Up to 40 g vibration stability version

Snap-in version

Up to 40 g vibration stability thanks to rugged corrugation

07/05

2

EPCOS AG

Please read the important notes, cautions and warnings.

Data sheet

B41607

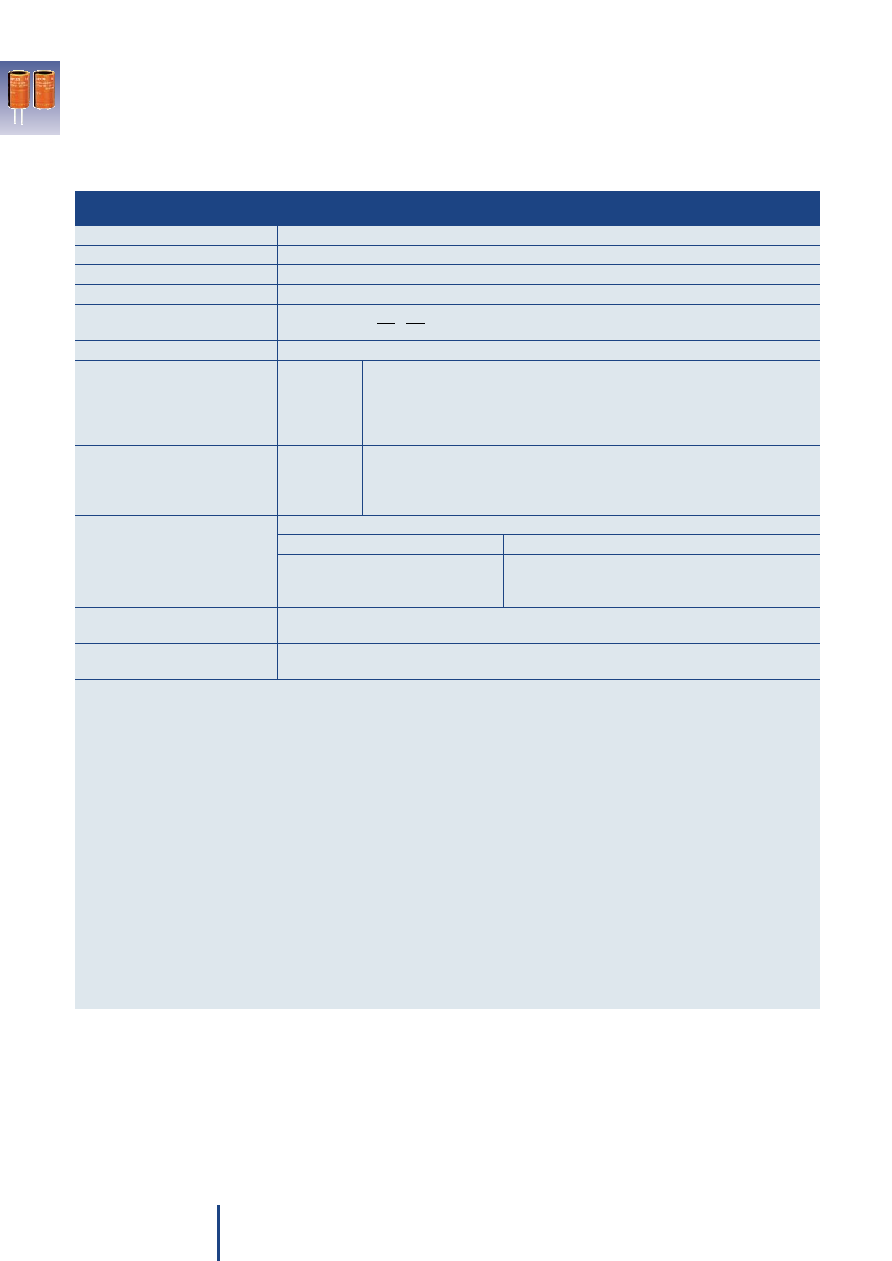

Specifications and characteristics in brief

Product

Rated voltage V

R

25 ... 63 VDC

Surge voltage V

surge

1.15 ∑ V

R

Rated capacitance C

R

800 ... 4700 µF

Capacitance tolerance

±20% ; M

Leakage current I

leak

(5 min, 20 ∞C)

Self-inductance ESL

15 nH

Useful life

Requirements:

150 ∞C; V

R

; 0.5 ∑ I~

R

>

2 000 h

C/C

±30% of initial value

125 ∞C; V

R

; I~

R

> 10 000 h

ESR

3 times initial specified limit

85 ∞C; V

R

; 2.1 ∑ I~

R

> 30 000 h

I

leak

initial specified limit

40 ∞C; V

R

; 2.1 ∑ I~

R

> 500 000 h

Voltage endurance test

Post test requirements:

125 ∞C; V

R

5 000 h

C/C

±10% of initial value

ESR

1.3 times initial specified limit

I

leak

initial specified limit

Vibration resistance

To IEC 60068-2-6, test Fc:

40 g vibration stability version

Snap-in version with 3 terminals

displacement amplitude 3 mm,

displacement amplitude 0.75 mm,

frequency range at 10 Hz ... 2 kHz,

frequency range at 10 Hz ... 2 kHz,

acceleration max. 40 g, duration 3 x 2 h

acceleration max. 10 g, duration 3 x 2 h

IEC climatic category

To IEC 60068-1:

55/125/56 (≠ 55 ∞C/+125 ∞C/56 days damp heat test)

Detail specification

Similar to CECC 30301-809

Sectional specification

IEC 60384-4

I

leak

0.006 ∑ µA

C

R

∑

V

R

+ 4 µA

µF V

Specifications and characteristics in brief

Features

s

High reliability and long useful life, up to 2000 h at 150 ∞C

s

High ripple current capability optimized for high frequencies

s

Vibration resistance up to 40 g

s

Shelf life of the capacitor up to 15 years at storage temperatures up to 40 ∞C. To ensure solderability,

the capacitors should be built into the application within one year of delivery. After a total of two years'

storage, the operating voltage must be applied for one hour to ensure the specified leakage current.

s

Variable pin configurations

≠ Up to 40 g vibration stability version with wired terminals.

Weldable and solderable terminals. Tinned copper leads (

1.2 mm).

≠ Snap-in with 3 terminals, protection against polarity reversal.

s

Without insulation sleeve upon request

07/05

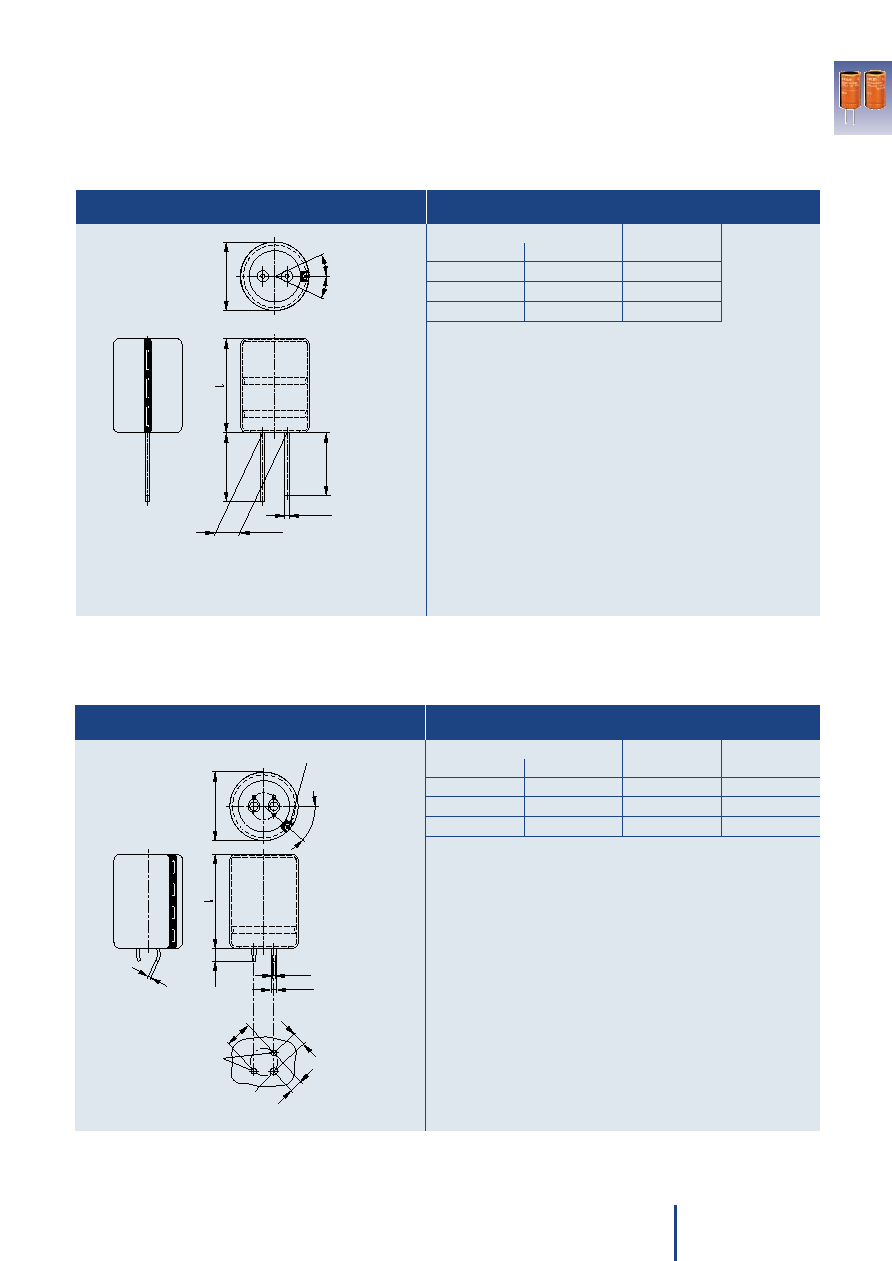

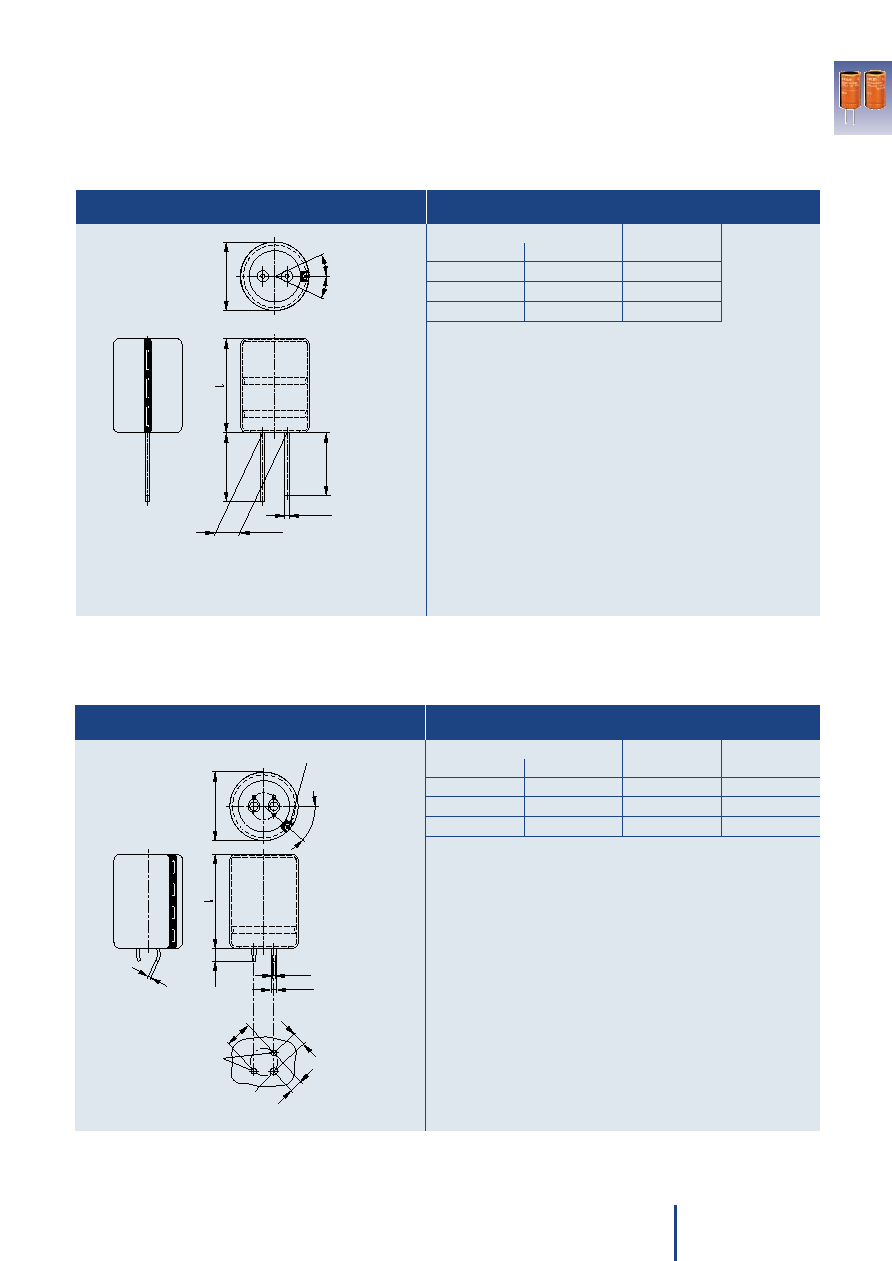

Dimensions (mm)

Approx. weight

Paking units

d +1

l ± 2

(g)

(pieces)

22

40

21

160

25

40

28

130

25

50

35

130

Dimensions (mm)

Approx. weight

d +1

l ± 2

(g)

22

40

21

25

40

28

25

50

35

3

EPCOS AG

Please read the important notes, cautions and warnings.

Data sheet

B41607

Dimensional drawing

Dimensions, weights and packing units

Large size capacitor, snap-in version with 3 terminals

Dimensional drawing

Dimensions and weights

Large size capacitor, up to 40 g vibration stability version with wired terminals

KAL0963-3-E

4

1

∞±

2

5

∞

d

0.8

1.5±0.2

Minus pole marking

¯2±0.1

3.

3±

0.

1

10

±0

.1

4.7

5±

0.1

¯2.5 min.

Mounting holes

1

4.5

_

+0.2

0.1

0.8

_

25

2

_

KAL0962-U-E

8.4±0.5

+0.04

¯1.2

0.02

_

2

23

_

positions for minus

Permissible range of

pole marking

d

)

25

∞

)

)

2

5

∞

Packing units on request.

07/05

25

2500

22 x 40

22

32

115

22

22

10.7

5.6

2.8

B41607A5258M***

3300

25 x 40

16

22

80

15

15

14.5

7.6

3.8

B41607A5338M***

4700

25 x 50

12

17

60

11

11

18.5

9.7

4.9

B41607A5478M***

40

1500

22 x 40

31

42

115

22

21

10.5

5.5

2.8

B41607A7158M***

2000

25 x 40

19

27

80

14

14

14.6

7.7

3.8

B41607A7208M***

2700

25 x 50

15

21

60

11

11

18.5

9.7

4.9

B41607A7278M***

55

1100

22 x 40

35

49

115

22

21

10.5

5.5

2.8

B41607A0118M***

1500

25 x 40

22

32

80

14

14

14.6

7.7

3.8

B41607A0158M***

2000

25 x 50

17

24

60

11

11

18.5

9.8

4.9

B41607A0208M***

63

800

22 x 40

40

56

115

22

22

10.3

5.4

2.7

B41607A8807M***

1100

25 x 40

27

38

90

14

14

14.5

7.6

3.8

B41607A8118M***

1500

25 x 50

20

28

65

11

11

18.5

9.7

4.9

B41607A8158M***

4

EPCOS AG

Please read the important notes, cautions and warnings.

Data sheet

B41607

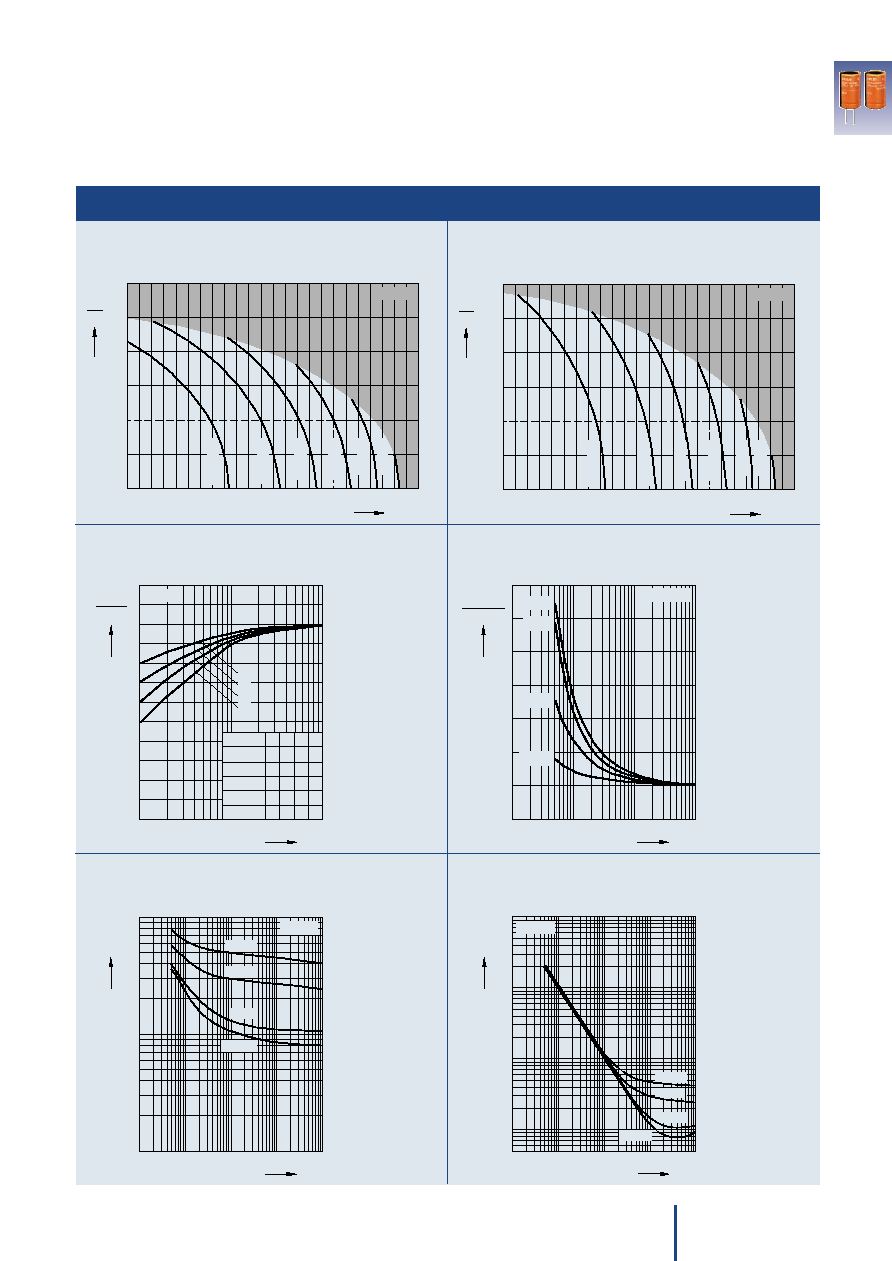

Technical data, case dimensions and ordering codes

V

R

C

R

Case

ESR

typ

ESR

max

ESR

max

ESR

max

Z

max

I~

max

I~

R

I~

max

Ordering code

100 Hz

dimensions 100 Hz

100 Hz

100 Hz

10 kHz

100 kHz 10 kHz

10 kHz

10 kHz

20 ∞C

d x l

20 ∞C

20 ∞C

≠40 ∞C

20 ∞C

20 ∞C

105 ∞C

125 ∞C

150 ∞C

VDC

µF

mm

m

m

m

m

m

A

A

A

*** = "002" for snap-in version with 3 terminals (protection against polarity reversal), fully insulated.

"009" for up to 40 g vibration stability version with wired terminals, fully insulated.

07/05

5

EPCOS AG

Please read the important notes, cautions and warnings.

Data sheet

B41607

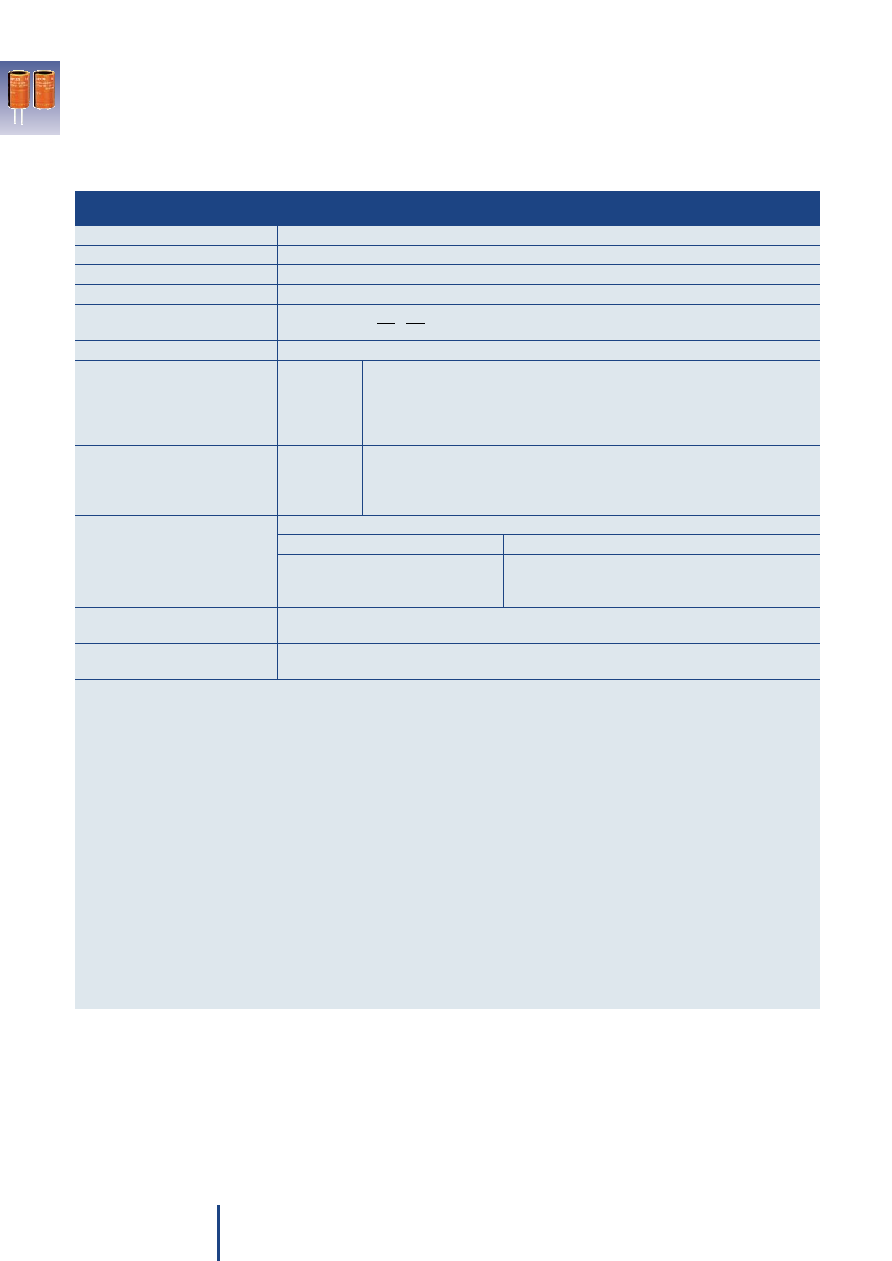

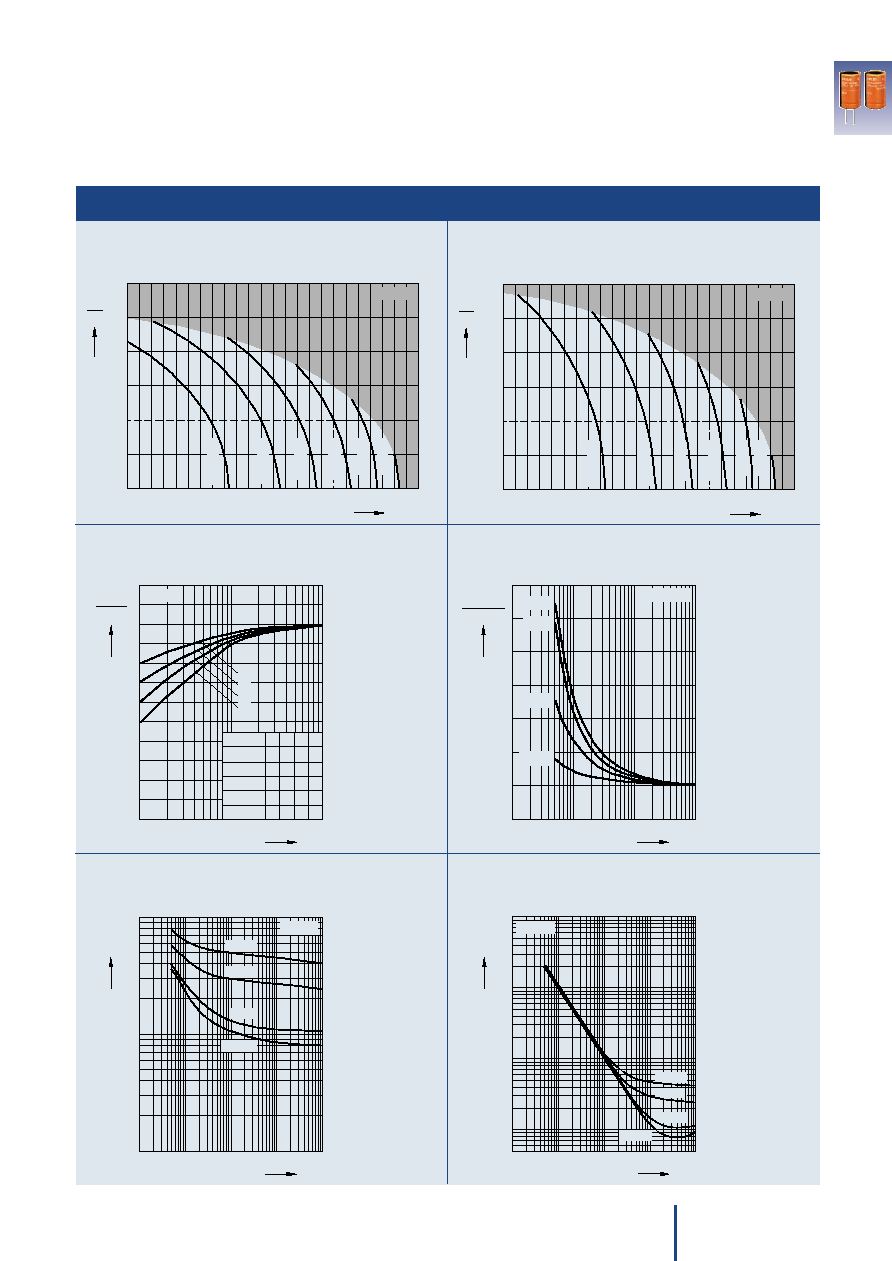

Characteristics

100

1.0

40

0

0.5

50

60

80

500 000 h

70

100 000 h

90

~

~

1.5

2.0

2.5

R

3.0

4 000 h

140

120

30 000 h

110

10 000 h

130

A

T

∞C

2 000 h

160

KAL0954-4

B41607

100

1.0

40

0

0.5

50

60

80

500 000 h

70

100 000 h

90

~

~

1.5

2.0

2.5

R

3.0

4 000 h

140

120

30 000 h

110

10 000 h

130

C

T

∞C

2 000 h

160

B41607

KAL0955-C

10

f

KAL0956-K

0

B41607

2

5

10

3

Hz 10

4

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.2

~

10 kHz

f

~

¯ [mm]

30 35

R

V

40 VDC

55 VDC

b a

c b

25 VDC

a a

c

d

b

a

5

63 VDC

c c

25

b

c

d

d

22

a

b

c

c

10

1

f

KAL0835-R

0

1

2

3

4

5

7

5 10

2

5 10

3

10

Hz

4

85 ∞C

20 ∞C

40 ∞C

_

125 ∞C

B41607

ESR

10 kHz

ESR

f

10

1

10

2

5

3

10

10

4

10

5

5

5

Hz

f

KAL0834-I

10

3

_

ESR

10

_

2

_

40 ∞C

_

25 ∞C

20 ∞C

_

> 60 ∞C

5

B41607

10

1

_

10

1

10

2

5

3

10

10

4

10

5

5

5

Hz

f

KAL0833-A

Z

10

2

_

10

1

40 ∞C

_

20 ∞C

_

> 60 ∞C

25 ∞C

_

B41607

10

_

1

10

0

5

5

5

Frequency factor of permissible ripple current I~

versus frequency f

Frequency characteristics of ESR

versus frequency f at different temperatures T

Typical behavior

Impedance Z

versus frequency f at different temperatures

Typical behavior for 1500 µF/55 V

Equivalent series resistance ESR

versus frequency f at different temperatures

Typical behavior for 1500 µF/55 V

Useful life

depending on ambient temperature T

A

under ripple

current operating conditions at V

R

Useful life

depending on case temperature T

C

under ripple

current operating conditions at V

R

07/05

6

EPCOS AG

Important notes

The following applies to all products

named in this publication:

1. Some parts of this publication

contain statements about the

suitability of our products for

certain areas of application.

These statements are based on

our knowledge of typical require-

ments that are often placed on

our products in the areas of appli-

cation concerned. We never-

theless expressly point out that

such statements cannot be re-

garded as binding statements

about the suitability of our

products for a particular cus-

tomer application. As a rule,

EPCOS is either unfamiliar with

individual customer applications

or less familiar with them than the

customers themselves. For these

reasons, it is always ultimately

incumbent on the customer to

check and decide whether an

EPCOS product with the proper-

ties described in the product

specification is suitable for use in

a particular customer application.

2. We also point out that in individ-

ual cases, a malfunction of

passive electronic compo-

nents or failure before the end

of their usual service life can-

not be completely ruled out in

the current state of the art,

even if they are operated as

specified. In customer applica-

tions requiring a very high level of

operational safety and especially

in customer applications in which

the malfunction or failure of a pas-

sive electronic component could

endanger human life or health

(e.g. in accident prevention or life-

saving systems), it must therefore

be ensured by means of suitable

design of the customer applica-

tion or other action taken by the

customer (e.g. installation of pro-

tective circuitry or redundancy)

that no injury or damage is sus-

tained by third parties in the event

of malfunction or failure of a pas-

sive electronic component.

3. The warnings, cautions and

product-specific notes must

be observed.

4. In order to satisfy certain technical

requirements, some of the

products described in this

publication may contain sub-

stances subject to restrictions

in certain jurisdictions (e.g.

because they are classed as

"hazardous"). Useful information

on this will be found in our Materi-

al Data Sheets on the Internet

(www.epcos.com/material).

Should you have any more de-

tailed questions, please contact

our sales offices.

5. We constantly strive to improve

our products. Consequently, the

products described in this

publication may change from

time to time. The same is true of

the corresponding product speci-

fications. Please check therefore

to what extent product descrip-

tions and specifications contained

in this publication are still applica-

ble before or when you place an

order.

We also reserve the right to

discontinue production and

delivery of products. Conse-

quently, we cannot guarantee that

all products named in this publi-

cation will always be available.

6. Unless otherwise agreed in indi-

vidual contracts, all orders are

subject to the current version

of the "General Terms of De-

livery for Products and Ser-

vices in the Electrical Indus-

try" published by the German

Electrical and Electronics In-

dustry Association (ZVEI).

7. The trade names EPCOS,

CeraDiode, CSSP, SIMID,

PhaseCap, PhaseMod, SIFI,

SIKOREL, SilverCap, SIOV,

SIP5D, SIP5K, TOPcap,

UltraCap, WindCap are trade-

marks registered or pending in

Europe and in other countries.

Further information will be found

on the Internet at

www.epcos.com/trademarks.

07/05

7

EPCOS AG

Cautions and warnings

The electrolytes used by EPCOS have not only been optimized with a view to the intended application, but also

with regard to health and environmental compatibility. They do not contain any solvents that are detrimental to

health, e.g. dimethyl formamide (DMF) or dimethyl acetamide (DMAC).

Furthermore, part of the high-voltage electrolytes used by EPCOS are self-extinguishing. They contain flame-

retarding substances which will quickly extinguish any flame that may have been ignited.

As far as possible, EPCOS does not use any dangerous chemicals or compounds to produce operating elec-

trolytes. However, in exceptional cases, such materials must be used in order to achieve specific physical and

electrical properties because no safe substitute materials are currently known. However, the amount of danger-

ous materials used in our products has been limited to an absolute minimum. Nevertheless, the following rules

should be observed when handling Al electrolytic capacitors:

s

Any escaping electrolyte should not come into contact with eyes or skin.

s

If electrolyte does come into contact with the skin, wash the affected parts immediately with running water.

If the eyes are affected, rinse them for 10 minutes with plenty of water. If symptoms persist, seek medical treat-

ment.

s

Avoid breathing in electrolyte vapor or mists. Workplaces and other affected areas should be well ventilated.

Clothing that has been contaminated by electrolyte must be changed and rinsed in water.

Personal safety

s

Make sure that polar capacitors are connected with the right polarity.

s

Voltages polarity clashes should be prevented by connecting a diode.

s

Do not damage the insulating sleeve, especially when ring clips are used for mounting.

s

Do not exceed the upper category temperature (UCT).

s

Make periodic inspections of the capacitors. Before the inspection, make sure that the power supply

is turned off and carefully discharge the electricity of the capacitors.

s

Do not apply any mechanical stress to the capacitor terminals.

s

The internal structure of single-ended capacitors may be damaged if excessive force is applied to

the lead wires.

s

Avoid any compressive, tensile or flexural stress.

s

Do not move the capacitor after soldering to the PC board.

s

Do not pick up the PC board by the soldered capacitor.

s

Do not insert the capacitor on the PC board with a hole space different to the lead space specified.

s

Do not exceed the specified time or temperature limits during soldering.

s

Capacitors should be dipped in solder for less than 10 seconds.

s

Do not allow halogenated hydrocarbons to come into contact with aluminum electrolytic capacitors.

s

Avoid external energy, such as fire or electricity.

s

Avoid overload of the capacitors.

Product safety

Failure to follow cautions and warnings may result in the worst case in premature failure, bursting and fire.

07/05

8

EPCOS AG

Product safety

Polarity

Make sure that polar capacitors are

connected with the right polarity. If

the opposite polarity were to be ap-

plied, this would cause an electrolyt-

ic process resulting in the formation

of a dielectric layer on the cathode

foil. In this case strong internal heat

generation and gas emission may

occur and destroy the capacitor.

Polar capacitors do not tolerate a

voltage reversal. Incorrect polarities

of up to 1.5 V are, however, permis-

sible for short periods of time as the

formation of a damaging oxide layer

on the cathode only starts at volt-

ages of this magnitude.

Reverse voltage

Aluminum electrolytic capacitors are

polar capacitors. Where necessary,

voltages of opposite polarity should

be prevented by connecting a

diode. The diode's conducting-state

voltage of approximately 0.8 V is

permissible. Reverse voltages

1.5 V

are tolerable for a duration of less

than 1 second, but not in continu-

ous or repetitive operation.

Breakdown strength of

insulating sleeves

The minimum breakdown strength of

the insulating sleeve is 2500 VAC or

3500 VDC. A test method for verifying

the breakdown strength of the slee-

ves is described in IEC 60384-4.

In order to ensure full breakdown

strength, care must be taken not to

damage the insulating sleeve, espe-

cially when ring clips are used for

mounting. The insulation can be im-

proved by using an insulating strip.

In such cases, attention must be

paid to any relevant regulations

(e.g. VDE, BSA or UL regulations).

Upper category tempera-

ture (UCT)

The upper category temperature is

the maximum permissible ambient

temperature at which a capacitor

may be continuously operated. If

this limit is exceeded, the capacitor

may fail prematurely.

For some type series, however, op-

eration at temperatures above the

UCT is permissible for short periods

of time. The maximum permissible

operating temperatures are specified

in the data sheets for the individual

type series under "Specifications

and characteristics in brief", section

"Useful life".

Maintenance

Make periodic inspections for the

capacitors that have been used in

the devices for industrial applica-

tions. Before the inspection, make

that the power supply is turned off

and carefully discharge the electricity

of the capacitors. To check the

capacitors, make sure of the polarity

when measuring the capacitors by

using a volt-ohm meter, for instance.

Also, do not apply any mechanical

stress to the capacitor terminals.

The following items should be

checked by the periodic inspections.

Significant damage to appearances:

venting, electrolyte leakage, etc.

Electrical characteristics: leakage

current, capacitance, tan

and other

characteristics prescribed in the

catalogs or product specifications.

If any of the above is found, replace

it or take any other proper measure.

Halogenated hydrocarbons may

cause serious damage if allowed to

come into contact with aluminum

electrolytic capacitors.

Mounting position

An overpressure vent ensures that

the gas can escape when the pres-

sure reaches a certain level.

To prevent electrolyte from leaking

out when the gas is "vented", the

capacitor should be mounted in an

upright position (90∞). All of these

mounting positions are intended to

avoid a vent-down installation of the

capacitor.

Mounting of single-ended

capacitors

For further information see page 67.

Soldering

Excessive time or temperature dur-

ing soldering will affect capacitor's

characteristics and cause damage

to the insulation sleeve. Capacitors

should be dipped in solder for less

than 10 seconds. Contact of the

sleeve with soldering iron must be

avoided.

Soldering, cleaning agents

Halogenated hydrocarbons may

cause serious damage if allowed to

come into contact with aluminum

electrolytic capacitors. These sol-

vents may dissolve or decompose

the insulating film and reduce the in-

sulating properties to below the per-

missible level. The capacitor seals

may be affected and swell, and the

solvents may even penetrate them.

This will lead to premature compo-

nent failure.

Because of this, measures must be

taken to prevent electrolytic capaci-

tors from coming into contact with

the solvents when using halogenat-

ed hydrocarbon solvents to clean

printed circuit boards after soldering

the components, or to remove flux

residues. If it is not possible to pre-

vent the electrolytic capacitors from

being wetted by the solvent, halo-

gen-free solvents must be used in

order to eliminate the possibility of

damage.

Passive flammability

Under the influence of high external

energy, such as fire or electricity, the

flammable parts may get inflamed.

Clause 38 of the relevant specifica-

tion CECC 30000 (Harmonized

System of Quality Assessment for

Electronic Components; Generic

Specification: Fixed Capacitors)

refers to IEC Publication 695-2-2

(Needle Flame Test) for testing the

passive flammability of capacitors.

And in CECC 30000, severities and

requirements for different categories

of flammability are listed. Most of

aluminum electrolytic capacitors

meet the requirements of category C.

Active flammability

In rare cases the component may

ignite caused by heavy overload or

some capacitor defect. One reason

could be the following: During the

operation of an aluminum electrolytic

capacitor with nonsolid electrolyte,

there is a small quantity of hydrogen

developed in the component. Under

normal conditions, this gas perme-

ates easily out of the capacitor. But

under exceptional circumstances,

higher gas amounts may develop

and may catch fire if a sparking

would occur at the same time.

As explained above a fire risk can't

be totally excluded. Therefore, it is

recommended to use special mea-

sures in critical applications (e.g. ad-

ditional encapsulation of the equip-

ment for mining applications).

07/05