PTC thermistors for overcurrent

protection

Leaded disks, coated,

42 V power net

Series/Type:

B599*3

Date:

March 2006

© EPCOS AG 2006. Reproduction, publication and dissemination of this publication, enclosures hereto and the

information contained therein without EPCOS' prior express consent is prohibited.

1) To ISO/TC22 WD24V-1E

2) Peak value of maximum DC operating voltage, incl. ripple.

Applications

Overcurrent protection for 42 V power net

Features

Lead-free terminals

Manufacturer's logo and type designation

stamped on in white

RoHS-compatible

Options

Leadless disks and leaded disks without

coating available on request

Thermistors with diameter b

11.0 mm are

also available on tape (to IEC 60286-2)

Delivery mode

Cardboard strips (standard)

Cardboard tape reeled or in Ammo pack on

request

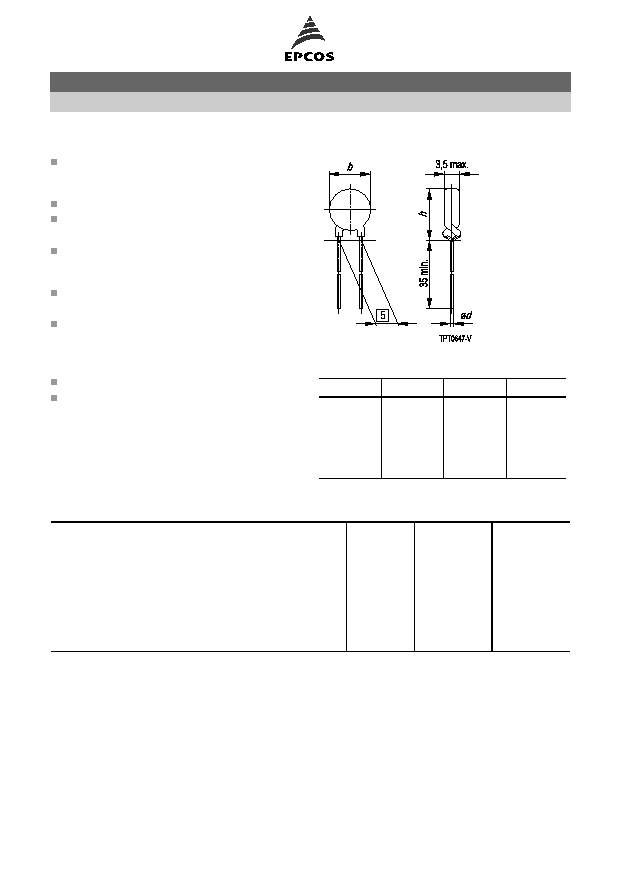

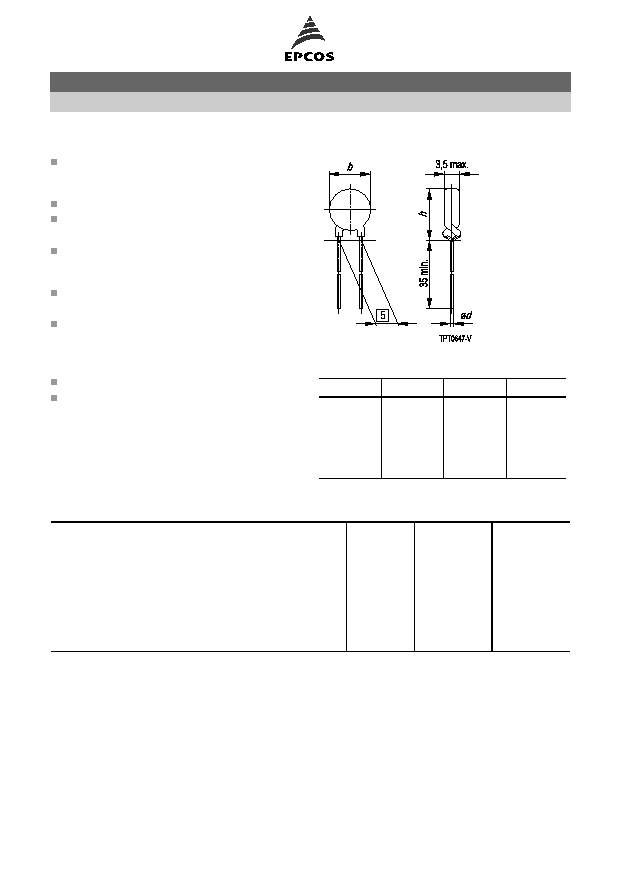

Dimensional drawing

Dimensions (mm)

Type

b

max

h

max

d

C943

17.5

21.0

0.6

C953

13.5

17.0

0.6

C963

11.0

14.5

0.6

C973

9.0

12.5

0.6

C983

6.5

10.0

0.6

General technical data

Max. operating voltage

(T

A

= 125

∞

C)

V

max

1)

54

VDC

Max. operating voltage

(t

400 ms)

V

max,dyn

2)

58

V

Rated voltage

V

R

42

VDC

Switching cycles

N

100

Reference temperature

(typ.)

T

ref

120

∞

C

Tolerance of R

R

R

R

±

20

%

Operating temperature range

(V = 0)

T

op

40/+125

∞

C

Operating temperature range

(V = V

max

)

T

op

40/+125

∞

C

Overcurrent protection

Leaded disks, coated, 42 V power net

C943 ... C983

Page 2 of 7

Please read Important notes and

Cautions and warnings at the end of this document.

Electrical specifications and ordering codes

Type

I

R

mA

I

S

mA

I

Smax

(V = V

max

)

A

I

r

(V = V

max

)

typ.

mA

R

R

R

min

Ordering code

C943

750

1300

8.0

50

1.0

0.7

B59943C0120A070

C953

430

770

6.0

40

1.8

1.2

B59953C0120A070

C963

320

560

5.0

30

2.7

1.8

B59963C0120A070

C973

230

410

4.0

20

4.2

2.9

B59973C0120A070

C983

140

240

2.0

15

10.0

6.8

B59983C0120A070

Overcurrent protection

Leaded disks, coated, 42 V power net

C943 ... C983

Page 3 of 7

Please read Important notes and

Cautions and warnings at the end of this document.

Characteristics (typical)

PTC resistance R

PTC

versus

PTC temperature T

PTC

(measured at low signal voltage)

PTC current I

PTC

versus PTC voltage V

PTC

(measured at 25

∞

C in still air)

Switching time t

S

versus switching current I

S

(measured at 25

∞

C in still air)

Rated current I

R

versus ambient temperature T

A

(measured in still air)

Overcurrent protection

Leaded disks, coated, 42 V power net

C943 ... C983

Page 4 of 7

Please read Important notes and

Cautions and warnings at the end of this document.

Cautions and warnings

General

EPCOS thermistors are designed for specific applications and should not be used for purposes

not identified in our specifications, application notes and data books unless otherwise agreed

with EPCOS during the design-in-phase.

Ensure suitability of thermistor through reliability testing during the design-in phase. The

thermistors should be evaluated taking into consideration worst-case conditions.

Storage

Store thermistors only in original packaging. Do not open the package before storage.

Storage conditions in original packaging: storage temperature

25

∞

C ... +45

∞

C, relative

humidity

75% annual mean, maximum 95%, dew precipitation is inadmissible.

Avoid contamination of thermistors surface during storage, handling and processing.

Avoid storage of thermistor in harmful environment with effect on function on long-term

operation (examples given under operation precautions).

Use thermistor within 6 months after delivery.

Handling

PTCs must not be dropped. Chip-offs must not be caused during handling of PTCs.

Components must not be touched with bare hands. Gloves are recommended.

Avoid contamination of thermistor surface during handling.

Soldering

Use rosin-type flux or non-activated flux.

Insufficient preheating may cause ceramic cracks.

Rapid cooling by dipping in solvent is not recommended.

Complete removal of flux is recommended.

Mounting

Electrode must not be scratched before/during/after the mounting process.

Contacts and housing used for assembly with thermistor have to be clean before mounting.

Especially grease or oil must be removed.

When PTC thermistors are encapsulated with sealing material, the precautions given in chapter

"Mounting instructions", "Sealing and potting" must be observed.

When the thermistor is mounted, there must not be any foreign body between the electrode of

the thermistor and the clamping contact.

The minimum force of the clamping contacts pressing against the PTC must be 10 N.

During operation, the thermistor's surface temperature can be very high. Ensure that adjacent

components are placed at a sufficient distance from the thermistor to allow for proper cooling at

the thermistors.

Ensure that adjacent materials are designed for operation at temperatures comparable to the

surface temperature of thermistor. Be sure that surrounding parts and materials can withstand

this temperature.

Avoid contamination of thermistor surface during processing.

Overcurrent protection

Leaded disks, coated, 42 V power net

C943 ... C983

Page 5 of 7

Please read Important notes and

Cautions and warnings at the end of this document.