2

09/06

Please read Cautions and warnings and

Important notes at the end of this document.

To IEC 60133

Delivery mode: sets

Magnetic characteristics (per set)

Approx. weight (per set)

Gapped

Ungapped

with

center hole

without

center hole

l/A

l

e

A

e

A

min

V

e

0.5

31.6

63

--

1990

0.46

33.2

72.6

58.1

2410

mm

≠1

mm

mm

2

mm

2

mm

3

m

13

14

g

Material

A

L

value

nH

s

approx.

mm

µ

e

Ordering code

1)

-D with center hole

-N with threaded sleeve

N48

160

±3%

0.50

64

B65661+0160A048

250

±3%

0.26

100

B65661+0250A048

315

±3%

0.22

126

B65661+0315A048

630

±3%

0.10

251

B65661+0630A048

1250

±5%

0.05

499

B65661D1250J048

Material

A

L

value

nH

µ

e

P

V

W/set

Ordering code

-D with center hole

-W without center hole

K1

220 +30/≠20%

88

B65661D0000R001

N48

3800 +30/≠20%

1520

B65661D0000R048

N30

8300 +30/≠20%

3020

B65661W0000R030

T38

16000 +40/≠30%

5820

B65661W0000Y038

N87

4400 +30/≠20%

1600

< 1.1 (200 mT, 100 kHz, 100 ∞C)

B65661W0000R087

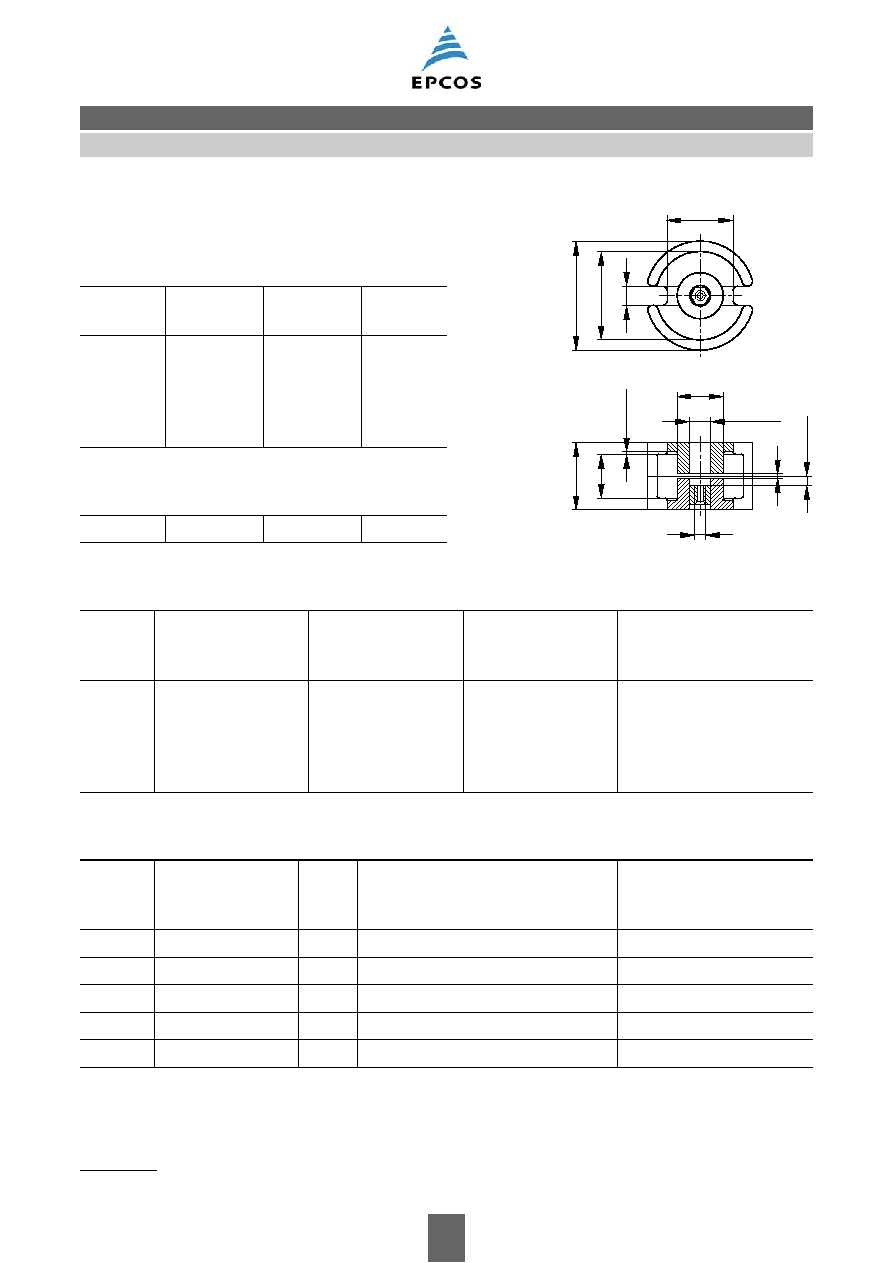

FPK0118-Q

s

2.9±0.15

M2

0.5+0.2

9.2+0.4

0.4

_

13.6

¯4.4+0.2

0.3

¯9.4

_

13.9 0.6

_

3.9+0.6

17.9+0.6

0.8

22

_

1) Replace the + by the code letter "D" or "N" for the required version.

B65661

Core

P 22

◊ 13

3

09/06

Please read Cautions and warnings and

Important notes at the end of this document.

Coil former

Standard:

to IEC 60133

Material:

GFR polyterephthalate (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155 ∞C), color code black

Valox 420-SE0

Æ

[E45329 (M)], GE PLASTICS B V

Winding:

see Data Book 2007, chapter "Processing notes, 2.1"

Insulating washer between core and coil former

For tolerance compensation and for insulation

Polycarbonate spring washer (UL 94 V-0, insulation class to IEC 60085: E 120 ∞C), 0.08 mm thick

Aryphan F685, [E167358 (M)], natural color, LOFO HIGH TECH FILM GMBH

Coil former

Insulating washer

Coil former

Ordering code

Sections

A

N

mm

2

l

N

mm

A

R

value

µ

1

23.4

44

67

B65662B0000T001

Insulating washer (reel packing, PU = 1 reel)

B65662A5000X000

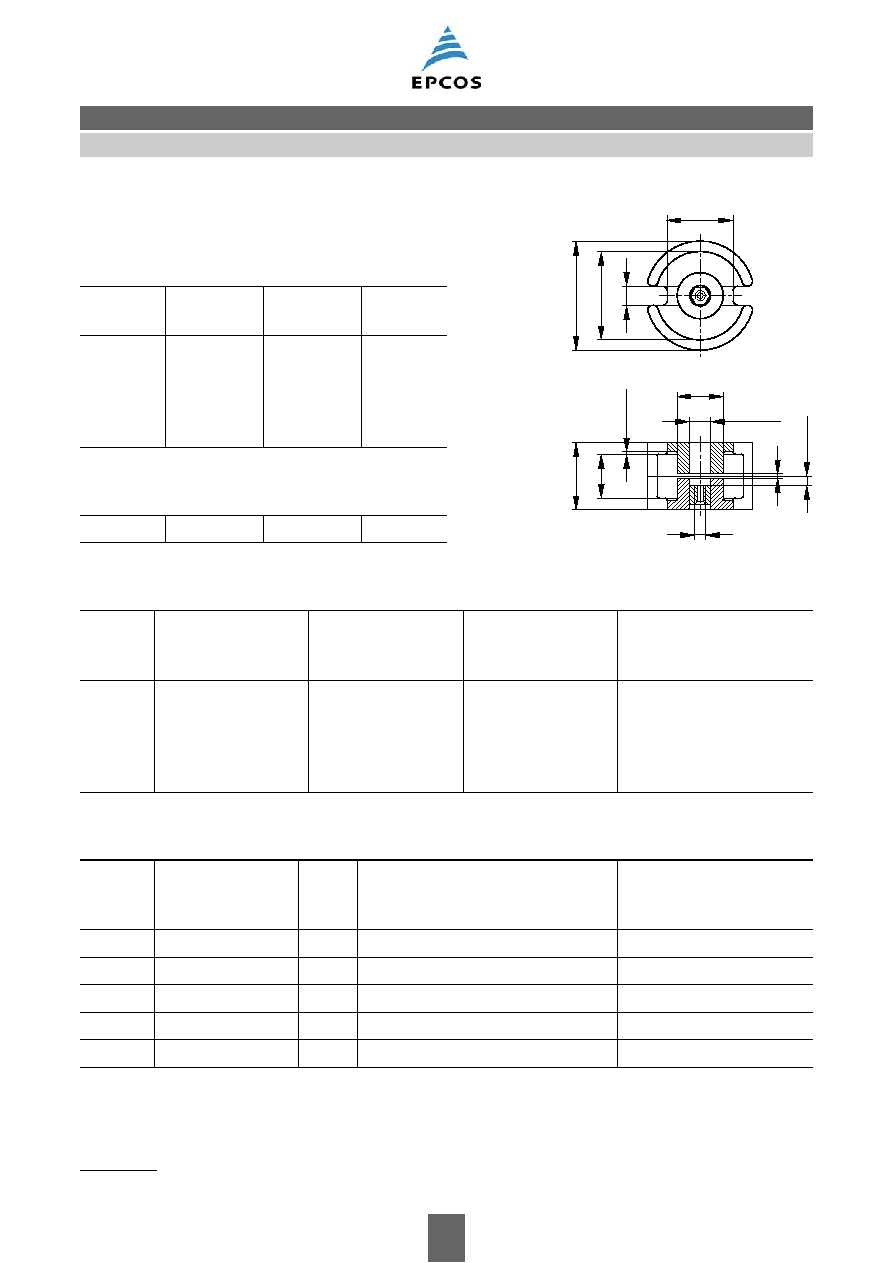

17.8

_

0.2

2.5+0.8

0.6

9

_

0.15

A

N

¯10.7

_

0.15

¯9.6+0.15

FPK0352-H

FPK0120-2

¯9,2±0,2

¯18,3±0,2

1,5±0,2

3,4

(preliminary data)

B65662

Accessories

P 22

◊ 13

5

09/06

Ferrites and accessories

Cautions and warnings

Mechanical stress and mounting

Ferrite cores have to meet mechanical requirements during assembling and for a growing number

of applications. Since ferrites are ceramic materials one has to be aware of the special behavior

under mechanical load.

As valid for any ceramic material, ferrite cores are brittle and sensitive to any shock, fast changing

or tensile load. Especially high cooling rates under ultrasonic cleaning and high static or cyclic loads

can cause cracks or failure of the ferrite cores.

For detailed information see Data Book 2007, chapter "General ≠ Definitions, 8.1".

Effects of core combination on A

L

value

Stresses in the core affect not only the mechanical but also the magnetic properties. It is apparent

that the initial permeability is dependent on the stress state of the core. The higher the stresses are

in the core, the lower is the value for the initial permeability. Thus the embedding medium should

have the greatest possible elasticity.

For detailed information see Data Book 2007, chapter "General ≠ Definitions, 8.2".

Heating up

Ferrites can run hot during operation at higher flux densities and higher frequencies.

NiZn-materials

The magnetic properties of NiZn-materials can change irreversible in high magnetic fields.

Processing notes

≠ The start of the winding process should be soft. Else the flanges may be destroid.

≠ To strong winding forces may blast the flanges or squeeze the tube that the cores can no more

be mount.

≠ To long soldering time at high temperature (>300 ∞C) may effect coplanarity or pin arrangement.

≠ Not following the processing notes for soldering of the J-leg terminals may cause solderability

problems at the transformer because of pollution with Sn oxyd of the tin bath or burned insulation

of the wire. For detailed information see Data Book 2007, chapter "Processing notes, 2.2".

≠ The dimensions of the hole arrangement have fixed values and should be understood as a

recommendation for drilling the printed circuit board. For dimensioning the pins, the group of

holes can only be seen under certain conditions, as they fit into the given hole arrangement. To

avoid problems when mounting the transformer, the manufacturing tolerances for positioning the

customers' drilling process must be considered by increasing the hole diameter.