Data Sheet

Data Sheet

Date:

September 2006

EPCOS AG 2006. Reproduction, publication and dissemination of this data sheet and the

information contained therein without EPCOS' prior express consent is prohibited.

Ferrites and accessories

PM 62/49

Core and accessories

Series/Type:

B65684, B65685

2

09/06

Please read Cautions and warnings and

Important notes at the end of this document.

To IEC 61247

Particularly suitable for power transformers

and energy storage chokes

Delivery mode: sets

Magnetic characteristics (per set)

l/A = 0.191 mm

≠1

l

e

= 109 mm

A

e

= 570 mm

2

A

min

= 470 mm

2

V

e

= 62000 mm

3

Approx. weight 280 g/set

Gapped

Ungapped

Material

A

L

value

nH

s

approx.

mm

µ

e

Ordering code

N27

315

±3%

2.60

48

B65684A0315A027

630

±3%

1.10

95

B65684A0630A027

Material

A

L

value

nH

µ

e

P

V

W/set

Ordering code

N27

9200 +30/≠20%

1400

< 9.5 (200 mT, 25 kHz, 100

∞C) B65684A0000R027

N87

9200 +30/≠20%

1400

< 5.8 (200 mT, 100 kHz, 100

∞C) B65684A0000R087

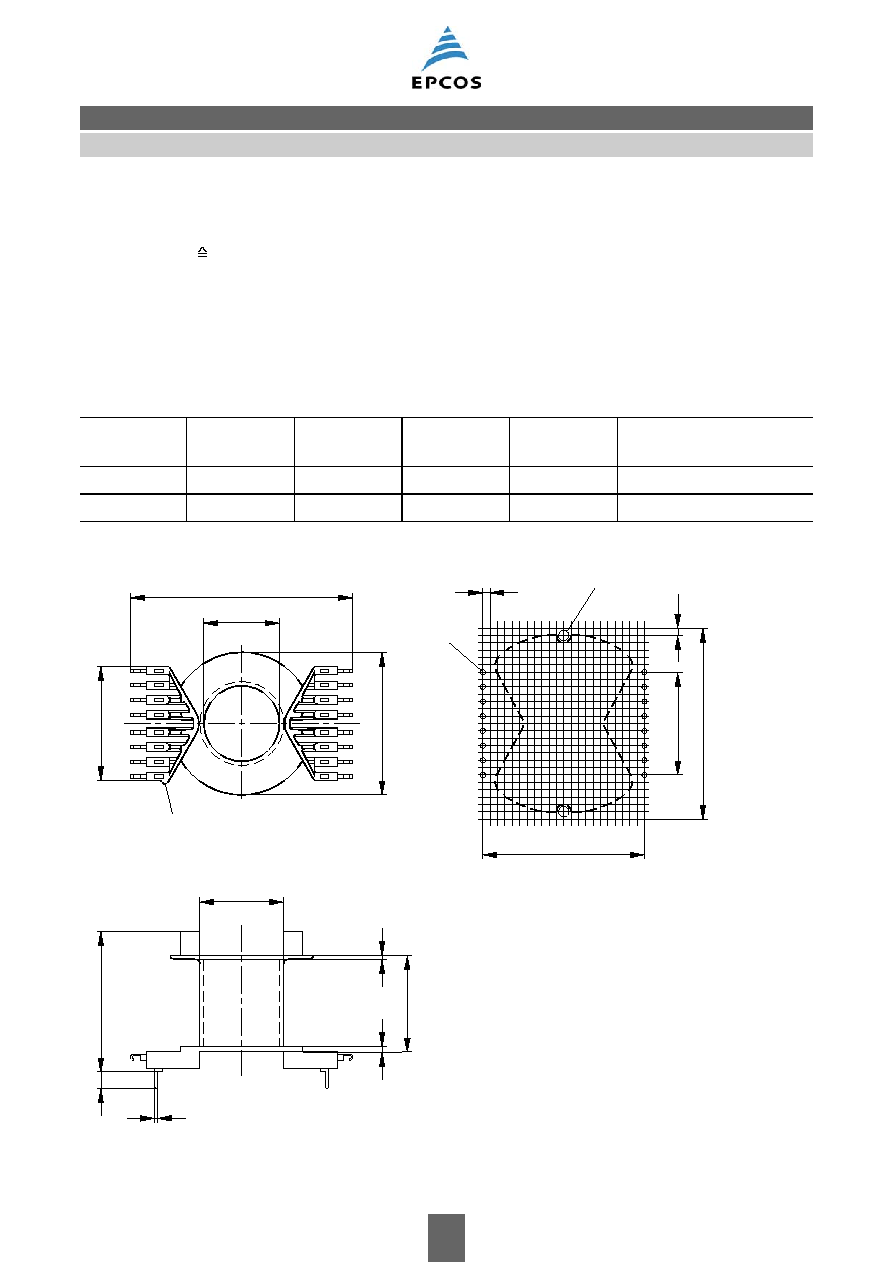

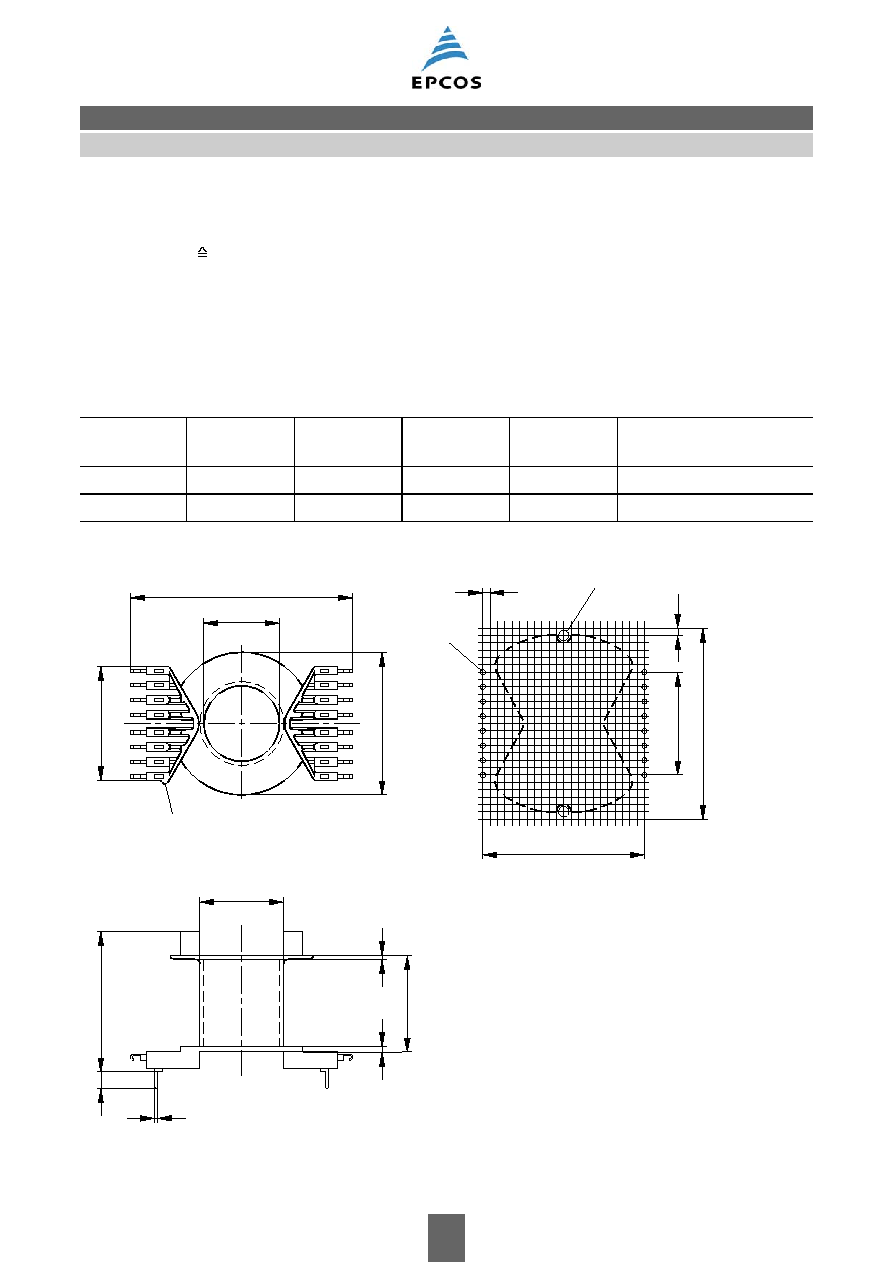

FPM0024-2

> 29

< 28.5

4+1

48.8+1.5

1.2+0.2

62 2

_

¯5.4+0.2

¯25.5 0.8

_

33.4+0.8

49

0.4

_

s

B65684

Core

PM 62/49

3

09/06

Please read Cautions and warnings and

Important notes at the end of this document.

Coil former

Material:

GFR polyterephthalate (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155

∞C), color code black

Valox 420-SE0

Æ

[E45329 (M)], GE PLASTICS B V

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 235

∞C, 2 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350

∞C, 3.5 s

Winding:

see Data Book 2007, chapter "Processing notes, 2.1"

Pins squared in the start-of-winding area.

Also available without solder pins.

Sections

A

N

mm

2

l

N

mm

A

R

value

µ

Solder

pins

Ordering code

1

270

120

15.4

16

B65685B1016T001

1

270

120

15.4

--

B65685A1000T001

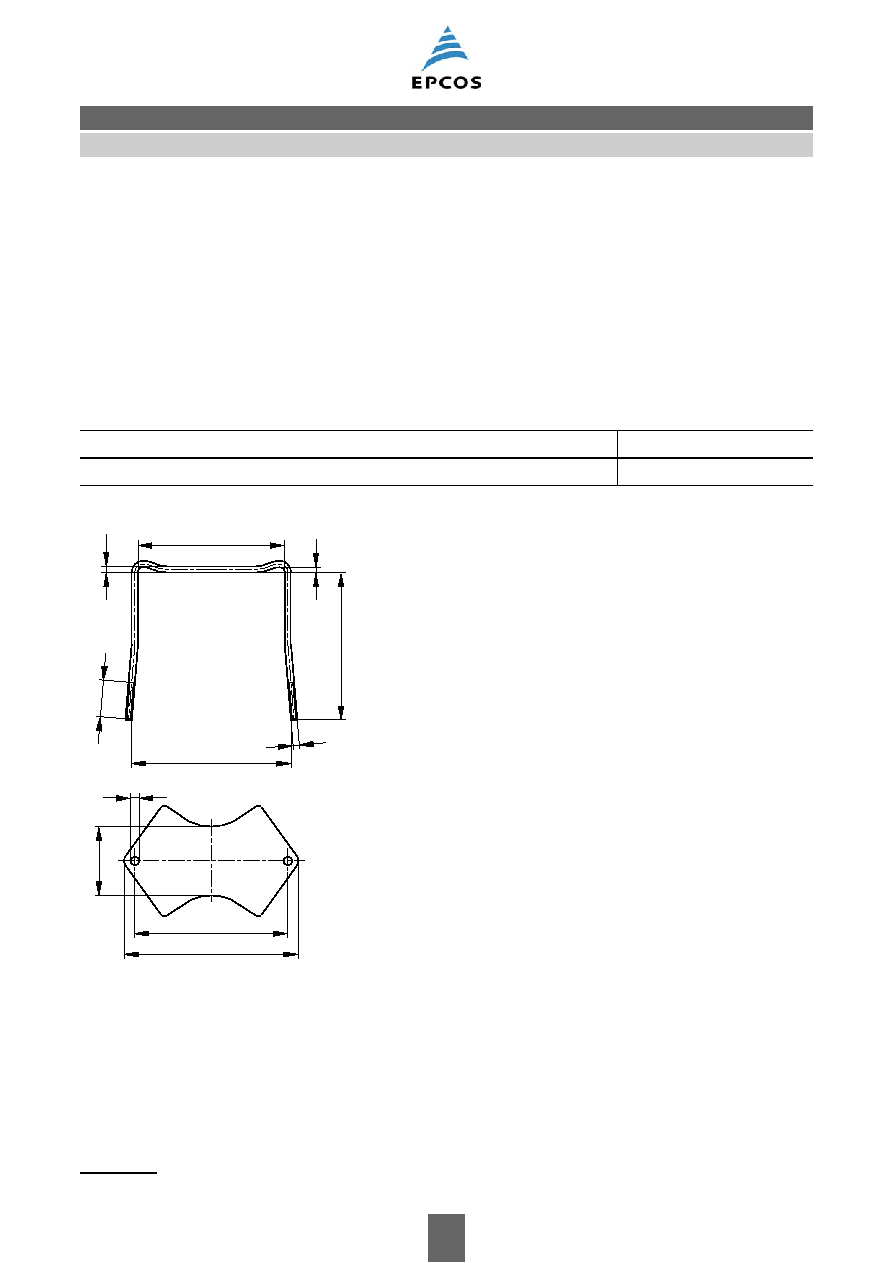

FPM0020-4-E

2.54

35.56

60.96

16

9

55.88

1

8

¯1.6+0.15

75.5 max.

48.5

25.7+0.3

38.9 max.

¯29 max.

33

1.4

1.5

48 max.

5.7

0.3

_

1.2 x 0.6

Marking of solder pin 1

Hole arrangement

View in mounting direction

¯3.5+0.2

0.5

_

0.3

_

2.54

B65685

Accessories

PM 62/49

4

09/06

Please read Cautions and warnings and

Important notes at the end of this document.

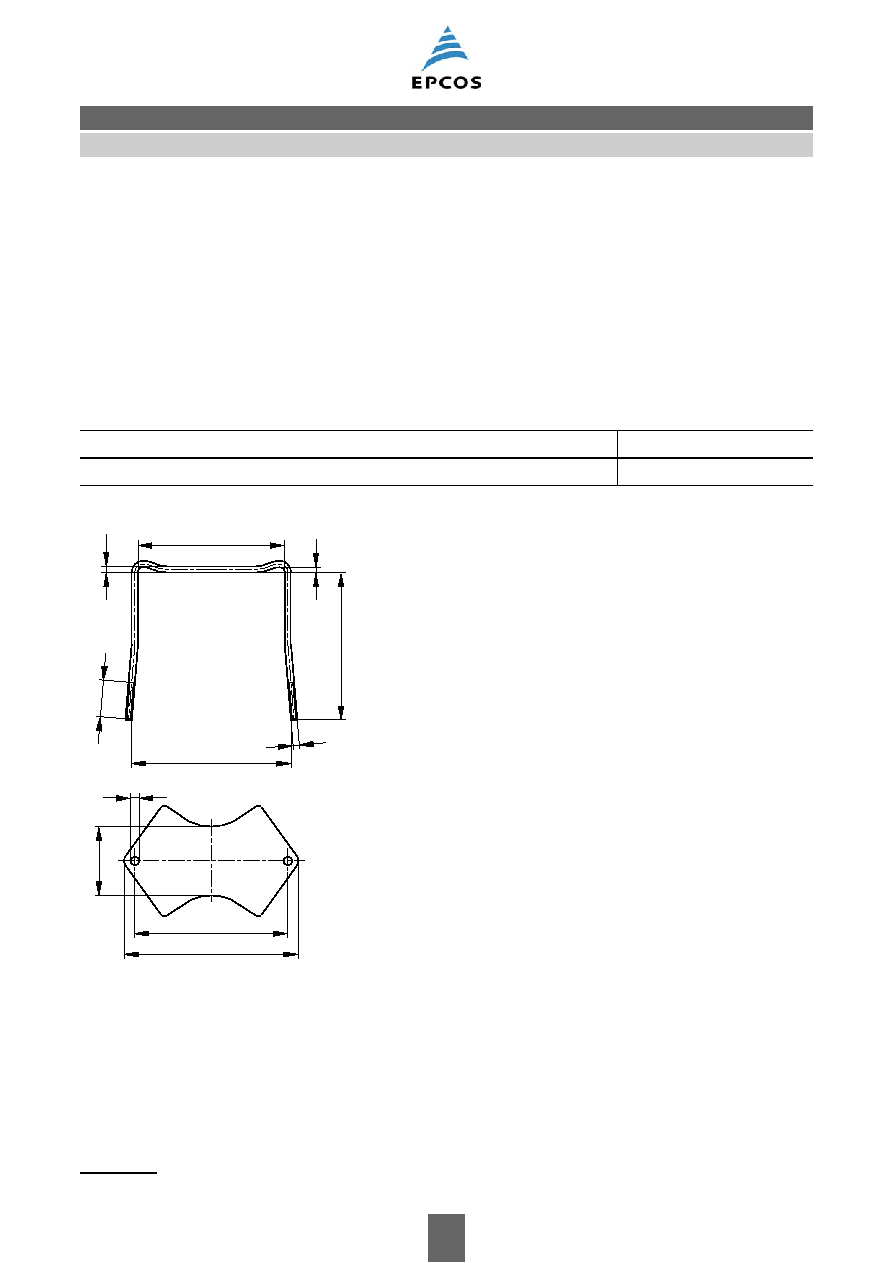

Mounting assembly

For chassis mounting

1)

or printed circuit boards

The set comprises a yoke and a base plate

Fixing nuts M3 and washers are supplied

Yoke

Material: Brass clamping yoke (

2.6 mm) with thread

Base plate

Material: Aluminum (0.6 mm)

Ordering code

Complete mounting assembly including nuts and washers

B65685A2000X000

FPM0009-T

59,8+0,3

2

59

1

_

15

64,8+1

M3

69 0,2

_

60,96±0,1

_

27,5

0,2

¯2,6

¯3,5+0,15

1) On a chassis the coil former must be mounted with its solder pins upward.

B65685

Accessories

PM 62/49

5

09/06

Ferrites and accessories

Cautions and warnings

Mechanical stress and mounting

Ferrite cores have to meet mechanical requirements during assembling and for a growing number

of applications. Since ferrites are ceramic materials one has to be aware of the special behavior

under mechanical load.

As valid for any ceramic material, ferrite cores are brittle and sensitive to any shock, fast changing

or tensile load. Especially high cooling rates under ultrasonic cleaning and high static or cyclic loads

can cause cracks or failure of the ferrite cores.

For detailed information see Data Book 2007, chapter "General ≠ Definitions, 8.1".

Effects of core combination on A

L

value

Stresses in the core affect not only the mechanical but also the magnetic properties. It is apparent

that the initial permeability is dependent on the stress state of the core. The higher the stresses are

in the core, the lower is the value for the initial permeability. Thus the embedding medium should

have the greatest possible elasticity.

For detailed information see Data Book 2007, chapter "General ≠ Definitions, 8.2".

Heating up

Ferrites can run hot during operation at higher flux densities and higher frequencies.

NiZn-materials

The magnetic properties of NiZn-materials can change irreversible in high magnetic fields.

Processing notes

≠ The start of the winding process should be soft. Else the flanges may be destroid.

≠ To strong winding forces may blast the flanges or squeeze the tube that the cores can no more

be mount.

≠ To long soldering time at high temperature (>300 ∞C) may effect coplanarity or pin arrangement.

≠ Not following the processing notes for soldering of the J-leg terminals may cause solderability

problems at the transformer because of pollution with Sn oxyd of the tin bath or burned insulation

of the wire. For detailed information see Data Book 2007, chapter "Processing notes, 2.2".

≠ The dimensions of the hole arrangement have fixed values and should be understood as a

recommendation for drilling the printed circuit board. For dimensioning the pins, the group of

holes can only be seen under certain conditions, as they fit into the given hole arrangement. To

avoid problems when mounting the transformer, the manufacturing tolerances for positioning the

customers' drilling process must be considered by increasing the hole diameter.