Metal Oxide Varistors

CT0603L25HSG

SMD multilayer varistor with Ni-barrier termination

B72500T8250L060

ISSUE DATE

28.01.2005

ISSUE

f

PUBLISHER

KB VS PE

PAGE

1/7

Designation system

CT

= Chip with three-layer- termination (Ag/Ni/Sn)

0603 = Dimensions of the device 06 x 03 (length x width in 1/100 inch)

L

= Tolerance of the varistor voltage (± 15%)

25

= Maximum operating voltage (RMS voltage)

HS

= Designed for protection of high speed data lines

G

= Taped version (cardboard tape, 7" reel, 4000 pieces/reel)

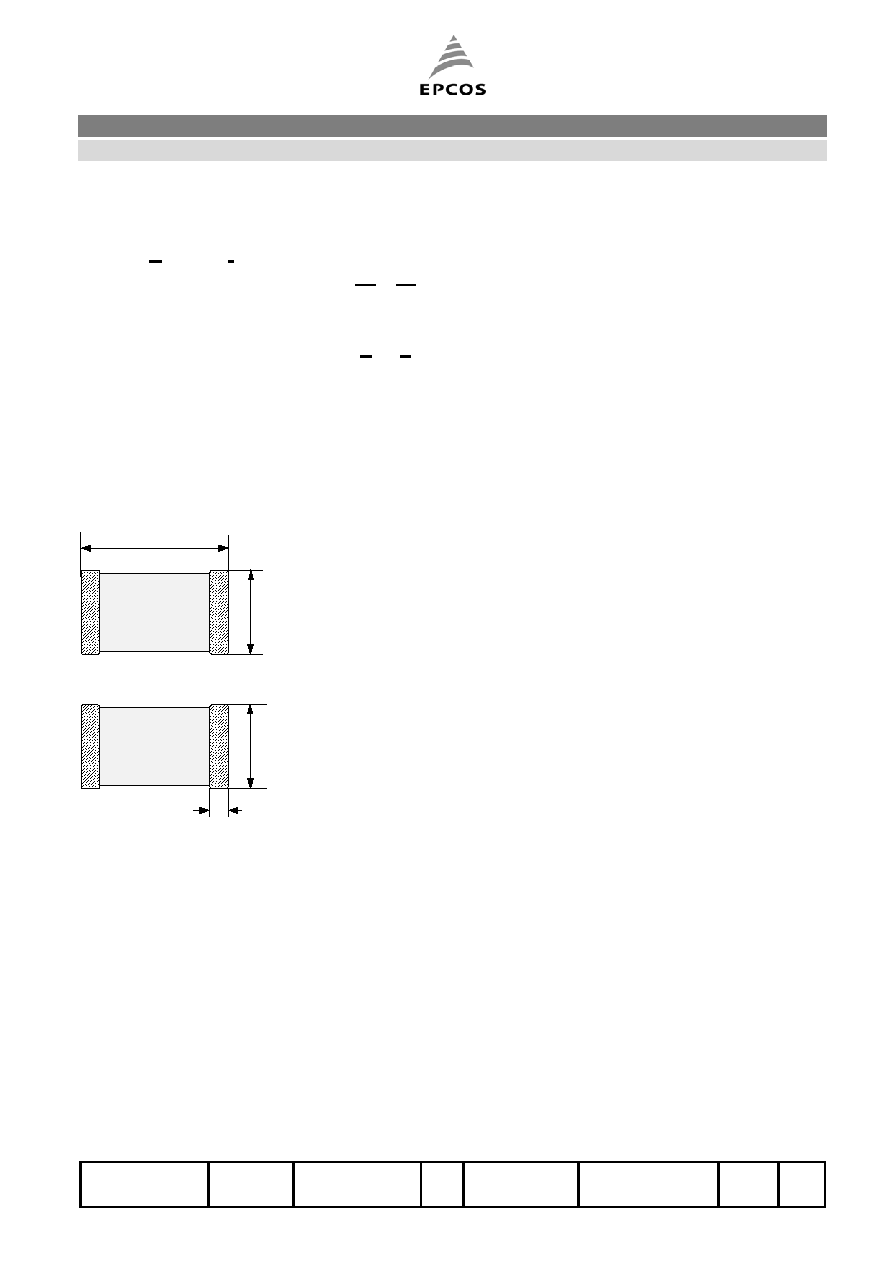

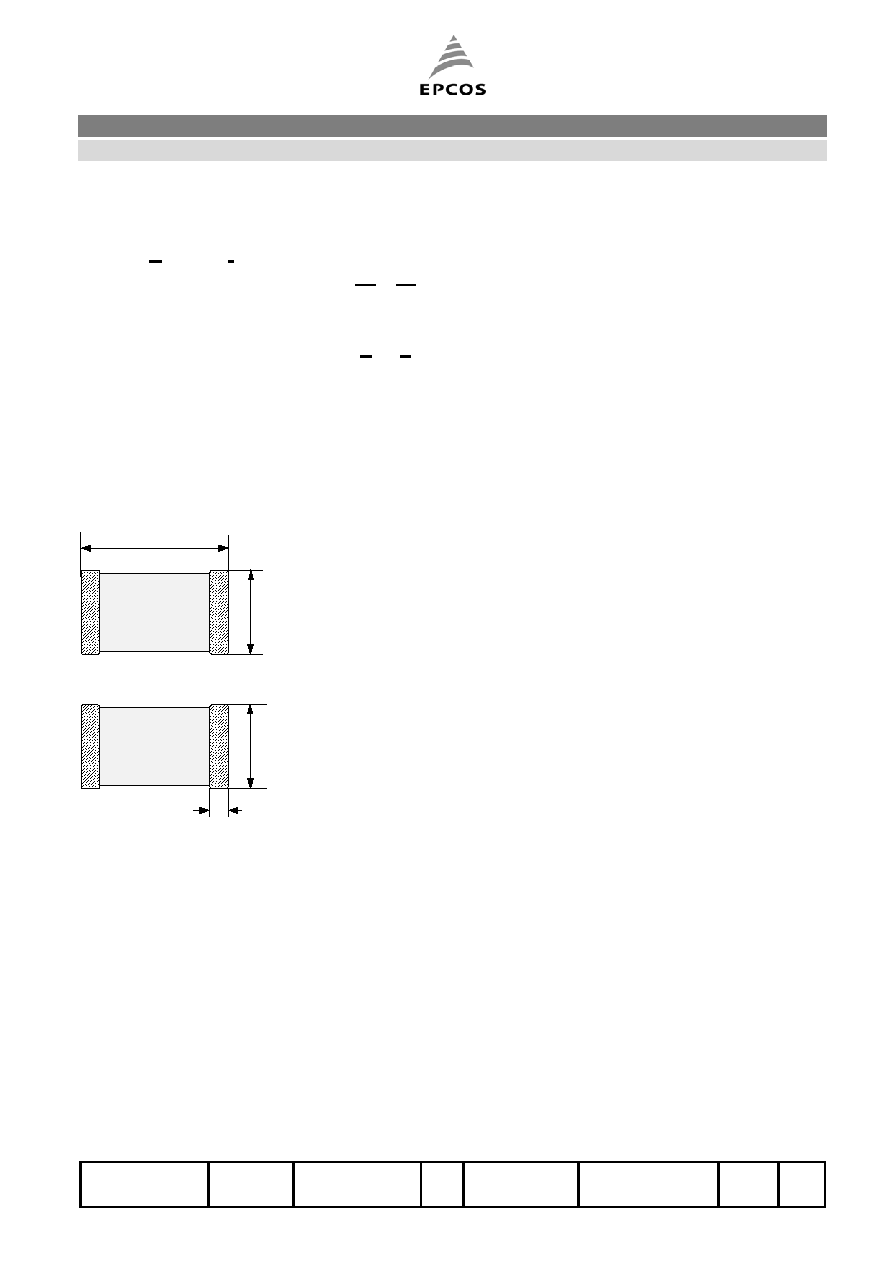

Figure

l = 1.6 ± 0.15

b = 0.8 ± 0.10

s = 0.9 max.

k = 0.1 ≠ 0.4

(all dimensions in mm)

As far as patents or other rights of third parties are concerned, liability is only assumed for components per se, not for

applications, processes and circuits implemented within components or assemblies. The information describes the type of

component and shall not be considered as assured characteristics. Terms of delivery and rights to change design reserved.

l

b

s

k

Metal Oxide Varistors

CT0603L25HSG

SMD multilayer varistor with Ni-barrier termination

B72500T8250L060

ISSUE DATE

28.01.2005

ISSUE

f

PUBLISHER

KB VS PE

PAGE

2/7

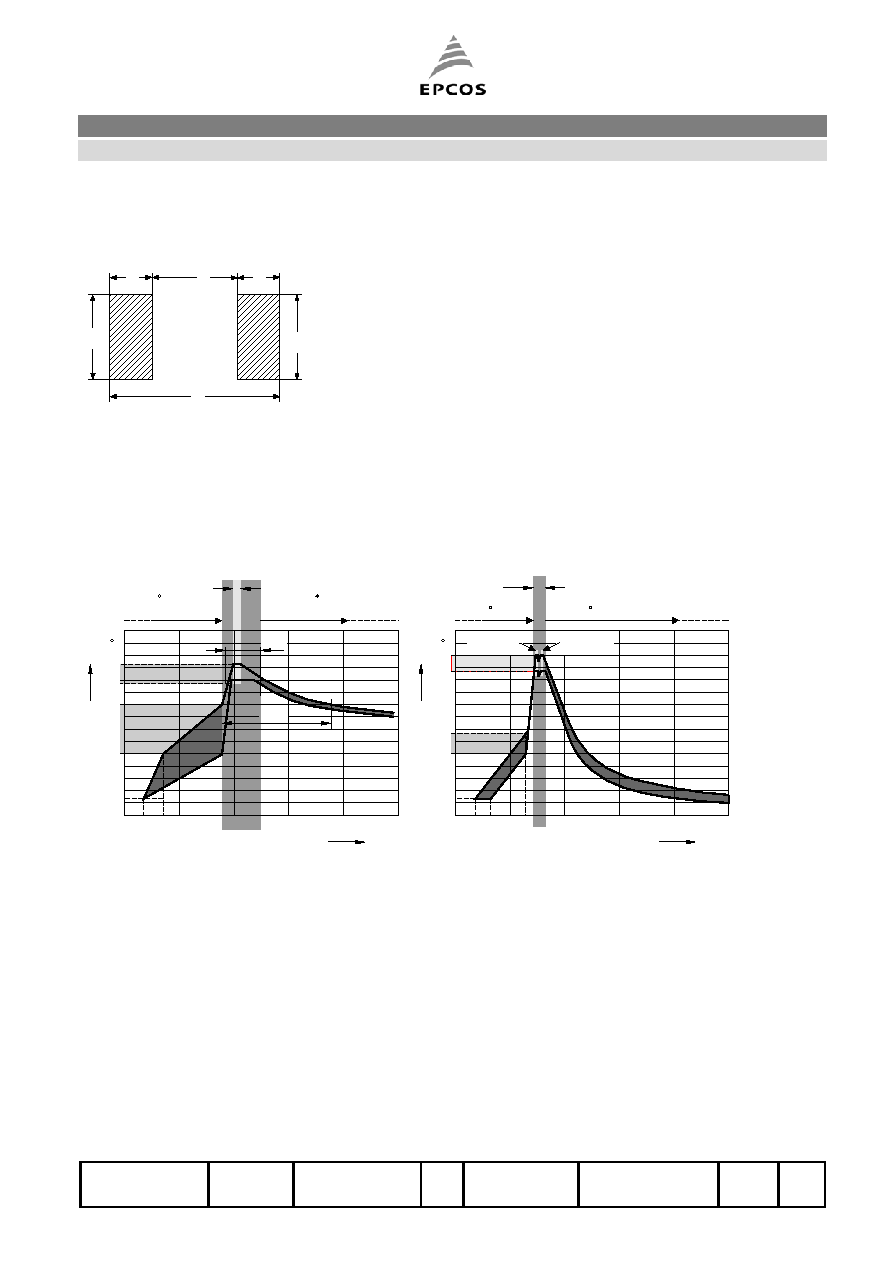

V-I-characteristic

10

-5

10

-4

10

-3

10

-2

10

-1

10

0

10

1

A

i

1

400

v

2

4

6

8

10

20

40

60

80

100

200

400

V

VAR9737A

100

0

10

20

30

40

50

60

70

80

90

%

-55

∞C

Ambient temperature

Max. current, energy, operating voltage and average power

dissipation depending on ambient temperature

70

80

90

100

110

120

130

140

150

Metal Oxide Varistors

CT0603L25HSG

SMD multilayer varistor with Ni-barrier termination

B72500T8250L060

ISSUE DATE

28.01.2005

ISSUE

f

PUBLISHER

KB VS PE

PAGE

3/7

Electrical data

Maximum operating voltage

RMS voltage

V

RMS

= 25 V

DC voltage

V

DC

= 32 V

Varistor voltage (@ 1 mA)

V

V

= 51.9 up to 70.1 V

Maximum clamping voltage (@ 1 A)

V

C

= 120 V

Maximum surge current (8/20 µs)

I

max

= 1 x 5 A

Maximum energy absorption (ESD)

E

max

= 50 mJ

(@ ESD according to ISO TR10605, 25 kV air discharge, 150 pF, 2 k)

Capacitance (@ 1 MHz, 1

V, 25 ∞C, typ.) C = 10 pF

Response time

< 0.5 ns

Operating temperature

-40 ... +125 ∞C

Storage temperature (mounted parts)

-40 ... +150 ∞C

Termination material

Ag/Ni/Sn

(thickness not specified, adjusted to fulfil wettability specification according to

IEC 60068-2-58)

Complies with following ESD standards:

IEC 61000-4-2 level 4 (8 kV contact, 15 kV air discharge)

ISO TR10605 level 4 (25 kV air discharge)

AEC Q200 002 level 6 (25 kV air discharge)

Metal Oxide Varistors

CT0603L25HSG

SMD multilayer varistor with Ni-barrier termination

B72500T8250L060

ISSUE DATE

28.01.2005

ISSUE

f

PUBLISHER

KB VS PE

PAGE

4/7

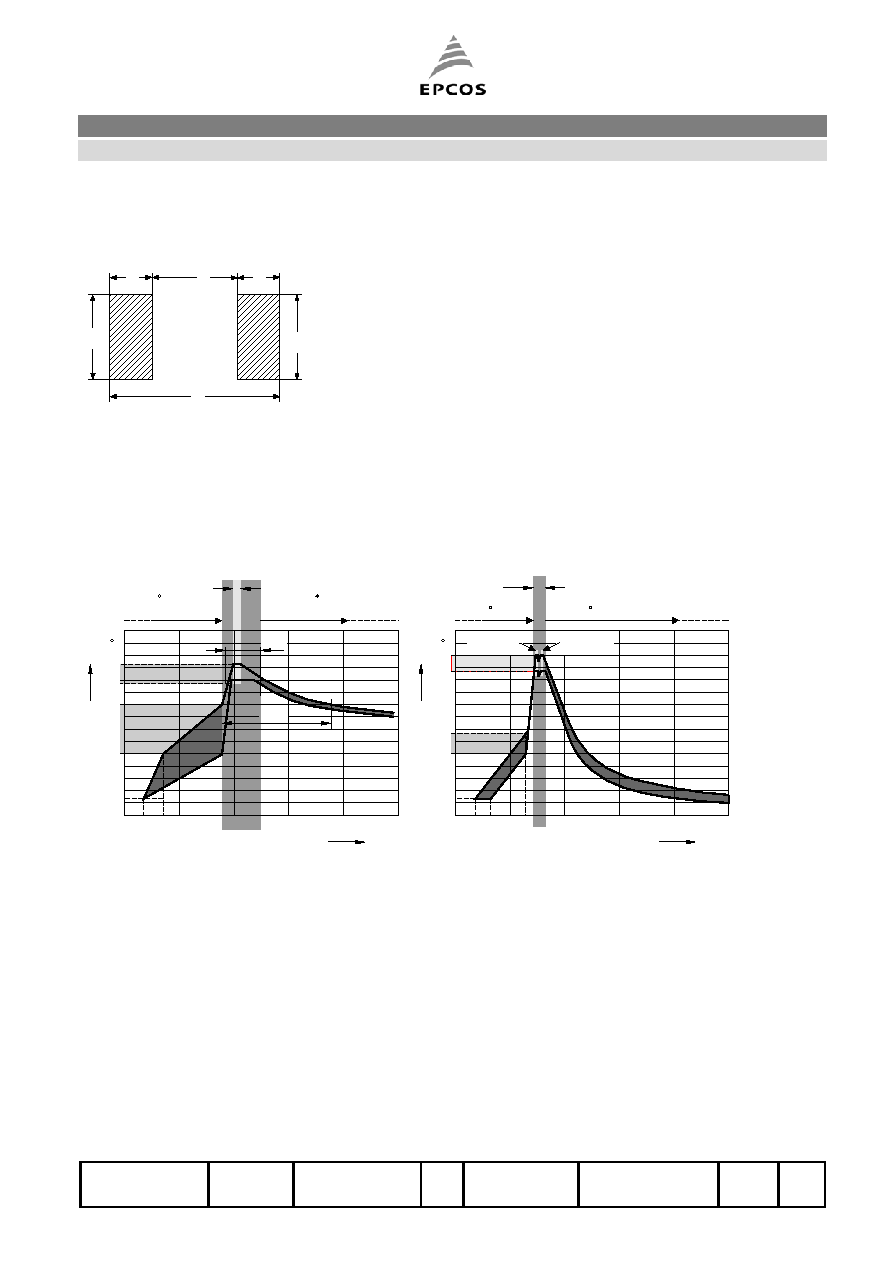

Stability to multiple ESD pulses

1)

0

20

40

60

80

0

1

10

100

1000

10000

number of ESD pulses

1)

15 kV air discharge, 150 pF, 330 , according to IEC 61000-4-2

Signal insertion loss

2)

-3.00

-2.50

-2.00

-1.50

-1.00

-0.50

0.00

0

20

40

60

80

100

frequency [MHz]

i

n

ser

t

i

on l

o

ss [

d

B

]

2)

typical values, measured with network analyzer HP8753 E/S containing S-parameter test set

Metal Oxide Varistors

CT0603L25HSG

SMD multilayer varistor with Ni-barrier termination

B72500T8250L060

ISSUE DATE

28.01.2005

ISSUE

f

PUBLISHER

KB VS PE

PAGE

5/7

Recommended geometry of solder pad

A = 1.0 mm

B = 1.0 mm

C = 1.0 mm

E = 3.0 mm

Recommended soldering temperature profile

100 s

at max. temp.

100

20

0

50

100

Preheating zone

max. 2

180

T

245

215

300

Soldering zone

max. 7 s

150

200

VAR0543-W-E

250

t

s

(natural air cooling)

40 s

max. 2

Cooling-down zone

C

C/s

C/s

2nd solder

Cooling-down zone

max. 5

100

20

0

50

100

1st solder

max. 2

Preheating zone

130

T

235

200

260

300

Soldering zone

max. 5 s

150

200

250

VAR0550-F-E

t

s

C

C/s

C/s (natural air cooling)

at max. temp.

10 s

wave

wave

This component should be soldered within 12 months after delivery from EPCOS. They

should be left in their original packings to avoid soldering problems due to oxidized terminals.

Storage temperature:

-25 to 45 ∞C

Relative humidity: < 75% annual average, < 95% on maximum 30 days in a year.

The usage of mild non-activated fluxes for soldering is recommended, as well as proper

cleaning of the PCB.

The components are suited for Pb-free soldering.

A

A

D

C

B

B