| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: D381A | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

General Description:

The Durel

D381A is part of a family of highly integrated EL

drivers based on Durel's patented three-port (3P) topology, which

offers built-in EMI shielding. This high-performance device uses

a proprietary circuit design for programmable wave-shaping for

low-noise performance in applications that are sensitive to audible

and electrical noise.

Data Sheet

D381A

Electroluminescent

Lamp Driver IC

MSOP-8

MSOP-10

∑ Flexible Wave Shaping Capability

∑ Cellular Phones and Handsets

∑ High Efficiency

∑ Data Organizers/PDAs

∑ External Clock Compatible

∑ LCD and Keypad Backlighting

∑ High Voltage AC Output

∑ High Performance with Low-profile Coils

Features

Applications

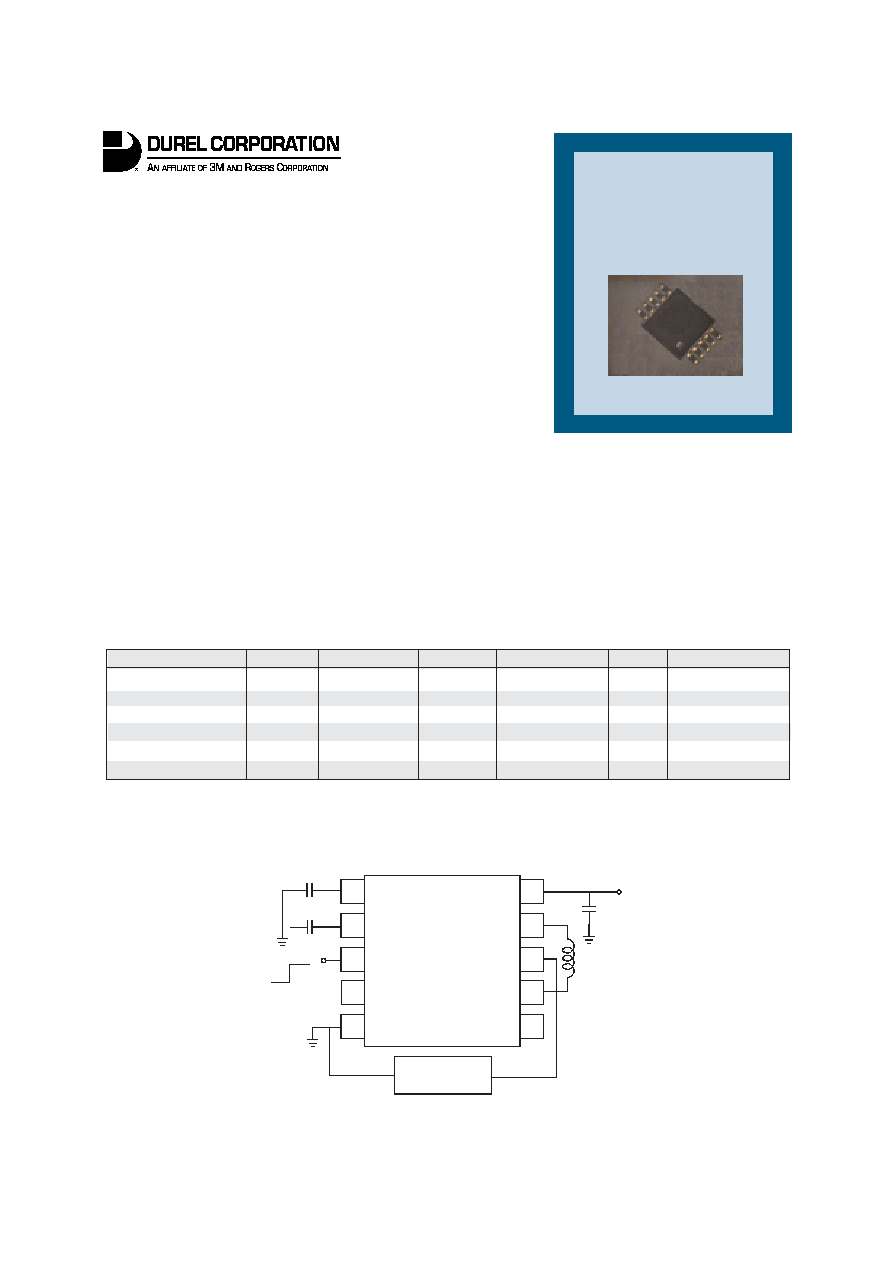

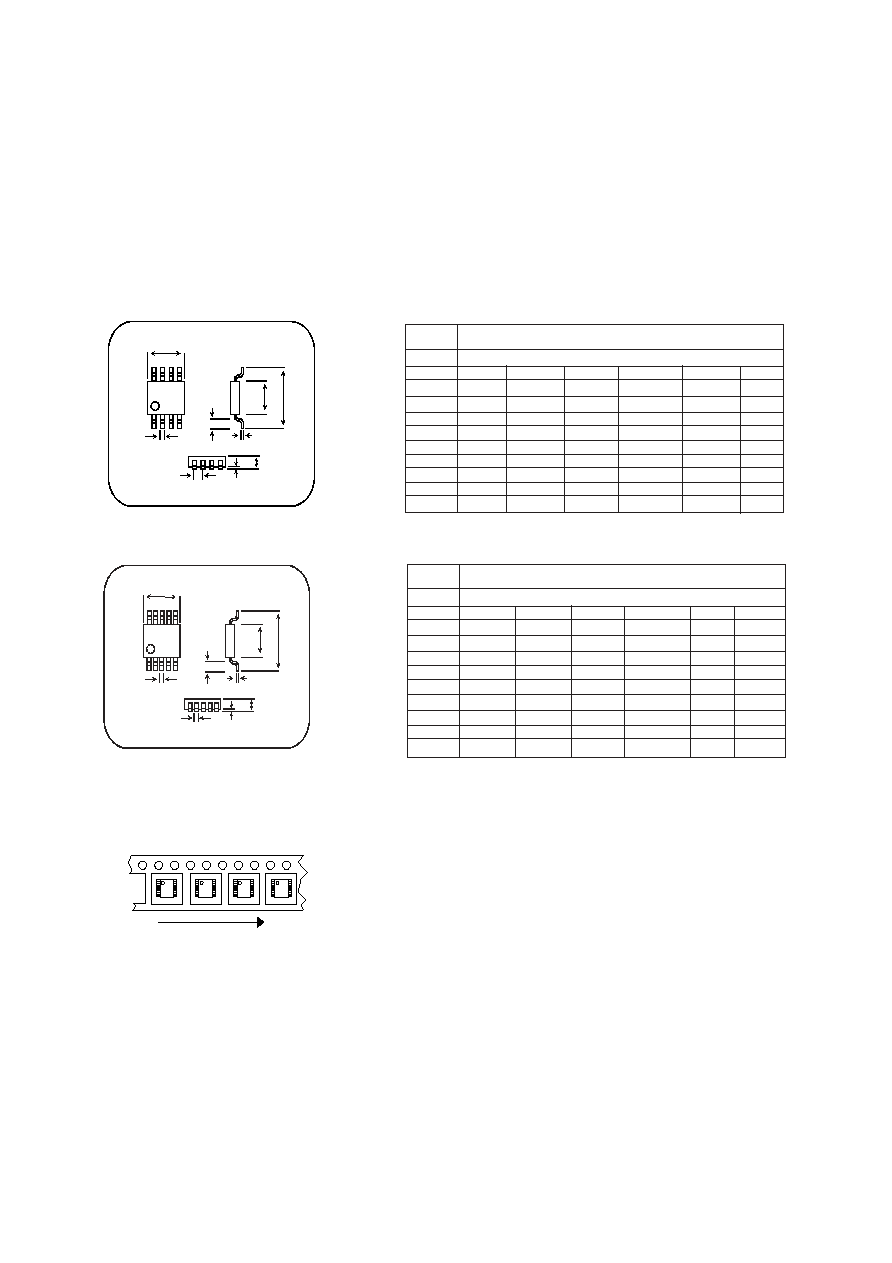

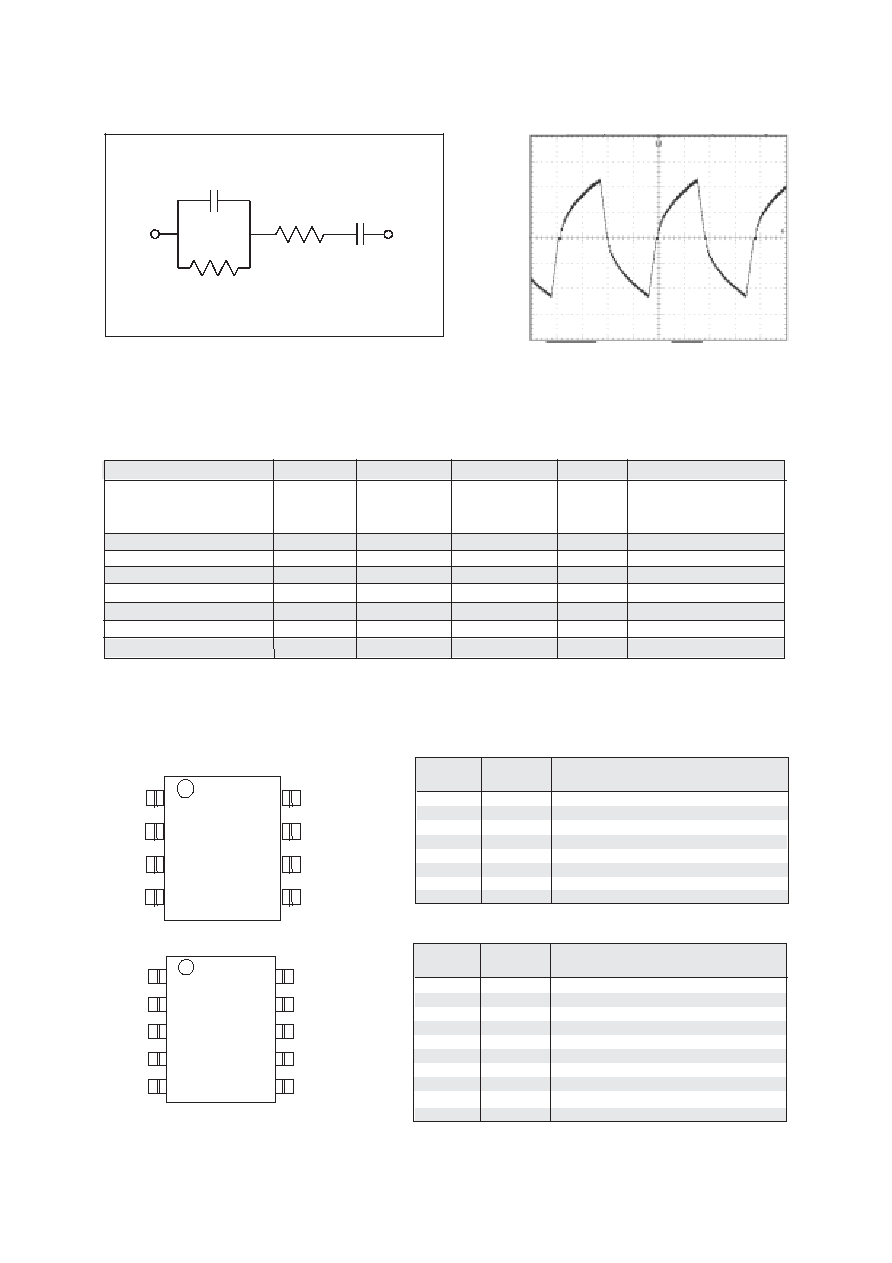

Standard Test Circuit

uA

E = GND

mA

E = 3.0V

uA

E = 3.0V

Vpp

Hz

CLF=10 nF

kHz

CHF=220 pF

Parameter

Symbol

Minimum

Typical

Maximum

Unit

Conditions

(Using Standard Test Circuit at Ta=25 ∞C unless otherwise specified.)

Lamp Driver Specifications:

Standby Current

0.04

1

Supply Current

I

43

Enable Current

40

50

60

Output Voltage

Vout

158

182

206

Lamp Frequency

LF

230

270

310

Inductor Frequency

HF

17

20

23

D381A

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

Load B

10 nF

220 pF

D381A

+3.3 V

0.1

µ

F

0.68

mH /

1.7 Ohms DCR

OFF

ON

GND

3.0V

2

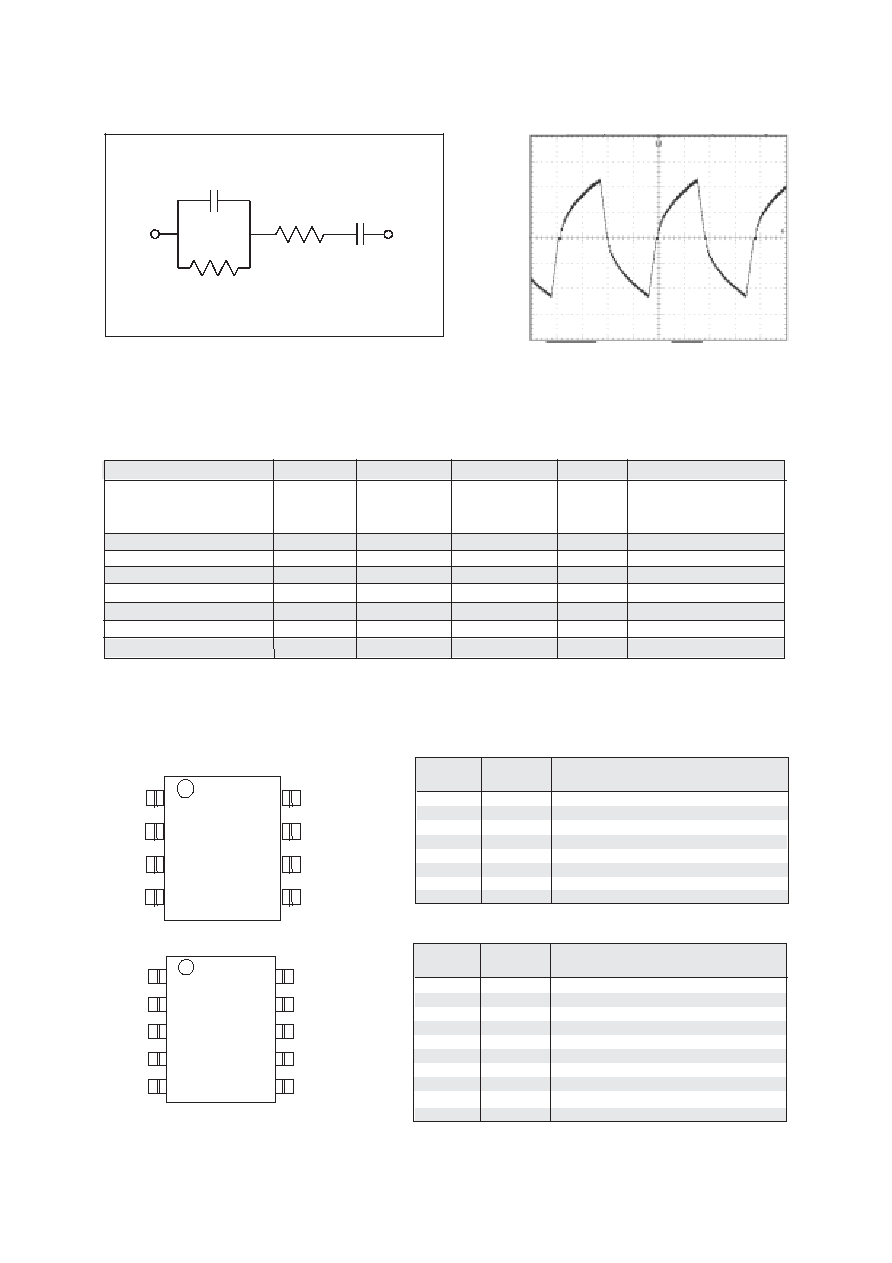

Typical Output Waveform

Load B*

Physical Data:

Absolute Maximum Ratings:

* Load B approximates a 5in

2

EL lamp.

Note: The above are stress ratings only. Functional operation of the device at these ratings or any other above

those indicated in the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods of time may affect reliability.

Parameter

Symbol

Minimum

Maximum

Unit

Comments

100

22 nF

10k

47 nF

1

2

3

4

5

10

9

8

7

6

1

CHF

High frequency oscillator capacitor/clock input

2

CLF

Lamp frequency capacitor/clock input

3

E

System enable: Wave-shaping resistor control

4

N/C

5

GND

System ground connection

6

N/C

7

L-

Negative input to inductor

8

VOUT

High voltage AC output to lamp

9

L+

Positive input to inductor

10

V+

DC power supply input

PIN # NAME

FUNCTION

PIN # NAME

FUNCTION

1

CHF

High frequency oscillator capacitor/clock input

2

CLF

Lamp frequency capacitor/clock input

3

E

System enable: Wave-shaping resistor control

4

GND

System ground connection

5

L-

Negative input to inductor

6

V

OUT

High voltage AC output to lamp

7

L+

Positive input to inductor

8

V+

DC power supply input

Supply voltage

Operating Range

V+

2.0

7.0

V

E = V+

Withstand Range

-0.4

7.0

E = GND

Enable Voltage

E

-0.4

V+

V

Output Voltage

V

OUT

220

Vpp

Peak-to-peak voltage

CHF Voltage

V

CHF

0

(V+) +0.3 V

External clock input

CLF Voltage

V

CLF

0

(V+) +0.3

V

External clock input

Operating Temperature

T

a

-40

85

∞C

Storage Temperature

T

s

-55

150

∞C

Lamp Resistance

Rlamp

100

1

2

3

4

8

7

6

5

3

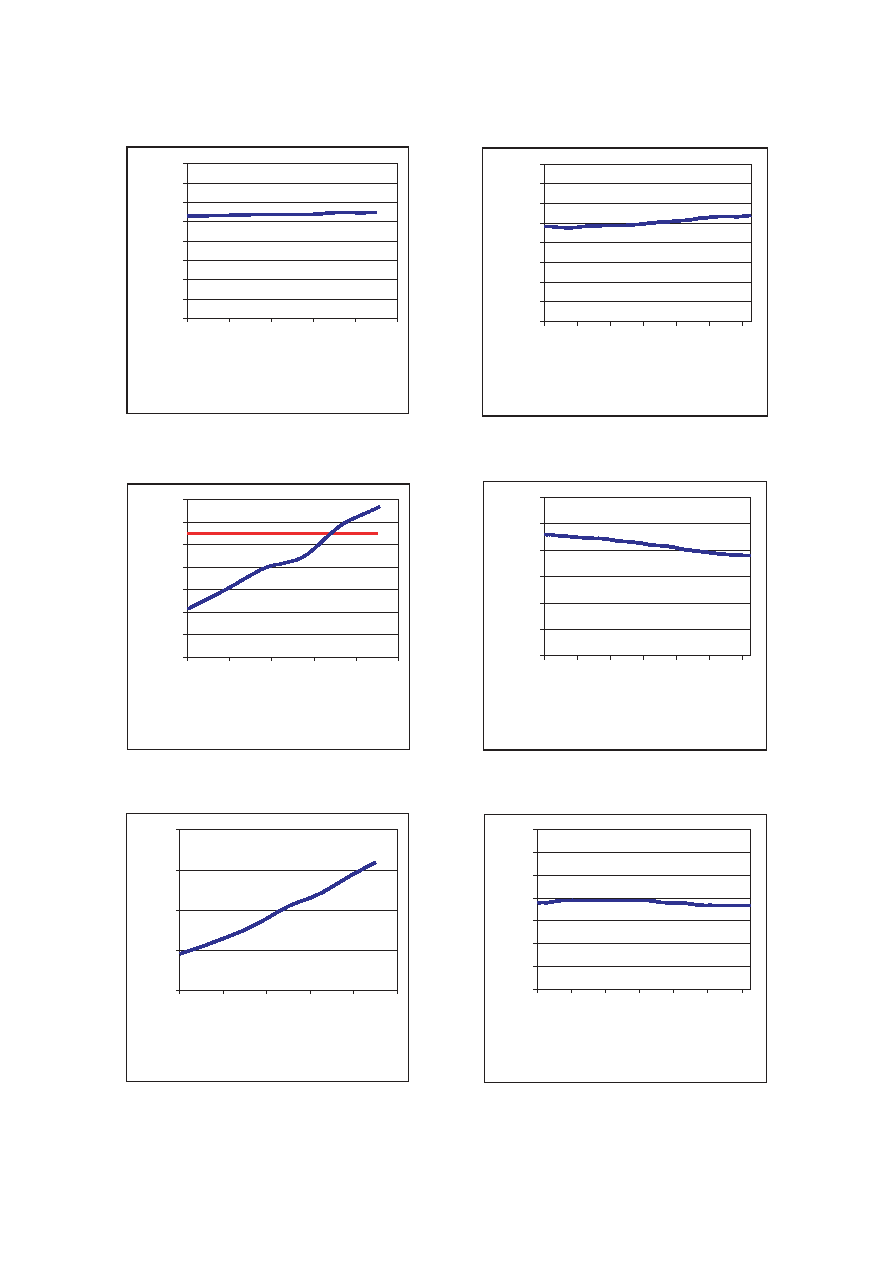

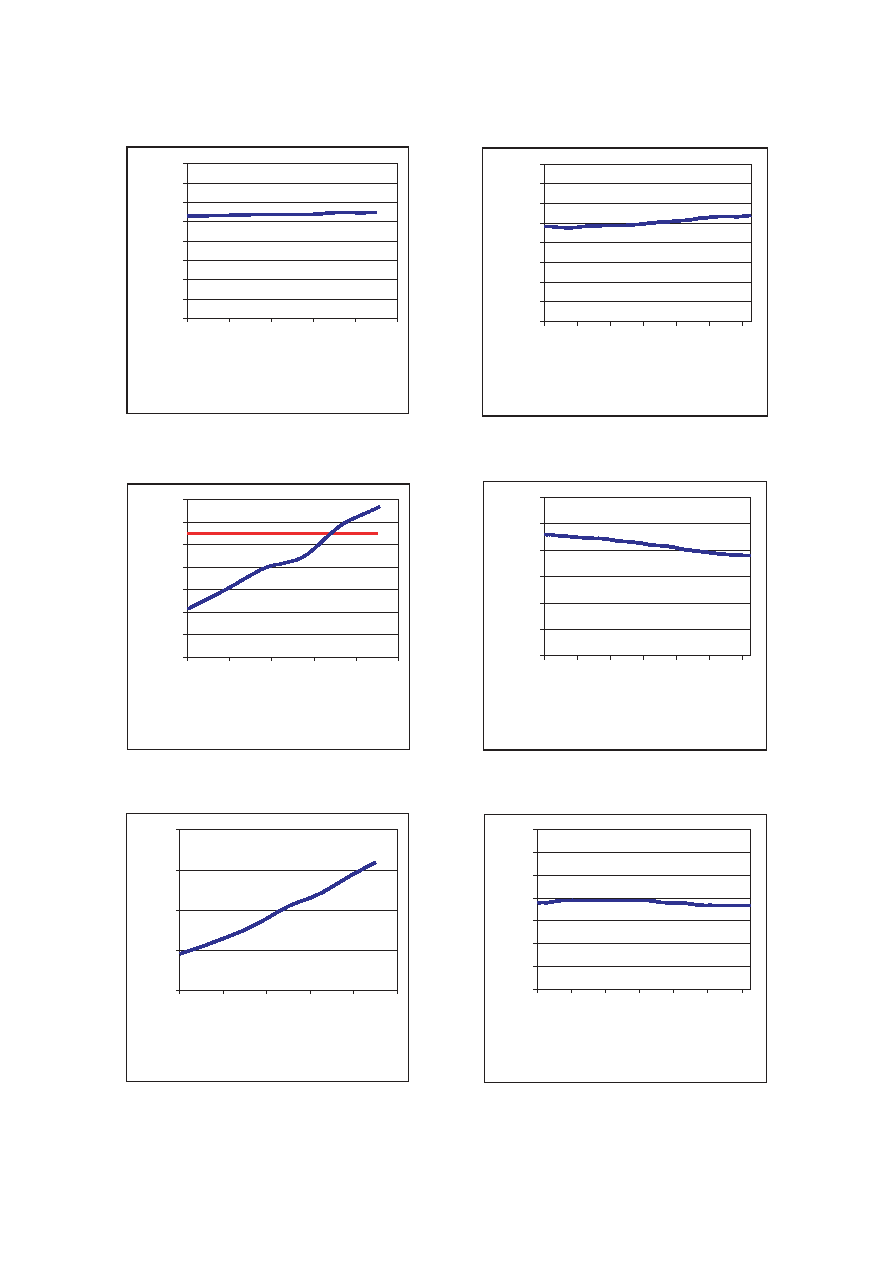

Output Voltage vs. DC Supply Voltage

0

40

80

120

160

200

240

280

2

3

4

5

6

7

DC Input Voltage

Output Voltage (Vpp)

Typical Performance Characteristics

Vout (max)=220Vpp

Output Frequency vs. DC Supply

Voltage

0

50

100

150

200

250

300

350

400

2

3

4

5

6

7

DC Input Voltage

LF (Hz)

Supply Current vs. DC Supply

Voltage

0

10

20

30

40

2

3

4

5

6

7

DC Input Voltage

Avg Supply Current (mA)

Output Frequency vs. Ambient

Temperature

0

50

100

150

200

250

300

350

400

-40

-20

0

20

40

60

80

Temperature ( C)

LF (Hz)

∞∞

∞∞

∞

Output Voltage vs. Ambient

Temperature

0

40

80

120

160

200

240

-40

-20

0

20

40

60

80

Temperature ( C)

Output Voltage (Vpp)

Supply Current vs. Ambient

Temperature

0

10

20

30

40

50

60

70

-40

-20

0

20

40

60

80

Temperature ( C)

Avg Supply Current (mA)

∞∞

∞∞

∞

∞∞

∞∞

∞

4

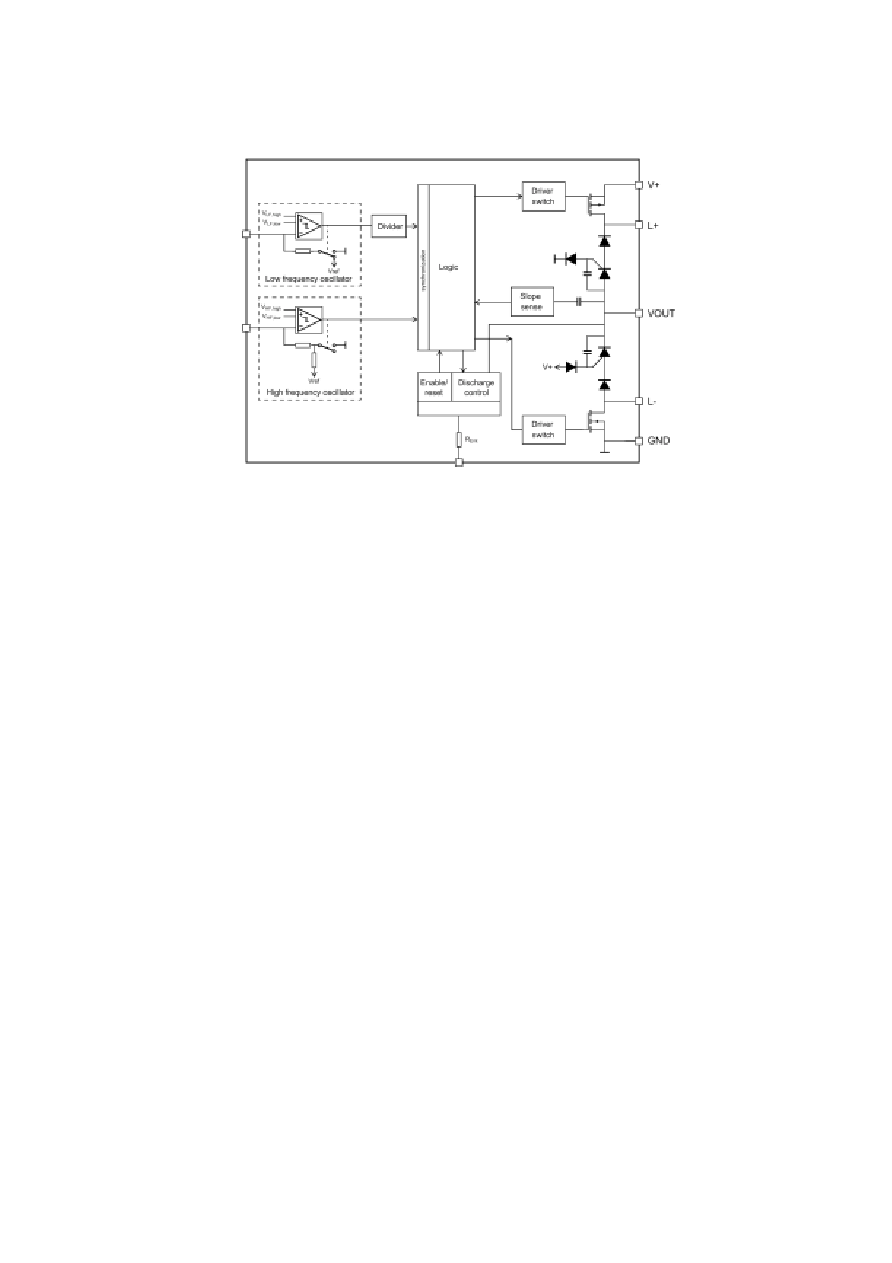

Theory of Operation

Electroluminescent (EL) lamps are essentially capacitors with one transparent electrode and a special phosphor material

in the dielectric. When a strong AC voltage is applied across the EL lamp electrodes, the phosphor glows. The

required AC voltage is typically not present in most systems and must be generated from a low voltage DC source.

Thus, Durel developed its patented Three-Port (3P) switch-mode inverter circuit to convert the available DC supply

to an optimal drive signal for high brightness and low-noise EL lamp applications. The Durel 3P topology offers the

simplicity of a single DC input, single AC output, and a shared common ground that provides an integrated EMI

shielding.

The D381A drives the EL lamp by repeatedly pumping charge through an external inductor with current from a DC

source and discharging into the capacitance of the EL lamp load. With each high frequency (HF) cycle the voltage on

the lamp is increased. At a period specified by the lamp frequency (LF) oscillator, the voltage on the lamp is discharged

to ground and the polarity of the inductive charging is reversed. By this means, an alternating positive and negative

voltage is developed at the single output lead of the device to one of the electrodes of the EL lamp. The other lamp

electrode is commonly connected to a ground plane, which can then be considered as electrical shielding for any

underlying circuitry on the application.

The EL driving system is divided into several parts: on-chip logic and control, on-chip high voltage output circuitry,

discharge logic circuitry, and off-chip components. The on-chip logic controls the output frequency (LF), as well as the

inductor switching frequency (HF), and HF and LF duty cycles. These signals are combined and buffered to regulate

the high voltage output circuitry. The output circuitry handles the power through the inductor and delivers the high

voltage to the lamp. The selection of off-chip components provides a degree of flexibility to accommodate various lamp

sizes, system voltages, and brightness levels. Since a key objective for EL driver systems is to save space and cost,

required off-chip components were kept to a minimum.

Durel provides a D381A Designer's Kit, which includes a printed circuit evaluation board intended to aid you in

developing an EL lamp driver configuration using the D381A that meets your requirements. A section on designing

with the D381A is included in this datasheet to serve as a guide to help you select the appropriate external components

to complete your D381A EL driver system.

Typical D381A configurations for driving EL lamps in various applications are shown on the following page. The

expected system outputs, such as lamp luminance, lamp output frequency and voltage and average supply current

draw, for the various sample configurations are also shown with each respective figure.

Block Diagram of the Driver Circuitry

CLF

CHF

E

5

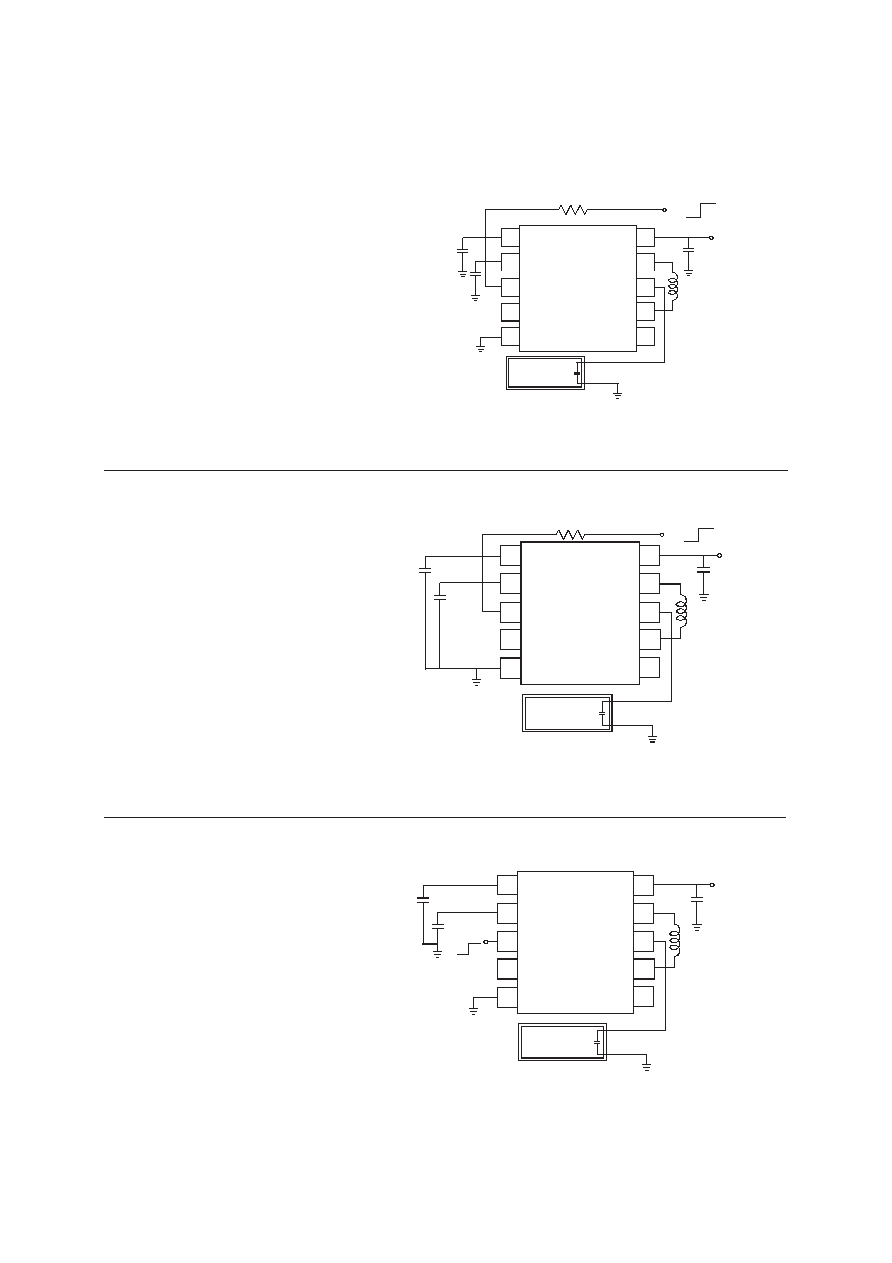

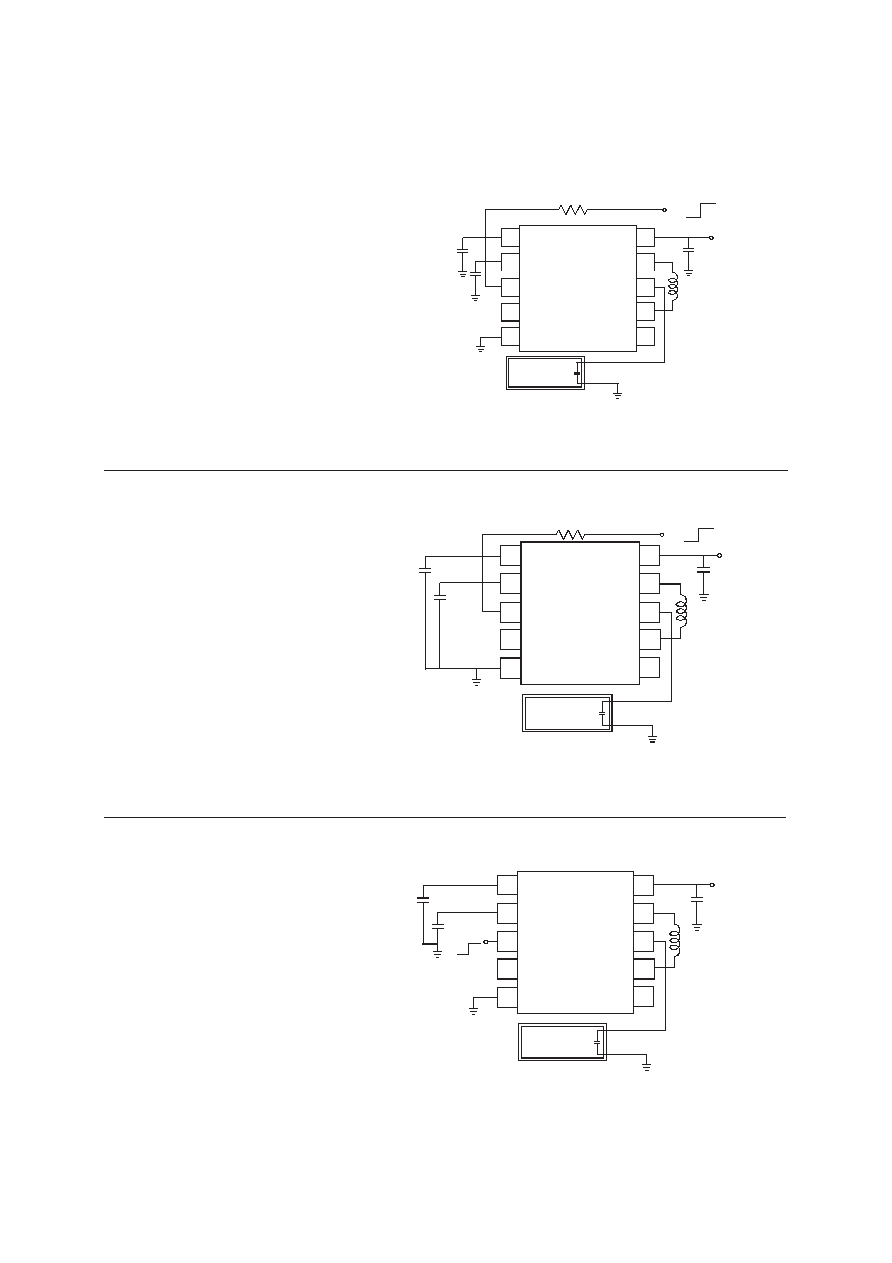

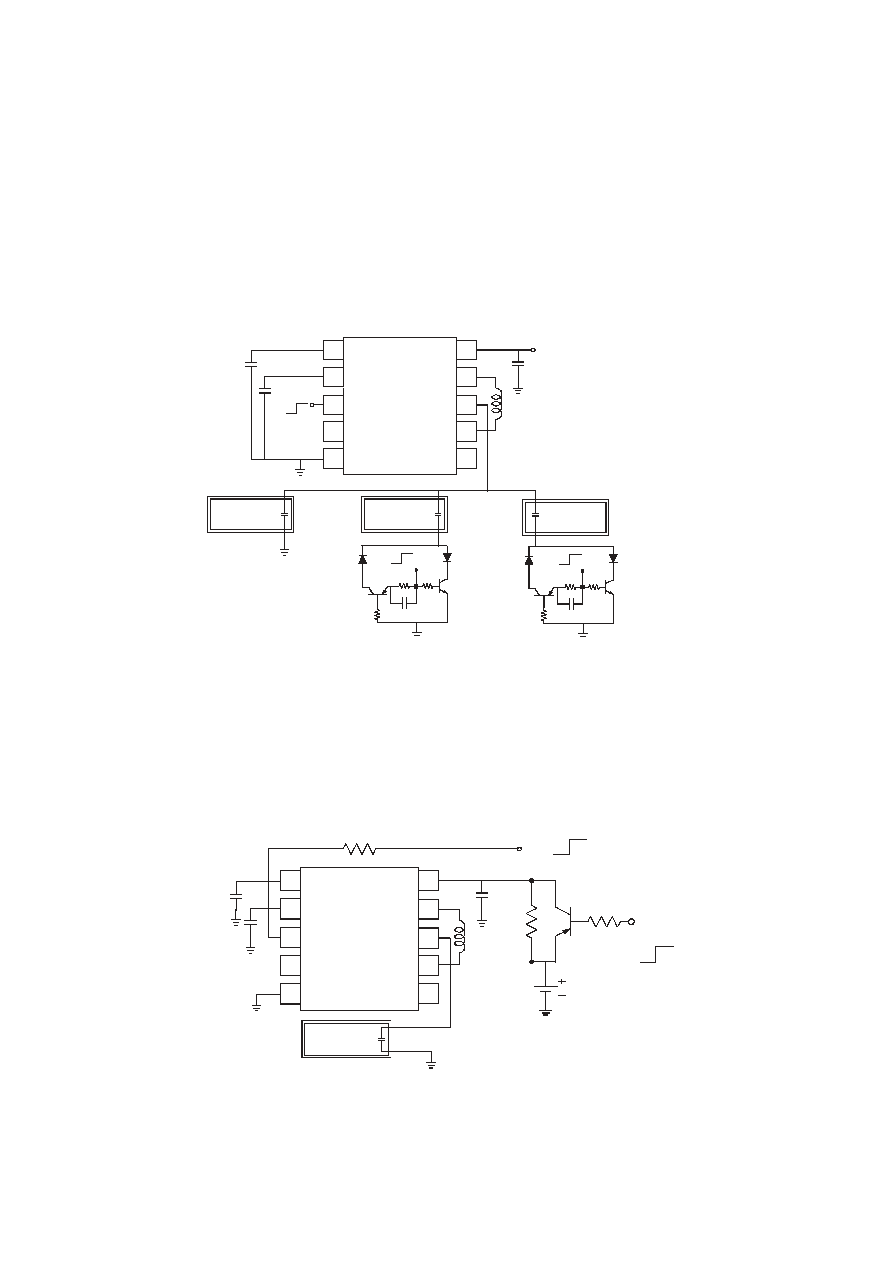

Typical D381A EL Driver Configurations

3.0V Handset LCD

Typical Output

Luminance= 9.7 fL (33.2 cd/m

2

)

Lamp Frequency = 392 Hz

Supply Current = 15 mA

Vout = 210 Vpp

Load = 1.5 in

2

(950 mm

2

)Durel Green EL

5.0V PDA

Typical Output

Luminance = 7.1 fL (24.35 cd/m

2

)

Lamp Frequency = 280 Hz

Supply Current = 18 mA

Vout = 211 Vpp

Load = 4 in

2

(2580 mm

2

) Durel Green EL

3.3V Handset LCD and Keypad

Typical Output

Luminance = 6.9 fL (23.6 cd/m

2

)

Lamp Frequency = 266 Hz

Supply Current = 13 mA

Vout = 200 Vpp

Load = 2.25in

2

(1550 mm

2

) Durel Green EL

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

1.5 in

2

EL Lamp

6.8 nF

.68mH Murata LQH4N

68 pF

D381A

3.0V

1.0

µ

F

82k

OFF

ON

GND

3.0V

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

2.25 in

2

EL Lamp

10 nF

1mH Sumida CLS62

68 pF

D381A

1.0 u F

82k

OFF

ON

GND

3.0V

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

4 in

2

EL Lamp

1.0 nF

Bujeon BDS4020S

1.5 mH

68 pF

D381A

+5.0 V

1.0 u F

OFF

ON

GND

5.0V

6

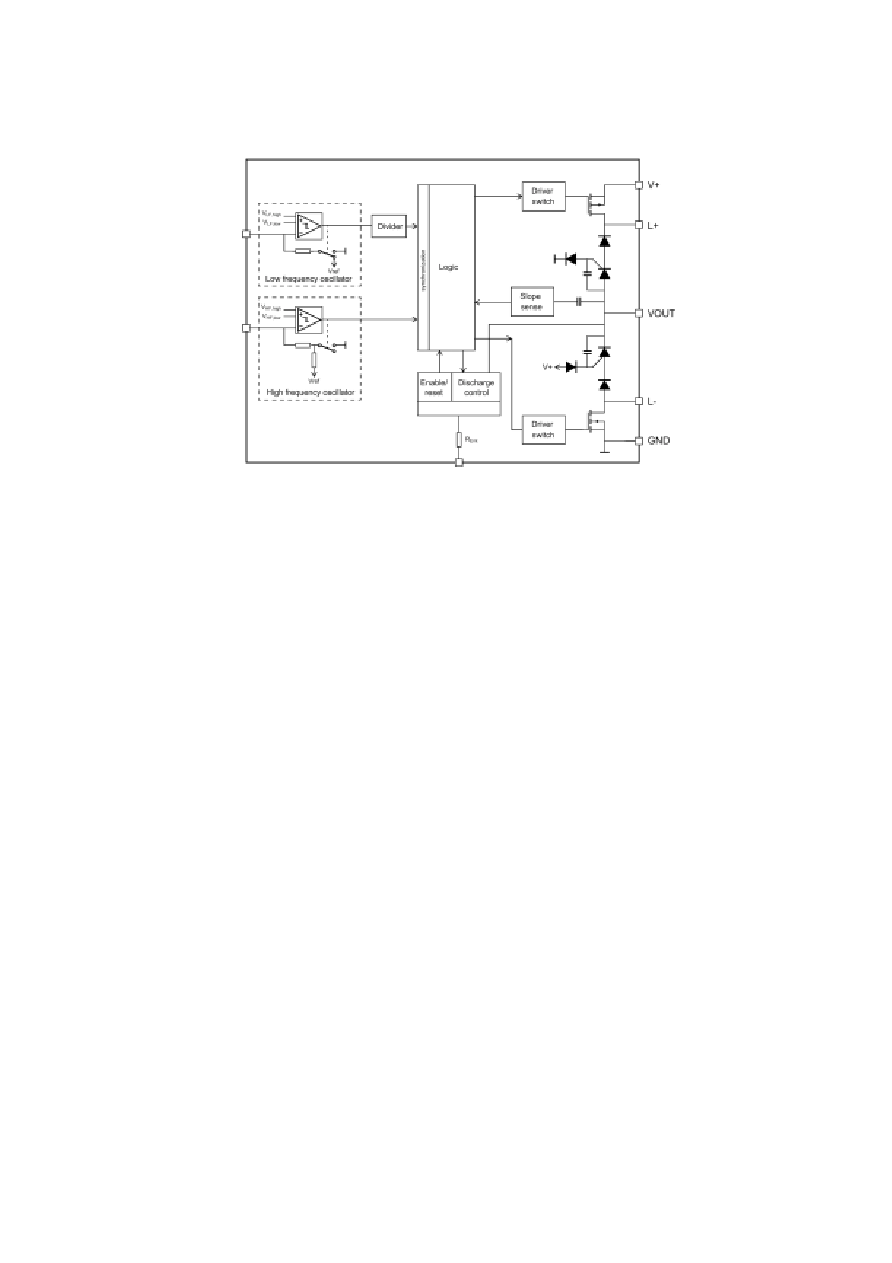

Designing With D381A

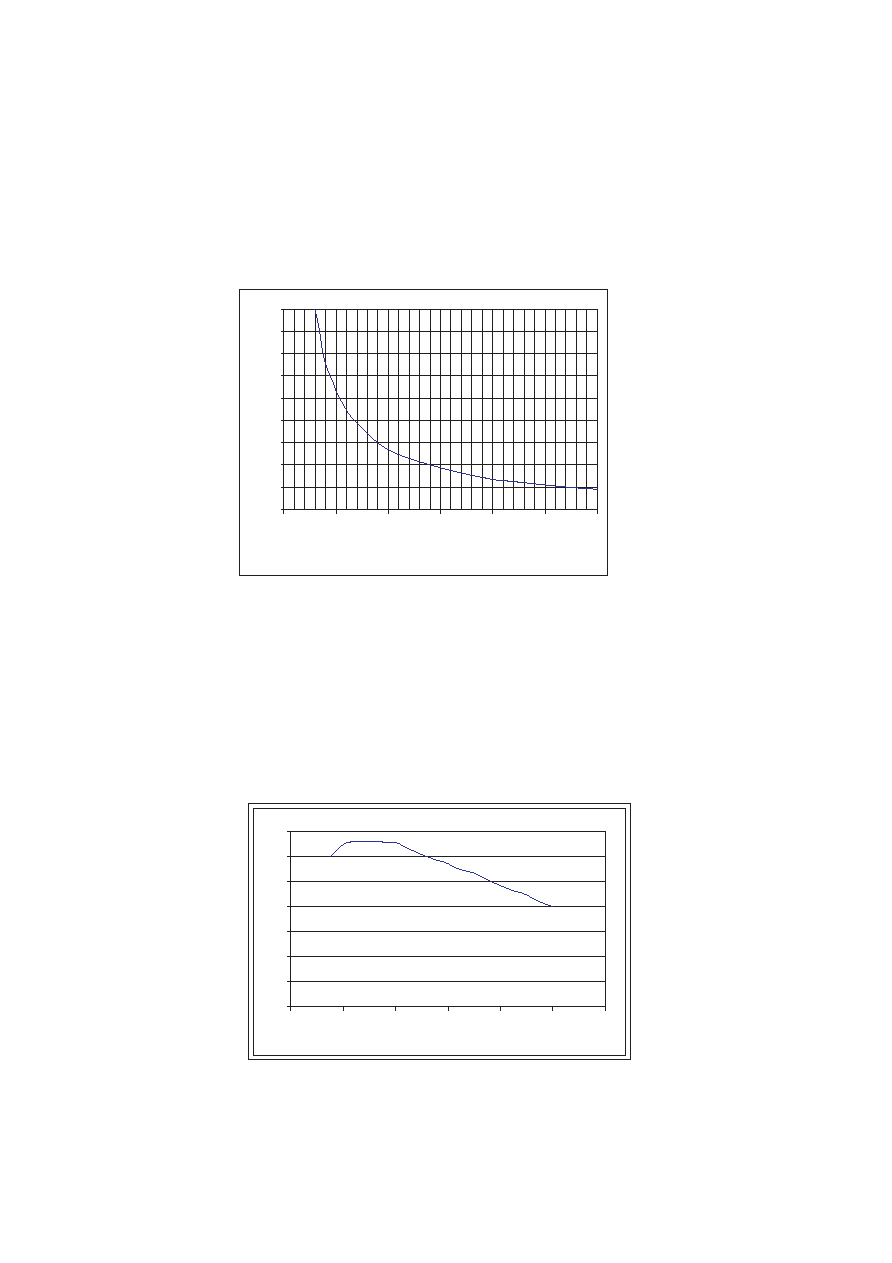

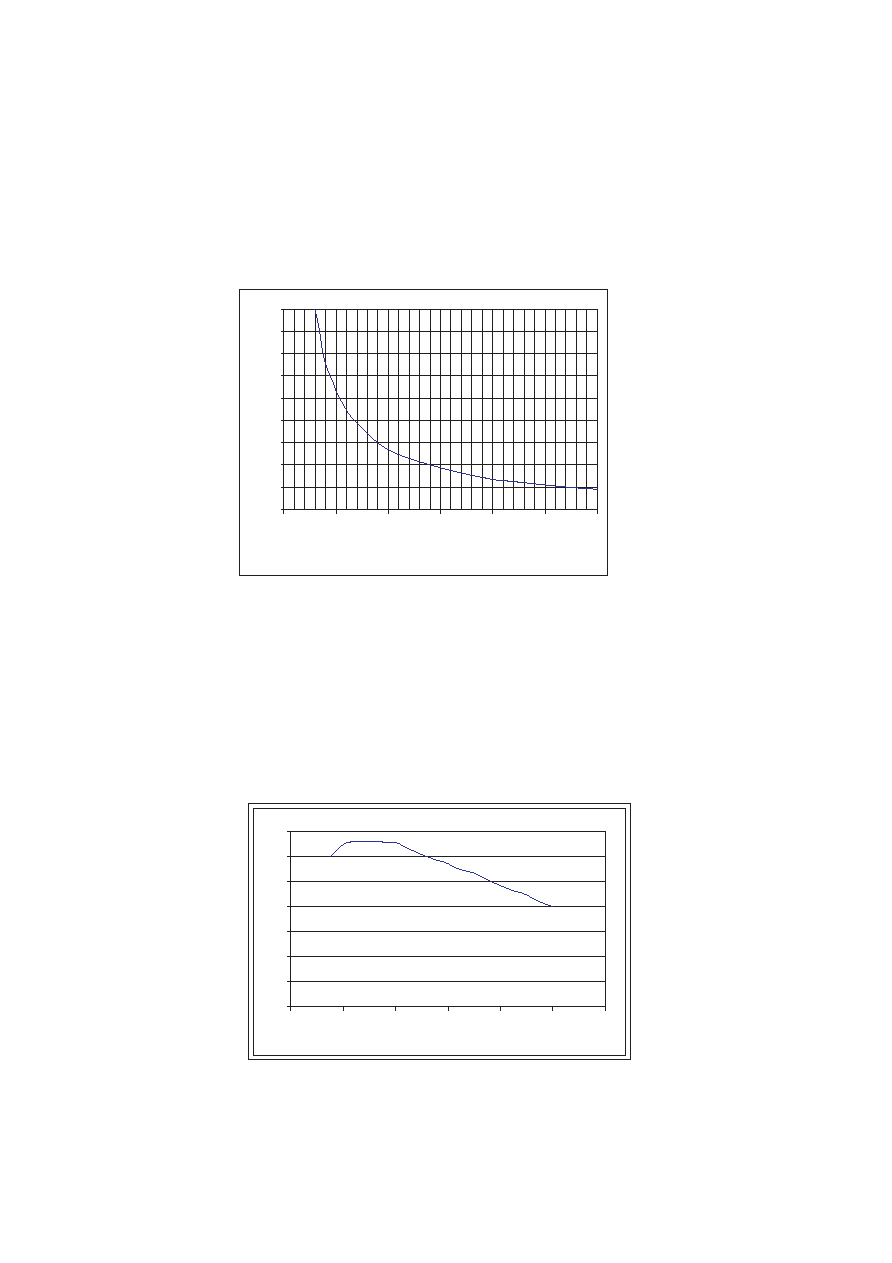

I. Lamp Frequency Capacitor (CLF) Selection

Selecting the appropriate value of lamp frequency capacitor (CLF) for the low frequency oscillator will specify the

output frequency of the D381A EL driver. Lamp frequencies of 200-500 Hz are typically used. Figure 1 graphically

represents the inversely proportional relationship between the CLF capacitor value and the oscillator frequency.

Alternatively, the lamp frequency may also be controlled with an external clock signal. There is an internal frequency

divider in the device so that the output lamp frequency will be half of the input clock signal. For example, if a 500Hz

input clock signal is used, the resulting lamp frequency will be 250Hz. The clock signal input voltage should not exceed

V+.

The selection of the CLF value can also affect the brightness of the EL lamp because of its control of the lamp frequency

(LF). Although input voltage and lamp size can change EL lamp frequency as well, LF mainly depends on the CLF

value selected or the frequency of the input clock signal to CLF. Figure 2 shows typical brightness of a D381A circuit

with respect to lamp frequency. In this example, the inductor and CHF values were kept constant while varying LF.

Figure 1: Typical Lamp Frequency vs. CLF Capacitor

Figure 2: Luminance vs. Lamp Frequency

(V+=3.0V, 2.4in

2

Durel 3 Green EL Lamp Load)

0

100

200

300

400

500

600

700

800

900

0

5

10

15

20

25

30

CLF (nF)

Lamp Frequency (Hz)

0

1

2

3

4

5

6

7

0

200

400

600

800

1000

1200

Lamp Frequency (Hz)

Lamp Luminance (fL)

7

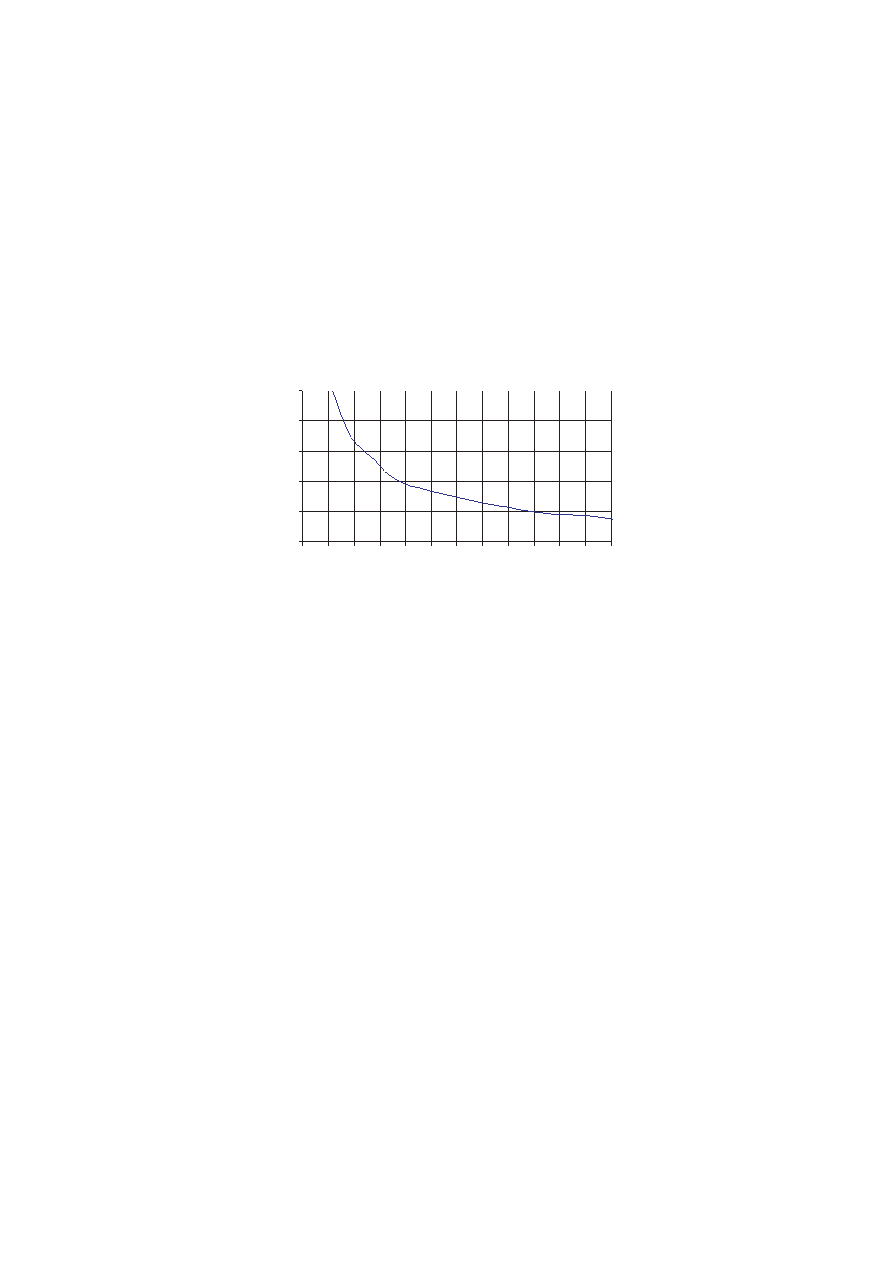

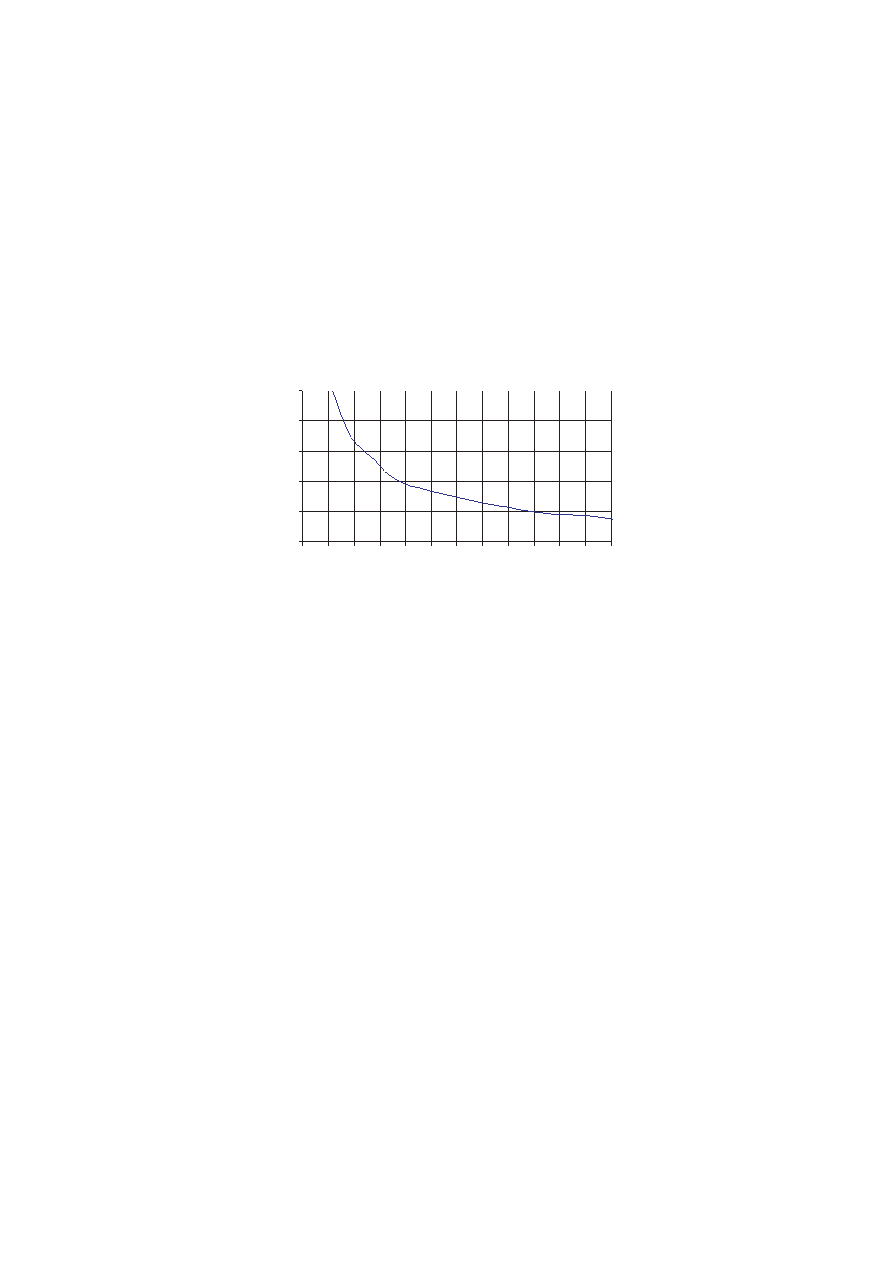

II. High Frequency Capacitor (CHF) Selection

Selecting the appropriate value of capacitor for the high frequency oscillator (CHF) will set the inductor switching

frequency of the D381A IC. High inductor frequency allows for more efficient use of inductor coils with lower values.

However, care must be taken that the charge pumping does not reach a continuous mode at very high frequency when

the voltage is not efficiently transferred to the lamp load. Figure 3 graphically represents the effect of the CHF value

on the oscillator frequency at V+=3.0V.

Figure 3: Typical InductorFrequency vs. CHF Capacitor

The inductor switching frequency may also be controlled with an external clock signal. The inductor will charge during

the low portion of the clock signal and discharge into the EL lamp during the high portion of the clock signal. The

positive duty cycle used for the external high frequency clock signal is usually between 15%-75%, with a typical value

of 15%-20% for maximum brightness. The clock signal input voltage should not exceed V+.

0

20

40

60

80

100

120

0

25

50

75 100 125 150 175 200 225 250 275 300

CHF (pF)

Inductor Frequency (kHz)

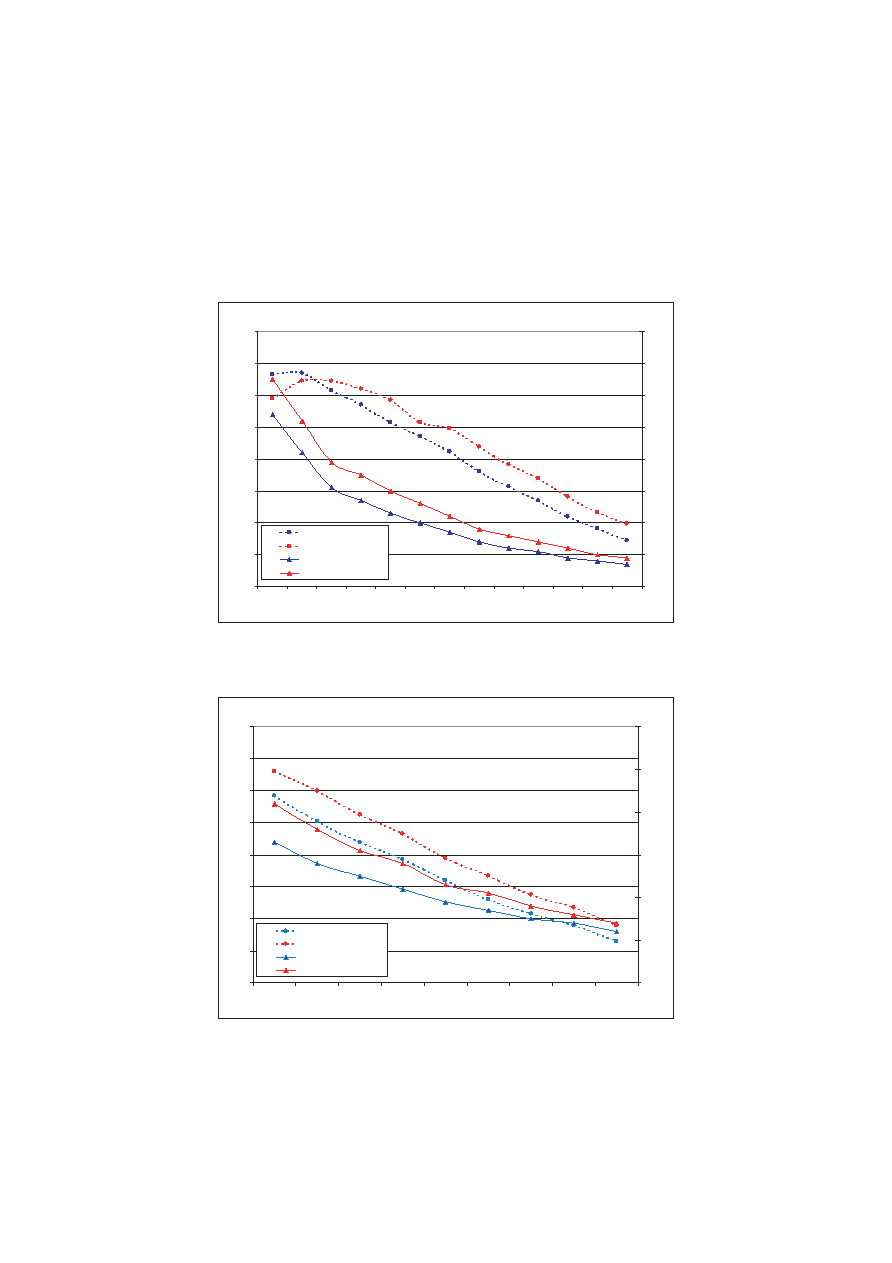

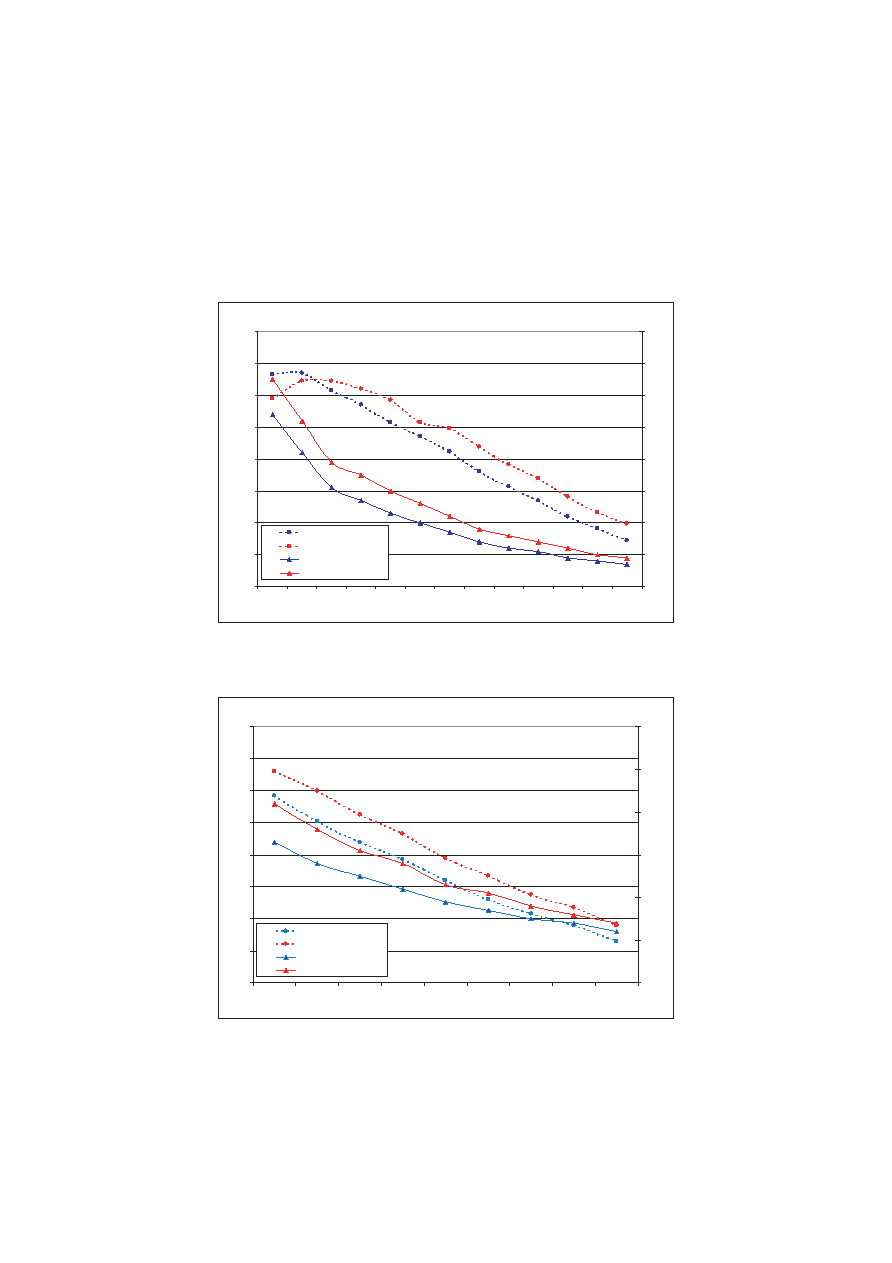

The inductor value and inductor switching frequency have the greatest impact on the output brightness and current

consumption of the EL driver. Figures 4 and 5 show the dependence of brightness and current draw of a D381A circuit

on coil values and CHF values for two sample EL lamps sizes and input voltages. The CLF value was chosen such that

the output voltage did not exceed 220Vpp. Please note that the DC resistance (DCR) of inductors with the same nominal

inductance value may vary with manufacturer and inductor type. Thus, inductors made by a different manufacturer

may yield different outputs, but the trend of the different curves should be similar.

III. Inductor (L) Selection

Figure 4: Brightness and current vs. inductor and CHF value

(Conditions: V+=3.0V, 2in

2

EL Lamp)

Figure 5: Brightness and current vs. inductor and CHF value

(Conditions: V+=5.0V, 4in

2

EL Lamp)

0

2

4

6

8

10

12

14

16

0.15

0.22

0.33

0.39

0.47

0.56

0.68

0.82

1.00

1.20

1.50

1.80

2.20

Inductor (mH)

0

10

20

30

40

50

60

70

80

68 pF Brightness

100 pF Brightness

68 pF Current

100 pF Current

Brightness (ftL)

Current (mA)

0

2

4

6

8

10

12

14

16

0.68

0.82

1

1.2

1.5

1.8

2.2

2.7

3.3

Inductor (mH)

0

10

20

30

40

50

60

68 pF Brightness

100 pF Brightness

68 pF Current

100 pF Current

Brightness (ftL)

Current (mA)

8

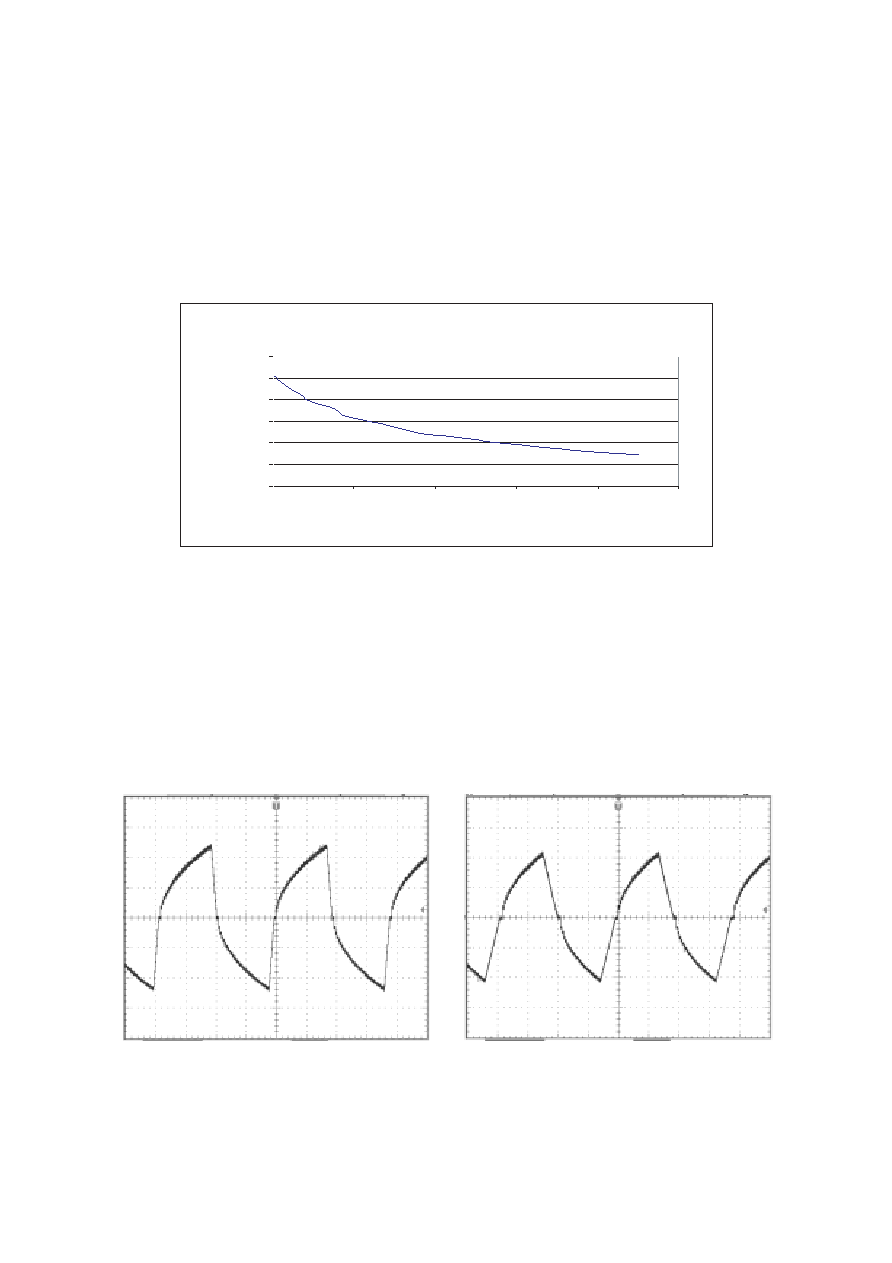

IV. Wave-Shape Selection

The D381A driver IC uses a patented wave-shaping technique for reducing audible noise from an EL lamp. The linear

discharge of the output waveform may be adjusted by selecting a proper value for the wave-shaping resistor (Rena) to

the E pin. The optimal discharge level for an application depends on the lamp size, lamp brightness, and application

conditions. To ensure that the D381A is configured optimally, various discharge levels should be evaluated. In many

cases, the lower discharge levels result in lower audible noise from the EL lamp.

9

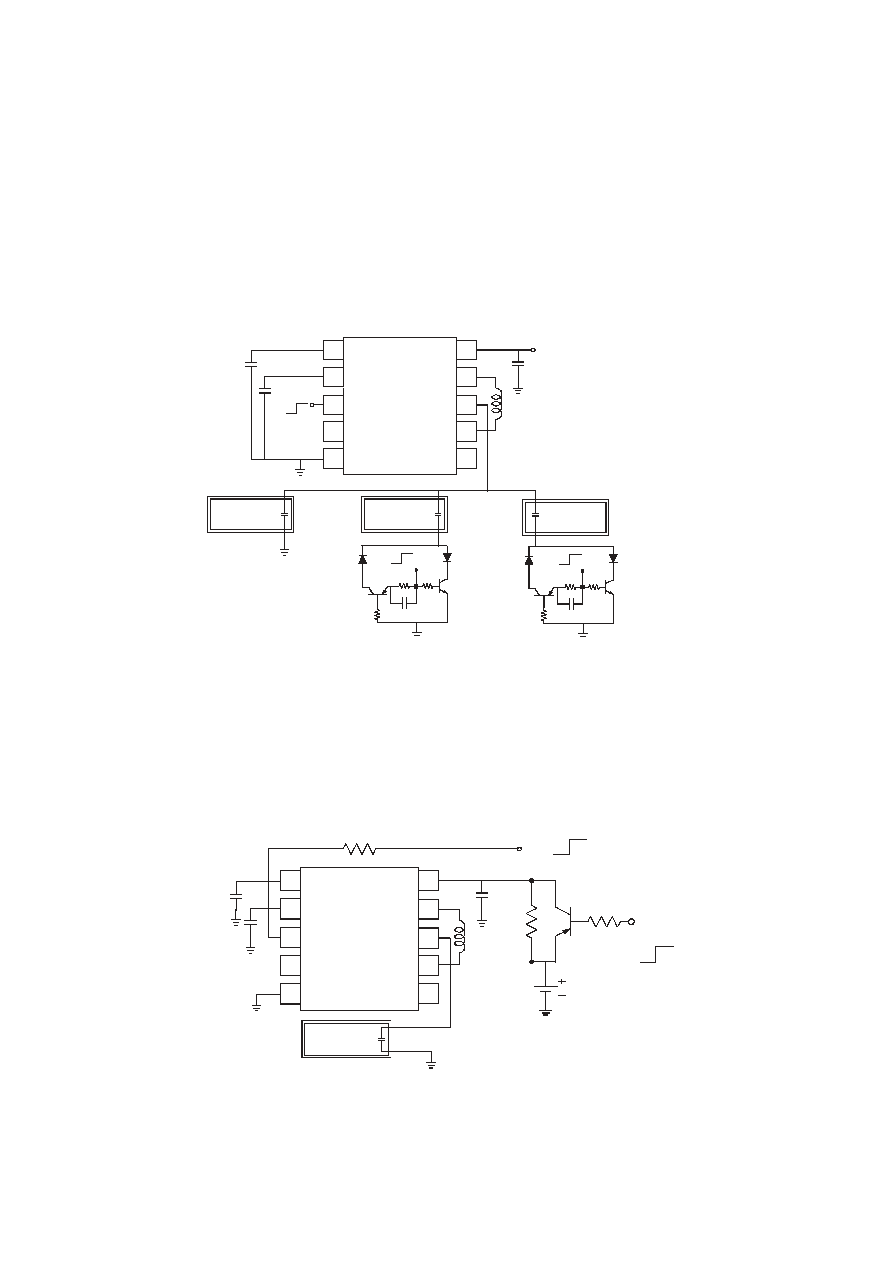

Typical waveshapes corresponding to the various discharge levels for a 4in

2

lamp are shown below. The waveshape

with the smoothest transition slope in the discharge portion of the waveform yields the lowest audible noise.

R

ena

=0

R

ena

=82k

Figure 6: R

ena

selection for discharge control (C

LOAD

=15nF), (E= 3V)

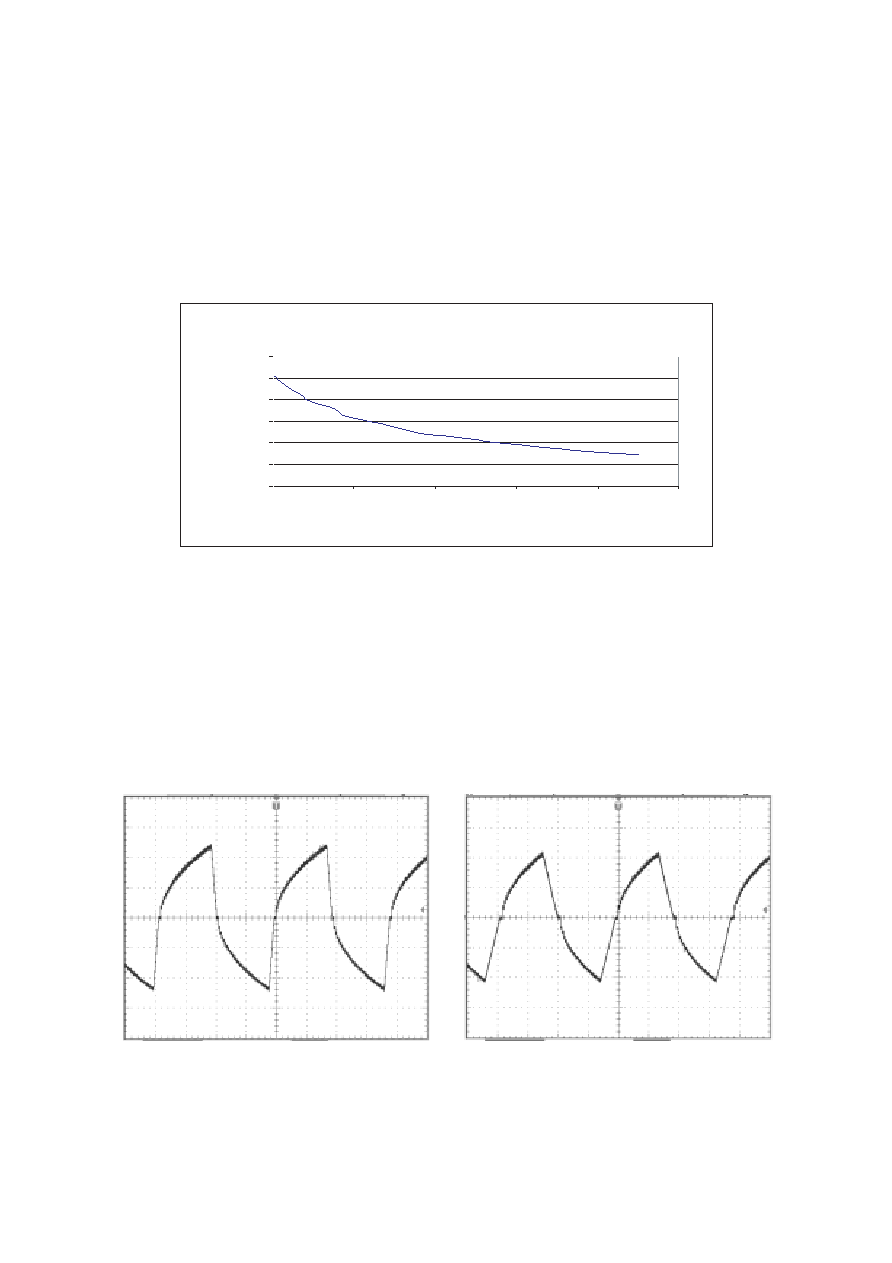

D381 Discharge Control

0.00

2.00

4.00

6.00

8.00

10.00

12.00

0.0

20.0

40.0

60.0

80.0

100.0

Rena (KOhm)

ldischarge (mA)

D381A Design Ideas

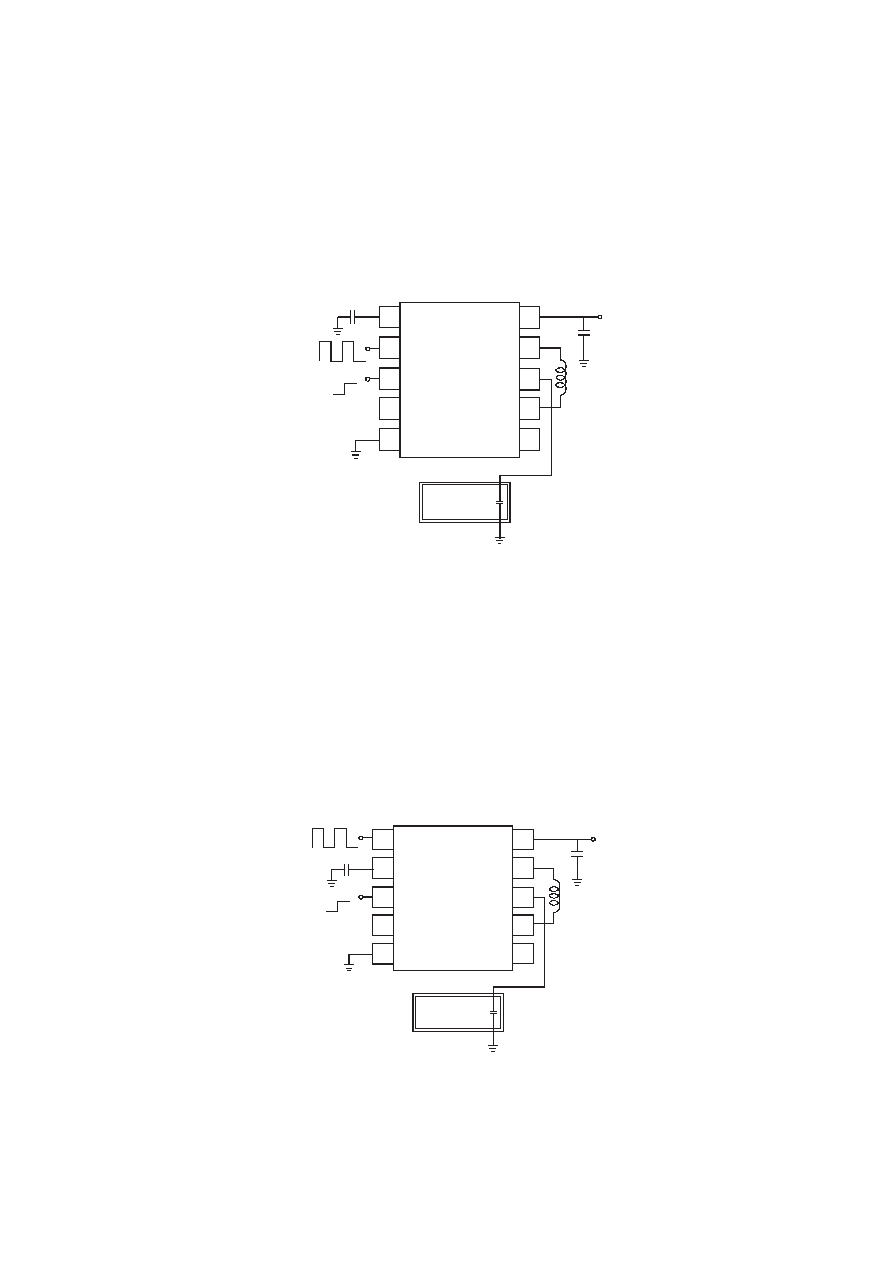

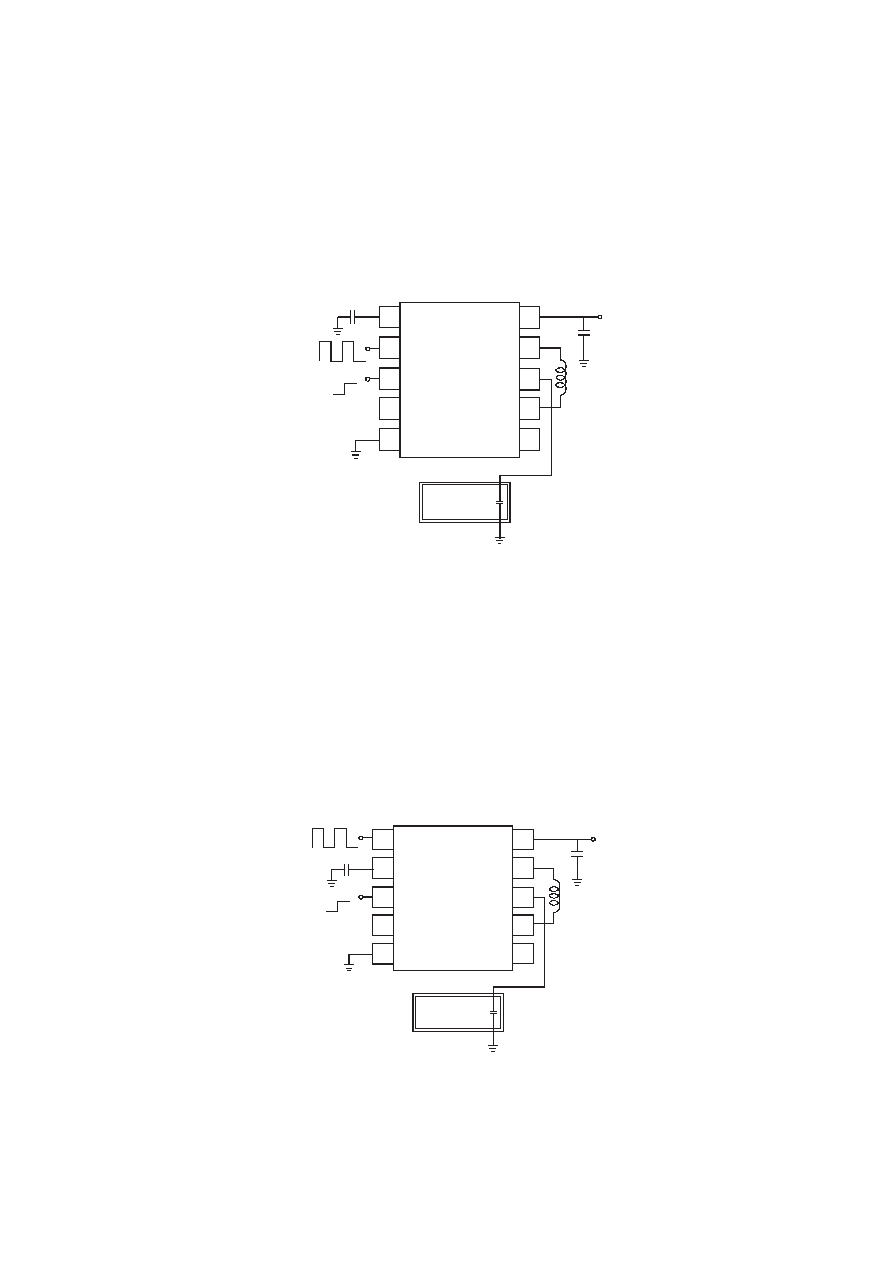

I. Driving Multi-segment Lamps

The D381A may be used to drive multiple EL lamp segments. An external transistor switching circuit is used to turn

each lamp segment on or off independently or simultaneously. A high signal at the corresponding E input will enable

the corresponding lamp segment. In this configuration, EL Lamp 1 is always turned on when the IC is enabled.

Otherwise, always make sure that at least one segment is selected when the D381A is enabled.

10

II. Two-Level Dimming

Two level dimming may be achieved with the circuit below. When DIM is low, the external PNP transistor is saturated

and the EL lamp runs at full brightness. When DIM is high, the external PNP turns off and the 47

resistor reduces the

voltage at (V+) and dims the EL lamp.

OFF

ON

V

bat

R

switch

1k

DIM

2N3906

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

EL

Lamp

CLF

L

CHF

D381A

V

ENA

1.0 u F

R

enable

BRIGHT

DIM

3V

0V

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E1

N/C

GND

N/C

L-

Vout

L+

V+

D381A

Vbat

0.1 u F

OFF

ON

EL Lamp 2

EL Lamp 3

E2

2.2K

4.7K

BAS21LT1

BAS21LT1

MMBT5401LT1

MMBT5551LT1

1K

E3

2.2K

4.7K

BAS21LT1

BAS21LT1

MMBT5401LT1

MMBT5551LT1

1K

EL Lamp 1

100 nF

100 nF

OFF

ON

OFF

ON

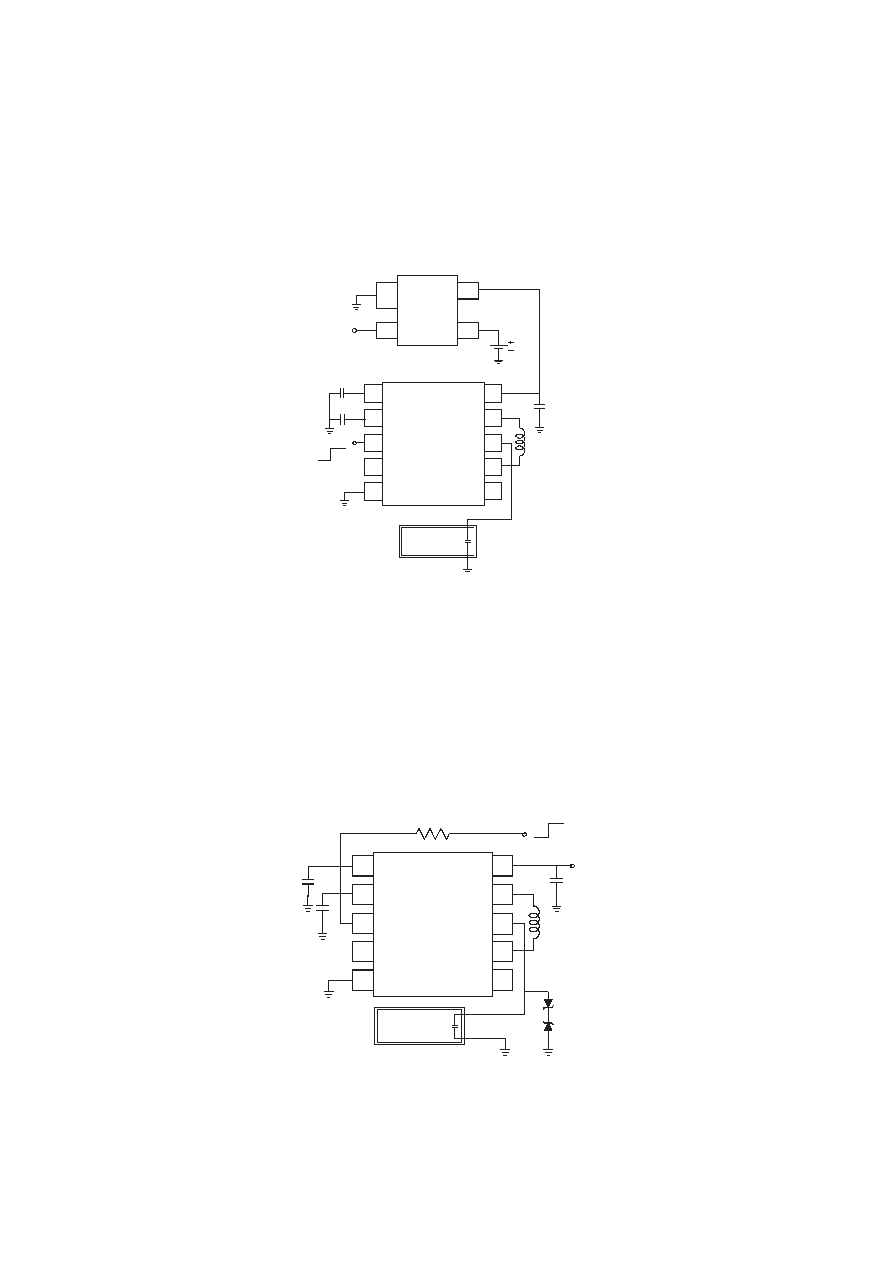

III. Lamp Frequency Control with an External Clock Signal

An external clock signal may be used to control the EL lamp frequency (LF) of the D381A instead of using a capacitor.

There is an internal frequency divider in the IC so that the output lamp frequency will be half of the input clock signal.

For example, if a 500Hz input clock signal is used, the resulting lamp frequency will be 250Hz. The clock signal voltage

should not exceed V+. A typical duty cycle for the clock input is +50%.

IV. EL Brightness through HF Clock Pulse Width Modulation

The inductor oscillating frequency may also be controlled on the D381A EL driver IC using an external clock input to

CHF. In addition, pulse-width modulation of the external HF clock signal to the D381A may be used to regulate the

brightness of the EL lamp load. High frequency input is typically in the range of 10kHz to 40kHz, with duty cycle in the

range of 15% to 100%. In general, a lower HF frequency results in higher brightness and using a lower duty cycle

results in higher brightness. The clock signal voltage should not exceed V+. Prior to finalization of the circuit, contact

Durel to verify that the frequency, duty cycle, and setup chosen are acceptable for EL driver performance.

11

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

D381A

Vbat

0.1 u F

OFF

ON

EL Lamp

1.0V Min

0.2V Max

10KHz - 40KHz

15%-75% Duty

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

D381A

Vbat

0.1 uF

OFF

ON

EL Lamp

1.0V Min

0.2V Max

200Hz - 2KHz

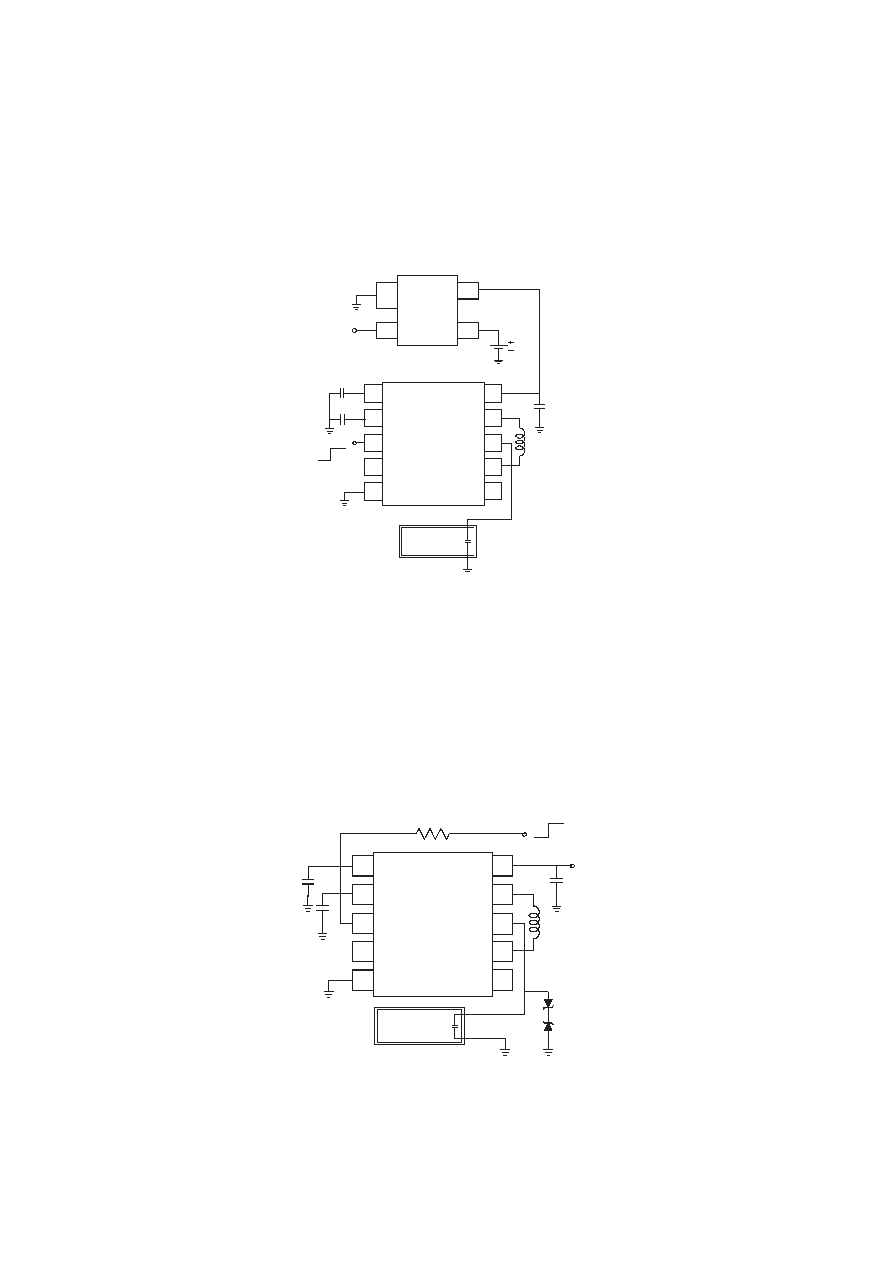

V. EL Lamp Brightness Regulation

Regulating the DC supply input voltage to the D381A will result in a constant brightness level from the EL lamp,

regardless of battery voltage. In this example, a Micrel voltage regulator is used.

12

VI. Output Voltage Limit Control

An EL driver system using the D381A driver IC should be designed such that the output voltage does not exceed the

maximum rated value of 220Vpp. A pair of zener diodes connected to the output as shown below is recommended to

limit Vout to within 200Vpp or less. This circuit protects the device from over-voltage when typical performance is near

the maximum limit for the D381A.

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

EL

Lamp

CLF

L

CHF

D381A

V

BAT

1.0 uF

R

enable

1N5271 or

equivalent

100V zener

diodes

OFF

ON

1

2

3

4

5

6

7

8

9

10

CHF

CLF

E

N/C

GND

N/C

L-

Vout

L+

V+

D381A

0.1 uF

OFF

ON

EL Lamp

Vbat

1 GND

2 E

OUT

IN

4

3

MIC5203

E

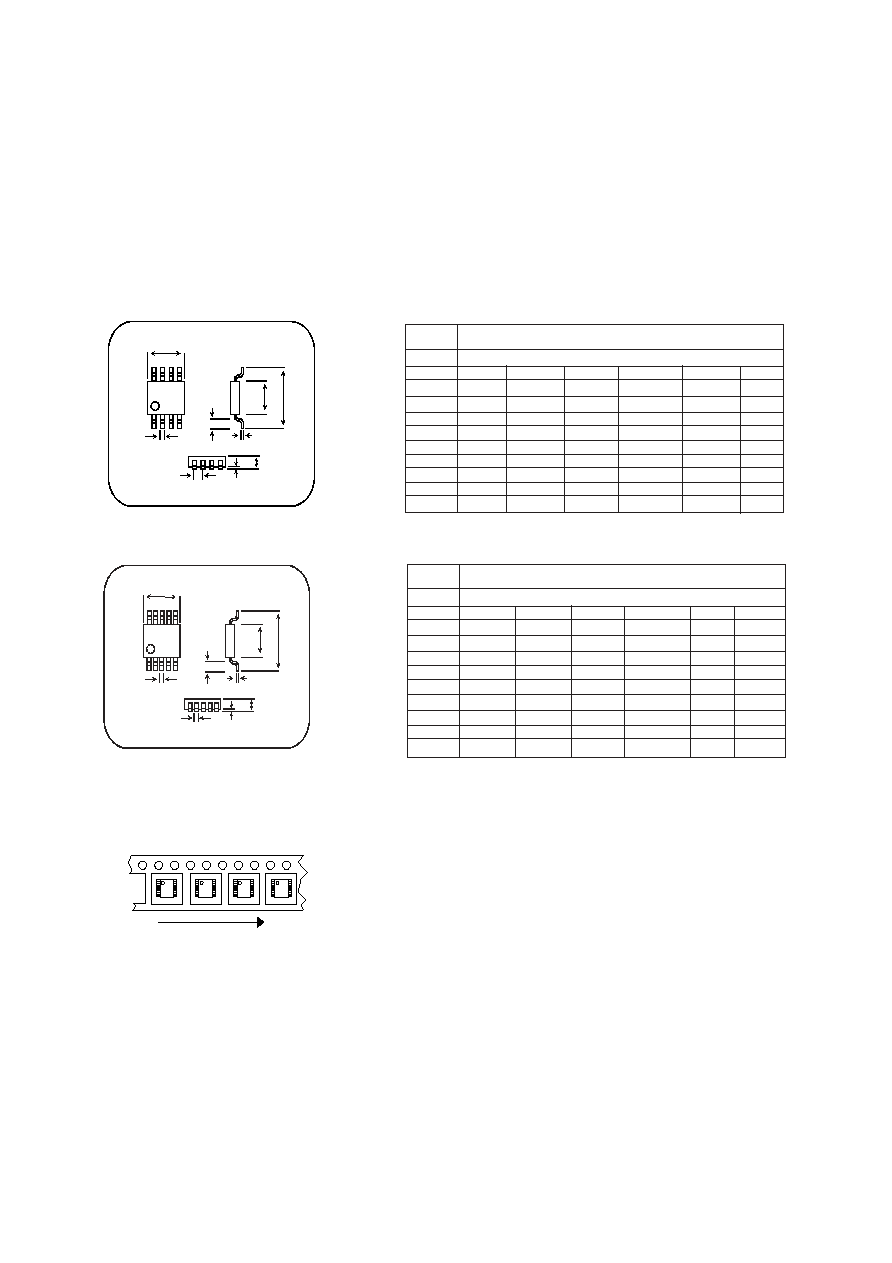

The D381A IC is available in standard MSOP-8 or MSOP-10 plastic package tape and reel. A Durel D381A Designer's

Kit (1DDD381AA-K01) provides a vehicle for evaluating and identifying the optimum component values for any

particular application using D381A. Durel engineers also provide full support to customers, including specialized

circuit optimization and application retrofits.

Ordering Information

MSOPs in Tape and Reel:

MSOP-8: 1DDD381AA-M02

MSOP-10: 1DDD381AA-M04

Tape Orientation

Embossed tape on 360 mm diameter per reel.

2500 units per reel.

13

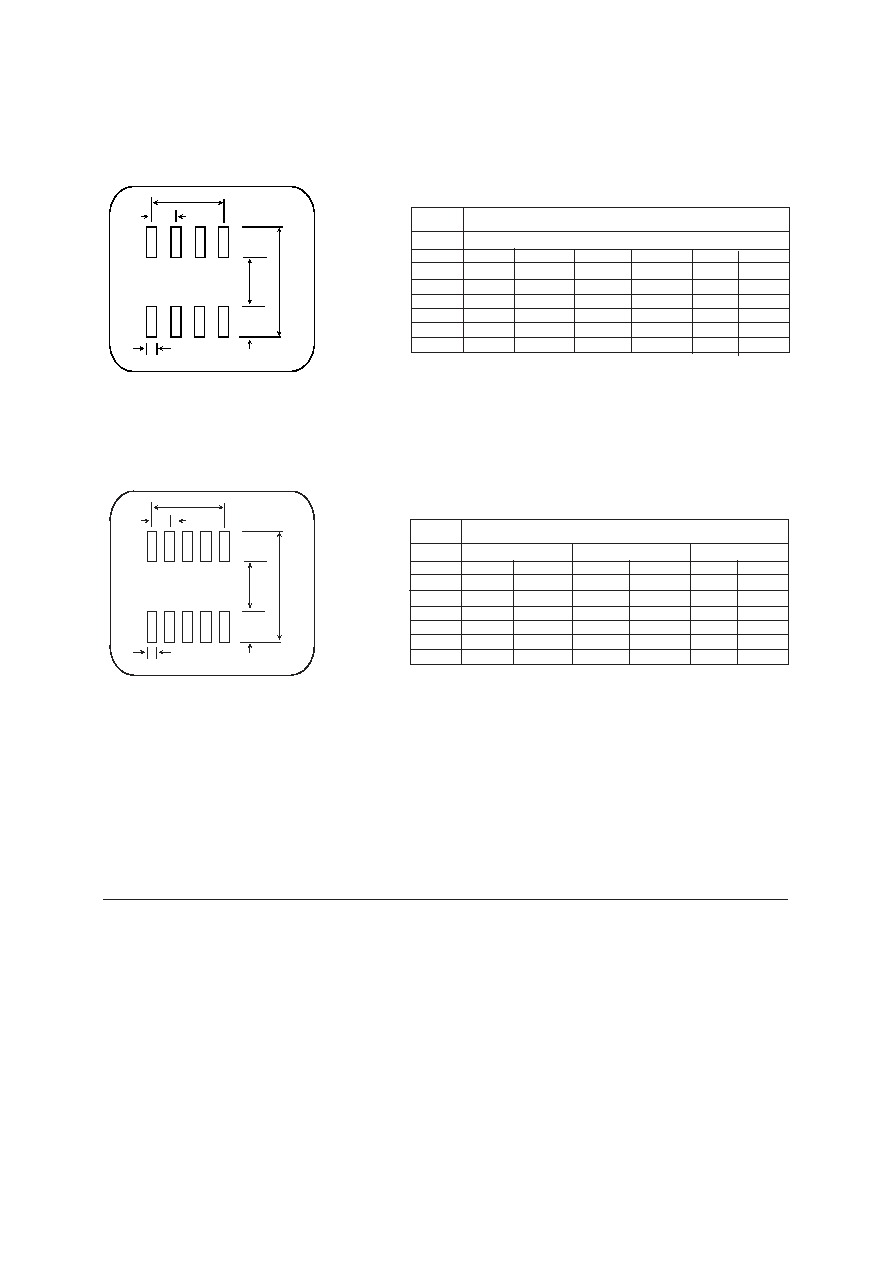

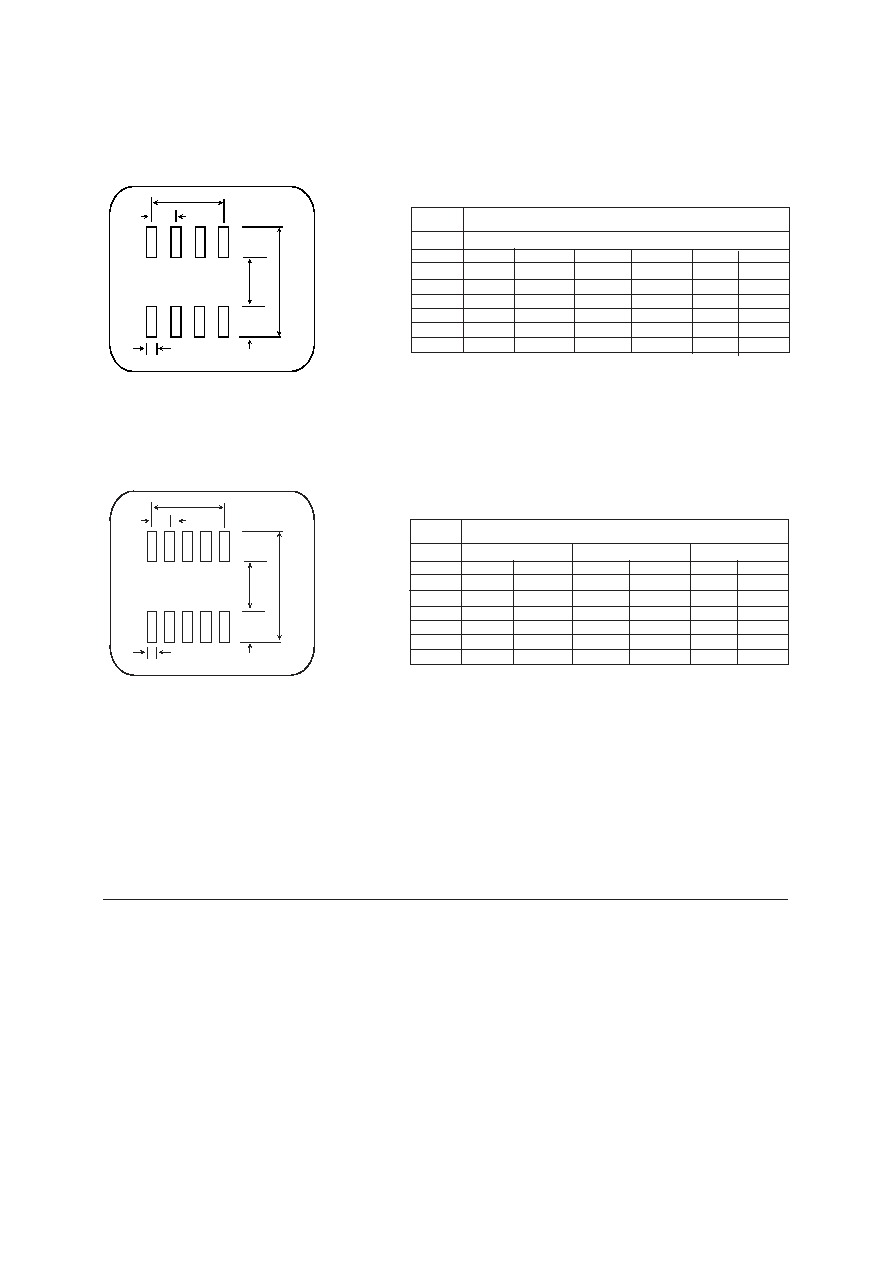

A

0.92

0.036

1.00

0.039

1.08

0.043

B

0.05

0.002

0.10

0.004

0.15

0.006

C

0.15

0.006

0.23

0.009

0.31

0.012

D

0.40

0.016

0.55

0.022

0.70

0.028

E

0.13

0.005

0.18

0.007

0.23

0.009

F

2.90

0.114

3.00

0.118

3.10

0.122

G

0.35

0.014

0.50

0.020

0.65

0.026

H

4.75

0.187

4.90

0.193

5.05

0.199

I

2.90

0.114

3.00

0.118

3.10

0.122

MSOPs are marked with part number (381A), 5-digit wafer lot code and a 3-digit date

code. Bottom of marking is on the Pin 1 side.

F

H

I

A

B

G

C

D

E

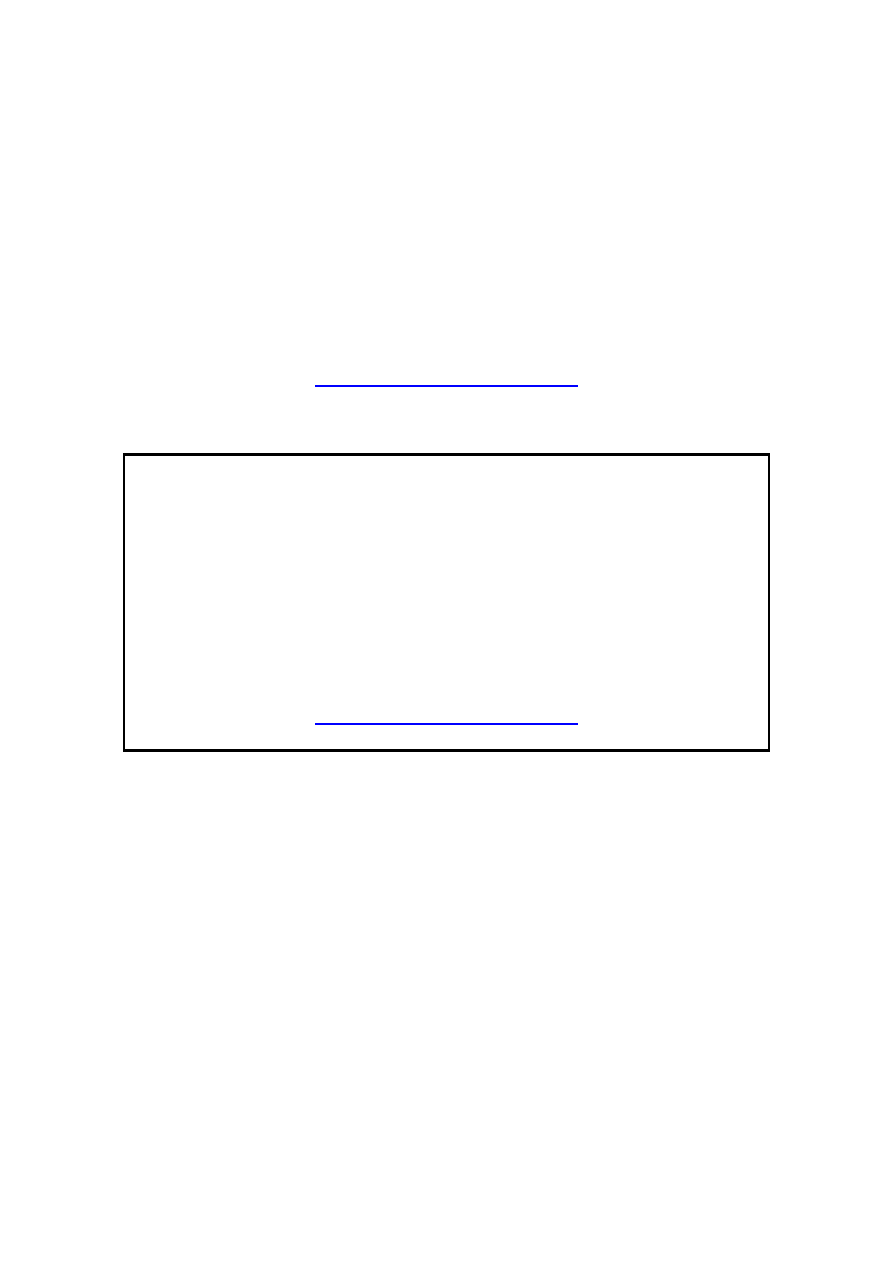

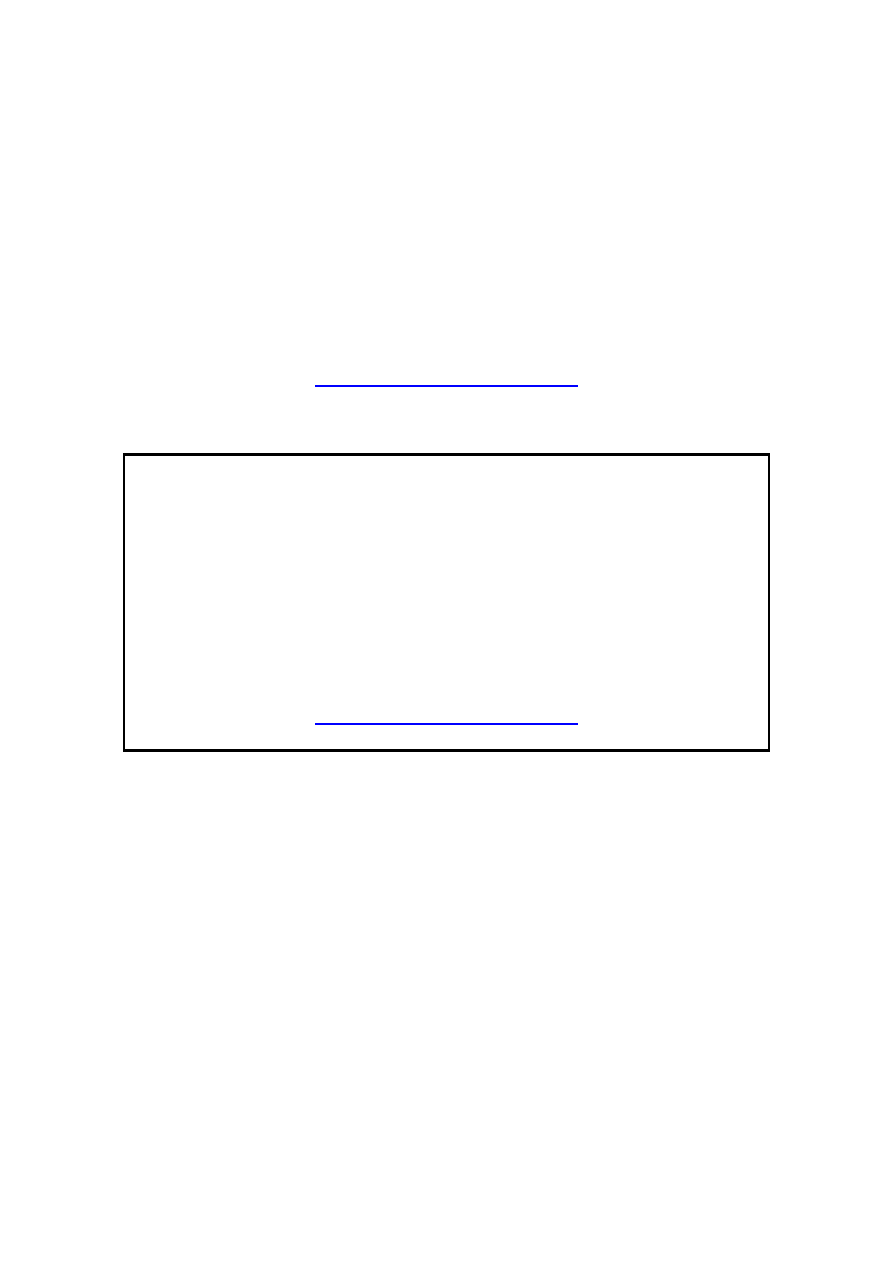

A

0.94

0.037

1.02

0.040

1.09

0.043

B

0.05

0.002

0.10

0.004

0.15

0.006

C

0.20

0.008

0.33

0.013

0.46

0.018

D

0.41

0.016

0.53

0.021

0.65

0.026

E

0.13

0.005

0.18

0.007

0.23

0.009

F

2.84

0.112

3.00

0.118

3.15

0.124

G

0.43

0.017

0.65

0.026

0.83

0.033

H

4.70

0.185

4.90

0.193

5.11

0.201

I

2.84

0.112

3.00

0.118

3.25

0.128

Description

mm.

in.

mm.

in.

mm.

in.

MSOP-8

Min.

Typical

Max.

mm.

in.

mm.

in.

mm.

in.

MSOP-10

Min.

Typical

Max.

MSOPs are marked with part number (381A), 5-digit wafer lot code and a 3-digit date

code. Bottom of marking is on the Pin 1 side.

F

H

I

A

B

G

C

D

E

14

The DUREL name and logo are registered trademarks of DUREL CORPORATION.

This information is not intended to and does not create any warranties, express or implied, including any warranty of merchantability or fitness for a

particular purpose. The relative merits of materials for a specific application should be determined by your evaluation.

This driver is covered by the following U.S. patents: #5,313,141, #5,347,198; #5,789,870 #6,043,610. Corresponding foreign patents are issued and pending.

DUREL Corporation

2225 W. Chandler Blvd.

Chandler, AZ 85224-6155

Tel: (480) 917-6000

FAX: (480) 917-6049

Website: http://www.durel.com

© 2001, 2002 Durel Corporation

Printed in U.S.A.

LIT-I 9040 Rev. A03

ISO 9001 Certified

RECOMMENDED PAD LAYOUT

e

c

a

b

d

f

mm.

in.

mm.

in.

mm.

in.

Min.

Typical

Max.

a

0.60

0.0236

0.6

0.0256

0.70

0.0276

b

1.90

0.0748

1.9

0.0768

2.00

0.0788

c

3.3

0.130

3.45

0.136

d

0.89

0.035

0.9

0.038

1.05

0.041

e

5.26

0.207

5.41

0.213

f

0.41

0.016

0.4

0.018

0.51

0.020

MSOP-8 PAD LAYOUT

e

c

a

b

d

f

mm.

in.

mm.

in.

mm.

in.

Min.

Typical

Max.

MSOP-10 PAD LAYOUT

a

0.5

0.0197

b

2.0

0.0788

c

3.3

0.130

3.45

0.136

d

0.89

0.035

0.97

0.038

1.05

0.041

e

5.26

0.207

5.41

0.213

f

0.3

0.012

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com