DATA SHEET

CHIP RESISTORS ARRAY

TC164 (8Pin/4R)

5%

Product Specification ≠ Mar. 24, 2004 V.4

Supersedes Date of Feb. 10,

2004

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

2

7

SERIES

TC

164

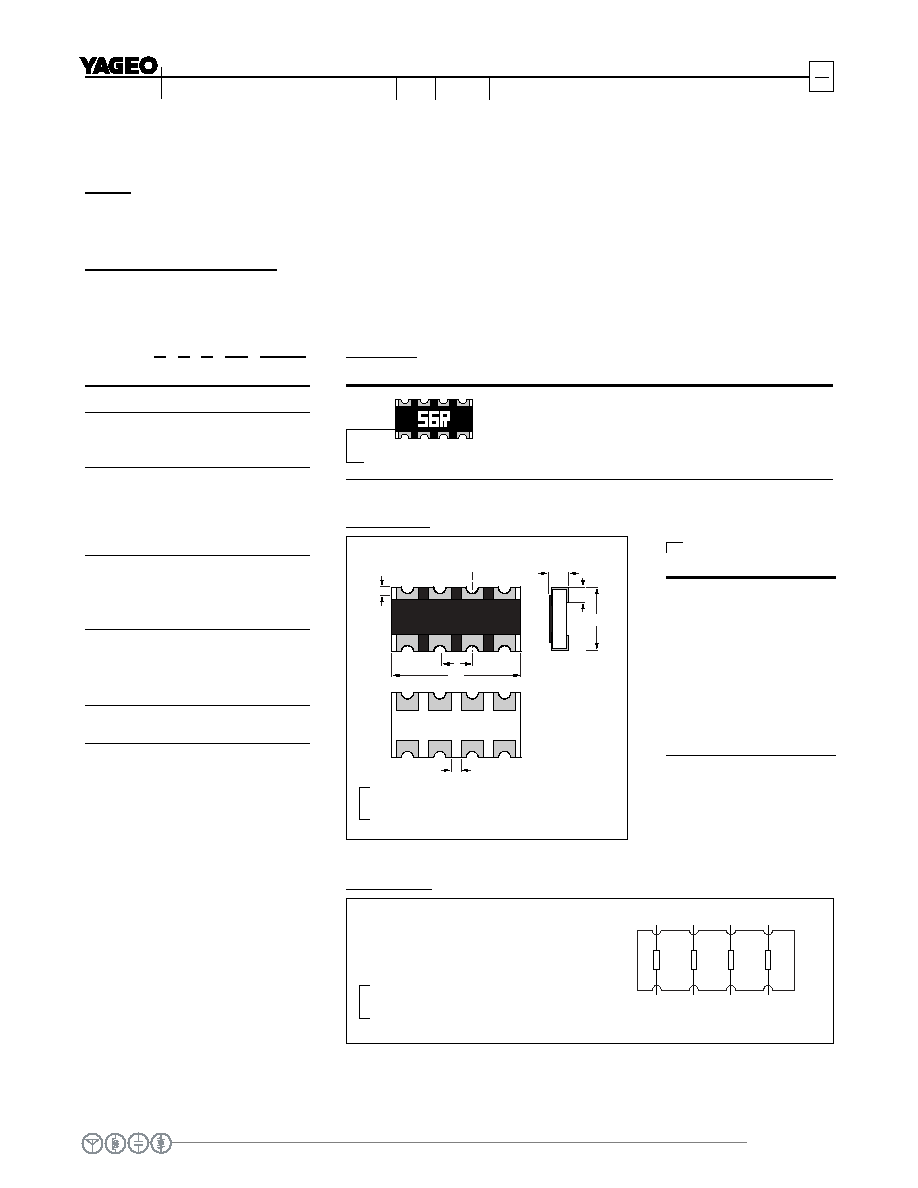

TYPE TC164

B (mm)

0.3±0.15

H (mm)

0.5±0.15

P (mm)

0.8±0.05

L (mm)

3.2±0.20

T (mm)

0.6±0.1

W

1

(mm)

0.3±0.15

W

2

(mm)

1.6±0.15

Table 1

YNSC021

H

a

a

P

L

B

T

W

1

W

2

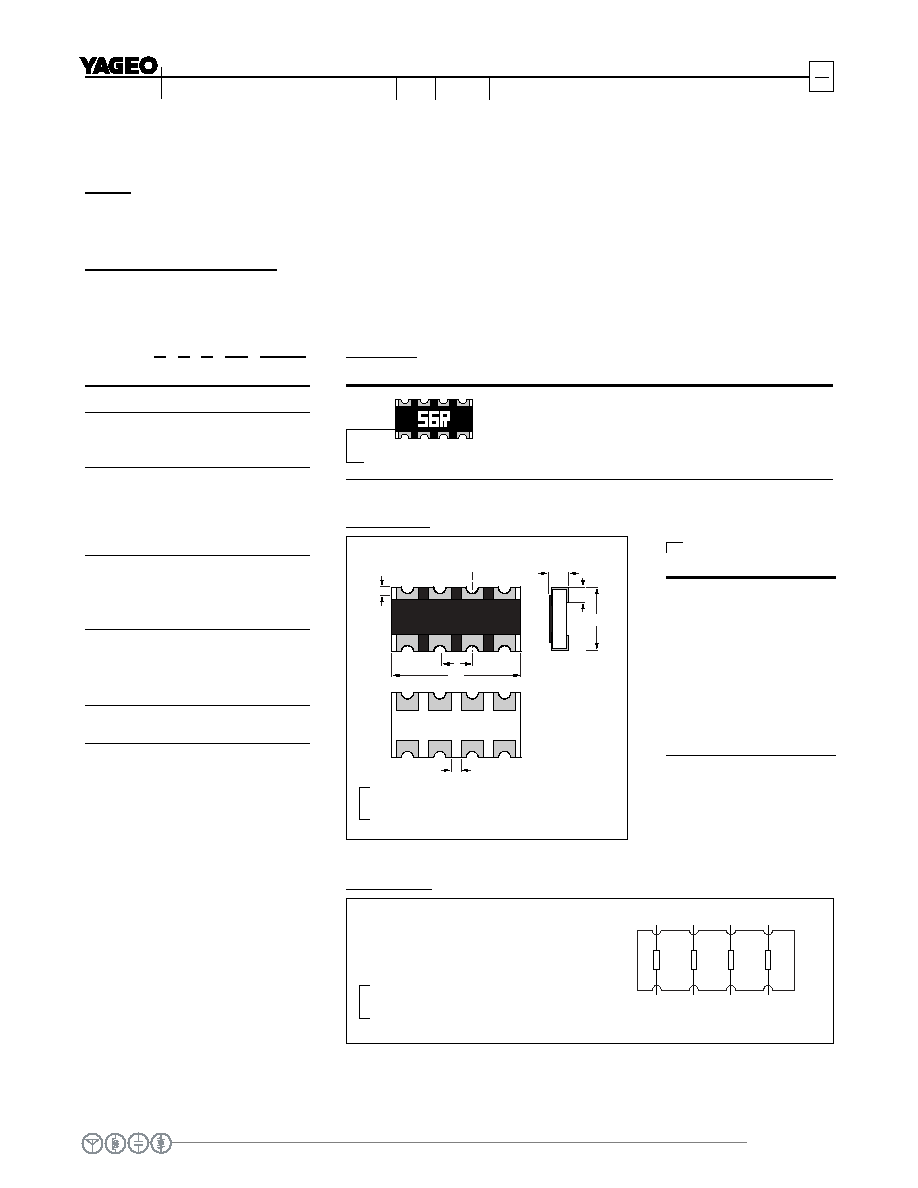

Fig. 2 TC164 series chip resistors construction

DIMENSION

SCHEMATIC

R1

R2

R3

R4

YNSC022

1

2

8

7

3

6

4

5

Fig. 3 Equivalent circuit diagram

For dimension see Fig. 2 and Table 1

R1=R2=R3=R4

TC164

First two digits for significant figure and

3rd digit for number of zeros

Letter R: decimal place

MARKING

Fig. 1 5% Marking, Value=56

YNSC020

TC164 ≠ X X X XX XXXX

(1) (2) (3) (4) (5)

(1) TOLERANCE

J = ±5%

(2) PACKAGING TYPE

R = Paper taping reel

(3) TEMPERATURE

CHARACTERISTIC OF

RESISTANCE

G = ±200ppm/∞C

≠ = Base on spec

(4) SPECIAL TYPE

07 = 7 inch dia. Reel

13 = 13 inch dia. Reel

(5) RESISTANCE VALUE:

56R, 560R, 5K6, 56K, 1M.

SCOPE

This specification describes TC164 series chip resistors made by thick film process.

ORDERING INFORMATION

Part number is identified by the series, size, tolerance, packing style, temperature coefficient, special type and

resistance value.

Concave termination

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

3

7

SERIES

TC

164

CHARACTERISTICS

TC164 1/16W

Operating Temperature Range

≠55∞C to +155∞C

Maximum Working Voltage

50V

Maximum Overload Voltage

100V

Dielectric Withstanding Voltage

100V

Number of Resistors

4

Resistance Range

10 to 1M

Zero Ohm Jumper <0.05

Temperature Coefficient

±200ppm/∞C

Rated Current 1.0A

Jumper Criteria

Maximum Current

2.0A

ELECTRICAL CHARACTERISTICS

POWER RATING

R

R

A

A

T

T

E

E

D

D

P

P

O

O

W

W

E

E

R

R

A

A

T

T

7

7

0

0

∞

∞

C

C

,

,

T

T

C

C

1

1

6

6

4

4

=

=

1

1

/

/

1

1

6

6

W

W

F

F

O

O

R

R

E

E

L

L

E

E

M

M

E

E

N

N

T

T

R

R

A

A

T

T

E

E

D

D

V

V

O

O

L

L

T

T

A

A

G

G

E

E

:

:

The DC or AC (rms) continuous

working voltage corresponding to

the rated power is determined by

the following formula:

V=(P X R)

Where

V=Continuous rated DC

or AC (rms) working voltage (V)

P=Rated power (W)

R=Resistance value (X)

Table 2

MRA632

70

100

-55

50

Tamb (

∞

C)

(%Prated)

0

0

50

100

155

Pmax

Fig. 4 Maximum dissipation (P

max

) in

percentage of rated power as

a function of the operating

ambient temperature (T

amb

)

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

4

7

SERIES

TC

164

CCB325

empty compartments

with cover tape

(min. 240 mm)

cover tape only

leader

400 mm

trailer (max. 260 mm)

trailer end

leader end

Fig. 7 Leader and trailer tape dimension

PACKING METHOD

L

L

E

E

A

A

D

D

E

E

R

R

/

/

T

T

R

R

A

A

I

I

L

L

E

E

R

R

T

T

A

A

P

P

E

E

S

S

P

P

E

E

C

C

I

I

F

F

I

I

C

C

A

A

T

T

I

I

O

O

N

N

PACKING STYLE

REEL DIMENSION

TC164

Paper Taping Reel (R)

7" (178 mm)

5,000

13" (330 mm)

20,000

gewidth

C

D

B

A

W

T

MSA284_b

DIMENSION TC164

A (mm)

2.0±0.1

B (mm)

3.5±0.1

W (mm)

8.0±0.2

E (mm)

1.75±0.1

F (mm)

3.5±0.05

P

0

(mm)

4.0±0.1

P

1

(mm)

4.0±0.1

P

2

(mm)

2.0±0.05

ÿD

0

(mm)

1.5+0.1/≠0

T (mm)

0.85±0.1

PAPER TAPE SPECIFICATION

TAPING REEL

DIMENSION TC164

Tape Width

8mm

ÿA (mm)

180+0/≠3

ÿB (mm)

60+1/≠0

ÿC (mm)

13.0±0.2

ÿD (mm)

21±0.8

W (mm)

9.0±0.3

T (mm)

11.4±1

Fig. 5 Reel dimension

Table 3

Table 4

Table 5 Packing style and packaging quantity

For dimension see Table 3

F

W

P0

P2

D 0

B

A

P1

E

MBD123_a

T

cover tape

Fig.6 Paper tape dimension

For dimension see Table 4

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

5

7

SERIES

TC

164

TYPE TEST

METHOD

ACCEPTANCE

STANDARD

Formula

Temperature

Coefficient of

Resistance

(T.C.R.)

Measure resistance at

+25∞C or specified room

temperature as R

1

, then

measure at ≠55∞C or

+155∞C respectively as R

2

.

Determine the

temperature coefficient of

resistance from the

following formula:

T.C.R. = ------------------------- ◊10

6

(ppm/∞C)

Where

t

1

=+25∞C or specified room temperature

t

2

=≠55∞C or +155∞C test temperature

R

1

=resistance at reference temperature in ohms

R

2

=resistance at test temperature in ohms

Refer to table 2

Thermal

Shock

At ≠55±3∞C for 2 minutes and at +155±2∞C for 2 minutes as one cycle. After 5

cycles, the specimen shall be stabilized at room temp.

Measure the resistance to determine R/R(%) after one more hour.

±(1.0%+0.05)

Low

Temperature

Operation

Place the specimen in a test chamber maintained at ≠65 (+0/≠5)∞C. After one hour

stabilization at this temperature, full rated working voltage shall be applied for 45

(+5/≠0) minutes. Have15 (+5/≠0 ) minutes after remove the voltage, the specimen

shall be removed from the chamber and stabilized at room temperature for 24 hrs.

Measure the resistance to determine R/R(%).

±(1.0%+0.05)

No visible damage

Short

Time

Overload

Apply 2.5 times of rated voltage but not exceeding the maximum overload voltage

for 5 seconds. Have the specimen stabilized at room temperature for 30 minutes

minimum.

Measure the resistance to determine R/R(%).

±(2.0%+0.05)

No visible damage

Insulation

Resistance

Place the specimen in the jig and apply a rated

continues overload voltage (R.C.O.V) for one

minute as shown.

Measure the insulation resistance.

Type TC164

Voltage (DC)

100V

10,000M

Dielectric

Withstand

Voltage

Place the specimen in the jig and apply a

specified value continuous overload voltage as

shown for one minute.

Type TC164

Voltage (AC)

100Vrms

Breakdown voltage>

specification and without

open/short

Resistance

To Soldering

Heat

Immerse the specimen in the solder pot at 260±5∞C. for 10±1 seconds. Have the

specimen stabilized at room temperature for 30 minutes minimum.

Measure the resistance to determine R/R(%).

±(1.0%+0.05)

No visible damage

R

2

≠R

1

R

1

(t

2

≠t

1

)

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

6

7

SERIES

TC

164

TYPE TEST

METHOD

ACCEPTANCE

STANDARD

Moisture

Resistance

Place the specimen in the test chamber and subject to 42 damp heat cycles. Each

one of which consists of the steps 1 to 7 as figure 9. The total length of test is 1,000

hours. Have the specimen stabilized at room temperature for 24 hours after testing.

Measure the resistance to determine R/R(%).

±(2.0%+0.05)

No visible damage

Life

Place the specimen in the oven at 70±2∞C. Apply the rated voltage to the specimen

at the 1.5 hours on and 0.5 hour off cycle. The total length of test is 1,000 hours.

Have the specimen stabilized at room temperature for one hour minimum after

testing.

Measure the R/R(%).

±(3.0%+0.1)

No visible damage

Solderability

Immerse the specimen in the solder pot at 235±5∞C for 5 sec.

At least 95% solder coverage on

the termination

Bending

Strength

Mount the specimen on a test board as

shown in the figure 8. Slowly apply the force

till the board is bent for 5±1 sec.

Measure the R/R(%) at this position.

Type

TC164

Bent Distance (d)

1mm

±(1.0%+0.05)

No visible damage

Fig. 8 Principle of the bending

test

www.yageo.com

Mar. 24, 2004 V.4

Chip Resistor Surface Mount

7

7

SERIES

TC

164

75

initial drying

24 hours

90

- 98% RH

80

- 98%

RH

temperature

tolerance

±2

∞C (±3.6 ∞F)

unless otherwise

specified

initial measurements

as specified in 2.2

0

STEP1

STEP3

STEP2

prior to first

cycle only

STEP4

one cycle 24 hours; repeat as specified in 2.5

voltage applied as specified in 2.4

circulation of conditioning air shall be at a

minimum cubic rate per minute equivalent to

10 times the volume of the chamber

STEP6

STEP7

HBK073

STEP5

5

10

15

end of final cycle;

measurements

as specified in 2.7

optional sub-cycle if specified

(2.3); sub-cycle performed during

any 5 of the first 9 cycles; humidity

uncontrolled during sub-cycle

20

time [h]

temperature

[

∞C]

25

50

25

0

90

- 98% RH

90

- 98% RH

+10 ∞C (+18 ∞F)

-2 ∞C (-3.6 ∞F)

80

- 98%

RH

rate of change of temperature is unspecified,

however, specimens shall not be subjected to

radiant heating from chamber conditioning processes

Fig. 9 Conditions by change of temperature