ACCESSORIES

LMSHELF = Mounting Shelf 300-450W

MXSHELF = Mounting Shelf 72-200W

C1063

R4

9/02 IH

General Description

The CCL/TCL Series provides functional emer-

gency lighting in a variety of wattages up to 450

watts. High performance electronics and rugged

18 gauge steel construction ensure long-term life

safety reliability.

Illumination

Illumination is accomplished with up to three

lamp heads mounted on the top of the unit. The

most popular lamp head for use with the CCL/TCL

Series is the "D" Series round sealed beam Par 36

tungsten lamp head. The "D" head is available up

to 30 watts.

CCL/TCL Series

High Capacity Steel Emergency Lighting Units

6 and 12 Volt, 75 to 450 Watts

Wet Cell Lead Calcium Battery

Housing

Constructed of 18 gauge steel with a tan epoxy powder

coat finish.

Knockouts provided for mounting up to three lamp

heads.

Bi-color LED charge monitor/indicator and a "press-to

test" switch are located on the front of the cabinet.

Choice of wedge base, sealed beam tungsten, or halogen

lamp heads

Electronics

120/277 VAC dual voltage input with surge-protected,

solid-state circuitry provides for a reliable charging

system.

Charging system is complete with low voltage

disconnect, AC lockout, brownout protection,

AC indicator lamp and test switch.

Includes two fused output circuits.

Utilizes a fully automatic voltage regulated two-rate cur-

rent limited solid-state charger -- initially provides a high

rate charge upon restoration of AC power, and provides

trickle charge to maintain batteries at full capacity once

float voltage is attained.

Optional ACCU-TEST Self Diagnostics includes an auto-

matic 3 minute discharge test every 30 days. A manual

test is available from 1 to 90 minutes.

Warranty

Three year full electronics warranty

One year full plus four year prorated battery warranty

Battery

Low maintenance, free electrolyte, wet cell, lead

calcium battery

Specific gravity disk indicators show relative state

charge at a glance

Operating temperature range of battery is 65�F

(19�C)

to 85�F

(30�C)

Battery supplies 90 minutes of emergency power

Code Compliance

UL 924 listed

NFPA 101

NEC BOCA and OSHA illumination standard

Performance

Input power requirements

120 VAC - 0.66 amps, 80 watts

277 VAC - 0.30 amps, 80 watts

Dimensions

TYPE:

CATALOG NO.:

Shown: CCL150DL2

Ordering Information

SERIES

DC

LAMP

# OF

FACTORY INSTALLED

WATTAGE

HEADS

HEADS

OPTIONS

1

CCL = 6 Volt

6 Volt

6 Volt

3 = Three

A = Ammeter

2

TCL = 12 Volt

75 = 75 Watts

DY = 8 Watt, Tungsten

2 = Two

ACF1 = 120 VAC Fuse

100 = 100 Watts

DA = 18 Watt, Tungsten

1 = One

ACF2 = 277 VAC Fuse

150 = 150 Watts

DL = 25 Watt, Tungsten

ACP1 = 120 VAC Power Switch

225 = 225 Watts

DC = 30 Watt, Tungsten

ACP2 = 277 VAC Power Switch

AD = ACCU-TEST Self-Diagnostics

12 Volt

(Includes standard voltmeter)

12 Volt

ADAL = ACCU-TEST with Alarm

150 = 150 Watt

DNY = 12 Watt, Tungsten

ADTD = ACCU-TEST with Time Delay

3

200 = 200 Watt

DE = 28 Watt, Tungsten

DCP = DC Power Switch

300 = 300 Watt

DK = 25 Watt, Tungsten

EX = Special Input Transformer

(Specify voltage and frequency)

450 = 450 Watt

DG = 30 Watt, Tungsten

TD1 = 120 VAC Time Delay

3

TTD2 = 277 VAC Time Delay

3

(Suggested lamp heads listed

V = Voltmeter

2

above. Refer to the Accessories Section for

W = White Housing

additional lamp head choices.)

CCL

150

DL

2

TD1

16.0"

(40.6 cm)

TCL300, TCL450

CCL75, CCL100, CCL150, CCL225,

TCL150, TCL200

6.0"

(15.2 cm)

7.6"

(19.3 cm)

12.0"

(30.5 cm)

27.0"

(12.7 cm)

6.0"

(15.2 cm)

7.6"

(19.3 cm)

12.0"

(30.5 cm)

Notes:

1) Some option combinations may impact UL list-

ing. consult factory for specifics.

2) Not available witj AD, ADAL, or ADTD options.

3) 15 minute delay.

Housing

18 gauge steel housing with a tan epoxy powder coat

finish.

Knockouts provided for mounting up to three lamp

heads.

The suggested lamp head is the "D" Series round

sealed beam Par 36 tungsten. To order lamp heads

other than the suggested "D" head, refer to Chloride

Accessories Section..

Self-Diagnostics

The ACCU-TEST Self-Diagnostics option conducts

automatic and manual tests, and indicates real time

status of the lamp, battery and charger via LED indica-

tor lamps. Automatic tests include: Systems analysis

every 10 seconds, with actual load tests performed for

a 3 minute duration every 30 days. A manual tests is

available from 1 to 90 minutes.

Battery

Low maintenance, free electrolyte, wet cell, lead calci-

um battery.

Standard sustained emergency operation is for 90

minutes with the illumination source providing full

light output.

The suggested operating temperature range for lead

calcium batteries is 65�F

(19�C)

to 85�F

(30�C)

and

should provide a service life of 5 years.

Performance

Input power requirements

120 VAC - 0.66 amps, 80 watts

277 VAC - 0.30 amps, 80 watts

Code Compliance

The CCL/TCL Series meets or exceeds all performance

standards as required by UL 924, NFPA 70, NFPA 101,

NEC and OSHA.

Specification Data for CCL/TCL Series Steel Emergency Lighting Units

Suggested Specification

Furnish and install Chloride Systems emergency lighting unit model ________. The unit shall be constructed to meet Underwriter's Laboratories, Inc. Standard #924

and the National Electrical Code (NEC).

INSTALLATION AND OPERATION - Unit shall be easily field connected to a 120 or 277 VAC, 60 hertz, unswitched power source. Installation must comply with the

NEC as well as other applicable codes. Upon utility power failure or brownout, the unit shall automatically transfer to battery power and maintain the required illumina-

tion level for a minimum period of 90 minutes. Upon restoration of utility power, the charger shall restore the battery to full charge within UL 924 requirements follow-

ing a rated discharge of not more than 90 minutes.

CHARGER - Product shall utilize a fully automatic, voltage regulated, two-rate current limited solid-state charger. The charging system shall maintain the battery at

full capacity without the need for periodic exercising or equalization. The following features shall be standard: Low voltage disconnect (LVD), brownout protection and

AC lockout.

BATTERY - The battery shall be a low maintenance, free electrolyte, wet cell, lead calcium battery. The lead calcium battery shall provide trouble-free operation in

temperatures up to 85�F (30�C).

HOUSING - The unit housing shall be constructed of 18 gauge steel with a tan epoxy powder coat finish.

Chloride Systems

ISO 9001

A2528

C1063

R4

9/02 IH

272 West Stag Park Service Road

�

Burgaw NC 28425

Telephone: (910) 259 1000

�

Facsimile: (800) 258 8803

www.chloridesys.com

Lamp Head Photometrics

(For DL, suggested head for CCL)

(For DK, suggested head for TCL)

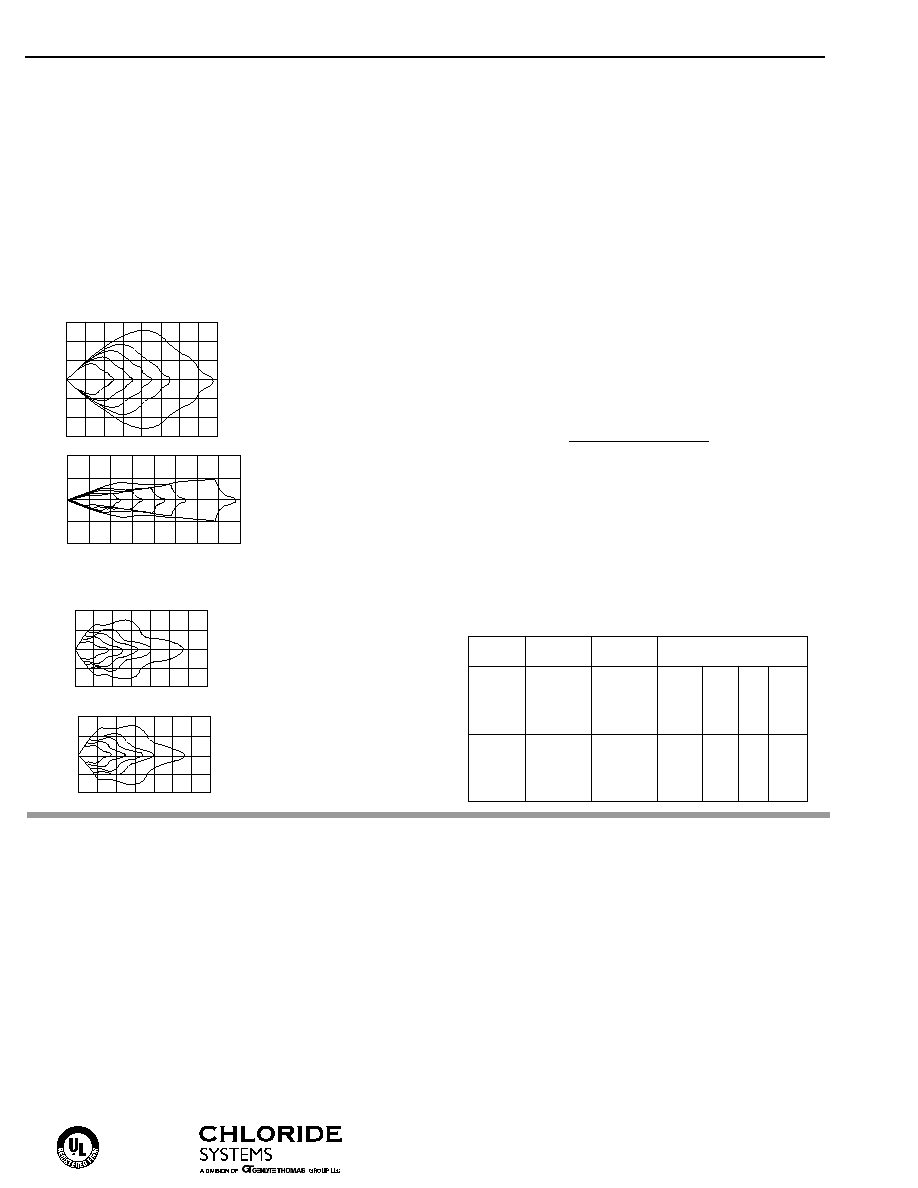

Operation

DC

Suggested

Watts to 87

1

/

2

Voltage

Unit

Lamp Head

of Rated Voltage*

1

1

/

2

hrs. 2 hrs. 4 hrs. 8 hrs.

6

CCL75

DL

75

56

28.5

15

CCL100

DL

100

75

38

20

CCL150

DL

150

112.5

57

30

CCL225

DL

225

169

85.5

45

12

TCL150

DK

150

112.5

57

30

TCL200

DK

200

150

96

34

TCL300

DK

300

225

114

60

TCL450

DK

450

337.5

171

90

Electronics

120/277 VAC dual voltage input with surge-protect-

ed, solid-state charging circuitry provides for a

reliable charging system. The charging system is

furnished with low voltage disconnect, AC lockout,

brownout protection, AC indicator lamp and test

switch.

The low voltage disconnect (LVD) feature will dis-

connect the battery prior to an unacceptable deep

discharge, but not before the required 90 minute

emergency operation.

The AC lockout feature prevents battery drain prior to

the initial energizing of utility power, and allows the

installer to complete all wiring and electrical connec-

tions without energizing the emergency circuit.

The brownout protection circuitry will automatically

switch the unit into the emergency mode if the utility

voltage sags below 20% of nominal.

Battery charging circuitry is entirely solid-state, and

utilizes a fully automatic, voltage regulated charger.

Battery recharge time after full discharge is less than

the required UL 924 standard.

Line sensitive electronics cause an instantaneous

transfer to battery power if utility power is lost, or a

brownout condition is detected. When line voltage is

present and stabilized, the transfer circuitry switches

back to normal operation and begins recharging the

battery. The transfer circuitry can be tested via a

momentary test switch located on the housing.

Vertical

20

30

50

10

0

Up 20

10

feet 0

10

Down 20

.2

.1

40

60

70

.3

1

.5

Horizontal

20

30

50

10

0

Left 20

10

feet 0

10

Right 20

.2

.1

40

60

70

.3

1

.5

20

30

50

10

0

Up 20

10

feet 0

10

Down 20

Photometric No. 3

40

60

70

80

1

.3

.2

.1

.5

Horizontal

20

30

50

10

0

Left 30

10

feet 0

10

20

Right 30

1

.3

.2

.1

20

.5

40

60

70

80