| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: P02221B2P | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

T

Specifications and information are subject to change without notice. 2005-07

Eudyna Devices Inc. 1,Kanai-cho, Sakae-ku, Yokohama, 244-0845 Japan

echnical Note

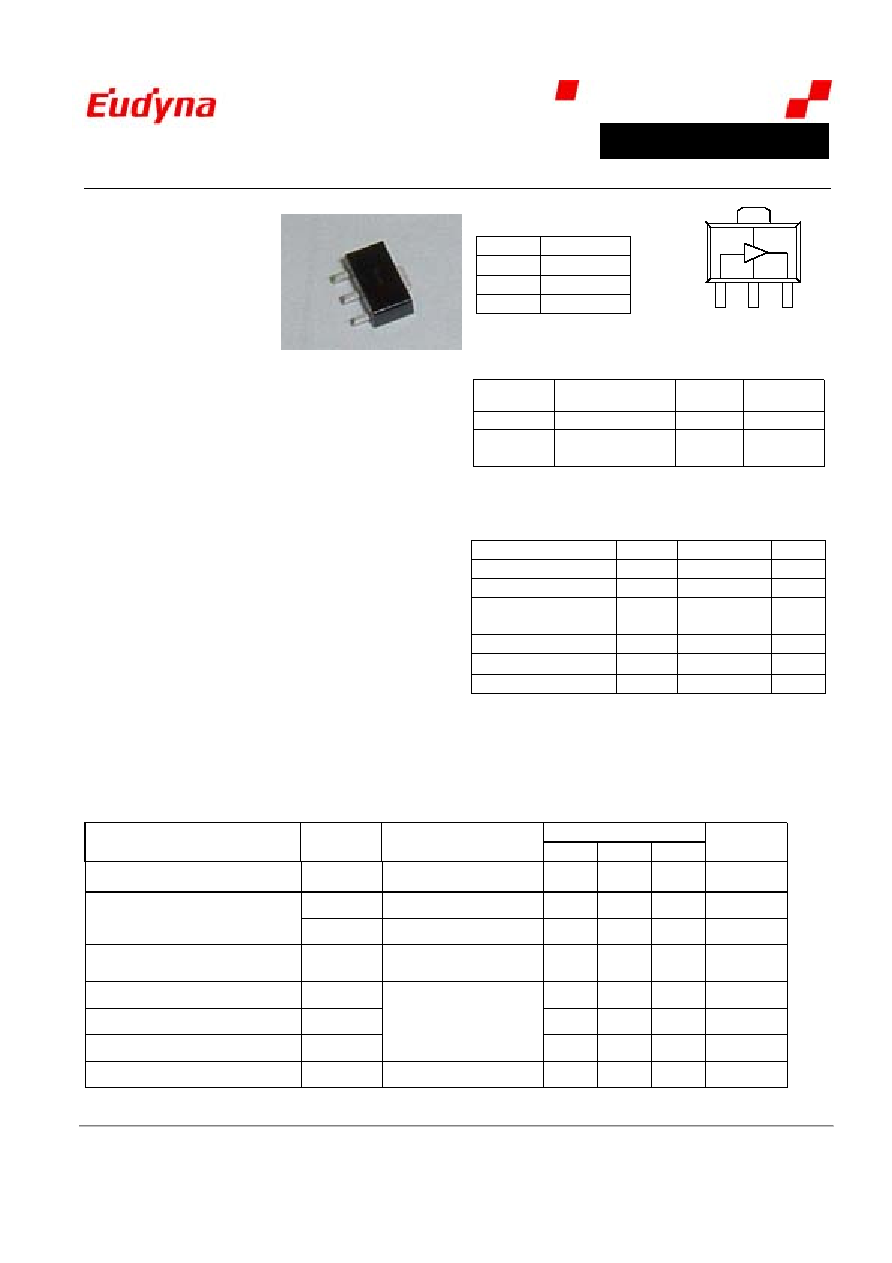

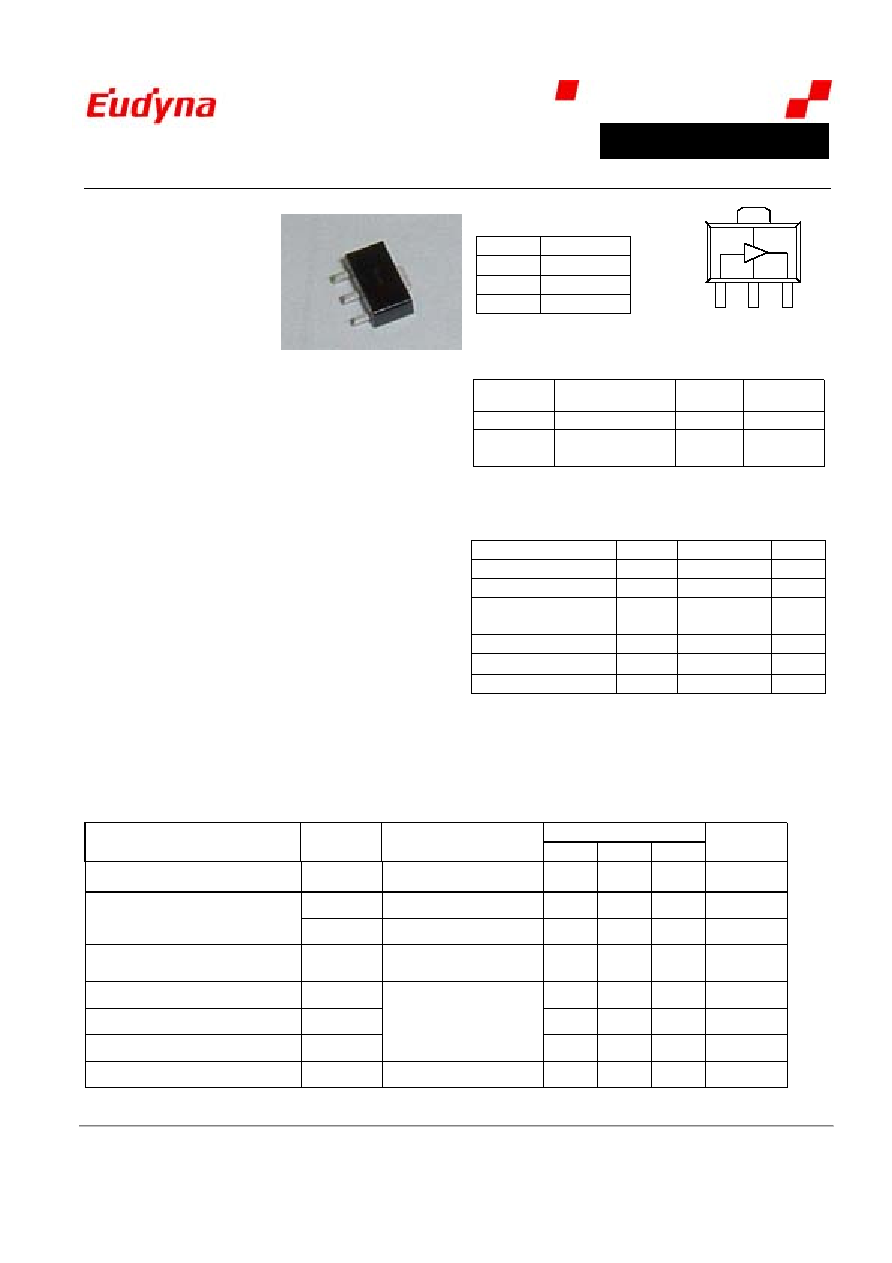

P02221B2P

500mW InGaP HBT Amplifier

Features

∑1.8 to 2.5GHz Frequency Band

∑+26.5dBm Output Power

∑+43dBm Output IP3

∑+5V Single Supply Voltage

∑14dB Gain at 2.14GHz

∑Highly Reliable InGaP HBT

∑Pb-free SOT-89 SMT Package

∑AuSn Die Attach for Low and

Stable Thermal Resistance

Applications

∑Wireless communication system

∑Cellular, PCS, PHS, W-CDMA, WLAN

Description

P02221B2P is a high performance InGaP/GaAs HBT

amplifier housed in a low-cost SOT-89 package. The

hetero-junction epitaxial structure has been designed to

achieve low distortion, which leads to high IP3. The device

needs only a +5V single power supply voltage in operation.

Utilization of AuSn die attach has realized a low and stable

thermal resistance.

Functional Diagram

Pin No.

Function

1 RF

Input

2, 4

Ground

3 RF

Output

Ordering Information

Part No

Description

Number

of devices

Container

P02221B2P

HBT Amplifier

1000

7" Reel

KP035J

2.14GHz

Application Circuit

1

Anti-static

Bag

Absolute Maximum Ratings

(@Tc=25∞C)

Parameter Symbol

Value

Units

Device Voltage

Vd

6

V

Device Current

Id

500

mA

RF Input Power

(continuous)

Pin 15

dBm

Power Dissipation

Pt

2

W

Junction Temperature

Tj

+150

∞C

Storage Temperature

Tstg

- 40 to +150

∞C

Tc: Case Temperature. Operating the device beyond any of these

values may cause permanent damage.

Electrical Specifications (@Tc=

+

25∞C, Vs=

+

5V) Measured at 2140MHz using application circuit.

Values

Parameter

Symbol Test

Conditions

Min.

Typ. Max.

Units

Consumption Current

Is

RF=off

247

294

341

mA

IP3_12 Pout=12dBm

S.C.L. --- 43 --- dBm

Output IP3

IP3_15 Pout=15dBm

S.C.L. 38.5 41 --- dBm

Output Power

@ 1dB Gain Compression

P1dB ---

24.5

26.5

---

dBm

Small Signal Gain

Ga

12.5

14

---

dB

Input Return Loss

S11

---

-10 --- dB

Output Return Loss

S22

Pin=-10dBm

---

-8 --- dB

Thermal Resistance

Rth

Junction-Case

---

37 --- ∞C/W

4

3

1

2

Phone : +81-45-853-8150 Fax : +81-45-853-8170 e-mail : www-sales-s@eudyna.com Web Site : www.eudyna.com

-1-

Technical Note

P02221B2P

500mW InGaP HBT Amplifier

Specifications and information are subject to change without notice. 2005-07

Eudyna Devices Inc. 1,Kanai-cho, Sakae-ku, Yokohama, 244-0845 Japan

Application Circuit : 2140MHz

Vs

RF in

RF out

R1

R2

R3

C1

C2

C3

L2

L1

C6

C7

C5

C4

L3

3.3

360

360

15nH

16nH

82pF

82pF

0.75pF

2.7nH

50 EL1

2.4pF

18pF

1uF

1000pF

DUT

4.5deg

Vd

-40

-30

-20

-10

0

10

20

1.9

2.0

2.1

2.2

2.3

Frequency (GHz)

S-parameters (dB)

S21

S12

S11

S22

RF in

RF out

R1

R2

R3

C1

C2

C3

C6

C7

C4

L1

L2

L3

Vs

Gnd

C5

Phone : +81-45-853-8150 Fax : +81-45-853-8170 e-mail : www-sales-s@eudyna.com Web Site : www.eudyna.com

-2-

Technical Note

P02221B2P

500mW InGaP HBT Amplifier

Specifications and information are subject to change without notice. 2005-07

Eudyna Devices Inc. 1,Kanai-cho, Sakae-ku, Yokohama, 244-0845 Japan

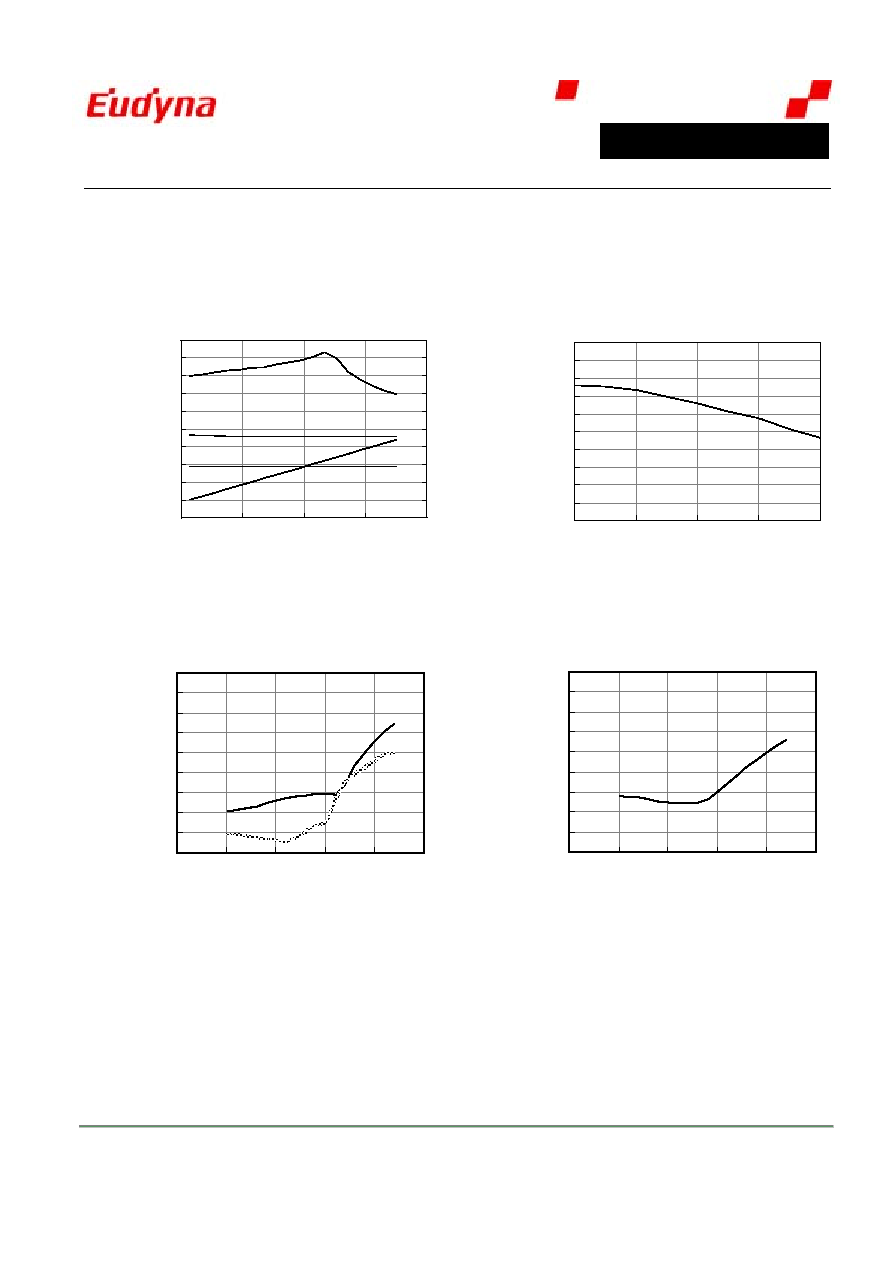

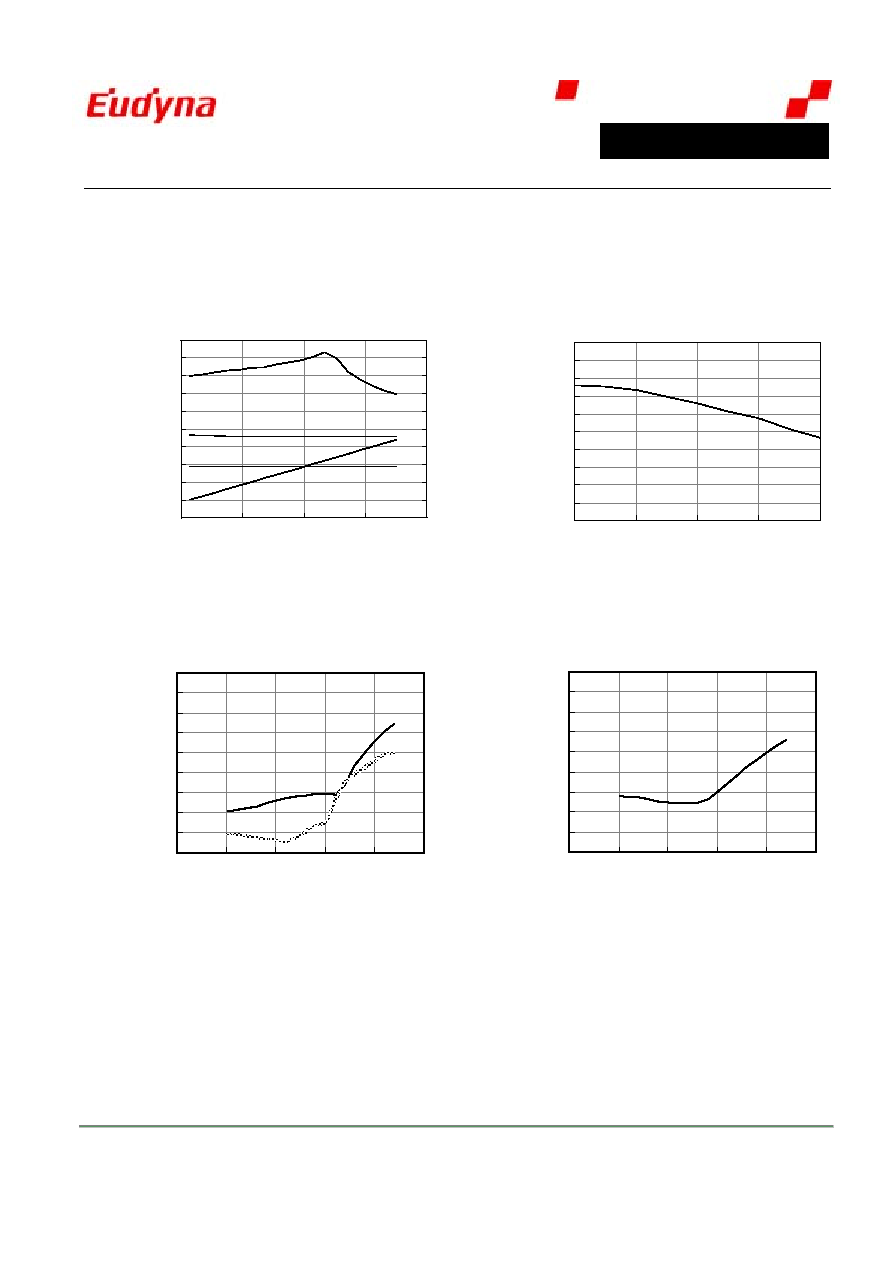

[Typical Performance]

KP035J Application Circuit

(Vs=5V, Tc=25∞C, f=2140MHz)

Pout (dBm)

Pout, Gain, IP3, Id vs Pin

0

5

10

15

20

25

30

35

40

45

50

-10

-5

0

5

10

Pin (dBm)

Gain (dB)

IP3 (dBm)

250

260

270

280

290

300

310

320

330

340

350

Is (mA)

IP3

Pout

Gain

Is

Gain vs Frequency

13.0

13.2

13.4

13.6

13.8

14.0

14.2

14.4

14.6

14.8

15.0

2.10

2.12

2.14

2.16

2.18

Frequency (GHz)

Gain (dB)

Pin=-10dBm

f1=2139.5MHz

f2=2140.5MHz

IM3, IM5 vs Pout

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0

5

10

15

20

25

Pout (dBm)

IM3 (dBc)

IM5 (dBc)

IM3

IM5

ACLR vs Pout

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0

5

10

15

20

25

Pout (dBm)

ACLR 5

M

Hz

(

d

Bc

)

3GPP Test Model 1

with 64DPCHs

ABS(I+Q)=100%

f1=2139.5MHz

f2=2140.5MHz

Phone : +81-45-853-8150 Fax : +81-45-853-8170 e-mail : www-sales-s@eudyna.com Web Site : www.eudyna.com

-3-

Technical Note

P02221B2P

500mW InGaP HBT Amplifier

Specifications and information are subject to change without notice. 2005-07

Eudyna Devices Inc. 1,Kanai-cho, Sakae-ku, Yokohama, 244-0845 Japan

Attention to Heat Radiation

In the layout design of the printed circuit board (PCB) on

which the InGaP HBT Amplifier are attached, the heat

radiation to minimize the device junction temperature should

be taken into account, since it significantly affects the MTTF

and RF performance. In any environment, the junction

temperature should be lower than the absolute maximum

rating during the device operation and it is recommended

that the thermal design has enough margin.

The junction temperature can be calculated by the following

formula.

T

jmax

=(Vd*Id-P

out

)(R

th

+R

board

+R

hs

)+T

a

Vd: Device voltage

Id: Device current

P

out

: Output power

R

th

: Thermal resistance between junction and case

R

board

: Thermal resistance of PCB

R

hs

: Thermal resistance of heat sink

T

a

: Ambient temperature

T

jmax

: Maximum junction temperature

Generally, there are two ways of heat radiation. One is the

plated thru hole and the other is the heat sink. Key points will

be illustrated in each case below. Note that no measure

against oscillation is adopted in the figures. In the design of

circuit and layout, you should take stabilizing into account if

necessary.

[Using Thru Hole]

Multiple plated thru holes are required directly below the

device.

Place more than 2 machine screws as close to the ground

pin (pin 4) as possible. The PCB is screwed on the

mounting plate or the heat sink to lower the thermal

resistance of the PCB.

Lay out a large ground pad area with multiple plated thru

holes around pin 4 of the device.

The required matching and feedback circuit described in

the application circuit examples should be connected to the

device, although it is not shown in the figure below.

[Using Heat Sink]

0.4 Plated Thru Holes

3 Plated Thru Hole

for 2.5 Machine Screws

Package Outline

4-R0.3

Heatsink

2

2.

95

0.

6

1.9

◊2.85

(4-R0.3)

5 Soldermask Keepout

3 Plated Thru Hole

for 2.5 Machine Screws

5 Soldermask Keepout

Grand Plane

Grand Plane

0.4 Plated Thru Holes

3 Plated Thru Hole

for 2.5 Machine Screws

Package Outline

4-R0.3

Heatsink

2

2.

95

0.

6

1.9

◊2.85

(4-R0.3)

5 Soldermask Keepout

3 Plated Thru Hole

for 2.5 Machine Screws

5 Soldermask Keepout

Grand Plane

Grand Plane

If you cannot get the junction temperature lower than the

absolute maximum rating only with the plated thru holes,

then you need to employ the heat sink. Attaching the heat

sink directly under pin 4 of the device improves the thermal

resistance between junction and ambient.

0.4 Plated Thru Holes

0.3 Plated Thru Holes

3 Plated Thru Hole

for 2.5 Machine Screws

5 Soldermask Keepout

Package Outline

Keepout

3 Plated Thru Hole

for 2.5 Machine Screws

Grand Plane

5 Soldermask

0.4 Plated Thru Holes

0.3 Plated Thru Holes

3 Plated Thru Hole

for 2.5 Machine Screws

5 Soldermask Keepout

Package Outline

Keepout

3 Plated Thru Hole

for 2.5 Machine Screws

Grand Plane

5 Soldermask

[Note]

Ground/thermal vias are critical for the proper device

performance. Drills of the recommended diameters should

be used in the fabrication of vias.

Add as much copper as possible to inner and outer layers

near the part to ensure optimal thermal performance.

Mounting screws can be added near the part to fasten the

board to heat sink. Ensure that the ground/thermal via

region contacts the heat sink.

Do not put solder mask on the backside of the PCB in the

region where the board contacts the heat sink.

RF trace width depends upon the PCB material and

construction.

Use 1 oz. Copper minimum.

Phone : +81-45-853-8150 Fax : +81-45-853-8170 e-mail : www-sales-s@eudyna.com Web Site : www.eudyna.com

-4-

Technical Note

P02221B2P

500mW InGaP HBT Amplifier

Specifications and information are subject to change without notice. 2005-07

Eudyna Devices Inc. 1,Kanai-cho, Sakae-ku, Yokohama, 244-0845 Japan

Package Drawing

Laser Marking

Convection Reflow Profile (Recommended)

[Note]

The reflow profile is different from the one for Sn-Pb

plating

1 2 3

1.5

± 0.08 1.5 ± 0.08

4.5

± 0.1

1.6+0.15

1.0

± 0.3

2.

5

±

0.

1

4.

0

±

0.

25

1.

1

±

0.

3

0.42

± 0.06

0.47

± 0.06

0.42

± 0.06

1.5

± 0.1

0.42+0.03

-0.02

0.1

± 0.05

-0.2

(1.7)

(0

.

2

5

)

(45∫)

1 2 3

1.5

± 0.08 1.5 ± 0.08

4.5

± 0.1

1.6+0.15

1.0

± 0.3

2.

5

±

0.

1

4.

0

±

0.

25

1.

1

±

0.

3

0.42

± 0.06

0.47

± 0.06

0.42

± 0.06

1.5

± 0.1

0.42+0.03

-0.02

0.1

± 0.05

-0.2

(1.7)

(0

.

2

5

)

(45∫)

If you use a soldering iron to attach the devices, please

beware of the followings.

(1) The tip of the iron should be grounded. Or you should

use an iron that is electrostatic discharge proof.

(2) The temperature of the iron tip should be lower than

240∞C and the soldering should be completed within 10

seconds.

Attention to ESD

Generally, GaAs devices are very sensitive to electrostatic

discharge (ESD). To reduce the ESD damage, please pay

attention to the followings. The devices should be stored

with the electrodes short-circuited by conductive materials.

The workstation and tools should be grounded for safe

dissipation of the static charges in the environment. The

workpeople are to wear anti-static clothing and wrist straps.

For safety reasons, resistance of 10M

or so should exist

between workpeople and ground.

1.3+0.1

-0

P

*

3

1

1.65MAX

B

A

(0.65)

*

2

A: 0.67+0 -0.1

B: 0.45

1,2,3: Lot No.

* * P: Product Type

Moisture Sensitivity Level

The moisture sensitivity level (MSL) of P02221B2P is 1,

which means that the "floor life" is unlimited below 30∞C

with relative humidity (Rh) of 85%.

Reliability and Environmental Issues

Eudyna's Yokohama Works, where the devices are

manufactured, has been accredited ISO-14001 since 1999.

We control the toxic materials in our products in accordance

with PRTR regulation.

Lead and Fluoride

To realize Pb-free products, Sn-Bi is used for the lead frame

plating. Any fluoride that has been determined by the

Montreal agreement is not used in the products.

60

120

180

240

0

100

200

300

T

e

m

p

er

at

u

r

e (

∞

C

)

0

Time (sec)

Preheat:160∞C

90 sec

< 45 sec

260

± 5∞C

5sec max

Time above 230∞C

60

120

180

240

0

100

200

300

T

e

m

p

er

at

u

r

e (

∞

C

)

0

Time (sec)

Preheat:160∞C

90 sec

< 45 sec

260

± 5∞C

5sec max

Time above 230∞C

60

120

180

240

0

100

200

300

T

e

m

p

er

at

u

r

e (

∞

C

)

0

Time (sec)

Preheat:160∞C

90 sec

< 45 sec

260

± 5∞C

5sec max

Time above 230∞C

Compliance with RoHS

This product is in compliance with Directive 2002/95/EC of

the European Parliament and of the Council of 27 January

2003 for the restriction of use of certain hazardous

substances in electrical and electronics equipment (RoHS

Directives).

Phone : +81-45-853-8150 Fax : +81-45-853-8170 e-mail : www-sales-s@eudyna.com Web Site : www.eudyna.com

-5-