| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MP3275AE | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

MP3275

1

Rev. 4.00

Fault Protected 16 Channel, 12-Bit

Data Acquisition Subsystem

FEATURES

∑

Fault Protected 16-Channel 12-Bit A/D

Converter with Sample & Hold, Reference,

Clock and 3-State Outputs

∑

Fast Conversion, less than 15

µ

S

∑

2's Complement and Serial Data Output

∑

Remote Analog Ground Sensing

∑

Overvoltage Protected Input (

50 V over the

Supply Voltages)

∑

Precision Reference for Long Term Stability and

Low Gain T.C.

∑

Guaranteed Linearity Over Temperature

∑

Guaranteed Performance at +12/≠5 V,

±

12 &

±

15 V

∑

Low Power (7 mW per Channel Typical)

∑

Parallel Version: MP3276

∑

32 Channel Version: MP3274

GENERAL DESCRIPTION

The MP3275 is a complete 16-channel, 12-bit Data Acquisi-

tion Subsystem with serial data port. Implemented using an ad-

vanced BiCMOS process, the converter combines a 16-channel

passive overvoltage-protected multiplexer instrumentation

amp, a sample & hold, a SAR, a 12-bit decoded D/A, a compa-

rator, a precision reference and the control logic to achieve an

accurate conversion in less than 15

µ

s, and a mux/instrumenta-

tion amp settling period of less than 10

µ

s.

A unique input design provides input overvoltage protection

to

50 V over the supply voltages. The circuit design can allow

for an overvoltage condition on unselected channels without dis-

rupting the measured channel or operation of the MP3275! The

internal 4 V reference has sufficient output current to provide

other system reference needs. Precision thin film scaling and

offset resistors are laser trimmed to provide for less than 2 LSB

INL for +10 V inputs on all channels.

In addition, the MP3275 will output either full scale (0111 ....)

for overrange and ≠ full scale (1000....) for underrange condi-

tions. This greatly simplifies microprocessor software develop-

ment.

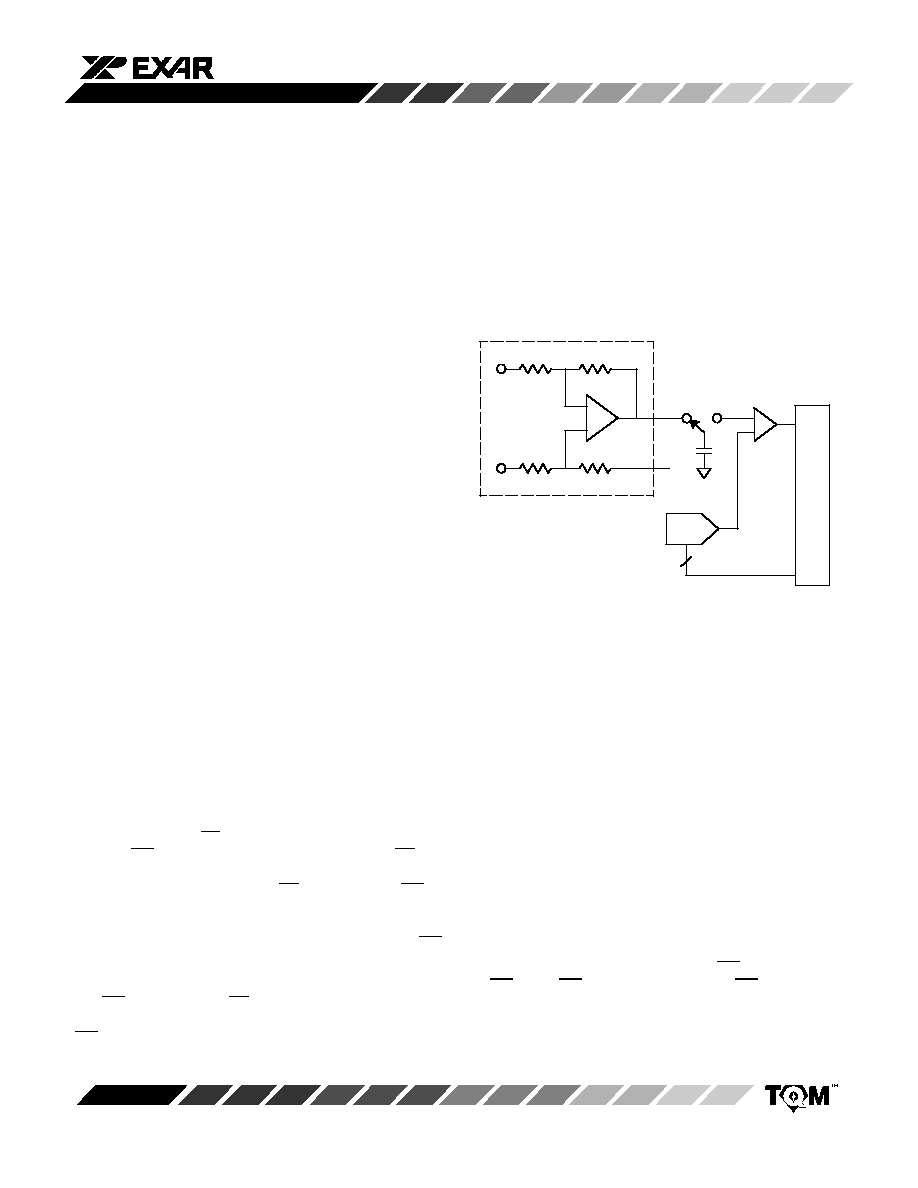

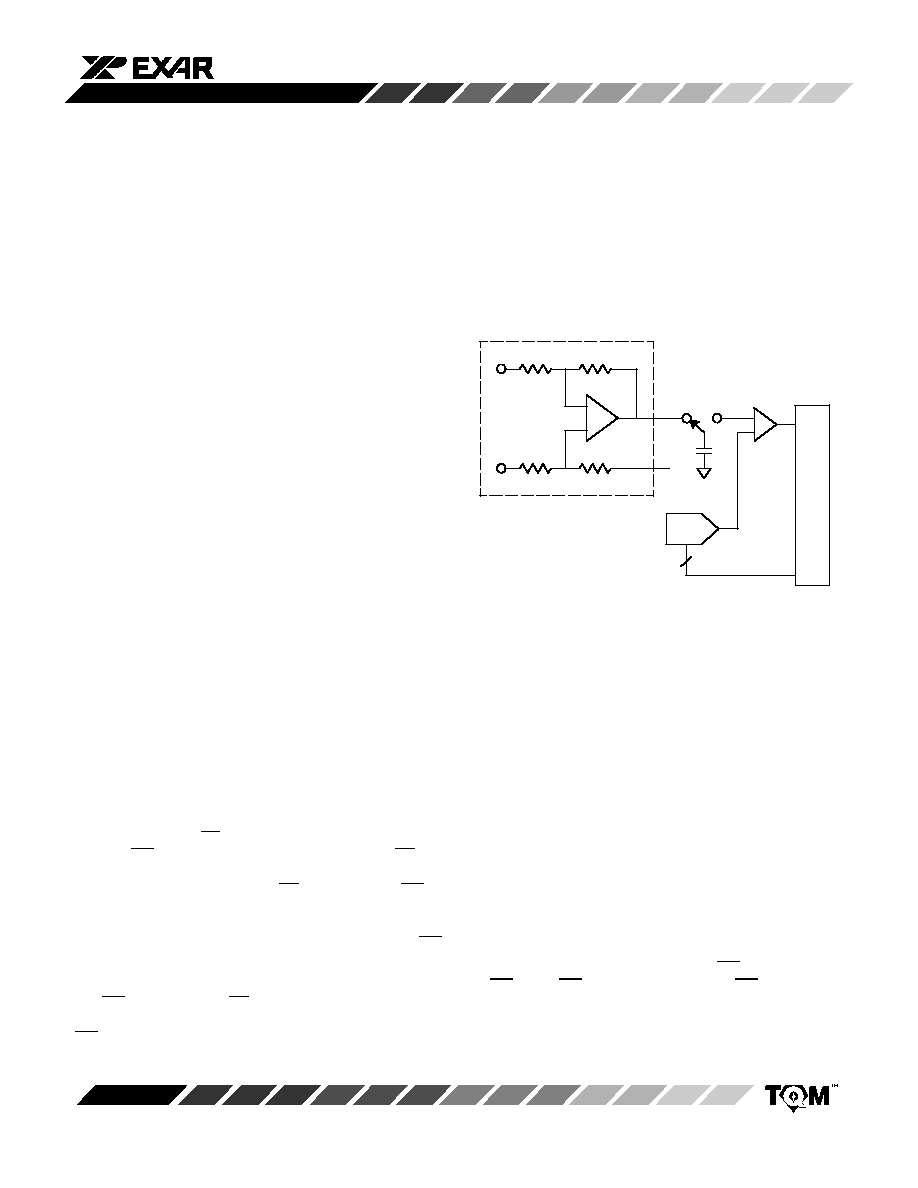

SIMPLIFIED BLOCK DIAGRAM

≠

+

Comp

SAR

4 V

REF

16

4

16

Ch.

MUX

AB0-3

(4 pins)

A

IN0

-15

(16 pins)

REF OUT

Control

Logic

GND REF.

DGND V

EE

VDAC

Latch/

Shift Register

3-State

Driver

12

SDO

REF IN /2

12

V

DD

V

CC

CLK

WR

RD

SDC

ADEN

STL

STS

V

REF

AGND

2

AGND

3

AGND

DGND

CS

MP3275

2

Rev. 4.00

ORDERING INFORMATION

Package

Type

Temperature

Range

Part No.

DNL

(LSB)

PQFP

≠40 to +85

∞

C

2

MP3275AE

INL

(LSB)

2

PIN CONFIGURATIONS

44 Pin PQFP

Q44

See the following

page for pin

numbers and

descriptions

33

23

22

12

1

11

34

44

Index

MP3275

3

Rev. 4.00

PIN OUT DEFINITIONS

1

V

EE

≠ Analog Supply. ≠4.75 To ≠ 16.5

2

A

IN

12

Channel 12 Analog Input, 1100

3

A

IN

13

Channel 13 Analog Input, 1101

4

A

IN

14

Channel 14 Analog Input, 1110

5

A

IN

15

Channel 15 Analog Input, 1111

6

GNDREF

+ Input To Mux / Instrumentation Amp

7

AGND

A/D Section Analog Ground

8

REF

Reference Output

9

AGND

3

Reference Analog Ground

10

DGND

Digital Logic And Output Ground

11

SDC

Serial Data Clock

12

N/C

No Connection

13

N/C

No Connection

14

N/C

No Connection

15

N/C

No Connection

16

SDO

Serial Data Out

17

STS

Conversion Status, Converting=1

18

STL

Input Settling Period State = 1

19

DGND

Digital Gnd, Low Current

20

RD

Enable Serial Data Out

21

CS

Chip Select

22

WR

Input Address And Conversion Control

PIN NO.

NAME

DESCRIPTION

PIN NO.

23

ADEN

Address Update Enable=1, Ignore=0

24

AB3

Input Address Bit 3, (MSB)

25

AB2

Input Address Bit 2

26

AB1

Input Address Bit 1

27

AB0

Input Address Bit 0, (LSB)

28

V

DD

Digital Logic & Output Supply, +4.75 to

+ 5.25 Volts

29

V

CC

Analog + Supply, +11.4 to + 16.5 Volts

30

A

IN

0

Channel 0 Analog Input, 0000

31

A

IN

1

Channel 1 Analog Input, 0001

32

A

IN

2

Channel 2 Analog Input, 0010

33

A

IN

3

Channel 3 Analog Input, 0011

34

N/C

No Connection

35

A

IN

4

Channel 4 Analog Input, 0100

36

A

IN

5

Channel 5 Analog Input, 0101

37

A

IN

6

Channel 6 Analog Input, 0110

38

A

IN

7

Channel 7 Analog Input, 0111

39

AGND

2

Agnd For Input Mux Section

40

A

IN

8

Channel 7 Analog Input, 1000

41

N/C

No Connection

42

A

IN

9

Channel 9 Analog Input, 1001

43

A

IN

10

Channel 10 Analog Input, 1010

44

A

IN

11

Channel 11 Analog Input, 1011

NAME

DESCRIPTION

MP3275

4

Rev. 4.00

ELECTRICAL CHARACTERISTICS TABLE

Unless Otherwise Specified: V

DD

= 5 V, V

CC

= 15 V, V

EE

= ≠15 V, GNDRef = 0 V, T

A

= 25

∞

C

25

∞

C

Parameter

Symbol

Min

Typ

Max

Min

Max

Units

Test Conditions/Comments

Resolution (All Grades)

N

12

12

Bits

KEY FEATURES

Resolution

12

12

Bits

Conversion Time, Per Channel

t

CONVR

15

15

µ

s

ACCURACY (A Grade)

1

Refer to

Table 6. for

output coding

Differential Non-Linearity

DNL

3/4

2

2

LSB

Integral Non-Linearity

INL

1

2

2

LSB

Best Fit Line

(Max INL ≠ Min INL)/2

Zero Code Error

EZS

2

5

10

LSB

fff to 000 [hex] transition

Full Scale Error

EFS

0.1

0.35

0.5

%

V

REF

IN = 4.000 V

POWER SUPPLY REJECTION

Max change in Full Scale

Calibration

V

CC

= 15 V

1.5 V or 12 V

0.6 V

1

1

LSB

V

DD

= 5 V

0.25 V

2

2.5

LSB

V

EE

= ≠15 V

1.5 V or

≠12 V

0.6 V

1

1

LSB

≠5 V

0.25 V

REFERENCE VOLTAGES

Voltage Output

V

REF(+)

3.975

4.0

4.025

3.970

4.030

V

Ref. Source Current

3.0

4.0

3.0

mA

Ref. Sink Current

20

µ

A

ANALOG INPUT

Input Voltage Range

3

V

IN

≠10

10

≠10

10

V

Ground Reference

GND Ref.

CM Range

2

≠3

+3

≠3

3

V

CM RR

TBD

LSB/V

Input Resistance

R

IN

100

130

100

k

Input Capacitance

2

C

IN

5

pF

Aperture Delay

2

t

AP

180

ns

From WR low to high after STL

high to low

Channel-to-Channel Isolation

2

≠80

≠70

dB

DC

DIGITAL INPUTS

WR, RD AB0-AB4,

ADEN, SDC

Logical "1" Voltage

V

IH

2.4

5.5

2.4

5.5

V

Logical "0" Voltage

V

IL

≠0.5

0.8

≠0.5

0.8

V

Leakage Currents

4

I

IN

≠5

5

≠10

10

µ

A

V

IN

=GND to V

DD

Input Capacitance

2

5

pF

Tmin to Tmax

MP3275

5

Rev. 4.00

ELECTRICAL CHARACTERISTICS TABLE (CONT'D)

Description

Symbol

Min

Typ

Max

Min

Max

Units

Conditions

DIGITAL OUTPUTS

C

OUT

=15 pF

(Data Format 2's Complement)

SDO, STS, STL

Logical "1" Voltage

V

OH

4.0

2.4

V

I

SOURCE

= 0.5 mA

Logical "0" Voltage

V

OL

0.4

0.4

V

I

SINK

= 1.6 mA

Tristate Leakage

I

OZ

≠5

5

≠5

5

µ

A

V

OUT

=GND to V

DD

POWER SUPPLIES

Operating Range

V

DD

+4.5

+5.5

+4.5

+5.5

V

V

CC

+11.4

+16.5

+11.4

+16.5

V

V

EE

≠4.75

≠16.5

≠4.75

≠16.5

V

Tested at ≠11.4 and ≠16.5 only

Operating Current

I

DD

2

7

7

mA

I

CC

5

8

8

mA

I

EE

1.5

3

3

mA

Power Dissipation

110

200

200

mW

25

∞

C

Tmin to Tmax

NOTES

1

Tester measures code transitions by dithering the voltage of the analog input (V

IN

). The difference between the measured and the

ideal code width is the DNL error. The INL error is the maximum distance (in LSB's) from the best fit line to any transition voltage

2

Guaranteed. Not tested.

3

All channel input pins and ground reference pin have protection which becomes active above

60 V.

4

All digital inputs have diodes to V

DD

and AGND. Input DC currents will not exceed specified limits for any input voltage between

AGND and V

DD

.

Specifications are subject to change without notice

ABSOLUTE MAXIMUM RATINGS (T

A

= +25

∞

C unless otherwise noted)

1, 2

V

CC

to AGND

0 to +16.5 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

EE

to AGND

0 to ≠16.5 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

DD

to AGND

0 to +7 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGND to DGND

±

1 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs or Outputs (WR, RD, CS, AB0-AB4, ADEN,

SDC) to DGND

≠0.5 V to V

DD

+0.5 V

. . . . . . . . . . . . . . . . . .

Analog Inputs (A

IN

0 ≠ A

IN

15, GND REF)

to AGND

±

60 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REF OUT

Indefinite short to DGND,

. . . . . . . . . . . . . . . . . . .

Momentary short to V

CC

Maximum Junction Temperature

150

∞

C

. . . . . . . . . . . . . . . . .

Package Power Dissipation Rating to 75

∞

C

PQFP

750 mW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Derates above 75

∞

C

10 mW/

∞

C

. . . . . . . . . . . . . . . . . . . . .

Lead Temperature, Soldering

300

∞

C, 10 Sec

. . . . . . . . . . . .

Storage Temperature (Ceramic)

≠65

∞

C to +150

∞

C

. . . . . . . .

NOTES:

1

Stresses above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. This is a

stress rating only and functional operation at or above this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

2

Any input pin which can see a value outside the absolute maximum ratings

should be protected by Schottky diode clamps

(HP5082-2835) from input pin to the supplies.

All logic inputs have protection diodes which will protect the device from

short transients outside the supplies of less than 100mA for less than 100

µ

s.

MP3275

6

Rev. 4.00

PRODUCT INFORMATION

Basic Description

The MP3275 is a fault protected data acquisition subsystem

available in monolithic form. This product contains all of the cir-

cuitry necessary to acquire 16 channels of quasi differential or

single-ended analog signals at

10 V input range and 15kHz

bandwidth. Connections to power, the analog input signals and

the digital system are all that is required. The MP3275's input

circuitry is protected against active input signals present with the

MP3275 power off. This is also the case for any channel exceed-

ing the MP3275 analog input dynamic range without interfering

with the channel being digitized. The channel address and

channel conversion can be managed in two ways: random

channel conversion or same channel conversion. Circuitry on

the chip adds a MUX/instrumentation amp settling delay of 10

µ

s

max, when a new channel is selected (ADEN = 1). Conversion

start is initiated without delay for the single-channel case (ADEN

= 0). Data is available in serial format.

TIMING

Control and Timing Considerations

The MP3275 can be operated in the stand-alone mode, with

one line for control and everything else hard-wired; or under mi-

croprocessor control, where changes can be made dynamically.

There are 4 control lines: ADEN, WR, CS and RD with their

functions described in

Table 1.

Note 1: If RD = 1, SDO remain high impedance. It is recommended that RD will not change during a conversion in

order to reduce noise. It is further recommended that RD = 1 during conversion to reject any noise present on the

SDO.

Table 1. Logic Truth Table

CS

WR

RD

ADEN

Data

STL

STS

Comments

1

X

X

X

≠≠

0

0

No operation

0

1

0

Hi-Z

0

0

No operation if ADEN = 0

0

1

1

Hi-Z

0

Input MUX channel selected, STL set on WR falling edge

0

0

1

X

Hi-Z

1

0

MUX select disabled

0

1

X

Hi-Z

0

Start convert on WR rising edge

0

1

1

X

Hi-Z

Start convert on STL falling edge

0

1

1

X

Hi-Z

0

STS goes low at end of conversion

0

1

X

≠≠

0

0

SDO enabled

0

X

0

X

ADC

0

0

Data from previous conversion on SDO

0

X

X

Hi-Z

0

0

SDO disabled

0

1

X

X

Hi-Z

0

1

SDO/RD disabled while STS high

0

X

0

X

Last ADC

1

0

Data from last conversion on SDO

0

0

0

Hi-Z

0

STL, MUX select disabled with ADEN = 0,

SDO disabled on STS rising edge

0

0

X

ADC

0

New data appears on SDO on falling edge of STS

Read ADC Data

(See Figure 2. and Table 3.)

ADC Channel Select and Start Convert

(See Figure 1. and Table 2.)

MP3275

7

Rev. 4.00

The MP3275 is easily interfaced to a wide variety of digital

systems. Discussion of the timing requirements of the MP3275

control signals follows.

Figure 1. shows a complete timing diagram for the MP3275

convert start operation.

WR is used to initiate a conversion.

A conversion is started by taking WR low, then high again

(conversion is enabled on the rising edge of WR). There are two

possible conditions that will affect conversion timing.

1. ADEN = 1. At the falling edge of WR, the input channel is

determined by the data present on the address bits. The

track and hold begins to settle after which STL returns low,

indicating that the multiplexer, buffer amp, and sample/hold

have settled to less than 1/2 LSB of final value. If the rising

edge of WR returns high prior to STL going low, conversion

will begin on the falling edge of STL. If the rising edge of WR

is delayed until after STL returns low, the input signal is sam-

pled and the conversion is started at the rising edge of WR

giving the user better control of the sampling time.

2. ADEN = 0. At the falling edge of WR the data present at the

address is ignored and the channel selected during the pre-

vious conversion remains selected. In this case the track

and hold settling time is omitted and STL never goes high. At

the rising edge of WR the input signal is sampled, and con-

version is started.

There are two possible states that the data output could be in

during a conversion.

1. If RD is held high during a conversion the output would re-

main high impedance throughout the conversion. This is the

preferred method of operation as any noise present on SDO

is rejected.

2. If RD is held low during a conversion, the data present SDO

will be from the previous conversion until the present conver-

sion is completed, when STS returns low. The data from the

new conversion will be available through SDO. The state of

RD should not change during a conversion.

Once a conversion is started and the STL or STS line goes

high, convert start commands will be ignored until the conver-

sion cycle is completed. The SDO output buffer cannot be en-

abled during conversion. In addition, all input and output

changes during conversion can introduce noise, and should be

avoided when possible.

ADC Control Timing

Table 2. ADC Write Timing

(See Figure 1.)

25

∞

C

Tmin to

Tmax

Limits

Comments/Test Conditions

Address to WR Set-Up Time

t

3

0

0

ns min

Address to WR Hold Time

t

4

0

0

ns min

WR Pulse Width

t

5

80

80

ns min

ADEN to WR Set-Up Time

t

6

0

ns min

ADC Conversion Timing

WR to STL

Delay

t

7

150

150

ns max

Load ckt of Figure 5, C

L

= 20 pF,

ADEN = 1

STL High (Settling Period)

t

8

10

15

µ

s max

Load ckt of Figure 5, C

L

= 20 pF

STL to STS Low (Converting)

t

9

15

20

µ

s max

Load ckt of Figure 5, C

L

= 20 pF

WR to STS High (ADEN = 0)

t

12

200

250

ns max

STL = 0 when ADEN = 0

WR to STS Low (ADEN = 1)

t

10

15

20

µ

s max

STS High to SDO Relinquish Time

t

13

150

150

ns max

Load ckt of Figure 4

STS Low to Data Valid (RD = 0)

t

14

50

50

ns max

Load ckt of Figure 3, C

L

= 20 pF

ADC Write Timing

Time

Interval

MP3275

8

Rev. 4.00

WR

ADDRESS

Figure 1. Timing for ADC Channel Select Start Conversion

STL

ADEN

STS

SDO

RD = 0

SDO

RD = 1

HIGH Z

Previous ADC Data

New ADC Data

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

11

10

t

t

12

t

14

t

13

Table 3. ADC Read Timing

(

See Figure 2.)

25

∞

C

Tmin to

Tmax

Limits

Comments/Test Conditions

RD to Data Valid Delay

t

17

100

150

ns max

Load ckt of

Figure 3., C

L

= 20 pF

150

200

ns max

Load ckt of

Figure 3., C

L

= 100 pF

SDO Relinquish Time after

t

18

100

150

ns max

Load ckt of

Figure 4.

RD High

RD Pulse Width

t

19

100

150

ns min

ADC Read Timing

Time

Interval

RD

DATA

Figure 2. Timing for ADC Read

t

18

t

Valid

17

MP3275

9

Rev. 4.00

Figure 3. Load Circuit for Data

Access Time Test

3k

C

L

a. High-Z to V

ON

DB

N

3k

b. High-Z to V

OL

+5 V

Figure 4. Load Circuit for

Bus Relinquish Time Test

3k

10pF

a. V

ON

to High-Z

3k

10pF

b. V

OL

to High-Z

+5 V

N

DB

N

DB

N

DB

C

L

C

L

Figure 5. Load Circuit for WR to STS Delay

DGND

STL, STS

Serial Data Output

The serial data output sequence is MSB (DB11) first to LSB

(DB0) last. The MSB (DB11) data bit appears at SDO when STS

goes low. The second most significant bit appears at SDO on

the SDC high-to-low transition next. The LSB (DB0) is present

at SDO on the 11th SDC high-to-low transition.

Further information regarding serial control and timing is

shown in

Figure 6., Table 4. and Table 5.

For a minimum interconnect serial environment, the channel

address state can be generated in at least two ways, using an

address counter, or using an address serial to parallel converter.

WR can then be used as the counter clock or shift register load

signal as well as the A/D converter start convert signal on the ris-

ing edge. (Note that the falling edge loads the address present at

the address port.)

SDC

SDO

Figure 6. Serial Data Mode Timing

DB11 (MSB)

DB10

t

21

t

22

SDC should be in a high state during the STS high period. SDC can make the first high to low transition after t

21

.

t

20

STS

See Table 4

«««««

«««««

MP3275

10

Rev. 4.00

Table 4. Serial Data Output Mode Timing

(

See Figure 6.)

25

∞

C

Tmin to

Tmax

Limits

Comments/Test Conditions

STS low to SDO Valid,

t

20

50

50

ns max

Load Ckt 4 of

Figure 3.

RD = 0

Minimum clock high pulse width

t

21

50

80

ns max

SDC low to data valid delay

t

22

150

200

ns max

Load ckt of

Figure 3., C

L

= 20pF

200

250

ns max

Load ckt of

Figure 3., C

L

= 100pF

Serial Data Output Timing

Time

Interval

Note 1: If RD = 1, data outputs remain high impedance. It is recommended that RD will not change during a con-

version in order to reduce noise. It is further recommended that RD = 1 during conversion to reject any noise

present on the data bus.

Table 5. Logic Truth Table ≠ Serial Data Output

WR

RD

ADEN

Data

STL

STS

Comments

1

0

Hi-Z

0

0

X

No operation if ADEN = 0

1

1

Hi-Z

0

X

Input MUX channel selected, STL

set on falling edge of WR

0

1

X

Hi-Z

1

0

X

MUX select disabled

1

X

Hi-Z

0

X

Start convert on WR rising edge

1

1

X

Hi-Z

X

Start convert on STL falling edge

1

1

X

Hi-Z

0

X

STS goes low at end of conversion

ADC Channel Select and Start Convert

DB0/SDC

1

X

≠≠

0

0

1

Serial output (SDO) and

serial clock input (SDC) enabled

X

X

X

MSB (DB11)

0

0

1

MSB data available at SDO

X

0

X

DB10

0

0

Next significant bit shifted out to SDO

X

0

X

DB10

0

0

0

No Operation

X

0

X

DB10

0

0

No Operation

X

0

X

DB9

0

0

Next significant bit shifted out to SDO

X

X

Hi-Z

0

0

X

Data outputs/SDC input disabled

1

X

X

Hi-Z

0

1

X

Data outputs/RD disabled when STS = 1

0

0

Hi-Z

0

1

STL, MUX select disabled when ADEN = 0

0

X

MSB (DB11)

0

1

New data appears at SDO on falling

edge of STS

Read ADC Data (

See Figure 6. and Table 4.)

Table 6. Key Output Codes vs. Input Voltage (2's Complement Code)

2's Complement Output Code (Hexidecimal)

Ideal Transition Voltage

+FS ≠ 1 1/2 LSB

0 V +1/2 LSB

0 V ≠1/2 LSB

≠FS +1/2 LSB

0111

0000

1111

1000

1111

0000

1111

0000

1110 (7fe) to

0000 (000) to

1111 (fff) to

0000(800) to

0111

0000

0000

1000

1111

0000

0000

0000

1111 (7ff)

0001 (001)

0000 (000)

0001 (801)

MP3275

11

Rev. 4.00

APPLICATION INFORMATION

The MP3275 is a complete A/D converter system, with its

own built-in reference and clock. It may be used by itself ("stand-

alone" operation), or it may be interfaced with a microprocessor.

Successful application of the MP3275 requires careful atten-

tion to four main areas:

1)

Physical layout.

2)

Connection/Trimming according to mode of operation.

3)

Conditioning of input signals.

4)

Control and Timing considerations.

Physical Layout

The 12-bit accuracy of the MP3275 represents a dynamic

range of 72dB. Precautions must be taken to avoid any interfer-

ing signals, whether conducted or radiated, to assure that this is

not degraded.

∑

Avoid placing the chip and its analog signals near logic

traces. In general, using a double sided printed circuit

card with a good ground plane on the component side is

recommended. Routing analog signals between ground

traces will help isolate digital control logic. If these lines

cross, do so at right angles. The GND Ref. is the positive

terminal of the MUX/Instrumentation amplifier and will

provide common mode noise rejection. It should be

close to and shielded together with the channel inputs in

order to take advantage of this feature.

∑

Power supplies should be quiet and well regulated.

Grounds should be tied together at the package and

back to the system ground with a single path. Bypass the

supplies at the device with a 0.01 to 0.1

µ

F ceramic cap

and a 10-47

µ

F tantalum type, in parallel.

"Stand-Alone" Operation

The MP3275 can be used in "stand-alone" operation, which is

useful in systems not requiring full computer bus interface capa-

bility.

For this operation, CS = 0, ADEN = 1, and conversion is con-

trolled by WR. The 3-state buffer SDO is enabled when RD goes

low. There are two possible conditions that the 3-state buffer

could be in during a conversion. If RD goes low prior to WR the

output buffer is enabled and the data from the previous conver-

sion is available at the outputs during STL = 1. At the end of the

present conversion which is initiated at the rising edge of WR,

STS returns low and the new conversion result is placed on the

output data buffer.

If WR goes low prior to RD, the data buffer remains in a high

impedance state and conversion is initiated at the rising edge of

WR. Upon the end of the conversion the STS returns low and

the conversion result is placed on the output data buffers.

Ground Reference

The ground reference pin can be used for remote ground

sensing of a common mode input signal with a maximum 6 V p-p

around AGND.

This common input can also be used to dither each input's

"zero". By averaging multiple conversions digitally, higher reso-

lution for each input conversion can be obtained. Patterns for

this dither can be a ramp, a stair step, or white noise.

COMP

S

A

R

VDAC

12

130k

26k

130k

26k

1 of 16

GND Ref.

Figure 7. Equivalent Input Circuit

1/2

V

REF

Quasi Differential Sampling

Method 1

For remote ground sensing where the remote ground does

not change more than

3 V from the A/D ground, connect GND

Ref to the remote ground.

Method 2

Where Method 1 applies to each channel or group of chan-

nels, add a mux to allow connecting the appropriate ground to

GND Ref.

Method 3

Use two parts. Tie both GND Ref pins together and connect

this node to the "common" remote GND. Control the sample

point by connecting each STL through an "OR" gate whose out-

put is "NAND" connect with WR (inverted WR). Use this output

as WR to both WR inputs. By controlling the WR, sample delay

differences between the two converters is minimized. Two parts

from the same date code will further minimize this difference.

Treat one A/D as the (+) terminal and the other as the (≠) termi-

nal of the differential signal. Now the difference can be taken

digitally.

MP3275

12

Rev. 4.00

A

≠≠

3.15

≠≠

0.124

A

1

0.25

≠≠

0.01

≠≠

A

2

2.6

2.8

0.102

0.110

B

0.3

0.4

0.012

0.016

C

0.13

0.23

0.005

0.009

D

16.95

17.45

0.667

0.687

D

1

13.9

14.1

0.547

0.555

e

1.00 BSC

0.039 BSC

L

0.65

1.03

0.026

0.040

0

∞

7

∞

0

∞

7

∞

Coplanarity = 4 mil max.

44 LEAD PLASTIC QUAD FLAT PACK

(14mm x 14mm PQFP, METRIC)

Q44

SYMBOL

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

33

23

22

12

1

11

34

44

D

D

1

D

D

1

B

e

L

A

2

C

A

1

A

MP3275

13

Rev. 4.00

Notes

MP3275

14

Rev. 4.00

Notes

MP3275

15

Rev. 4.00

Notes

MP3275

16

Rev. 4.00

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to im-

prove design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits de-

scribed herein, conveys no license under any patent or other right, and makes no representation that the circuits are

free of patent infringement. Charts and schedules contains here in are only for illustration purposes and may vary

depending upon a user's specific application. While the information in this publication has been carefully checked;

no responsibility, however, is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly

affect its safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation

receives, in writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the

user assumes all such risks; (c) potential liability of EXAR Corporation is adequately protected under the circum-

stances.

Copyright EXAR Corporation

Datasheet April 1995

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.