| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MP8798AS | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

MP8798

1

Rev. 3.00

FEATURES

∑

10-Bit Resolution

∑

4-Channel Mux

∑

Sampling Rates from <1 kHz to 1 MHz

∑

Very Low Power CMOS - 30 mW (typ)

∑

Power Down; Lower Consumption ≠ 3 mW (typ)

∑

Input Range between GND and V

DD

∑

No S/H Required for Analog Signals less than 100 kHz

∑

No S/H Required for CCD Signals less than 1 MHz

∑

Single Power Supply (4 to 6 Volts)

∑

Latch-Up Free

∑

High ESD Protection: 4000 Volts Minimum

∑

3 V Version: MP87L98

CMOS

Very Low Power, 1 MSPS 10-Bit

Analog-to-Digital Converter with 4-Channel Mux

BENEFITS

∑

Reduced Board Space (Small Package)

∑

Reduced External Parts, No Sample/Hold Needed

∑

Suitable for Battery & Power Critical Applications

∑

Designer can Adapt Input Range & Scaling

APPLICATIONS

∑ µ

P/DSP Interface and Control Applications

∑

High Resolution Imaging ≠ Scanners & Copiers

∑

Wireless Digital Communications

∑

Multiplexed Data Acquisition

GENERAL DESCRIPTION

The MP8798 is a flexible, easy to use, precision 10-bit

Analog-to-Digital Converter with 4-channel mux that operates

over a wide range of input and sampling conditions. The

MP8798 can operate with pulsed "on demand" conversion

operation or continuous "pipeline" operation for sampling rates

up to 1 MHz. The elimination of the S/H, requirements, very low

power, and small package size offer the designer a low cost

solution. No sample and hold is required for charge couple

device applications, up to 1 MHz, or multiplexed input

applications when the signal source bandwidth is limited to 100

kHz. The input architecture of the MP8798 allows direct

interface to any analog input range between AGND and AV

DD

(0

to 2 V, 1 to 4 V, 0 to 5 V, etc.). The user simply sets V

REF(+)

and

V

REF(≠)

to encompass the desired input range.

Scaled reference resistor tap 1/2 R allows for customizing

the transfer curve as well as providing a 1/2 span reference

voltage. Digital outputs are CMOS and TTL compatible.

The MP8798 uses a two-step flash technique. The first

segment converts the 4 MSBs and consists of 15 autobalanced

comparators, latches, an encoder, and buffer storage registers.

The second segment converts the remaining 6 LSBs.

When the power down input is "high", the data outputs DB9 to

DB0 hold the current values and V

REF(≠)

is disconnected from

V

REF1(≠).

The power consumption during the power down mode

is approximately 3mW.

Specified for operation over the commercial / industrial (≠40

to +85

∞

C) temperature range, the MP8798 is available in plastic

dual-in-line (PDIP), surface mount (SOIC), and shrink small

outline (SSOP) packages.

ORDERING INFORMATION

Package

Type

Temperature

Range

Part No.

DNL

(LSB)

INL

(LSB)

SOIC

≠40 to +85

∞

C

MP8798AS

1

2

PDIP

≠40 to +85

∞

C

MP8798AN

1

2

SSOP

≠40 to +85

∞

C

MP8798AQ

1

2

MP8798

2

Rev. 3.00

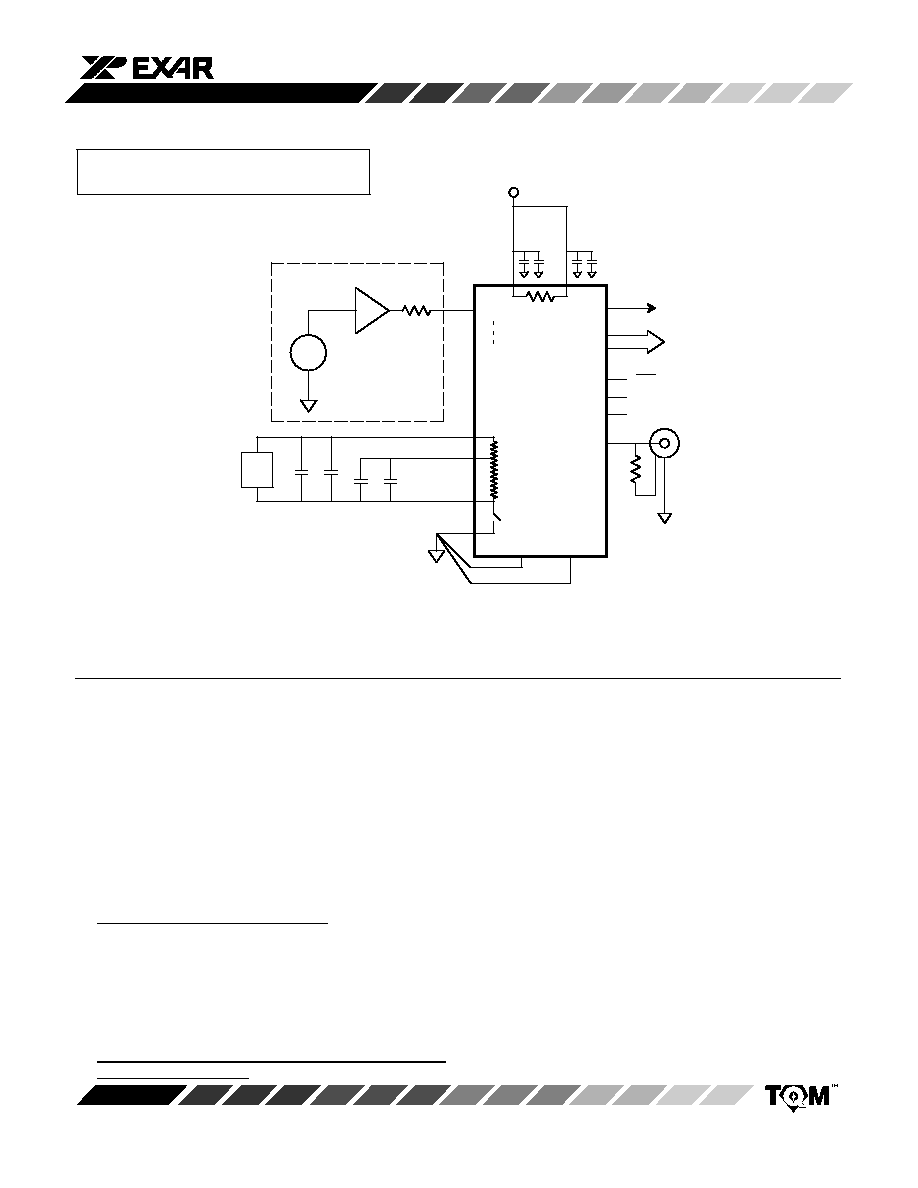

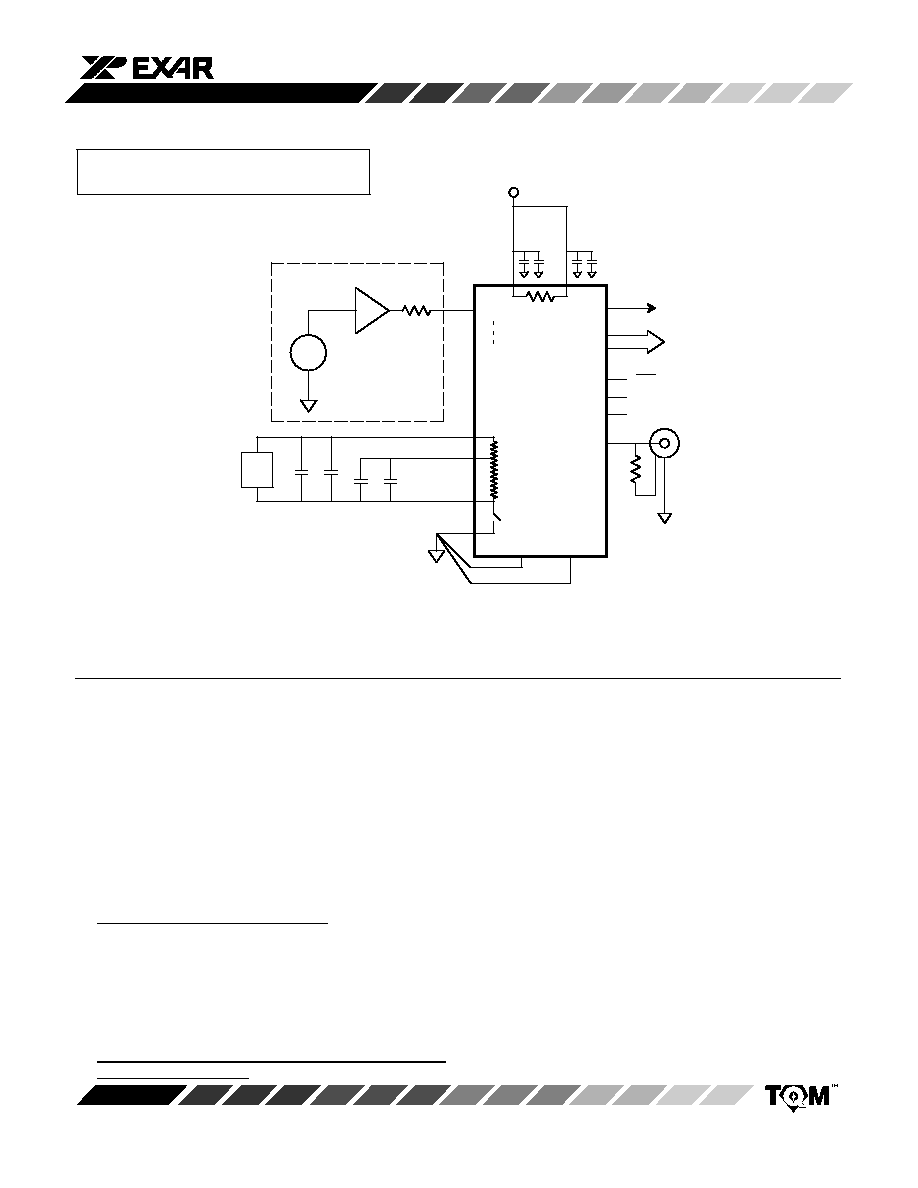

SIMPLIFIED BLOCK AND TIMING DIAGRAM

OFW

10

DFF

N

N

CLK

Ladder

Fine

Com-

Adder

4

5

6

CLK

1/2 R

B

AGND DGND

Coarse

Comparators

N

OFW

Resolution

parators

N-1

N-1

AV

DD

DV

DD

V

REF(+)

V

REF1(≠)

DB9-DB0

DB9-DB0

1 or 4

MUX

A

IN1

A

IN4

S

2 to 4

Decoder

A1

A0

WR

A

IN2

A

IN3

PD

V

REF(≠)

4

Latch

B

S

PIN CONFIGURATIONS

See Packaging Section for

Package Dimensions

28 Pin SOIC (Jedec, 0.300") ≠ S28

28 Pin SSOP ≠ A28

DB2

DB1

DB0

PD

AGND

1/2 R

AV

DD

A

IN4

V

REF(≠)

V

REF(+)

DGND

A1

A0

CLK

DB8

DV

DD

DB3

DB4

DB5

DB6

DB7

28

1

15

14

2

3

4

5

6

7

17

16

8

9

19

18

10

11

23

22

21

20

27

26

25

24

12

13

DB9

OFW

A

IN3

A

IN2

A

IN1

V

REF1(≠)

WR

13

16

14

15

1

2

3

4

5

6

7

8

9

10

28

27

26

25

24

23

22

21

20

19

11

18

12

17

DB2

DB1

DB0

PD

AGND

1/2 R

AV

DD

A

IN4

V

REF(≠)

V

REF(+)

DGND

A1

A0

CLK

DB8

DV

DD

DB3

DB4

DB5

DB6

DB7

DB9

OFW

A

IN3

A

IN2

A

IN1

V

REF1(≠)

WR

28 Pin PDIP (0.300")

NN28

MP8798

3

Rev. 3.00

PIN OUT DEFINITIONS

1

DB3

Data Output Bit 3

2

DB4

Data Output Bit 4

3

DB5

Data Output Bit 5

4

DB6

Data Output Bit 6

5

DB7

Data Output Bit 7

6

DGND

Digital Ground

7

DV

DD

Digital V

DD

8

WR

Write (Active Low)

9

A1

Address 1 Input

10

A0

Address 0 Input

11

CLK

Clock Input

12

DB8

Data Output Bit 8

13

DB9

Data Output Bit 9 (MSB)

14

OFW

Overflow Output

PIN NO.

NAME

DESCRIPTION

15

V

REF(+)

Upper Reference Voltage

16

V

REF(≠)

Lower Reference Voltage

17

V

REF1(≠)

Lower Reference Voltage

18

1/2 R

Reference Ladder Tap

19

A

IN1

Analog Signal Input 1

20

A

IN2

Analog Signal Input 2

21

A

IN3

Analog Signal Input 3

22

A

IN4

Analog Signal Input 4

23

AGND

Analog Ground

24

AV

DD

Analog V

DD

25

PD

Power Down

26

DB0

Data Output Bit 0 (LSB)

27

DB1

Data Output Bit 1

28

DB2

Data Output Bit 2

PIN NO.

NAME

DESCRIPTION

TRUTH TABLE FOR INPUT CHANNEL SELECTION

0

0

0

A

IN1

0

0

1

A

IN2

0

1

0

A

IN3

0

1

1

A

IN4

1

X

X

Previous selection

WR

A1

SELECTED ANALOG INPUT

A0

Note: WR, A1, A0 are internally connected to GND through

500k

resistance.

MP8798

4

Rev. 3.00

ELECTRICAL CHARACTERISTICS TABLE

Unless Otherwise Specified: AV

DD

= DV

DD

= 5 V, F

S

= 1 MHz (50% Duty Cycle),

V

REF(+)

= 4.6, V

REF(≠)

= AGND, T

A

= 25

∞

C

25

∞

C

Parameter

Symbol

Min

Typ

Max

Units

Test Conditions/Comments

KEY FEATURES

Resolution

10

Bits

Sampling Rate

F

S

.001

1

MHz

For Rated Performance

ACCURACY

2

Differential Non-Linearity

DNL

3/4

1

LSB

Integral Non-Linearity

INL

2

LSB

Best Fit Line

(Max INL ≠ Min INL)/2

Zero Scale Error

EZS

+0.50

LSB

Reference from V

REF(+)

to V

REF(≠)

Full Scale Error

EFS

≠2.5

LSB

REFERENCE VOLTAGES

Positive Ref. Voltage

V

REF(+)

AV

DD

V

Negative Ref. Voltage

V

REF(≠)

AGND

V

Differential Ref. Voltage

5

D

V

REF

0.5

AV

DD

V

Ladder Resistance

R

L

525

675

900

Ladder Temp. Coefficient

1

R

TCO

2000

ppm/

∞

C

Ladder Switch Resistance

1

12

Ladder Switch Off Leakage

1

I

LKG-SW

50

nA

ANALOG INPUT

1

Input Bandwidth

100

kHz

Input Voltage Range

7

V

IN

V

REF(≠)

V

REF(+)

V

Input Capacitance

3

C

IN

60

pF

Aperture Delay

t

AP

35

45

ns

DIGITAL INPUTS

Logical "1" Voltage

V

IH

2.0

V

Logical "0" Voltage

V

IL

0.8

V

Leakage Currents

I

IN

V

IN

=DGND to DV

DD

CLK

100

µ

A

PD, (Internal Res to DGND)

≠5

30

µ

A

Input Capacitance

5

pF

Clock Timing (

See NO TAG)

1

Clock Period

T

S

1000

ns

Rise & Fall Time

4

t

R

, t

F

10

ns

"High" Time

6

t

B

250

500,000

ns

"Low" Time

6

t

S

150

500,000

ns

MP8798

5

Rev. 3.00

ELECTRICAL CHARACTERISTICS TABLE (CONT'D)

25

∞

C

Specifications are subject to change without notice

Parameter

Symbol

Min

Typ

Max

Units

Test Conditions/Comments

DIGITAL OUTPUTS

C

OUT

=15 pF

Logical "1" Voltage

V

OH

DV

DD

-0.5

V

I

LOAD

= 2 mA

Logical "0" Voltage

V

OL

0.4

V

I

LOAD

= 4 mA

Tristate Leakage

I

OZ

0

5

µ

A

V

OUT

= 0 to DV

DD

Data Hold Time (

See NO TAG)

1

t

HLD

30

35

ns

Data Valid Delay

1

t

DL

35

45

ns

Write Pulse Width

1

t

WR

40

ns

Multiplexer Address Setup Time

1

t

AS

80

ns

Multiplexer Address Hold Time

1

t

AH

0

ns

Delay from WR to Multiplexer

1

Enable

t

MUXEN1

80

ns

Power Down Time

1

t

PD

300

ns

Power Up Time

1

t

PU

200

ns

POWER SUPPLIES

8

Power Down (I

DD

)

I

PD-DD

0.6

1.2

mA

Operating Voltage (AV

DD

, DV

DD

)

V

DD

4

5

6.5

V

Current (AV

DD

+ DV

DD

)

I

DD

6

10

mA

V

IN

= 2 V

NOTES:

1

Guaranteed. Not tested.

2

Tester measures code transition voltages by dithering the voltage of the analog input (V

IN

). The difference between the measured

code width and the ideal value (V

REF

/1024) is the DNL error (

see NO TAG). The INL error is the maximum distance (in LSBs) from

the best fit line to any transition voltage (

See Figure 7.).

3

See V

IN

input equivalent circuit (

see Figure 9.).

4

Clock specification to meet aperture specification (t

AP

). Actual rise/fall time can be less stringent with no loss of accuracy.

5

Specified values guarantee functional device. Refer to other parameters for accuracy.

6

System can clock MP8798 with any duty cycle as long as all timing conditions are met.

7

Input range where input is converted correctly into binary code. Input voltage outside specified range converts to zero or full scale

output.

8

DV

DD

and AV

DD

are connected through the silicon substrate. Connect together at the package.

ABSOLUTE MAXIMUM RATINGS (T

A

= +25

∞

C unless otherwise noted)

1, 2

V

DD

(to GND)

+7 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

REF(+)

& V

REF(≠)

GND ≠0.5 to V

DD

+0.5 V

. . . . . . . . . . . . . .

V

IN

GND ≠0.5 to V

DD

+0.5 V

. . . . . . . . . . . . . . . . . . . . . . . . . .

All Inputs

GND ≠0.5 to V

DD

+0.5 V

. . . . . . . . . . . . . . . . . . . . .

All Outputs

GND ≠0.5 to V

DD

+0.5 V

. . . . . . . . . . . . . . . . . . .

Storage Temperature

≠65 to +150

∞

C

. . . . . . . . . . . . . . . . . . .

Lead Temperature (Soldering 10 seconds)

+300

∞

C

. . . . . . .

Package Power Dissipation Rating to 75

∞

C

SOIC, PDIP

1000mW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Derates above 75

∞

C

14mW/

∞

C

. . . . . . . . . . . . . . . . . . . . .

NOTES:

1

Stresses above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. This is a

stress rating only and functional operation at or above this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

2

Any input pin which can see a value outside the absolute maximum ratings

should be protected by Schottky diode clamps

(HP5082-2835) from input pin to the supplies.

All inputs have protection diodes which will protect the device from short

transients outside the supplies of less than 100mA for less than 100

µ

s.

3

V

DD

refers to AV

DD

and DV

DD

. GND refers to AGND and DGND.

MP8798

6

Rev. 3.00

AUTO

BALANCE

CLOCK

DATA

ANALOG

INPUT

SAMPLE

N≠1

Figure 1. MP8798 Timing Diagram

SAMPLE

N

SAMPLE

N+1

AUTO

BALANCE

N-1

T

S

V

IH

V

IL

V

OH

V

OL

t

F

t

B

t

R

t

S

t

DL

t

HLD

THEORY OF OPERATION

Analog-to-Digital Conversion

The MP8798 converts analog voltages into 1024 digital

codes by encoding the outputs of 15 coarse and 67 fine compa-

rators. Digital logic is used to generate the overflow bit. The con-

version is synchronous with the clock and it is accomplished in 2

clock periods.

The reference resistance ladder is a series of 1025 resistors.

The first and the last resistor of the ladder are half the value of

the others so that the following relations apply:

R

REF

= 1024

R V

REF

= V

REF(+)

≠ V

REF(≠)

= 1024

LSB

The clock signal generates the two internal phases,

B

(CLK

high) and

S

(CLK low = sample) (

See Figure 2.). The rising

edge of the CLK input marks the end of the sampling phase (

S

).

Internal delay of the clock circuitry will delay the actual instant

when

S

disconnects the latches from the comparators. This de-

lay is called aperture delay (t

AP

).

The coarse comparators make the first pass conversion and

selects a ladder range for the fine comparators. The fine compa-

rators are connected to the selected range during the next

B

phase.

Figure 2. MP8798 Comparators

S

B

B

S

Latch

Ref

Ladder

COARSE COMPARATOR

S

S

B

B

Latch

Selected

Range

FINE COMPARATOR

V

IN

V

IN

V

TAP

V

TAP

A

IN

Sampling, Ladder Sampling, and Conversion Timing

Figure 3. shows this relationship as a timing chart. A

IN

sam-

pling, ladder sampling and output data relationships are shown

for the general case where the levels which drive the ladder

need to change for each sampled A

IN

time point. The ladder is

referenced for both last A

IN

sample and next A

IN

sample at the

same time. If the ladder's levels change by more than 1 LSB,

one of the samples must be discarded. Also note that the clock

low period for the discarded A

IN

can be reduced to the minimum

t

S

time of 150 ns.

Figure 3. A

IN

Sampling, Ladder Sampling & Conversion Timing

Settle by Clock Update Time

Reference Stable Time ≠ For Sample A

IN

1

Sample A

IN

1

Reference Stable Time ≠ For Sample A

IN

2

Hold Reference Value Past

Clock Change for t

AP

Time

Short Cycle Sample will be discarded

Sample A

IN

2

A

IN

X1

Not Used

A

IN

X0

Sample A

IN

1

A

IN

X1

Sample A

IN

2

Sample Ladder

for A

IN

1

Sample Ladder

for A

IN

X1

Sample Ladder

for A

IN

2

Sample Ladder

for A

IN

X2

Compare Ladder

V/S A

IN

X0

Compare Ladder

V/S A

IN

1

Compare Ladder

V/S A

IN

X1

Compare Ladder

V/S A

IN

2

DATA A

IN

0

DATA A

IN

X0

DATA A

IN

1

DATA A

IN

X1

Not Used

Not Used

DATA

Ladder Compare

(LSB Bank)

Ladder Sample

Window (MSB Bank)

A

IN

Sample

Window

Clock

Update

References

External

Internal

External

t

S

F

B

F

S

F

B

F

S

F

B

F

S

MP8798

7

Rev. 3.00

Accuracy of Conversion: DNL and INL

The transfer function for an ideal A/D converter is shown in

Figure 4.

Figure 4. Ideal A/D Transfer Function

3FF

3FE

3FD

V

REF(≠)

V

REF(+)

DIGITAL

CODES

000

002

LSB

OFW = 0

V

0.5

LSB

0.5

LSB

001

OFW = 1

1 LSB

V001

V002

V

3FE

V

3FF

V

0FW

The overflow transition (V

OFW

) takes place at:

V

IN

= V

OFW

= V

REF(+)

≠ 0.5

LSB

The first and the last transitions for the data bits take place at:

V

IN

= V001 = V

REF(≠)

+ 0.5

LSB

V

IN

= V

3FF

= V

REF(+)

≠ 1.5

LSB

LSB = V

REF

/ 1024 = (V

3FF

≠ V001) / 1022

Note that the overflow transition is a flag and has no impact on

the data bits.

In a "real" converter the code-to-code transitions don't fall

exactly every V

REF

/1024 volts.

A positive DNL (Differential Non-Linearity) error means that

the real width of a particular code is larger than 1 LSB. This error

is measured in fractions of LSBs.

A Max DNL specification guarantees that ALL code widths

(DNL errors) are within the stated value. A specification of Max

DNL = + 0.5 LSB means that all code widths are within 0.5 and

1.5 LSB. If V

REF

= 4.608 V then 1 LSB = 4.5 mV and every code

width is within 2.25 and 6.75 mV.

N + 1

N

N ≠ 1

Output

Codes

Analog

Input

(N+1) Code Width = V

(N+1)

≠ V

(N)

LSB = [ V

REF(+)

≠ V

REF(≠)

] / 1024

DNL

(N)

= [ V

(N+1)

≠ V

(N)

] ≠ LSB

Figure 5. DNL Measurement

On Production Tester

LSB

DNL

V

(N+1)

V

(N)

The formulas for Differential Non-linearity (DNL), Integral

Non-Linearity (INL) and zero and full scale errors (E

ZS

, E

FS

) are:

DNL (001) = V002 ≠ V001 ≠ LSB

: : :

DNL (3FE) = V

3FF

≠ V

3FE

≠ LSB

E

FS

(full scale error) = V

3FF

≠ [V

REF(+)

≠1.5

LSB]

E

ZS

(zero scale error) = V

001

≠ [V

REF(≠)

+ 0.5

LSB]

Figure 6. Real A/D Transfer Curve

DIGITAL

CODES

0.5

LSB

000

001

002

3FE

3FF

V

1.5

LSB

V001

V002

V

3FE

V

3FF

V

REF(≠)

V

REF(+)

E

ZS

E

FS

Figure 6. shows the zero scale and full scale error terms.

MP8798

8

Rev. 3.00

Figure 7. gives a visual definition of the INL error. The chart

shows a 3-bit converter transfer curve with greatly exaggerated

DNL errors to show the deviation of the real transfer curve from

the ideal one.

After a tester has measured all the transition voltages, the

computer draws a line parallel to the ideal transfer line. By defi-

nition the best fit line makes equal the positive and the negative

INL errors. For example, an INL error of ≠1 to +2 LSB's relative

to the Ideal Line would be +1.5 LSB's relative to the best fit line.

7

6

5

4

3

2

1

Figure 7. INL Error Calculation

Output

Codes

Analog Input (Volt)

Best Fit Line

EFS

EZS

LSB

Ideal Transfer Line

Real Transfer Line

INL

Clock and Conversion Timing

A system will clock the MP8798 continuously or it will give

clock pulses intermittently when a conversion is desired. The

timing of

Figure 8a shows normal operation, while the timing of

Figure 8b keeps the MP8798 in balance and ready to sample the

analog input.

Figure 8. Relationship of Data to Clock

CLOCK

DATA

b. Single sampling

N

N

BALANCE

CLOCK

DATA

a. Continuous sampling

N

N+1

N

N+1

Analog Input

The MP8798 has very flexible input range characteristics.

The user may set V

REF(+)

and V

REF(≠)

to two fixed voltages and

then vary the input DC and AC levels to match the V

REF

range.

Another method is to first design the analog input circuitry and

then adjust the reference voltages for the analog input range.

One advantage is that this approach may eliminate the need for

external gain and offset adjust circuitry which may be required

by fixed input range A/Ds.

The MP8798's performance is optimized by using analog in-

put circuitry that is capable of driving the A

IN

input.

Figure 9.

shows the equivalent circuit for A

IN

.

300

15 pF

Figure 9. Analog Input Equivalent Circuit

V

DD

A

IN

40

S

60 pF

87 pF

160

4

1 pF

10 pF

Channel

Selection

4

Control

R Series

40

R MUX

500

87 pF

1/2 [ V

REF(+)

+ V

REF(≠)

]

S

B

4 pF

+

MP8798

9

Rev. 3.00

Analog Input Multiplexer

The MP8798 includes a 4-channel analog input multiplexer.

The relationship between the clock, the multiplexer address, the

WR and the output data is shown in

Figure 10.

WR

Clock

DB0-DB9

…………………………

…………………………

……

……

t

CLKS2

t

WR

t

CLKH2

Address

t

AS

t

AH

Sample N

Old Address

Sample M

New Address

Sample

M+1

N-2 Valid

N-1 Valid

Old Address

N Valid

Old Address

M Valid

New Address

Figure 10. MUX Address Timing

t

CLKS2

= t

CLKH2

= 0

A1, A0

MUXEN

(Internal Signal)

t

AS

t

AH

WR

t

WR

t

MUXEN1

Figure 11. Analog MUX Timing

Reference Voltages

The input/output relationship is a function of V

REF

:

A

IN

= V

IN

≠ V

REF(≠)

V

REF

= V

REF(+)

≠ V

REF(≠)

DATA = 1023

(A

IN

/V

REF

)

A system can increase total gain by reducing V

REF

.

Digital Interfaces

The logic encodes the outputs of the comparators into a bi-

nary code and latches the data in a D-type flip-flop for output.

The functional equivalent of the MP8798 (

Figure 12.) is com-

posed of:

1)

Delay stage (t

AP

) from the clock to the sampling phase

(

S

).

2)

An ideal analog switch which samples V

IN

.

3)

An ideal A/D which tracks and converts V

IN

with no

delay.

4)

A series of two DFF's with specified hold (t

HLD

) and

delay (t

DL

) times.

t

AP

, t

HLD

and t

DL

are specified in the Electrical Characteristics

table.

Figure 12. MP8798 Functional Equivalent

Circuit and Interface Timing

V

IN

S

A/D

MP8798

CLK

DB9-DB0

N

N+1

N-1

N

t

DL

t

HLD

D Q

D Q

DB9-DB0

CLK

V

IN

t

AP

MP8798

10

Rev. 3.00

Power Down

Figure 13. shows the relationship between the clock,

sampled A

IN

to output data relationship and the effect of power

down.

««««««

««««««

Figure 13. Power Down Timing Diagram

N-2 Valid

DB0-DB9

CLK

V

IN

PD

I

DD

, IV

REF(+)

SAMPLE

N

SAMPLE

M

SAMPLE

M+1

N-1 Valid

N Valid

M Valid

t

CLKS1

t

CLKH1

t

PD

t

PU

MP8798

11

Rev. 3.00

APPLICATION NOTES

Figure 14. Typical Circuit Connections

OFW

CLK

DB9 - DB0

AGND

DGND

(Substrate)

MP8798

A

IN1

V

REF(+)

V

REF(≠)

1/2 R

Buffer

AV

DD

DV

DD

C

1D,

C

2D

C

1A,

C

2A

C

1

= 4.7 or 10

µ

F Tantalum

C

2

= 0.1

µ

F Chip Cap or low inductance capacitor

R

T

= Clock Transmission Line Termination

Reference

Voltage

Source

V

REF1(≠)

A

IN

C

1

C

2

C

1

C

2

+

≠

+5 V

R

T

1 of 4

A

IN4

Z

100

W

Resistive

Isolation of

50 to 100

W

A0

A1

WR

The following information will be useful in maximizing the per-

formance of the MP8798.

1. All signals should not exceed AV

DD

+0.5 V or AGND ≠0.5 V

or DV

DD

+0.5 V or DGND ≠0.5 V.

2. Any input pin which can see a value outside the absolute

maximum ratings (AV

DD

or DV

DD

+0.5 V or AGND ≠0.5 V)

should be protected by diode clamps (HP5082-2835) from

input pin to the supplies. All MP8798 inputs have input pro-

tection diodes which will protect the device from short tran-

sients outside the supply ranges.

3. The design of a PC board will affect the accuracy of MP8798.

Use of wire wrap is not recommended.

4. The analog input signal (V

IN

) is quite sensitive and should be

properly routed and terminated. It should be shielded from

the clock and digital outputs so as to minimize cross coupling

and noise pickup.

5. The analog input should be driven by a low impedance (less

than 50

).

6. Analog and digital ground planes should be substantial and

common at one point only. The ground plane should act as a

shield for parasitics and not a return path for signals. To re-

duce noise levels, use separate low impedance ground

paths.

DGND should not be shared with other digital cir-

cuitry. If separate low impedance paths cannot be provided,

DGND should be connected to AGND next to the MP8798.

7.

DV

DD

should not be shared with other digital circuitry to

avoid conversion errors caused by digital supply transients.

DV

DD

for the MP8798 should be connected to AV

DD

next to

the MP8798.

8. DV

DD

and AV

DD

are connected inside the MP8798 through

the N ≠ doped silicon substrate. Any DC voltage difference

between DV

DD

and AV

DD

will cause undesirable internal

currents.

9. Each power supply and reference voltage pin should be

decoupled with a ceramic (0.1

µ

F) and a tantalum (10

µ

F) ca-

pacitor as close to the device as possible.

10. The digital output should not drive long wires. The capacitive

coupling and reflection will contribute noise to the conver-

sion. When driving distant loads, buffers should be used.

100

resistors in series with the digital outputs in some ap-

plications reduces the digital output disruption of A

IN

.

MP8798

12

Rev. 3.00

Figure 15. Example of a Reference Voltage Source

0.1

µ

F

MP5010

+5 V

+

≠

+

≠

5 k

100k

Figure 16.

5 V Analog Input

V

REF(+)

V

IN

+

≠

R

R

A

IN1

V

REF(≠)

5 V

+5 V

+5 V

DB0

AGND

AV

DD

For R = 5k use Beckman Instruments #694-3-R10k resistor array or equivalent.

NOTE: High R values affect the input BW of ADC due to the (R

C

IN

of ADC) time constant. Therefore, for different

applications the R value needs to be selected as a tradeoff between A

IN

settling time and power dissipation.

1 of 4

A

IN4

Figure 17.

10 V Analog Input

V

REF(+)

V

IN

+

≠

2R

R

A

IN1

V

REF(≠)

10 V

+5 V

+5 V

DB0

For R = 5k use Beckman Instruments #694-3-R10k resistor array or equivalent.

NOTE: High R values affect the input BW of ADC due to the (R

C

IN

of ADC) time constant. Therefore, for different

applications the R value needs to be selected as a tradeoff between A

IN

settling time and power dissipation.

2R

1 of 4

A

IN4

AGND

AV

DD

MP8798

13

Rev. 3.00

Figure 18. A/D Ladder and A

IN

with Programmed Control

(of V

REF(+),

V

REF(≠),

1/2 TAP.)

V

IN

+

≠

@ Power Down write values to DAC 3, 2, 1 = DAC 4 to minimize power consumption.

Only A

IN

and Ladder detail shown.

DAC4

DAC3

DAC1

MP8798

V

REF(+)

1/2

V

REF(+)

V

REF1(≠)

DAC MP7641

DAC8

DAC7

DAC6

DAC5

V

IN

+

≠

V

IN

+

≠

V

IN

+

≠

A

IN4

A

IN1

A

IN2

A

IN3

MP8798

14

Rev. 3.00

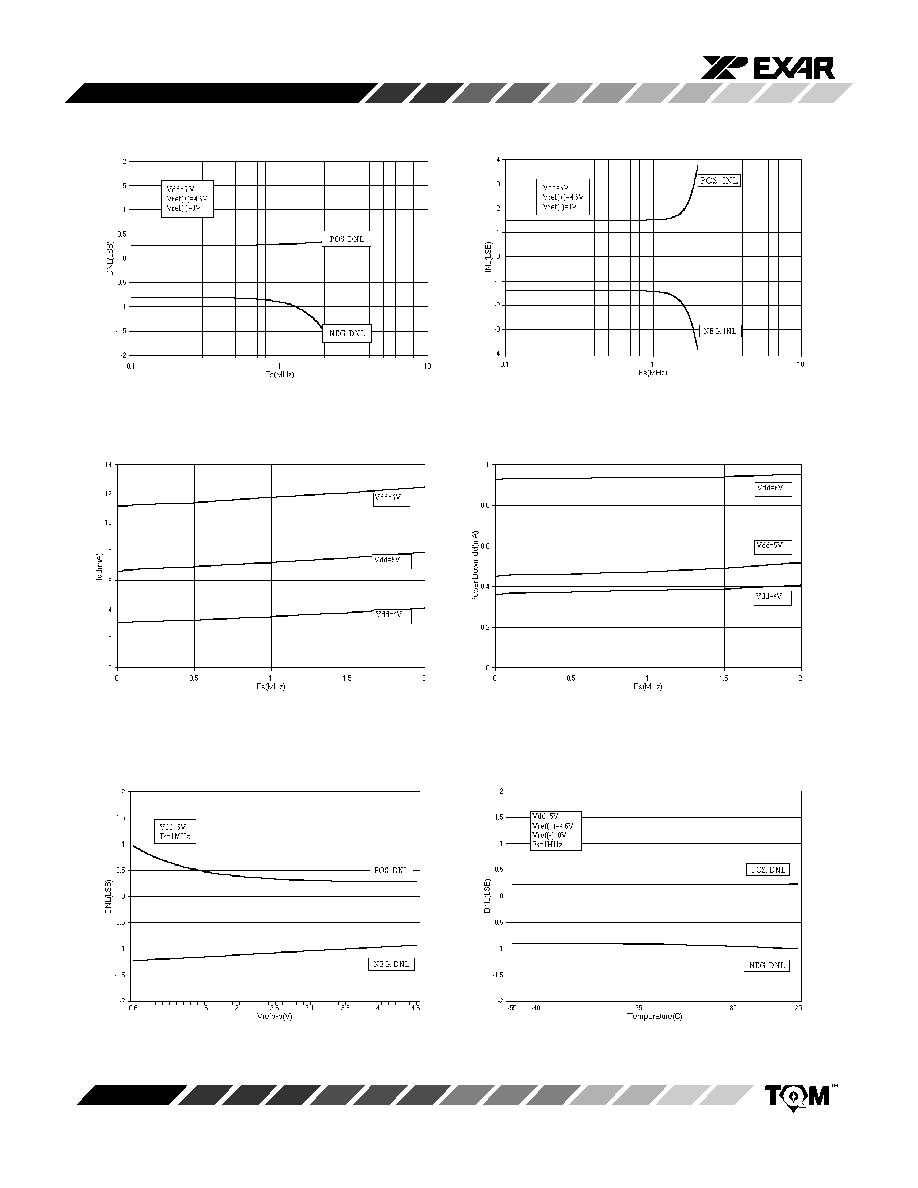

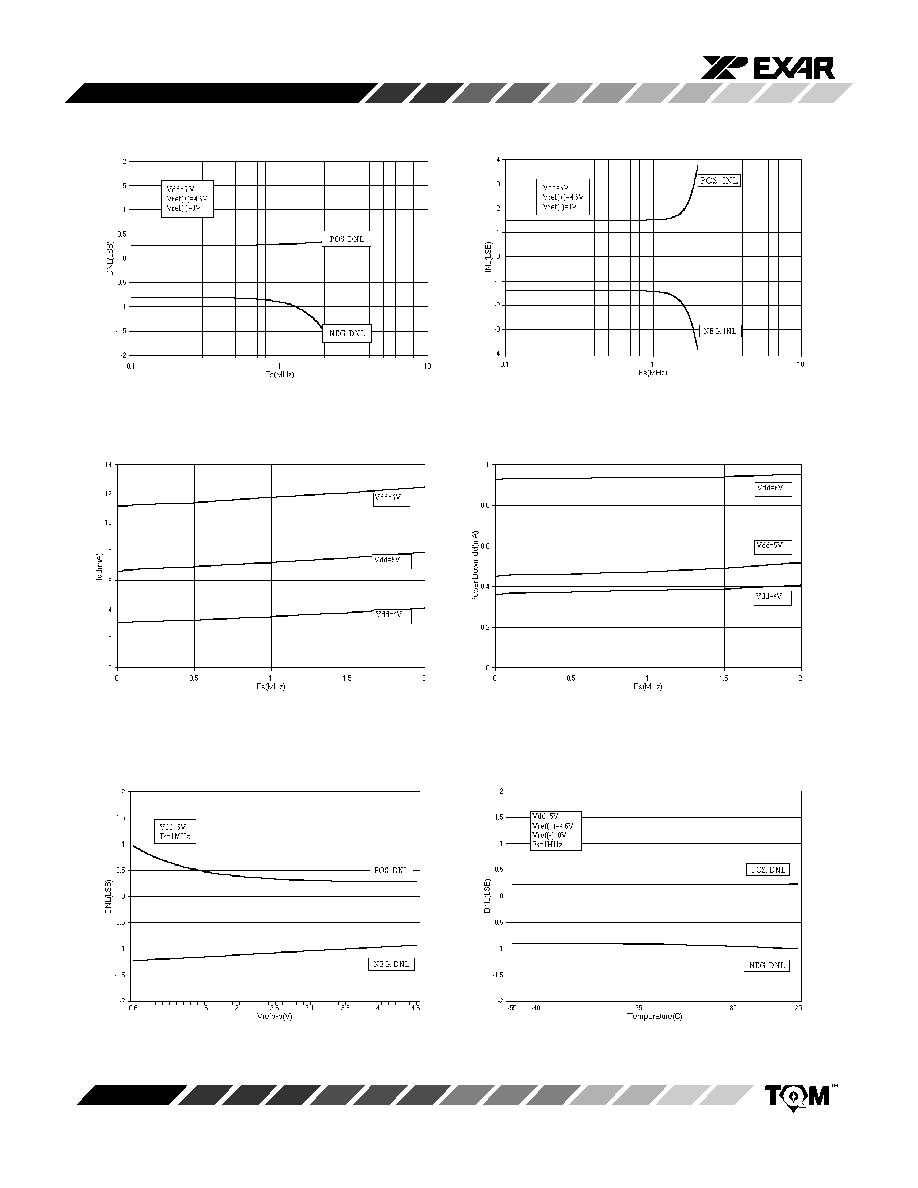

PERFORMANCE CHARACTERISTICS

Graph 1. DNL vs. Sampling Frequency

Graph 2. INL vs. Sampling Frequency

Graph 3. Supply Current vs.

Sampling Frequency

Graph 4. Power Down Current vs.

Sampling Frequency

Graph 5. DNL vs. Reference Voltage

Graph 6. DNL vs. Temperature

MP8798

15

Rev. 3.00

Graph 7. Supply Current vs.

Temperature

Graph 8. Power Down Current vs.

Temperature

Graph 9. Reference Resistance vs.

Temperature

MP8798

16

Rev. 3.00

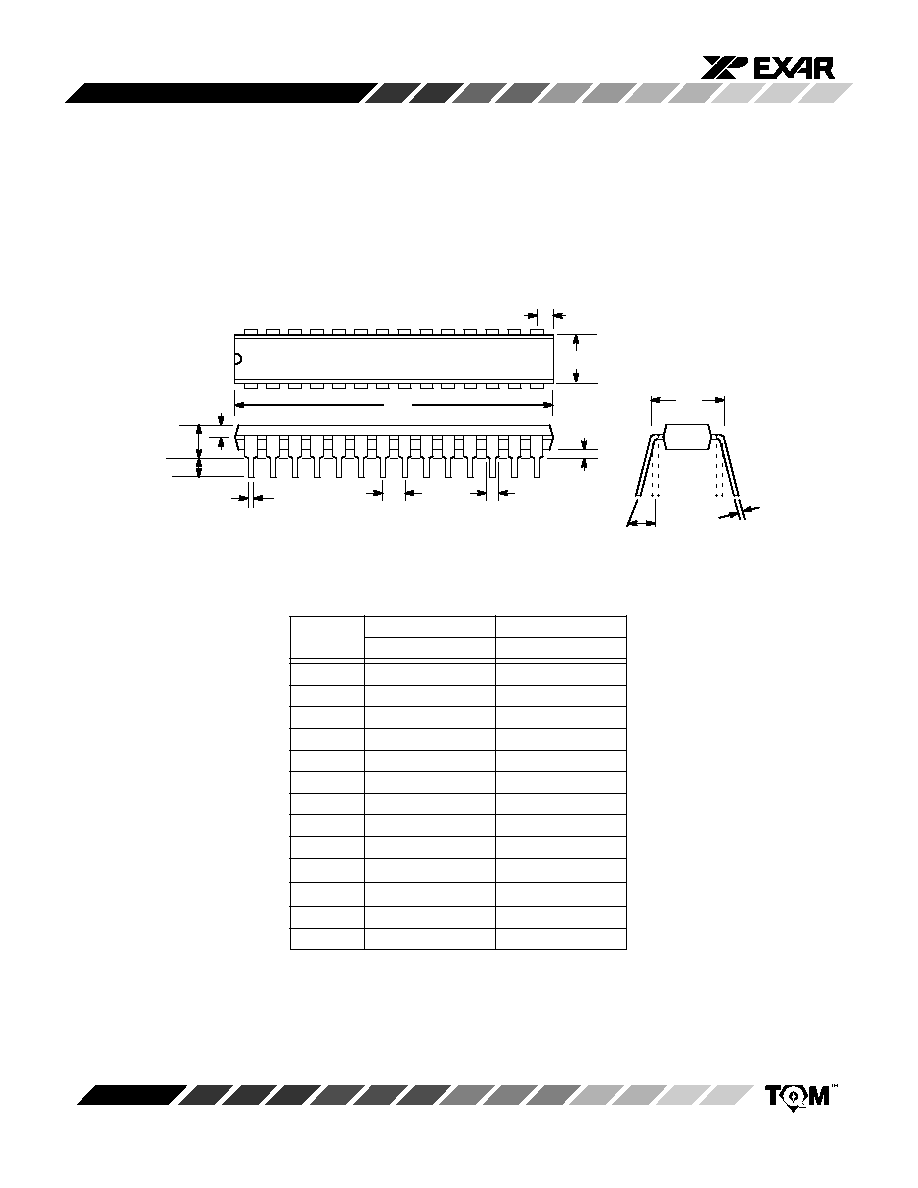

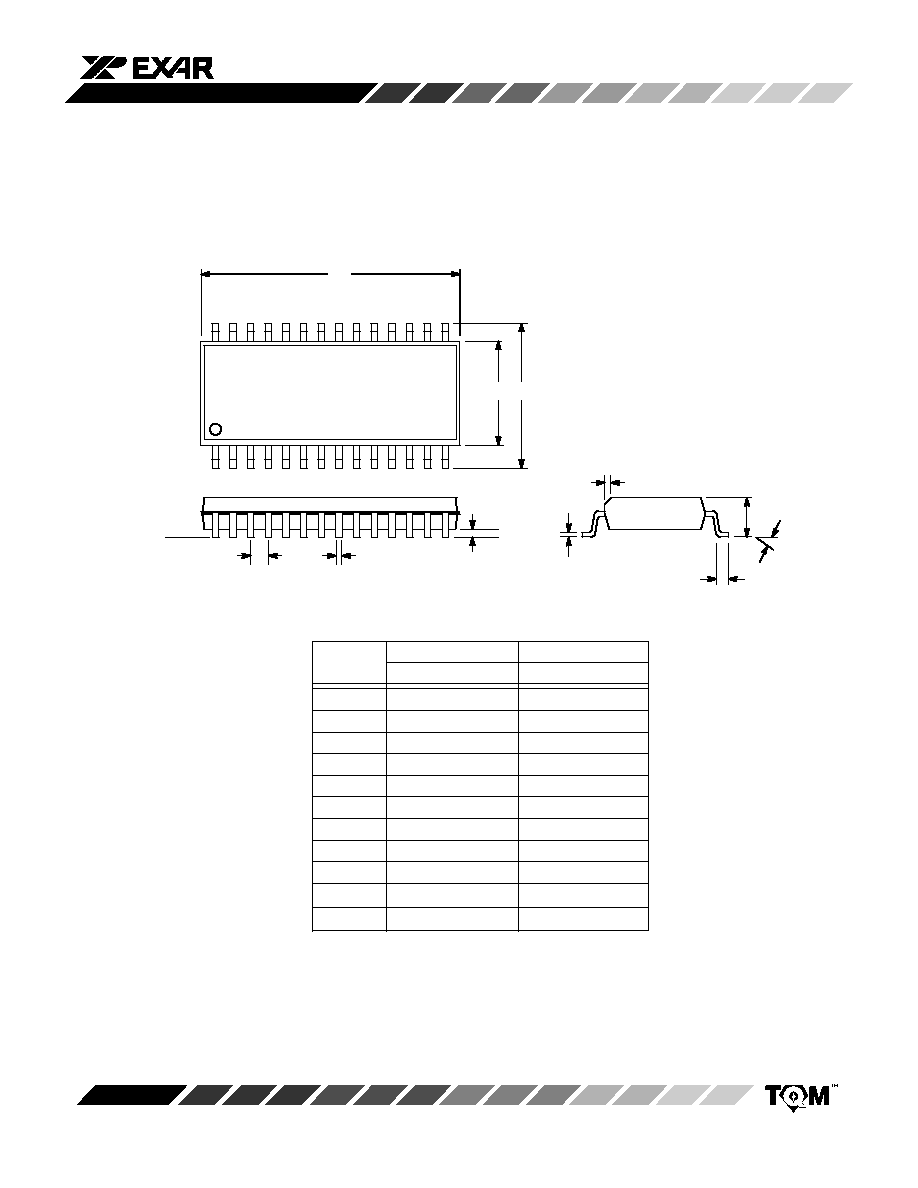

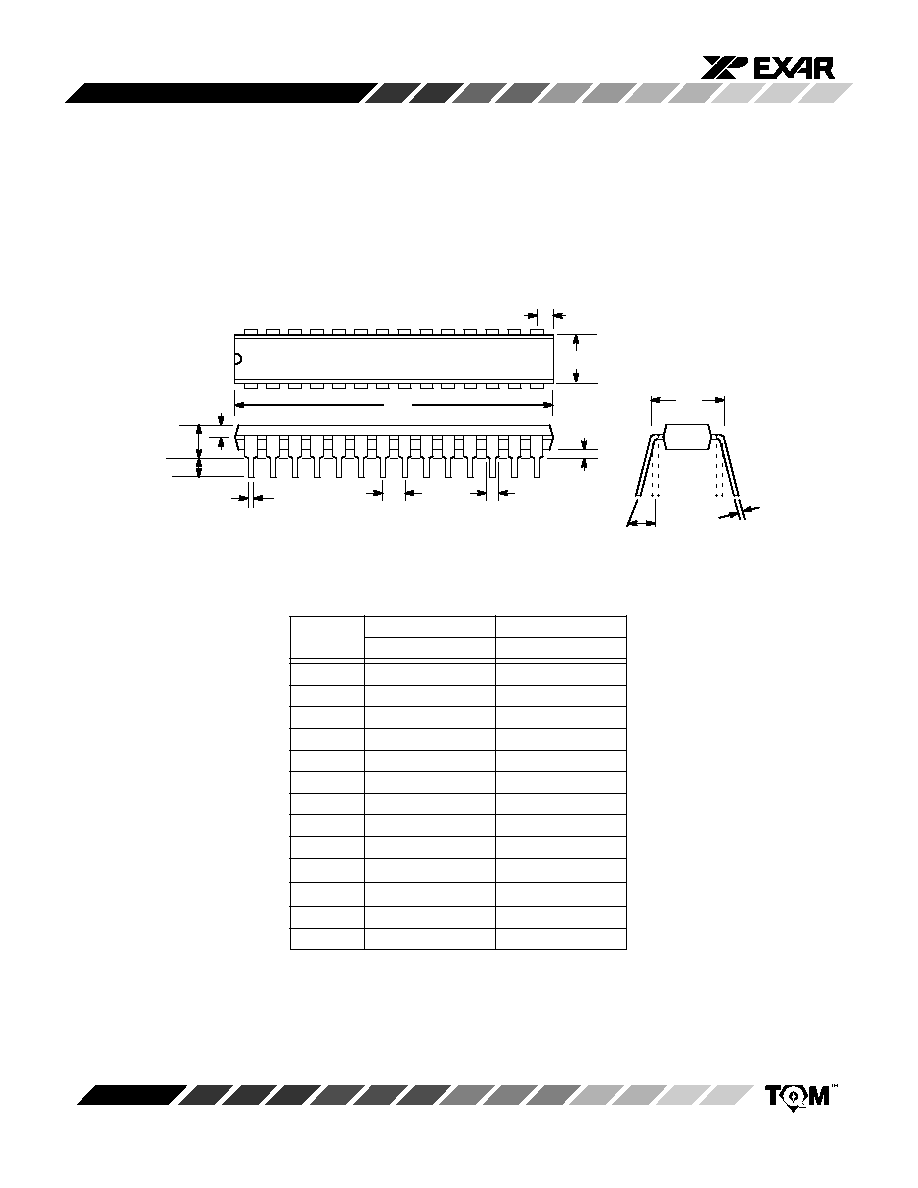

28 LEAD PLASTIC DUAL-IN-LINE

(300 MIL PDIP)

NN28

SYMBOL

MIN

MAX

MIN

MAX

INCHES

A

0.130

0.230

3.30

5.84

A

1

0.015

≠≠

0.381

≠≠

B

0.014

0.023

0.356

0.584

B

1

(1)

0.038

0.065

0.965

1.65

C

0.008

0.015

0.203

0.381

D

1.340

1.485

34.04

37.72

E

0.290

0.325

7.37

8.26

E

1

0.240

0.310

6.10

7.87

e

0.100 BSC

2.54 BSC

L

0.115

0.150

2.92

3.81

0

∞

15

∞

0

∞

15

∞

Q

1

0.055

0.070

1.40

1.78

S

0.020

0.100

0.508

2.54

MILLIMETERS

Note:

(1)

The minimum limit for dimensions B1 may be 0.023"

(0.58 mm) for all four corner leads only.

28

1

15

14

D

e

B

1

A

1

E

1

A

L

B

Q

1

Seating

Plane

C

E

S

MP8798

17

Rev. 3.00

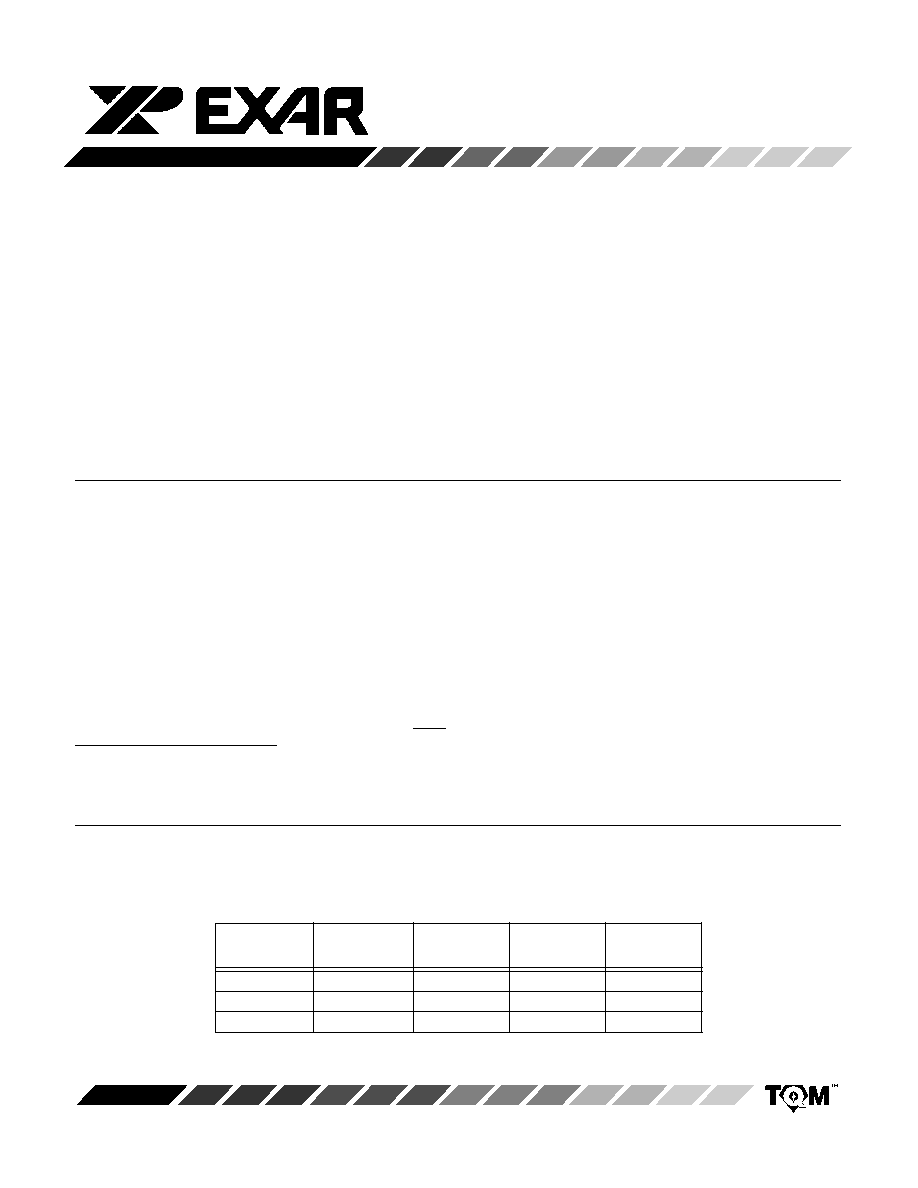

SYMBOL

MIN

MAX

MIN

MAX

A

0.097

0.104

2.464

2.642

A1

0.0050

0.0115

0.127

0.292

B

0.014

0.019

0.356

0.483

C

0.0091

0.0125

0.231

0.318

D

0.701

0.711

17.81

18.06

E

0.292

0.299

7.42

7.59

e

0.050 BSC

1.27 BSC

H

0.400

0.410

10.16

10.41

h

0.010

0.016

0.254

0.406

L

0.016

0.035

0.406

0.889

0

∞

8

∞

0

∞

8

∞

INCHES

MILLIMETERS

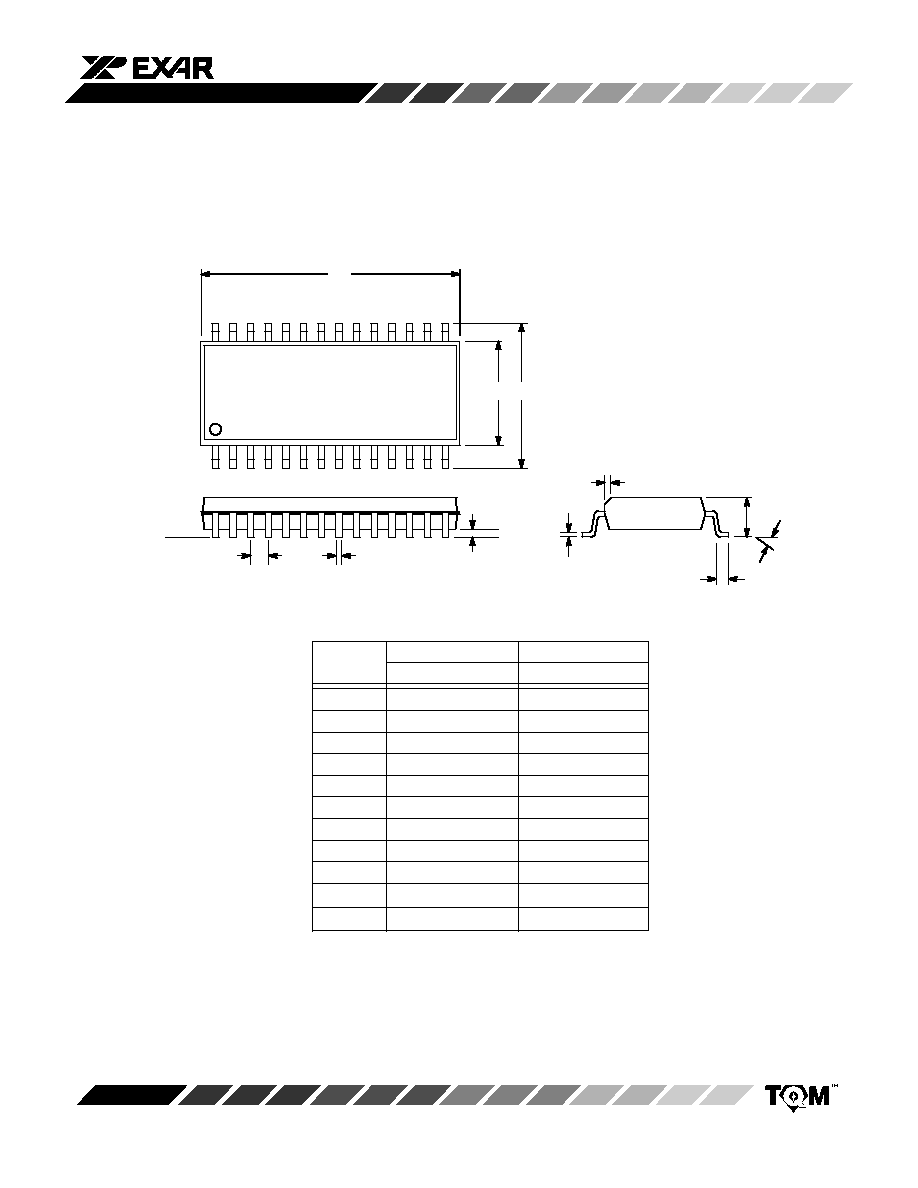

28 LEAD SMALL OUTLINE

(300 MIL JEDEC SOIC)

S28

e

D

E

H

B

A

L

C

A

1

Seating

Plane

h x 45

∞

28

15

14

MP8798

18

Rev. 3.00

SYMBOL

MIN

MAX

MIN

MAX

A

1.73

2.05

0.068

0.081

A

1

0.05

0.21

0.002

0.008

B

0.20

0.40

0.008

0.016

C

0.13

0.25

0.005

0.010

D

10.07

10.40

0.397

0.409

E

5.20

5.38

0.205

0.212

e

0.65 BSC

0.0256 BSC

H

7.65

8.1

0.301

0.319

L

0.45

0.95

0.018

0.037

0

∞

8

∞

0

∞

8

∞

INCHES

MILLIMETERS

28 LEAD SHRINK SMALL OUTLINE PACKAGE

(SSOP)

A28

e

D

E

H

B

A

L

C

A

1

Seating

Plane

28

15

14

1

MP8798

19

Rev. 3.00

Notes

MP8798

20

Rev. 3.00

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to im-

prove design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits de-

scribed herein, conveys no license under any patent or other right, and makes no representation that the circuits are

free of patent infringement. Charts and schedules contains here in are only for illustration purposes and may vary

depending upon a user's specific application. While the information in this publication has been carefully checked;

no responsibility, however, is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly

affect its safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation

receives, in writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the

user assumes all such risks; (c) potential liability of EXAR Corporation is adequately protected under the circum-

stances.

Copyright 1993 EXAR Corporation

Datasheet April 1995

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.