www.fairchildsemi.com

REV. 1.1.7 4/4/03

Features

∑ Highly flexible dual synchronous switching PWM

controller includes modes for:

≠ DDR mode with in-phase operation for reduced

channel interference

≠ 90∞ phase shifted two-stage DDR Mode for reduced

input ripple

≠ Dual Independent regulators 180∞ phase shifted

∑ Complete DDR Memory power solution

≠ V

TT

Tracks VDDQ/2

≠ VDDQ/2 Buffered Reference Output

∑ Lossless current sensing on low-side MOSFET or

precision over-current using sense resistor

∑ V

CC

Under-voltage Lockout

∑ Converters can operate from +5V or 3.3V or Battery

power input (5 to 24V)

∑ Excellent dynamic response with Voltage Feed-Forward

and Average Current Mode control

∑ Power-Good Signal

∑ Also supports DDR-II and HSTL

∑ Light load Hysteretic mode maximizes efficiency

∑ QSOP28, TSSOP28

Applications

∑ DDR V

DDQ

and V

TT

voltage generation

∑ Mobile PC dual regulator

∑ Server DDR power

∑ Hand-Held PC power

General Description

The FAN5236 PWM controller provides high efficiency and

regulation for two output voltages adjustable in the range

from 0.9V to 5.5V that are required to power I/O, chip-sets,

and memory banks in high-performance notebook comput-

ers, PDAs and Internet appliances. Synchronous rectification

and hysteretic operation at light loads contribute to a high

efficiency over a wide range of loads. The hysteretic mode of

operation can be disabled separately on each PWM converter

if PWM mode is desired for all load levels. Efficiency is even

further enhanced by using MOSFET's R

DS(ON)

as a current

sense component.

Feed-forward ramp modulation, average current mode con-

trol scheme, and internal feedback compensation provide

fast response to load transients. Out-of-phase operation with

180 degree phase shift reduces input current ripple. The con-

troller can be transformed into a complete DDR memory

power supply solution by activating a designated pin. In

DDR mode of operation one of the channels tracks the out-

put voltage of another channel and provides output current

sink and source capability -- features essential for proper

powering of DDR chips. The buffered reference voltage

required by this type of memory is also provided. The

FAN5236 monitors these outputs and generates separate

PGx (power good) signals when the soft-start is completed

and the output is within ±10% of its set point. A built-in

over-voltage protection prevents the output voltage from

going above 120% of the set point. Normal operation is auto-

matically restored when the over-voltage conditions go

away. Under-voltage protection latches the chip off when

either output drops below 75% of its set value after the soft-

start sequence for this output is completed. An adjustable

over-current function monitors the output current by sensing

the voltage drop across the lower MOSFET. If precision cur-

rent-sensing is required, an external current-sense resistor

may optionally be used.

FAN5236

Dual Mobile-Friendly DDR / Dual-output PWM Controller

PRODUCT SPECIFICATION

FAN5236

2

REV. 1.1.7 4/4/03

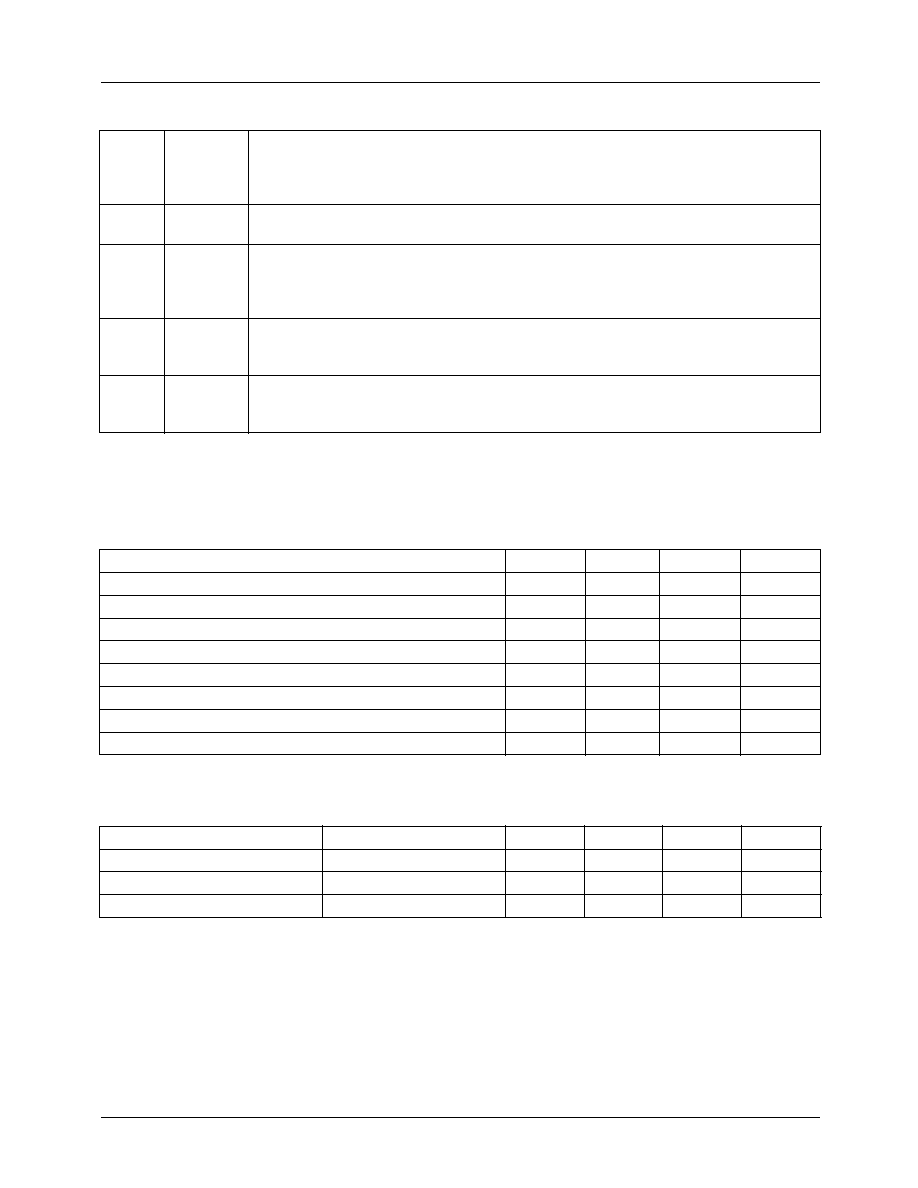

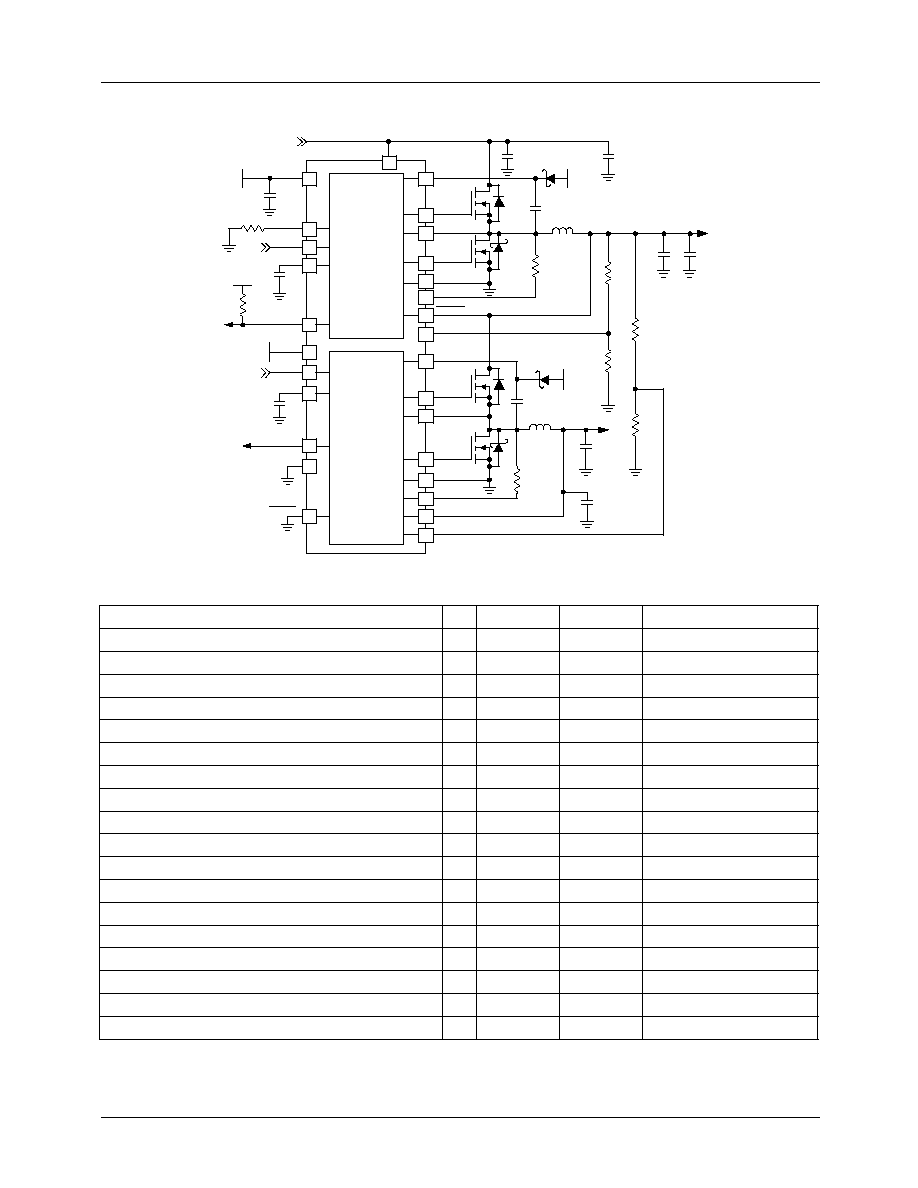

Generic Block Diagrams

Figure 1. Dual output regulator

Figure 2. Complete DDR Memory Power Supply

FAN5236

VIN (BATTERY)

= 5 to 24V

Q1

C

OUT1

VOUT1

= 2.5V

DDR

L

OUT1

Q2

C

OUT2

VOUT2

= 1.8V

L

OUT2

PWM 1

PWM 2

ILIM1

ILIM2/

REF2

VCC

+5

Q3

Q4

FAN5236

Q1

C

OUT1

VDDQ

= 2.5V

DDR

L

OUT1

Q2

C

OUT2

VTT =

VDDQ/2

L

OUT2

PWM 1

PWM 2

ILIM1

PG2/REF

R

R

VCC

+5

+5

ILIM2/REF2

VIN (BATTERY)

= 5 to 24V

Q3

Q4

1.25V

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

3

Pin Configurations

Pin Definitions

Pin

Number

Pin Name

Pin Function Description

1

AGND

Analog Ground.

This is the signal ground reference for the IC. All voltage levels are

measured with respect to this pin.

2

27

LDRV1

LDRV2

Low-Side Drive.

The low-side (lower) MOSFET driver output. Connect to gate of low-side

MOSFET.

3

26

PGND1

PGND2

Power Ground.

The return for the low-side MOSFET driver. Connect to source of low-

side MOSFET.

4

25

SW1

SW2

Switching node.

Return for the high-side MOSFET driver and a current sense input.

Connect to source of high-side MOSFET and low-side MOSFET drain.

5

24

HDRV1

High-Side Drive.

High-side (upper) MOSFET driver output. Connect to gate of high-side

MOSFET.

6

23

BOOT1

BOOT2

BOOT.

Positive supply for the upper MOSFET driver. Connect as shown in Figure 3.

7

22

ISNS1

ISNS2

Current Sense input.

Monitors the voltage drop across the lower MOSFET or external

sense resistor for current feedback.

8

21

EN1

EN2

Enable

. Enables operation when pulled to logic high. Toggling EN will also reset the

regulator after a latched fault condition. These are CMOS inputs whose state is

indeterminate if left open.

9

20

FPWM1

FPWM2

Forced PWM mode.

When logic low, inhibits the regulator from entering hysteretic mode.

Otherwise tie to VOUT. The regulator uses VOUT on this pin to ensure a smooth

transition from Hysteretic mode to PWM mode. When VOUT is expected to exceed VCC,

tie to VCC.

10

19

VSEN1

VSEN2

Output Voltage Sense.

The feedback from the outputs. Used for regulation as well as

PG, under-voltage and over-voltage protection and monitoring.

11

ILIM1

Current Limit 1.

A resistor from this pin to GND sets the current limit.

12

17

SS1

SS2

Soft Start.

A capacitor from this pin to GND programs the slew rate of the converter

during initialization. During initialization, this pin is charged with a 5

µ

A current source.

13

DDR

DDR Mode Control.

High = DDR mode. Low = 2 separate regulators operating 180∞ out

of phase.

AGND

LDRV1

PGND1

SW1

HDRV1

BOOT1

ISNS1

EN1

FPWM1

VSEN1

ILIM1

SS1

DDR

VIN

FAN5236

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC

LDRV2

PGND2

SW2

HDRV2

BOOT2

ISNS2

EN2

FPWM2

VSEN2

ILIM2/REF2

SS2

PG2/REF2OUT

PG1

QSOP-28 or TSSOP-28

JA

= 90

∞C/W

PRODUCT SPECIFICATION

FAN5236

4

REV. 1.1.7 4/4/03

Absolute Maximum Ratings

Absolute maximum ratings are the values beyond which the device may be damaged or have its useful life

impaired. Functional operation under these conditions is not implied.

Recommended Operating Conditions

Note 1: Industrial temperature range (≠40 to + 85∞C) may be special ordered from Fairchild. Please contact your authorized Fairchild

representative for more information.

14

VIN

Input Voltage.

Normally connected to battery, providing voltage feed-forward to set the

amplitude of the internal oscillator ramp. When using the IC for 2-step conversion from 5V

input, connect through 100K to ground, which will set the appropriate ramp gain and

synchronize the channels 90∞ out of phase.

15

PG1

Power Good Flag.

An open-drain output that will pull LOW when VSEN is outside of a

±10% range of the 0.9V reference.

16

PG2 /

REF2OUT

Power Good 2.

When not in DDR Mode: Open-drain output that pulls LOW when the

VOUT is out of regulation or in a fault condition

Reference Out 2.

When in DDR Mode, provides a buffered output of REF2. Typically

used as the VDDQ/2 reference.

18

ILIM2 /

REF2

Current Limit 2.

When not in DDR Mode, A resistor from this pin to GND sets the current

limit.

Reference

for reg #2 when in DDR Mode. Typically set to VOUT1 / 2.

28

VCC

VCC.

This pin powers the chip as well as the LDRV buffers. The IC starts to operate when

voltage on this pin exceeds 4.6V (UVLO rising) and shuts down when it drops below 4.3V

(UVLO falling).

Parameter

Min.

Typ.

Max.

Units

VCC Supply Voltage:

6.5

V

VIN

27

V

BOOT, SW, ISNS, HDRV

33

V

BOOTx to SWx

6.5

V

All Other Pins

≠0.3

VCC+0.3

V

Junction Temperature (T

J

)

≠40

150

∞C

Storage Temperature

≠65

150

∞C

Lead Soldering Temperature, 10 seconds

300

∞C

Parameter

Conditions

Min.

Typ.

Max.

Units

Supply Voltage VCC

4.75

5

5.25

V

Supply Voltage VIN

24

V

Ambient Temperature (T

A

)

Note 1

≠10

85

∞C

Pin Definitions

(continued)

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

5

Electrical Specifications

Recommended operating conditions, unless otherwise noted.

Parameter

Conditions

Min.

Typ.

Max.

Units

Power Supplies

VCC Current

LDRV, HDRV Open, VSEN forced

above regulation point

2.2

3.0

mA

Shut-down (EN=0)

30

µ

A

VIN Current ≠ Sinking

VIN = 24V

10

30

µ

A

VIN Current ≠ Sourcing

VIN = 0V

≠15

≠30

µ

A

VIN Current ≠ Shut-down

1

µ

A

UVLO Threshold

Rising VCC

4.3

4.55

4.75

V

Falling

4.1

4.25

4.45

V

UVLO Hysteresis

300

mV

Oscillator

Frequency

255

300

345

KHz

Ramp Amplitude, pk≠pk

VIN = 16V

2

V

Ramp Amplitude, pk≠pk

VIN = 5V

1.25

V

Ramp Offset

0.5

V

Ramp / VIN Gain

VIN

3V

125

mV/V

Ramp / VIN Gain

1V < VIN < 3V

250

mV/V

Reference and Soft Start

Internal Reference Voltage

0.891

0.9

0.909

V

Soft Start current (I

SS

)

at start-up

5

µ

A

Soft Start Complete Threshold

1.5

V

PWM Converters

Load Regulation

I

OUTX

from 0 to 5A, VIN from 5 to 24V

-2

+2

%

VSEN Bias Current

50

80

120

nA

VOUT pin input impedance

45

55

65

K

Under-voltage Shutdown

as % of set point. 2

µ

S noise filter

70

75

80

%

Over-voltage threshold

as % of set point. 2

µ

S noise filter

115

120

125

%

I

SNS

Over-Current threshold

R

ILIM

= 68.5K

see Figure 11.

112

140

168

µ

A

Output Drivers

HDRV Output Resistance

Sourcing

12

15

Sinking

2.4

4

LDRV Output Resistance

Sourcing

12

15

Sinking

1.2

2

PG (Power Good Output) and Control pins

Lower Threshold

as % of set point, 2

µ

S noise filter

≠86

≠94

%

Upper Threshold

as % of set point, 2

µ

S noise filter

108

116

%

PG Output Low

IPG = 4mA

0.5

V

Leakage Current

V

PULLUP

= 5V

1

µ

A

PG2/REF2OUT Voltage

DDR = 1, 0 mA < I

REF2OUT

10mA

99

1.01

%

VREF2

PRODUCT SPECIFICATION

FAN5236

6

REV. 1.1.7 4/4/03

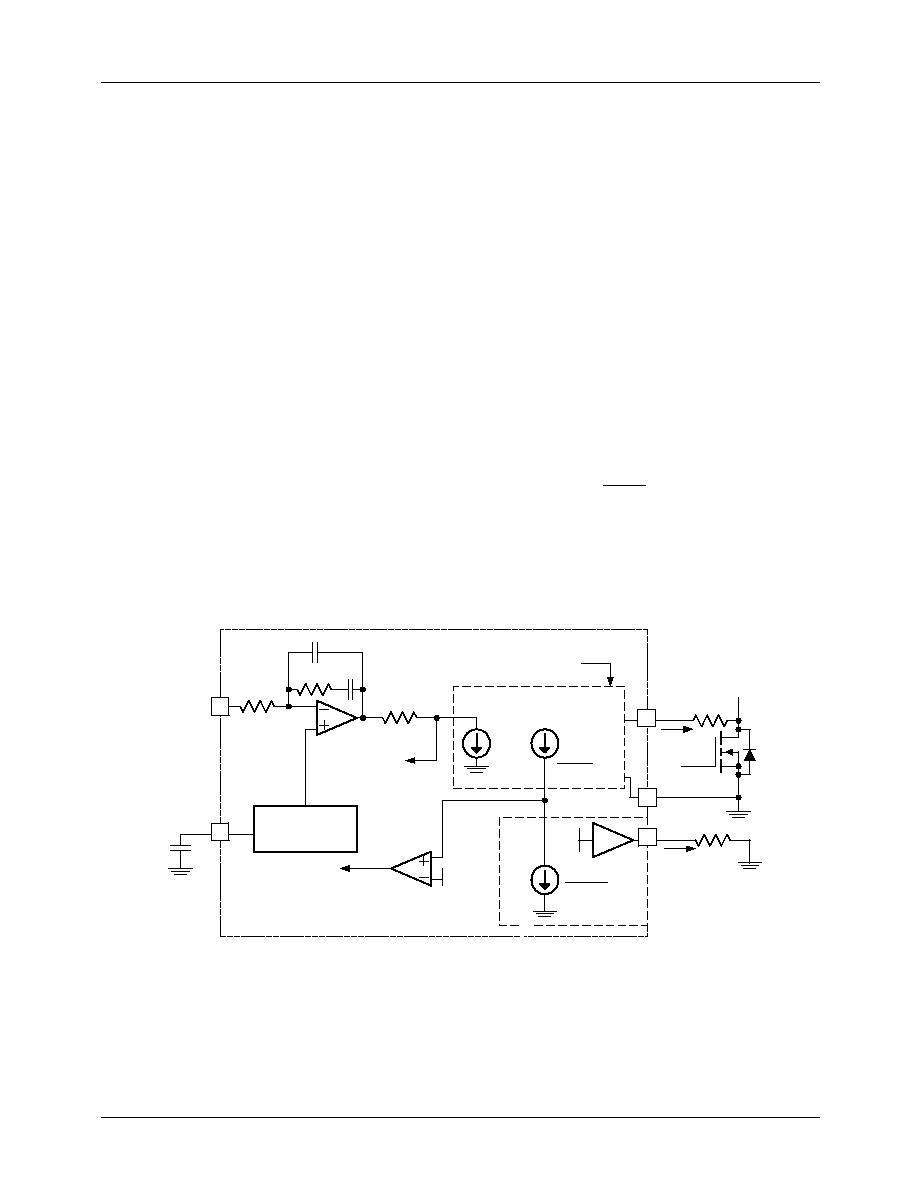

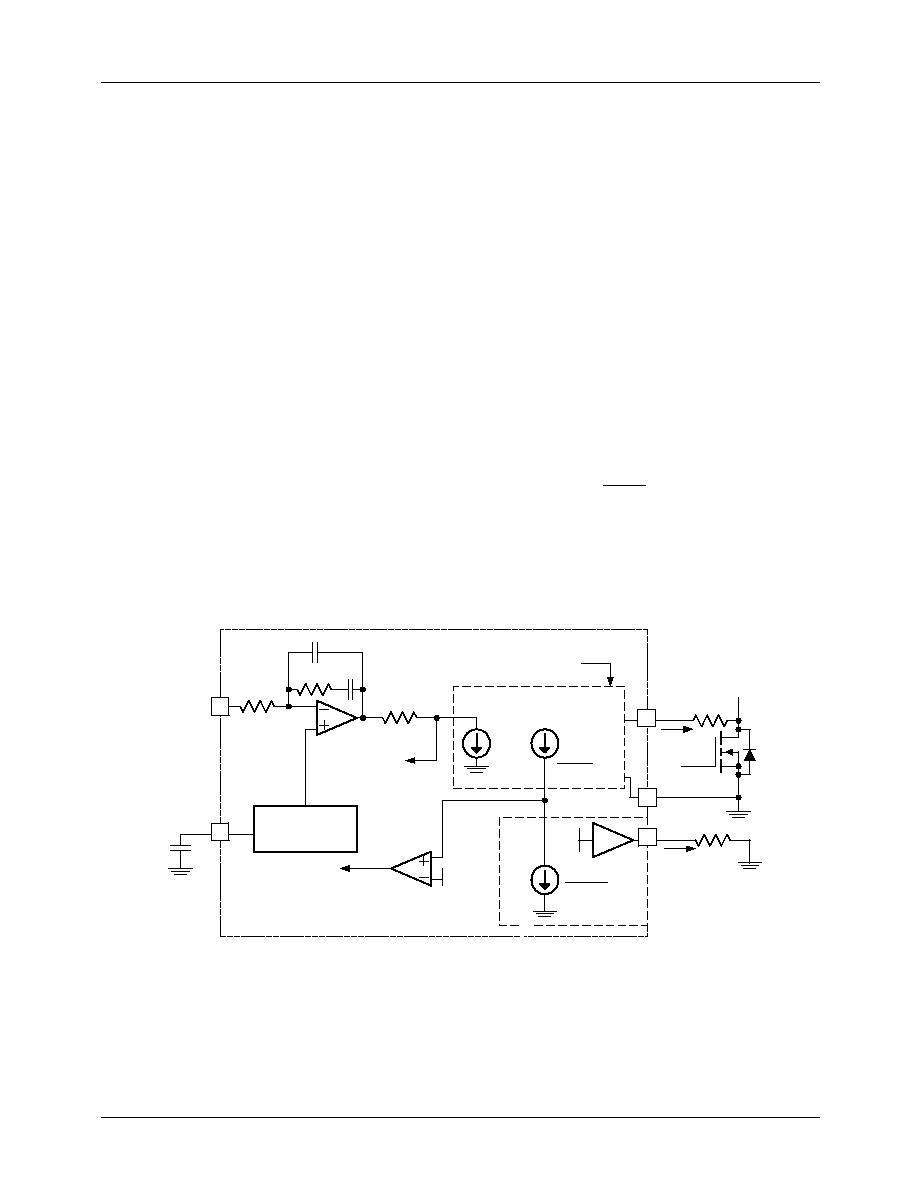

Figure 3. IC Block Diagram

DDR, EN Inputs

Input High

2

V

Input Low

0.8

V

FPWM Inputs

FPWM Low

0.1

V

FPWM High

FPWM connected to output

0.9

V

Electrical Specifications

Recommended operating conditions, unless otherwise noted.

(continued)

Parameter

Conditions

Min.

Typ.

Max.

Units

REF2

PGOOD

EN

C

BOOT

Q1

Q2

5V

VDD

ADAPTIVE

GATE

CONTROL LOGIC

CURRENT PROCESSING

HDRV

SW

LDRV

PGND

BOOT

VDD

HYST

ISNS

VIN

C

OUT

VOUT

PWM/HYST

PWM

S/H

ILIM

R

ILIM

R

SENSE

ILIM det.

HYST

SS

FPWM/VOUT

SS

DUTY

CYCLE

CLAMP

PWM

S

R

Q

RAMP

MODE

DDR

OSC

I

OU T

RAMP

CLK

OVP

POR/UVLO

Reference and

Soft Start

FPWM

L

OU T

VREF

EA

PWM/HYST

VSEN

FPWM/VOUT

VIN

DDR

DDR

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

7

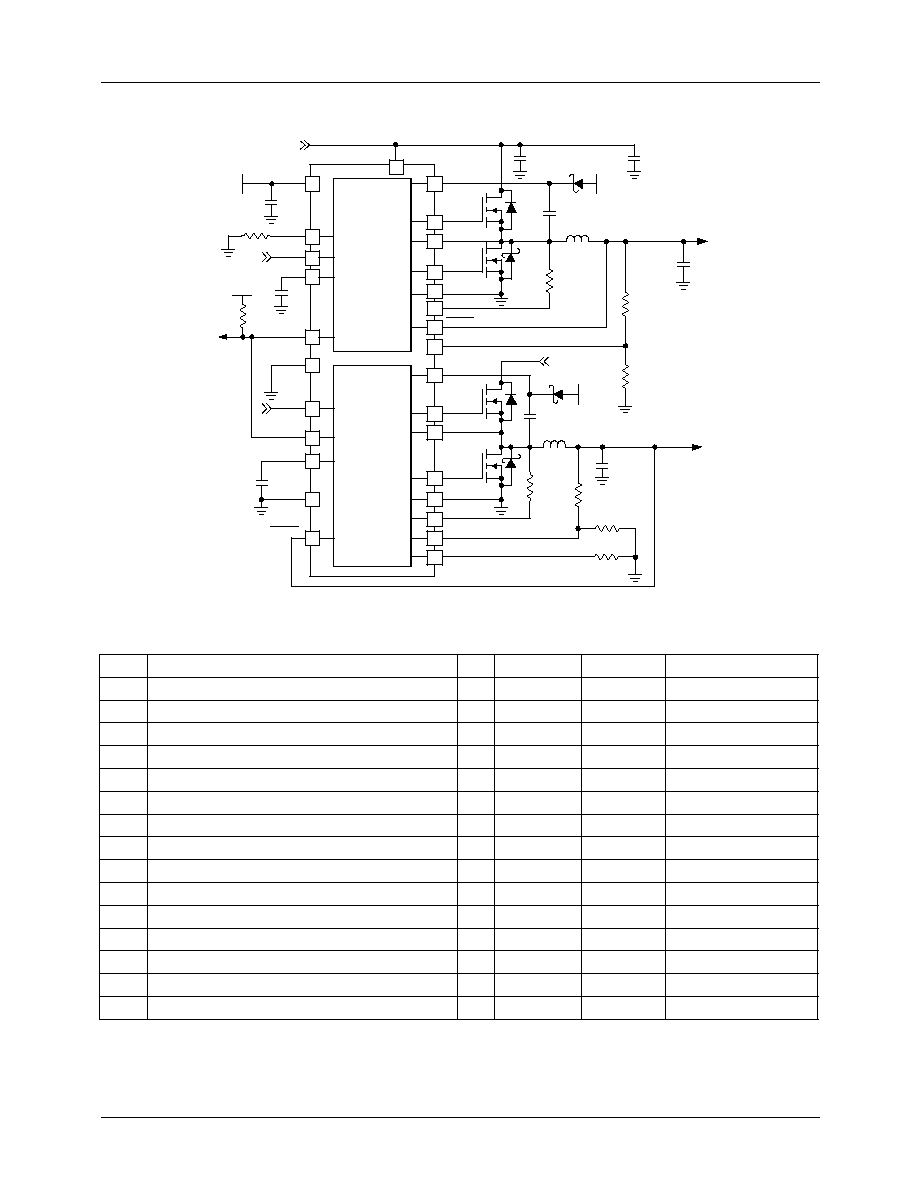

Typical Applications

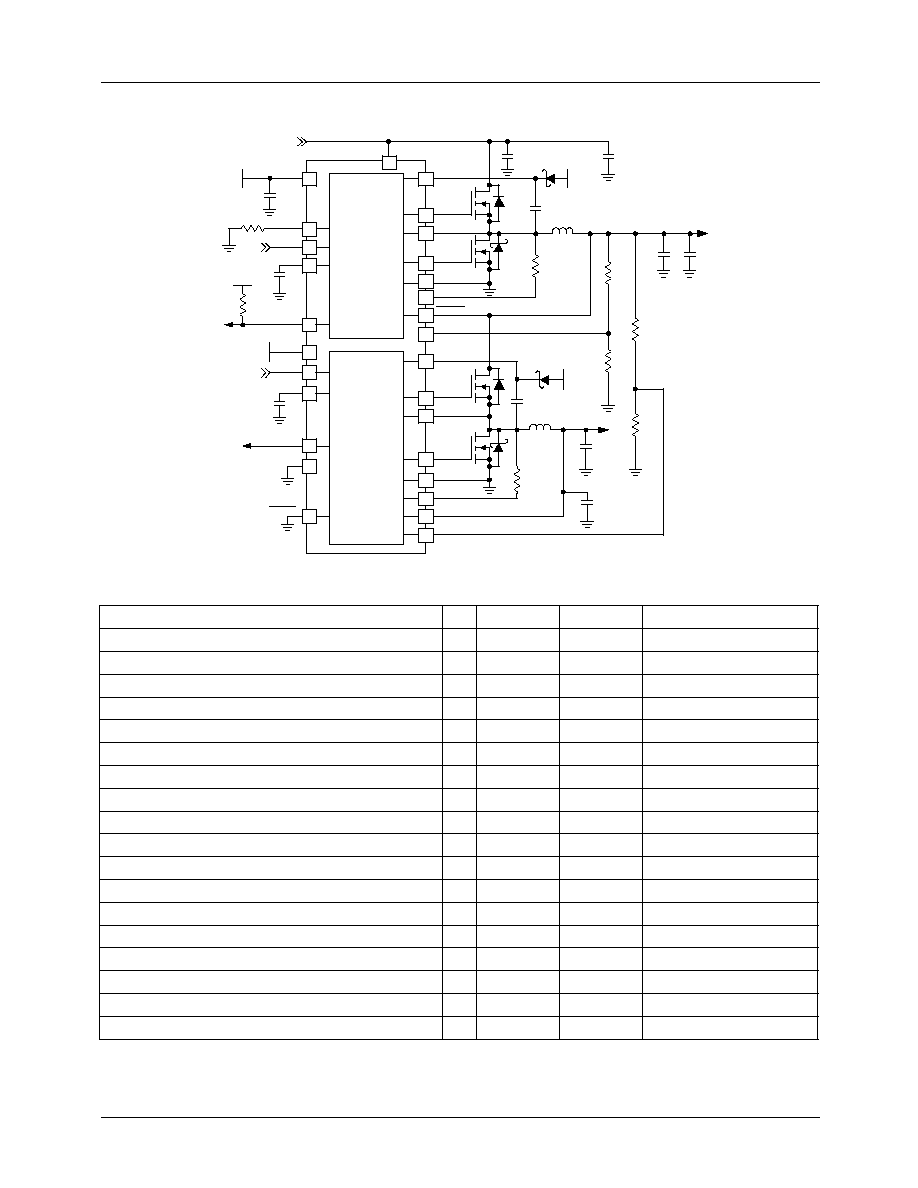

Figure 4. DDR Regulator Application

Table 1. DDR Regulator BOM

Note 1

: Suitable for typical notebook computer application of 4A continuous, 6A peak for VDDQ. If continuous operation above

6A is required use single SO-8 packages for Q1A (FDS6612A) and Q1B (FDS6690S) respectively. Using FDS6690S,

change R7 to 1200

. Refer to Power MOSFET Selection, page 15 for more information.

Description

Qty

Ref.

Vendor

Part Number

Capacitor 68

µ

f, Tantalum, 25V, ESR 150m

1

C1

AVX

TPSV686*025#0150

Capacitor 10nf, Ceramic

2

C2, C3

Any

Capacitor 68

µ

f, Tantalum, 6V, ESR 1.8

1

C4

AVX

TAJB686*006

Capacitor 150nF, Ceramic

2

C5, C7

Any

Capacitor 180

µ

f, Specialty Polymer 4V, ESR 15m

2

C6A, C6B

Panasonic

EEFUE0G181R

Capacitor 1000

µ

f, Specialty Polymer 4V, ESR 10m

1

C8

Kemet

T510E108(1)004AS4115

Capacitor 0.1

µF, Ceramic

2

C9

Any

18.2K

, 1% Resistor

3

R1, R2

Any

1.82K

, 1% Resistor

1

R6

Any

56.2K

, 1% Resistor

2

R3

Any

10K

, 5% Resistor

2

R4

Any

3.24K

, 1% Resistor

1

R5

Any

1.5K

, 1% Resistor

2

R7, R8

Any

Schottky Diode 30V

2

D1, D2

Fairchild

BAT54

Inductor 6.4

µH, 6A, 8.64m

1

L1,

Panasonic

ETQ-P6F6R4HFA

Inductor 0.8

µH, 6A, 2.24m

1

L2

Panasonic

ETQ-P6F0R8LFA

Dual MOSFET with Schottky

1

Q1, Q2

Fairchild

FDS6986S (note 1)

DDR Controller

1

U1

Fairchild

FAN5236

FPWM1 (VOUT1)

2

C6A

VDDQ

= 2.5V

DDR

L1

Q1B

5

27

C8A

VTT =

VDDQ/2

L2

24

PWM 1

PWM 2

ILIM1

PG2/REF

14

13

11

16

R5

R6

18

28

VCC

+5

+5

ILIM2/REF2

Q2B

1.25V@10mA

C7

D1

+5

6

4

R7

7

25

R8

23

D2

+5

9

22

C4

19

VSEN2

ISNS2

1

AGND

R3

3

26

PGND2

SW2

HDRV2

ISNS1

PGND2

EN1

8

EN2

21

Q1A

Q2A

20

FPWM2

10

VSEN1

R2

R1

LDRV1

BOOT2

HDRV1

SW1

BOOT1

VIN

LDRV2

C5

C1

PG1

15

+5

R4

C9

VIN (BATTERY)

= 5 to 24V

SS1

12

C2

SS2

17

C3

C6B

C8B

PRODUCT SPECIFICATION

FAN5236

8

REV. 1.1.7 4/4/03

Typical Applications

(continued)

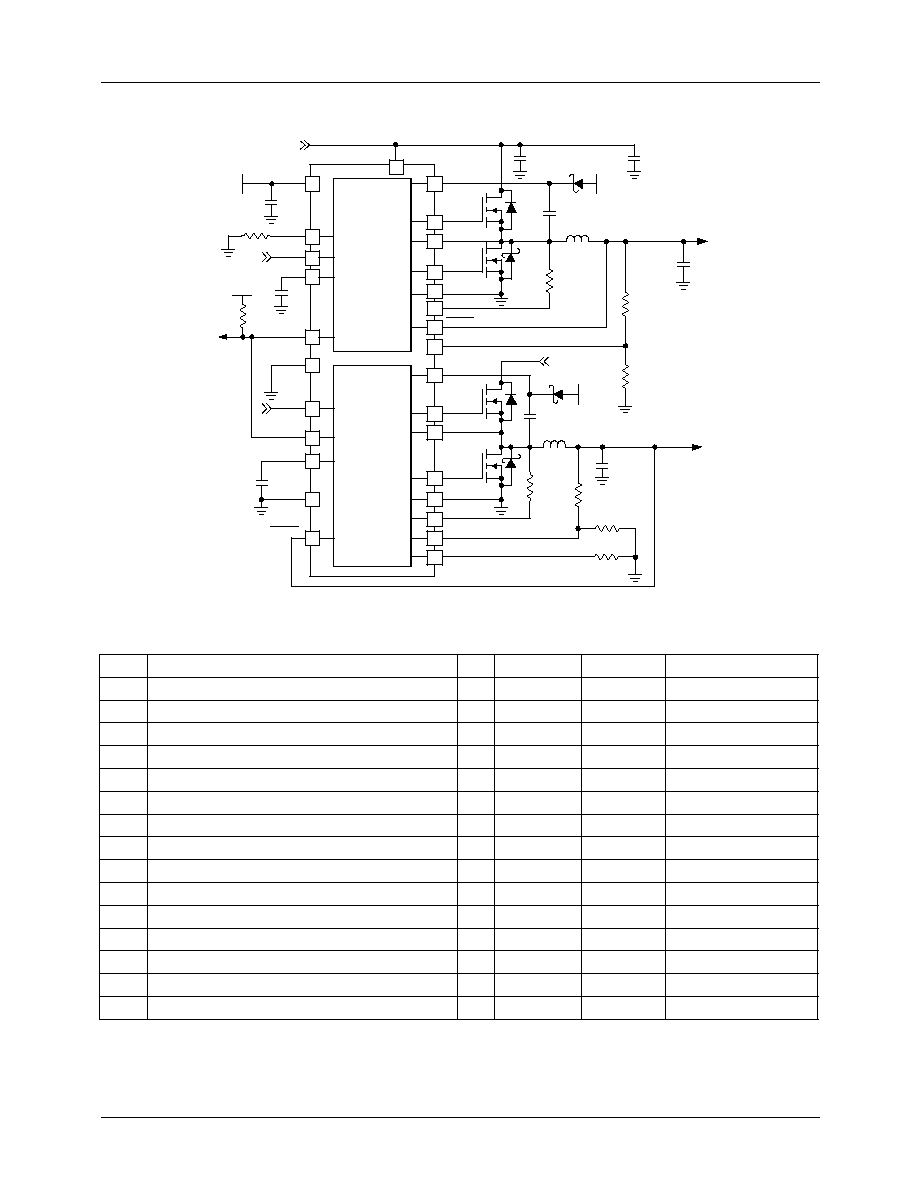

Figure 5. Dual Regulator Application

Table 2. Dual Regulator BOM

Note 1: If currents above 4A continuous required, use single SO-8 packages for Q1A/Q2A (FDS6612A) and Q1B/Q2B

(FDS6690S) respectively. Using FDS6690S, change R6/R7 as required. Refer to Power MOSFET Selection, page 15

for more information.

Item

Description

Qty

Ref.

Vendor

Part Number

1

Capacitor 68

µf, Tantalum, 25V, ESR 95m

1

C1

AVX

TPSV686*025#095

2

Capacitor 10nf, Ceramic

2

C2, C3

Any

3

Capacitor 68

µf, Tantalum, 6V, ESR 1.8

1

C4

AVX

TAJB686*006

4

Capacitor 150nF, Ceramic

2

C5, C7

Any

5

Capacitor 330

µf, Poscap, 4V, ESR 40m

2

C6, C8

Sanyo

4TPB330ML

5

Capacitor 0.1

µF, Ceramic

2

C9

Any

11

56.2K

, 1% Resistor

2

R1, R2

Any

12

10K

, 5% Resistor

2

R3

Any

13

3.24K

, 1% Resistor

1

R4

Any

14

1.82K

, 1% Resistor

3

R5, R8, R9

Any

15

1.5K

, 1% Resistor

2

R6, R7

Any

27

Schottky Diode 30V

2

D1, D2

Fairchild

BAT54

28

Inductor 6.4

µH, 6A, 8.64m

1

L1, L2

Panasonic

ETQ-P6F6R4HFA

29

Dual MOSFET with Schottky

1

Q1

Fairchild

FDS6986S (note 1)

30

DDR Controller

1

U1

Fairchild

FAN5236

FPWM1 (VOUT1)

2

C6

DDR

L1

Q1B

5

27

C8

1.8V@6A

L2

24

PWM 1

PWM 2

ILIM1

14

13

11

R4

R5

18

28

VCC

+5

ILIM2

Q2B

C7

D1

+5

6

4

R6

7

25

R7

23

D2

+5

9

22

C4

19

VSEN2

ISNS2

1

R2

PG1

15

+5

3

26

PGND2

SW2

HDRV2

ISNS1

PGND2

Q1A

Q2A

20

FPWM2

R8

R9

10

VSEN1

LDRV1

BOOT2

HDRV1

SW1

BOOT1

VIN

LDRV2

C5

C1

VIN

R1

2.5V@6A

PG2

16

EN2

21

R3

VIN (BATTERY)

= 5 to 24V

C9

SS2

17

C3

AGND

EN1

8

SS1

12

C2

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

9

Circuit Description

Overview

The FAN5236 is a multi-mode, dual channel PWM control-

ler intended for graphic chipset, SDRAM, DDR DRAM or

other low voltage power applications in modern notebook,

desktop, and sub-notebook PCs. The IC integrates a control

circuitry for two synchronous buck converters. The output

voltage of each controller can be set in the range of 0.9V to

5.5V by an external resistor divider.

The two synchronous buck converters can operate from

either an unregulated DC source (such as a notebook battery)

with voltage ranging from 5.0V to 24V, or from a regulated

system rail of 3.3V to 5V. In either mode of operation the IC

is biased from a +5V source. The PWM modulators use an

average current mode control with input voltage feed-for-

ward for simplified feedback loop compensation and

improved line regulation. Both PWM controllers have inte-

grated feedback loop compensation that dramatically

reduces the number of external components.

Depending on the load level, the converters can operate

either in fixed frequency PWM mode or in a hysteretic mode.

Switch-over from PWM to hysteretic mode improves the

converters' efficiency at light loads and prolongs battery run

time. In hysteretic mode, comparators are synchronized to

the main clock that allows seamless transition between the

operational modes and reduced channel-to-channel interac-

tion. The hysteretic mode of operation can be inhibited inde-

pendently for each channel if variable frequency operation is

not desired.

The FAN5236 can be configured to operate as a complete

DDR solution. When the DDR pin is set high, the second

channel can provide the capability to track the output voltage

of the first channel. The PWM2 converter is prevented from

going into hysteretic mode if the DDR pin is set high. In

DDR mode, a buffered reference voltage (buffered voltage of

the REF2 pin), required by DDR memory chips, is provided

by the PG2 pin.

Converter Modes and Synchronization

Table 3. Converter modes and Synchronization

When used as a dual converter (as in Figure 5), out-of-phase

operation with 180 degree phase shift reduces input current

ripple.

For the "2-step" conversion (where the VTT is converted

from VDDQ as in Figure 4) used in DDR mode, the duty

cycle of the second converter is nominally 50% and the opti-

mal phasing depends on VIN. The objective is to keep noise

generated from the switching transition in one converter

from influencing the "decision" to switch in the other con-

verter.

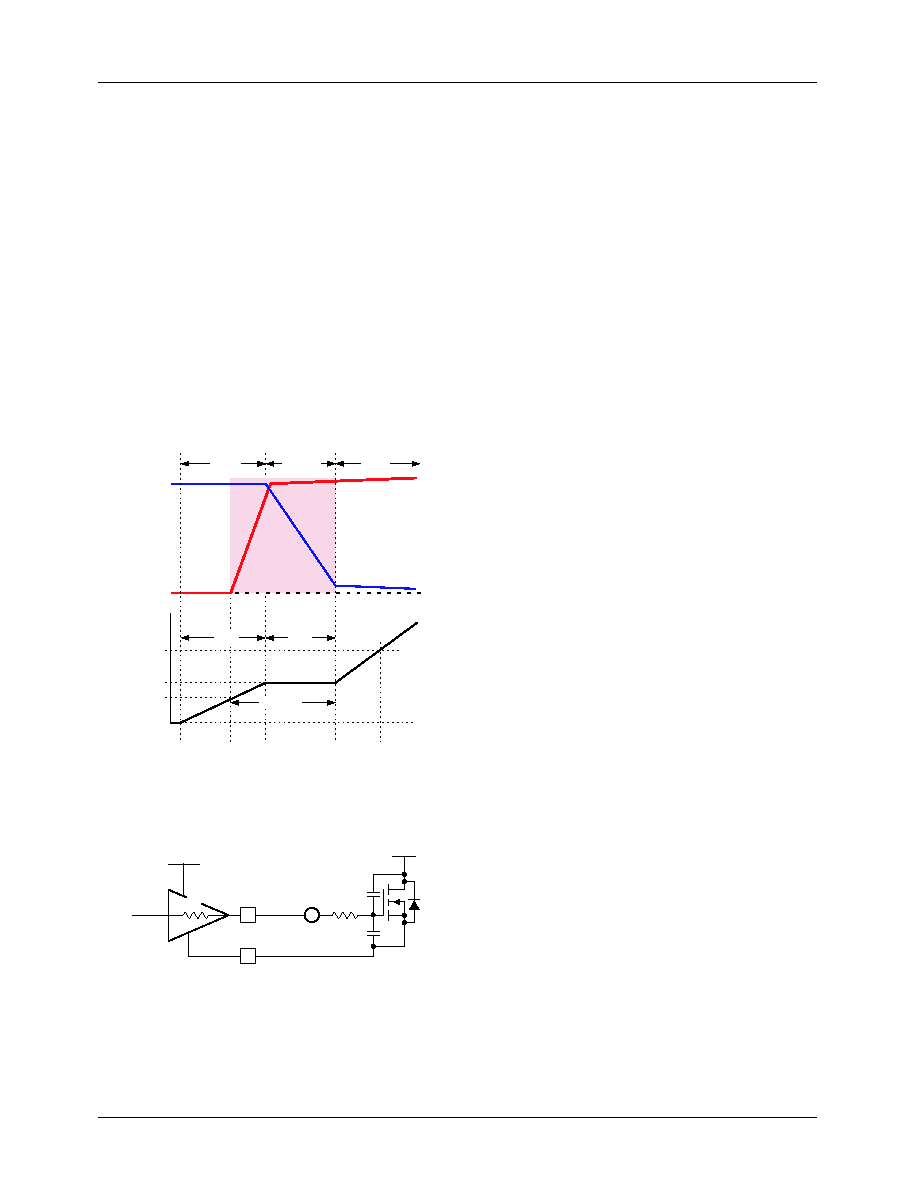

When VIN is from the battery, it's typically higher than 7.5V.

As shown in Figure 6, 180∞ operation is undesirable since

the turn-on of the VDDQ converter occurs very near the

decision point of the VTT converter.

Figure 6. Noise-susceptible 180∞ phasing for DDR1

In-phase operation is optimal to reduce inter-converter inter-

ference when VIN is higher than 5V, (when VIN is from a

battery), as can be seen in Figure 7. Since the duty cycle

of PWM1 (generating VDDQ) is short, it's switching point

occurs far away from the decision point for the VTT

regulator, whose duty cycle is nominally 50%.

Figure 7. Optimal In-Phase operation for DDR1

When VIN

5V, 180∞ phase shifted operation can be

rejected for the same reasons demonstrated Figure 6.

In-phase operation with VIN

5V is even worse, since the

switch point of either converter occurs near the switch point

of the other converter as seen in Figure 8. In this case, as

VIN is a little higher than 5V it will tend to cause early

termination of the VTT pulse width. Conversely, VTT's

switch point can cause early termination of the VDDQ pulse

width when VIN is slightly lower than 5V.

Mode

VIN

VIN Pin

DDR

Pin

PWM 2 w.r.t.

PWM1

DDR1

Battery

VIN

HIGH

IN PHASE

DDR2

+5V

R to GND

HIGH

+ 90∞

DUAL

ANY

VIN

LOW

+ 180∞

VDDQ

VTT

CLK

VDDQ

VTT

CLK

PRODUCT SPECIFICATION

FAN5236

10

REV. 1.1.7 4/4/03

Figure 8. Noise-susceptible In-Phase operation for DDR2

These problems are nicely solved by delaying the 2

nd

con-

verter's clock by 90∞ as shown in Figure 9. In this way, all

switching transitions in one converter take place far away

from the decision points of the other converter.

Figure 9. Optimal 90∞ phasing for DDR2

Initialization and Soft Start

Assuming EN is high, FAN5236 is initialized when VCC

exceeds the rising UVLO threshold. Should VCC drop

below the UVLO threshold, an internal Power-On Reset

function disables the chip.

The voltage at the positive input of the error amplifier is lim-

ited by the voltage at the SS pin which is charged with a 5

µA

current source. Once C

SS

has charged to VREF (0.9V) the

output voltage will be in regulation. The time it takes SS to

reach 0.9V is:

where T

0.9

is in seconds if C

SS

is in

µF.

When SS reaches 1.5V, the Power Good outputs are enabled

and hysteretic mode is allowed. The converter is forced into

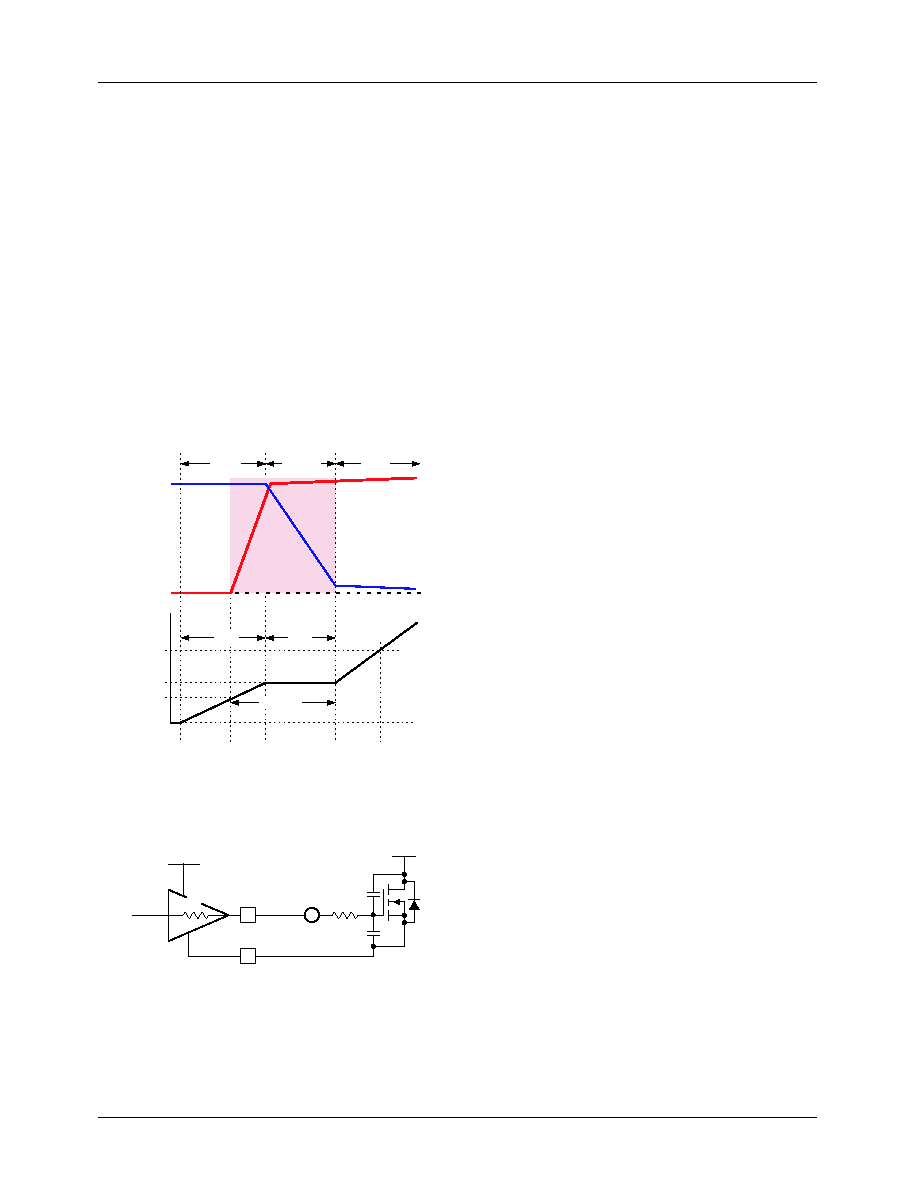

PWM mode during soft start.

Operation Mode Control

The mode-control circuit changes the converter's mode of

operation from PWM to Hysteretic and visa versa, based on

the voltage polarity of the SW node when the lower MOS-

FET is conducting and just before the upper MOSFET turns

on. For continuous inductor current, the SW node is negative

when the lower MOSFET is conducting and the converters

operate in fixed-frequency PWM mode as shown in Figure

10. This mode of operation achieves high efficiency at nomi-

nal load. When the load current decreases to the point where

the inductor current flows through the lower MOSFET in the

`reverse' direction, the SW node becomes positive, and the

mode is changed to hysteretic, which achieves higher effi-

ciency at low currents by decreasing the effective switching

frequency.

To prevent accidental mode change or "mode chatter" the

transition from PWM to Hysteretic mode occurs when the

SW node is positive for eight consecutive clock cycles (see

Figure 10). The polarity of the SW node is sampled at the

end of the lower MOSFET's conduction time. At the transi-

tion between PWM and hysteretic mode both the upper and

lower MOSFETs are turned off. The phase node will `ring'

based on the output inductor and the parasitic capacitance on

the phase node and settle out at the value of the output volt-

age.

The boundary value of inductor current, where current

becomes discontinuous, can be estimated by the following

expression.

VDDQ

VTT

CLK

VDDQ

VTT

CLK

T

0.9

0.9

C

SS

◊

5

-----------------------

=

(1)

I

LOAD DIS

(

)

V

IN

V

OUT

≠

(

)V

OUT

2F

SW

L

OUT

V

IN

--------------------------------------------------

=

(2)

Figure 10. Transitioning between PWM and Hysteretic Mode

PWM Mode

Hysteretic Mode

Hysteretic Mode

PWM Mode

1

2

3

4

5

6

7

8

V

CORE

I

L

0

V

CORE

I

L

0

1

2

3

4

5

6

7

8

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

11

Hysteretic Mode

Conversely, the transition from Hysteretic mode to PWM

mode occurs when the SW node is negative for 8 consecutive

cycles.

A sudden increase in the output current will also cause a

change from hysteretic to PWM mode. This load increase

causes an instantaneous decrease in the output voltage due to

the voltage drop on the output capacitor ESR. If the load

causes the output voltage (as presented at VSNS) to drop

below the hysteretic regulation level (20mV below VREF),

the mode is changed to PWM on the next clock cycle.

In hysteretic mode, the PWM comparator and the error

amplifier that provide control in PWM mode are inhibited

and the hysteretic comparator is activated. In hysteretic

mode the low side MOSFET is operated as a synchronous

rectifier, where the voltage across ( V

DS(ON)

) it is monitored,

and it is switched off when V

DS(ON)

goes positive (current

flowing back from the load) allowing the diode to block

reverse conduction.

The hysteretic comparator initiates a PFM signal to turn on

HDRV at the rising edge of the next oscillator clock, when

the output voltage (at VSNS) falls below the lower threshold

(10mV below VREF) and terminates the PFM signal when

VSNS rises over the higher threshold (5mV above VREF).

The switching frequency is primarily a function of:

1.

Spread between the two hysteretic thresholds

2.

I

LOAD

3.

Output Inductor and Capacitor ESR

A transition back to PWM (Continuous Conduction Mode or

CCM) mode occurs when the inductor current rises suffi-

ciently to stay positive for 8 consecutive cycles. This occurs

when:

where

V

HYSTERESIS

= 15mV and ESR is the equivalent

series resistance of C

OUT

.

Because of the different control mechanisms, the value of the

load current where transition into CCM operation takes place

is typically higher compared to the load level at which transi-

tion into hysteretic mode occurs. Hysteretic mode can be

disabled by setting the FPWM pin low.

I

LOAD CCM

(

)

V

HYSTERESIS

2 ESR

---------------------------------------

=

(3)

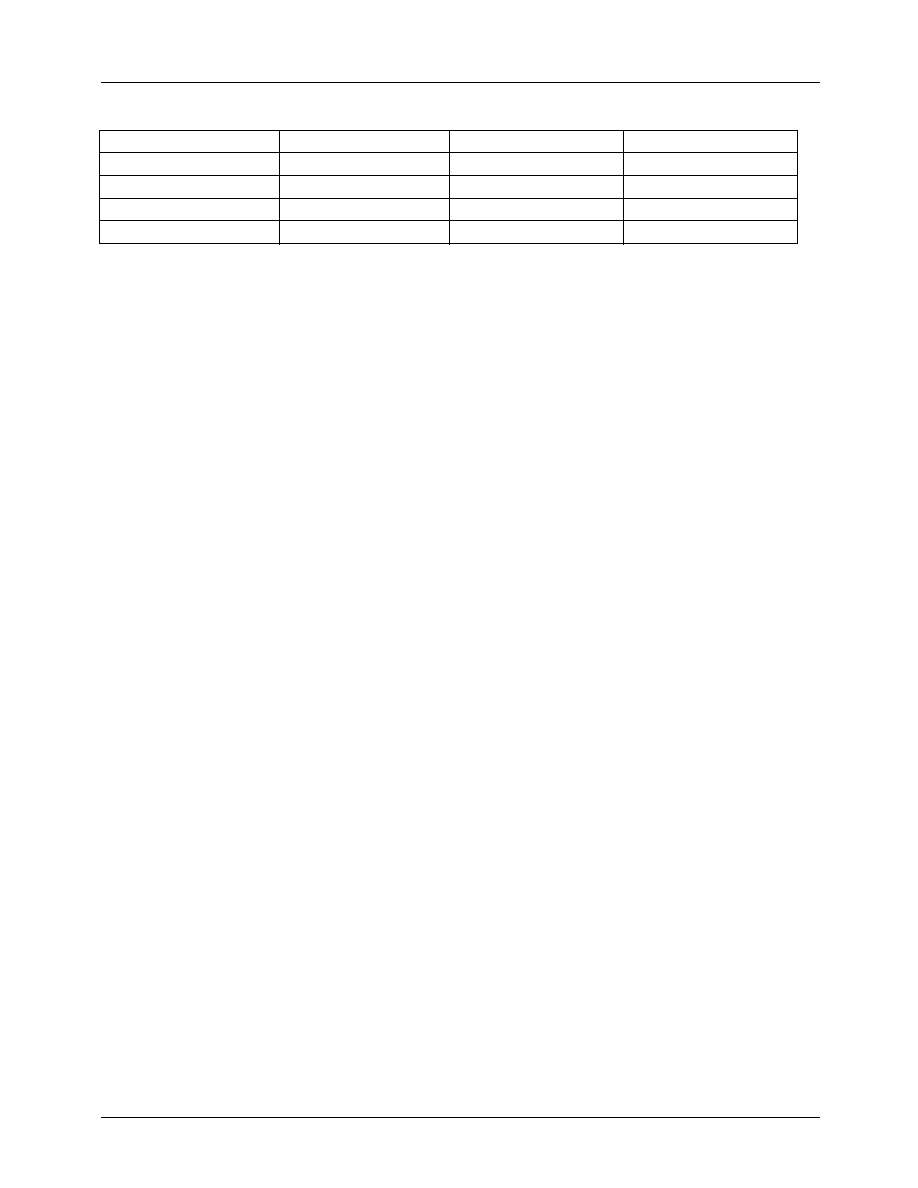

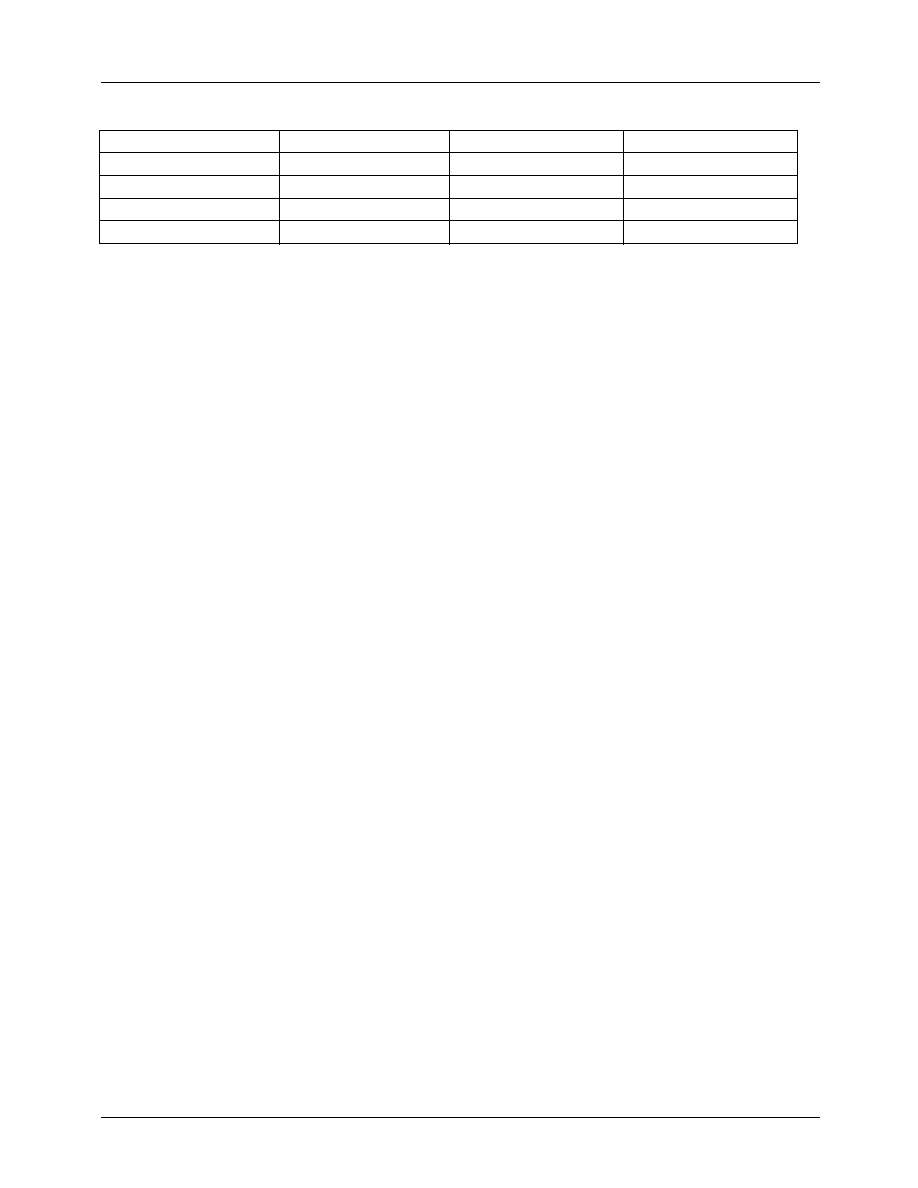

Figure 11. Current Limit / Summing Circuits

LDRV

PGND

ISNS

in +

in Ò

2.5V

ILIM det.

R

SENSE

SS

1.5M

C

SS

VSEN

V to I

Reference and

Soft Start

17pf

I1B =

ISNS

9

I2 =

4 * ILIM

3

ILIM

0.9V

R

ILIM

ILIM mirror

S/H

TO PWM COMP

4.14K

300K

I1A =

ISNS

0.17pf

PRODUCT SPECIFICATION

FAN5236

12

REV. 1.1.7 4/4/03

Current Processing Section

The following discussion refers to Figure 11.

The current through R

SENSE

resistor (ISNS) is sampled

shortly after Q2 is turned on. That current is held, and

summed with the output of the error amplifier. This effec-

tively creates a current mode control loop. The resistor con-

nected to ISNSx pin (R

SENSE

) sets the gain in the current

feedback loop. For stable operation, the voltage induced by

the current feedback at the PWM comparator input should be

set to 30% of the ramp amplitude at maximum load currrent

and line voltage. The following expression estimates the

recommended value of R

SENSE

as a function of the maxi-

mum load current (I

LOAD(MAX)

) and the value of the

MOSFET's R

DS(ON)

:

R

SENSE

must, however, be kept higher than:

Setting the Current Limit

A ratio of ISNS is also compared to the current established

when a 0.9 V internal reference drives the ILIM pin. The

threshold is determined at the point

when the

. Since

therefore

,

Since the tolerance on the current limit is largely dependent

on the ratio of the external resistors it is fairly accurate if the

voltage drop on the Switching Node side of R

SENSE

is an

accurate representation of the load current. When using the

MOSFET as the sensing element, the variation of R

DS(ON)

causes proportional variation in the ISNS. This value not

only varies from device to device, but also has a typical junc-

tion temperature coefficient of about 0.4% / ∞C (consult the

MOSFET datasheet for actual values), so the actual current

limit set point will decrease propotional to increasing

MOSFET die temperature. A factor of 1.6 in the current

limit setpoint should compensate for all MOSFET R

DS(ON)

variations, assuming the MOSFET's heat sinking will keep

its operating die temperature below 125∞C.

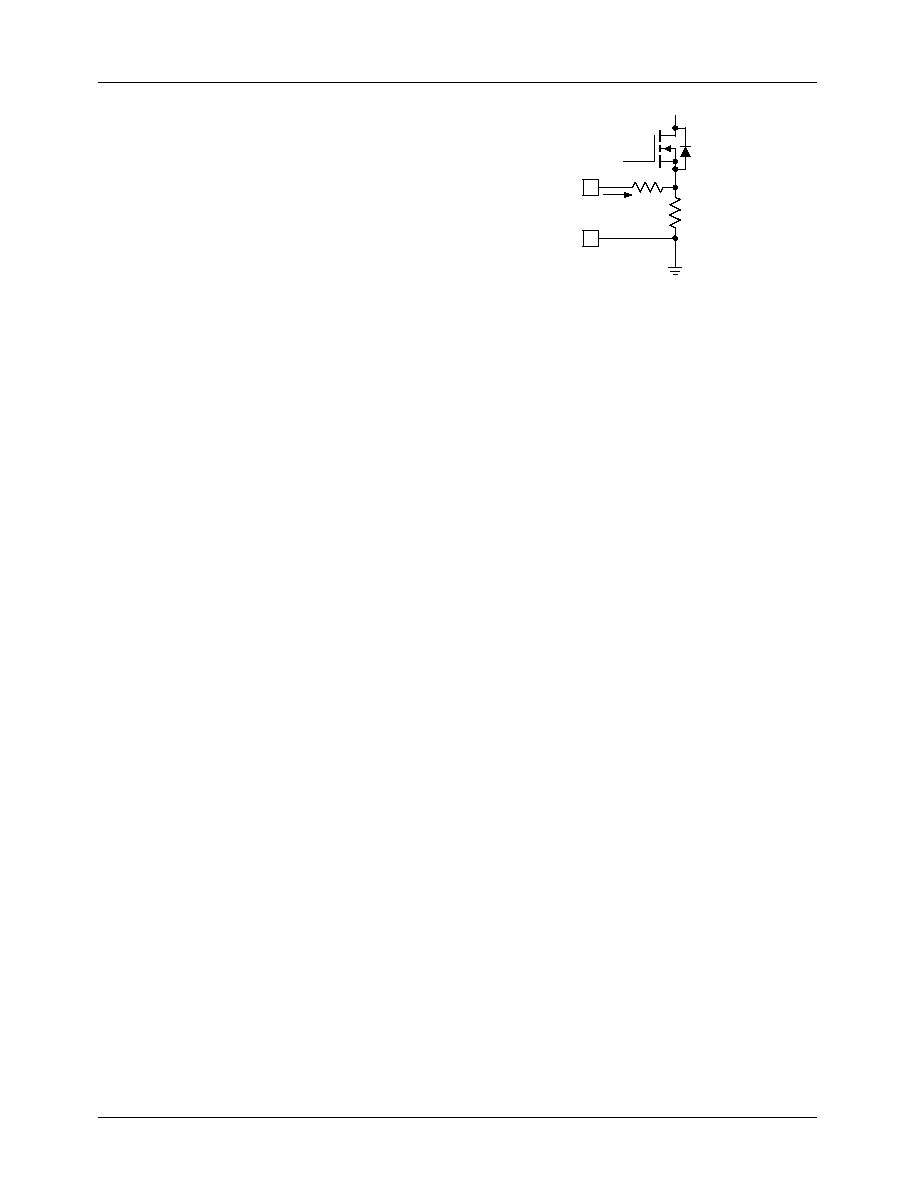

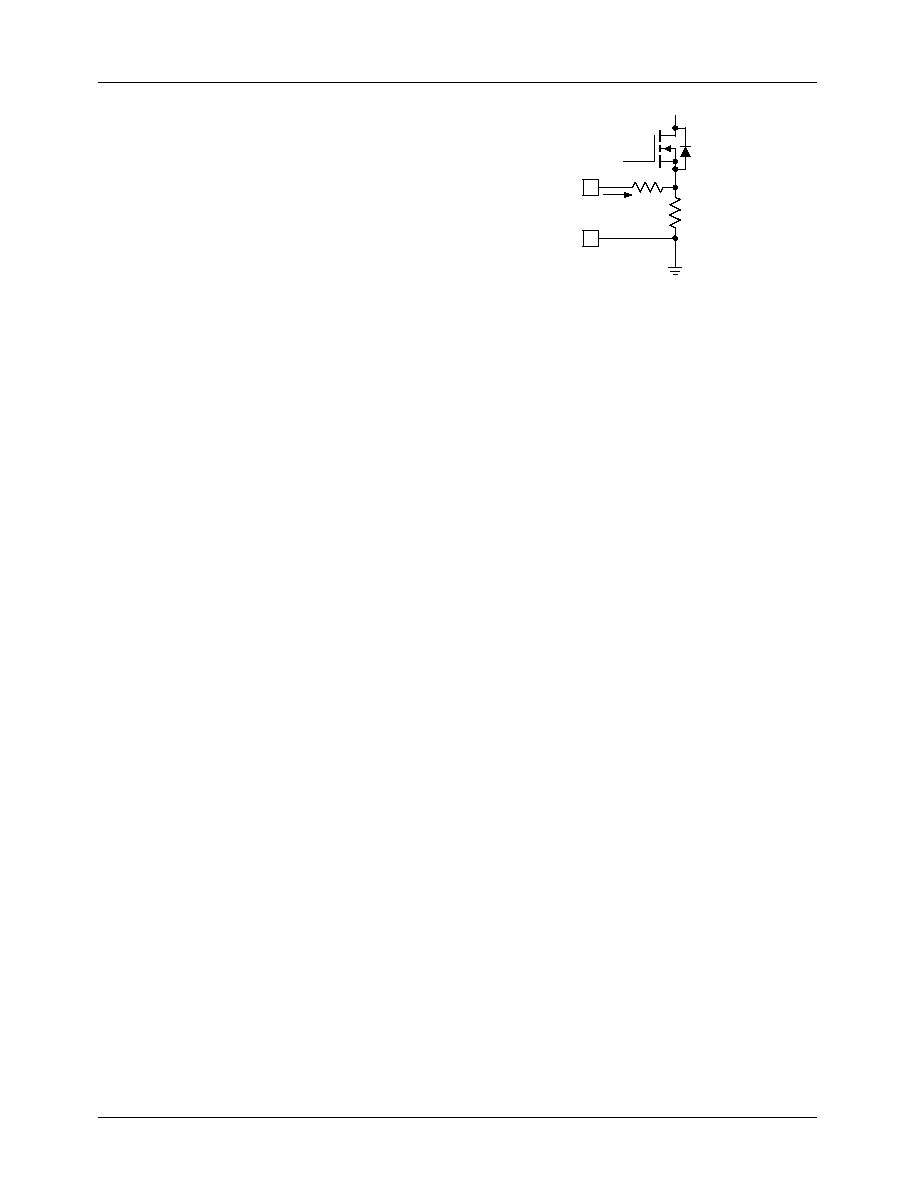

Figure 12. Improving current sensing accuracy

More accurate sensing can be achieved by using a resistor

(R1) instead of the R

DS(ON)

of the FET as shown in Figure

12. This approach causes higher losses, but yields greater

accuracy in both V

DROOP

and I

LIMIT

. R1 is a low value

(e.g. 10m

) resistor.

Current limit (I

LIMIT

) should be set sufficiently high as to

allow inductor current to rise in response to an output load

transient. Typically, a factor of 1.3 is sufficient. In addition,

since I

LIMIT

is a peak current cut-off value, we will need to

multiply I

LOAD(MAX)

by the inductor ripple current (we'll

use 25%). For example, in Figure 5 the target for I

LIMIT

would be:

I

LIMIT

> 1.2

◊ 1.25 ◊ 1.6 ◊ 6A 14A

(6)

Duty Cycle Clamp

During severe load increase, the error amplifier output can

go to its upper limit pushing a duty cycle to almost 100% for

significant amount of time. This could cause a large increase

of the inductor current and lead to a long recovery from a

transient, over-current condition, or even to a failure espe-

cially at high input voltages. To prevent this, the output of

the error amplifier is clamped to a fixed value after two clock

cycles if severe output voltage excursion is detected, limiting

the maximum duty cycle to

This circuit is designed to not interfere with normal PWM

operation. When FPWM is grounded, the duty cycle clamp

is disabled and the maximum duty cycle is 87%.

Gate Driver section

The Adaptive gate control logic translates the internal PWM

control signal into the MOSFET gate drive signals providing

necessary amplification, level shifting and shoot-through

protection. Also, it has functions that help optimize the IC

performance over a wide range of operating conditions.

Since MOSFET switching time can vary dramatically from

type to type and with the input voltage, the gate control logic

provides adaptive dead time by monitoring the gate-to-

source voltages of both upper and lower MOSFETs.

R

SENSE

I

LOAD MAX

(

)

R

DS ON

(

)

4.1K

∑

∑

0.30

0.125

V

IN MAX

(

)

∑

∑

-----------------------------------------------------------------------------

100

≠

=

(4a)

R

SENSE MIN

(

)

I

LOAD MAX

(

)

R

DS ON

(

)

∑

150

µA

-----------------------------------------------------------

100

≠

=

(4b)

ISNS

9

--------------

ILIM

4

◊

3

-----------------------

>

ISNS

I

LOAD

R

DS ON

(

)

◊

100

R

+

SENSE

--------------------------------------------

=

I

LIMIT

0.9V

R

ILIM

---------------

4

3

---

◊

9

100

R

SENSE

+

(

)

◊

R

DS ON

(

)

-------------------------------------------------

◊

=

(5a)

or

R

ILIM

11.2

I

LIMIT

----------------

100

R

SENSE

+

(

)

R

DS ON

(

)

----------------------------------------

◊

=

(5b)

LDRV

PGND

ISNS

R

SENSE

R1

Q2

DC

MAX

V

OUT

V

IN

--------------

2.4

V

IN

---------

+

=

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

13

The lower MOSFET drive is not turned on until the gate-to-

source voltage of the upper MOSFET has decreased to less

than approximately 1 volt. Similarly, the upper MOSFET is

not turned on until the gate-to-source voltage of the lower

MOSFET has decreased to less than approximately 1 volt.

This allows a wide variety of upper and lower MOSFETs to

be used without a concern for simultaneous conduction, or

shoot-through.

There must be a low-resistance, low-inductance path

between the driver pin and the MOSFET gate for the adap-

tive dead-time circuit to work properly. Any delay along that

path will subtract from the delay generated by the adaptive

dead-time circit and shoot-through may occur.

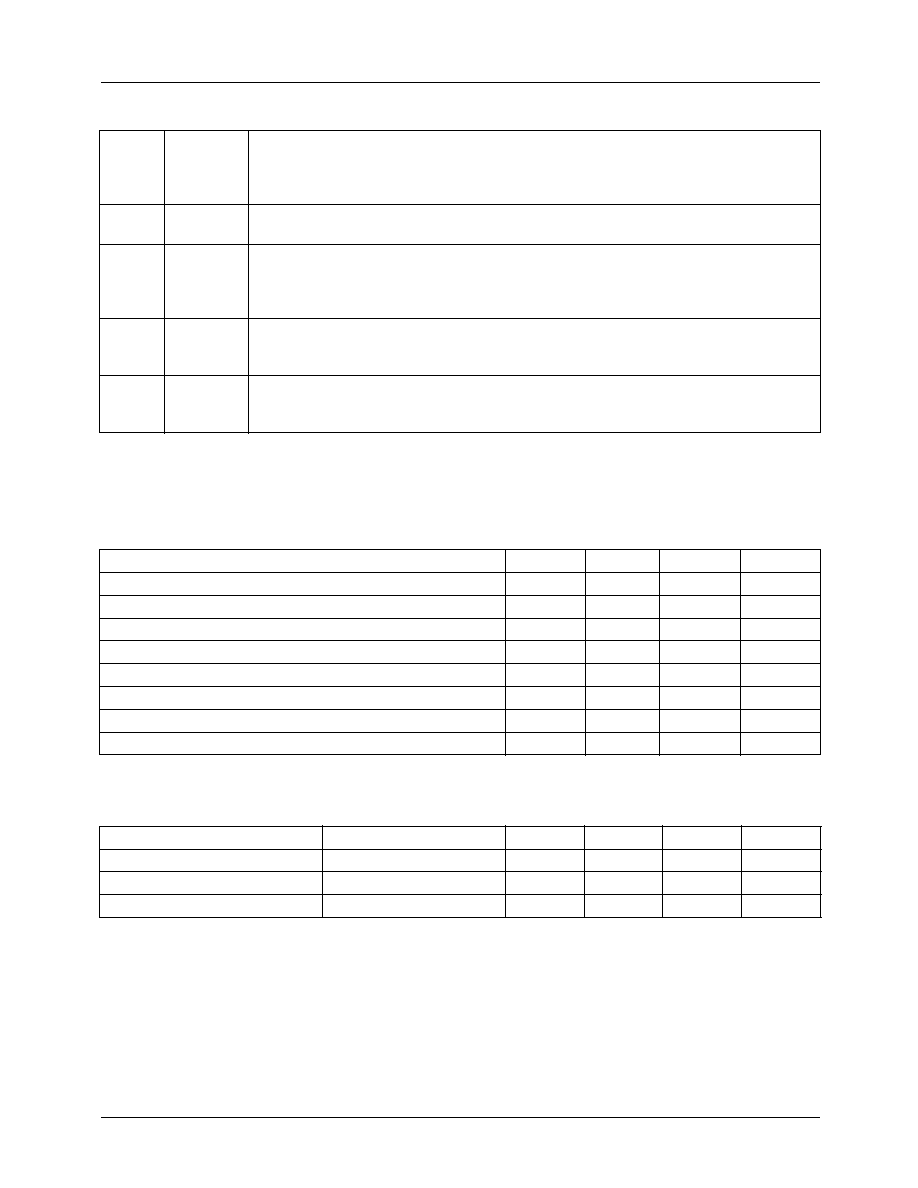

Frequency Loop Compensation

Due to the implemented current mode control, the modulator

has a single pole response with -1 slope at frequency deter-

mined by load

where R

O

is load resistance, C

O

is load capacitance.

For this type of modulator, Type 2 compensation circuit is

usually sufficient. To reduce the number of external compo-

nents and simplify the design task, the PWM controller has

an internally compensated error amplifier. Figure 13 shows a

Type 2 amplifier and its response along with the responses of

a current mode modulator and of the converter. The Type 2

amplifier, in addition to the pole at the origin, has a zero-pole

pair that causes a flat gain region at frequencies between the

zero and the pole.

This region is also associated with phase `bump' or reduced

phase shift. The amount of phase shift reduction depends the

width of the region of flat gain and has a maximum value of

90 degrees. To further simplify the converter compensation,

the modulator gain is kept independent of the input voltage

variation by providing feed-forward of VIN to the oscillator

ramp.

The zero frequency, the amplifier high frequency gain and

the modulator gain are chosen to satisfy most typical appli-

cations. The crossover frequency will appear at the point

where the modulator attenuation equals the amplifier high

frequency gain. The only task that the system designer has to

complete is to specify the output filter capacitors to position

the load main pole somewhere within one decade lower than

the amplifier zero frequency. With this type of compensation

plenty of phase margin is easily achieved due to zero-pole

pair phase `boost'.

Figure 13. Compensation

Conditional stability may occur only when the main load

pole is positioned too much to the left side on the frequency

axis due to excessive output filter capacitance. In this case,

the ESR zero placed within the 10kHz...50kHz range gives

some additional phase `boost'. Fortunately, there is an oppo-

site trend in mobile applications to keep the output capacitor

as small as possible.

If a larger inductor value or low ESR values are called for by

the application, additional phase margin can be achieved by

putting a zero at the LC crossover frequency. This can be

achieved with a capacitor across across the feedback resistor

(e.g. R5 from Figure 5) as shown below.

Figure 14. Improving Phase Margin

The optimal value of C(Z) is:

Protection

The converter output is monitored and protected against

extreme overload, short circuit, over-voltage and under-

voltage conditions.

A sustained overload on an output sets the PGx pin low and

latches-off the whole chip. Operation can be restored by

cycling the VCC voltage or by toggling the EN pin.

F

PO

1

2

R

O

C

O

----------------------

=

(7)

F

Z

1

2

R

2

C

1

--------------------

6kHz

=

=

(8a)

F

P

1

2

R

2

C

2

--------------------

600kHz

=

=

(8b)

R1

R2

EA Out

C1

C2

REF

V

IN

C

on

ve

rter

0

14

18

modulator

F

P0

F

Z

F

P

erro

r a

mp

C(OUT)

VOUT

C(Z)

R5

VSEN

L(OUT)

R6

C Z

( )

L OUT

(

) C OUT

(

)

◊

R5

------------------------------------------------------

=

(9)

PRODUCT SPECIFICATION

FAN5236

14

REV. 1.1.7 4/4/03

If VOUT drops below the under-voltage threshold, the chip

shuts down immediately.

Over-Current sensing

If the circuit's current limit signal ("ILIM det" as shown in

Figure 11) is high at the beginning of a clock cycle, a pulse-

skipping circuit is activated and HDRV is inhibited. The

circuit continues to pulse skip in this manner for the next 8

clock cycles. If at any time from the 9

th

to the 16

th

clock

cycle, the "ILIM det" is again reached, the over-current

protection latch is set, disabling the the chip. If "ILIM det"

does not occur between cycle 9 and 16, normal operation is

restored and the over-current circuit resets itself.

Figure 15. Over-Current protection waveforms

Over-Voltage / Under-voltage Protection

Should the VSNS voltage exceed 120% of VREF (0.9V) due

to an upper MOSFET failure, or for other reasons, the over-

voltage protection comparator will force LDRV high. This

action actively pulls down the output voltage and, in the

event of the upper MOSFET failure, will eventually blow the

battery fuse. As soon as the output voltage drops below the

threshold, the OVP comparator is disengaged.

This OVP scheme provides a `soft' crowbar function which

helps to tackle severe load transients and does not invert the

output voltage when activated -- a common problem for

latched OVP schemes.

Similarly, if an output short-circuit or severe load transient

causes the output to droop to less than 75% of its regulation

set point. Should this condition occur, the regulator will shut

down.

Over-Temperature Protection

The chip incorporates an over temperature protection circuit

that shuts the chip down when a die temperature of about

150∞C is reached. Normal operation is restored at die

temperature below 125∞C with internal Power On Reset

asserted, resulting in a full soft-start cycle.

Design and Component Selection

Guidelines

As an initial step, define operating input voltage range, out-

put voltage, minimum and maximum load currents for the

controller.

Setting the Output Voltage

The interal reference is 0.9V. The output is divided down by

a voltage divider to the VSEN pin (for example, R5 and R6

in Figure 4). The output voltage therefore is:

To minimize noise pickup on this node, keep the resistor to

GND (R6) below 2K. We selected R6 at 1.82K. Then choose

R5:

For DDR applications converting from 3.3V to 2.5V, or other

applications requiring high duty cycles, the duty cycle clamp

must be disabled by tying the converter's FPWM to GND.

When converter's FPWM is GND, the converter's maximum

duty cycle will be greater than 90%. When using as a DDR

converter with 3.3V input, set up the converter for In-Phase

synchronization by tying the VIN pin to +5V.

Output Inductor Selection

The minimum practical output inductor value is the one that

keeps inductor current just on the boundary of continuous

conduction at some minimum load. The industry standard

practice is to choose the minimum current somewhere from

15% to 35% of the nominal current. At light load, the

controller can automatically switch to hysteretic mode of

operation to sustain high efficiency. The following equations

help to choose the proper value of the output filter inductor.

where

I is the inductor ripple current and V

OUT

is the

maximum ripple allowed.

for this example we'll use:

V

IN

= 20V, V

OUT

= 2.5V

I = 20% * 6A = 1.2A

F

SW

= 300KHz.

therefore

L

6µH

1

2

3

CH1 5.0V

CH2 2.0A

CH2 100mV

M 10.0µs

IL

SHUTDOWN

PGOOD

8 CLK

VOUT

0.9V

R6

------------

V

OUT

0.9V

≠

R5

---------------------------------

=

(10a)

R5

1.82K

(

) V

OUT

0.9

≠

(

)

0.9

-----------------------------------------------------

3.24K

=

=

(10b)

I

2

I

MIN

◊

V

OUT

ESR

------------------

=

=

(11)

L

V

IN

V

OUT

≠

F

SW

I

◊

------------------------------

V

OUT

V

IN

--------------

◊

=

(12)

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

15

Output Capacitor Selection

The output capacitor serves two major functions in a switch-

ing power supply. Along with the inductor it filters the

sequence of pulses produced by the switcher, and it supplies

the load transient currents. The output capacitor require-

ments are usually dictated by ESR, Inductor ripple current

(

I) and the allowable ripple voltage (V).

In addition, the capacitor's ESR must be low enough to allow

the converter to stay in regulation during a load step. The

ripple voltage due to ESR for the converter in Figure 5 is

120mV P-P. Some additional ripple will appear due to the

capacitance value itself:

which is only about 1.5mV for the converter in Figure 5 and

can be ignored.

The capacitor must also be rated to withstand the RMS

current which is approximately 0.3 X (

I), or about 400mA

for the converter in Figure 5. High frequency decoupling

capacitors should be placed as close to the loads as

physically possible.

Input Capacitor Selection

The input capacitor should be selected by its ripple current

rating.

Two-Stage Converter Case

In DDR mode (Figure 4), the VTT power input is powered

by the VDDQ output, therefore all of the input capacitor rip-

ple current is produced by the VDDQ converter. A conserva-

tive estimate of the output

current required for the 2.5V regulator is:

As an example, if average I

VDDQ

is 3A, and average I

VTT

is

1A, I

VDDQ

current will be about 3.5A. If average input volt-

age is 16V, RMS input ripple current will be:

where D is the duty cycle of the PWM1 converter:

therefore:

Dual Converter 180∞ phased

In Dual mode (Figure 5), both converters contribute to the

capacitor input ripple current. With each converter operating

180∞ out of phase, the RMS currents add in the following

fashion:

which for the dual 3A converters of Figure 5, calculates to:

Power MOSFET Selection

Losses in a MOSFET are the sum of its switching (P

SW

) and

conduction (P

COND

) losses.

In typical applications, the FAN5236 converter's output volt-

age is low with respect to its input voltage, therefore the

Lower MOSFET (Q2) is conducting the full load current for

most of the cycle. Q2 should therefore be selected to mini-

mize conduction losses, thereby selecting a MOSFET with

low R

DS(ON)

.

In contrast, the high-side MOSFET (Q1) has a much shorter

duty cycle, and it's conduction loss will therefore have less

of an impact. Q1, however, sees most of the switching losses,

so Q1's primary selection criteria should be gate charge.

High-Side Losses:

Figure 15 shows a MOSFET's switching interval, with the

upper graph being the voltage and current on the Drain to

Source and the lower graph detailing V

GS

vs. time with a

constant current charging the gate. The x-axis therefore is

also representative of gate charge (Q

G

) . C

ISS

= C

GD

+ C

GS

,

and it controls t1, t2, and t4 timing. C

GD

receives the current

from the gate driver during t3 (as V

DS

is falling). The gate

charge (Q

G

) parameters on the lower graph are either

specified or can be derived from MOSFET datasheets.

Assuming switching losses are about the same for both the

rising edge and falling edge, Q1's switching losses, occur

during the shaded time when the MOSFET has voltage

across it and current through it.

ESR

V

I

--------

<

(13)

V

I

C

OUT

8

◊

F

SW

◊

-----------------------------------------

=

(14)

I

REG1

I

VDDQ

I

VTT

2

------------

+

=

I

RMS

I

OUT MAX

(

)

D

D

2

≠

=

(15)

D

V

OUT

V

IN

--------------

<

2.5

16

-------

=

(16)

I

RMS

3.5

2.5

16

-------

2.5

16

-------

2

≠

1.49A

=

=

(17)

I

RMS

I

RMS 1

( )

2

I

RMS 2

( )

2

+

or

=

(18a)

I

RMS

I

1

( )

2

D

1

D

1

2

≠

(

)

I

2

( )

2

D

2

D

2

2

≠

(

)

+

=

(18b)

I

RMS

1.4A

=

PRODUCT SPECIFICATION

FAN5236

16

REV. 1.1.7 4/4/03

These losses are given by:

P

UPPER

= P

SW

+ P

COND

P

UPPER

is the upper MOSFET's total losses, and P

SW

and

P

COND

are the switching and conduction losses for a given

MOSFET. R

DS(ON)

is at the maximum junction temperature

(T

J

). t

S

is the switching period (rise or fall time) and is t2+t3

Figure 15.

The driver's impedance and C

ISS

determine t2 while t3's

period is controlled by the driver's impedance and Q

GD

.

Since most of t

S

occurs when V

GS

= V

SP

we can use a

constant current assumption for the driver to simplify the

calculation of t

S

:

Figure 16. Switching losses and Q

G

Figure 17. Drive Equivalent Circuit

Most MOSFET vendors specify Q

GD

and Q

GS

. Q

G(SW)

can

be determined as: Q

G(SW)

= Q

GD

+ Q

GS

≠ Q

TH

where Q

TH

is

the the gate charge required to get the MOSFET to it's

threshold (V

TH

). For the high-side MOSFET, V

DS

= VIN,

which can be as high as 20V in a typical portable applica-

tion. Care should also be taken to include the delivery of the

MOSFET's gate power (P

GATE

) in calculating the power

dissipation required for the FAN5236:

P

GATE

= Q

G

◊ VCC ◊ F

SW

(21)

where Q

G

is the total gate charge to reach VCC.

Low-Side Losses

Q2, however, switches on or off with its parallel shottky

diode conducting, therefore V

DS

0.5V. Since P

SW

is

proportional to V

DS

, Q2's switching losses are negligible

and we can select Q2 based on R

DS(ON)

only.

Conduction losses for Q2 are given by:

where R

DS(ON)

is the R

DS(ON)

of the MOSFET at the highest

operating junction temperature and

is the minimum duty cycle for the converter.

Since D

MIN

< 20% for portable computers, (1-D)

1

produces a conservative result, further simplifying the

calculation.

The maximum power dissipation (P

D(MAX)

) is a function of

the maximum allowable die temperature of the low-side

MOSFET, the

J-A

, and the maximum allowable ambient

temperature rise:

J-A

, depends primarily on the amount of PCB area that can

be devoted to heat sinking (see FSC app note AN-1029 for

SO-8 MOSFET thermal information).

P

SW

V

DS

I

L

◊

2

----------------------

2

◊

t

S

◊

F

SW

=

(19a)

P

COND

V

OUT

V

IN

--------------

I

OUT

2

◊

R

DS ON

(

)

◊

=

(19b)

V

SP

t1

t2

t3

4.5V

t4

t5

Q

G(SW)

V

DS

I

D

Q

GS

Q

GD

V

TH

V

GS

C

ISS

C

RSS

C

ISS

C

ISS

= C

GS

|| C

GD

C

GD

R

D

R

GATE

C

GS

HDRV

5V

SW

VIN

G

t

S

Q

G SW

(

)

I

DRIVER

---------------------

Q

G SW

(

)

VCC

V

SP

≠

R

DRIVER

R

GATE

+

-----------------------------------------------

-----------------------------------------------------

=

(20)

P

COND

1

D

≠

(

) I

OUT

2

◊

R

DS ON

(

)

◊

=

(22)

D

V

OUT

V

IN

--------------

=

P

D MAX

(

)

T

J MAX

(

)

T

A MAX

(

)

≠

J

A

≠

--------------------------------------------------

=

(23)

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

17

Layout Considerations

Switching converters, even during normal operation,

produce short pulses of current which could cause substan-

tial ringing and be a source of EMI if layout constrains are

not observed.

There are two sets of critical components in a DC-DC

converter. The switching power components process large

amounts of energy at high rate and are noise generators. The

low power components responsible for bias and feedback

functions are sensitive to noise.

A multi-layer printed circuit board is recommended. Dedi-

cate one solid layer for a ground plane. Dedicate another

solid layer as a power plane and break this plane into smaller

islands of common voltage levels.

Notice all the nodes that are subjected to high dV/dt voltage

swing such as SW, HDRV and LDRV, for example. All

surrounding circuitry will tend to couple the signals from

these nodes through stray capacitance. Do not oversize

copper traces connected to these nodes. Do not place traces

connected to the feedback components adjacent to these

traces. It is not recommended to use High Density Intercon-

nect Systems, or micro-vias on these signals. The use of

blind or buried vias should be limited to the low current

signals only. The use of normal thermal vias is left to the

discretion of the designer.

Keep the wiring traces from the IC to the MOSFET gate and

source as short as possible and capable of handling peak

currents of 2A. Minimize the area within the gate-source

path to reduce stray inductance and eliminate parasitic ring-

ing at the gate.

Locate small critical components like the soft-start capacitor

and current sense resistors as close as possible to the respec-

tive pins of the IC.

The FAN5236 utilizes advanced packaging technologies

with lead pitches of 0.6mm. High performance analog semi-

conductors utilizing narrow lead spacing may require special

considerations in PWB design and manufacturing. It is

critical to maintain proper cleanliness of the area surround-

ing these devices. It is not recommended to use any type of

rosin or acid core solder, or the use of flux in either the

manufacturing or touch up process as these may contribute

to corrosion or enable electromigration and/or eddy currents

near the sensitive low current signals. When chemicals such

as these are used on or near the PWB, it is suggested that the

entire PWB be cleaned and dried completely before applying

power.

PRODUCT SPECIFICATION

FAN5236

18

REV. 1.1.7 4/4/03

Mechanical Dimensions

28-Pin QSOP

A

0.069

1.75

Symbol

Inches

Min.

Max.

Min.

Max.

Millimeters

Notes

A1

0.004

0.10

0.061

1.54

0.053

1.35

0.010

0.25

A2

-

-

B

0.008

0.012

0.20

0.30

D

0.386

0.394

9.81

10.00

H

0.150

0.157

3.81

3.98

0.016

0.050

0.41

1.27

E

0.025 BSC

0.635 BSC

e

h

L

0.228

0.244

0.0099

0.0196

5.80

6.19

0.26

0.49

0

∞

8

∞

0

∞

8

∞

6

5

7

9

3

4

N

28

28

C

0.007

0.010

0.18

0.25

Notes:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Symbols are defined in the "MO Series Symbol List" in

Section 2.2 of Publication Number 95.

Dimensioning and tolerancing per ANSI Y14.5M-1982.

Dimension "D" does not include mold flash, protrusions

or gate burrs. Mold flash, protrusions shall not exceed

0.25mm (0.010 inch) per side.

Dimension "E" does not include interlead flash or

protrusions. Interlead flash and protrusions shall not

exceed 0.25mm (0.010 inch) per side.

The chamber on the body is optional. If it is not present,

a visual index feature must be located within the

crosshatched area.

"L" is the length of terminal for soldering to a substrate.

"N" is the maximum number of terminals.

Terminal numbers are shown for reference only.

Dimension "B" does not include dambar protrusion.

Allowable dambar protrusion shall be 0.10mm (0.004

inch) total in excess of "B" dimension at maximum

material condition.

Controlling dimension: INCHES. Converted millimeter

dimensions are not necessarily exact.

H

E

A

A2

D

e

B

A1

≠ C ≠

ccc C

LEAD COPLANARITY

SEATING

PLANE

L

C

FAN5236

PRODUCT SPECIFICATION

REV. 1.1.7 4/4/03

19

Mechanical Dimensions

28-Pin TSSOP

9.7

± 0.1

15

≠ B ≠

0.1 C

PIN # 1 IDENT

14

ALL Lead Tips

0.2

LAND PATTERN RECOMMENDATION

0.65

0.42

B A

≠ A ≠

4.4

±

0.1

1.78

4.16

7.72

0.51 TYP

28

3.2

6.4

1.2 MAX

ALL LEAD TIPS

0.65

0.19≠0.30

0.13

0.90

See Detail A

0.09≠0.20

0.10

± 0.05

0

∞≠8∞

R0.31

R0.16

.025

GAGE PLANE

SEATING PLANE

DETAIL A

0.61

± 0.1

DIMENSIONS ARE IN MILLIMETERS

NOTES:

A. Conforms to JEDEC registration MO-153, variation AB,

Ref. Note 6, dated 7/93.

B. Dimensions are in millimeters.

C. Dimensions are exclusive of burrs, mold flash, and tie bar extensions.

D Dimensions and Tolerances per ANsI Y14.5M, 1982

1.00

12.00

∞ Top & Botom

+0.15

≠0.10

B

C

A

≠ C ≠

PRODUCT SPECIFICATION

FAN5236

LIFE SUPPORT POLICY

FAIRCHILD'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and (c) whose failure to perform

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in a significant injury of the user.

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

www.fairchildsemi.com

4/4/03 0.0m 004

Stock#DS30005236

2002 Fairchild Semiconductor Corporation

Ordering Information

Part Number

Temperature Range

Package

Packing

FAN5236QSC

-10∞C to 85∞C

QSOP-28

Rails

FAN5236QSCX

-10∞C to 85∞C

QSOP-28

Tape and Reel

FAN5236MTC

-10∞C to 85∞C

TSSOP-28

Rails

FAN5236MTCX

-10∞C to 85∞C

TSSOP-28

Tape and Reel

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO

ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME

ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.