| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: FAN5616 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©2005 Fairchild Semiconductor Corporation

1

www.fairchildsemi.com

November 2005

FAN5616 Rev. 1.0.0

F

AN5616 High-Efficienc

y

,

Constant-Current LED Driver with Adaptive Char

g

e

Pump

FAN5616

High-Efficiency, Constant-Current LED Driver with

Adaptive Charge Pump

Features

3-Channel Parallel LED Driver for a Large Range of

Forward Voltages

Adaptive V

OUT

Adjustment to the Highest Diode

Forward Voltage

Internally Matched LED Current Sources

Matched LED Currents with Matched or Unmatched

LEDs

Built-in Charge Pump with Three Modes of Operation:

1x, 1.5x, and 2x

Up to 90% Efficiency

Up to 50kHz PWM Dimming Frequency

Low EMI, Low Ripple

Up to 120mA Output Current

Drives up to 3 LEDs at 40mA each

External Resistor to Set Maximum (100%) LED

Current

Built-in 2-bit DAC to Control LED Current in Digital

Mode

2.5V to 5.5V Input Voltage Range

I

CC

< 1µA in Shutdown Mode

1MHz Operating Frequency

Shutdown Isolates Output from Input

Smart Soft-Start Limits In-Rush Current

Short Circuit Protection

Minimal External Components Needed

Available in a 3x3mm 16-lead MLP Package

Applications

Cell Phones

PDAs, DSCs, and MP3 Players

Description

The FAN5616 generates a regulated output current from

a battery with an input voltage between 2.7V to 5.5V.

Switch reconfiguration and fractional switching tech-

niques are utilized to achieve high efficiency over the

entire input voltage range. The adaptive nature of the

built-in charge pump eliminates the need for LED pre-

selection (matching) and ensures operation with high

efficiency. The driver's built-in, proprietary, auto-sense

circuitry ensures the same high efficiency regardless of

the number of LEDs. When the input voltage is suffi-

ciently high to sustain the LED's programmed current

level, the FAN5616 reconfigures itself to operate as a lin-

ear regulator, and the charge pump is turned off.

The FAN5616 supports both digital and PWM LED

brightness control methods. The built-in 2-bit DAC offers

a selection of four LED current levels, each level is a per-

centage of the maximum LED current set by the external

R

SET

resistor.

The FAN5616 includes built-in shutdown, short circuit

and thermal protection circuitry. A built-in smart soft-start

circuitry prevents excessive current draw during power

on while allowing for an increased PWM frequency for

dimming.

Minimal external components are required. Only two

0.1µF to 1µF bucket capacitors, a 4.7µF input capacitor

and a 1µF output capacitor are needed for proper opera-

tion.

The FAN5616 is available in a 3x3mm 16-lead MLP

package.

Ordering Information

Product Number

Package Type

Order Code

FAN5616

3x3mm 16-Lead MLP

FAN5616MPX

2

www.fairchildsemi.com

FAN5616 Rev. 1.0.0

F

AN5616 High-Efficienc

y

,

Constant-Current LED Driver with Adaptive Char

g

e

Pump

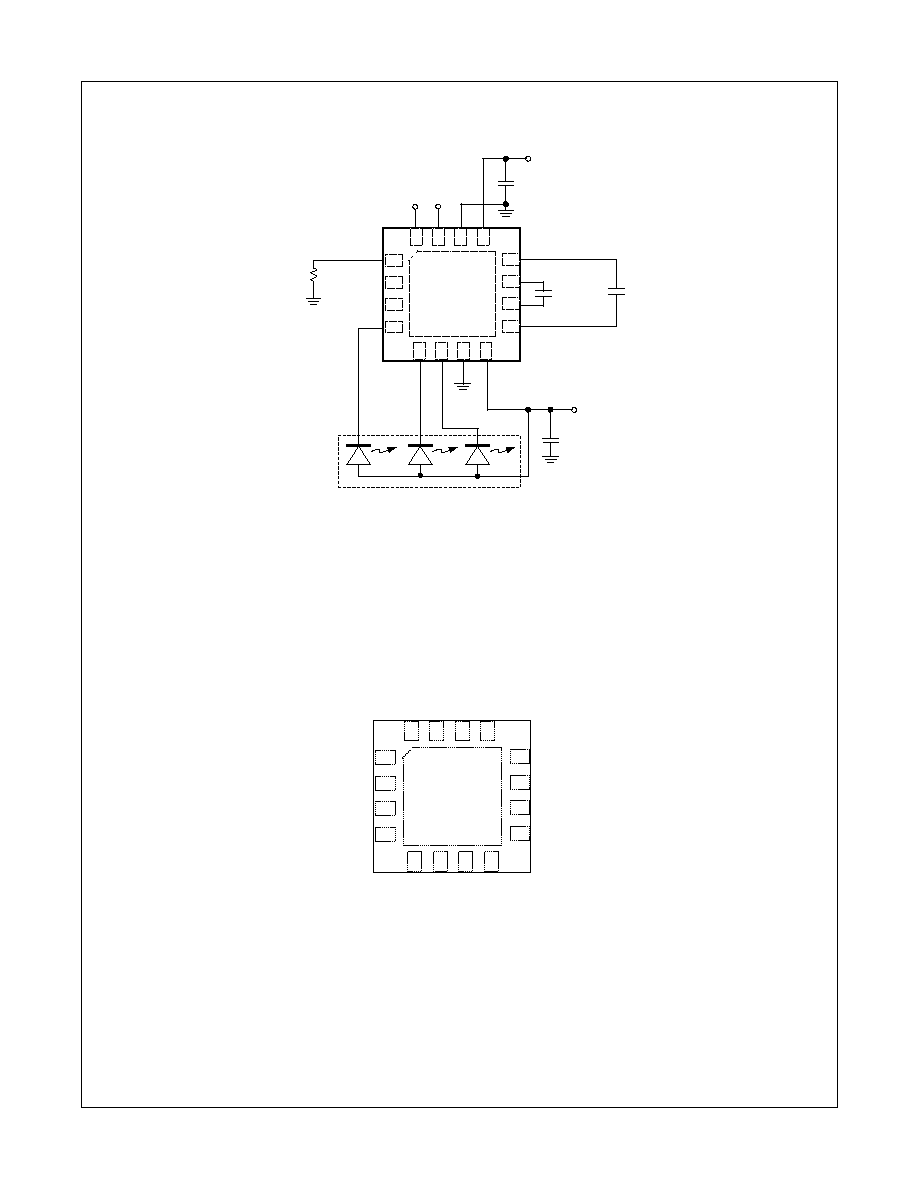

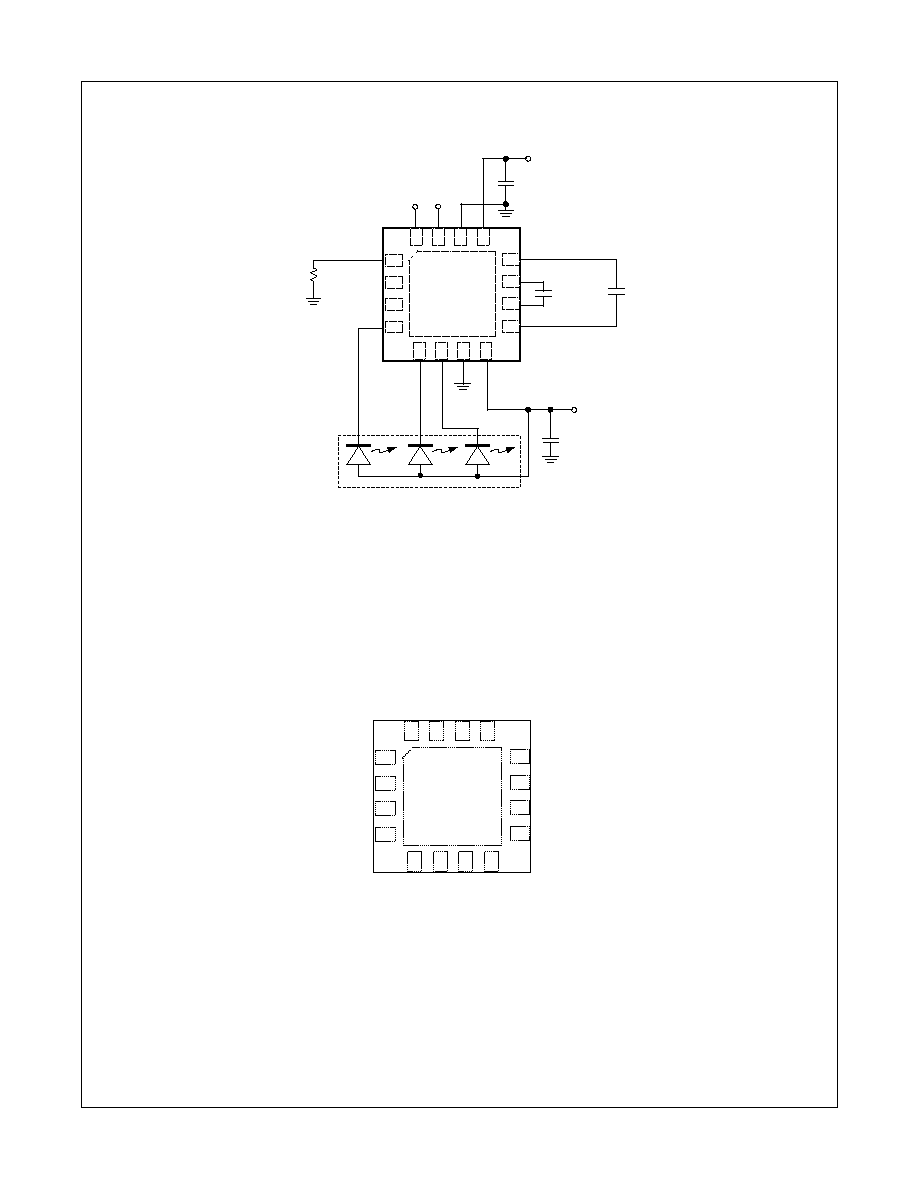

Typical Application

Figure 1. Typical Application

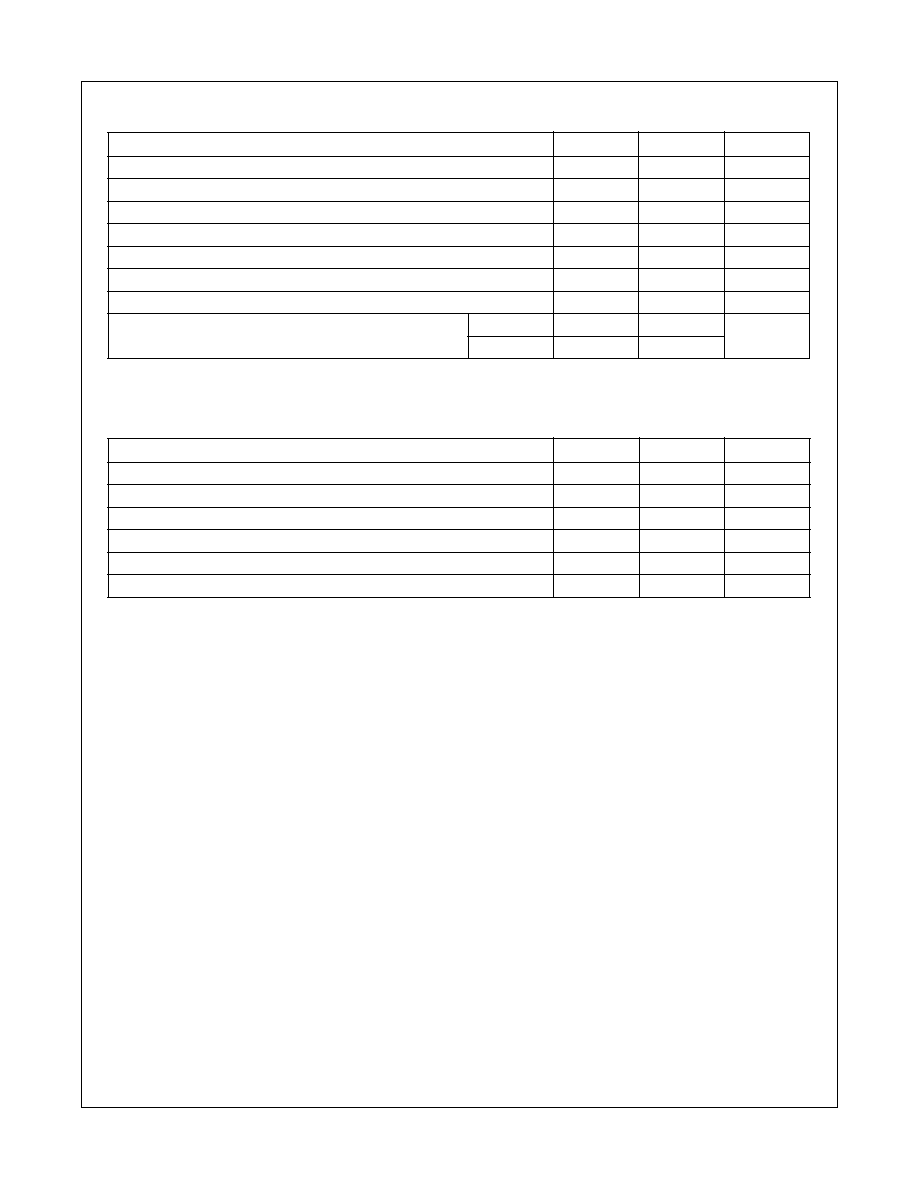

Pin Assignment

Figure 2. Pin Assignment

V

IN

C

IN

V

OUT

C

OUT

EN1

EN2

CAP1

NC

GND

CAP2

R

SET

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P1

(GND)

Top View

CAP1+

CAP1-

NC

GND

V

IN

V

OUT

LED-

LED-

PGND

LED-

CAP2-

CAP2+

EN1

EN2

R

SET

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P1

(GND)

3x3mm 16-Lead MLP

3

www.fairchildsemi.com

FAN5616 Rev. 1.0.0

F

AN5616 High-Efficienc

y

,

Constant-Current LED Driver with Adaptive Char

g

e

Pump

Pin Description

Pin No.

Pin Name

Pin Description

P1

GND

Ground.

P1 must be soldered to the PCB ground.

1

R

SET

R

SET

Pin.

Connect this pin to the resistor used to set the maximum LED current.

2

NC

No Connection.

3

NC

No Connection.

4

LED-

1st LED Cathode.

Connect this pin to the LED's cathode.

5

LED-

2nd LED Cathode.

Connect this pin to the LED's cathode.

6

LED-

3rd LED Cathode.

Connect this pin to the LED's cathode.

7

PGND

Power Ground.

8

V

OUT

Output Voltage.

Connect this pin to all of the LED's anodes.

9

CAP2+

Bucket Capacitor 2.

Connect this pin to the positive terminal of the bucket capacitor.

10

CAP1+

Bucket Capacitor 1.

Connect this pin to the positive terminal of the bucket capacitor.

11

CAP1-

Bucket Capacitor 1.

Connect this pin to the negative terminal of the bucket capacitor.

12

CAP2-

Bucket Capacitor 2.

Connect this pin to the negative terminal of the bucket capacitor.

13

V

IN

Supply Voltage Input.

14

GND

Ground.

15

EN1

Enable Input.

16

EN2

Enable Input.

4

www.fairchildsemi.com

FAN5616 Rev. 1.0.0

F

AN5616 High-Efficienc

y

,

Constant-Current LED Driver with Adaptive Char

g

e

Pump

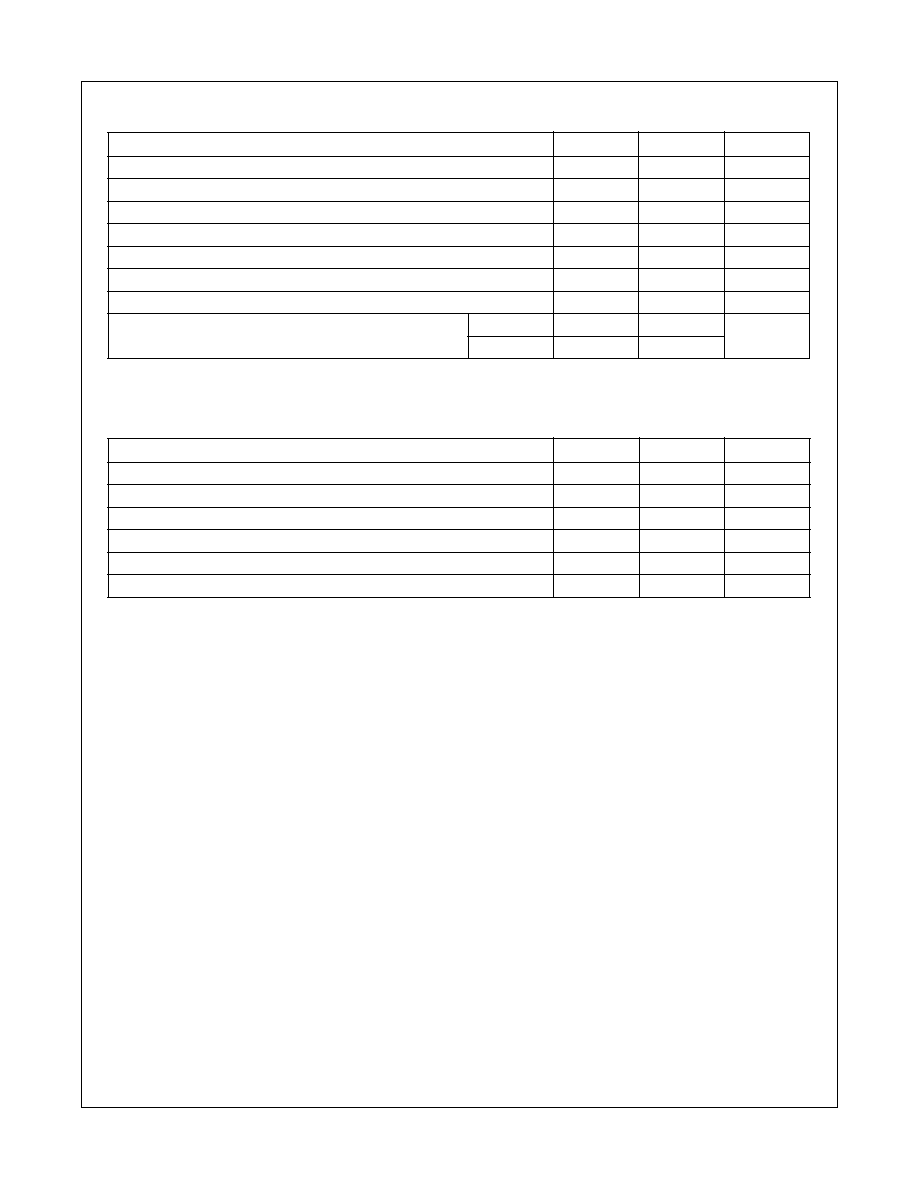

Absolute Maximum Ratings

(Note1)

Recommended Operating Conditions

Notes:

1. Stresses above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. This

is a stress rating only and functional operation of the device at these or any other conditions above those indicated

in the operational section of this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Absolute maximum ratings apply individually only, not in combination.

Unless otherwise specified all other voltages are referenced to GND.

2. Junction to ambient thermal resistance,

JA

, is a strong function of PCB material, board thickness, thickness

and number of via used, diameter of via used, available copper surface, and attached heat sink characteristics.

A reasonable estimated value for

JA

for zero air flow at 0.5W is 60∞C/W.

3. Using Mil Std. 883E, method 3015.7(Human Body Model) and EIA/JESD22C101-A (Charge Device Model).

Parameter

Min

Max

Unit

V

IN

, V

OUT

, EN1, EN2, GND

-0.3

6

V

Voltage On All Other Pins

GND ≠ 0.3

V

IN

+ 0.3

V

CAP+, CAP- to GND

-0.3

V

IN

+ 0.3

V

Thermal Resistance ≠ Junction to Tab (

JC

) (Note 2)

8

∞C/W

Lead Soldering Temperature (10 seconds)

260

∞C

Junction Temperature

150

∞C

Storage Temperature

-65

150

∞C

Electrostatic Discharge Protection (ESD) Level (Note 3)

HBM

2.5

kV

CDM

1.5

Parameter

Min

Max

Unit

Supply Voltage Range

2.5

5.5

V

LED Forward Voltage

4

V

Current Through Each LED

2

40

mA

PWM Dimming Signal Frequency

0.2

50

kHz

Operating Ambient Temperature

-40

+85

∞C

Operating Junction Temperature

-40

+125

∞C

5

www.fairchildsemi.com

FAN5616 Rev. 1.0.0

F

AN5616 High-Efficienc

y

,

Constant-Current LED Driver with Adaptive Char

g

e

Pump

Electrical Characteristics

Unless otherwise noted, V

IN

= 2.7V to 5.5V, I

LED

= 2mA to 20mA, EN1 = EN2 = HIGH, T

A

= -40∞C to +85∞C. Typical

values are at 25∞C.

Notes:

1. Current Matching refers to the absolute value of the difference in the current between the two LED branches.

2. Efficiency is expressed as a ratio between the electrical power into the LEDs and the total power consumed from

the input power supply.

Some competitors calculate the efficiency as a function of V

OUT

instead of LED V

F

. Their method does not account

for the power lost due to the cathode voltage not being equal to zero. This method allows them to provide an

"improved" efficiency up to 5%.

Parameter

Conditions

Min

Typ

Max

Unit

Input Under-Voltage Lockout

V

IN

falling

1.6

V

V

IN

rising

2.3

I

LED

/I

SET

Ratio

V

IN

= 3.6V, I

OUT

= 15mA

240

255

270

I

LED

/I

SET

Ratio

I

LED

= 2 to 20mA

230

260

280

I

LED

/I

SET

Ratio

EN1 = HIGH, EN2 = LOW

86

EN1 = LOW, EN2 = HIGH

173

Current Matching with Unmatched

LEDs (Note 1)

2mA

I

LED

15mA

2.8V

LED V

F

<4V

0.6

+3

%

Reference Voltage for Current Set

588

600

612

mV

Start Up time

C

OUT

= 1µF, V

IN

= 3.6V,

I

LED

= 15mA

200

270

500

µS

Minimum Cathode Voltage

I

LED

= 15mA

170

250

mV

Quiescent Current

V

IN

= 5.5V, I

OUT

= 5mA

250

µA

Shutdown Supply Current

EN1 = EN2 = Logic "L"

0.1

1

µA

Output Short Circuit Current

V

IN

= 5.5V, V

OUT

= 0V

65

80

mA

V

OUT

Over-voltage Protection

6

V

V

IN

at Mode Transition from 1x to 1.5x

LED V

f

= 3.5V, I

LED

= 3 x 20mA

3.9

V

V

IN

at Mode Transition from 1.5x to 2x

LED V

f

= 3.5V, I

LED

= 3 x 20mA

2.9

V

Peak Efficiency (Note 2)

V

IN

= 3.75V, LED V

f

= 3.4V,

I

LED

= 18mA

90

%

Oscillator Frequency

0.8

1

1.2

MHz

Thermal Shutdown Threshold

150

∞C

Thermal Shutdown Hysteresis

15

∞C

"EN1" Logic Input Low Voltage

0.4

V

"EN1" Logic Input High Voltage

1.6

V

"EN2" Logic Input Low Voltage

0.4

V

"EN2" Logic Input High Voltage

1.6

V

(

(

)

)

LEDj

LEDi

LEDj

LEDi

I

I

100

x

I

I

Current Matching (%)

+

, where i, j = 1, 2 or 3

≠

≠

≠

≠

IN

IN

3

1

i

LEDi

LEDi

I

x

V

I

x

V

Efficiency

=

≠

≠

≠