| ÐлекÑÑоннÑй компоненÑ: NDS9955 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

May 1998

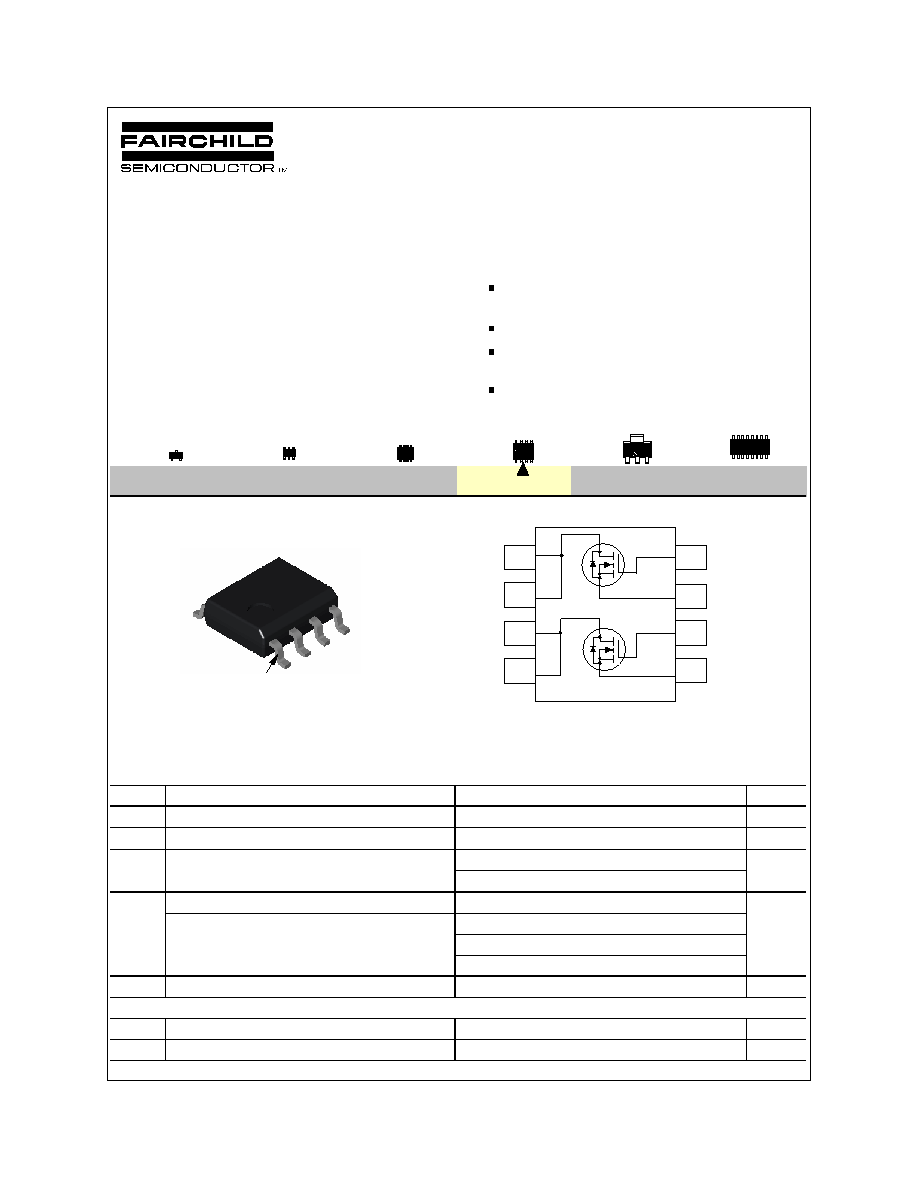

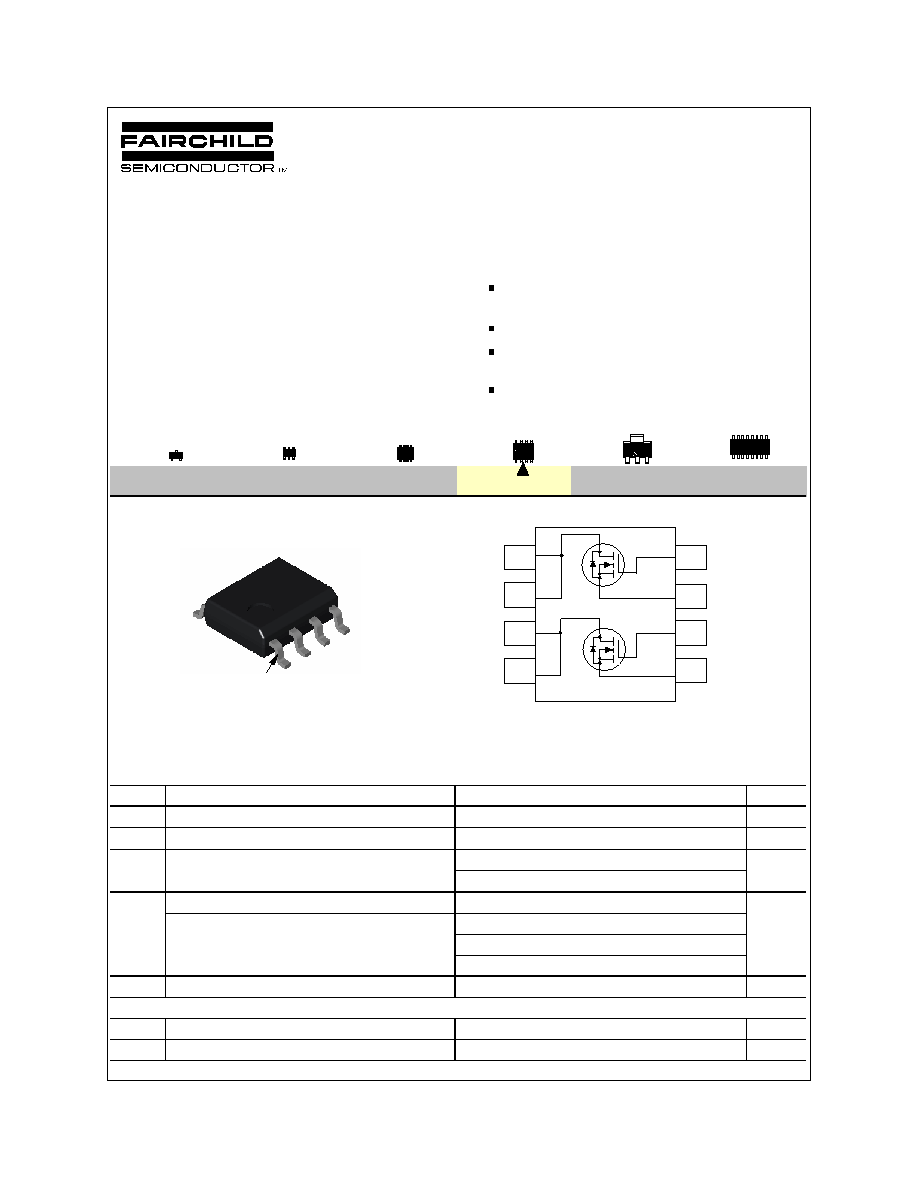

NDS9955

Dual N-Channel Enhancement Mode Field Effect Transistor

General Description Features

Absolute Maximum Ratings

T

A

= 25

o

C unless other wise noted

Symbol

Parameter

NDS9955

Units

V

DSS

Drain-Source Voltage

50

V

V

GSS

Gate-Source Voltage

±20

V

I

D

Drain Current - Continuous

(Note 1a)

3

A

- Pulsed

10

P

D

Power Dissipation for Dual Operation

2

W

Power Dissipation for Single Operation

(Note 1a)

1.6

(Note 1b)

1

(Note 1c)

0.9

T

J

,T

STG

Operating and Storage Temperature Range

-55 to 150

°C

THERMAL CHARACTERISTICS

R

JA

Thermal Resistance, Junction-to-Ambient

(Note 1a)

78

°C/W

R

JC

Thermal Resistance, Junction-to-Case

(Note 1)

40

°C/W

NDS9955 Rev.A

3.0 A, 50 V. R

DS(ON)

= 0.130

@ V

GS

= 10 V,

R

DS(ON)

= 0.200

@ V

GS

= 4.5 V.

High density cell design for extremely low R

DS(ON)

.

High power and current handling capability in a widely

used surface mount package.

Dual MOSFET in surface mount package.

SOT-23

SuperSOT

TM

-8

SOIC-16

SO-8

SOT-223

SuperSOT

TM

-6

SO-8 N-Channel enhancement mode power field effect

transistors are produced using Fairchild's proprietary, high

cell density, DMOS technology. This very high density

process is especially tailored to provide superior switching

performance and minimize on-state resistance. These

devices are particularly suited for low voltage applications

such as disk drive motor control, battery powered circuits

where fast switching, low in-line power loss, and resistance

to transients are needed.

S1

D1

S2

G1

SO-8

D2

D2

D1

G2

NDS

9955

pin

1

1

5

7

8

2

3

4

6

© 1998 Fairchild Semiconductor Corporation

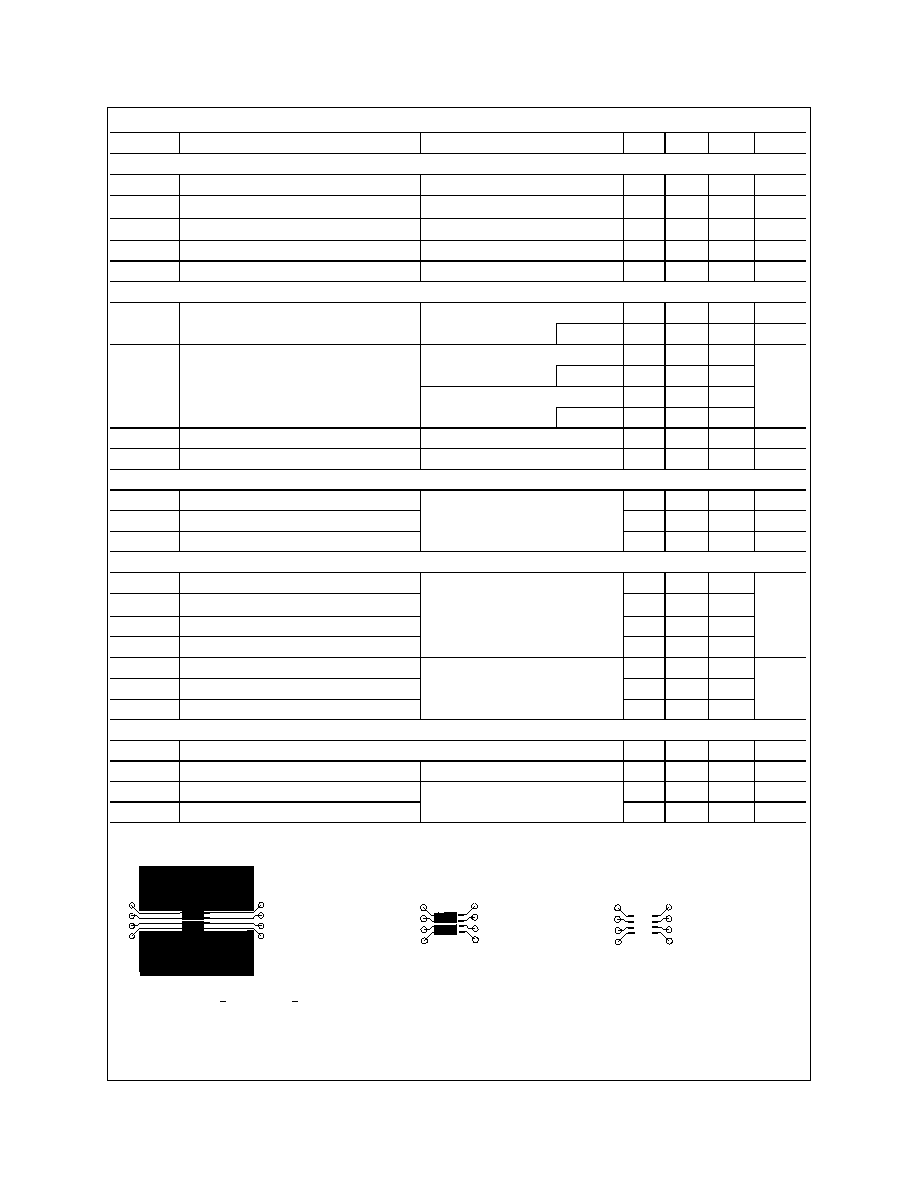

Electrical Characteristics

(

T

A

= 25

O

C unless otherwise noted )

Symbol

Parameter

Conditions

Min

Typ

Max

Units

OFF CHARACTERISTICS

BV

DSS

Drain-Source Breakdown Voltage

V

GS

= 0 V, I

D

= 250 µA

50

V

BV

DSS

/

T

J

Breakdown Voltage Temp. Coefficient

I

D

= 250 µA, Referenced to 25

o

C

60

mV/

o

C

I

DSS

Zero Gate Voltage Drain Current

V

DS

= 40 V, V

GS

= 0 V

2

µA

I

GSSF

Gate - Body Leakage, Forward

V

GS

= 20 V, V

DS

= 0 V

100

nA

I

GSSR

Gate - Body Leakage, Reverse

V

GS

= -20 V, V

DS

= 0 V

-100

nA

ON CHARACTERISTICS

(Note 2)

V

GS(th)

Gate Threshold Voltage

V

DS

= V

GS

, I

D

= 250 µA

1

1.7

3

V

T

J

=125°C

0.7

2.2

R

DS(ON)

Static Drain-Source On-Resistance

V

GS

= 10 V, I

D

= 3 A

0.076

0.13

T

J

=125°C

0.124

0.2

V

GS

= 4.5 V, I

D

= 1.5 A

0.103

0.2

T

J

=125°C

0.166

0.3

I

D(ON)

On-State Drain Current

V

GS

= 10 V, V

DS

= 10 V

10

A

g

FS

Forward Transconductance

V

DS

= 10 V, I

D

= 3 A

5.3

S

DYNAMIC CH ARACTERISTICS

C

iss

Input Capacitance

V

DS

= 25 V, V

GS

= 0 V,

f = 1.0 MHz

345

pF

C

oss

Output Capacitance

110

pF

C

rss

Reverse Transfer Capacitance

25

pF

SWITCHING CHARACTERISTICS

(Note 2)

t

D(on)

Turn - On Delay Time

V

DS

= 25 V, I

D

= 1 A

5

20

ns

t

r

Turn - On Rise Time

V

GS

= 10 V , R

GEN

= 6

7.5

20

t

D(off)

Turn - Off Delay Time

20

70

t

f

Turn - Off Fall Time

7

5

Q

g

Total Gate Charge

V

DS

= 25 V, I

D

= 2 A,

12.9

30

nC

Q

gs

Gate-Source Charge

V

GS

= 10 V

1.7

Q

gd

Gate-Drain Charge

3.2

DRAIN-SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

I

S

Maximum Continuous Drain-Source Diode Forward Current

1.3

A

V

SD

Drain-Source Diode Forward Voltage

V

GS

= 0 V, I

S

= 1.3 A

(Note 2)

0.8

1.2

V

t

rr

Reverse Recovery Time

V

GS

= 0 V, I

F

= 1.3 A,

dI

F

/dt = 100 A/µs

40

ns

I

rr

Reverse Recovery Current

1.5

A

Notes:

1. R

JA

is the sum of the junction-to-case and case-to-ambient thermal resistance where the case thermal reference is defined as the solder mounting surface of the drain pins. R

JC

is guaranteed by

design while R

CA

is determined by the user's board design.

Scale 1 : 1 on letter size paper

2. Pulse Test: Pulse Width < 300µs, Duty Cycle < 2.0%.

NDS9955 Rev.A

c. 135

O

C/W on a 0.003 in

2

pad of 2oz copper.

b. 125

O

C/W on a 0.02 in

2

pad of 2oz copper.

a. 78

O

C/W on a 0.5 in

2

pad of 2oz copper.

NDS9955 Rev.A

0

1

2

3

4

5

0

5

10

15

20

V , DRAIN-SOURCE VOLTAGE (V)

I , DRAIN-SOURCE CURRENT (A)

DS

D

3.5V

3.0V

4.0V

V = 10V

GS

6.0V

4.5V

5.0V

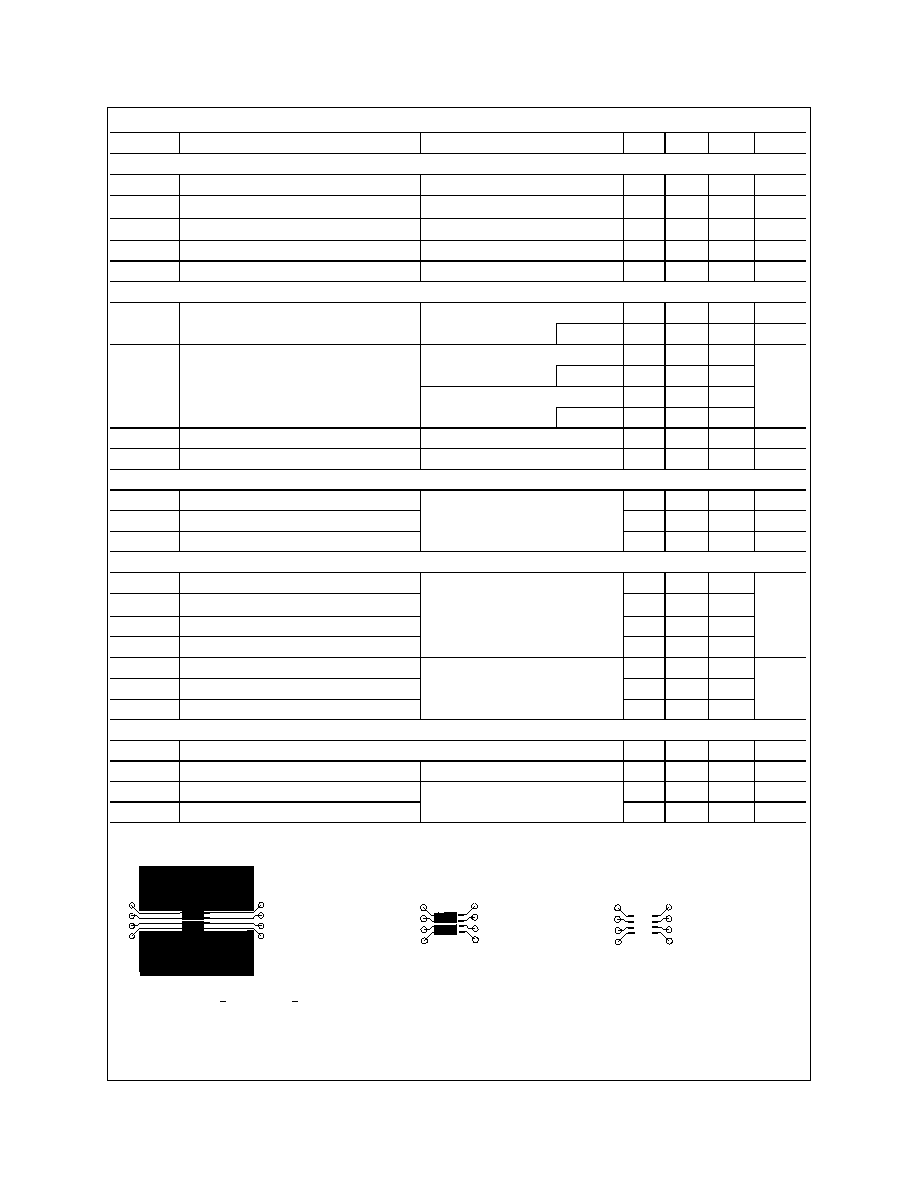

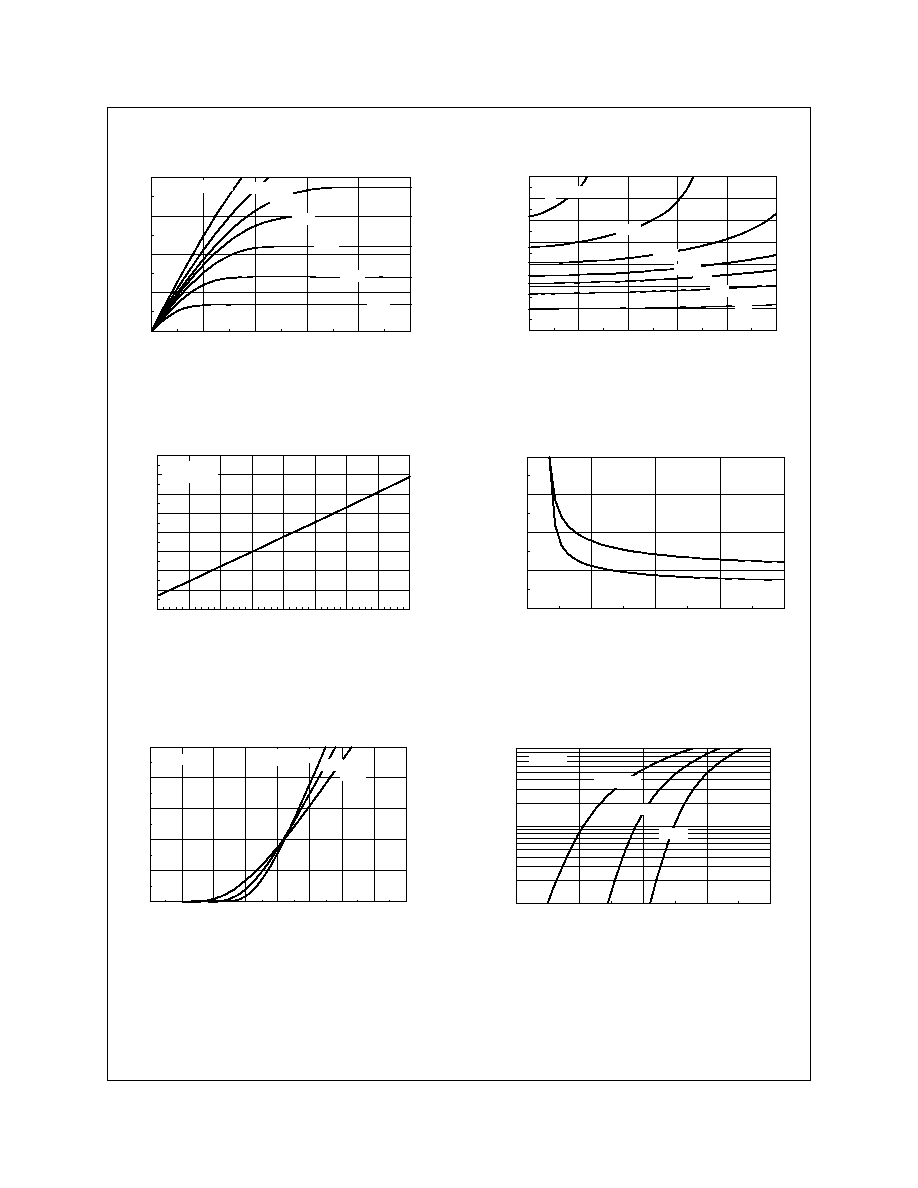

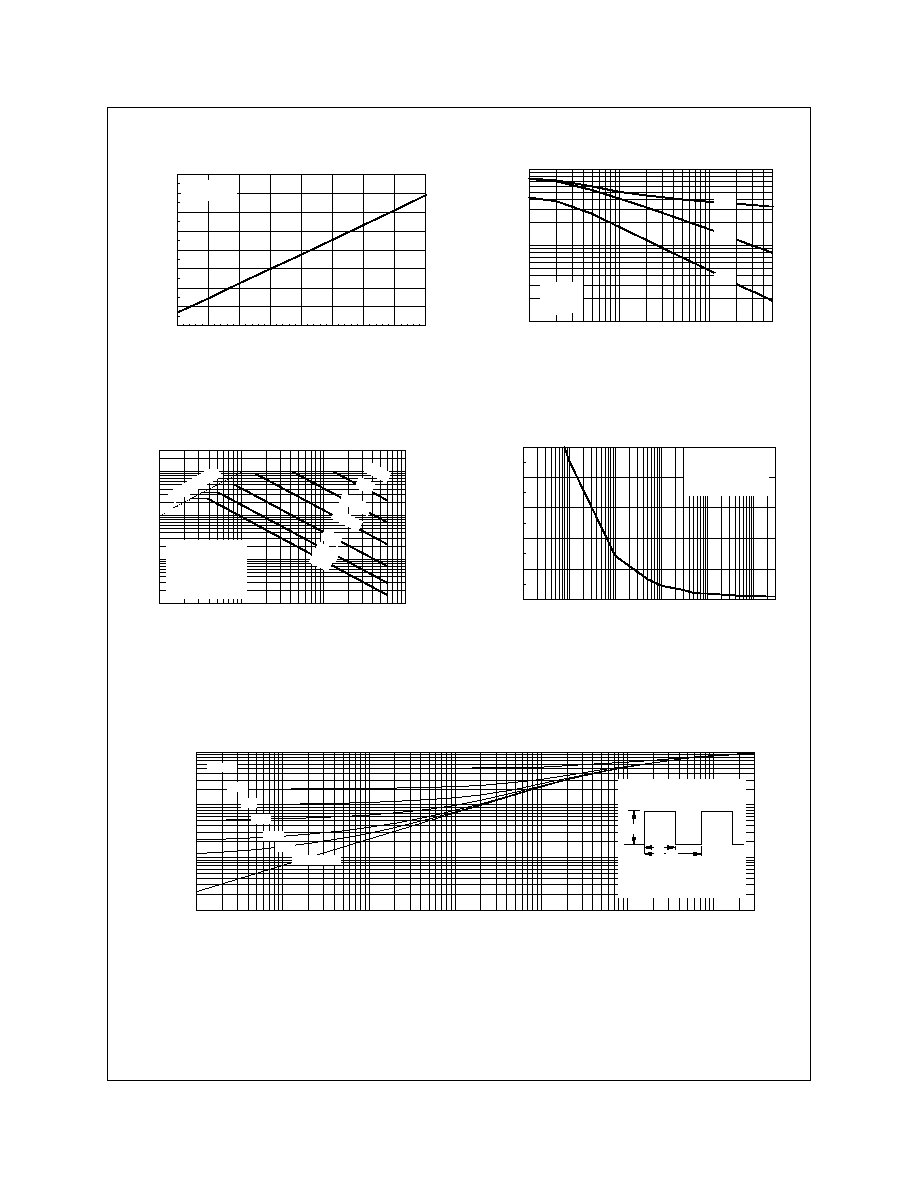

Typical Electrical Characteristics

Figure 1. On-Region Characteristics.

Figure 2. On-Resistance Variation with

Drain Current and Gate Voltage.

-50

-25

0

25

50

75

100

125

150

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

T , JUNCTION TEMPERATURE (°C)

DRAIN-SOURCE ON-RESISTANCE

J

R , NORMALIZED

DS(ON)

V = 10V

GS

I = 3.0A

D

Figure 3. On-Resistance Variation With

Temperature.

1

1.5

2

2.5

3

3.5

4

4.5

5

0

2

4

6

8

10

V , GATE TO SOURCE VOLTAGE (V)

I , DRAIN CURRENT (A)

V = 5V

DS

GS

D

T = -55°C

J

125°C

25°C

Figure 5 . Transfer Characteristics.

Figure 6. Body Diode Forward Voltage

Variation with Source Current

and Temperature.

2

4

6

8

10

0

0.1

0.2

0.3

0.4

V , GATE TO SOURCE VOLTAGE (V)

GS

R , ON-RESISTANCE (OHM)

DS(ON)

I = 2A

D

T =125°C

A

T =25°C

A

Figure 4. On-Resistance

Variation with

Gate-to-Source Voltage.

0

2

4

6

8

10

0.75

1

1.25

1.5

1.75

2

2.25

2.5

I , DRAIN CURRENT (A)

DRAIN-SOURCE ON-RESISTANCE

V = 3.0V

GS

D

R , NORMALIZED

DS(ON)

10V

4.5 V

6.0V

5.0V

4.0 V

3.5 V

0.4

0.6

0.8

1

1.2

0.1

0.2

0.3

0.5

1

2

3

5

10

V , BODY DIODE FORWARD VOLTAGE (V)

I , REVERSE DRAIN CURRENT (A)

25°C

-55°C

V = 0V

GS

SD

S

T = 125°C

J

NDS9955 Rev.A

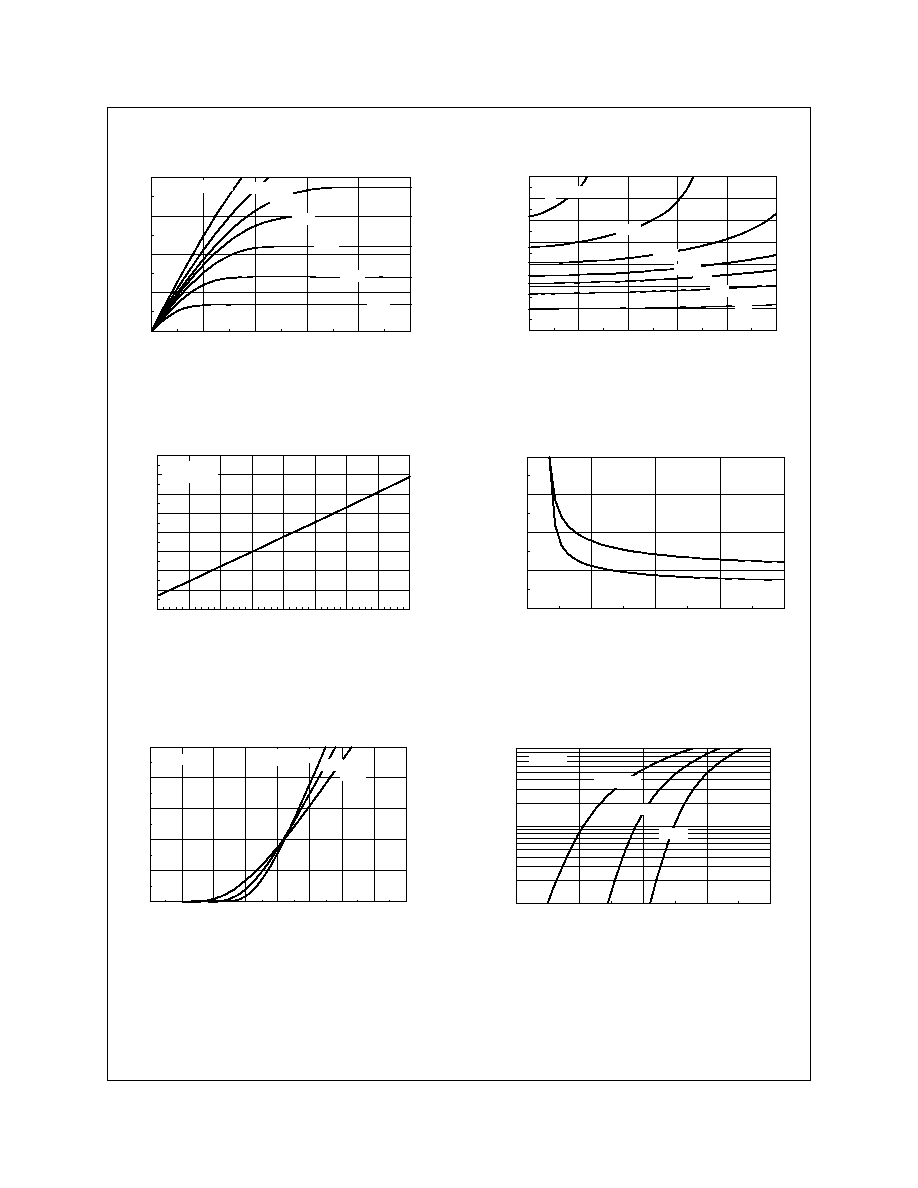

Figure 10. Single Pulse Maximum Power

Dissipation.

Figure 8. Capacitance Characteristics.

Figure 7. Gate Charge Characteristics.

Figure 9. Maximum Safe Operating Area

.

Typical Electrical Characteristics

(continued)

0.0001

0.001

0.01

0.1

1

10

100

300

0.001

0.002

0.005

0.01

0.02

0.05

0.1

0.2

0.5

1

t , TIME (sec)

TRANSIENT THERMAL RESISTANCE

r(t), NORMALIZED EFFECTIVE

1

Single Pulse

D = 0.5

0.1

0.05

0.02

0.01

0.2

Duty Cycle, D = t /t

1

2

R (t) = r(t) * R

R =135 °C/W

JA

JA

JA

T - T = P * R (t)

JA

A

J

P(pk)

t

1

t

2

Figure 11. Transient Thermal Response Curve.

Thermal characterization performed using the conditions described in Note 1c. Transient

thermal response will change depending on the circuit board design.

-50

-25

0

25

50

75

100

125

150

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

T , JUNCTION TEMPERATURE (°C)

DRAIN-SOURCE ON-RESISTANCE

J

R , NORMALIZED

DS(ON)

V = 10V

GS

I = 3A

D

0.1

0.3

1

3

10

20

50

10

20

50

100

200

400

1000

V , DRAIN TO SOURCE VOLTAGE (V)

CAPACITANCE (pF)

DS

C

iss

f = 1 MHz

V = 0 V

GS

C

oss

C

rss

0.1

0.2

0.5

1

2

5

10

20

50

100

0.01

0.03

0.1

0.3

1

3

10

30

V , DRAIN-SOURCE VOLTAGE (V)

I , DRAIN CURRENT (A)

RDS(ON) LIMIT

D

A

DC

DS

1s

100ms

10ms

1ms

10s

V =10V

SINGLE PULSE

R = 135°C/W

T = 25°C

JA

GS

A

100us

0.001

0.01

0.1

1

10

100

300

0

10

20

30

40

50

SINGLE PULSE TIME (SEC)

POWER (W)

SINGLE PULSE

R =135°C/W

T = 25°C

JA

A

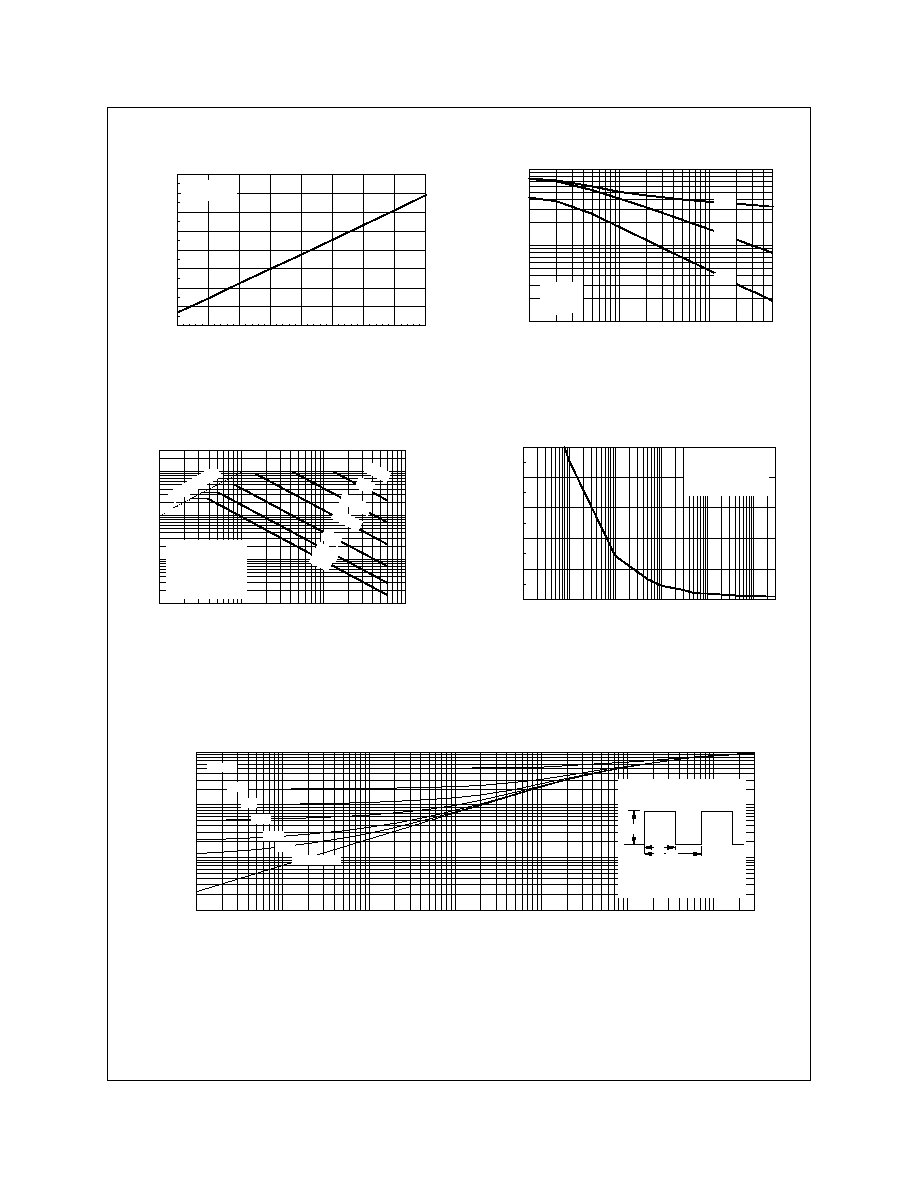

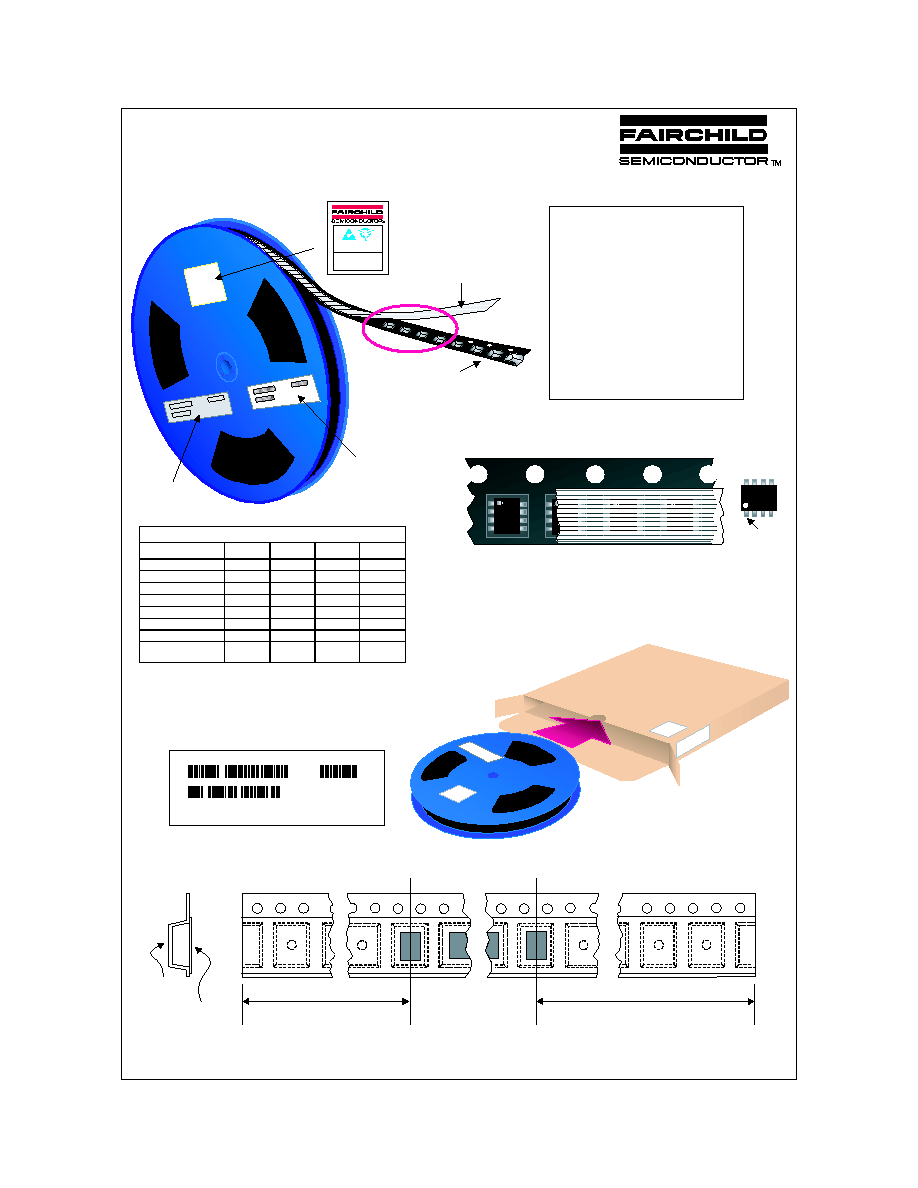

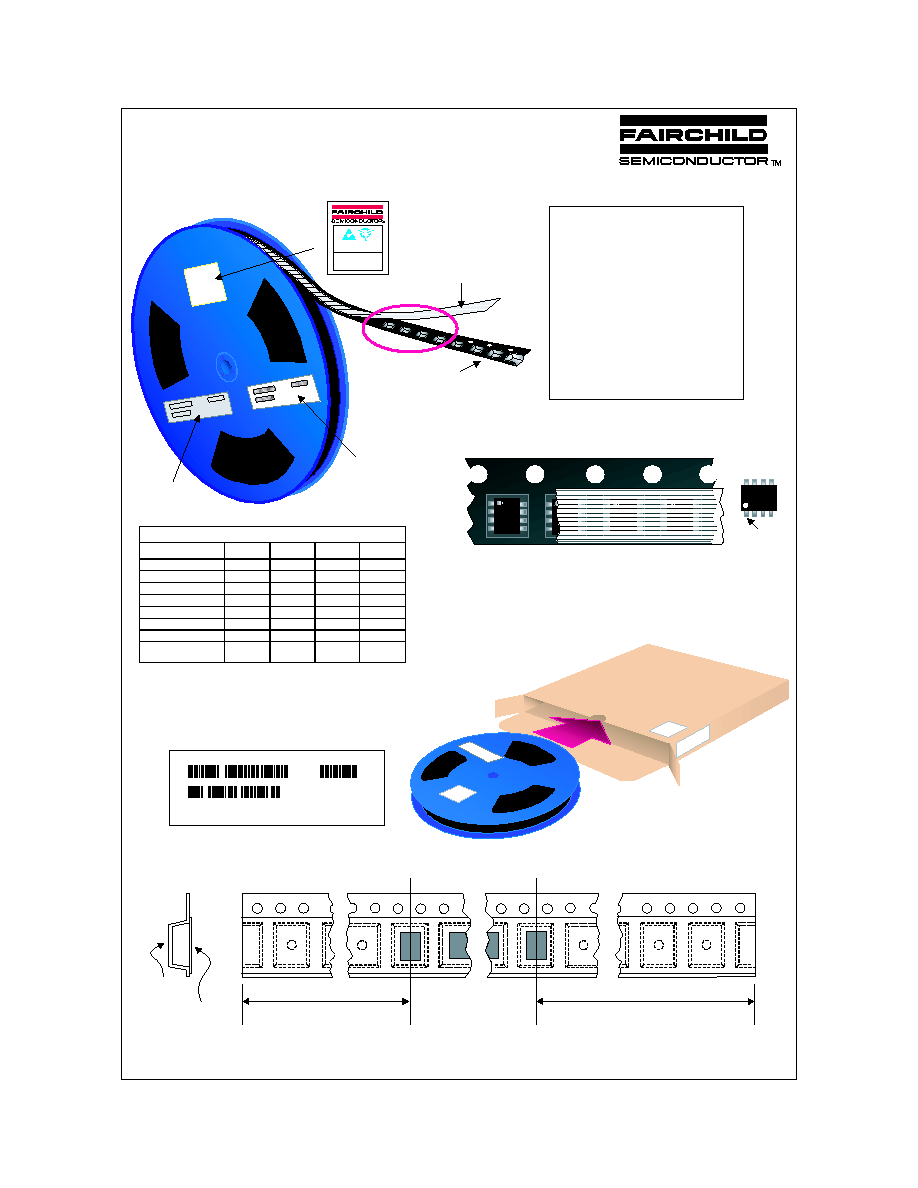

SOIC(8lds) Packaging

Configuration: Figure 1.0

Components

Leader Tape

1680mm minimum or

210 empty pockets

Trailer Tape

640mm minimum or

80 empty pockets

SOIC(8lds) Tape Leader and Trailer

Configuration: Figure 2.0

Cover Tape

Carrier Tape

Note/Comments

Packaging Option

SOIC (8lds) Packaging Information

Standard

(no flow code)

L86Z

F011

Packaging type

Reel Size

TNR

13" Dia

Rail/Tube

-

TNR

13" Dia

Qty per Reel/Tube/Bag

2,500

95

4,000

Box Dimension (mm)

343x64x343

530x130x83

343x64x343

Max qty per Box

5,000

30,000

8,000

D84Z

TNR

7" Dia

500

184x187x47

1,000

Weight per unit (gm)

0.0774

0.0774

0.0774

0.0774

Weight per Reel (kg)

0.6060

-

0.9696

0.1182

F63TN Label

ESD Label

343mm x 342mm x 64mm

Standard Intermediate box

ESD Label

F63TNR Label sample

F63TNLabel

LOT: CBVK741B019

FSID: FDS9953A

D/C1: D9842 QTY1:

SPEC REV:

SPEC:

QTY: 2500

D/C2:

QTY2:

CPN:

N/F: F (F63TNR)3

F852

NDS

9959

SOIC-8 Unit Orientation

F

85

2

NDS

99

59

Pin 1

Static Dissipative

Embossed Carrier Tape

F63TNR

Label

Antistatic Cover Tape

ESD Label

EL ECT RO ST AT IC

SEN SIT IVE DEVI CES

DO NO T SHI P OR STO RE N EAR ST RO NG EL ECT ROST AT IC

EL ECT RO M AGN ETI C, M AG NET IC O R R ADIO ACT IVE FI ELD S

TNR D ATE

PT NUMB ER

PEEL STREN GTH MIN ___ __ ____ __ ___gms

MAX ___ ___ ___ ___ _ gms

Customized

Label

Packaging Description:

SOIC-8 parts are shipped in tape. The carrier tape is

made from a dissipative (carbon filled) polycarbonate

resin. The cover tape is a multilayer film (Heat Activated

Adhesive in nature) primarily composed of polyester film,

adhesive layer, sealant, and anti-static sprayed agent.

These reeled parts in standard option are shipped with

2,500 units per 13" or 330cm diameter reel. The reels are

dark blue in color and is made of polystyrene plastic (anti-

static coated). Other option comes in 500 units per 7" or

177cm diameter reel. This and some other options are

further described in the Packaging Information table.

These full reels are individually barcode labeled and

placed inside a standard intermediate box (illustrated in

figure 1.0) made of recyclable corrugated brown paper.

One box contains two reels maximum. And these boxes

are placed inside a barcode labeled shipping box which

comes in different sizes depending on the number of parts

shipped.

F

85

2

NDS

99

59

F

85

2

NDS

99

59

F

85

2

NDS

99

59

SO-8 Tape and Reel Data and Package Dimensions

July 1999, Rev. B