| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LMA406 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

LMA406

L

OW

N

OISE

PHEMT

MMIC

Phone: (408) 988-1845

http:// www.filss.com

Revised: 12/5/00

Fax: (408) 970-9950

Email: sales@filss.com

∑

FEATURES

18 GHz to 40 GHz Frequency Band

4.5 dB Noise Figure

12dB Gain

14 dBm Output Power at Saturation

+3 V Single Bias Supply

∑

DESCRIPTION AND APPLICATIONS

The Filtronic Solid State LMA406 is a low noise PHEMT amplifier that operates from 18 to 40GHz.

This 2-stage amplifier provides 12dB nominal gain with 4.5dB typical noise figure and 1-dB gain

compression power output of +10dBm that is designed for commercial mmW (millimeter-wave)

PCN/PCS applications. Ground is provided to the circuitry through vias to the backside

metallization.

∑

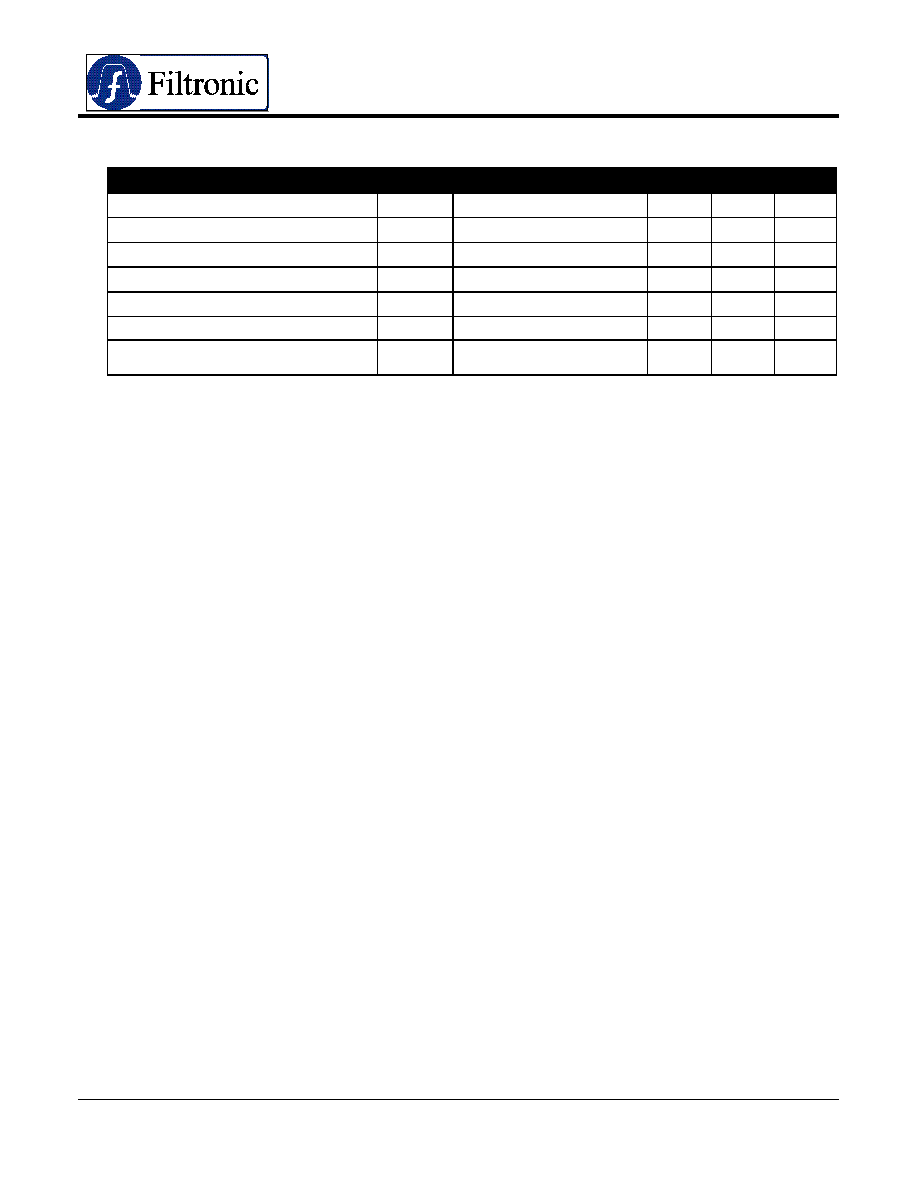

ELECTRICAL SPECIFICATIONS @ T

Ambient

= 25∞C

(V

DD

= +3.0V, Z

IN

= Z

OUT

= 50

)

Parameter

Symbol

Test Conditions

Min

Typ

Max

Units

Frequency Band

F

18

40

GHz

Small Signal Gain

S

21

30% I

DSS

(Pad B&D Ground)

9

11.5

dB

30% I

DSS

(Pad A&C Ground)

9

12.5

dB

Saturated Drain Current

I

DSS

R

S

= 0/0

40

80

120

mA

Small Signal Gain Flatness

S

21

±

1

±

2.5

dB

Noise Figure

NF

50% I

DSS

4.5

6.0

dB

Input Return Loss

S

11

-12

dB

Output Return Loss

S

22

-14

dB

Reverse Isolation

S

12

-32

-38

dB

LMA406

L

OW

N

OISE

PHEMT

MMIC

Phone: (408) 988-1845

http:// www.filss.com

Revised: 12/5/00

Fax: (408) 970-9950

Email: sales@filss.com

∑

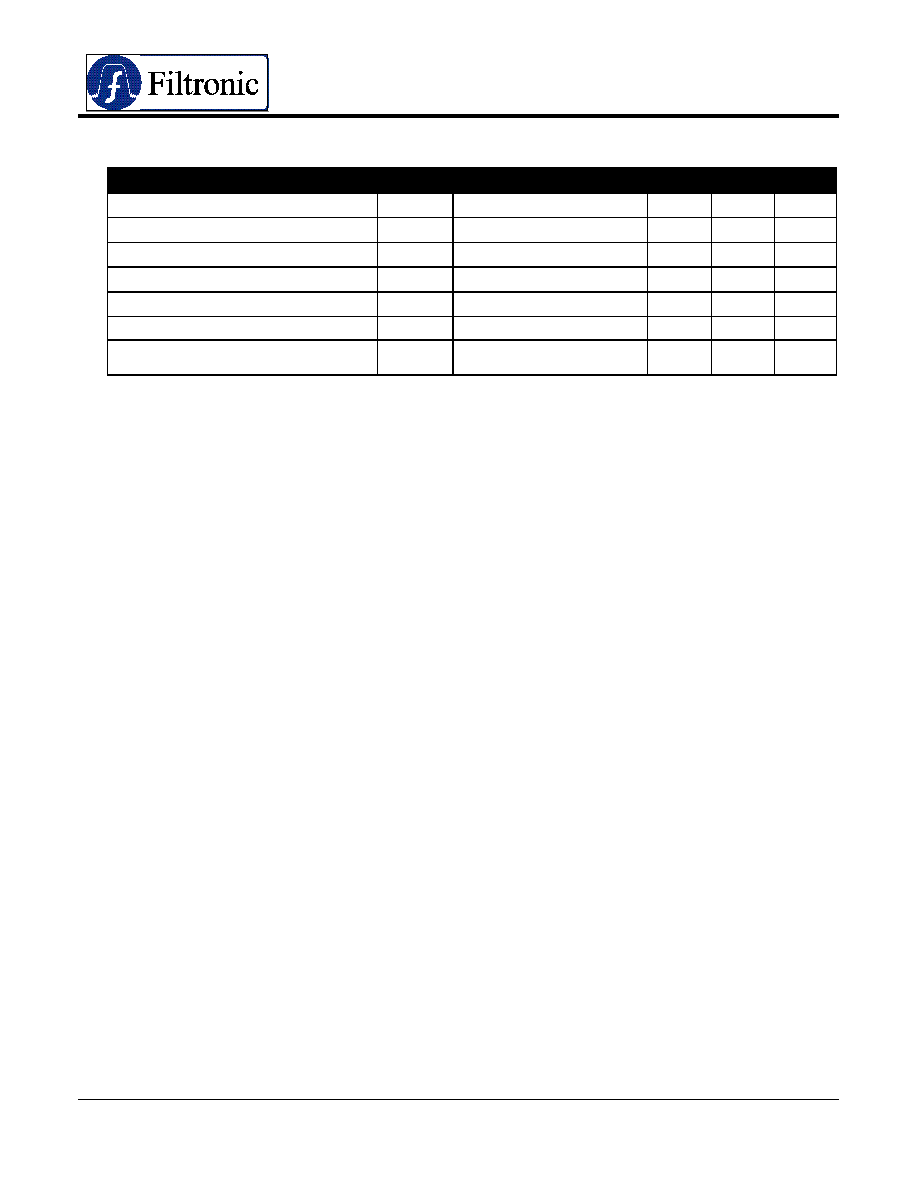

ABSOLUTE MAXIMUM RATINGS

Parameter

Symbol

Test Conditions

Min

Max

Units

Drain Voltage

V

D

T

Ambient

= 22

±

3

∞

C

4

V

Operating Current

I

OP

T

Ambient

= 22

±

3

∞

C

120

mA

RF Input Power

P

IN

T

Ambient

= 22

±

3

∞

C

10

dBm

Total Power Dissipation

P

TOT

T

Ambient

= 22

±

3

∞

C

.48

W

Channel Operating Temperature

T

CH

T

Ambient

= 22

±

3

∞

C

150

∫C

Storage Temperature

T

STG

--

-65

165

∫C

Maximum Assembly Temperature

(1 min. max.)

T

MAX

--

300

∫C

Notes:

∑

Operating conditions that exceed the Absolute Maximum Ratings could result in permanent damage to the device.

∑

Recommended Continuous Operating Limits should be observed for reliable device operation.

∑

Power Dissipation defined as: P

TOT

(P

DC

+ P

IN

) ≠ P

OUT

, where

P

DC

: DC Bias Power

P

IN

: RF Input Power

P

OUT

: RF Output Power

∑

This GaAs MMIC is susceptible to damage from Electrostatic Discharge. Proper precautions should be used when

handling these devices.

LMA406

L

OW

N

OISE

PHEMT

MMIC

Phone: (408) 988-1845

http:// www.filss.com

Revised: 12/5/00

Fax: (408) 970-9950

Email: sales@filss.com

∑

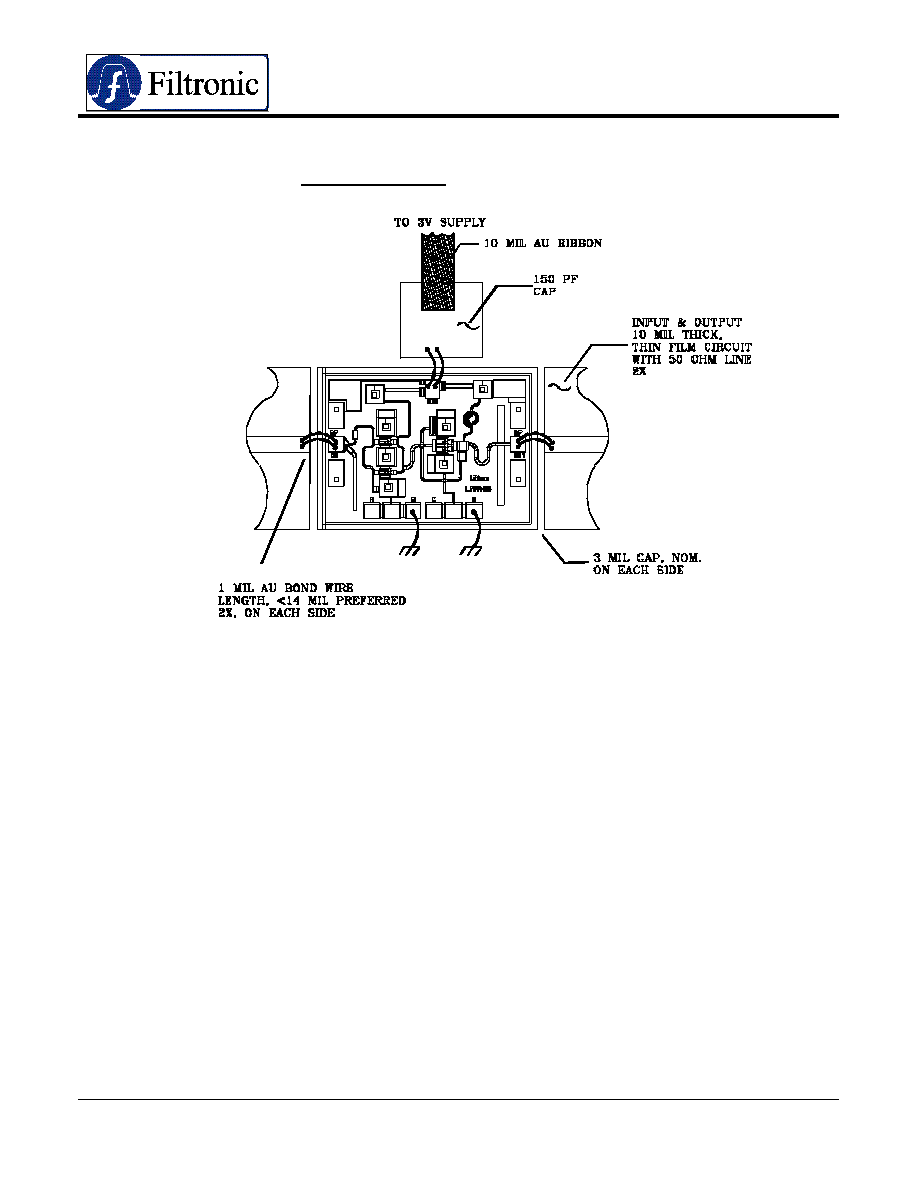

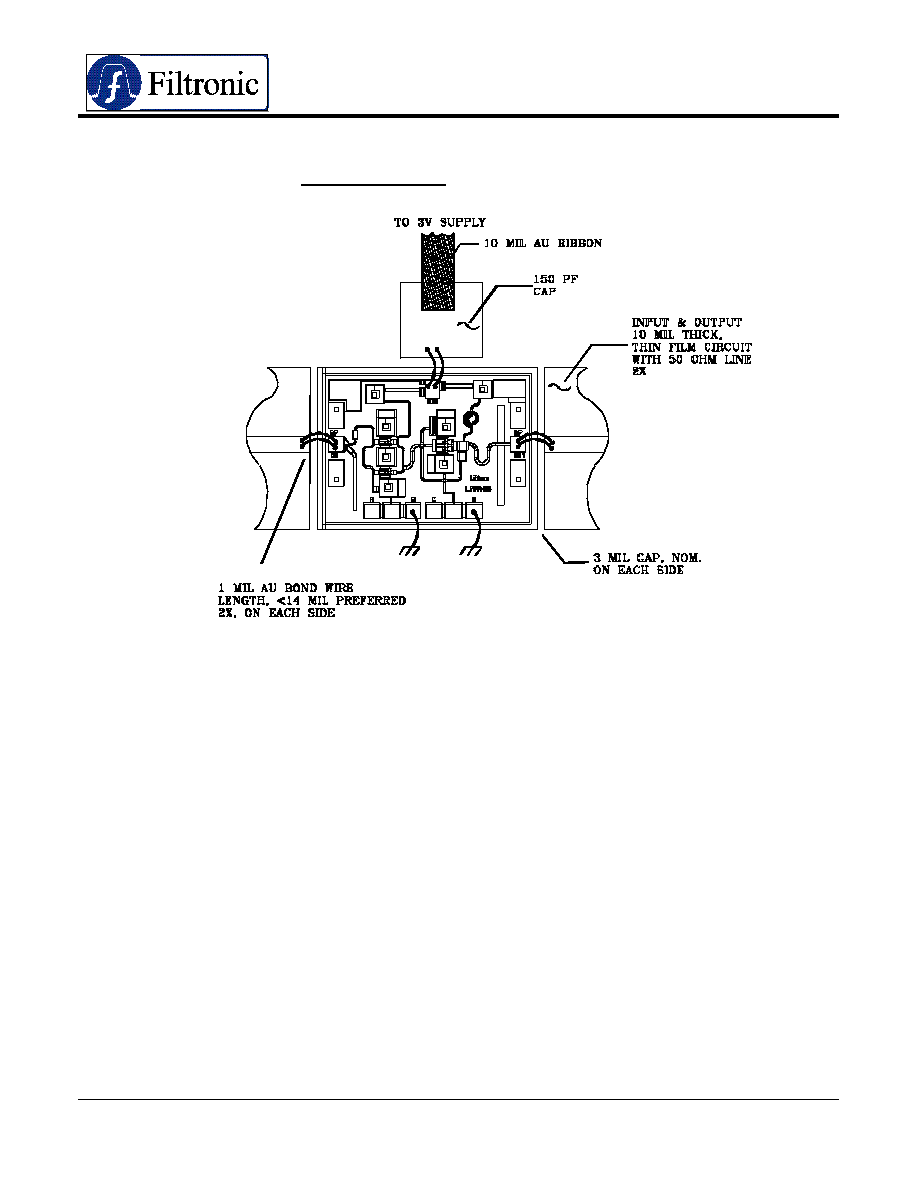

ASSEMBLY DRAWING

LOW NOISE BIAS: PAD B & D TO GND

Notes:

∑

Recommended lead bond technique is thermocompression wedge bonding with 0.001" (25µm) diameter wire. The

bond tool force shall be 35-38 gram. Bonding stage temperature shall be 230-240∞C, heated tool (150-160∞C) is

recommended. Ultrasonic bonding is not recommended.

∑

The recommended die attach is Ablebond silver epoxy, the stabilize bake temperature is set at 150∞C for 45 minutes.

∑

Bond on bond or stitch bond acceptable.

∑

Conductor over conductor acceptable. Conductors must not short.

LMA406

L

OW

N

OISE

PHEMT

MMIC

Phone: (408) 988-1845

http:// www.filss.com

Revised: 12/5/00

Fax: (408) 970-9950

Email: sales@filss.com

∑

ASSEMBLY DRAWING

HIGH GAIN BIAS:

PAD A & C TO GND

Notes:

∑

Recommended lead bond technique is thermocompression wedge bonding with 0.001" (25µm) diameter wire. The

bond tool force shall be 35-38 gram. Bonding stage temperature shall be 230-240∞C, heated tool (150-160∞C) is

recommended. Ultrasonic bonding is not recommended.

∑

The recommended die attach is Ablebond silver epoxy, the stabilize bake temperature is set at 150∞C for 45 minutes.

∑

Bond on bond or stitch bond acceptable.

∑

Conductor over conductor acceptable. Conductors must not short.

LMA406

L

OW

N

OISE

PHEMT

MMIC

Phone: (408) 988-1845

http:// www.filss.com

Revised: 12/5/00

Fax: (408) 970-9950

Email: sales@filss.com

∑

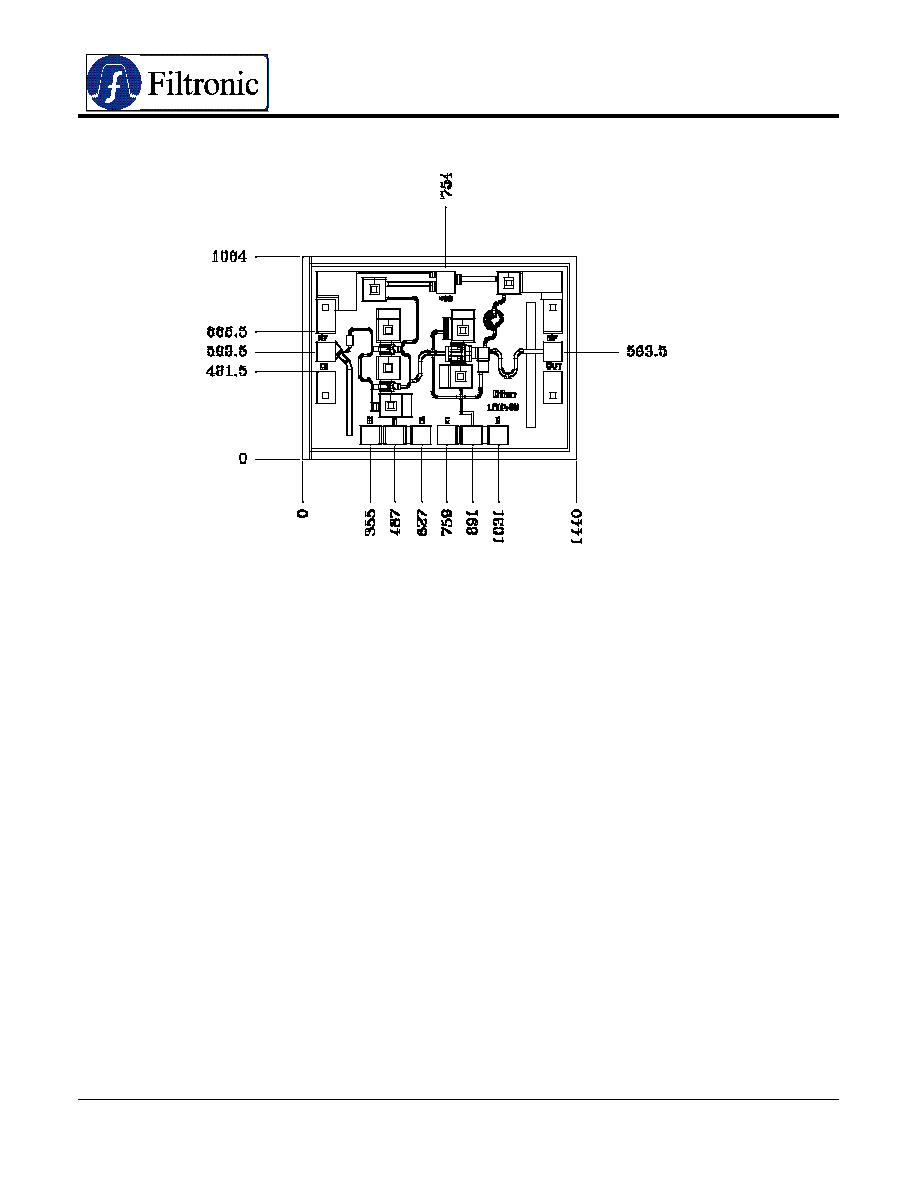

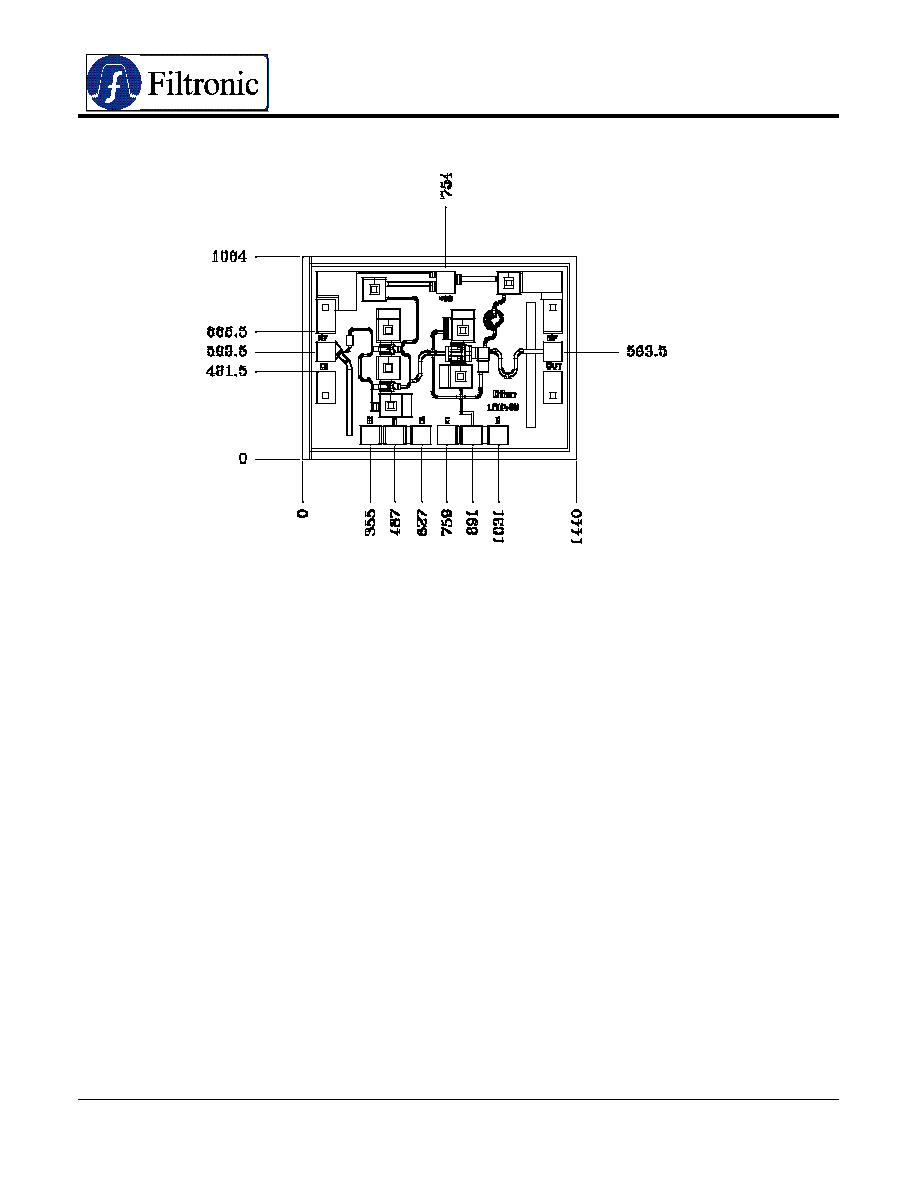

MECHANICAL OUTLINE

Notes:

∑

All units are in microns (µm).

∑

All bond pads are 100 X 100 µm

2

.

∑

Bias pad (V

DD

) size is 100 X 121.5 µm

2

.

∑

Unless otherwise specified.

∑

HANDLING PRECAUTIONS

To avoid damage to the devices care should be exercised during handling. Proper Electrostatic

Discharge (ESD) precautions should be observed at all stages of storage, handling, assembly, and

testing. These devices should be treated as Class 1A (0-500 V). Further information on ESD control

measures can be found in MIL-STD-1686 and MIL-HDBK-263.

All information and specifications are subject to change without notice.