MC100ES6221

Rev 5, 04/2005

Freescale Semiconductor

Technical Data

© Freescale Semiconductor, Inc., 2005. All rights reserved.

Low Voltage 1:20 Differential

ECL/PECL/HSTL Clock Fanout Buffer

The MC100ES6221 is a bipolar monolithic differential clock fanout buffer.

Designed for most demanding clock distribution systems, the MC100ES6221

supports various applications that require the distribution of precisely aligned

differential clock signals. Using SiGe technology and a fully differential

architecture, the device offers very low skew outputs and superior digital signal

characteristics. Target applications for this clock driver is high performance clock

distribution in computing, networking and telecommunication systems.

Features

∑

1:20 differential clock fanout buffer

∑

100 ps maximum device skew

∑

SiGe technology

∑

Supports DC to 2 GHz operation of clock or data signals

∑

ECL/PECL compatible differential clock outputs

∑

ECL/PECL/HSTL compatible differential clock inputs

∑

Single 3.3 V, ≠3.3 V, 2.5 V or ≠2.5 V supply

∑

Standard 52 lead LQFP package with exposed pad for enhanced thermal

characteristics

∑

Supports industrial temperature range

∑

Pin and function compatible to the MC100EP221

∑

52-lead Pb-free Package Available

Functional Description

The MC100ES6221 is designed for low skew clock distribution systems and

supports clock frequencies up to 2 GHz. The device accepts two clock sources.

The CLK0 input can be driven by ECL or PECL compatible signals, the CLK1 input accepts HSTL compatible signals. The

selected input signal is distributed to 20 identical, differential ECL/PECL outputs. If V

BB

is connected to the CLK0 or CLK1 input

and bypassed to GND by a 10 nF capacitor, the MC100ES6221 can be driven by single-ended ECL/PECL signals utilizing the

V

BB

bias voltage output.

In order to meet the tight skew specification of the device, both outputs of a differential output pair should be terminated, even

if only one output is used. In the case where not all ten outputs are used, the output pairs on the same package side as the parts

being used on that side should be terminated.

The MC100ES6221 can be operated from a single 3.3 V or 2.5 V supply. As most other ECL compatible devices, the

MC100ES6221 supports positive (PECL) and negative (ECL) supplies. The MC100ES6221 is pin and function compatible to the

MC100EP221.

MC100ES6221

LOW VOLTAGE DUAL

1:20 DIFFERENTIAL ECL/PECL/HSTL

CLOCK FANOUT BUFFER

AE SUFFIX

52-LEAD LQFP PACKAGE

Pb-FREE PACKAGE

CASE 1336A-01

TB SUFFIX

52-LEAD LQFP PACKAGE

EXPOSED PAD

CASE 1336A-01

Advanced Clock Drivers Devices

2

Freescale Semiconductor

MC100ES6221

Figure 1. MC100ES6221 Logic Diagram

Figure 2. 52-Lead Package Pinout (Top View)

0

1

CLK0

CLK0

CLK1

CLK1

CLK_SEL

V

CC

Q0

Q0

Q1

Q1

Q2

Q2

Q3

Q3

Q16

Q16

Q17

Q17

Q18

Q18

Q19

Q19

V

BB

V

EE

V

EE

∑

∑

∑

V

EE

V

CC

∑

∑

∑

V

CC

Q5

Q5

Q4

Q4

Q3

Q3

Q2

Q2

Q1

Q1

Q0

Q0

Q12

Q12

Q13

Q13

Q14

Q14

Q15

Q15

Q16

Q16

Q17

Q17

V

CC

Q6

Q7

Q8

Q9

V

CC

V

CC

C

L

K_

SE

L

CL

K0

CL

K0

V

BB

CL

K1

CL

K1

V

EE

Q1

9

Q1

9

Q1

8

Q1

8

40

41

42

43

44

45

46

47

48

49

50

51

52

25

24

23

22

21

20

19

18

17

16

15

14

1

2

3

4

5

6

7

8

9

10 11 12 13

39 38 37 36

35 34 33 32 31 30 29 28 27

26

MC100ES6221

Q6

Q7

Q8

Q9

Q1

0

Q1

0

Q1

1

Q1

1

V

CC

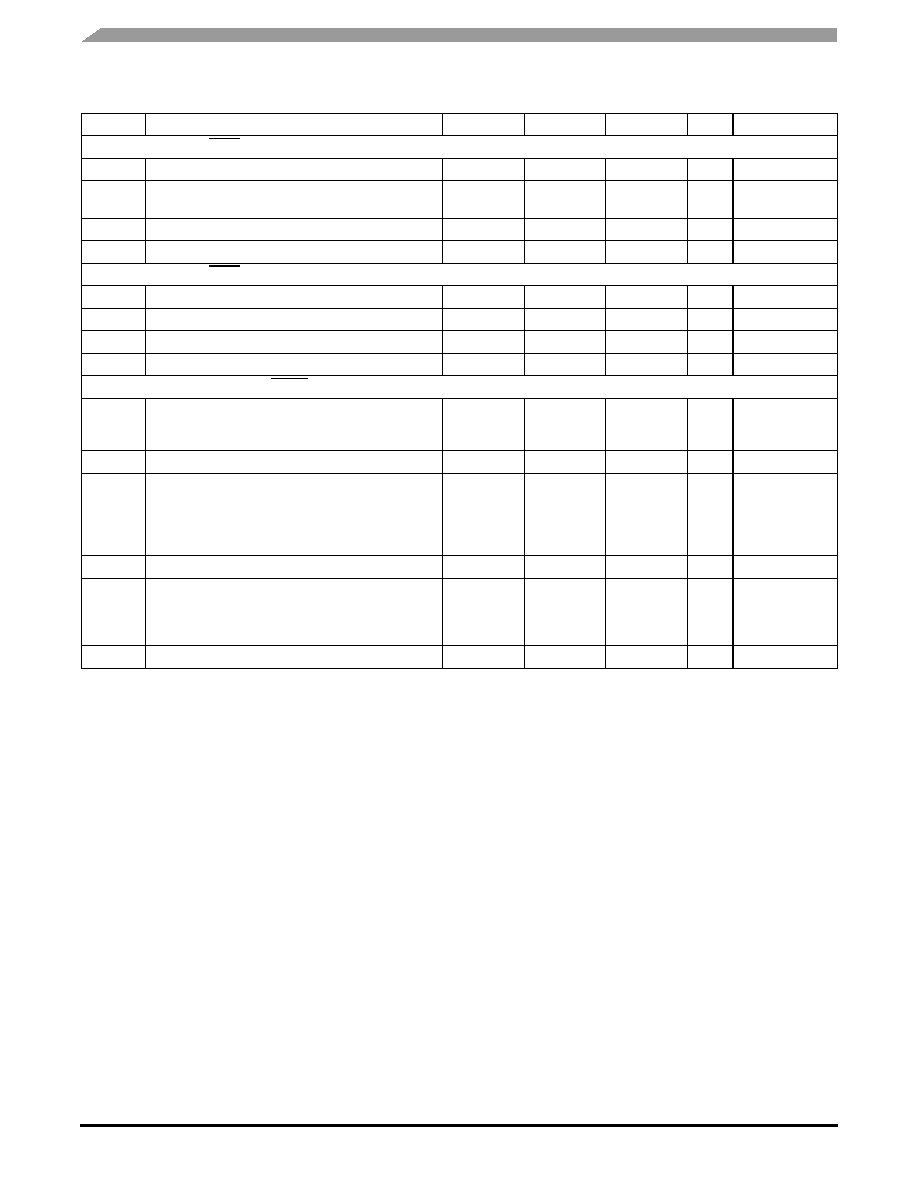

Table 1. Pin Configuration

Pin

I/O

Type

Function

CLK0, CLK0

Input

ECL/PECL

Differential reference clock signal input

CLK1, CLK1

Input

HSTL

Alternative differential reference clock signal input

CLK_SEL

Input

ECL/PECL

Reference clock input select

QA[0≠19], QA[0≠19]

Output

ECL/PECL

Differential clock outputs

V

EE

(1)

1. In ECL mode (negative power supply mode), V

EE

is either ≠3.3 V or ≠2.5 V and V

CC

is connected to GND (0 V). In PECL mode (positive

power supply mode), V

EE

is connected to GND (0 V) and V

CC

is either

+3.3 V or +2.5 V. In both modes, the input and output levels are

referenced to the most positive supply (V

CC

).

Supply

Negative power supply

V

CC

Supply

Positive power supply. All V

CC

pins must be connected to the positive

power supply for correct DC and AC operation.

V

BB

Output

DC

Reference voltage output for single ended ECL and PECL operation

Table 2. Function Table

Pin

0

1

CLK_SEL

CLK0, CLK0 input pair is the reference clock. CLK0 can be

driven by ECL or PECL compatible signals.

CLK1, CLK1 input pair is the reference clock. CLK1 can be

driven by HSTL compatible signals.

Advanced Clock Drivers Devices

Freescale Semiconductor

3

MC100ES6221

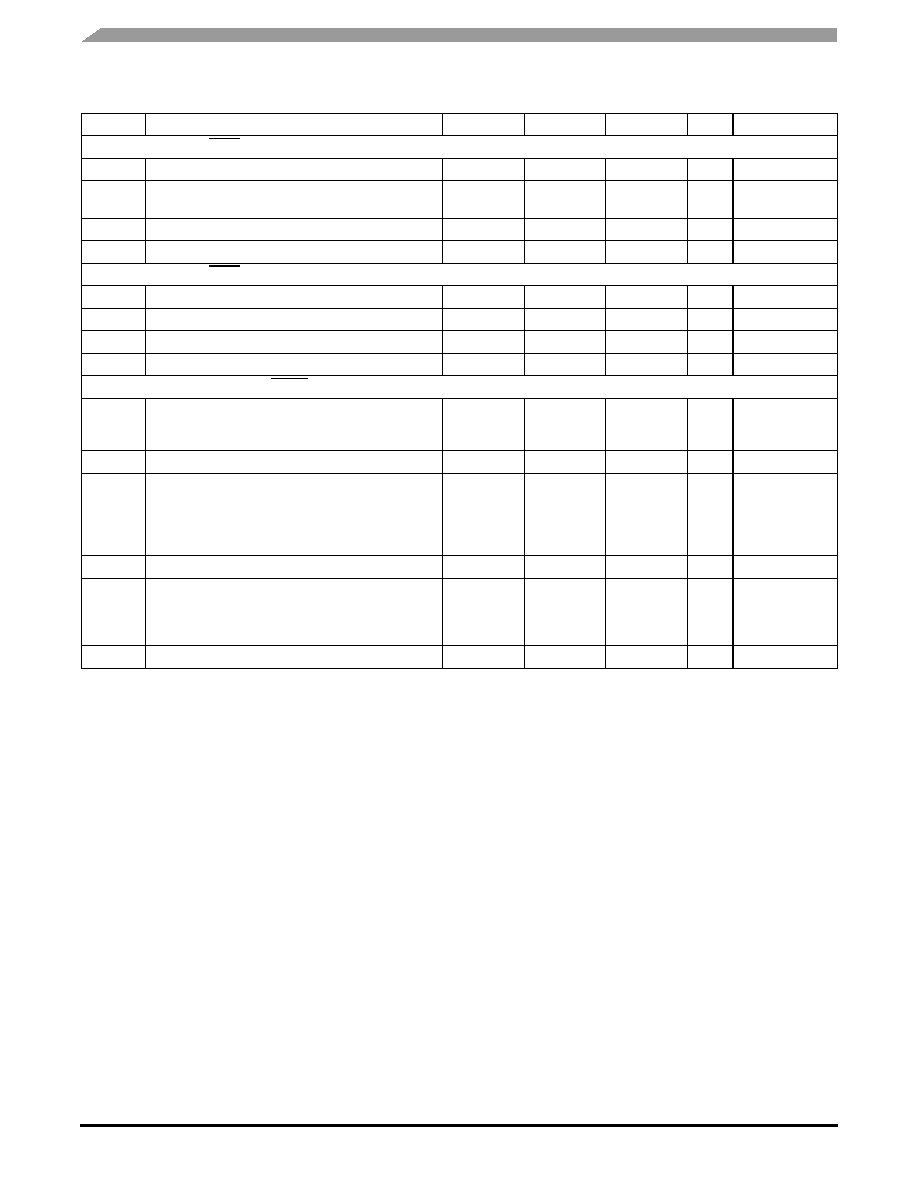

Table 3. Absolute Maximum Ratings

(1)

1. Absolute maximum continuous ratings are those maximum values beyond which damage to the device may occur. Exposure to these

conditions or conditions beyond those indicated may adversely affect device reliability. Functional operation at absolute-maximum-rated

conditions is not implied.

Symbol

Characteristics

Min

Max

Unit

Condition

V

CC

Supply Voltage

≠0.3

3.6

V

V

IN

DC Input Voltage

≠0.3

V

CC

+ 0.3

V

V

OUT

DC Output Voltage

≠0.3

V

CC

+ 0.3

V

I

IN

DC Input Current

±20

mA

I

OUT

DC Output Current

±50

mA

T

S

Storage Temperature

≠65

125

∞C

T

FUNC

Functional Temperature Range

T

A

= ≠40

T

J

=

+110

∞C

Table 4. General Specifications

Symbol

Characteristics

Min

Typ

Max

Unit

Condition

V

TT

Output Termination Voltage

V

CC

≠ 2

(1)

1. Output termination voltage V

TT

= 0 V for V

CC

= 2.5 V operation is supported but the power consumption of the device will increase.

V

MM

ESD Protection (Machine Model)

200

V

HBM

ESD Protection (Human Body Model)

4000

V

CDM

ESD Protection (Charged Device Model)

2000

V

LU

Latch-Up Immunity

200

mA

C

IN

Input Capacitance

4.0

pF

Inputs

JA

,

JB

,

JC

Thermal Resistance (junction-to-ambient,

junction-to-board, junction-to-case)

See

Table 9. Thermal Resistance

∞C/W

T

J

Operating Junction Temperature

(2)

(continuous operation)

MTBF = 9.1 years

2. Operating junction temperature impacts device life time. Maximum continuous operating junction temperature should be selected according

to the application life time requirements (See application note AN1545 for more information). The device AC and DC parameters are

specified up to 110

∞C junction temperature allowing the MC100ES6221 to be used in applications requiring industrial temperature range. It

is recommended that users of the MC100ES6221 employ thermal modeling analysis to assist in applying the junction temperature

specifications to their particular application.

0

110

∞C

Advanced Clock Drivers Devices

4

Freescale Semiconductor

MC100ES6221

Table 5. PECL DC Characteristics (V

CC

= 2.5 V

± 5% or V

CC

= 3.3 V

± 5%, V

EE

= GND, T

J

= 0

∞C to + 110∞C)

Symbol

Characteristics

Min

Typ

Max

Unit

Condition

Clock Input Pair CLK0, CLK0

(1)

(PECL differential signals)

1. The input pairs CLK0, CLK1 are compatible to differential signaling standards. CLK0 is compatible to LVPECL signals and CLK1 meets both

HSTL differential signal specifications. The difference between CLK0 and CLK1 is the differential input threshold voltage (V

CMR

).

V

PP

Differential Input Voltage

(2)

2. V

PP

(DC) is the minimum differential input voltage swing required to maintain device functionality.

0.1

1.3

V

Differential operation

V

CMR

Differential Cross Point Voltage

(3)

3. V

CMR

(DC) is the crosspoint of the differential input signal. Functional operation is obtained when the crosspoint is within the V

CMR

(DC)

range and the input swing lies within the V

PP

(DC) specification.

1.0

V

CC

≠ 0.3

V

Differential operation

I

IN

Input Current

(1)

±100

µA

V

IN

= V

IL

or V

IN

= V

IH

Clock Input Pair CLK1, CLK1

(4)

(HSTL differential signals)

4. Clock inputs driven by differential HSTL compatible signals. Only applicable to CLK1, CLK1.

V

DIF

Differential Input Voltage

(5)

5. V

DIF

(DC) is the minimum differential HSTL input voltage swing required for device functionality.

0.2

1.4

V

V

X

Differential Cross Point Voltage

(6)

6. V

X

(DC) is the crosspoint of the differential HSTL input signal. Functional operation is obtained when the crosspoint is within the V

X

(DC)

range and the input swing lies within the V

PP

(DC) specification.

0

0.68 - 0.9

V

CC

≠ 0.7

V

V

IH

Input High Voltage

V

X

+ 0.1

V

X

+ 0.7

V

V

IL

Input Low Voltage

V

X

≠ 0.7

V

X

≠ 0.1

V

I

IN

Input Current

±100

µA

V

IN

= V

X

± 0.2 V

Clock Inputs (PECL single ended signals)

V

IH

Input Voltage High

V

CC

≠ 1.165

V

CC

≠ 0.880

V

V

IL

Input Voltage Low

V

CC

≠ 1.810

V

CC

≠ 1.475

V

I

IN

Input Current

(7)

7. Inputs have internal pullup/pulldown resistors which affect the input current.

±100

µA

V

IN

= V

IL

or V

IN

= V

IH

PECL Clock Outputs (Q0≠19, Q0≠19)

V

OH

Output High Voltage

V

CC

≠ 1.1

V

CC

≠ 1.005

V

CC

≠ 0.7

V

I

OH

= ≠30 mA

(8)

8. Equivalent to a termination of 50

to V

TT.

V

OL

Output Low Voltage

V

CC

≠ 1.9

V

CC

≠ 1.705

V

CC

≠ 1.4

V

I

OL

= ≠5 mA

(8)

Supply current and V

BB

I

EE

(9)

9. I

CC

calculation:

I

CC

= (number of differential output used) x (I

OH

+ I

OL

)

+ I

EE

I

CC

= (number of differential output used) x (V

OH

≠ V

TT

)

˜ R

load

+ (V

OL

≠ V

TT

)

˜ R

load

+ I

EE

.

Maximum Quiescent Supply Current without

Output Termination Current

84

160

mA

V

EE

pins

V

BB

Output Reference Voltage (f

ref

< 1.0 GHz)

(10)

10. Using V

BB

to bias unused single-ended inputs is recommended only up to a clock reference frequency of 1 GHz. Above 1 GHz, only

differential input signals should be used with the MC100ES6221.

V

CC

≠ 1.42

V

CC

≠ 1.20

V

I

BB

= 0.4 mA

Advanced Clock Drivers Devices

Freescale Semiconductor

5

MC100ES6221

Table 6. ECL DC Characteristics (V

EE

=

≠

2.5 V

± 5% or V

EE

=

≠

3.3 V

± 5%, V

CC

= GND, T

J

= 0

∞C to + 110∞C)

Symbol

Characteristics

Min

Typ

Max

Unit

Condition

Clock Input Pair CLK0, CLK0 (ECL differential signals)

V

PP

Differential Input Voltage

(1)

1. V

PP

(DC) is the minimum differential input voltage swing required to maintain device functionality.

0.1

1.3

V

Differential operation

V

CMR

Differential Cross Point Junction to top of

Package Voltage

(2)

2. V

CMR

(DC) is the crosspoint of the differential input signal. Functional operation is obtained when the crosspoint is within the V

CMR

(DC)

range and the input swing lies within the V

PP

(DC) specification.

V

EE

+ 1.0

≠0.3

V

Differential operation

I

IN

Input Current

(1)

±100

µA

V

IN

= V

IL

or V

IN

= V

IH

Clock Inputs (ECL single ended signals)

V

IH

Input Voltage High

≠1.165

≠0.880

V

V

IL

Input Voltage Low

≠1.810

≠1.475

V

I

IN

Input Current

(3)

3. Inputs have internal pullup/pulldown resistors which affect the input current.

±100

µA

V

IN

= V

IL

or V

IN

= V

IH

ECL Clock Outputs (Q0≠A19, Q0≠Q19)

V

OH

Output High Voltage

≠1.1

≠1.005

≠0.7

V

I

OH

= ≠30 mA

(4)

4. Equivalent to a termination of 50

to V

TT

.

V

OL

Output Low Voltage

≠1.9

≠1.705

≠1.4

V

I

OL

= ≠5 mA

(4)

Supply Current and V

BB

I

EE

(5)

5. I

CC

calculation:

I

CC

= (number of differential output used) x (I

OH

+ I

OL

) + I

EE

I

CC

= (number of differential output used) x (V

OH

≠ V

TT

)

˜ R

load

+ (V

OL

≠ V

TT

)

˜ R

load

+ I

EE

.

Maximum Quiescent Supply Current without

Output Termination Current

84

160

mA

V

EE

pins

V

BB

Output Reference Voltage (f

ref

< 1.0 GHz)

(6)

6. V

BB

can be used to bias unused single-ended inputs up to a clock reference frequency of 1 GHz. Above 1 GHz, only differential signals

should be used with the MC100ES6221.

≠1.42

≠1.20

V

I

BB

= 0.4 mA

Advanced Clock Drivers Devices

6

Freescale Semiconductor

MC100ES6221

Table 7. AC Characteristics (ECL: V

EE

=

≠

3.3 V

±

5% or V

EE

=

≠

2.5 V

±

5%, V

CC

= GND) or

(PECL: V

CC

= 3.3 V

±

5% or V

CC

= 2.5 V

±

5%, V

EE

= GND, T

J

= 0

∞C to + 110∞C)

(1)

1. AC characteristics apply for parallel output termination of 50

to V

TT

.

Symbol

Characteristics

Min

Typ

Max

Unit

Condition

Clock Input Pair CLK0, CLK0 (PECL or ECL differential signals)

V

PP

Differential Input Voltage

(2)

(peak-to-peak)

2. V

PP

(AC) is the minimum differential ECL/PECL input voltage swing required to maintain AC characteristics including t

PD

and

device-to-device skew.

0.2

1.3

V

V

CMR

Differential Input Crosspoint Voltage

(3)

PECL

ECL

3. V

CMR

(AC) is the crosspoint of the differential ECL/PECL input signal. Normal AC operation is obtained when the crosspoint is within the

V

CMR

(AC) range and the input swing lies within the V

PP

(AC) specification. Violation of V

CMR

(AC) or V

PP

(AC) impacts the device

propagation delay, device and part-to-part skew.

1.0

V

EE

+ 1.0

V

CC

≠ 0.3

≠0.3 V

V

V

f

CLK

Input Frequency

0

2000

MHz

Differential

t

PD

Propagation Delay CLK0 to Q0-19

400

540

670

ps

Differential

Clock Input Pair CLK1, CLK1 (HSTL differential signals)

V

DIF

Differential Input Voltage

(4)

(peak-to-peak)

4. V

DIF

(AC) is the minimum differential HSTL input voltage swing required to maintain AC characteristics including t

PD

and device-to-device

skew. Only applicable to CLKB.

0.2

1.3

V

V

X

Differential Input Crosspoint Voltage

(5)

5. V

X

(AC) is the crosspoint of the differential HSTL input signal. Normal AC operation is obtained when the crosspoint is within the V

X

(AC)

range and the input swing lies within the V

DIF

(AC) specification. Violation of V

X

(AC) or V

DIF

(AC) impacts the device propagation delay,

device and part-to-part skew.

0.1

0.68≠0.9

V

CC

≠ 1.0

V

f

CLK

Input Frequency

0

1000

MHz

Differential

t

PD

Propagation Delay CLK1 to Q0≠19

650

780

950

ps

Differential

PECL/ECL Clock Outputs (Q0≠19, Q0≠19)

V

O(P-P)

Differential Output Voltage (peak-to-peak)

f

O

< 1.0 GHz

f

O

< 2.0 GHz

0.375

TDB

0.630

0.250

V

V

t

sk(O)

Output-to-Output Skew

50

100

ps

Differential

t

sk(PP)

Output-to-Output Skew (part-to-part)

using CLK0

using CLK1

parts at one given T

J

, V

CC

, f

ref

270

300

250

ps

ps

ps

Differential

t

JIT(CC)

Output Cycle-to-Cycle Jitter

RMS (1

)

1

ps

t

SK(P)

DC

Q

Output Pulse Skew

(6)

Output Duty Cycle

f

REF

< 0.1 GHz

f

REF

< 1.0 GHz

6. Output pulse skew is the absolute difference of the propagation delay times: | t

pLH

≠ t

pHL

|.

49.5

45.0

30

50

50

50

50.5

55.0

ps

%

%

DC

REF

= 50%

DC

REF

= 50%

t

r

, t

f

Output Rise/Fall Time

50

350

ps

20% to 80%

Advanced Clock Drivers Devices

Freescale Semiconductor

7

MC100ES6221

Figure 3. MC100ES6221 Test Reference

Figure 4. MC100ES6221 AC Test Reference Measurement Waveform

Differential Pulse

Generator

Z = 50

R

T

= 50

Z

0

= 50

DUT

MC100ES6221

V

TT

R

T

= 50

Z

0

= 50

V

TT

t

PD

(CLK

N

to Q

X

)

V

CMR

= V

CC

≠ 1.3 V

V

PP

= 0.8 V

CLK

N

CLK

N

Q

X

Q

X

Advanced Clock Drivers Devices

8

Freescale Semiconductor

MC100ES6221

APPLICATIONS INFORMATION

Understanding the Junction Temperature Range of the

MC100ES6221

To make the optimum use of high clock frequency and low

skew capabilities of the MC100ES6221, the MC100ES6221

is specified, characterized and tested for the junction

temperature range of T

J

= 0

∞C to +110∞C. Because the exact

thermal performance depends on the PCB type, design,

thermal management and natural or forced air convection,

the junction temperature provides an exact way to correlate

the application specific conditions to the published

performance data of this data sheet. The correlation of the

junction temperature range to the application ambient

temperature range and vice versa can be done by

calculation:

T

J

= T

A

+ R

thja

P

tot

Assuming a thermal resistance (junction to ambient) of

17

∞C/W (2s2p board, 200 ft/min airflow, see

Table 8

) and a

typical power consumption of 1148 mW (all outputs

terminated 50 ohms to V

TT

, V

CC

= 3.3 V, frequency

independent), the junction temperature of the MC100ES6221

is approximately T

A

+ 21∞C, and the minimum ambient

temperature in this example case calculates to

≠

21

∞C (the

maximum ambient temperature is 89

∞C. See

Table 8

).

Exceeding the minimum junction temperature specification of

the MC100ES6221 does not have a significant impact on the

device functionality. However, the continuous use the

MC100ES6221 at high ambient temperatures requires

thermal management to not exceed the specified maximum

junction temperature. Please see the application note

AN1545 for a power consumption calculation guideline.

Maintaining Lowest Device Skew

The MC100ES6221 guarantees low output-to-output bank

skew of 50 ps and a part-to-part skew of max. 270 ps. To

ensure low skew clock signals in the application, both outputs

of any differential output pair need to be terminated

identically, even if only one output is used. When fewer than

all nine output pairs are used, identical termination of all

output pairs within the output bank is recommended. This will

reduce the device power consumption while maintaining

minimum output skew.

Power Supply Bypassing

The MC100ES6221 is a mixed analog/digital product. The

differential architecture of the MC100ES6221 supports low

noise signal operation at high frequencies. In order to

maintain its superior signal quality, all V

CC

pins should be

bypassed by high-frequency ceramic capacitors connected

to GND. If the spectral frequencies of the internally generated

switching noise on the supply pins cross the series resonant

point of an individual bypass capacitor, its overall impedance

begins to look inductive and thus increases with increasing

frequency. The parallel capacitor combination shown ensures

that a low impedance path to ground exists for frequencies

well above the noise bandwidth.

Figure 5. V

CC

Power Supply Bypass

Table 8. Ambient Temperature Ranges (P

tot

= 1148 mW)

R

thja

(2s2p board)

T

A, min

(1)

1. The MC100ES6221 device function is guaranteed from

T

A

= ≠40

∞C to T

J

= 110

∞C

T

A, max

Natural convection

20

∞C/W

≠23

∞C

87

∞C

100 ft/min

18

∞C/W

≠21

∞C

89

∞C

200 ft/min

17

∞C/W

≠20

∞C

90

∞C

400 ft/min

16

∞C/W

≠18

∞C

92

∞C

800 ft/min

15

∞C/W

≠17

∞C

93

∞C

V

CC

MC100ES6221

V

CC

33...100 nF

0.1 nF

Advanced Clock Drivers Devices

Freescale Semiconductor

9

MC100ES6221

APPLICATIONS INFORMATION

Using the Thermally Enhanced Package of the

MC100ES6221

The MC100ES6221 uses a thermally enhanced exposed

pad (EP) 52 lead LQFP package. The package is molded so

that the lead frame is exposed at the surface of the package

bottom side. The exposed metal pad will provide the low

thermal impedance that supports the power consumption of

the MC100ES6221 high-speed bipolar integrated circuit and

eases the power management task for the system design. A

thermal land pattern on the printed circuit board and thermal

vias are recommended in order to take advantage of the

enhanced thermal capabilities of the MC100ES6221. Direct

soldering of the exposed pad to the thermal land will provide

an efficient thermal path. In multilayer board designs, thermal

vias thermally connect the exposed pad to internal copper

planes. Number of vias, spacing, via diameters and land

pattern design depend on the application and the amount of

heat to be removed from the package. A nine thermal via

array, arranged in a 3 x 3 array and using a 1.2 mm pitch in

the center of the thermal land is a requirement for

MC100ES6221 applications on multi-layer boards. The

recommended thermal land design comprises a 3 x 3 thermal

via array as shown in

Figure 6

, providing an efficient heat

removal path.

Figure 6. Recommended Thermal Land Pattern

The via diameter is should be approx. 0.3 mm with 1 oz.

copper via barrel plating. Solder wicking inside the via

resulting in voids during the solder process must be avoided.

If the copper plating does not plug the vias, stencil print solder

paste onto the printed circuit pad. This will supply enough

solder paste to fill those vias and not starve the solder joints.

The attachment process for exposed pad package is

equivalent to standard surface mount packages.

Figure 7

shows a recommend solder mask opening with respect to the

recommended 3 x 3 thermal via array. Because a large solder

mask opening may result in a poor release, the opening

should be subdivided as shown in

Figure 7

. For the nominal

package standoff 0.1 mm, a stencil thickness of 5 to 8 mils

should be considered.

Figure 7. Recommended Solder Mask Openings

For thermal system analysis and junction temperature

calculation the thermal resistance parameters of the package

is provided:

It is recommended that users employ thermal modeling

analysis to assist in applying the general recommendations

to their particular application. The exposed pad of the

MC100ES6221 package does not have an electrical low

impedance path to the substrate of the integrated circuit and

its terminals. The thermal land should be connected to GND

through connection of internal board layers.

4.8

Thermal via array (3x3),

1.2 mm pitch,

0.3 mm diameter

Exposed pad

land pattern

all units mm

4.

8

Table 9. Thermal Resistance

(1)

1. Applicable for a 3 x 3 thermal via array.

ConvectionL

FPM

R

THJA

(2)

∞C/W

2. Junction to ambient, four conductor layer test board (2S2P), per

JES51≠7 and JESD 51≠5.

R

THJA

(3)

∞C/W

3. Junction to ambient, single layer test board, per JESD51≠3.

R

THJC

∞C/W

R

THJB

(4)

∞C/W

4. Junction to board, four conductor layer test board (2S2P) per

JESD 51≠8.

Natural

20

48

4

(5)

29

(6)

5. Junction to exposed pad.

6. Junction to top of package.

16

100

18

47

200

17

46

400

16

43

800

15

41

Exposed pad land

pattern

4.8

Thermal via array (3x3),

1.2 mm pitch,

0.3 mm diameter

1.0

0.2

all units mm

4.

8

1.0

0.2

Advanced Clock Drivers Devices

10

Freescale Semiconductor

MC100ES6221

PACKAGE DIMENSIONS

NOTES:

1.

2.

3.

4.

5.

6.

7.

8.

DIMENSIONS ARE IN MILLIMETERS.

INTERPRET DIMENSIONS AND TOLERANCES PER

ASME Y14.5M, 1994.

DATUMS A, B AND D TO BE DETERMINED AT DATUM

PLANE H.

DIMENSION TO BE DETERMINED AT SEATING PLANE

C.

THIS DIMENSION DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR PROTRUSION

SHALL NOT CAUSE THE LEAD WIDTH TO EXCEED

0.46 mm. DAMBAR CANNOT BE LOCATED ON THE

LOWER RADIUS OR THE FOOT. MINIMUM SPACE

BETWEEN PROTRUSION AND ADJACENT LEAD

SHALL NOT BE LESS THAN 0.07 mm.

THIS DIMENSION DOES NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS 0.25mm

PER SIDE. THIS DIMENSION IS MAXIMUM PLSTIC

BODY SIZE DIMENSION INCLUDING MOLD MISMATCH.

EXACT SHAPE OF EACH CORNER IS OPTIONAL.

THESE DIMENSIONS APPLY TO THE FLAT SECTION

OF THE LEAD BETWEEN 0.10mm AND 0.25mm FROM

THE LEAD TIP.

52

0.2 H A-B D

1

40

39

14

13

26

27

B

5

10

4X

4X 13 TIPS

0.2 C A-B D

A

D

PIN 1

INDEX

7

6

5

6

12

10

12

4

4

4

4

6

6

6

6

B

B

0.65

48X

X=A, B OR D

CL

VIEW Y

X

0.05

0.25

GAUGE PLANE

1.3

(0.2)

R

(1)

0.75

0.20

VIEW AA

7∞

1.5

0.05

0.45

0∞ MIN 0.20

0.08

0∞

R

0.20

0.08

(12∞)

4X

SEATING

PLANE

1.7 MAX

VIEW AA

0.1 C

C

H

A-B

M

0.08

D

C

52X

0.40

J

J

0.22

52X

5

(12∞)

4X

SECTION B-B

0.20

PLATING

BASE METAL

8

8

8

8

0.35

(0.3)

0.09

0.20

0.07

0.16

4.78

4.58

VIEW J-J

EXPOSED PAD

VIEW Y

4.78

4.58

CASE 1336A-01

ISSUE O

52-LEAD LQFP PACKAGE

Advanced Clock Drivers Devices

Freescale Semiconductor

11

MC100ES6221

NOTES

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

MC100ES6221

Rev. 5

04/2005

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. "Typical" parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including "Typicals", must be validated for each customer application by

customer's technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

FreescaleTM and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2005. All rights reserved.