G3SBA20 AND G3SBA60

GLASS PASSIVATED SINGLE-PHASE BRIDGE RECTIFIER

Reverse Voltage - 200 and 600 Volts

Forward Current - 4.0 Amperes

FEATURES

® Plastic package has Underwriters Laboratory Flammability

Classification 94V-0

® This series is UL listed under the Recognized Component

Index, file number E54214

® High case dielectric

strength of 1500 V

RMS

® Ideal for printed circuit boards

® Glass passivated chip junction

® High surge current capability

® High temperature soldering guaranteed:

260°C/10 seconds, 0.375 (9.5mm) lead length,

5lbs. (2.3kg) tension

MECHANICAL DATA

Case: Molded plastic body over passivated junctions

Terminals: Plated leads solderable per MIL-STD-750,

Method 2026

Mounting Position: Any

(NOTE 3)

Mounting Torque: 5 in. - lb. max.

Weight: 0.15 ounce, 4.0 grams

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified.

SYMBOLS G3SBA20

G3SBA60

UNITS

Maximum repetitive peak reverse voltage

V

RRM

200

600

Volts

Maximum RMS voltage

V

RMS

140

420

Volts

Maximum DC blocking voltage

V

DC

200

600

Volts

Maximum average forward rectified T

C

=100°C

(NOTE 1)

4.0

output current at

T

A

=25°C

(NOTE 2)

I

(AV)

2.3

Amps

Peak forward surge current single sine-wave

superimposed on rated load (JEDEC Method)

I

FSM

80

Amps

Rating for fusing (t<8.3ms)

I

2

t

32

A

2

sec

Maximum instantaneous forward voltage drop

per leg at 2.0A

V

F

1.05

Volts

Maximum DC reverse current at T

A

=25°C

5.0

rated DC blocking voltage per leg T

A

=125°C

I

R

400

mA

Typical thermal resistance per leg

(NOTE 2)

R

QJA

26

(NOTE 1)

R

QJC

5.0

°C/W

Operating junction and storage temperature range

T

J

, T

STG

-55 to +150

°C

NOTES:

(1) Unit case mounted on Al plate heatsink.

(2) Units mounted on P.C.B. with 0.5 x 0.5" (12 x 12mm) copper pads and 0.375" (9.5mm) lead length

(3) Recommended mounting position is to bolt down on heatsink with silicone thermal compound for maximum heat transfer with #6 screw

0.125 (3.2) x 45

o

CHAMFER

0.085 (2.16)

0.065 (1.65)

0.020 R (TYP.)

0.880 (22.3)

0.860 (21.8)

0.100 (2.54)

0.085 (2.16)

0.160 (4.1)

0.140 (3.5)

0.075

(1.9) R.

0.080

0.060

(2.03)

(1.52)

0.050 (1.27)

0.040 (1.02)

0.080

0.065

(2.03)

(1.65)

0.210

0.190

(5.33)

(4.83)

Polarity shown on front side of case, positive lead by beveled corner

0.140 (3.56)

0.130 (3.30)

9

o

TYP.

5

o

TYP.

0.085 (2.16)

0.075 (1.90)

0.022 (0.56)

0.018 (0.46)

0.310 (7.9)

0.290 (7.4)

0.740 (18.8)

0.720 (18.3)

0.710 (18.0)

0.690 (17.5)

Dimensions in inches and (millimeters)

Case Style GBU

Polarity shown on front side of case, positive lead beveled corner.

If preferred, marking may be on reverse side of case.

Lead forming option with 7.5mm spacing is available.

2/24/99

NEW PRODUCT NEW PRODUCT NEW PRODUCT

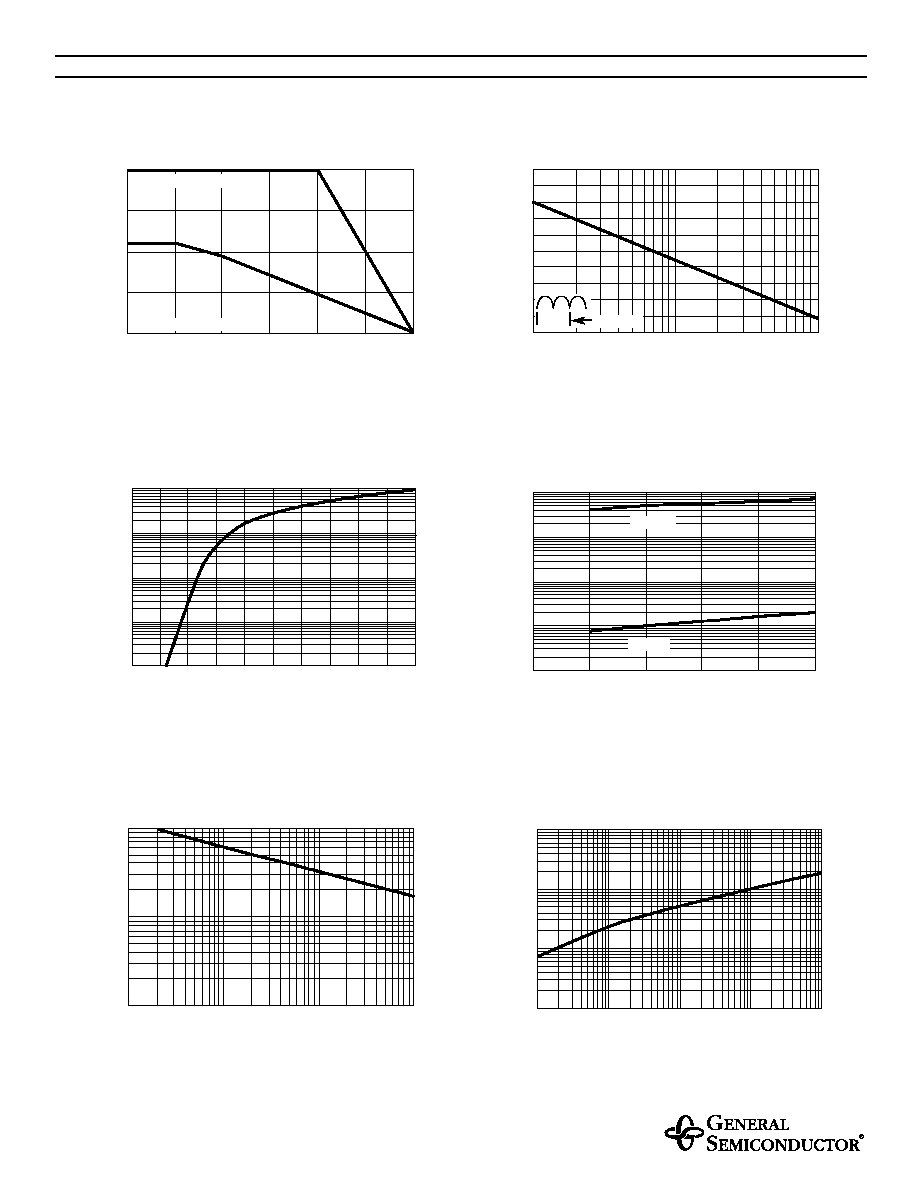

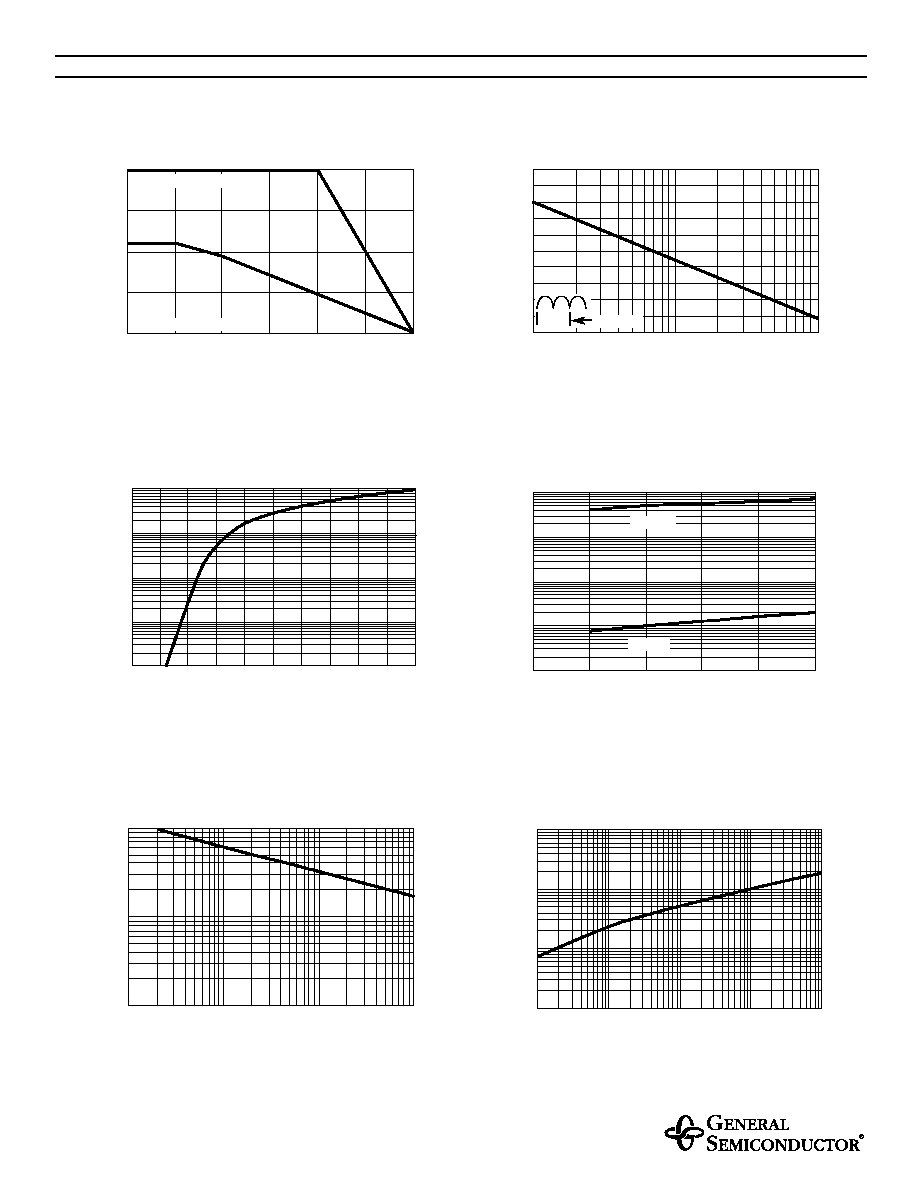

RATINGS AND CHARACTERISTICS CURVES G3SBA20 THRU G3SBA60

0

1

2

3

4

0

25

50

75

100

125

150

1

10

100

0.1

1

10

100

0.01

0.1

1

10

100

0

20

40

60

80

100

0.01

0.1

1

10

100

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

2.4

0

10

20

30

40

50

60

70

80

90

100

1

100

0.1

1

10

100

0.01

0.1

1

10

100

FIG. 1 - DERATING CURVE OUTPUT

RECTIFIED CURRENT

TEMPERATURE, °C

P.C.B. MOUNTING, T

A

PERCENT OF RATED PEAK REVERSE

VOLTAGE, %

INSTANTANEOUS FORWARD VOLTAGE,

VOLTS

INST

ANT

ANEOUS REVERSE

CURRENT

, MICROAMPERES

FIG. 3 - TYPICAL FORWARD CHARACTERISTICS

PER LEG

INST

ANT

ANEOUS FOR

W

ARD

CURRENT

, AMPERES

FIG. 5 - TYPICAL JUNCTION CAPACITANCE

PER LEG

REVERSE VOLTAGE, VOLTS

T

A

=25°C

A

VERAGE FOR

W

ARD OUTPUT

CURRENT

, AMPERES

FIG. 4 - TYPICAL REVERSE CHARACTERISTICS

PER LEG

NUMBER OF CYCLES AT 60 Hz

PEAK FOR

W

ARD SURGE

CURRENT

,

AMPERES

FIG. 2 - MAXIMUM NON-REPETITIVE PEAK

FORWARD SURGE CURRENT PER LEG

T

A

=125°C

FIG. 6 - TYPICAL TRANSIENT THERMAL

IMPEDANCE

TRANSIENT

THERMAL

IMPEDANCE, °C/W

t, HEATING TIME, sec.

1.0 CYCLE

JUNCTION CAP

ACIT

ANCE, pF

HEAT-SINK MOUNTING, Tc