| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L2783 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

The Hamamatsu laser galvatron is an opto-galvanic sensor

taking advantage of the resonance phenomenon between the

discharge plasma and incident laser.

A laser is entered into a discharge plasma produced at the

see-through cathode of the galvatron. When the wavelength of

the laser is resonant with the absorbed wavelengths of atoms

and molecules inside the discharge plasma, the electrical

properties of the discharge plasma are altered. This

phenomenon is known as the opto-galvanic effect. The

galvatron L2783 series make use of an opto-galvanic signal

obtained by changes in the electrical properties, and it can be

used to calibrate the absolute wavelength of the incident laser

and stabilize the laser frequency.

Since the L2783 series are constructed with see-through

cathodes made with 63 elements and 6 types of filler gases,

any type of a galvatron can be selected to obtain the absorbed

wavelength of a discharge plasma which can resonate with the

wavelengths of the laser used.

OPTO-GALVANIC SENSOR

LASER GALVATRON

Æ

(SEE-THROUGH HOLLOW CATHODE LAMP)

L2783 SERIES

Laser Sensor Using The Opto-Galvanic Effect

Highly Stable Output, See-Through Cathode

Optimality for Laser Wavelength Calibration and Laser Frequency Stabilization

Information furnished by HAMAMATSU is believed to be reliable. However, no responsibility is assumed for possible inaccuracies or omissions. Specifications are

subject to change without notice. No patent rights are granted to any of the circuits described herein. ©2001 Hamamatsu Photonics K.K

Subject to local technical requirements and regulations, availability of products included in this promotional material may vary. Please consult with our sales office.

FEATURES

GHigh Stability Opto-Galvanic Signal

With respect to the incident laser beam, a highly stable, sensitive opto-

galvanic signal can be obtained.

GSee-Through Cathode

Since a see-through cathode is used, a laser does not strike the cath-

ode surface. So, it produces no photoelectric noise.

GBrewster Window with No Laser Interference

The input and output windows are inclined 10

∞ each so that no laser re-

flects to be returned. So, there are no laser interference results.

GSelective Cathode Materials and Filler Gases

This series can be selected from 63 elements and Ne (our standard

gas), other of filler gases in order to suit your applications. As for the

other filler gases, please contact us.

APPLICATIONS

GCalibration of dye laser absolute wavelength

GStabilization of laser frequency

GOptical communications

GMeasuring instrument standard

LASER GALVATRON

Æ

(SEE-THROUGH HOLLOW CATHODE LAMP)

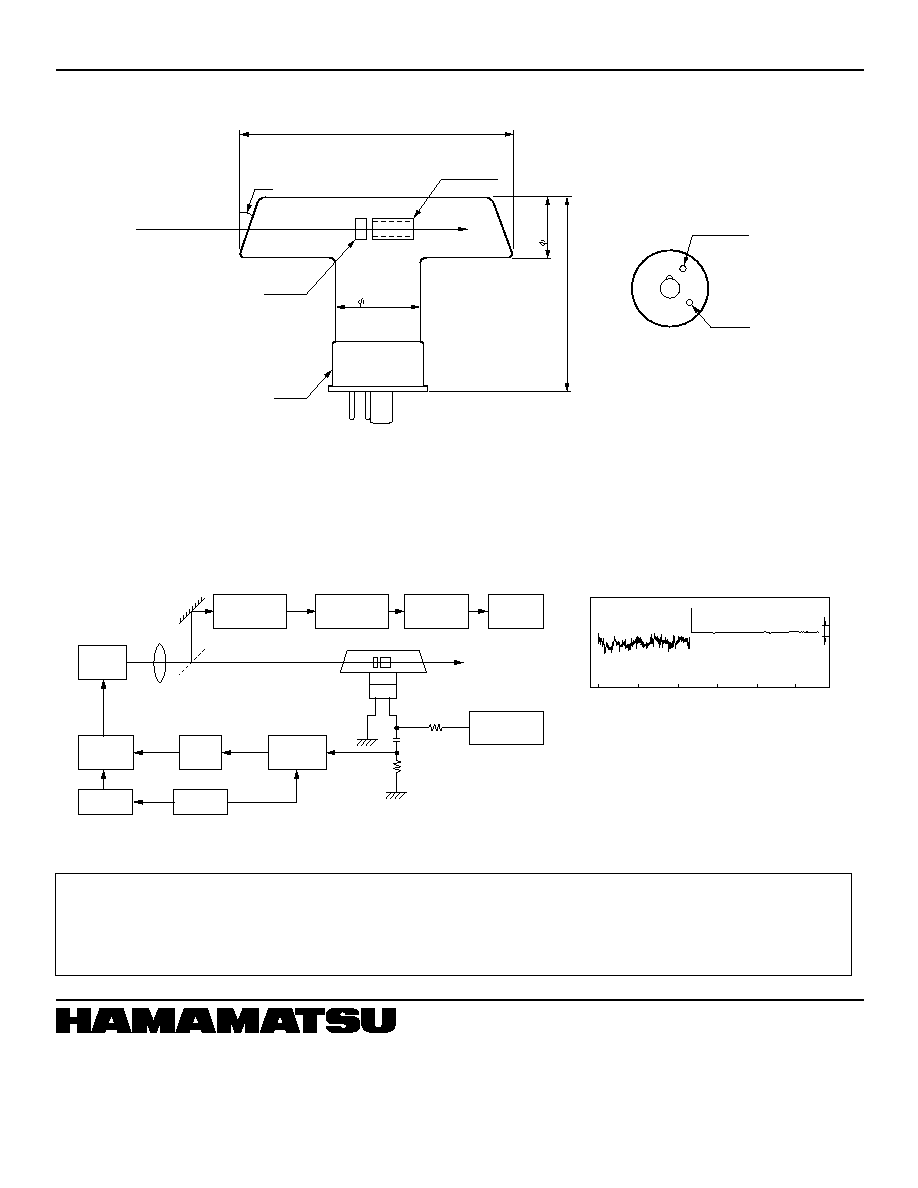

CONSTRUCTION

Galvatrons are constructed with a see-through cathode, a ring-

shaped anode mounted inside a T-shaped, Brewster glass bulb

and a filler gas. The construction is shown in Figure 1.

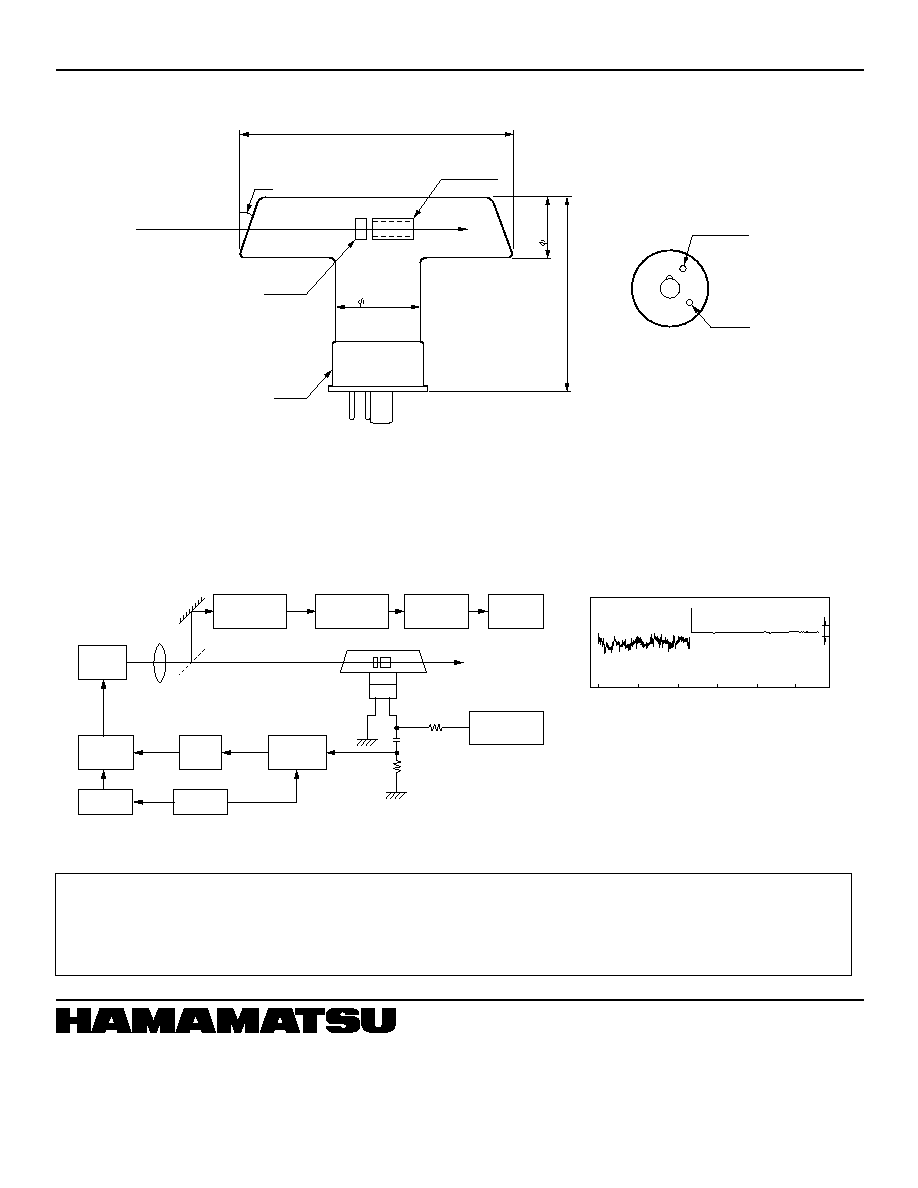

OPERATION CIRCUIT

To obtain an opto-galvanic signal using a galvatron, a driving

circuit for the laser galvatron to produce a discharge plasma

and a signal output circuit are required.

Figure 3 shows a schematic diagram for the driving and signal

circuits (operation circuit as a whole) of the galvatron.

PRINCIPLE OF OPERATION

When operating the galvatron, a discharge plasma is generated

at the hole of the see-through cathode. When a laser enters the

hole, and then the absorbed wavelengths of atoms and

molecules inside the discharge plasma resonate with the

wavelength of the incident laser, the electronic properties of the

discharge plasma are altered, such as discharge voltage,

discharge current and impedance, by which an opto-galvanic

signal is obtained. Figure 2 shows the relationship between the

absorbed wavelength and the opto-galvanic signal. When the

laser wavelength and the absorbed wavelength are perfectly

resonant (C), the strongest opto-galvanic signal is obtained.

When they are not resonant (B, D), the opto-galvanic signal

becomes much smaller than in the above case.

The absorbed spectral widths of atoms and molecules of the

cathode material and filler gas are sharper than that of the

incident laser beam. Since the absorbed wavelength is

generally known, observing the opto-galvanic signal obtained

here allows you to measure the peak absolute wavelength of

the incident laser with high precision.

In addition, since the opto-galvanic signal is obtained in

response to changes in the output and the frequency of the

incident laser, galvatrons can also be applied to stabilize the

incident laser.

To operate the galvatron properly, care should be taken to the

following precautions and assemble the operation circuit.

Using the operation circuit of Figure 3, the opto-galvanic signal

obtained when a dye laser beam excited by excimer laser pas-

ses through the galvatron is shown in Figure 4. The relationship

between the incident laser power and the opto-galvanic signal is

shown in Figure 5.

∑ A high voltage DC power supply with an output voltage of from 0 to

1000 V dc, an output current more than 20 mA and a ripple voltage

less than 0.5 mV should be used.

∑ A resistor R is used as a limit resistor for the discharge current and

a signal detection resistor.

For this reason, when using with a constant voltage power supply,

the resistor should be always added in to stabilize the galvatron in

operation.

∑ The capacitor C is used to obtain only AC current.

When using our recommended 0.047

µF capacitor, the signal

change from about 80 Hz to several KHz can be observed.

In addition, when changing the value to 0.5

µF, the lower frequency

than 80 Hz can be observed.

∑ In the measurements of opto-galvanic signals, it is difficult to obtain

the exact signal if there is an external electromagnetic induction.

For this reason, the circuit portion surrounded by dashed lines

shown in Figure 3 should be packed in a shield case. A shielded

cable should also be used.

Figure 1: Typical Construction of Galvatron

Figure 3: Schematic Diagram

Figure 4: Opto-Galvanic Signal of Galvatron

Figure 5: Incident Laser Power vs. Opto-Galvanic Signal

Figure 2: Absorbed Wavelength and Opto-Galvanic Signal

TLSOC0031EA

TLSOC0032EA

TLSOB0056EA

TLSOB0057EA

WAVELENGTH: 632.8 nm Ne line

LASER POWER: 7 mJ

LASER

INPUT WINDOW

OUTPUT WINDOW

ANODE

CATHODE

LASER SPECTRUM

KNOWN WAVELENGTH

(ABSORBED SPECTRUM OF

DISCHARGE PLASMA

SPECTRAL INTENSITY

WAVELENGTH

OPTO-GALVANIC

SIGNAL INTENSITY

TIME

C

B, D

A

B

C

D

E

HV DC POWER

R

SIGNAL

TERMINAL

RECOMMENDED

CIRCUIT CONSTANT

C = 0.047

µF

(WITHSTAND VOLTAGE 1 kV)

R = 40 k

(30 W)

SHIELD CASE

0 to 20 mA

C

OPTO-GALVANIC SIGNAL (V)

LASER POWER (mJ)

10

5

0

1

2

3

4

5

6

7

CONDITIONS

FOR DYE LASER

DYE: RHODAMINE 6 G

PULSE WIDTH: 5 ns

FREQUENCY: 10 Hz

FOR GALVATRON

(Ne FILTER GAS, Ba CATHODE)

OPERATION CURRENT: 10 mA

Ne LINE: 632.8 nm

(ABSORBED SPECTRUM)

SPECIFICATIONS

Cathode materials used for the L2783 series are shown in Table 1 respectively.

They can be selected according to your applications.

Type numbers for the L2783 series are organized as follows:

(L2783-47NE-Ag is used as an example here.)

Table 2: Filler Gas and Window Material Specifications

Table 1: Cathode Materials and Main Absorbed Wavelengths

Filler Gas

Window Material

Discharge Current

Charge Start Voltage

Guaranteed Life *

3

Ne *

1

UV glass *

2

The current value varies depending on the cathode material used. Handle the galvatron following the

instruction provided on it.

DC 400 V

As, Ga, Hg

Other cathode materials

: 3,000 mA hours

: 5,000 mA hours

Name

Atomic

No.

Absorption

wavelength

(nm)

Name

Atomic

No.

Absorption

wavelength

(nm)

Name

Atomic

No.

Absorption

wavelength

(nm)

Ag

Al

As

Au

B

Ba

Bi

Ca

Cd

Co

Cr

Cs

Cu

Dy

Er

Fe

Ga

Gd

Ge

Hf

Hg

Silver

Aluminum

Arsenic

Gold

Boron

Barium

Bismuth

Calcium

Cadmium

Cobalt

Chromium

Cesium

Copper

Dysprosium

Erbium

Iron

Gallium

Gadolinium

Germanium

Hafnium

Mercury

47

13

33

79

5

56

83

20

48

27

24

55

29

66

68

26

31

64

32

72

80

328.0683

309.2713

193.696

242.795

249.6778

553.551

223.0608

422.673

228.8018

240.725

357.869

852.110

324.7540

421.172

400.797

248.327

294.3637

368.413

265.1575

307.288

253.6519

Rh

Ru

Sb

Sc

Se

Si

Sm

Sn

Sr

Ta

Tb

Te

Ti

Tl

Tm

V

W

Y

Yb

Zn

Zr

Rhodium

Ruthenium

Antimony

Scandium

Selenium

Silicon

Samarium

Tin

Strontium

Tantalum

Terbium

Tellurium

Titanium

Thallium

Thulium

Vanadium

Tungsten

Yttrium

Ytterbium

Zinc

Zirconium

45

44

51

21

34

14

62

50

38

73

65

52

22

81

69

23

74

39

70

30

40

343.4893

349.894

217.5890

391.18213

196.030

251.6123

429.6750

224.6053

460.7331

271.4674

432.648

214.275

364.2675

276.787

371.792

306.638

255.135

407.738

398.7994

213.856

360.119

Ho

In

Ir

K

La

Li

Lu

Mg

Mn

Mo

Na

Nb

Nd

Ni

Os

Pb

Pd

Pr

Pt

Rb

Re

Holmium

Indium

Iridium

Potassium

Lanthanum

Lithium

Lutetium

Magnesium

Manganese

Molybdenum

Sodium

Niobium

Neodymium

Nickel

Osmium

Lead

Palladium

Praseodymium

Platinum

Rubidium

Rhenium

67

49

77

19

57

3

71

12

25

42

11

41

60

28

76

82

46

59

78

37

75

410.384

303.936

208.882

766.4907

550.1340

670.7844

335.956

285.2129

279.482

313.2594

588.9953

334.906

463.424

232.003

290.9061

216.999

244.7909

495.1357

265.9454

780.0227

346.047

L2783 -- 47 NE -- Ag

Atomic number

of the cathode

material used

(Silver in this case)

Abbreviation

for the filler

gas used

Symbol for

the cathode

material used

(Neon gas in this case)

As already stated, 6 types of filler gases are used. They are all

abbreviated as follows. NE for neon, H for hydrogen, HE for helium,

ANE for argon + neon, KNE for krypton + neon, and XNE for xenon

+ neon.

*1 Other filler gas (H, He, Ar+Ne, Kr+Ne, Xe+Ne) is available as custom made product.

*2 UV glass transmits a light of wavelength longer than 185 nm. If using lasers of wavelength short than that value, synthetics silica that can transmit lasers

of wavelength longer than 160 nm should be used. Hamamatsu has such synthetic silica available to you.

*3 When Ne is used as filler gas.

LASER GALVATRON

Æ

(SEE-THROUGH HOLLOW CATHODE LAMP)

TLSO1028E02

AUG. 2001 IP

Printed in Japan (500)

DIMENSIONAL OUTLINE

APPLICATION: Frequency Stabilization of 1.3

µm DFB Laser

A laser frequency of a light beam of 1.3

µm semiconductor DFB laser, well used in the optical communications field, can be stabil-

ized using the argon absorption line of the galvatron.

When a light beam of 1.3

µm DFB laser passes through the hole of the see-through cathode, an opto-galvanic signal is obtained.

The amount of opto-galvanic signals changes as the frequency is changed. A feedback circuit is provided so that the signal always

remains constant. By returning this signal change to the input current source of the laser as a feedback, the frequency of the DFB

laser can be stabilized with precision.

WARRANTY

The period of the Hamamatsu galvatron warranty is one year. The warranty is limited to replacement of the galvatron. The

warranty shall not apply, even within this one year period, in cases where the operating life of the galvatron in hours has been

exceeded, or in cases where trouble or failure has been encountered as a result of natural calamity, accident, or misuse.

TLSOA0054EA

TLSOC0033EA

REFERENCES:

Y. C. CHUNG

R. W. TKACH

AT & T Bell Laboratories

Crawford Hill Laboratory

Lightwave System Research Department

Holmdel, NJ07733, USA

16th March 1988

LASER

120

± 3

CATHODE

ANODE

10

∞

ANODE

BASE

38

± 1

25

±

1

82

±

3

CATHODE

SUITABLE SOCKET: E678-8A

BASE PIN CONNECTIONS

FREQUENCY

FREE TRANSIT

TIME

10 MHz

WHEN LOCKED

0

BEAM

SPLITTER

DFB

LASER

FABRY-PEROT

INTER-

FEROMETER

Ge PIN

PHOTODIODE

LOCK-IN

AMP.

LOCK-IN

AMP.

RECORDER

CONSTANT

VOLTAGE

POWER SUPPLY

STABLE

RESISTOR

GALVATRON

P.I

POWER

SUPPLY

ATTENUATOR

OSCILLATOR

10

20

30

40

50

MIRROR

HAMAMATSU PHOTONICS K.K., Electron Tube Center

314-5, Shimokanzo, Toyooka-village, Iwata-gun, Shizuoka-ken, 438-0193, Japan, Telephone: (81)539/62-5248, Fax: (81)539/62-2205

U.S.A.: Hamamatsu Corporation: 360 Foothill Road, P. O. Box 6910, Bridgewater. N.J. 08807-0910, U.S.A., Telephone: (1)908-231-0960, Fax: (1)908-231-1218 E-mail: usa@hamamatsu.com

Germany: Hamamatsu Photonics Deutschland GmbH: Arzbergerstr. 10, D-82211 Herrsching am Ammersee, Germany, Telephone: (49)8152-375-0, Fax: (49)8152-2658 E-mail: info@hamamatsu.de

France: Hamamatsu Photonics France S.A.R.L.: 8, Rue du Saule Trapu, Parc du Moulin de Massy, 91882 Massy Cedex, France, Telephone: (33)1 69 53 71 00, Fax: (33)1 69 53 71 10 E-mail: infos@hamamatsu.fr

United Kingdom: Hamamatsu Photonics UK Limited: 2 Howard Court, 10 Tewin Road Welwyn Garden City Hertfordshire AL7 1BW, United Kingdom, Telephone: 44-(0)1707-294888, Fax: 44(0)1707-325777 E-mail: info@hamamatsu.co.uk

North Europe: Hamamatsu Photonics Norden AB: Smidesv‰gen 12, SE-171-41 SOLNA, Sweden, Telephone: (46)8-509-031-00, Fax: (46)8-509-031-01 E-mail: info@hamamatsu.se

Italy: Hamamatsu Photonics Italia: S.R.L.: Strada della Moia, 1/E, 20020 Arese, (Milano), Italy, Telephone: (39)02-935 81 733, Fax: (39)02-935 81 741 E-mail: info@hamamatsu.it

HOMEPAGE URL http://www.hamamatsu.com