1

SMT Ultra-Miniature Coaxial Connectors - Mating Heights Owing to the Lowest Profile and the Lightest

U.FL Series

2002.3

E.FL

U.FL

2.4

(2.5Max

)

3.2Max

Dia.0.81

2.5Max

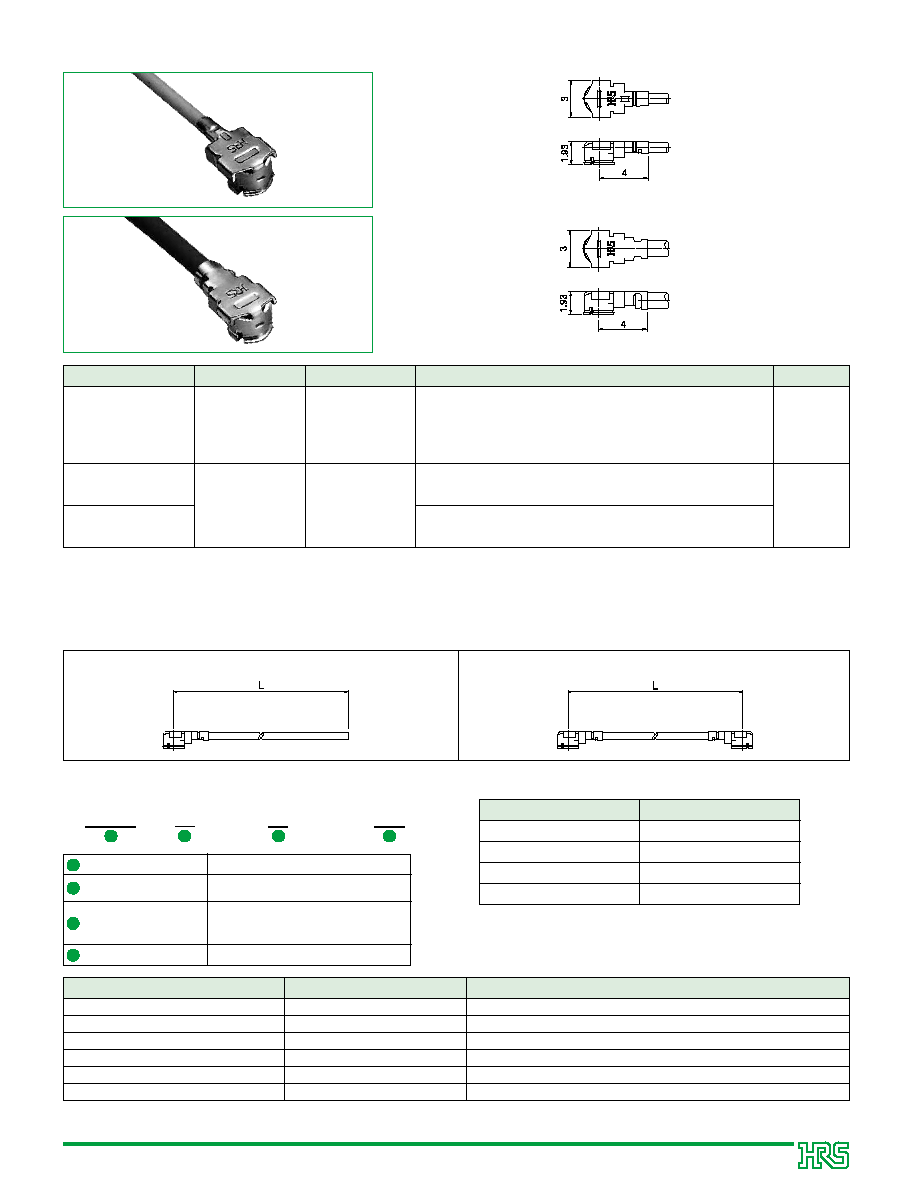

U.FL-R-SMT

U.FL-LP-040

Dia.1.13

Dia.1.32

2.5Max

U.FL-R-SMT

U.FL-LP-066

s

Features

1. Mating Heights Owing to Lowest Profile

Height from the printed circuit board when mates a receptacle with

a (right-angle) plug is 2.5 mm maximum. This low Profile is at the

world's shortest level.

2. Extremely Small Board Occupation Area

In comparison with our E.FL Series of SMT coaxial connectors, the

receptacles offer a reduction of approximately 18% of the board

occupation area resulting in an area of just 7.7 mm

2

.

3. World's Lightest

These are the world's lightest coaxial connectors.

Receptacle: 15.7 mg

Right-angle plugs

For

ÿ

0.81 mm cable: 53.7 mg

For

ÿ 1.13 &

1.32 mm cable: 59.1 mg

4. Can Be Used Up to a Frequency of 6 GHz

To meet the frequency requirements of a wide variety of miniature

equipment, these connectors offer high frequency performance

from DC to 6 GHz.

5. Can Be Used with Automatic Mounting

The embossed tape packaging specification of the receptacles

permits automatic mounting.

6. Use of Ultra-Fine Teflon Cable

From among the types of suitable cable,

ÿ

0.8 mm (single shield)

outside diameter ultra-fine Teflon coaxial cable has been made a

standard specification in consideration of improving the

construction qualities and construction area.

An external diameter

ÿ

1.32 mm (double shield) &

ÿ1.13mm (single

shield)

ultra-fine Teflon coaxial cable specification is also available.

7. Simple Removal of Connectors

The extraction jig permits simple removal of connectors.

8. Mating Checks Are Easy

Subminiature size notwithstanding, the lock sensation permits a

check of sure mating.

Figure 1. Mating Height Comparison

(with Hirose Electric Products)

Figure 2. U.FL-LP-040 and U.FL-R-SMT

Figure 3. U.FL-LP-066and U.FL-R-SMT

q

Space Factor of Mated Connector

s

Applications

Mobile phones, wireless communications

equipment, electronic measuring instruments,

GPS, wireless LAN, Bluetooth etc.

Meets up to 6 GHz Requirement

2

s

Product Specifications

*V.S.W.R. Measurement System

The above V.S.W.R. standard values were measured using the measurement system of the diagram below.

NOTE 1: Cable type connectors were measured with SMA conversion adapters

attached to both ends of the harness product of a suitable 100cm cable.

NOTE 2: Board type connectors were mounted to a 50

glass epoxy board and

measurements were conducted with SMA conversion adapters attached.

Ratings

Nominal characteristic impedance

50

¯

Rated voltage

60 V AC (rms)

Rated frequency

DC to 6 GHz

Operating temperature range

-40∞C to +90∞C

Operating humidity

90% max.

Item

Specification

Conditions

1. Contact resistance

Center: 20 m

¯

max.

Outside: 10 m

¯

max.

Dia.0.81Cable

1.35

Dia.1.13Cable

1.4

Dia.1.32Cable

1.5

3 to 6 GHz

Measured at 10 mA max.

2. Insulation resistance

3. Withstand voltage

4. V.S.W.R.*

5. Female contact holding force

6. Repetitive operation

7. Vibration

8. Shock

9. Humidity resistance

9.

(Steady state)

10. Temperature cycle

11. Salt spray test

500 M

¯

min.

No line or insulation breakdown

1.3 max.

0.15 N min.

Contact resistance

25 m

¯

max. (Center)

15 m

¯

max. (Outside)

No momentary disconnections of 1 µs min.

No damage, cracks, or parts looseness min.

No momentary disconnections of 1 µs min.

No damage, cracks, or parts looseness

No damage, cracks, or parts looseness

Insulation resistance 100 M

¯

min.(High temperature)

Insulation resistance 500 M

¯

min.(Pry)

No damage, cracks, or parts looseness

Contact resistance 25 m

¯

max. (Center)

15 m

¯

max. (Outside)

No excessive corrosion

Measured at 100 V DC

200 V AC for 1 minute

DC to 3 GHz

Measured with a

ÿ

0.475 pin gauge

30 cycles of insertion and disengagement

Frequency of 10 to 100 Hz, single amplitude of 1.5 mm,

acceleration of 59 m/s

2

, for 5 cyles in the direction of each of the 3 axes

Acceleration of 735 m/s

2

, 11 ms duration, sine half-wave

waveform, for 6 cycles in the direction of each of the 3 axes

Temperature of 40∞C, humidity of 95%,

let stand for 96 hours

Temperature: +40∞C

/

5 to 35∞C

/

+90∞C

/

5 to 35∞C

Time:

30 min.

/

Within 5 min.

/

30 min.

/

Within 5 min.

Cycles: 5

48 hours continuous exposure to 5% salt water

Part

Material

Finish

Remarks

Shell

Phosphor bronze

Silver plating

----------

Male center contact

Brass

Gold plating

----------

Female center contact

Phosphor bronze

Gold plating

----------

Insulator

Plug

Black

UL94V-0

Receptacle

Beige

UL94V-0

LCP

PBT

s

Materials

3

s

Plugs

Please order plugs with the cable assembly specifications.

s

Cable Assembly

Dimension of U.FL Series assembly products should be made as indicated below.

Please contact Hirose Sales Representative about cable length and cable end treatment.

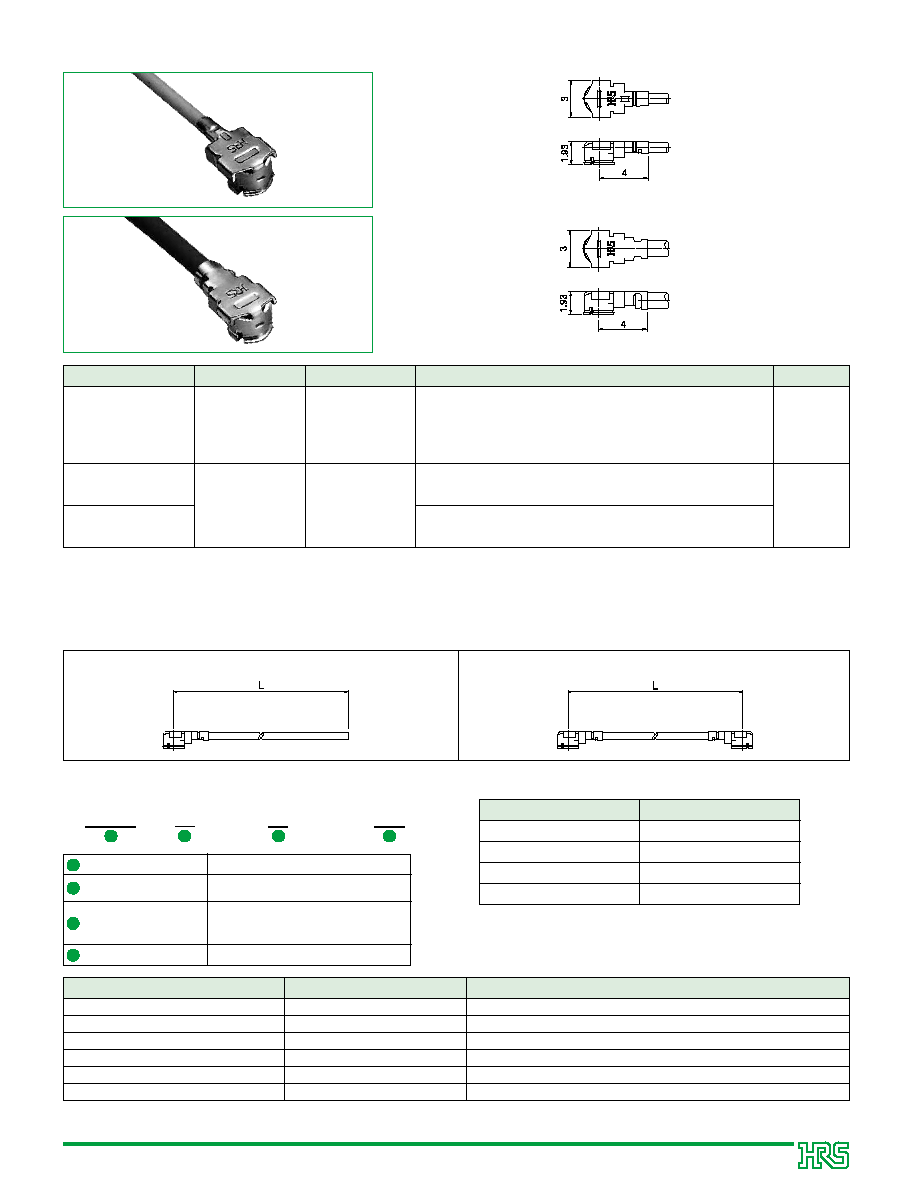

Single-Ended Cable Assembly

Double-Ended Cable Assembly

U.FL - [] LP - [] - A -

(L)

q

Ordering Information

Series name

Assembly type

Cable type

Overall length (mm)

U.FL

Blank: Single ended

2: Double ended

04

: For use with

ÿ

0.81 cable

5016 : For use with

ÿ

1.13 cable

066 : For use with

ÿ

1.32 cable

Length L is expressed in mm units.

Overall Length L (mm)

00

35<

=L

<

=

0

200

0

200<L

<

=0

500

0

500<L

<

=

1000

1000<L

<

=1000

Standard Tolerance (mm)

±

0

4

±

0

8

±

12

±

1.5%

q

Cable Assembly Overall Length Standard Tolerance

Note: Shortest length L is 35 mm.

Form of Plug After Cable Wiring

Form of Plug After Cable Wiring

U.FL-LP-066

U.FL-LP-040

Item

HRS No.

Part No.

Applicable Cable

Weight (mg)

Right-angle plug shell

(for

ÿ

0.81 cable)

CL331-0451-2

U.FL-LP-040

RF-MF5010 Manufactured by Nissei Electric Co., Ltd.

J12B0964 Manufactured by Junkosha Co., Ltd.

CO-6F-SB-CX50 Manufactured by Hitachi Cable, Ltd.

53.7/unit

Right-angle plug shell

(for

ÿ

1.13 cable)

RF-MF5016 Manufactured by Nissei Electric Co., Ltd.

J12B1054 Manufactured by Junkosha Co., Ltd.

59.1/unit

Right-angle plug shell

(for

ÿ

1.32 cable)

A12B0733 Manufactured by Junkosha Co., Ltd.

CO-6F-DSB-CX-50 Manufactured by Hitachi Cable, Ltd.

Dia. 0.81mm Double Ended Cable Assembly

Dia. 0.81mm Single Ended Cable Assembly

Dia. 1.13mm Double Ended Cable Assembly

Dia. 1.13mm Single Ended Cable Assembly

Dia. 1.32mm Double Ended Cable Assembly

Dia. 1.32mm Single Ended Cable Assembly

321-1937-2-

**

321-1998-7-

**

321-2493-6-

**

321-2492-3-

**

321-2170-7-

**

321-2573-3-

**

U.FL-2LP-04-A-(L)

U.FL-LP-04-A-(L)

U.FL-2LP-5016-A-(L)

U.FL-LP-5016-A-(L)

U.FL-2LP-066-A-(L)

U.FL-LP-066-A-(L)

Part No. of Cable Assembly

CL No.

Description

3

1

2

4

1

2

3

4

CL331-0452-5

U.FL-LP-066

4

HRS No.

CL331-0471-0-01

CL331-0471-0-10

Part No.

U.FL-R-SMT(01)

U.FL-R-SMT(10)

Sales Quantity

Pack sales (100 pieces per pack)

Reel sales (2,500 pieces per reel)

Weight (mg)

15.7/unit

s

Receptacles

NOTE 1: Receptacles of the (01) specification are sold by

the pack with 100 pieces per pack. Please order

in pack units.

NOTE 2: Receptacles of the (10) specification are sold by

the reel (which contains 2,500 pieces). Please

order in reel units.

NOTE 3: Permissible value for mold resin which gets onto

the center contact.

Recommended PCB Footprints

q

Packaging Specifications

Embossed Carrier Tape Dimensions

Reel Dimensions

(Note 3)

Unreeling direction

5

HRS No.

CL311-0300-2

Product No.

HRMP-U.FLJ

HRS No.

CL311-0301-5

Product No.

HRMJ-U.FLP

HRS No.

CL331-0466-0

Product No.

U.FL-R-1

s

Conversion Adapter

q

SMA Conversion Adapter

(Coupling portion: U.FL side jack - SMA side plug)

q

SMA Conversion Adapter

(Coupling portion: U.FL side plug - SMA side jack)

s

Inspection Receptacle

This receptacle is used for inspecting the continuity,

withstand voltage, and other aspects of the harness

product.

NOTE: The U.FL side coupling portion has a weaker lock than

the regular product and, therefore, cannot be used for

purposes other than performance measurements.

NOTE: The U.FL side coupling portion has a weaker lock than

the regular product and, therefore, cannot be used for

purposes other than performance measurements.

NOTE: The U.FL side coupling portion does not have a lock

and, therefore, cannot be used for purposes other than

continuity and withstand voltage inspections.

HRS No.

CL331-0494-5

CL331-0441-9

Product No.

U.FL-LP-N-2

E.FL-LP-N

-2

s

Extraction Jig

This jig is used for extraction from a coupled condition.

U.FL

50

90

ÿ15

5

2.1

U.FL-LP-N-2

6

s

Usage Precautions

1. Plugs

(1) Connection/

disconnection of

connectors

(2) Permissible load on

the cable after

connector coupling.

(3) Precautions

1) To disconnect connectors, hook the end portion of E.FL-LP-N and U.FL-LP-N-2 onto the connector cover and pull off

vertically in the direction of the connector coupling axis.

1)

To remove the connector directly, hold the connector cover and pull off

vertically in the direction of the connector coupling axis. (Please exercise

caution so as not to injure fingertips or nails.)

2) To couple the connectors, the coupling axes of both connectors are

aligned and the connectors are inserted as perpendicularly as possible.

Do not attempt to insert on an extreme angle.

After the connectors are coupled, do not apply a load to the cable in excess of the values indicated in the diagram

below.

Please note that excessive twisting in the action of insertion or removal will cause damage.

(1) Recommended

temperature profile

(Reference)

Recommended Temperature Profile (Reference)

1) The temperature indicates the printed circuit board surface temperature of the connector lead portion.

2) The reflow soldering method should be performed at a peak temperature of 240∞C or less at the surface of the

printed circuit board.

3) The temperature profile will change depending on conditions which include such factors as the size of the board,

the solder used, and the solder thickness.

(3) Recommended screen

thickness

0.15 mm

(2) Recommended hand

soldering conditions

(Reference)

Soldering iron temperature: 350∞C

Soldering time: Within 5 seconds

2. Receptacles

U.FL-LP-040

2N or less

2N or less

4N or less

U.FL-R-SMT

U.FL-R-SMT

U.FL-LP-040

U.FL-LP-066

U.FL-LP-N-2

E.FL-LP-N