| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HMC259 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

4 - 112

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

M

IXERS

4

DIE

Features

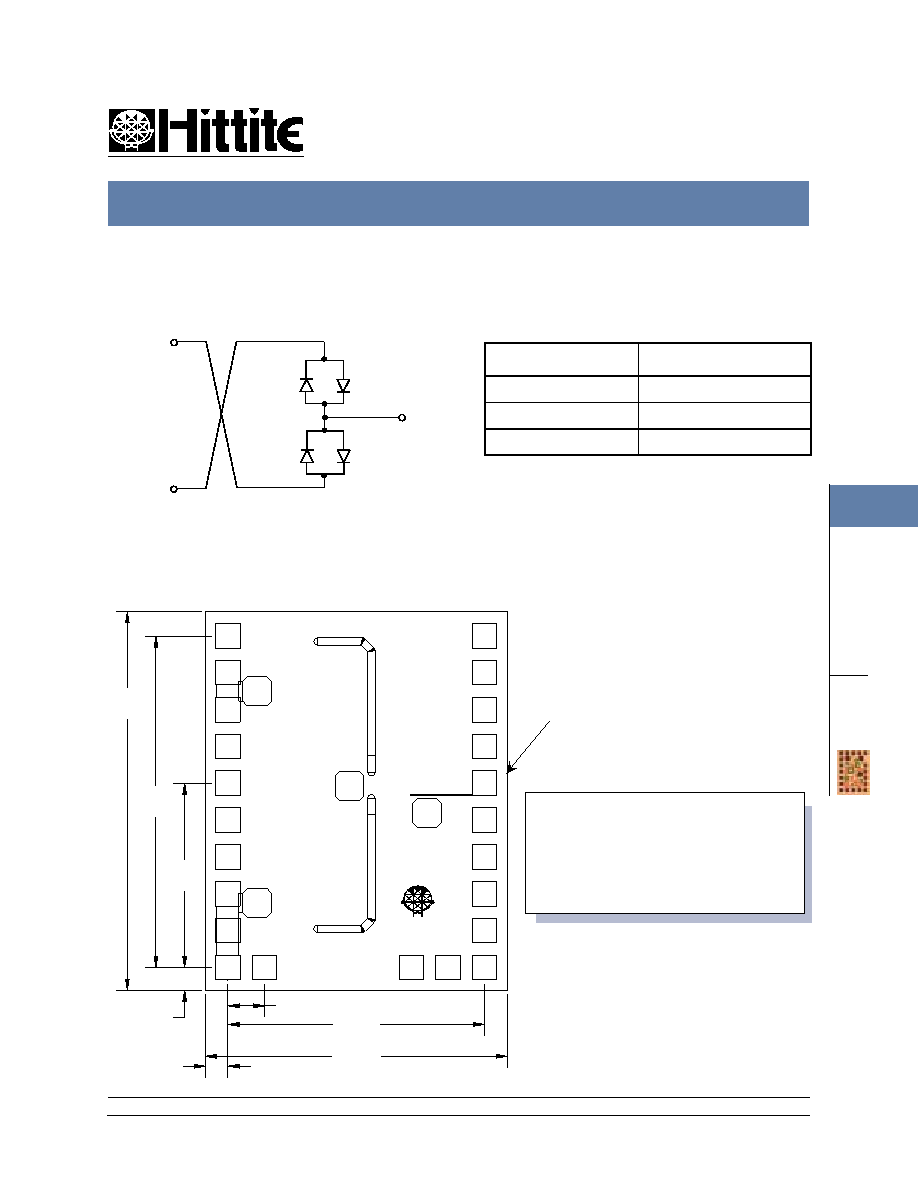

SUB-HARMONICALLY PUMPED (x2) LO

HIGH 2LO/RF ISOLATION: > 35dB

SMALL SIZE: 1.24mm x 1.55mm

IDEAL FOR 38 GHz RADIOS, E1 & T1

Parameter

IF = 1 GHz

IF = 1 GHz

Units

Min.

Typ.

Max.

Min.

Typ.

Max.

Frequency Range, RF

28 - 40

36 - 40

GHz

Frequency Range LO

14 - 20

18 - 20

GHz

Frequency Range, IF

DC - 12

DC - 4

GHz

Conversion Loss

14

17

12

15

dB

Noise Figure (SSB)

14

17

12

15

dB

2 LO to RF Isolation

28

35

40

50

dB

2 LO to IF Isolation

58

65

63

68

dB

RF to IF Isolation

25

30

25

32

dB

LO to IF Isolation

10

15

12

17

dB

IP3 (Input)

2

5

2

6

dBm

1 dB Compression (Input)

-7

-4

-7

-1

dBm

Local Oscillator Drive Level

+13

+15

+18

+13

+15

+18

dBm

General Description

The HMC259 chip is a broadband sub-harmoni-

cally pumped (x2) balanced MMIC passive mixer

which can be used as an upconverter or

downconverter. The chip utilizes a GaAs MESFET

process resulting in a small overall chip area of

1.9mm

2

. This chip has a very wide IF bandwidth

of DC-13 GHz. The 2LO to RF isolation is

excellent eliminating the need for additional fil-

tering . This mixer chip is designed to be used in

38GHz point to point radios, Local Multi-Point

Distribution Systems (LMDS), and SATCOM ap-

plications. All data is with the chip in a 50 ohm test

fixture connected via 0.025 mm (1 mil) diameter

wire bonds of minimal length <0.31 mm (<12

mils). This device is a much smaller and more

reliable replacement to hybrid diode mixer de-

signs.

GaAs MMIC SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

Guaranteed Performance*,

LO Drive=+15dBm, - 55 to + 85 deg C

HMC259

* Configured as a downconverter

4 - 113

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

4

M

IXERS

DIE

-30

-25

-20

-15

-10

-5

0

24

26

28

30

32

34

36

38

40

CONVERSI

ON

GAI

N

(

d

B)

RF FREQUENCY (GHz)

+13 dBm

+16 dBm

+15 dBm

+14 dBm

Return Loss @ LO = +15 dBm

-40

-35

-30

-25

-20

-15

-10

-5

0

0

5

10

15

20

25

30

35

40

RETURN

L

O

SS

(

d

B)

FREQUENCY (GHz)

LO & RF

IF

-25

-20

-15

-10

-5

0

24

26

28

30

32

34

36

38

40

CONVERSI

ON

GAI

N

(

d

B)

RF FREQUENCY (GHz)

+85 C

-55 C

+25 C

-80

-60

-40

-20

0

24

26

28

30

32

34

36

38

40

IS

OL

A

T

ION

(

d

B

)

RF FREQUENCY (GHz)

RF/IF

LO/IF

RF/LO

2LO/RF

2LO/IF

-30

-25

-20

-15

-10

-5

0

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

I

F

CONVERSI

ON

GAI

N

(

d

B)

IF FREQUENCY (GHz)

Conversion Gain vs. Temperature

@ LO = +15 dBm

IF Bandwidth @ LO =+15dBm

Isolation @ LO = +15 dBm

HMC259 SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

Conversion Gain vs. LO Drive

-30

-25

-20

-15

-10

-5

0

24

26

28

30

32

34

36

38

40

CONVERSI

ON

GAI

N

(

d

B)

RF FREQUENCY (GHz)

Upconverter Performance

Conversion Gain @ LO = +15dBm

HMC259

4 - 114

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

M

IXERS

4

DIE

0

10

20

30

40

50

60

24

26

28

30

32

34

36

38

40

SECOND

O

RDER

I

NTERCEPT

(

d

Bm

)

RF FREQUENCY (GHz)

+25 C

-55 C

+85 C

0

4

8

12

16

20

24

26

28

30

32

34

36

38

40

THI

R

D

O

RDER

I

NTERCEPT

(

d

Bm)

RF FREQUENCY (GHz)

+14 dBm

+16 dBm

+15 dBm

0

10

20

30

40

50

60

24

26

28

30

32

34

36

38

40

SECOND

O

RDER

I

NTERCEPT

(

d

Bm

)

RF FREQUENCY (GHz)

+15 dBm

+16 dBm

+14 dBm

0

4

8

12

16

20

24

26

28

30

32

34

36

38

40

THI

R

D

O

RDER

I

NTERCEPT

(

d

Bm)

RF FREQUENCY (GHz)

+25 C

+85 C

-55 C

Input IP2 vs. LO Drive

Input IP3 vs. LO Drive

Input IP3 vs. Temperature

@ LO = 0 dB

m

Input IP2 vs. Temperature

@ LO = 0 dBm

HMC259 SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

nLO

mRF

± 5

± 4

± 3

± 2

± 1

0

-3

-2

-37

-1

-46

-48

-22

0

-28

+29

1

X

-24

-29

2

-40

-44

-81

3

-76

RF = 30 GHz @ -15 dBm

LO = 14 GHz @ +15 dBm

All values in dBc below IF power level

MXN Spurious Outputs

@ LO Drive = 0 dBm

-5

-4

-3

-2

-1

0

1

2

3

4

5

24

26

28

30

32

34

36

38

40

P1dB

(

d

Bm

)

RF FREQUENCY (GHz)

+25 C

+85 C

-55 C

P1dB vs. Temperature

@ LO =+15 dBm

HMC259

4 - 115

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

4

M

IXERS

DIE

HMC259 SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

Outline Drawing

( See Die Handling, Mounting, Bonding Note Page 4-116)

Absolute Maximum Ratings

RF / IF Input

+13 dBm

LO Drive

+23 dBm

Storage Temperature

-65 to +150 deg C

Operating Temperature

-55 to +85 deg C

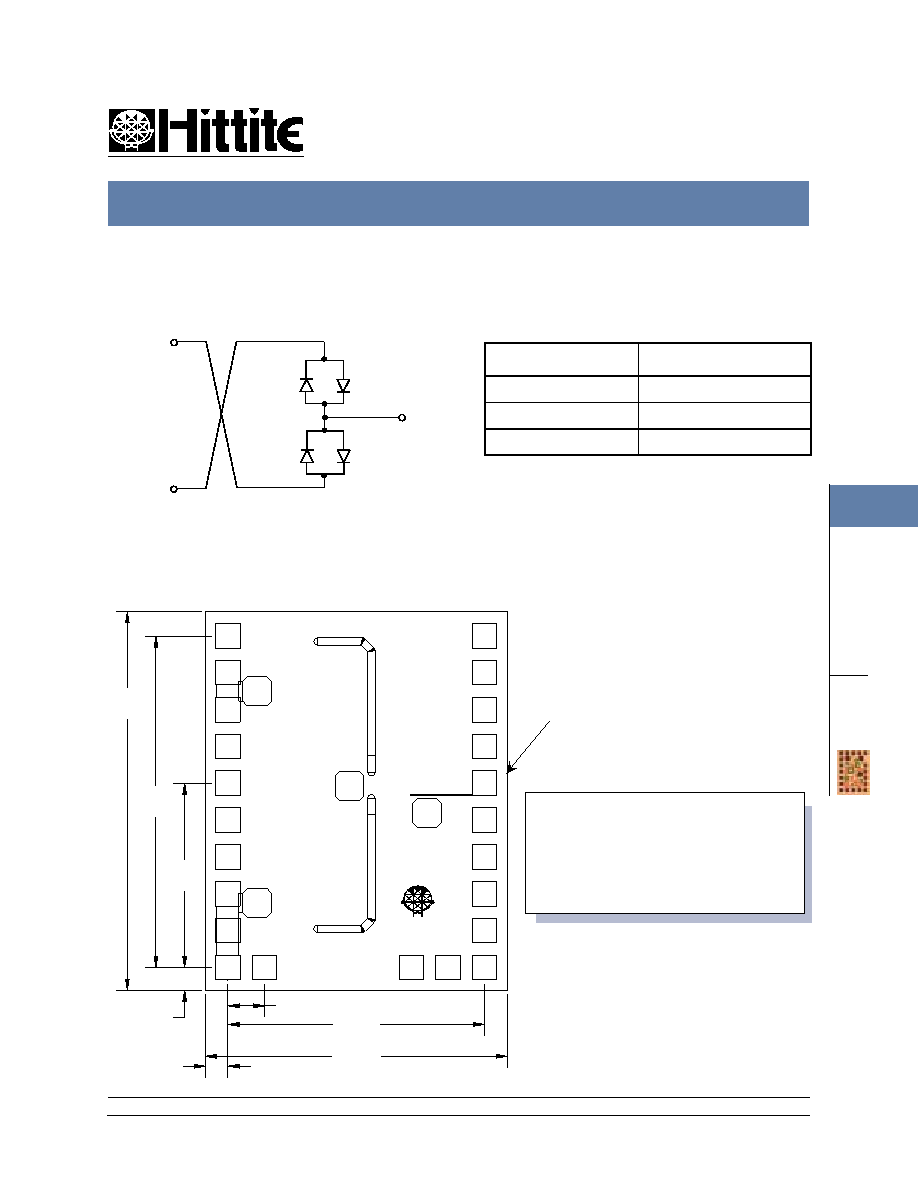

Schematic

1.55

(0.061)

1.35

(0.053)

0.76

(0.030)

0.10

(0.004)

0.10

(0.004)

0.15

(0.006)

1.04

(0.041)

1.24

(0.049)

LO

H i t t i t e

IF

RF

BACKSIDE

IS GROUND

ALL DIMENSION IN MILLIMETERS (INCHES)

ALL TOLERANCES ARE ±0.025 (0.001)

DIE THICKNESS IS 0.100 (0.004) BACKSIDE IS GROUND

BOND PADS ARE 0.100 (0.004) SQUARE

BOND PAD SPACING, CTR-CTR: 0.150 (0.006)

BACKSIDE METALLIZATION : GOLD

BOND PAD METALLIZATION : GOLD

RF

IF

LO

HMC259

4 - 116

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

M

IXERS

4

DIE

HMC259 SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

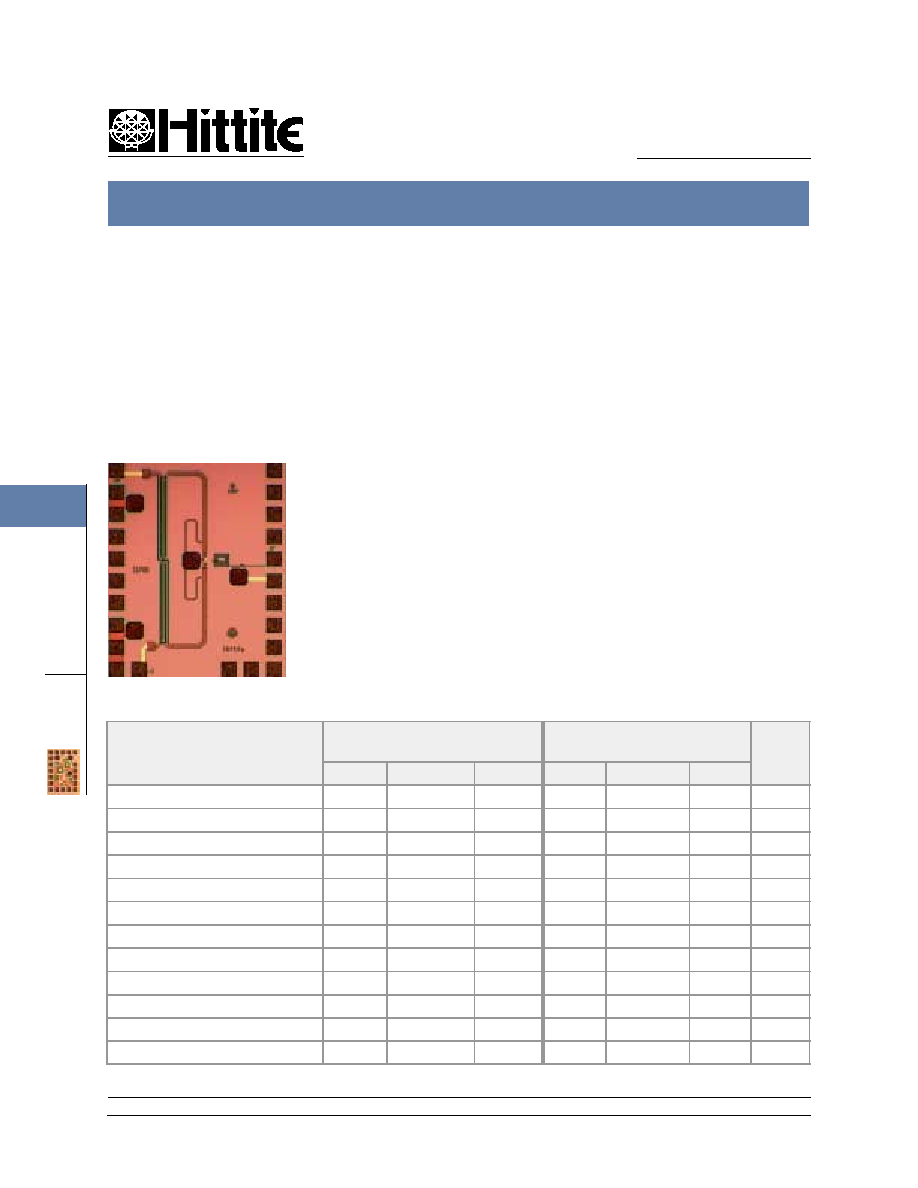

MIC Assembly Techniques for HMC259

LO

IF

RF

Mounting & Bonding Techniques for Millimeterwave GaAs

MMICs

The die should be attached directly to the ground plane eutectically

or with conductive epoxy (see HMC general Handling, Mounting,

Bonding Note).

50 Ohm Microstrip transmission lines on 0.127mm (5 mil) thick

alumina thin film substrates are recommended for bringing RF to

and from the chip (Figure 1). If 0.254mm (10 mil) thick alumina thin

film substrates must be used, the die should be raised 0.150mm (6

mils) so that the surface of the die is coplanar with the surface of the

substrate. One way to accomplish this is to attach the 0.102mm (4

mil) thick die to a 0.150mm (6 mil) thick molybdenum heat spreader

(moly-tab) which is then attached to the ground plane (Figure 2).

Microstrip substrates should brought as close to the die as

possible in order to minimize bond wire length. Typical die-to-substrate spacing is 0.076mm (3 mils).

Figure 3: Typical HMC259 Assembly

HMC259

4 - 117

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373

Web Site: www.hittite.com

M I C R O W A V E C O R P O R A T I O N

F

EBRUARY

2001

y2k

new!

4

M

IXERS

DIE

Ball or wedge bond with 0.025 mm (1 mil) diameter pure gold wire. Thermosonic wirebonding with a nominal

stage temperature of 150 deg. C and a ball bonding force of 40 to 50 grams or wedge bonding force of 18 to

22 grams is recommended. Use the minimum level of ultrasonic energy to achieve reliable wirebonds.

Wirebonds should be started on the chip and terminated on the package or substrate. All bonds should be

as short as possible <0.31 mm (12 mils).

Handling Precautions

Wire Bonding

The chip is back-metallized and can be die mounted with AuSn eutectic preforms or with electrically

conductive epoxy. The mounting surface should be clean and flat.

Eutectic Die Attach:

A 80/20 gold tin preform is recommended with a work surface temperature of 255 deg. C and a tool tem-

perature of 265 deg. C. When hot 90/10 nitrogen/hydrogen gas is applied, tool tip temperature should be

290 deg. C.

DO NOT expose the chip to a temperature greater than 320 deg. C for more than 20 seconds. No more

than 3 seconds of scrubbing should be required for attachment.

Epoxy Die Attach:

Apply a minimum amount of epoxy to the mounting surface so that a thin epoxy fillet is observed around

the perimeter of the chip once it is placed into position.

Cure epoxy per the manufacturer's schedule.

Mounting

Follow these precautions to avoid permanent damage.

Cleanliness: Handle the chips in a clean environment. DO NOT attempt to clean the chip using liquid

cleaning systems.

Static Sensitivity: Follow ESD precautions to protect against > ± 250V ESD strikes ( see page 8 - 2 ).

Transients: Suppress instrument and bias supply transients while bias is applied. Use shielded signal and

bias cables to minimize inductive pick-up.

General Handling: Handle the chip along the edges with a vacuum collet or with a sharp pair of bent twee-

zers. The surface of the chip has fragile air bridges and should not be touched with vacuum collet, twee-

zers, or fingers.

HMC259 SUB-HARMONICALLY PUMPED MIXER 28 - 40 GHz

HMC259