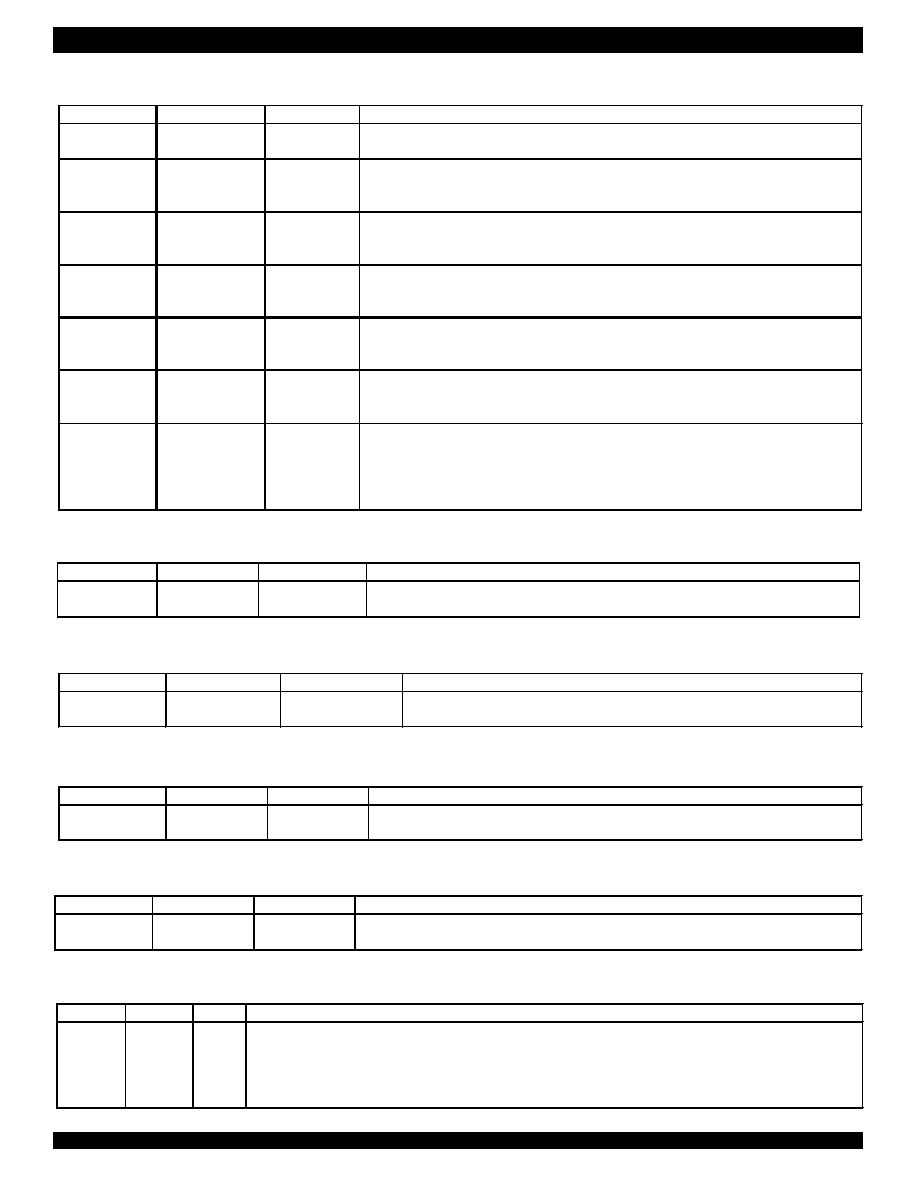

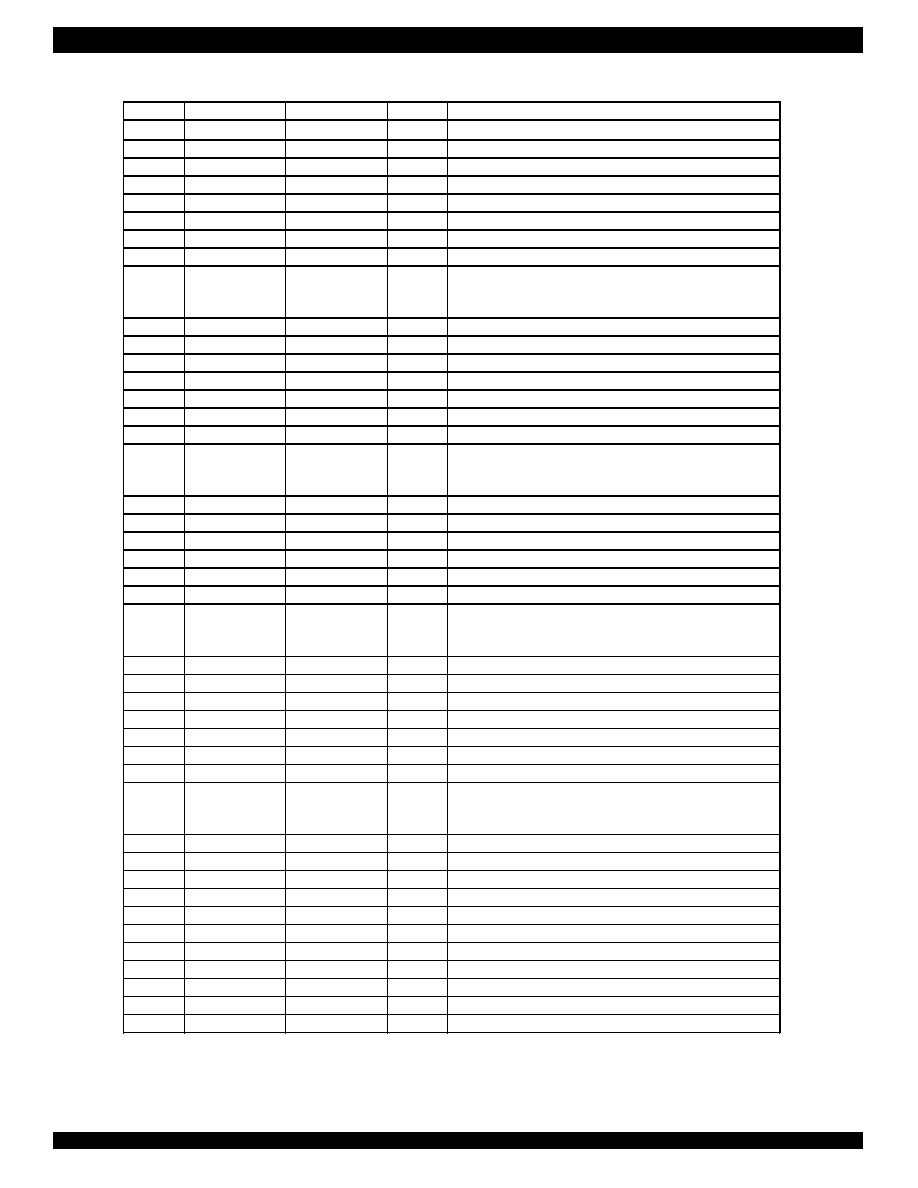

| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 82V2058 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

FEATURES

Fully integrated octal E1 short haul line interface which

supports 120

E1 twisted pair and 75

E1 coaxial appli-

cations

Selectable single rail or dual rail mode and AMI or HDB3

line encoder/decoder

Built-in transmit pre-equalization meets G.703

Selectable transmit/receive jitter attenuator meets ETSI

CTR12/13, ITU G.736, G.742 and G.823 specifications

SONET/SDH optimized jitter attenuator meets ITU G.783

mapping jitter specification

Digital/analog LOS detector meets ITU G.775 and ETS 300

233

OCTAL E1 SHORT HAUL

LINE INTERFACE UNIT

IDT82V2058

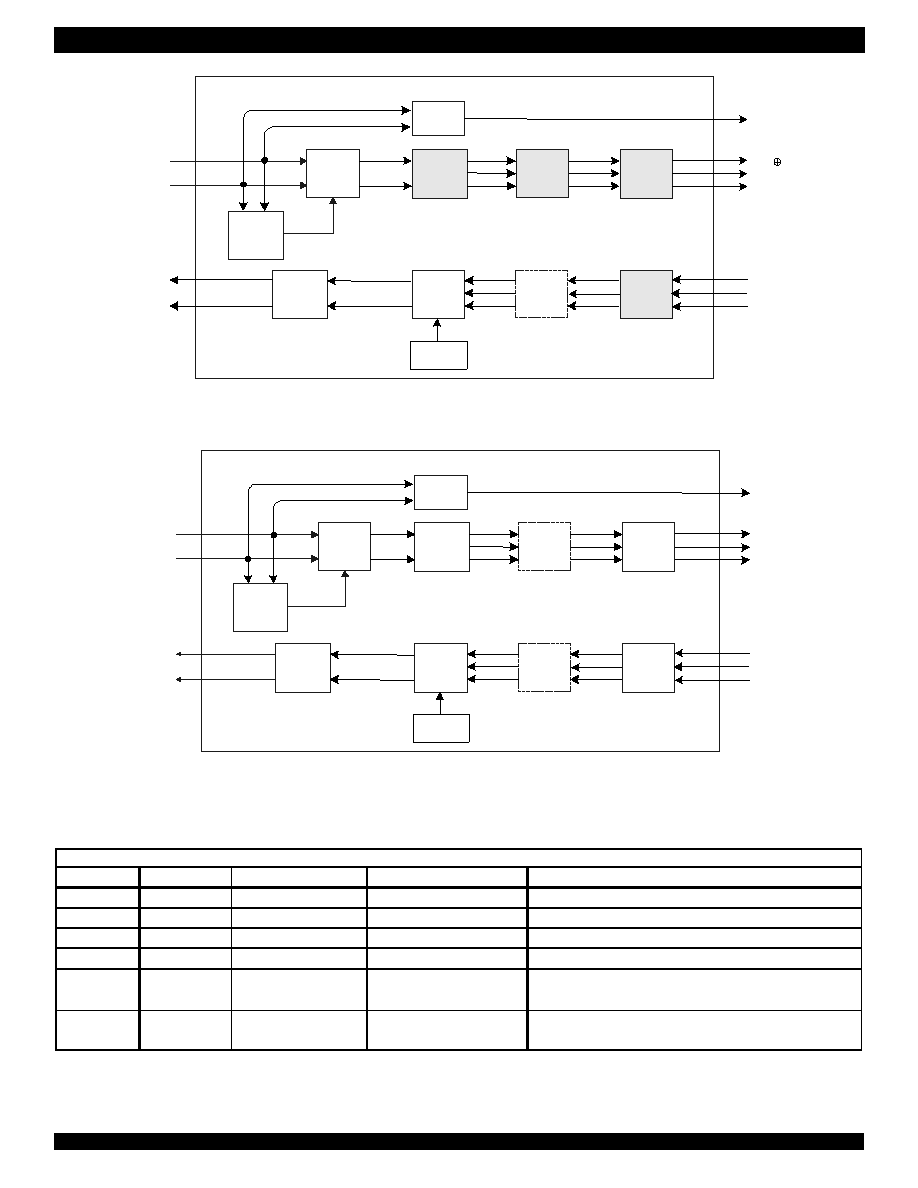

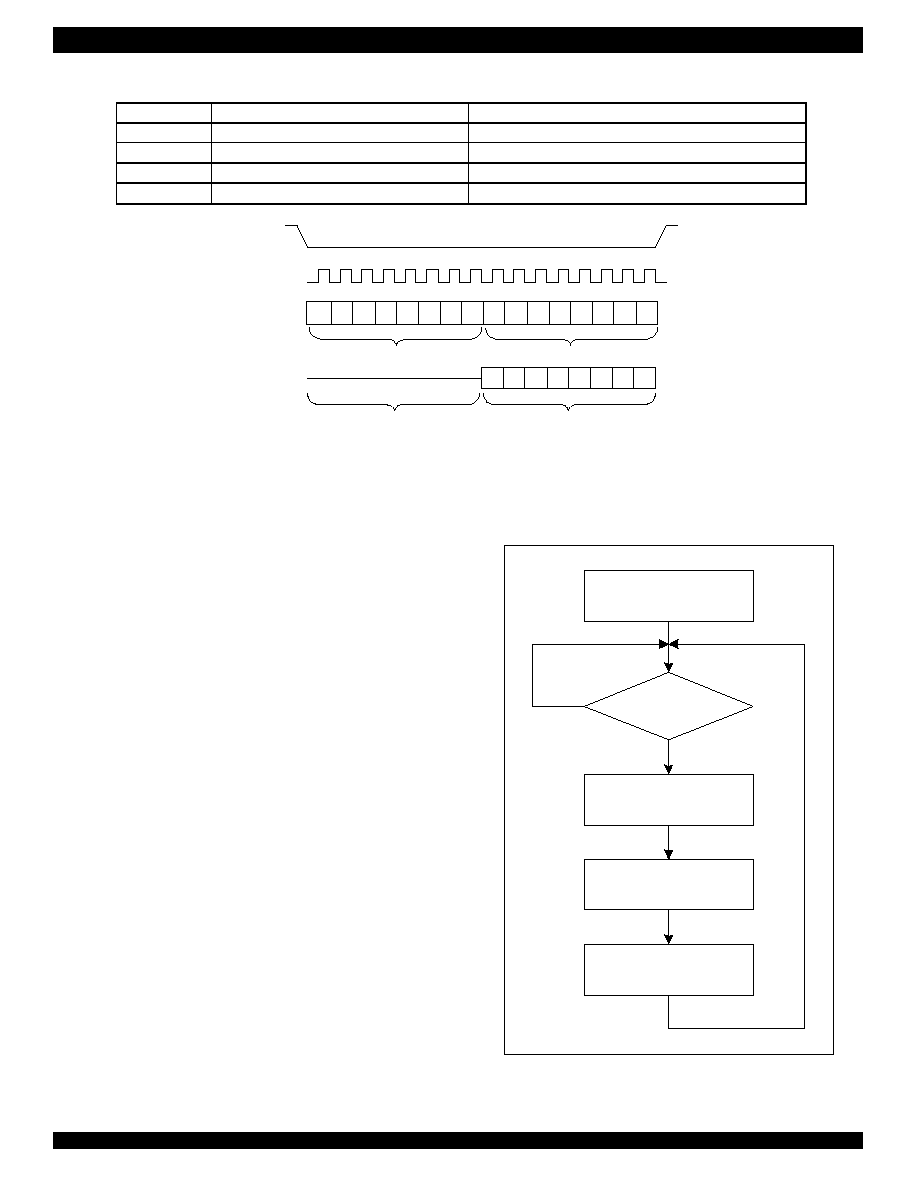

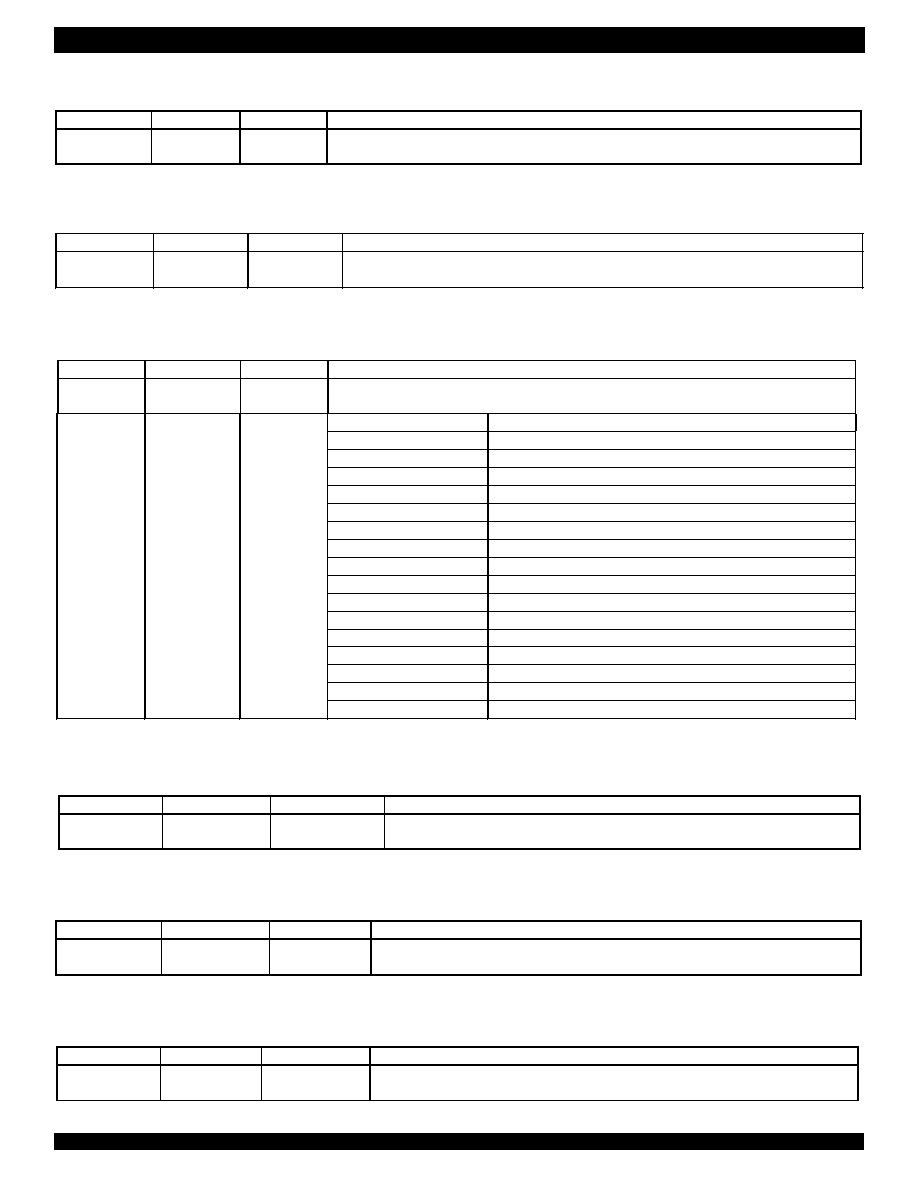

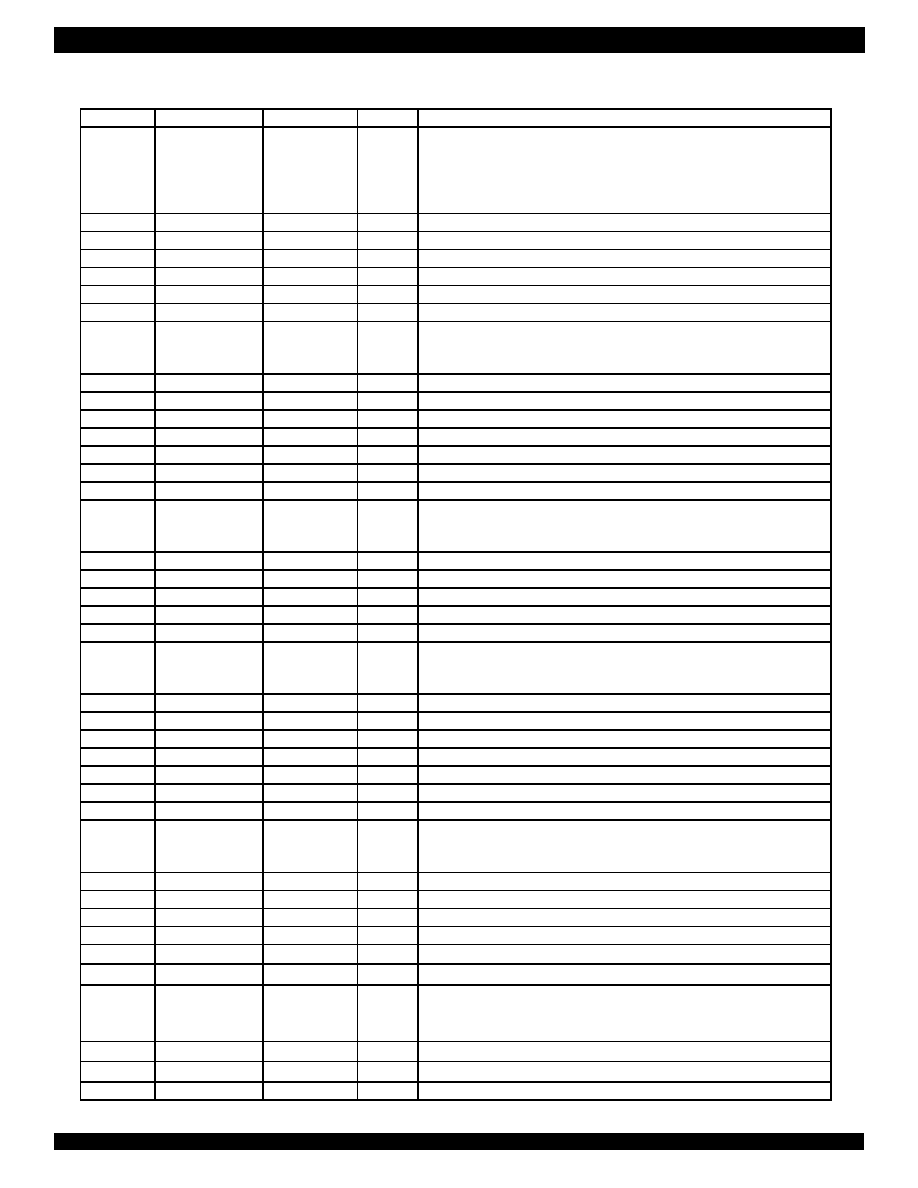

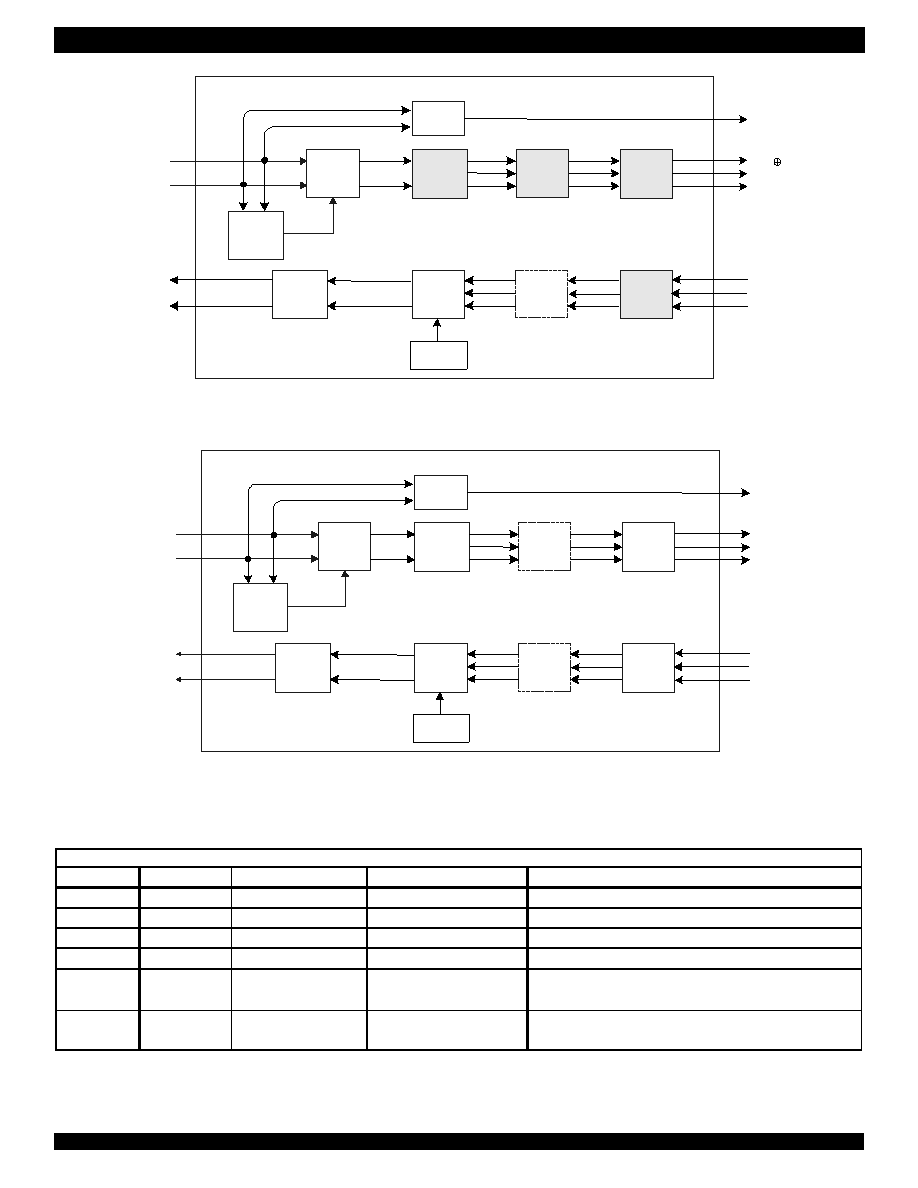

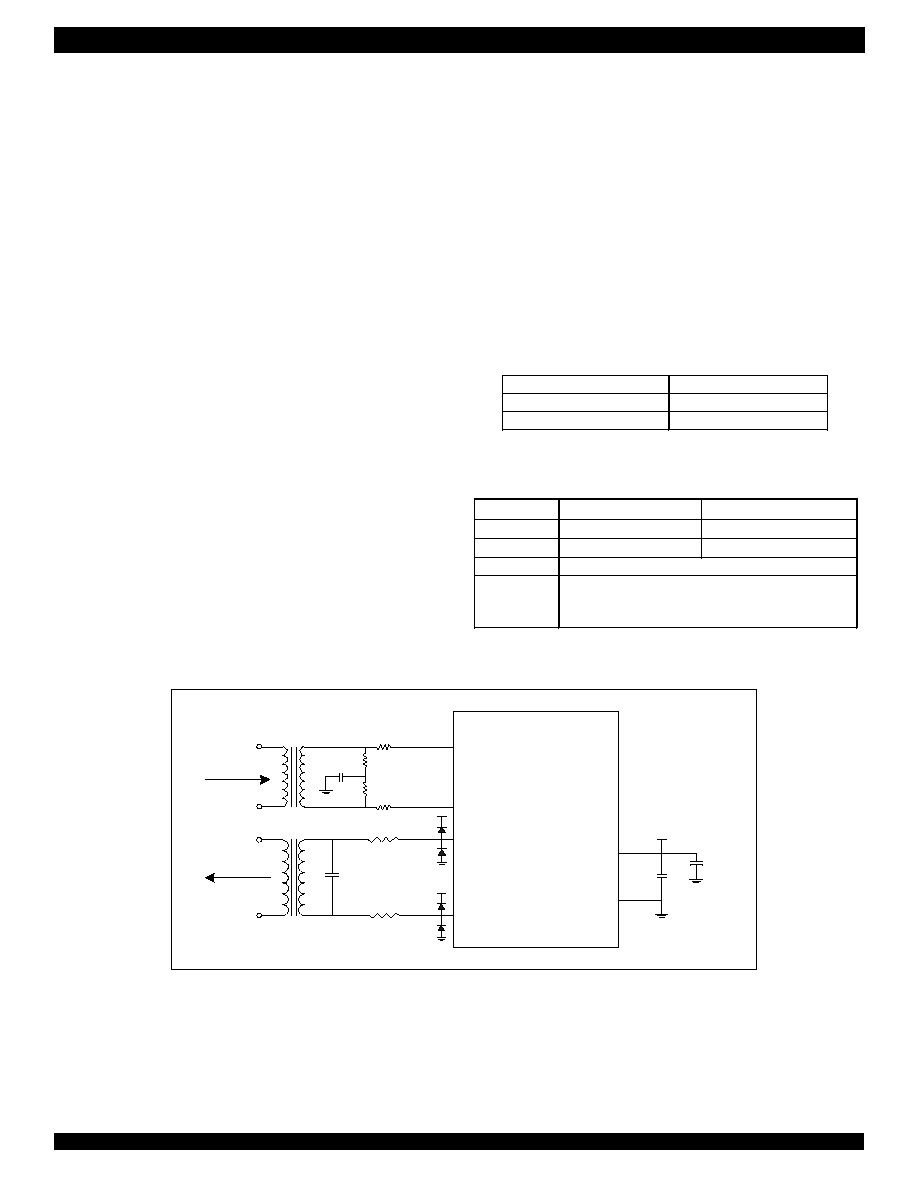

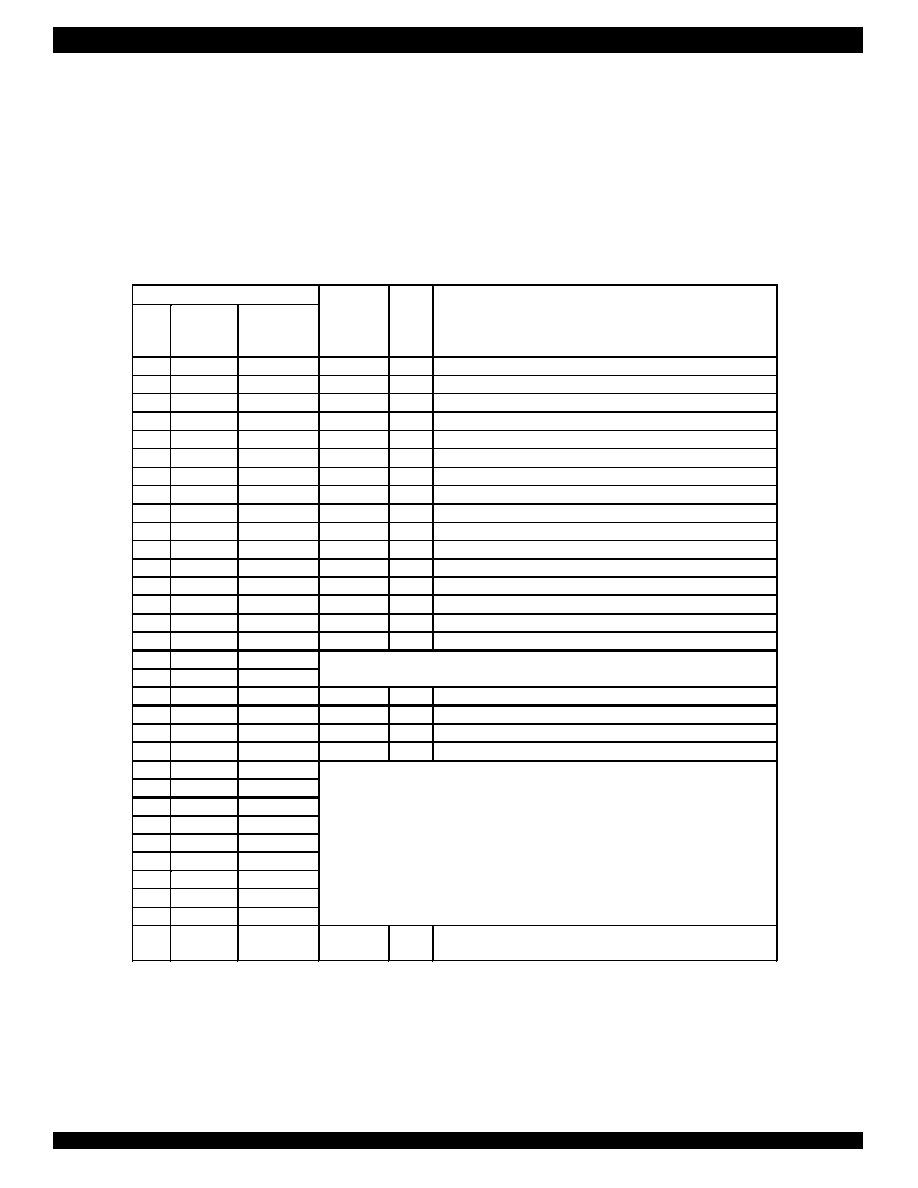

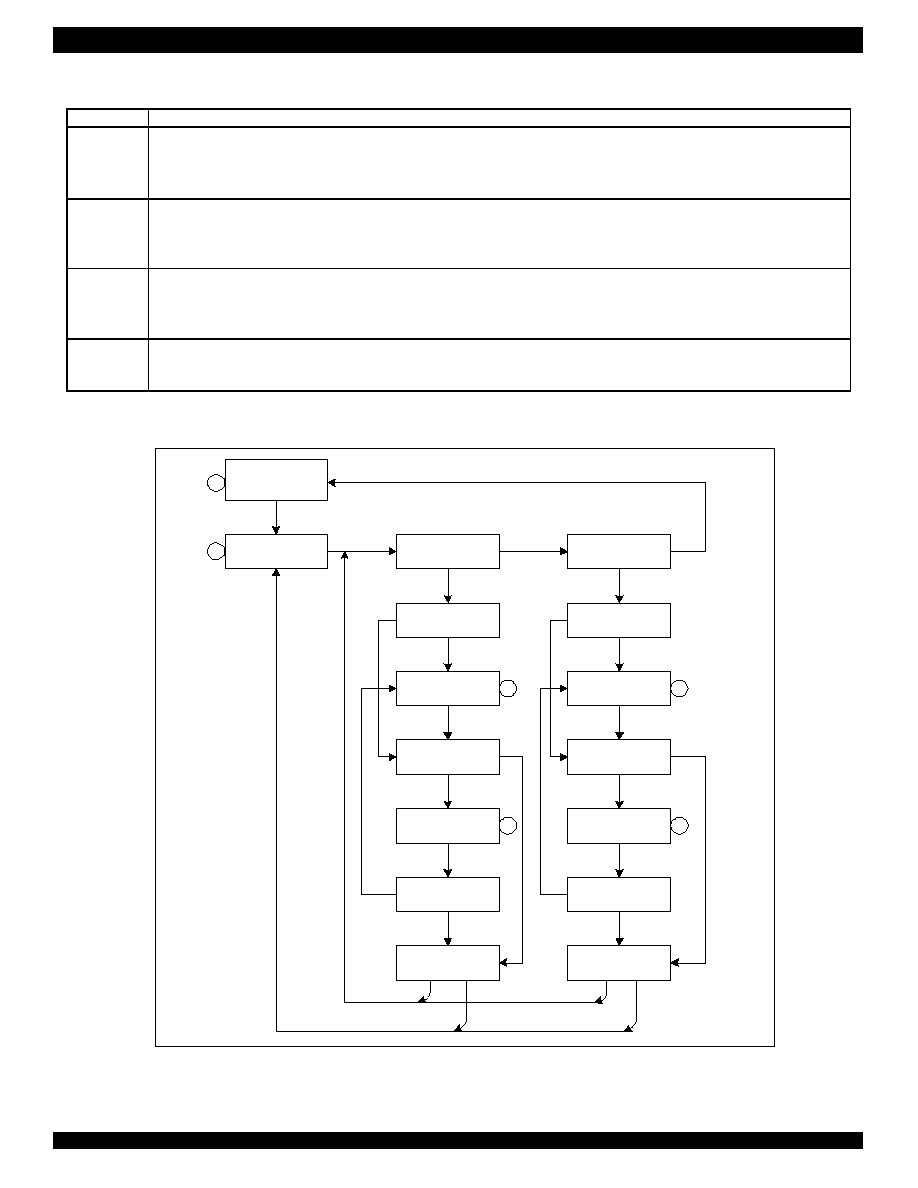

FUNCTIONAL BLOCK DIAGRAM

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Remote

Loopback

Analog

Loopback

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

Digital

Loopback

AIS

Detector

One of Eight Identical Channels

Register

File

Clock

Generator

MODE[2:0]

CS

/JAS

SCLK/ALE/

AS

RD

/R/

W

SDI/

WR

/

DS

SD0/RDY/

ACK INT

LP/D/AD[7:0]

MC/A[4:0]

OE

MCLK

TRST TCK TMS TDI TDO

JTAG TAP

RTIPn

RRINGn

TTIPn

TRINGn

VDD IO

VDDT

VDDD

VDDA

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

G.772

Monitor

Transmit

All Ones

Control Interface

CLKE

Figure - 1. Block Diagram

The IDT logo is a registered trademark of Integrated Device Technology, Inc.

INDUSTRIAL TEMPERATURE RANGES

1

JANUARY 2003

DSC-6038/9

©

2002 Integrated Device Technology, Inc.

ITU G.772 non-intrusive monitoring for in-service testing

for any one of channel1 to channel7

Low impedance transmit drivers with tri-state

Selectable hardware and parallel/serial host interface

Local and remote loopback test functions

Hitless Protection Switching (HPS) for 1 to 1 protection

without relays

JTAG boundary scan for board test

3.3V supply with 5V tolerant I/O

Low power consumption

Operating temperature range: -40∞C to +85∞C

Available in 144-pin Thin Quad Flat Pack (TQFP_144_DA)

and 160-pin Plastic Ball Grid Array (PBGA) packages

2

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

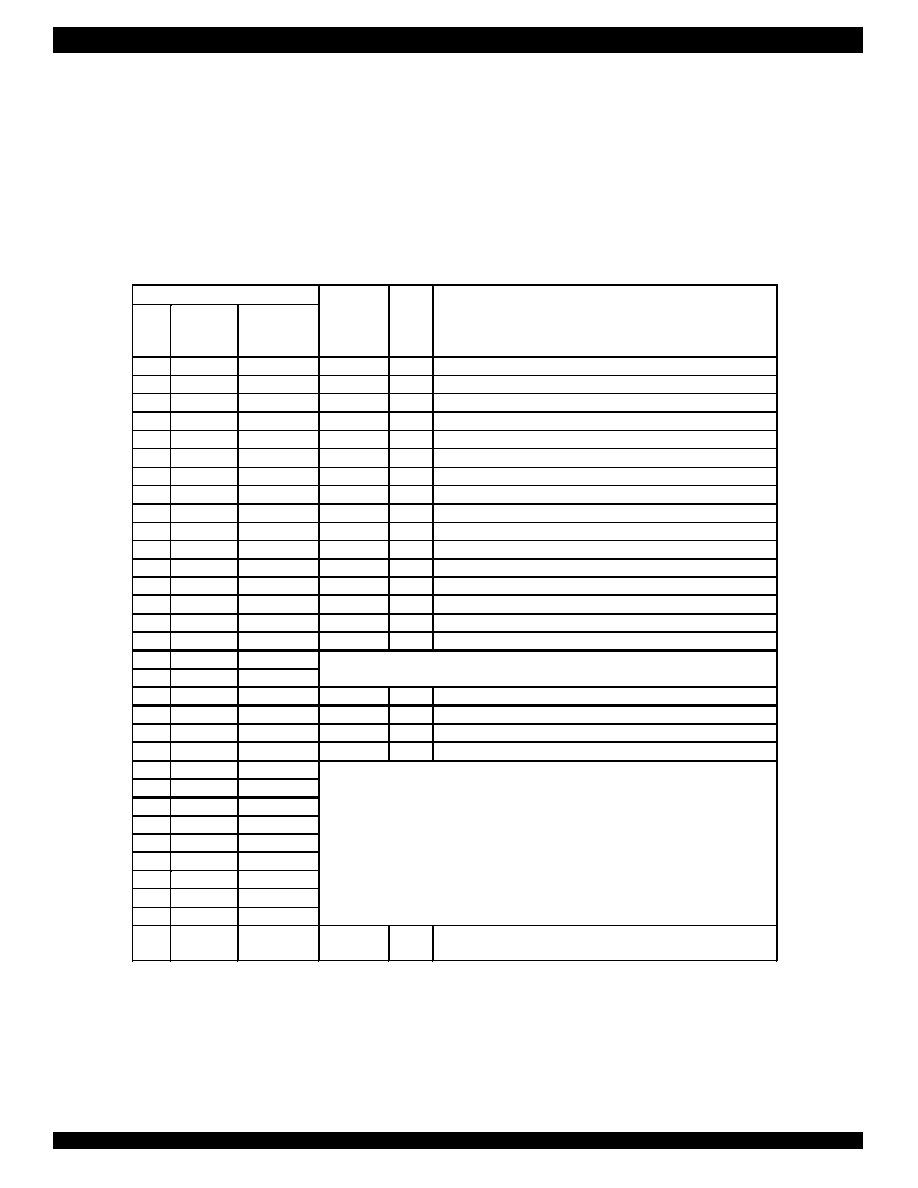

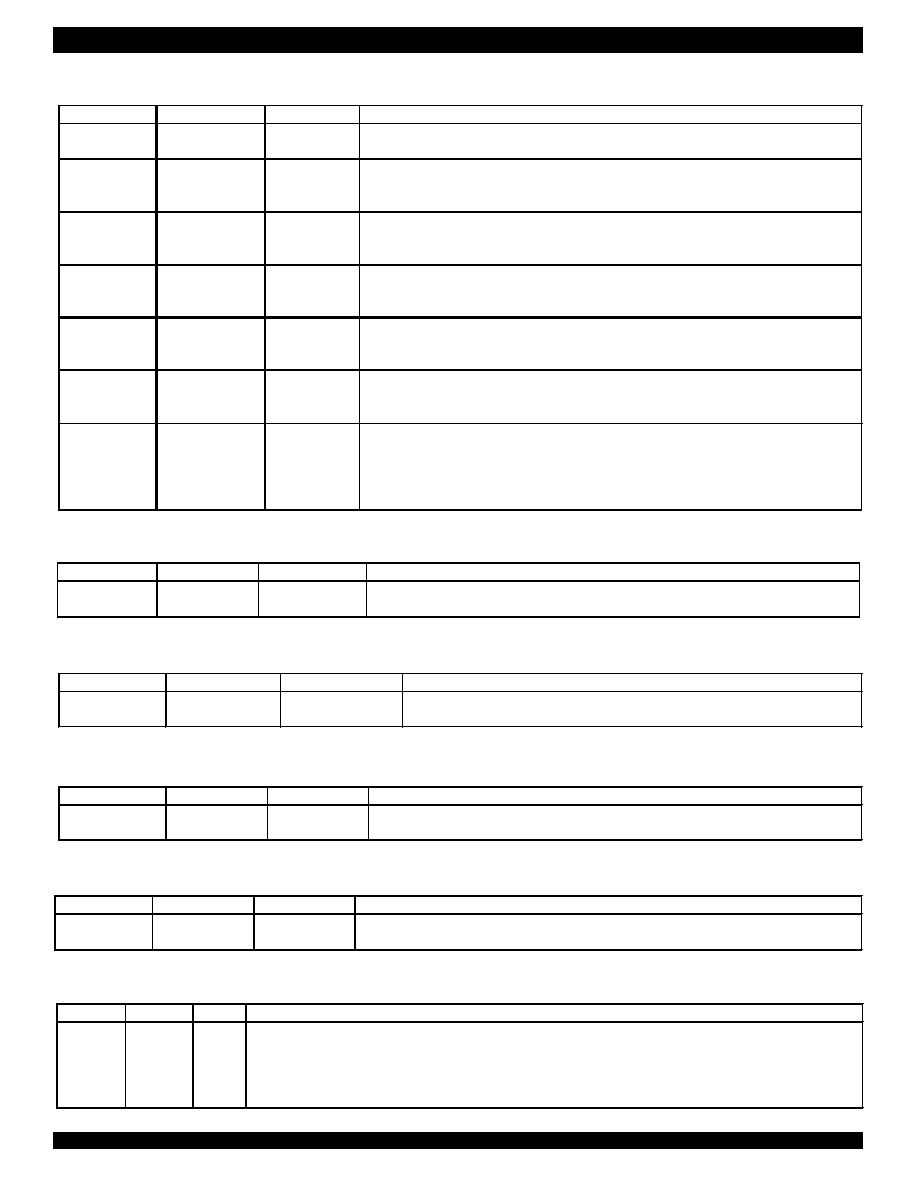

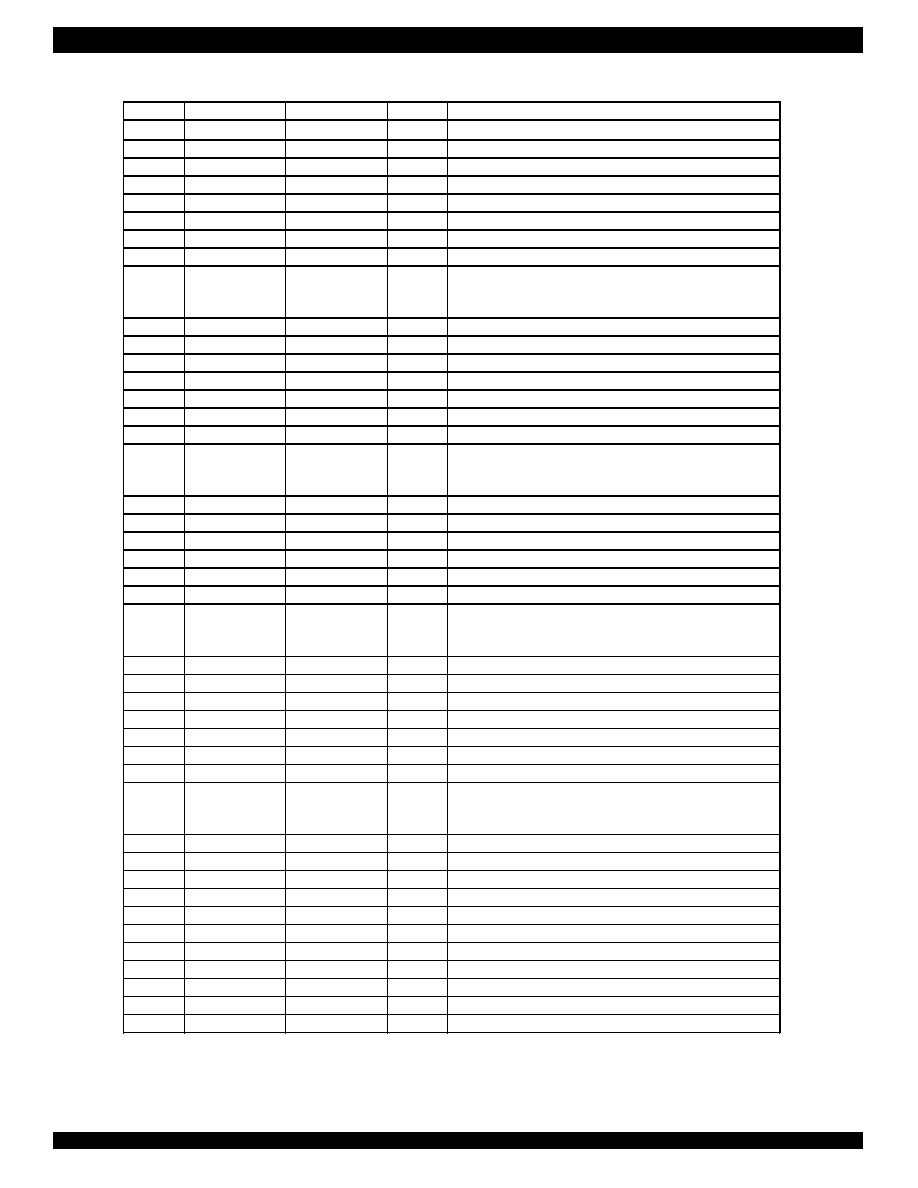

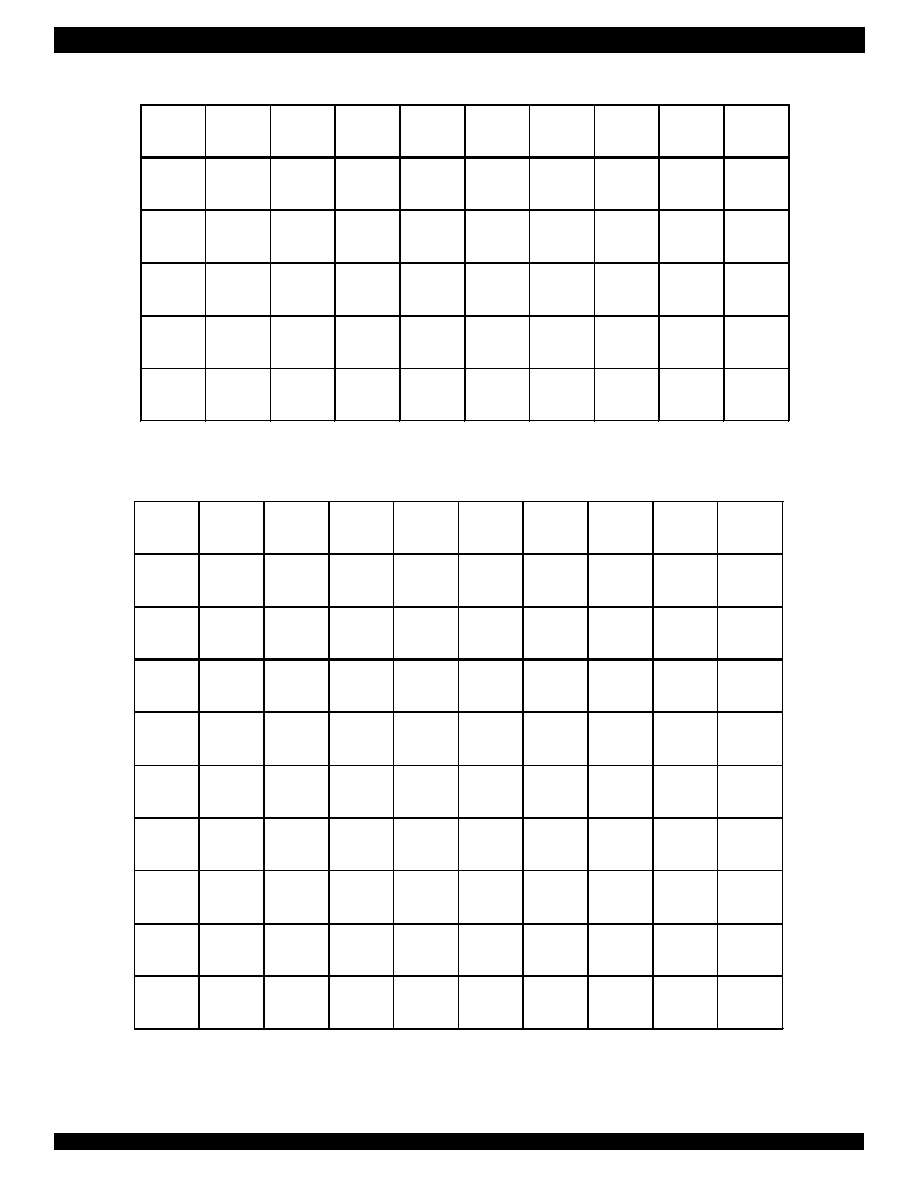

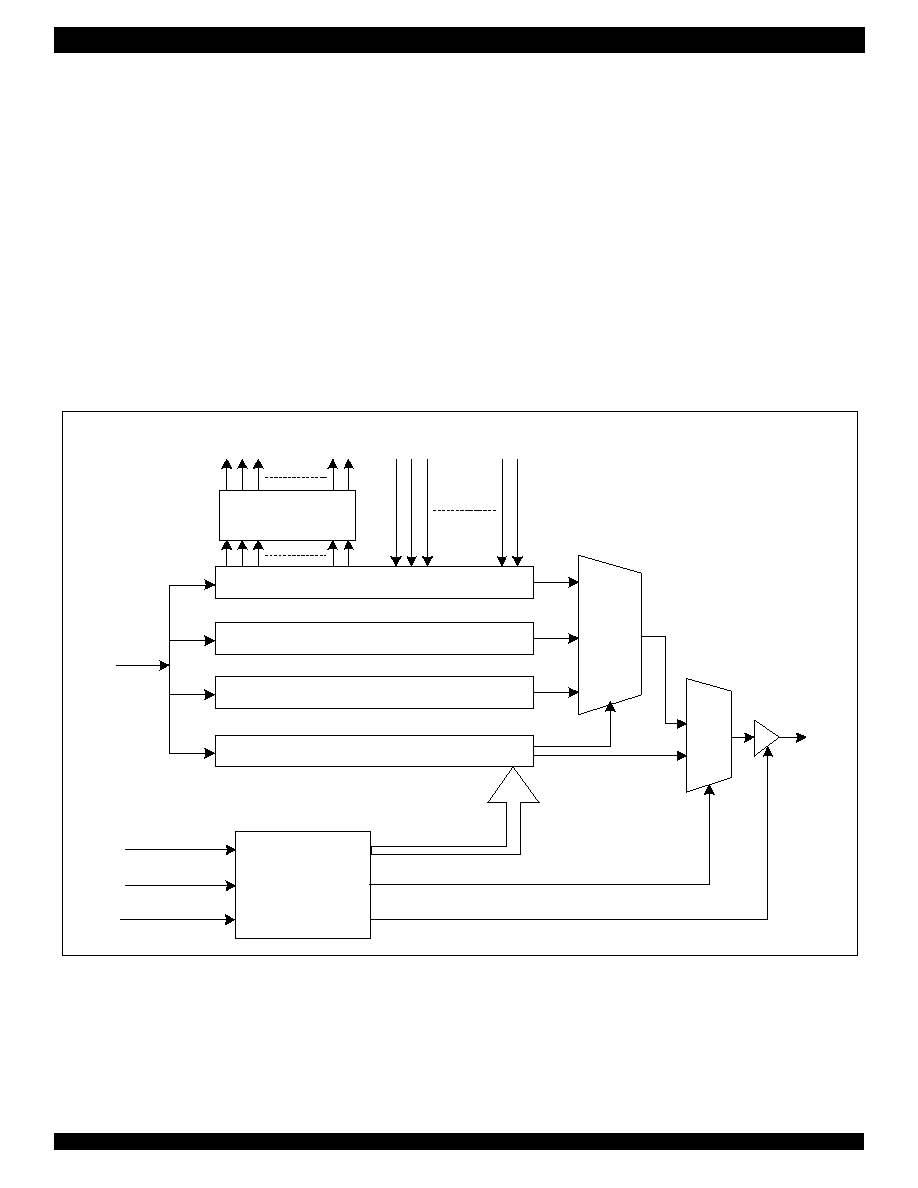

Figure - 2. TQFP144 Package Pin Assignment

DESCRIPTION:

The IDT82V2058 is a single chip, 8-channel E1 short haul PCM

transceiver with a reference clock of 2.048MHz. It contains 8 transmit-

ters and 8 receivers.

Both receivers and transmitters can be programmed to work either

in single rail mode or dual rail mode. AMI or HDB3 encoder/decoder

is selectable in single rail mode. Pre-encoded transmit data in NRZ

format can be accepted when the device is configured in dual rail

mode. The receivers perform clock and data recovery by using

integrated digital phase-locked loop. As an option, the raw sliced data

(no retiming) can be output on the receive data pins. Transmit

equalization is implemented with low-impedance output drivers that

provide shaped waveforms to the transformer, guaranteeing template

conformance.

A jitter attenuator is integrated in the IDT82V2058 and can be

switched into either the transmit path or the receive path. The jitter at-

PIN CONFIGURATIONS

tenuation performance meets ETSI CTR12/13, ITU G.736, G.742, and

G.823 specifications.

The IDT82V2058 offers hardware control mode and software con-

trol mode. Software control mode works with either serial host interface

or parallel host interface. The latter works via an Intel/Motorola com-

patible 8-bit parallel interface for both multiplexed or non-

multiplexed applications. Hardware control mode uses

multiplexed pins to select different operation mode when host in-

terface is not available to the device.

The IDT82V2058 also provides loopback testing functions and

JTAG boundary scan testing functions. As the monitoring function is

integrated, IDT82V2058 can be configured as a 7-channel transceiver

with non-intrusive protected monitoring points.

The IDT82V2058 can be used for SDH/SONET multiplexers, cen-

tral office or PBX, digital access cross connects, digital radio base sta-

tions, remote wireless modules and microwave transmission systems.

BPVI3/TDN3

RCLK3

RD3/RDP3

CV3/RDN3

LOS3

RTIP3

RRING3

VDDT3

TTIP3

TRING3

GNDT3

RRING2

RTIP2

GNDT2

TRING2

TTIP2

VDDT2

RTIP1

RRING1

VDDT1

TTIP1

TRING1

GNDT1

RRING0

RTIP0

GNDT0

TRING0

TTIP0

VDDT0

MODE1

LOS0

CV0/RDN0

RD0/RDP0

RCLK0

BPVI0/TDN0

TD0/TDP0

1 2 3 4

5 6 7 8 9 10

1

1 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

108 107 106 105

104 103 102 101 100 99

98 97 96 95 94 93

92 91 90 89 88

87 86 85 84 83 82

81 80 79 78 77 76

75 74 73

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

TD7/TDP7

TCLK7 LOS6

CV6/RDN6

RD6/RDP6

RCLK6

BPVI6/TDN6

TD6/TDP6

TCLK6 MCLK

MODE2

A4

MC3/A3 MC2/A2 MC1/A1 MC0/A0

VDDIO GNDIO VDDD GNDD

LP0/D0/AD0

LP1/D1/AD1 LP2/D2/AD2 LP3/D3/AD3 LP4/D4/AD4 LP5/D5/AD5 LP6/D6/AD6

LP7/D7/AD7

TCLK1

TD1/TDP1

BPVI1/TDN1

RCLK1

RD1/RDP1

CV1/RDN1

LOS1 TCLK0

TD4/TDP4 TCLK4 LOS5 CV5/RDN5

RD5/RDP5 RCLK5 BPVI5/TDN5 TD5/TDP5 TCLK5 TDI

TDO TCK TMS TRST IC IC

VDDIO GNDIO VDDA GNDA MODE0/CODE

CS

/JAS

SCLK/ALE/

AS

RD

/R/

W

SDI/

WR

/

DS

SDO/RDY/

ACK

INT

TCLK2 TD2/TDP2 BPVI2/TDN2 RCLK2 RD2/RDP2 CV2/RDN2

LOS2 TCLK3 TD3/TDP3

BPVI4/TDN4

RCLK4

RD4/RDP4

CV4/RDN4

LOS4

OE

CLKE

VDDT4

TTIP4

TRING4

GNDT4

RTIP4

RRING4

GNDT5

TRING5

TTIP5

VDDT5

RRING5

RTIP5

VDDT6

TTIP6

TRING6

GNDT6

RTIP6

RRING6

GNDT7

TRING7

TTIP7

VDDT7

RRING7

RTIP7

LOS7

CV7/RDN7

RD7/RDP7

RCLK7

BPVI7/TDN7

IDT

82V2058DA

3

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

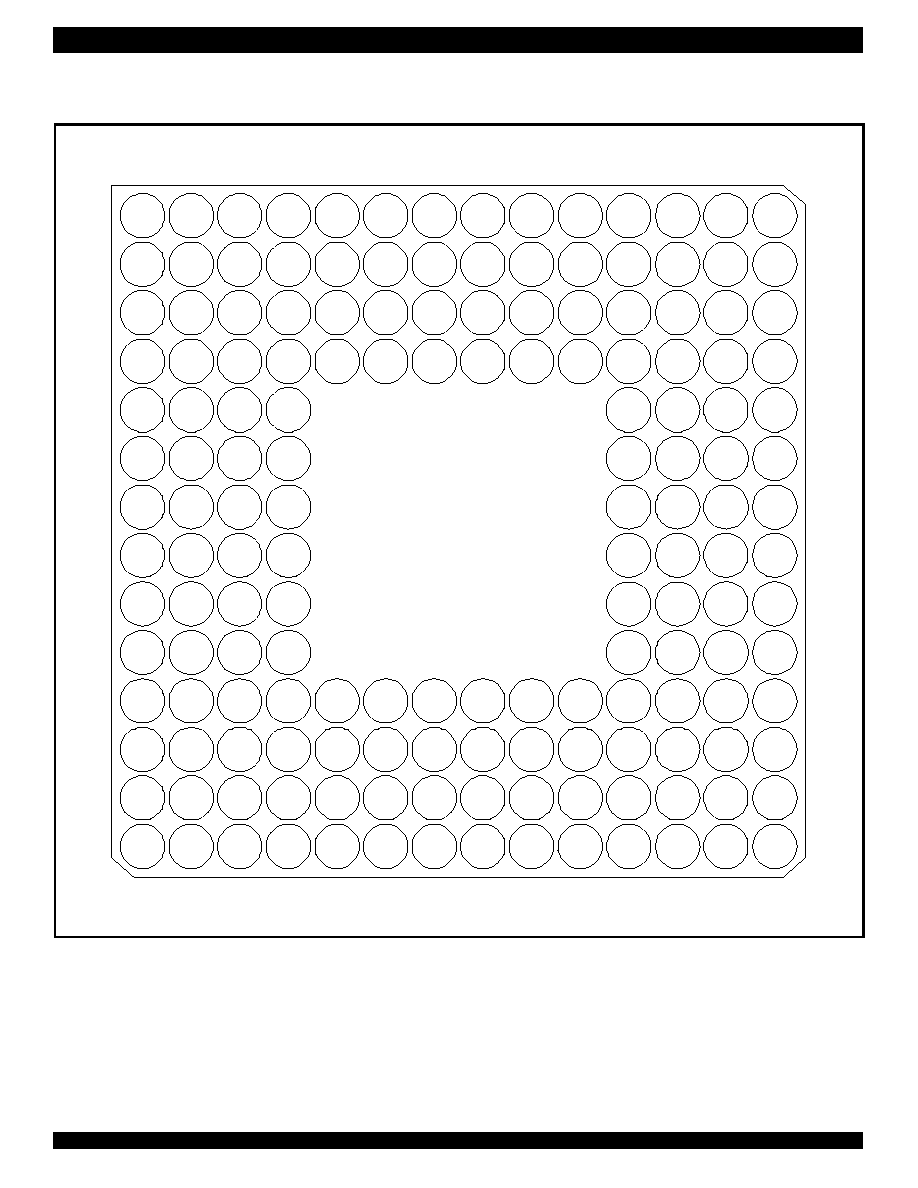

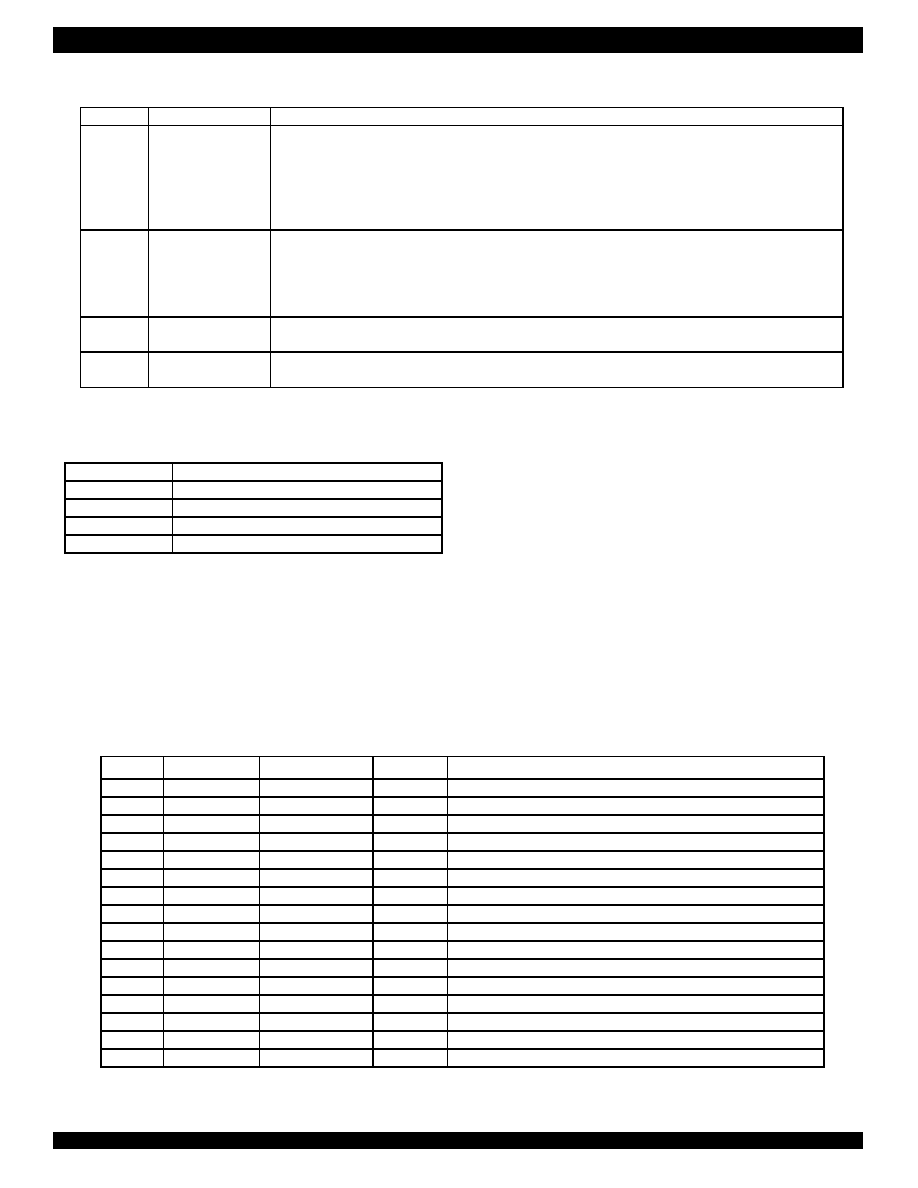

PIN CONFIGURATIONS (CONTINUED)

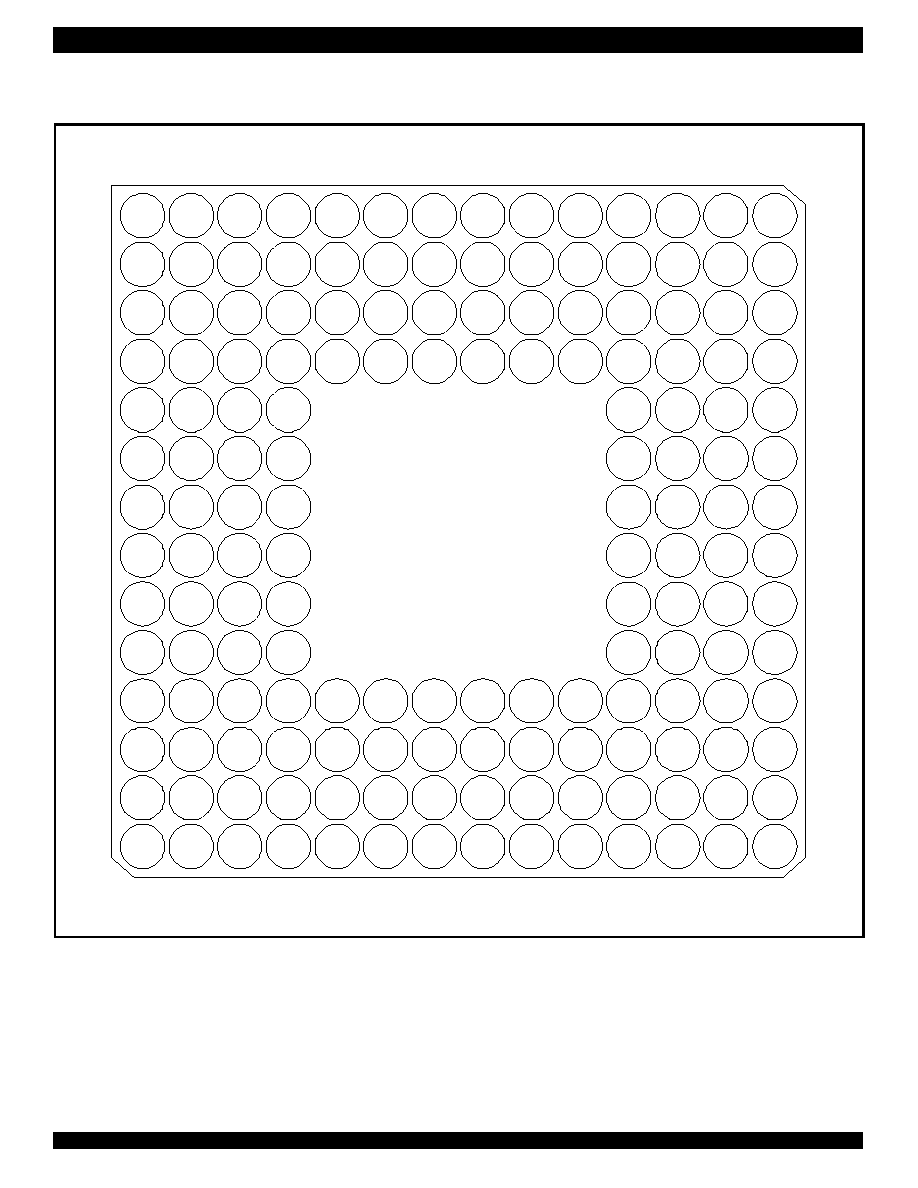

Figure - 2b. PBGA160 Package Pin Assignment

VDDT

4

TRING

4

GNDT

4

RTIP

4

RTIP

7

GNDT

7

TRING

7

VDDT

7

RDN

7

RCLK

4

RDP

4

RDN

4

RDP

7

RCLK

7

VDDT

5

TRING

5

GNDT

5

RTIP

5

RTIP

6

GNDT

6

VDDT

6

RDN

6

RCLK

5

RDP

5

RDN

5

RDP

6

RCLK

6

VDDT

5

TTIP

5

GNDT

5

RRING

5

RRING

6

GNDT

6

TTIP

6

VDDT

6

TDN

6

TCLK

5

TDP

5

TDN

5

TDP

6

TCLK

6

LOS

4

LOS

7

LOS

6

OE

CLKE

LOS

5

MODE

2

MCLK

TMS

A4

MC

3

TCK

TDO

TDI

MC

2

MC

1

GNDIO

GNDIO

MC

0

VDDIO

IC

TRST

LP

0

VDDIO

GNDA

GNDD

LP

1

VDDA

IC

MODE

0

LP

2

VDDD

CS

LP

3

LP

4

SDI

RD

SCLK

LP

5

LP

6

LOS

3

LOS

0

LOS

1

SDO

INT

LOS

2

MODE

1

LP

7

VDDT

2

TTIP

2

GNDT

2

RRING

2

RRING

1

GNDT

1

TTIP

1

VDDT

1

TDN

1

TCLK

2

TDP

2

TDN

2

TDP

1

TCLK

1

VDDT

2

TRING

2

GNDT

2

RTIP

2

RTIP

1

GNDT

1

TRING

1

VDDT

1

RDN

1

RCLK

2

RDP

2

RDN

2

RDP

1

RCLK

1

VDDT

3

TTIP

3

GNDT

3

RRING

0

GNDT

0

TTIP

0

VDDT

0

TDN

0

TCLK

3

TDP

3

TDN

3

TDP

0

TCLK

0

VDDT

3

TRING

3

GNDT

3

RTIP

3

RTIP

0

GNDT

0

TRING

0

VDDT

0

RDN

0

RCLK

3

RDP

3

RDN

3

RDP

0

RCLK

0

VDDT

7

TTIP

7

GNDT

7

RRING

7

RRING

4

GNDT

4

TTIP

4

VDDT

4

TDN

4

TCLK

7

TDP

7

TDN

7

TDP

4

TCLK

4

TRING

6

IDT82V2058

Bottom View

RRING

3

A B C D E F G H J K L M N P

A B C D E F G H J K L M N P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

4

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

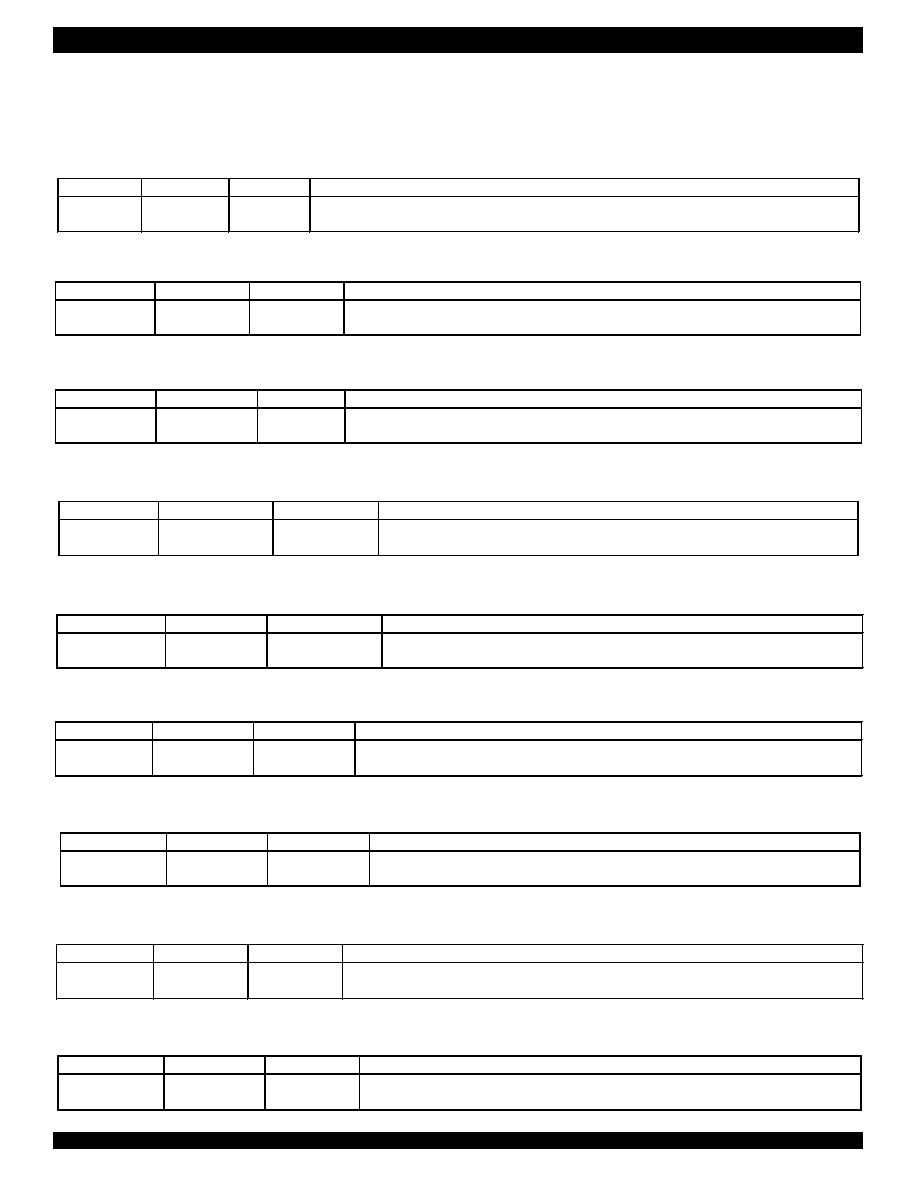

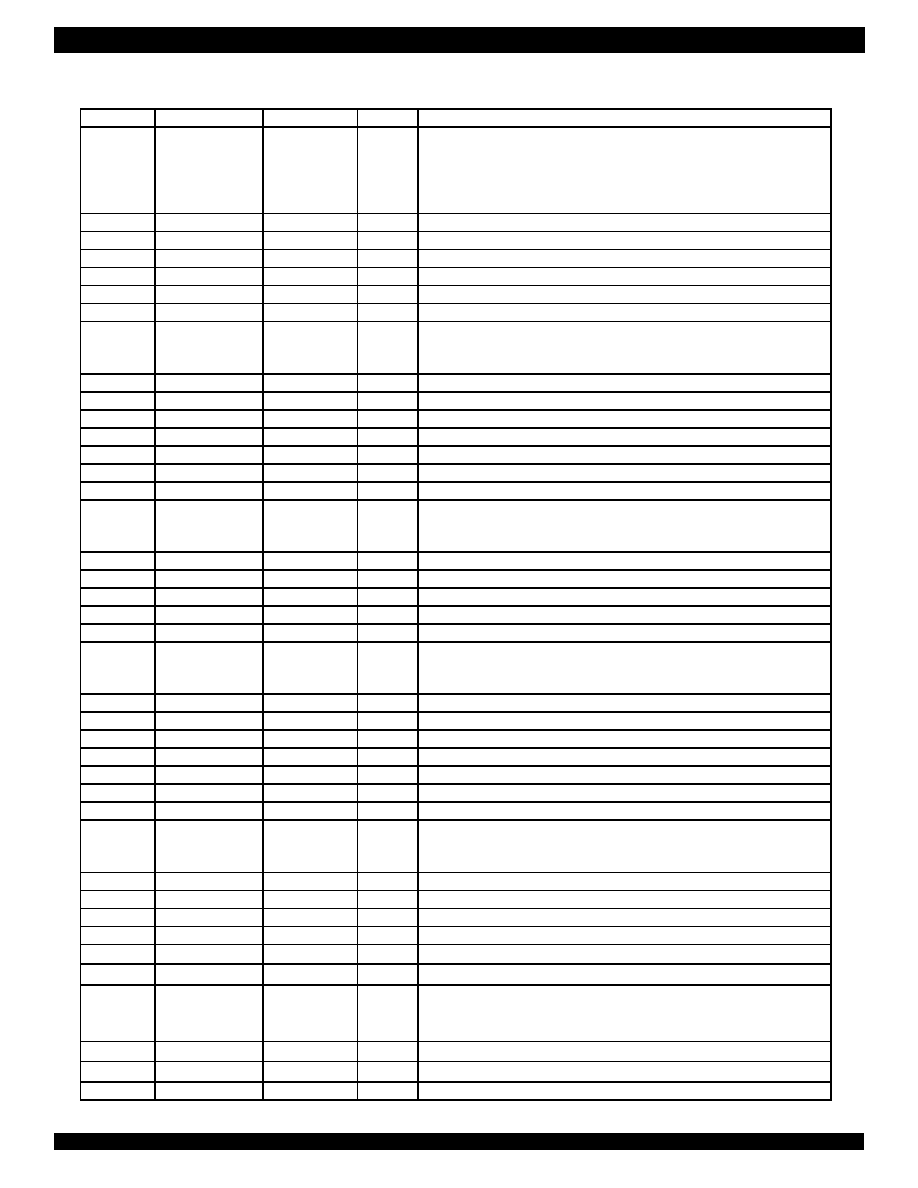

Pin No.

Name

Type

QFP144 BGA160

Description

Transmit and Receive Line Interface

TTIP0

TTIP1

TTIP2

TTIP3

TTIP4

TTIP5

TTIP6

TTIP7

TRING0

TRING1

TRING2

TRING3

TRING4

TRING5

TRING6

TRING7

Analog

Output

45

52

57

64

117

124

129

136

46

51

58

63

118

123

130

135

N5

L5

L10

N10

B10

D10

D5

B5

P5

M5

M10

P10

A10

C10

C5

A5

TTIPn/TRINGn: Transmit Bipolar Tip/Ring for Channel 0~7

These pins are the differential line driver outputs. They will be in high impedance state if pin OE

is low or the corresponding pin TCLKn is low (pin OE is globe control, while pin TCLKn is per-

channel control). In host mode, each pin can be in high impedance state by programming a "1" to

the corresponding bit in Register OE

1

.

RTIP0

RTIP1

RTIP2

RTIP3

RTIP4

RTIP5

RTIP6

RTIP7

RRING0

RRING1

RRING2

RRING3

RRING4

RRING5

RRING6

RRING7

Analog

Input

48

55

60

67

120

127

132

139

49

54

61

66

121

126

133

138

P7

M7

M8

P8

A8

C8

C7

A7

N7

L7

L8

N8

B8

D8

D7

B7

RTIPn/RRINGn: Receive Bipolar Tip/Ring for Channel 0~7

These pins are the differential line receiver inputs.

1

Register name is indicated by bold capital letter. OE: Output Enable Register.

PIN DESCRIPTION

5

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Pin No.

Name

Type

QFP144 BGA160

Description

TDn: Transmit Data for Channel 0~7

When the device is in Single Rail mode, the NRZ data to be transmitted is input on this pin. Data

on TDn is sampled into the device on falling edges of TCLKn, and encoded by AMI or HDB3 line

code rules before being transmitted to the line.

BPVIn: Bipolar Violation Insertion for Channel 0~7

Bipolar violation insertion is available in Signal Rail mode 2 (see table-1) with AMI enabled. A low-

to-high transition on this pin will make the next logic one to be transmitted on TDn pin the same

polarity as the previous pulse, and violate the AMI rule. This is for testing.

TDPn/TDNn: Positive/Negative Transmit Data for Channel 0~7

When the device is in Dual Rail mode, the NRZ data to be transmitted for positive/negative pulse

is input on this pin. Data on TDPn/TDNn are active high and sampled into the device on falling

edges of TCLKn. The line code in Dual Rail mode is as the follows :

TDPn

TDNn

Output Pulse

0

0

Space

0

1

Negative Pulse

1

0

Positive Pulse

1

1

Space

TD0/TDP0

TD1/TDP1

TD2/TDP2

TD3/TDP3

TD4/TDP4

TD5/TDP5

TD6/TDP6

TD7/TDP7

BPVI0/TDN0

BPVI1/TDN1

BPVI2/TDN2

BPVI3/TDN3

BPVI4/TDN4

BPVI5/TDN5

BPVI6/TDN6

BPVI7/TDN7

I

37

30

80

73

108

101

8

1

38

31

79

72

109

102

7

144

N2

L2

L13

N13

B13

D13

D2

B2

N3

L3

L12

N12

B12

D12

D3

B3

Pulling pin TDNn high for more than 16 consecutive TCLK clock cycles will configure the

corresponding channel into Single Rail mode 1 (see table-1 on Page13).

TCLKn: Transmit Clock for Channel 0~7

The clock of 2.048 MHz to be transmitted is input on this pin. The transmit data at TDn/TDPn or

TDNn is sampled into the device on falling edges of TCLKn.

Pulling TCLKn high for more than 16 MCLK cycles, the corresponding transmitter is set in

Transmit All One (TAO) state (when MCLK is clocked). In TAO state, the TAO generator adopts

MCLK as the time reference.

If TCLKn is Low, the corresponding transmit channel is set into power down state, while driver

output ports become high impedance.

The different operating modes of TCLKn are summarized as follows:

MCLK

TCLKn

Transmitter Mode

Clocked

Clocked

Normal operation

Clocked

High (

16 MCLK) Transmit All One (TAO) signals to line side in the

corresponding transmit channel.

Clocked

Low (

64 MCLK) Corresponding transmit channel is set into power down state.

TCLKn is clocked Normal operation

TCLKn is high

(

16 TCLK1)

Transmit All One (TAO) signals to the line

side in the corresponding transmit channel.

TCLKn is low

(

64 TCLK1)

Corresponding transmit channel is set into

power down state.

High/Low

TCLK1 is clocked

The receive path is not affected by the status of TCLK1.

When MCLK is high, all receive paths just slice the incoming

data stream. When MCLK is low, all the receive paths are

powered down.

TCLK0

TCLK1

TCLK2

TCLK3

TCLK4

TCLK5

TCLK6

TCLK7

I

36

29

81

74

107

100

9

2

N1

L1

L14

N14

B14

D14

D1

B1

High/Low

TCLK1 is not

available

(High/Low)

All eight transmitters (TTIPn & TRINGn) will be in high

impedance state.

PIN DESCRIPTION (CONTINUED)

6

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Pin No.

Name

Type

QFP144 BGA160

Description

RD0/RDP0

RD1/RDP1

RD2/RDP2

RD3/RDP3

RD4/RDP4

RD5/RDP5

RD6/RDP6

RD7/RDP7

CV0/RDN0

CV1/RDN1

CV2/RDN2

CV3/RDN3

CV4/RDN4

CV5/RDN5

CV6/RDN6

CV7/RDN7

O

Tri-state

40

33

77

70

111

104

5

142

41

34

76

69

112

105

4

141

P2

M2

M13

P13

A13

C13

C2

A2

P3

M3

M12

P12

A12

C12

C3

A3

RDn: Receive Data for Channel 0~7

In Single Rail mode, the received NRZ data is output on this pin. The data is decoded by AMI or HDB3

line code rule.

CVn: Code Violation for Channel 0~7

In Single Rail mode, the bipolar violation, code violation and excessive zeros will be reported by driving

pin CVn to high level for a full clock cycle. However, only bipolar violation is indicated when AMI

decoder is selected.

RDPn/RDNn: Positive/Negative Receive Data for Channel 0~7

In Dual Rail mode with clock recovery, these pins output the NRZ data. A high signal on RDPn

indicates the receipt of a positive pulse on RTIPn/RRINGn while a high signal on RDNn indicates the

receipt of a negative pulse on RTIPn/RRINGn.

The output data at RDn or RDPn/RDNn are valid on the falling edges of RCLK when the CLKE input is

in High level, or valid on the rising edges of RCLK when CLKE is Low.

In Dual Rail mode without clock recovery, these pins output the raw RZ sliced data. In this data

recovery mode, the active polarity of RDPn/RDNn is determined by pin CLKE. When pin CLKE is Low,

RDPn/RDNn is active low. When pin CLKE is High, RDPn/RDNn is active high.

In hardware mode, RDn or RDPn/RDNn will remain active during LOS. In host mode, these pins will

either remain active or insert alarm indication signal (AIS) into the receive path, determined by bit AISE

in register GCF (Global Configuration register).

RDn or RDPn/RDNn is set into high impedance when the corresponding receiver is power down.

RCLK0

RCLK1

RCLK2

RCLK3

RCLK4

RCLK5

RCLK6

RCLK7

O

Tri-state

39

32

78

71

110

103

6

143

P1

M1

M14

P14

A14

C14

C1

A1

RCLKn: Receive Clock for Channel 0~7

In clock recovery mode, this pin outputs the recovered clock from signal received on RTIPn/RRINGn.

The received data are clocked out of the device on rising edges of RCLKn if pin CLKE is low, or on

falling edges of RCLKn if pin CLKE is high.

In data recovery mode, RCLKn is the output of an internal exclusive OR (XOR) which is connected with

RDPn and RDNn. The clock is recovered from the signal on RCLKn externally.

If receiver n is power down, the corresponding RCLKn is in high impedance.

MCLK

I

10

E1

MCLK: Master Clock

This is the independent, free running reference clock. A clock of 2.048 MHz is supplied to this pin as

the clock reference of the device for normal operation.

In receive path, when MCLK is high, the device slices the incoming bipolar line signal into RZ pulse

(Data Recovery mode). When MCLK is low, all the receivers are power down, and the output pins

RCLKn, RDPn and RDNn are switched to high impedance.

In transmit path, the operation mode is decided by the combination of MCLK and TCLKn (see TCLKn

pin description for detail).

Note that wait state generation via RDY/ACK is not available if MCLK is not provided.

LOS0

LOS1

LOS2

LOS3

LOS4

LOS5

LOS6

LOS7

O

42

35

75

68

113

106

3

140

K4

K3

K12

K11

E11

E12

E3

E4

LOSn: Loss of Signal Output for Channel 0~7

A high level on this pin indicates the loss of signal when there is no transition over a specified period of

time or hasn't enough ones density in the received signal. The transition will return to low automatically

when there is enough transitions over a specified period of time with a certain ones density in the

received signal. The LOS assertion and desertion criteria are described in the

Functional Description.

PIN DESCRIPTION (CONTINUED)

7

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Pin No.

Name

Type

QFP144 BGA160

Description

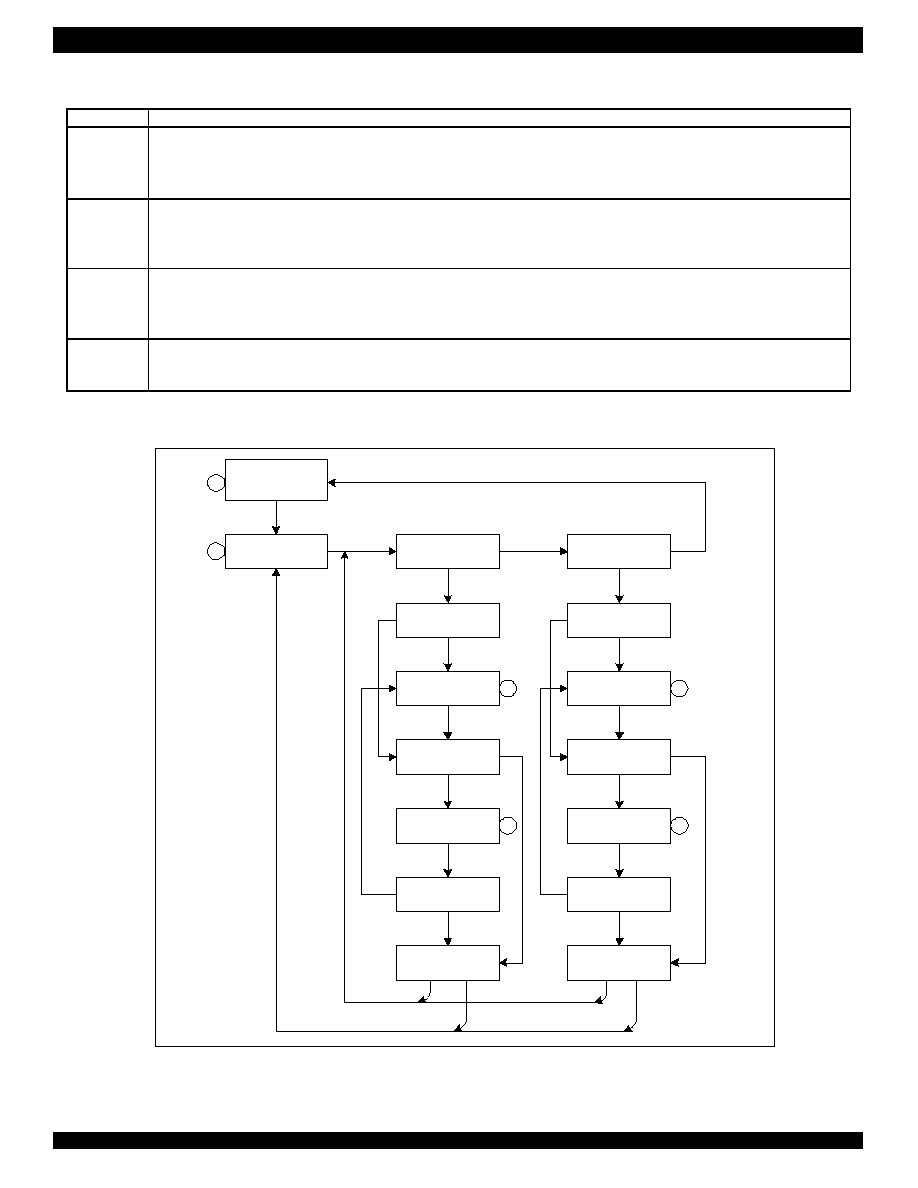

Hardware/Host Control Mode

MODE2: Control Mode Select 2

The signal on this pin determines which control mode is selected to control the device:

MODE2

Control Interface

Low

Control by Hardware mode

VDDIO/2

Control by Serial Host Interface

High

Control by Parallel Host Interface

Hardware control pins include MODE[2:0], TS[2:0], LOOP[7:0], CODE, CLKE, JAS and OE.

Serial host Interface pins include CS, SCLK, SDI, SDO and INT.

Parallel host Interface pins include CS, A[4:0], D[7:0], WR/DS, RD/R/W, ALE/AS, INT and RDY/ACK. The

device supports multiple parallel host interface as follows (refer to MODE1 and MODE0 pin descriptions

below for details):

MODE[2:0]

Host Interface

100

Non-multiplexed Motorola mode interface.

101

Non-multiplexed Intel mode interface.

110

Multiplexed Motorola mode interface.

MODE2

I

(Pulled

to

VDDIO

/2)

11

E2

111

Multiplexed Intel mode interface.

MODE1

I

43

K2

MODE1: Control Mode Select 1

In parallel host mode, the parallel interface operates with separate address bus and data bus when this

pin is Low, and operates with multiplexed address and data bus when this pin is High.

In serial host mode and hardware mode, this pin should be grounded.

MODE0

/CODE

I

88

H12 MODE0: Control Mode Select 0

In host mode, the parallel host interface is configured for Motorola compatible hosts when this pin is Low,

or for Intel compatible hosts when this pin is High.

CODE: Line Code Rule Select

In hardware control mode, the HDB3 encoder/decoder is enabled when this pin is Low, and AMI

encoder/decoder is enabled when this pin is High. The selections affect all the channels.

In serial host mode, this pin should be grounded.

CS: Chip Select (Active Low)

In host mode, this pin is asserted low by the host to enable host interface. A transition from High to Low

must occur on this pin for each Read/Write operation and the level must not return to High until the

operation is over.

JAS: Jitter Attenuator Select

In hardware control mode, this pin globally determines the Jitter Attenuator position:

JAS

Jitter Attenuator (JA) Configuration

Low

JA in transmit path

VDDIO/2

JA not used

CS/JAS

I

(Pulled

to

VDDIO

/2)

87

J11

High

JA in receive path

PIN DESCRIPTION (CONTINUED)

8

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Pin No.

Name

Type

QFP144 BGA160

Description

SCLK

/ALE

/AS

I

86

J12 SCLK: Shift Clock

In serial host mode, the signal on this pin is the shift clock for the serial interface. Data on pin SDO is

clocked out on falling edges of SCLK if pin CLKE is Low, or on rising edges of SCLK if pin CLKE is

High. Data on pin SDI is always sampled on rising edges of SCLK.

ALE: Address Latch Enable

In parallel Intel multiplexed host mode, the address on AD[4:0] is sampled into the device on falling

edges of ALE (Signals on AD[7:5] are ignored). In non-multiplexed host mode, ALE should be pulled

High.

AS: Address Strobe (Active Low)

In parallel Motorola multiplexed host mode, the address on AD[4:0] is latched into the device on falling

edges of AS (Signals on AD[7:5] are ignored). In non-multiplexed host mode, AS should be pulled

High.

(Note: This pin is ignored in hardware control mode.)

RD/R/W

I

85

J13 RD: Read Strobe (Active Low)

In parallel Intel multiplexed or non-multiplexed host mode, this pin is active low for read operation.

R/W: Read/Write Select

In parallel Motorola multiplexed or non-multiplexed host mode, the pin is active low for write operation

and high for read operation.

(Note: This pin is ignored in hardware control mode)

SDI

/WR

/DS

I

84

J14 SDI: Serial Data Input

In serial host mode, this pin input the data to the serial interface. Data on this pin is sampled on rising

edges of SCLK.

WR: Write Strobe (Active Low)

In parallel Intel host mode, this pin is active low during write operation. The data on D[7:0] (in non-

multiplexed mode) or AD[7:0] (in multiplexed mode) is sampled into the device on rising edges of WR.

DS: Data Strobe (Active Low)

In parallel Motorola host mode, this pin is active low. During a write operation (R/W = 0), the data on

D[7:0] (in non-multiplexed mode) or AD[7:0] (in multiplexed mode) is sampled into the device on rising

edges of DS. During a read operation (R/W=1), the data is driven to D[7:0] (in non-multiplexed mode)

or AD[7:0] (in multiplexed mode) by the device on rising edges of DS.

In parallel Motorola non-multiplexed host mode, the address information on the 5 bits of address bus

A[4:0] are latched into the device on the falling edge of DS.

(Note: This pin is ignored in hardware control mode)

SDO

/RDY

/ACK

O

83

K14 SDO: Serial Data Output

In serial host mode, the data is output on this pin. In serial write operation, SDO is always in High

impedance. In serial read operation, SDO is in High impedance only when SDI is in

address/command byte. Data on pin SDO is clocked out of the device on falling edges of SCLK if pin

CLKE is Low, or on rising edges of SCLK if pin CLKE is High.

RDY: Ready Output

In parallel Intel host mode, the high level of this pin reports to the host that bus cycle can be

completed, while low reports the host must insert wait states.

ACK: Acknowledge Output (Active Low)

In parallel Motorola host mode, the low level of this pin indicates that valid information on the data bus

is ready for a read operation or acknowledges the acceptance of the written data during a write

operation.

PIN DESCRIPTION (CONTINUED)

9

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

PIN DESCRIPTION (CONTINUED)

Name

Type Pin No. Description

QFP144 BGA160

INT

O

82

K13

INT: Interrupt (Active Low)

Open

This is the open drain, active low interrupt output. Four sources may cause the interrupt (refer

Drain

to

Interrupt Handling of Functional Description for details).

LP7/D7/AD7

I/O

28

K1

LPn: Loopback Select 7~0

LP6/D6/AD6

27

J1

In hardware control mode, pin LPn configures the corresponding channel in different loopback

LP5/D5/AD5 Tri-State

26

J2

mode, as follows:

LP4/D4/AD4

25

J3

LPn Loopback Configuration

LP3/D3/AD3

24

J4

Low Remote Loopback

LP2/D2/AD2

23

H2

VDDIO/2 No Loopback

LP1/D1/AD1

22

H3

High Analog Loopback

LP0/D0/AD0

21

G2

Refer to

Loopback Configuration of Functional Description for details.

Dn: Data Bus 7~0

In non-multiplexed host mode, these pins are the bi-directional data bus.

ADn: Address/Data Bus 7~0

In multiplexed host mode, these pins are the multiplexed bi-directional address/data bus.

In serial host mode, these pins should be grounded.

A4

I

12

F4

MCn: Performance Monitor Configuration 4~0

MC3/A3

13

F3

In hardware control mode, A4 must be connected to GND. MC[3:0] are used to select one

MC2/A2

14

F2

transmitter or receiver of the channel 1 to 7 for non-intrusive monitoring. Channel 0 is used as

MC1/A1

15

F1

the monitoring channel. If a transmitter is monitored, signals on the corresponding pins TTIPn

MC0/A0

16

G3

and TRINGn are internally transmitted to RTIP0 and RRING0. If a receiver is monitored, signals

on the corresponding pins RTIPn and RRINGn are internally transmitted to RTIP0 and RRING0.

The clock and data recovery circuit in receiver 0 can then output the monitored clock to pin

RCLK0 as well as the monitored data to RDP0 and RDN0 pins. The signals monitored by cha-

nnel 0 can be routed to TTIP0/TRING0 by activating the remote loopback in this channel.

Performance Monitor Configuration determined by MC[3:0] is shown below. Note that if MC[2:0]

= 000, the device is in normal operation of all the channels.

MC[3:0] Monitoring Configuration

0000 Normal operation without monitoring

0001 Monitoring receiver 1

0010 Monitoring receiver 2

0011 Monitoring receiver 3

0100 Monitoring receiver 4

0101 Monitoring receiver 5

0110 Monitoring receiver 6

0111 Monitoring receiver 7

1000 Normal operation without monitoring

1001 Monitoring transmitter 1

1010 Monitoring transmitter 2

1011 Monitoring transmitter 3

1100 Monitoring transmitter 4

1101 Monitoring transmitter 5

1110 Monitoring transmitter 6

1111 Monitoring transmitter 7

An: Address Bus 4~0

When pin MODE1 is low, the parallel host interface operates with separate address and data

bus. In this mode, the signal on this pin is the address bus of the host interface.

10

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Pin No.

Name

Type

QFP144 BGA160

Description

OE

I

114

E14

OE: Output Driver Enable

Pulling this pin to low can make all driver output into high impedance state immediately for redundancy

application without external mechanical relays. In this condition, all the other internal circuits remain

active.

CLKE

I

115

E13

CLKE: Clock Edge Select

The signal on this pin determins the active edge of RCLKn and SCLK in clock recovery mode, or

determines the active level of RDPn and RDNn in the data recovery mode. (Refer to

Functional

Description and Table-2).

JTAG Signals

TRST

I

Pull up

95

G12

TRST: JTAG Test Port Reset (Active Low)

This is the active low asynchronous reset to the JTAG Test Port. This pin has an internal pullup resistor

and it can be left disconnected.

TMS

I

Pull up

96

F11

TMS: JTAG Test Mode Select

The signal on this pin controls the JTAG test performance and is clocked into the device on rising edges

of TCK. This pin has an internal pullup resistor and it can be left disconnected.

TCK

I

97

F14

TCK: JTAG Test Clock

This pin input the clock of the JTAG Test. The data on TDI and TMS are clocked into the device on rising

edges of TCK, while the data on TDO is clocked out of the device on falling edges of TCK.

TDO

O

Tri-state

98

F13

TDO: JTAG Test Data Output

This pin output the serial data of the JTAG Test. The data on TDO is clocked out of the device on falling

edges of TCK. TDO is a Tri-state output signal. It is active only when scanning of data is out.

TDI

I

Pull up

99

F12

TDI: JTAG Test Data Input

This pin input the serial data of the JTAG Test. The data on TDI is clocked into the device on rising edges

of TCK. This pin has an internal pullup resistor and it can be left disconnected.

IC

-

93

G13

IC: Internal Connected

(Leave it open for normal operation.)

IC

-

94

H13

IC: Internal Connected

(Leave it open for normal operation.)

Supplies and Grounds

VDDIO

-

17

92

G1

G14

3.3V I/O Power Supply

GNDIO

-

18

91

G4

G11

I/O GND

VDDT0

VDDT1

VDDT2

VDDT3

VDDT4

VDDT5

VDDT6

VDDT7

-

44

53

56

65

116

125

128

137

N4,P4

L4,M4

L11,M11

N11,P11

A11,B11

C11,D11

C4,D4

A4,B4

3.3V / 5V Power Supply for Transmitter Driver

All VDDT pins must be connected to either 3.3V or 5V. It is not allowed to leave any of the VDDT pins

open (not-connected) even if the channel is not used.

GNDT0

GNDT1

GNDT2

GNDT3

GNDT4

GNDT5

GNDT6

GNDT7

-

47

50

59

62

119

122

131

134

N6,P6

L6,M6

L9,M9

N9,P9

A9,B9

C9,D9

C6,D6

A6,B6

Analog GND for Transmitter Driver

VDDD

VDDA

-

19

90

H1

H14

3.3V Digital / Analog Core Power Supply

GNDD

GNDA

-

20

89

H4

H11

Digital / Analog Core GND

PIN DESCRIPTION (CONTINUED)

11

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

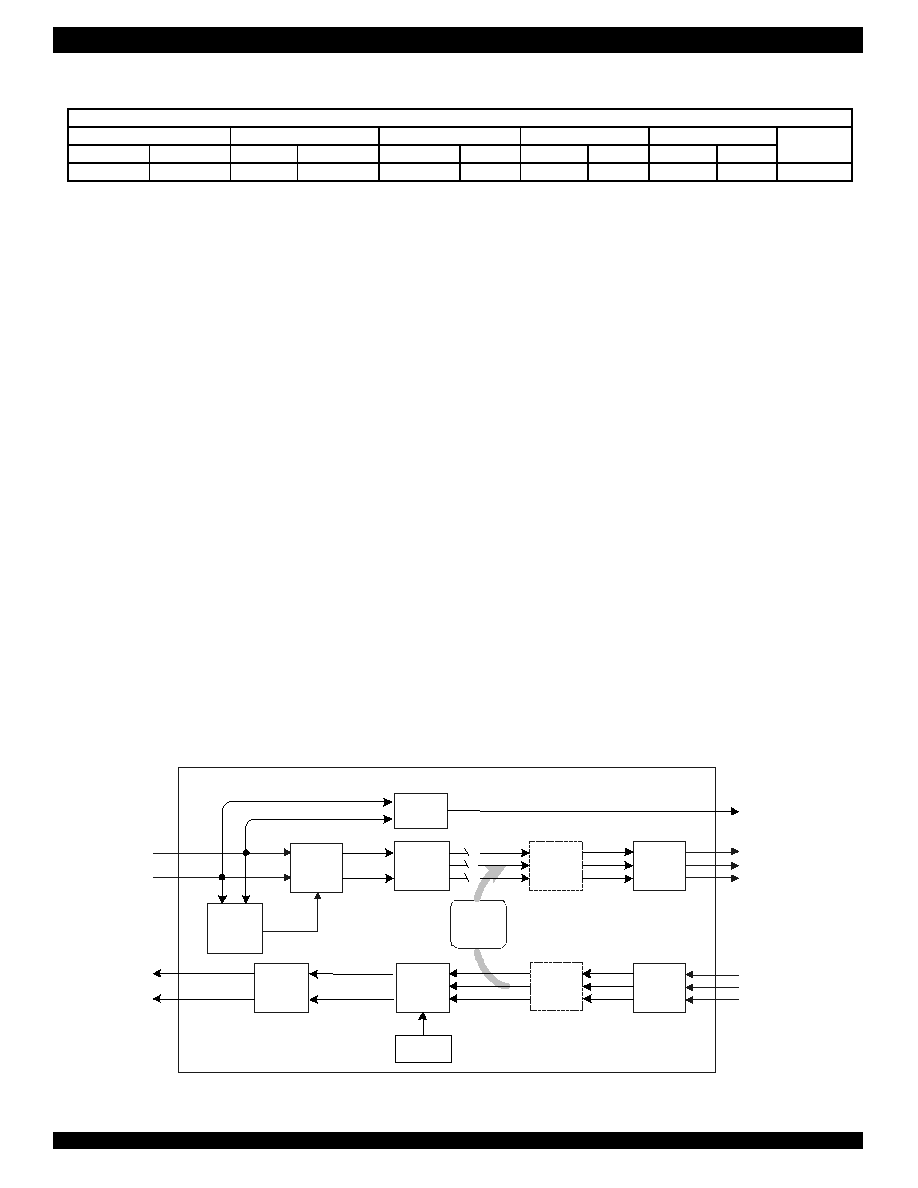

FUNCTIONAL DESCRIPTION

OVERVIEW

The IDT82V2058 is a fully integrated octal short-haul line interface

unit, which contains eight transmit and receive channels for use in E1

applications. The receiver performs clock and data recovery. As an

option, the raw sliced data (no retiming) can be output to the system.

Transmit equalization is implemented with low-impedance output driv-

ers that provide shaped waveforms to the transformer, guaranteeing

template conformance. A selectable jitter attenuation may be placed in

the receive path or the transmit path. Moreover, multiple testing func-

tions, such as error detection, loopback and JTAG boundary scan are

also provided. The device is optimized for flexible software control

through a serial or parallel host mode interface. Hardware control is

also available. Figure-1 shows One of the Eight Identical Channels

operation.

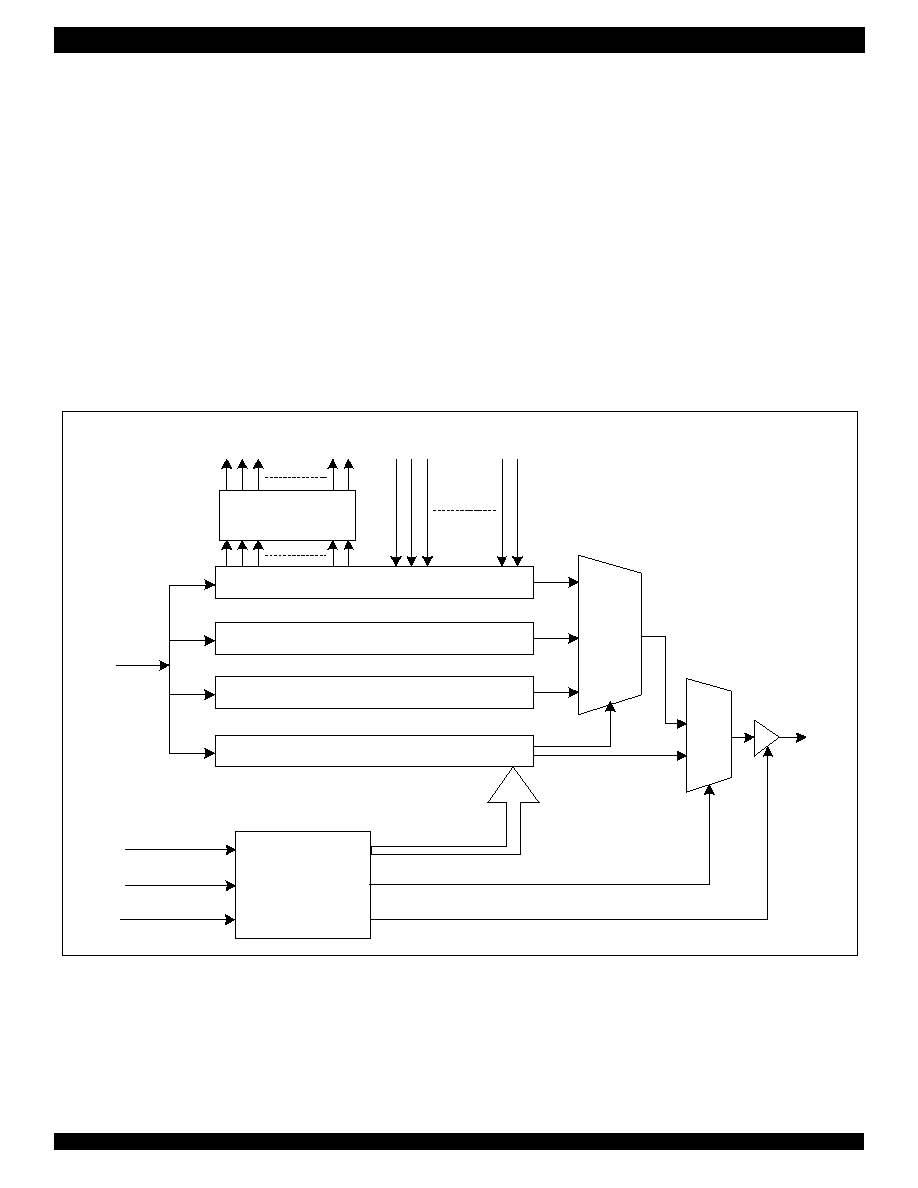

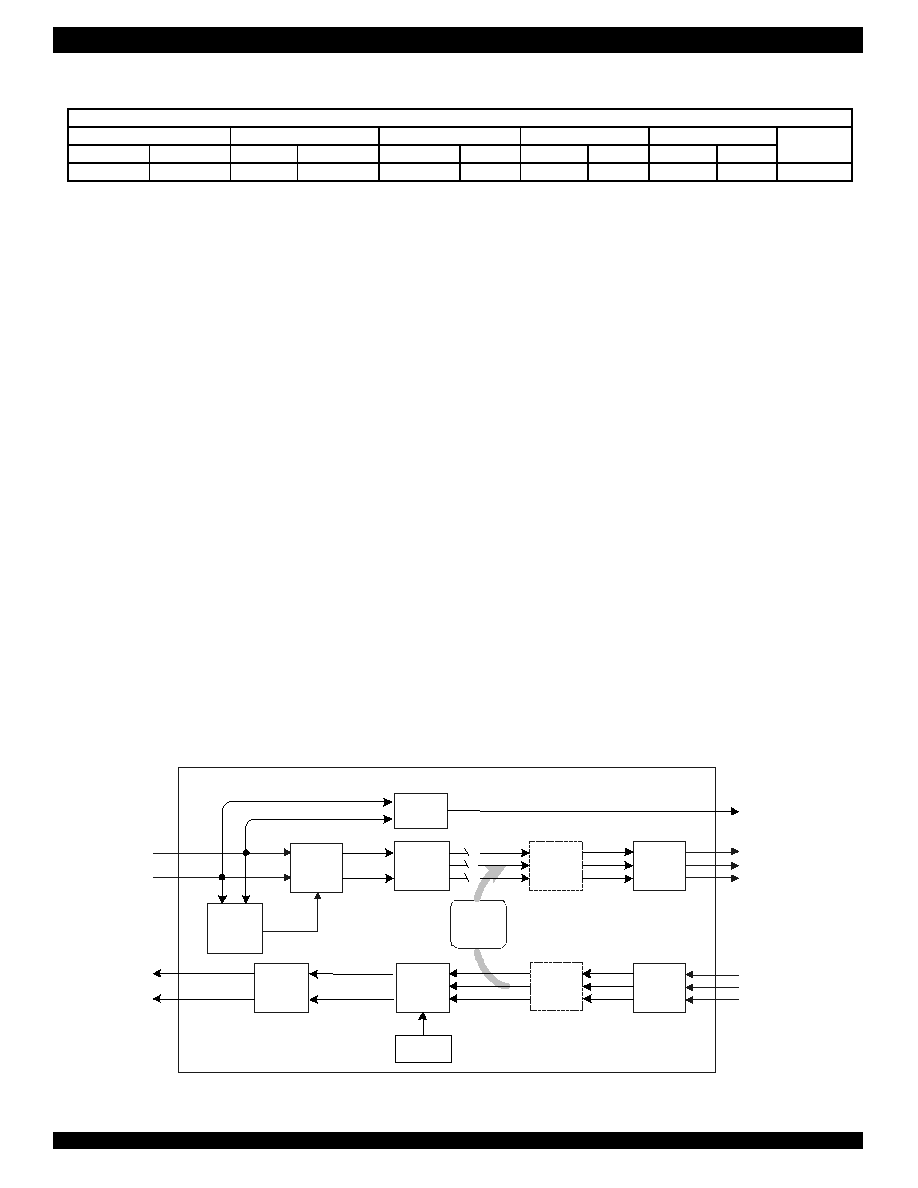

SYSTEM INTERFACE

The system interface of each channel can be configured to

operate in different modes:

1. Single Rail interface with clock recovery.

2. Dual Rail interface with clock recovery.

3. Dual Rail interface with data recovery (that is, with raw data slic-

ing only and without clock recovery).

Therefore, each signal pin on system side has multiple functions

depending on which operation mode the device is in.

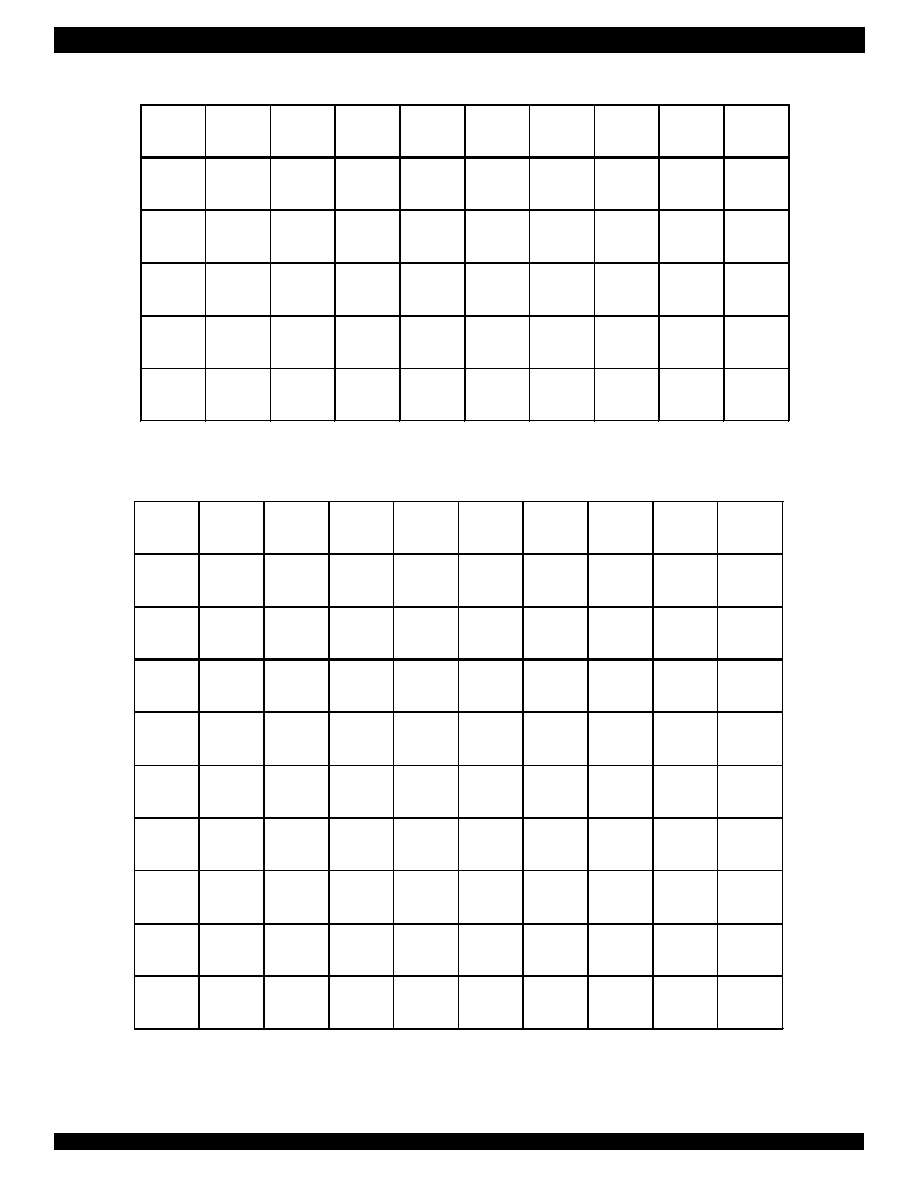

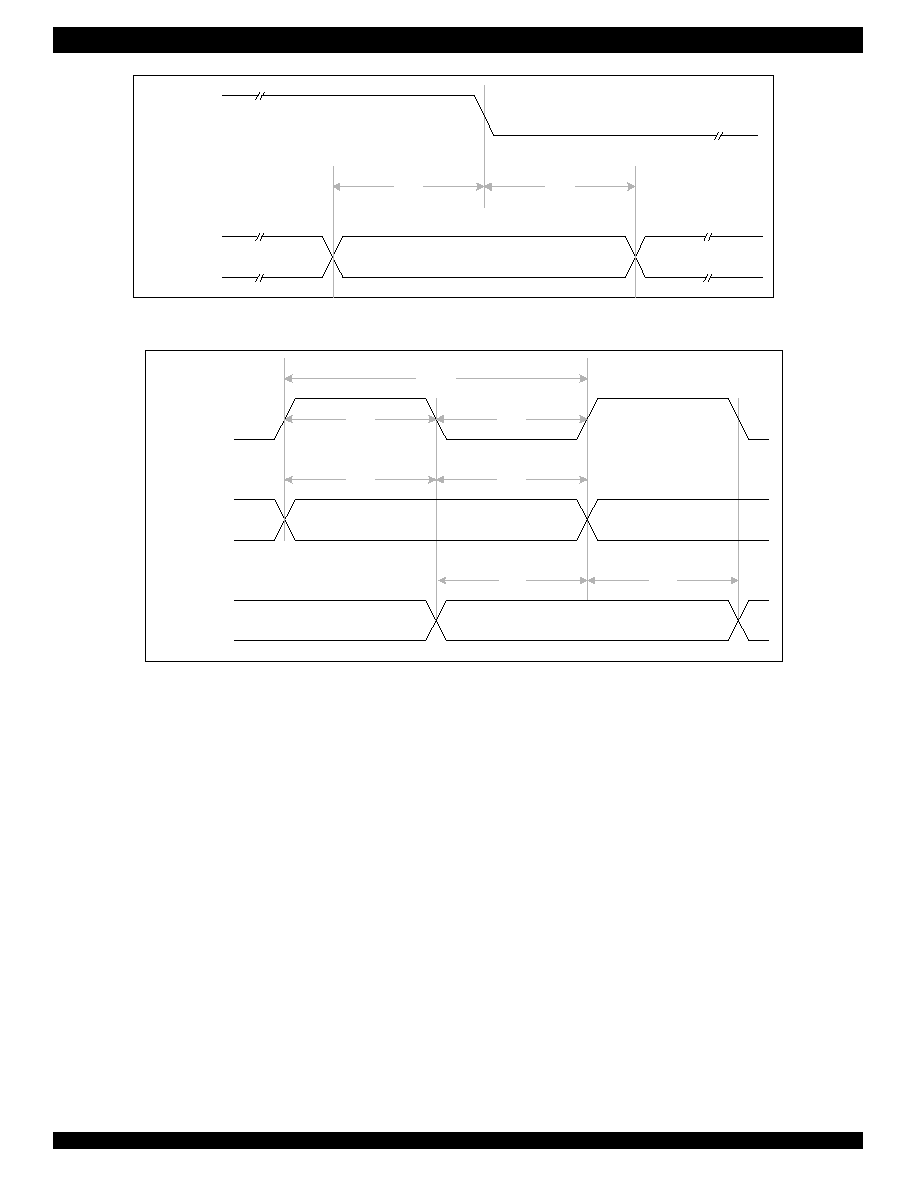

Dual Rail interface consists of TDPn

1

, TDNn, TCLKn, RDPn, RDNn

and RCLKn. Data transmitted from TDPn and TDNn appears on

TTIPn and TRINGn at the line interface; data received from the RTIPn

and RRINGn at the line interface are transferred to RDPn and RDNn

while the recovered clock extracting from the received data stream

outputs on RCLKn. In Dual Rail operation, the clock/data recovery

mode is selectable. Dual Rail interface with clock recovery shown in

Figure-3 is a default configuration mode. Dual Rail interface with data

recovery is shown in Figure-4. Pin RDPn and RDNn, in this condition,

NOTE:

1. The footprint `n' (n = 0 - 7) indicates one of the eight channels

2. The first letter "e-"indicates expanded register.

3. The grey blocks are bypassed and the dotted blocks are selectable

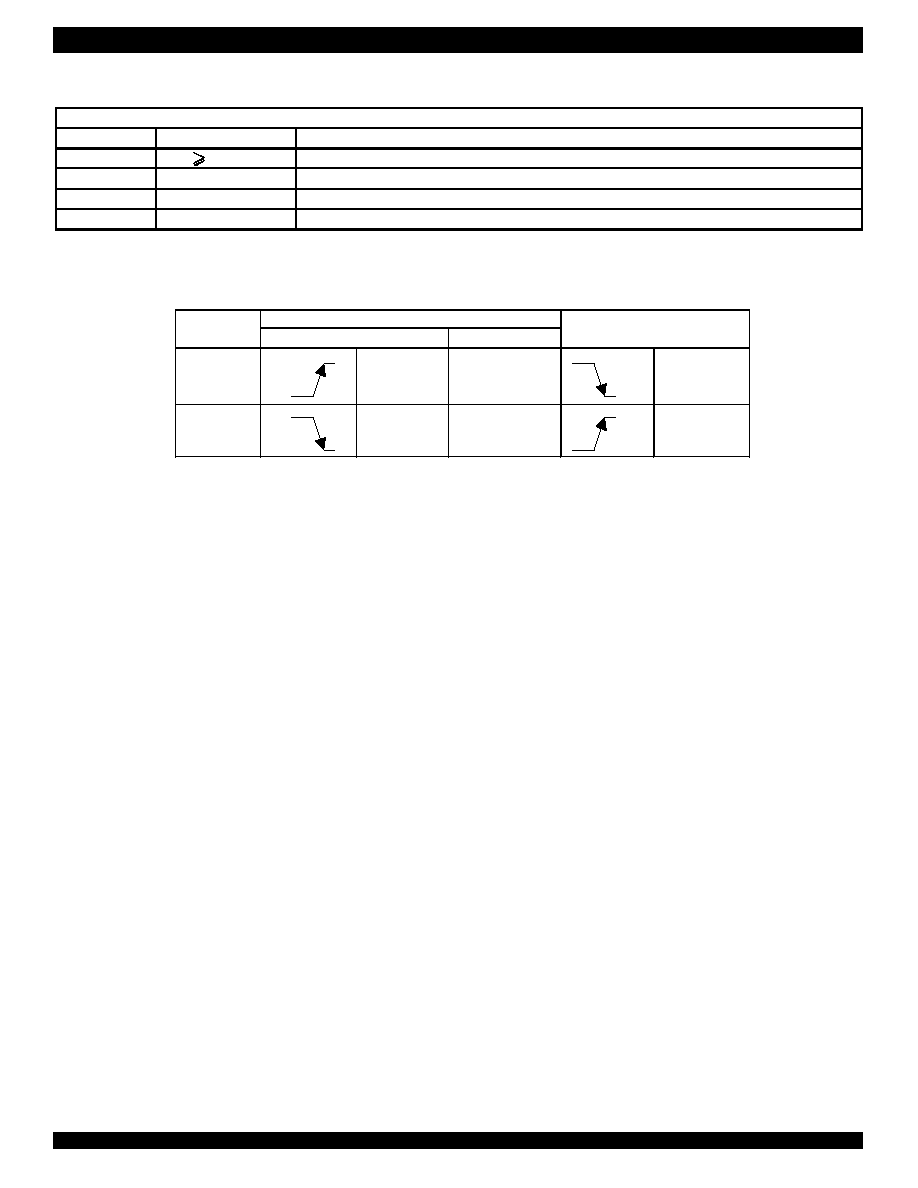

Figure - 3. Dual Rail Interface with Clock Recovery

3

Jitter

Attenuator

Jitter

Attenuator

HDB3/

AMI

Decoder

HDB3/

AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDPn

RDNn

TCLKn

TDNn

TDPn

Transmit

All Ones

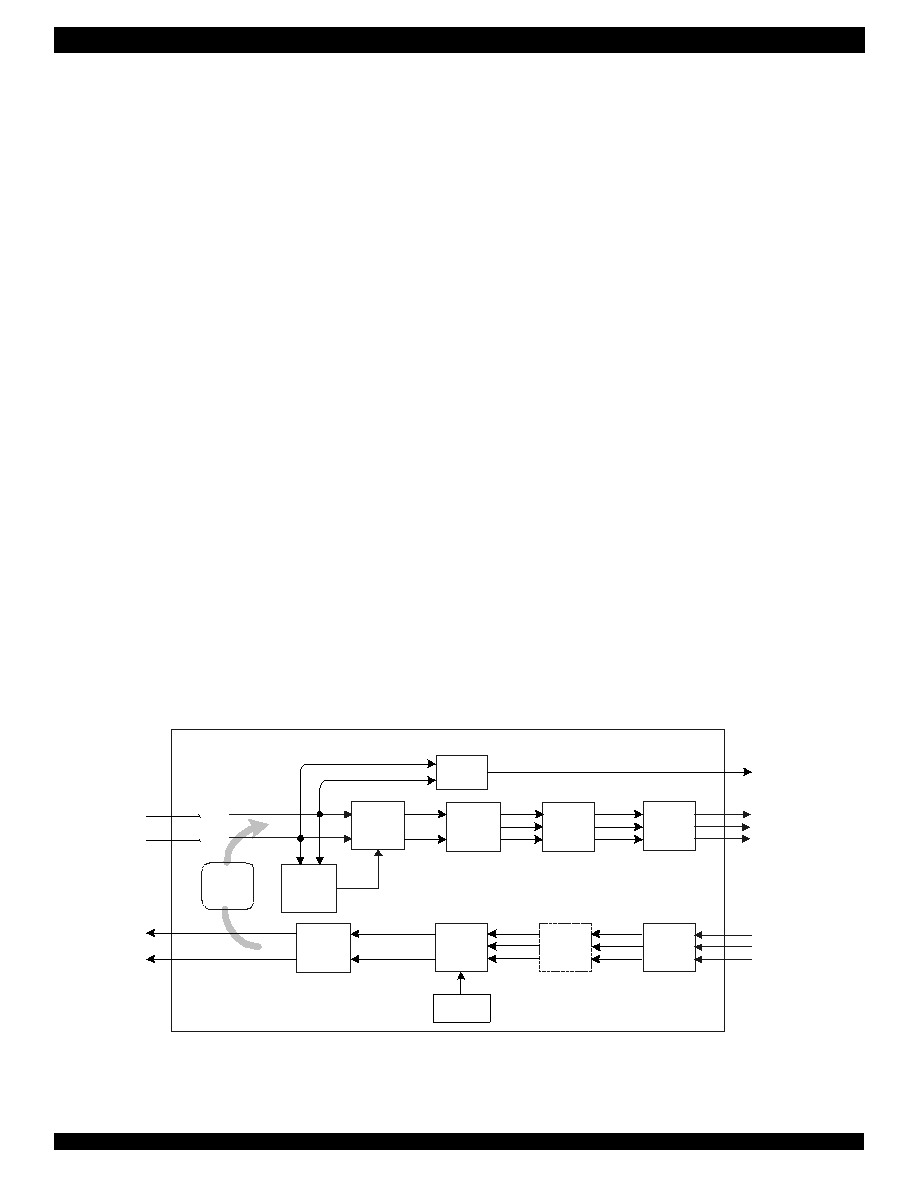

are raw RZ slice output and internally connected to an EXOR which is

fed to the RCLKn output for external clock recovery applications.

In Single Rail mode, data transmitted from TDn appears on TTIPn

and TRINGn at the line interface. Data received from the RTIPn and

RRINGn at the line interface appears on RDn while the recovered

clock extracting from the received data stream outputs on RCLKn.

When the device is in Single Rail interface, the selectable AMI or

HDB3 line encoder/decoder is available and any code violation in the

received data will be indicated at the CVn pin. The Single Rail mode

can be divided into 2 sub-modes. Single Rail mode1, whose interface

is composed of TDn, TCLKn, RDn, CVn and RCLKn, is realized by

pulling pin TDNn to high for more than 16 consecutive TCLK cycles.

Single Rail mode 2, whose interface is composed of TDn, TCLKn,

RDn, CVn, RCLKn and BPVIn, is realized by setting bit CRS in e-

CRS

2

and bit SING in e-SING. The difference between them is that, in

the latter mode bipolar violation can be inserted via pin BPVIn if AMI

line code is selected.

The configuration of different system interface is summarized in

Table-1.

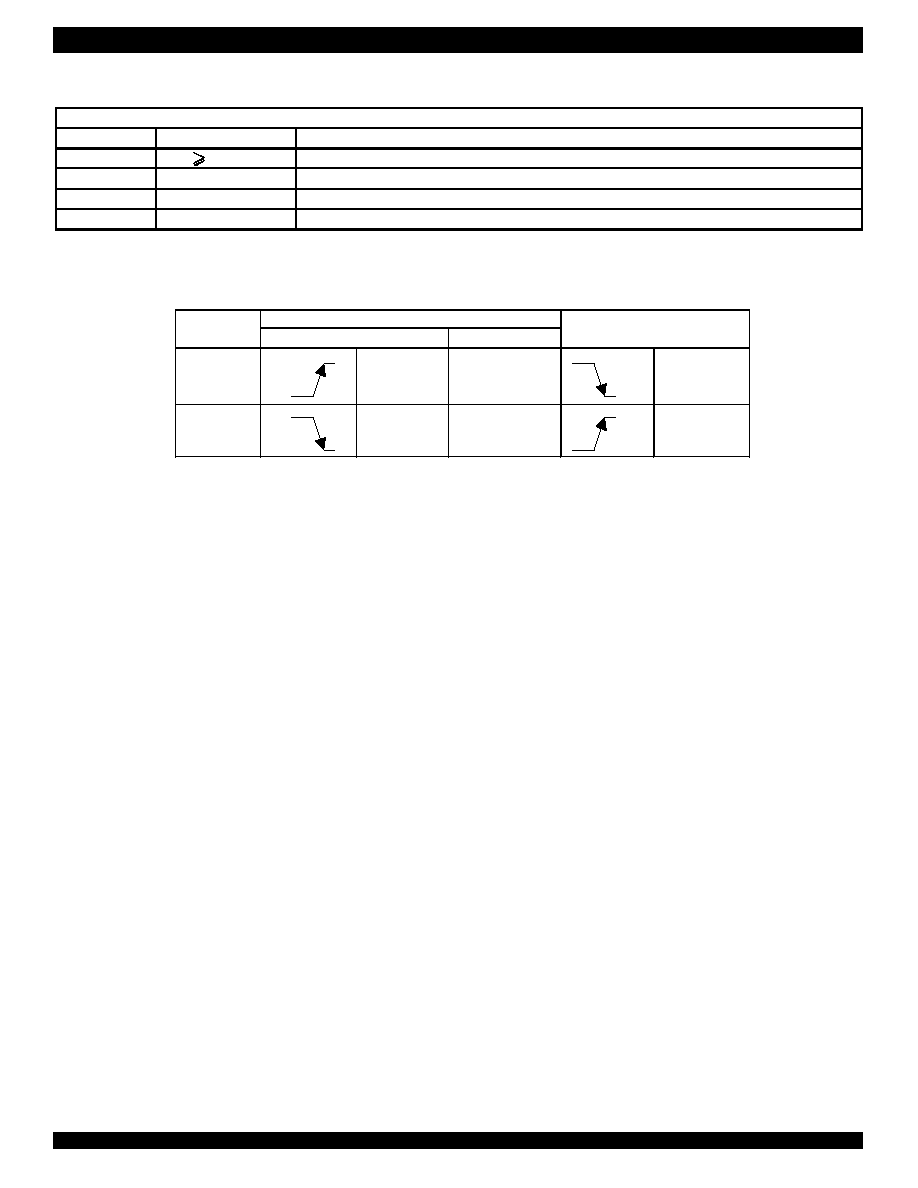

CLOCK EDGES

The active edge of RCLK and SCLK(serial interface clock) are also

selectable. If pin CLKE is Low, the active edge of RCLK is the rising

edge, as for SCLK, that is falling edge. On the contrary, if CLKE is

High, the active edge of RCLK is the falling edge and that of SCLK is

rising edge. Pins RDn/RDPn, CVn/RDNn and SDO are always active

high, and those output signals are valid on the active edge of RCLK

and SCLK respectively. See Table-2 for details. However, in dual rail

mode without clock recovery, pin CLKE is used to set the active level

for RDPn/RDNn raw slicing output: High for active high polarity and

Low for active low. It should be noted that data on pin SDI are always

active high and is sampled on the rising edge of SCLK. The data on

pin TD/TDP or BPVI/TDN are also always active high but is sampled

on the falling edge of TCLK, despite the level on CLKE.

12

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Jitter

Attenuator

Jitter

Attenuator

HDB3/

AMI

Decoder

HDB3/

AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn

CVn

TCLKn

TDNn/BPVIn

TDn

Transmit

All Ones

Figure - 6. Single Rail Mode

Figure - 4. Dual Rail Interface with Data Recovery

Jitter

Attenuator

HDB3/

AMI

Decoder

HDB3/

AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

(RDP RDN)

RDPn

RDNn

TCLKn

TDNn

TDPn

Transmit

All Ones

Jitter

Attenuator

Host Mode

MCLK

TDNn

CRSn in

e-CRS

SINGn in

e-SING

Interface

clocked

H

0

0

Single Rail mode 1

clocked

pulse

0

1

Single Rail mode 2

clocked

pulse

0

0

Dual Rail with Clock Recovery

clocked

pulse

1

0

Dual Rail with Data Recovery

H

pulse

-

-

Receive just slice the incoming data.

Transmit is determined by the status of TCLKn.

L

pulse

-

-

Receive is power down.

Transmit is determined by the status of TCLKn.

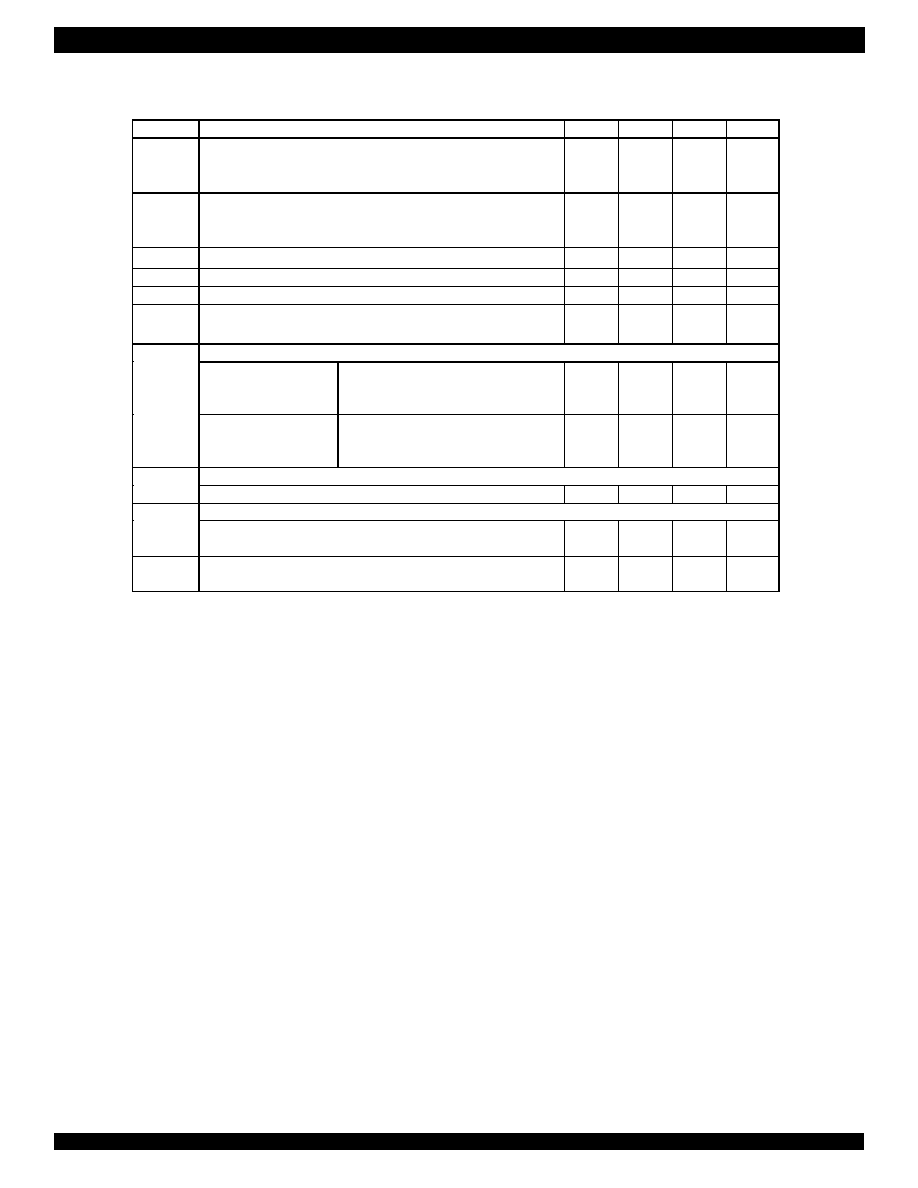

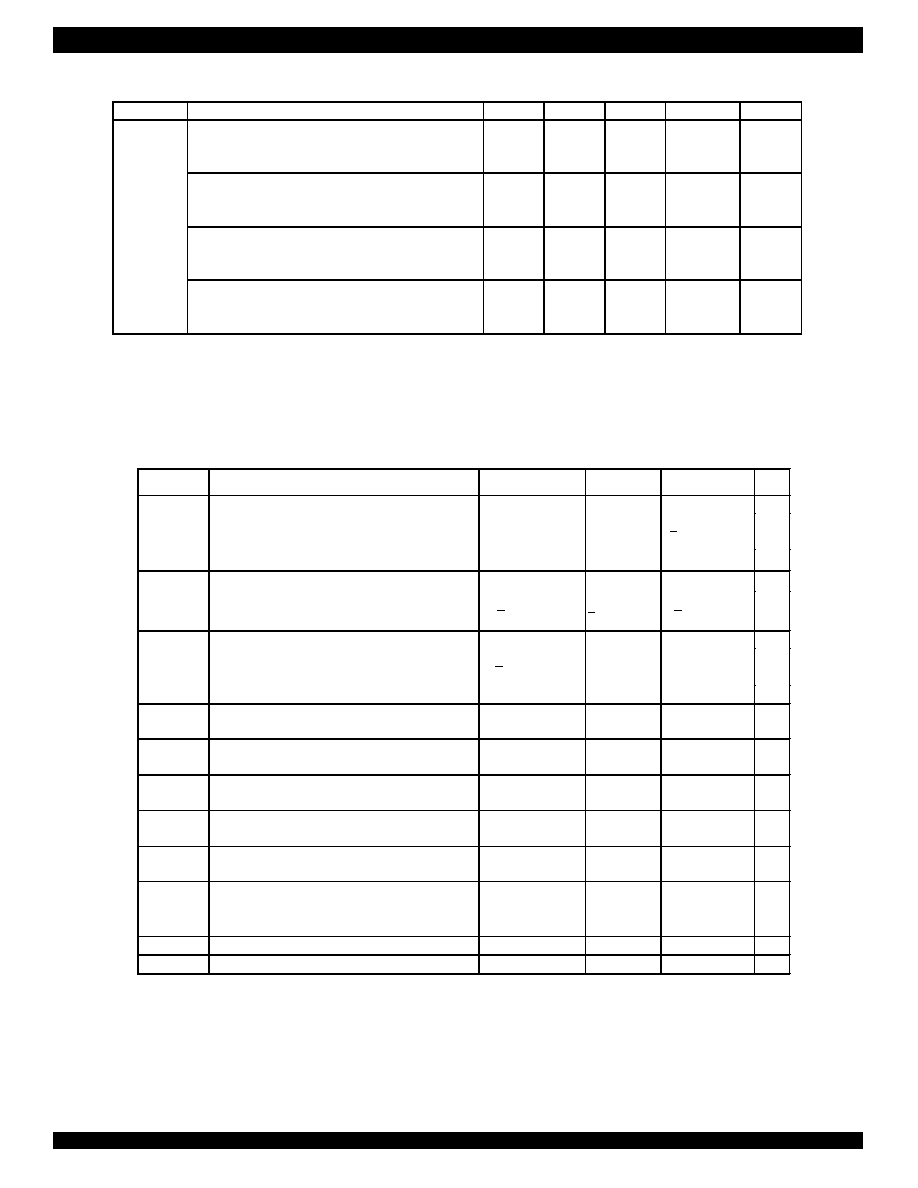

TABLE - 1a. SYSTEM INTERFACE CONFIGURATION (Host Mode)

13

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

RECEIVER

In receive path, the line signals couple into RRINGn and RTIPn via

a transformer and are converted into RZ digital pulses by a data

slicer. Adaptation for attenuation is achieved using an integral peak

detector that sets the slicing levels. Clock and data are recovered

from the received RZ digital pulses by a digital phase-locked loop that

provides excellent jitter accommodation. After passing through the

selectable jitter attenuator, the recovered data are decoded using

HDB3 or AMI line code rules and clocked out of pin RDn in single rail

mode, or presented on RDPn/RDNn in an undecoded dual rail NRZ

format. Loss of signal, alarm indication signal, line code violations and

excessive zero are detected. These various changes in status may

be enabled to generate interrupts.

Peak Detector and Slicer

The slicer determines the presence and polarity of the received

pulses. In data recovery mode, the raw positive slicer output appears

on RDPn while the negative slicer output appears on RDNn. In clock

and data recovery mode, the slicer output is sent to Clock and Data

Recovery circuit for abstracting retimed data and optional decoding.

The slicer circuit has a built-in peak detector from which the slicing

threshold is derived. The slicing threshold is default to 50% (typical) of

the peak value.

Signals with an attenuation of up to 12 dB (from 2.4V) can be re-

covered accurately by the receiver. To provide immunity from impul-

sive noise, the peak detectors are held above a minimum level of

0.150 V typically, despite the received signal level.

Clock and Data Recovery

The function of Clock and Data Recovery is accomplished by

Digital Phase Locked Loop (DPLL). The DPLL is clocked 16 times of

the received clock rate, i.e. 32.768 MHz in E1 mode. The recovered

data and clock from DPLL is then sent to the selectable Jitter

Attenuator or decoder circuit for further processing.

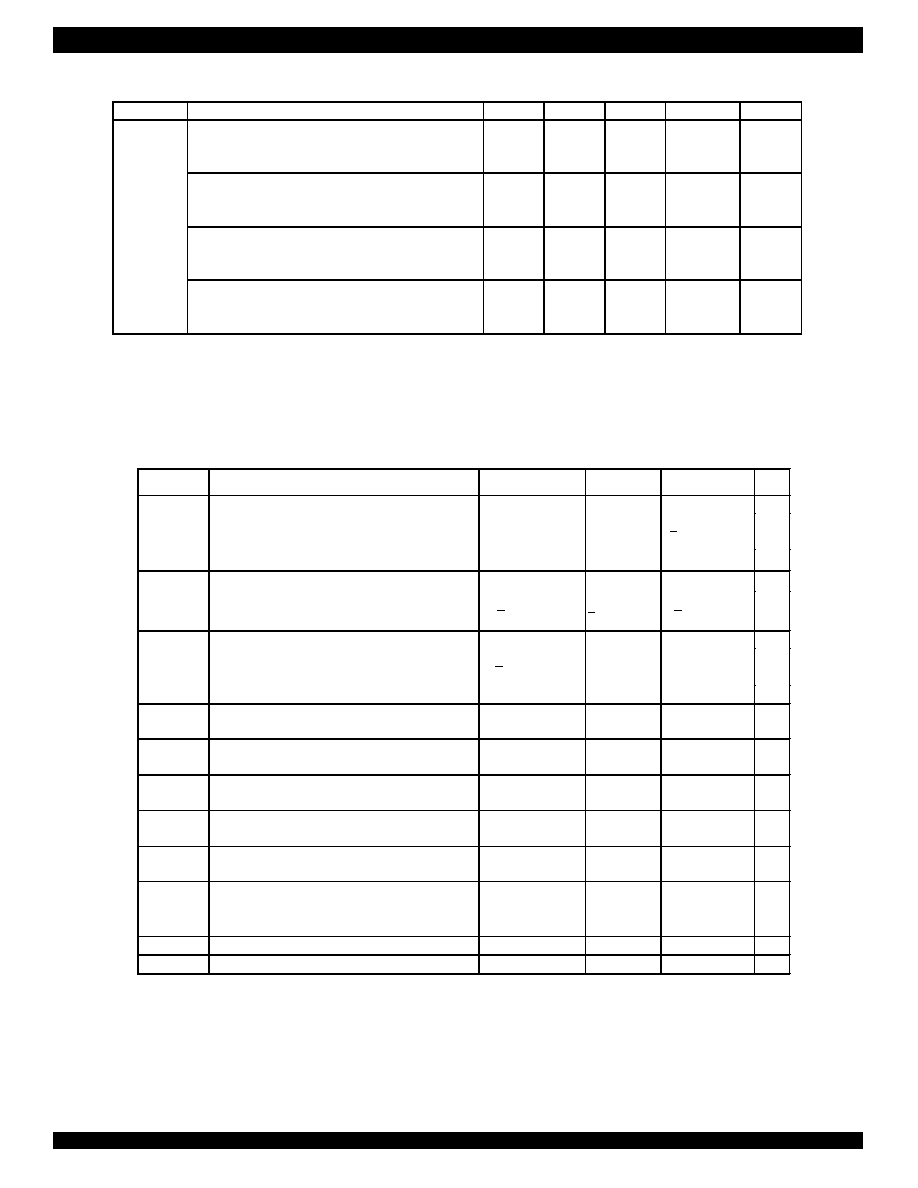

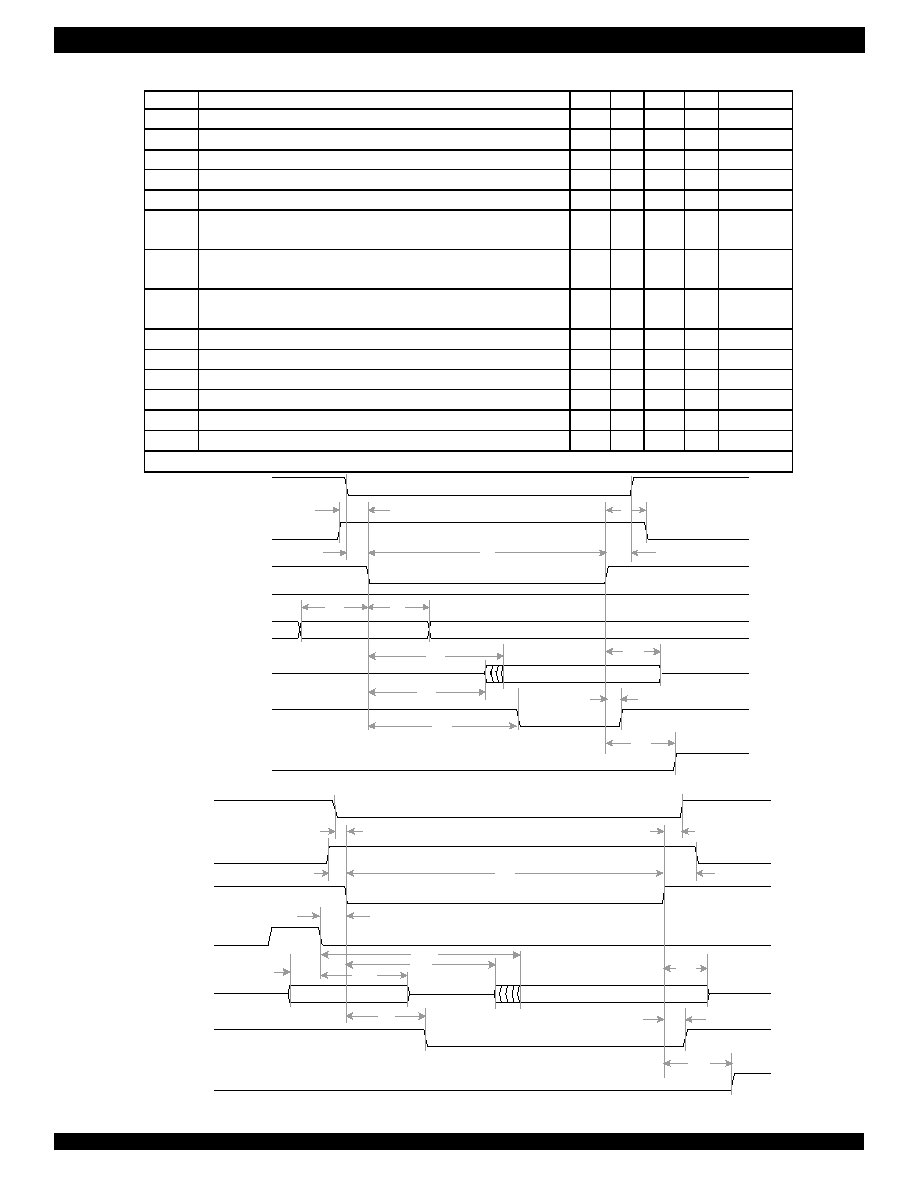

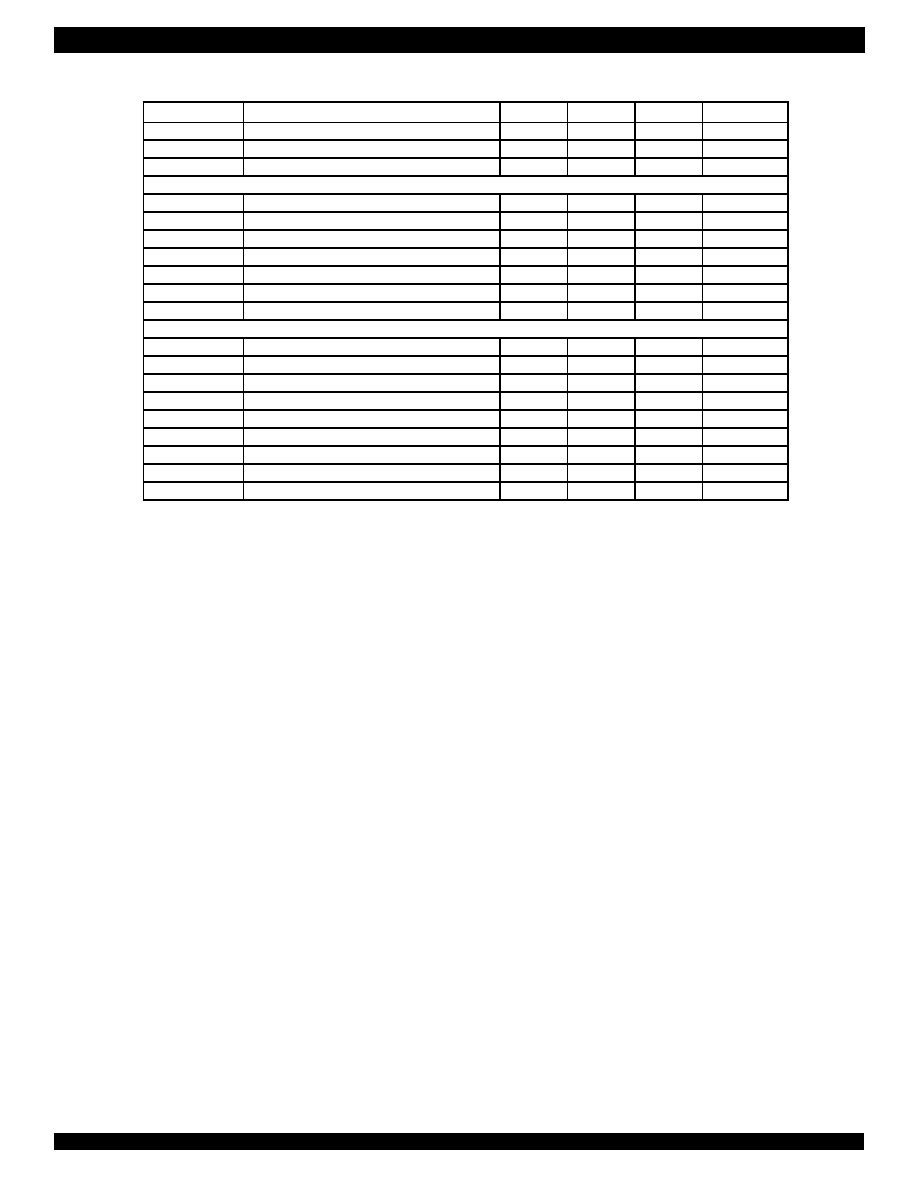

RD/RDP and CV/RDN

Pin CLKE

Clock recovery

Slicer output

SDO

Low

RCLK

Active High

Active Low

SCLK Active High

High

RCLK

Active High

Active High

SCLK

Active High

TABLE - 2. ACTIVE CLOCK EDGE AND ACTIVE LEVEL

The clock recovery and data recovery mode can be selected on

per channel basis by setting the bit CRSn in e-CRS. When bit CRSn is

defaulted to `0', the corresponding channel operates in data and clock

recovery mode. The recovered clock is output on pin RCLKn and re-

timed NRZ data are output on pin RDPn/RDNn in dual rail mode or on

RDn in single rail mode. When CRSn is `1', dual rail with data

recovery mode is enabled in the corresponding channel and the clock

recovery function is bypassed. In this condition, the analog line signal

are converted to RZ digital bit streams on the RDPn/RDNn pins and

internally connected to an EXOR which is fed to the RCLKn output for

external clock recovery applications.

Moreover, Pulling MCLK to H level, all the receivers will enter the

dual rail with data recovery mode. In this case, e-CRS is ignored.

HDB3/AMI Line Code Rule

Selectable HDB3 or AMI line coding/decoding is provided when the

device is configured in single rail mode. HDB3 rules is enabled by set-

ting bit CODE in register GCF (global control configuration) to `0' or

pulling pin CODE to Low. AMI rule is enabled by setting bit CODE in

GCF to `1' or pulling pin CODE to High. All the setting above are ef-

fected to eight channels.

Individual line code rule selection for each channel, if need, is

available by setting bit SINGn in e-SING to `1' (to activate bit CODEn in

e-CODE) and programming bit CODEn to select line code rules in the

corresponding channel: `0' for HDB3, while `1' for AMI. In this case, the

value in bit CODE in GCF or pin CODE for global control is unaffected

in the corresponding channel and only affect in other channels.

In dual rail mode, the decoder/encoder are bypassed. Bit CODE in

GCF, bit CODEn in e-CODE and pin CODE are ignored.

The configuration of the Line Code Rule is summarized in Table-3.

TABLE - 1b. SYSTEM INTERFACE CONFIGURATION (Hardware Mode)

Hardware Mode

MCLK

TDNn

Interface

clocked

H ( 16 MCLK)

Single Rail mode 1

clocked

pulse

Dual Rail with Clock Recovery

H

pulse

Receive just slice the incoming data. Transmit is determined by the status of TCLKn.

L

pulse

Receive is power down. Transmit is determined by the status of TCLKn.

14

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

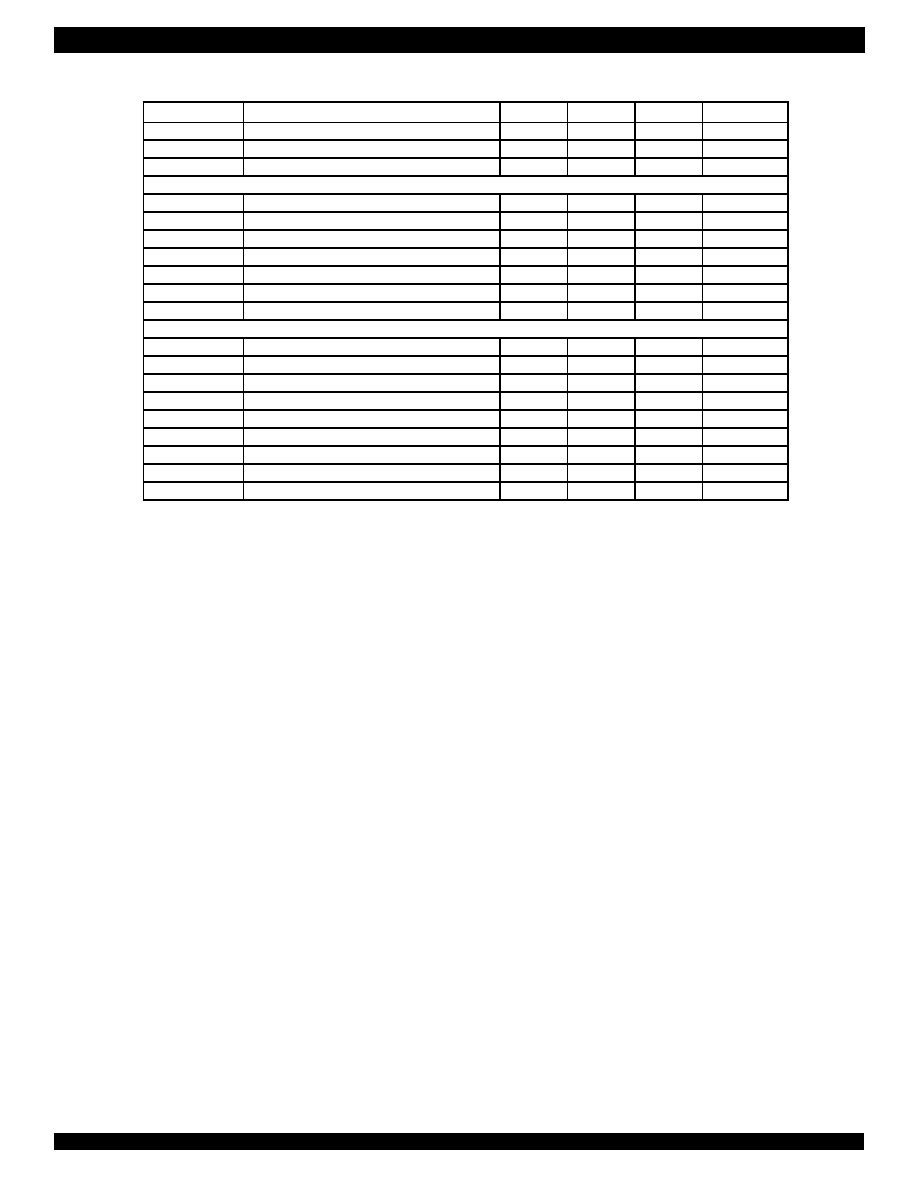

TABLE - 5. AIS CONDITION

TABLE - 4. LOS CONDITION IN CLOCK RECOVERY MODE

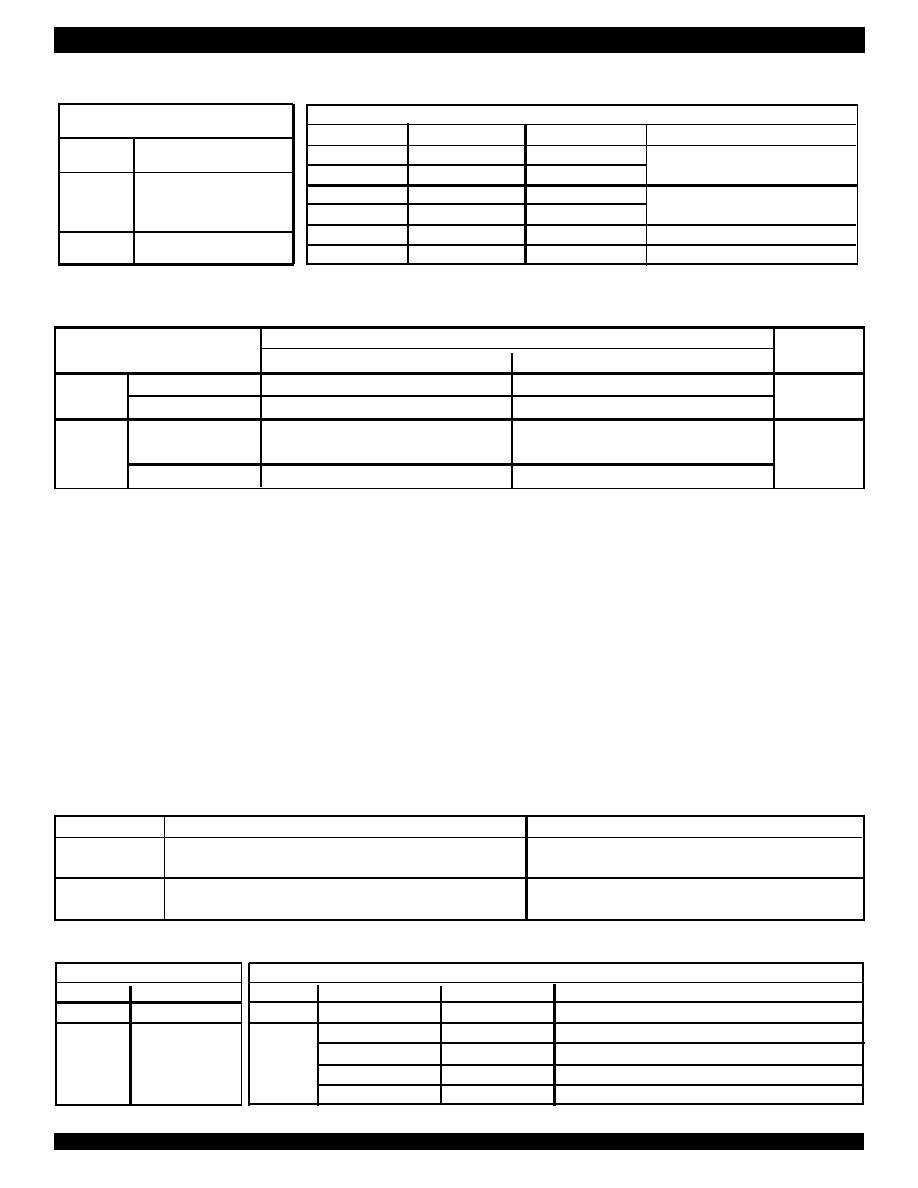

TABLE - 3. CONFIGURATION OF THE LINE CODE RULE

Loss of Signal (LOS) Detection

The Loss of Signal Detector monitors the amplitude and density of

the received signal on Receiver line before the transformer

(measured on port A, B in Figure 12). The loss condition is reported

by pulling pin LOSn to high. In the same time, LOS alarm registers

track LOS condition. When LOS detected or cleared, an interrupt will

generate if not masked. In host mode, the detection supports the ITU-

G.775 and ETSI 300233. In hardware mode, it only supports the ITU-

G.775 specification.

Table-4 summarizes the conditions of LOS in clock recovery

mode.

In data recovery mode, the LOS condition is cleared upon

detecting the signal level exceeds 540mV.

During LOS, the RDPn/RDNn output the sliced data when bit

AISE(Alam Indication Signal Enable) in register GCF is 0 or output all

ones as AIS (Alarm Indication Signal) when bit AISE is set to 1; The

RCLKn is replaced by MCLK only if the AISE is set.

Alarm Indication Signal Detection (AIS)

Alarm Indication Signal is available only in host mode with clock

recovery, as Table-5 shows.

Error Detection

The device can detects excessive zero, bipolar violations and

HDB3 code violations, refer to figure-7, 8, 9. All the three kinds of er-

rors are reported in both host mode and hardware mode with HDB3

line code rule is used. Moreover, in host mode, the expanded regis-

ters e-CZER and e-CODV are used to determine whether the exces-

TABLE - 6. ERROR DETECTION

STANDARD Signal on

G.775 for E1

ETSI 300233 for E1 pin LOSn

LOS

Continuous Intervals

32

2048 (1 ms)

H

Detected

Amplitude

below typ. 310mV (Vpp)

below typ. 310mV (Vpp)

LOS

Density

12.5% (4 marks in a sliding 32-bit period)

12.5% (4 marks in a sliding 32-bit period)

L

Cleared

with no more that 15 continuous zeros

with no more than 15 continuous zeros

Amplitude

exceed typ. 540mV (Vpp)

exceed typ. 540mV (Vpp)

ITU G.755 for E1 (register LAC defaulted to 0)

ETSI 300233 for E1 (register LAC is 1)

AIS Detected

Less than 3 zeros contained in each of two consecutive

Less than 3 zeros contained in a 512-bit stream

512-bit stream are received

are received

AIS Cleared

3 or more zeros contained in each of two consecutive

3 or more zeros contained in a 512-bit stream

512-bit stream are received

are received

Hardware Mode

Host Mode

Line Code

Pin CVn Reports

Line Code CODVn in

e-CODV CZERn in e-CZER

Pin CVn Reports

AMI

Bipolar Violation

AMI

-

-

Bipolar Violation

HDB3

Bipolar Violation

HDB3

0

0

Bipolar Violation + Code Violation

+ Code Violation

0

1

Bipolar Violation + Code Violation + Excessive Zero

+ Excessive Zero

1

0

Bipolar Violation

1

1

Bipolar Violation + Excessive Zero

Host Mode

CODE in

GCF CODEn in e-CODE SINGn in e-SINGn

Line Code Rule

0

0 / 1

0

All channels in HDB3

0

0

1

1

0 / 1

0

All channels in AMI

1

1

1

0

1

1

CHn in AMI

1

0

1

CHn in HDB3

Hardware Mode

CODE

Line Code Rule

L

All channels in HDB3

H All channels in AMI

15

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

-300

-200

-100

0

100

200

300

Time (ns)

-0.20

0.00

0.20

0.40

0.60

0.80

1.00

1.20

Normalized Amplitude

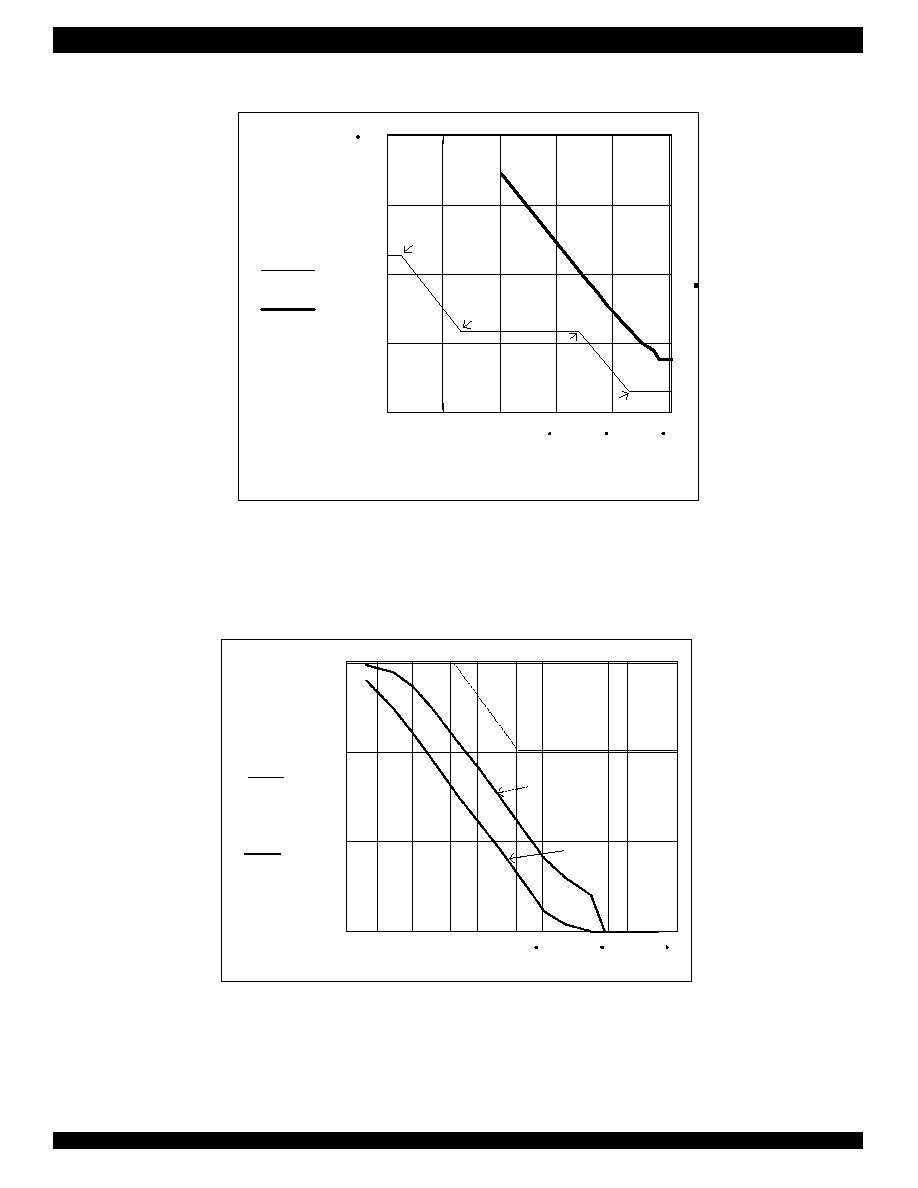

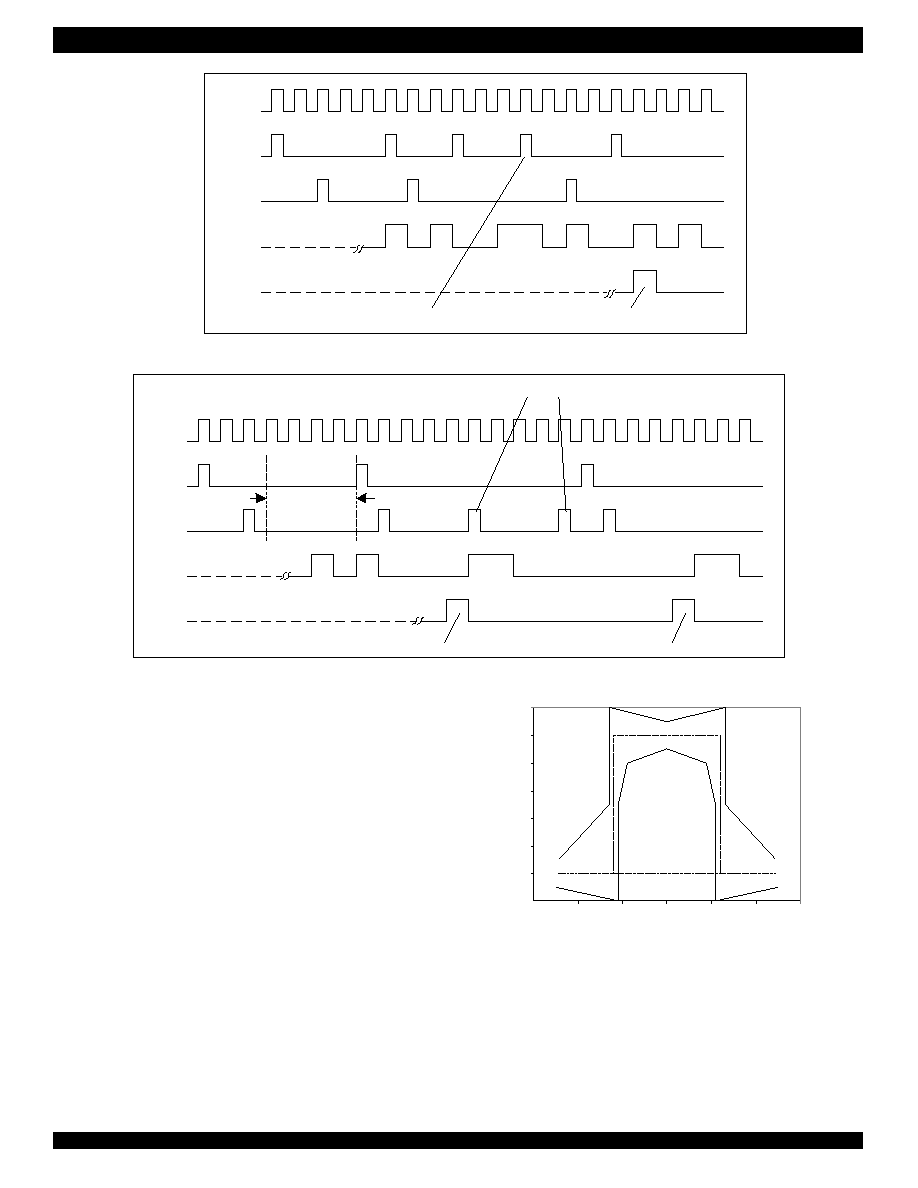

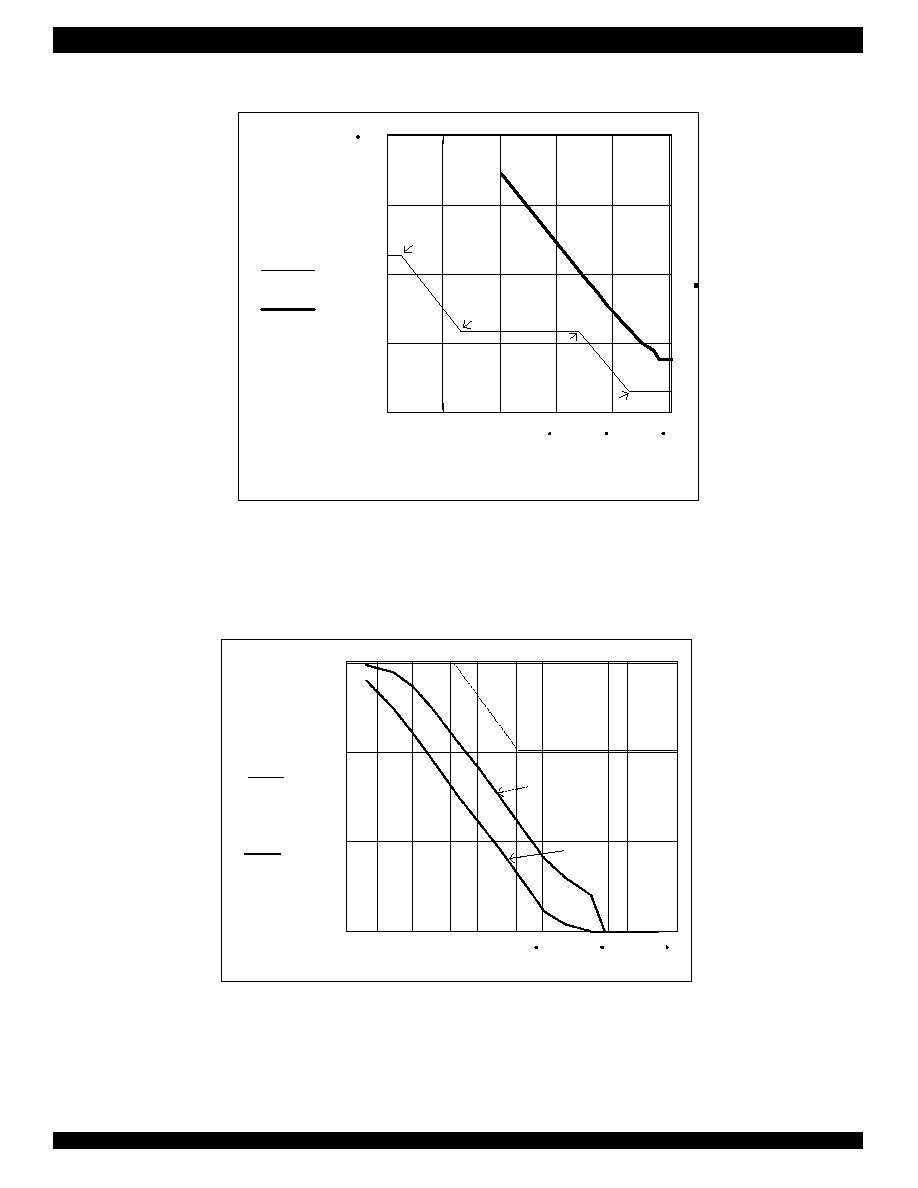

Figure - 9. CEPT Waveform Template

sive zero and code violation are reported respectively. When

configured in AMI decoding mode, only bipolar violation can be re-

ported.

The error detection is available only in single rail mode where the

pin RDNn/CVn is used as error report output (CVn pin).

The configuration and report status of error detection are summa-

rized in Table-6.

TRANSMITTER

In transmit path, data in NRZ (non return to zero) format are

clocked into the device on TDn and encoded by AMI or HDB3 line

code rules when single rail mode is configured or pre-encoded data

in NRZ format are input on TDPn and TDNn when dual rail mode is

configured. The data are sampled into the device on falling edges of

TCLKn. Jitter attenuator, if enabled, is provided with a FIFO which the

data to be transmitted are passing through. A low jitter clock is

generated by an integral digital phase-locked loop and is used to

read data from the FIFO. The shape of the pulses should meet the

E1 pulse template after the signal is passed through different cable

types. Bipolar violation, for diagnosing, can be inserted on pin BPVIn

if AMI line code rule is enabled.

Waveform Shaper

E1 pulse template, specified in ITU-T G.703, is shown in Figure-9.

The device has built-in transmit waveform templates for cable of 75

or 120

.

The built-in waveform shaper use an internal high frequency clock

which is 16XMCLK as clock reference. This function will be bypassed

when MCLK is unavailable.

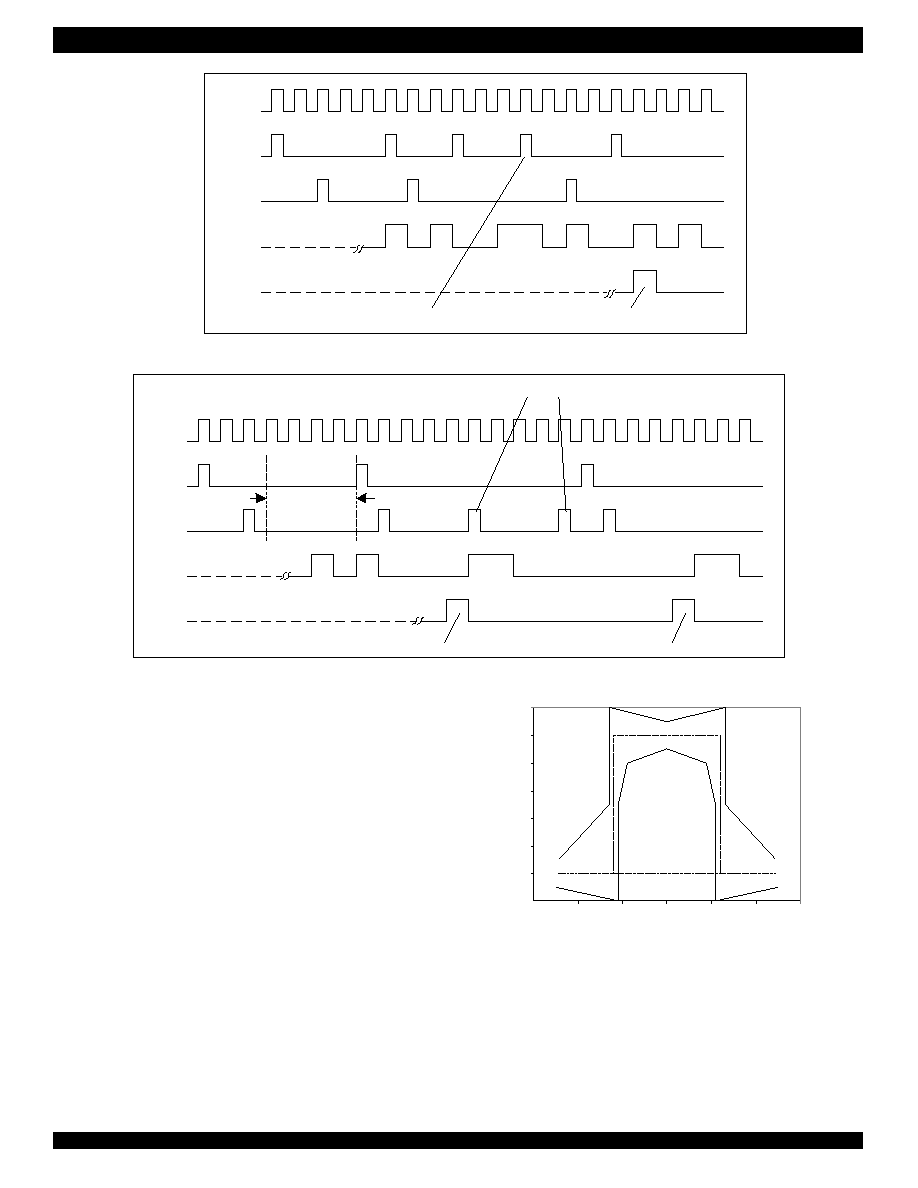

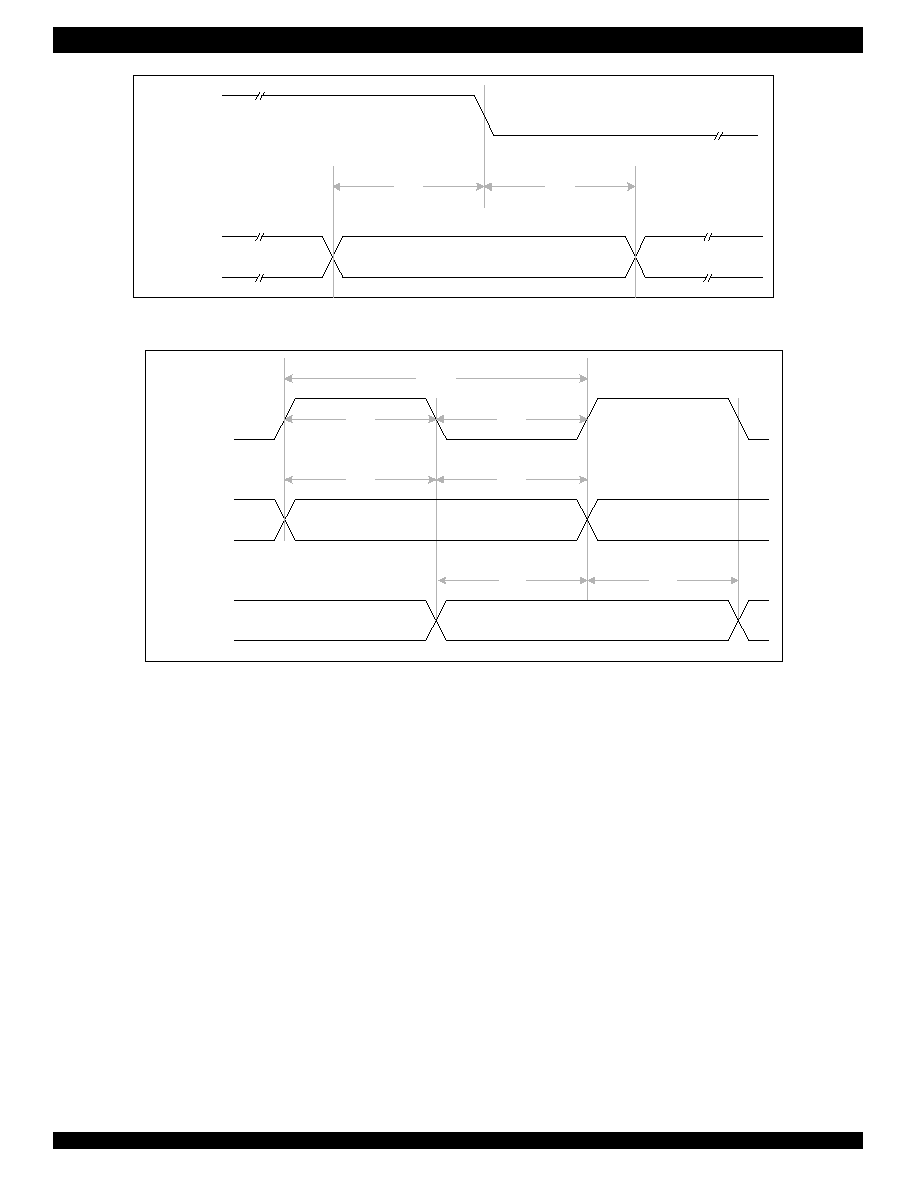

Figure - 7. AMI Bipolar Violation

Bipolar Violation detected

Bipolar violation

CLK

RTIP

RRING

RD

CV

1

2

3

4

5

V

6

7

1

2

3

4

5

6

V

Figure - 8. HDB3 Code Violation & Excessive Zero

Code violation detected

Excessive zero detected

CLK

RTIP

RRING

RD

CV

Code violation

4 consecutive zeros

1

2

3

4

V

V

5

6

1

2

3

4

5

6

16

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Bipolar Violation Insertion

When configured in single rail mode 2 with AMI line code enabled,

pin TDNn/BPVIn is used as BPVI input. A low-to-high transition on this

pin inserts a bipolar violation on the next available mark in the trans-

mit data stream. Sampling occurs on the falling edge of TCLK. But in

TAOS with analog loopback mode and remote loopback mode, the

BPVI is disabled. In TAOS with digital loopback mode, the BPVI is

looped back to system side, so

the data to be transmitted

on TTINGn

and TRINGn are all ones with no bipolar violation.

JITTER ATTENUATOR

The jitter attenuator is provided for narrow-band width jitter transfer

and can be selected to work either in transmit path or in receive path

or not used. The selection is accomplished by setting pin JAS in hard-

ware mode or configuring bits JACF1 and JACF0 in register GCF in

host mode which are both effected to all the channels.

For applications which require line synchronization, the line clock

is need to be extracted for the internal synchronization, the jitter

attenuator is set in the receive path. Another use of the jitter attenuator

is to provide clock smoothing in the transmit path for applications such

as synchronous/asynchronous demultiplexing applications. In these

applications, TCLK will have an instantaneous frequency that is higher

than the nominal E1 data rate and in order to set the average long-

term TCLK frequency within the transmit line rate specifications, peri-

ods of TCLK are suppressed (gapped).

The jitter attenuator integrates a FIFO which can accommodate a

gapped TCLK. In host mode, the FIFO length can be 32 X 2 or 64 X 2

bits by programming bit JADP in GCF. In hardware mode, it is fixed to

64 X 2 bits. The FIFO length determines the maximum permissible

gap width (see table-7), exceeding these values will cause FIFO over-

flow or underflow. The data is 16 or 32 bits' delay through the jitter

FIFO Length

Max. Gap Width

64 bit

56 UI

32 bit

28 UI

TABLE - 7. GAP WIDTH LIMITATION

attenuator in the corresponding transmit or receive path. The constant

delay feature is crucial for the applications requiring "hitless" switching.

In host mode, bit JABW in GCF determines the jitter attenuator 3dB

corner frequency (fc). In hardware mode, the fc is fixed to 1.7Hz.

Generally, the lower the fc is, the higher the attenuation. However,

lower fc comes at the expense of increased acquisition time.

Therefore, the optimum fc is to optimize both the attenuation and the

acquisition time. In addition, the longer FIFO length results in an

increased throughput delay and also influences the 3dB corner

frequency. Generally, it's recommended to use the lower corner

frequency and the shortest FIFO length that can still meet jitter

attenuation requirements.

The output jitter specifications include: ITU-T G.736, ITU-T G.742,

ITU-T G.783 and ETSI CTR 12/13.

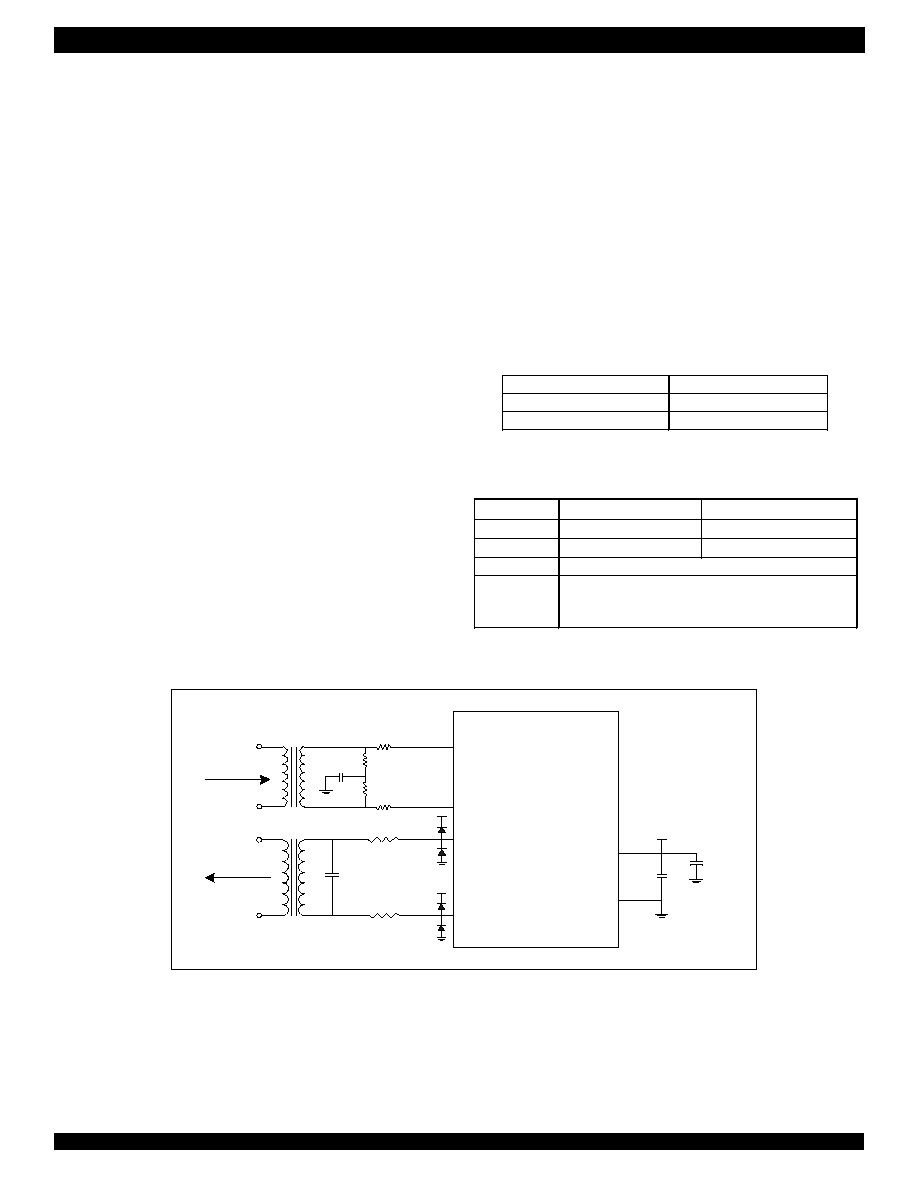

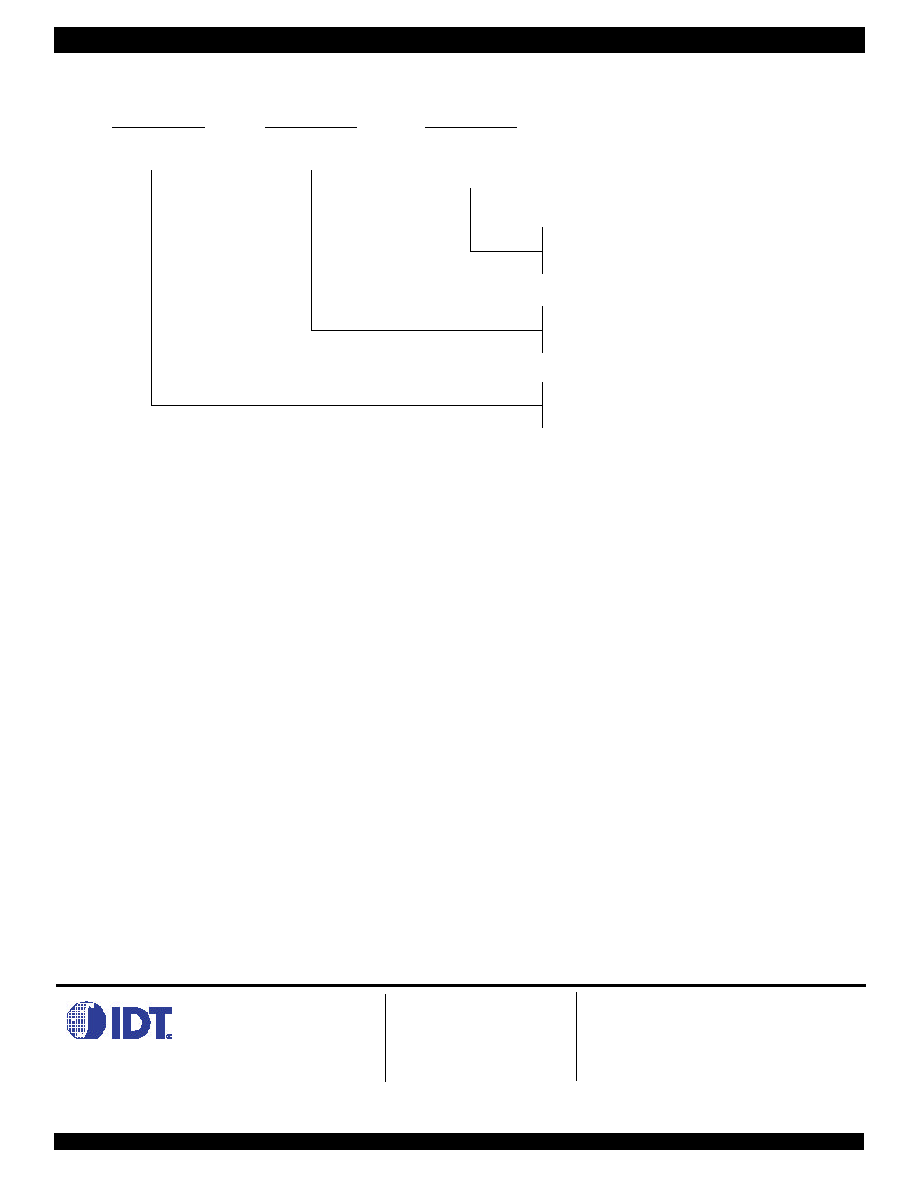

Figure - 10. External Transmit/Receive Line Circuitry

0.22

µ

F

∑

∑

∑

∑ ∑

R

X

Line

1k

R

R

R

R

∑

∑

T

X

Line

R

T

R

T

RTIPn

RRINGn

TRINGn

TTIPn

∑

∑

0.1

µ

F

GNDTn

VDDDn

VDDT

IDT82V2058

One of Eight Identical Channels

VDDT

∑

∑

VDDT

D4

D3

D2

D1

2:1

1

2:1

1

1k

Cp

2

68

µ

F

3

A

B

NOTE:

1. Pulse T1124 transformer is recommended to use in Standard (STD) operating temperature range (0∞ to 70∞C), while Pulse T1114 transformer is recommended to use in Extended (EXT)

operating temperature range is -40∞ to +85∞C. See Transformer Specifications Table for details.

2. Typical value. Adjust for actual board parasitics to obtain optimum return loss.

3. Common decoupling capacitor for all VDDT and GNDT pins.

Component

75

Coax

120

Twisted Pair

R

T

9.5

±

1%

9.5

±

1%

R

R

9.31

±

1%

15

±

1%

Cp

2200pf

D1 ≠ D4

Nihon Inter Electronics - EP05Q03L, 11EQS03L,

EC10QS04, EC10QS03L

Motorola ≠ MBR0540T1

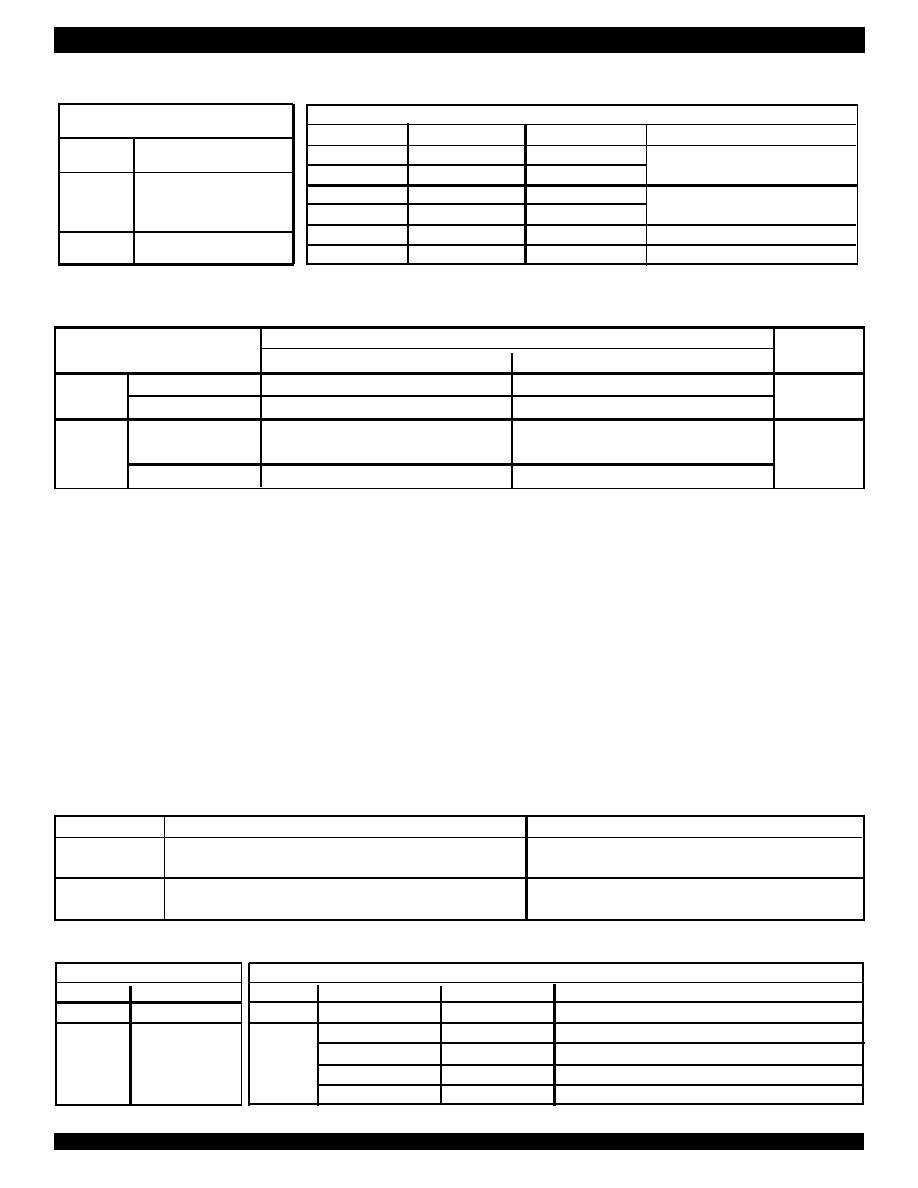

TABLE - 8. EXTERNAL COMPONENTS VALUES

17

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

Digital

Loopback

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Figure - 11. Digital Loopback

LINE INTERFACE CIRCUITRY

The transmit and receive interface RTIP/RRING and TTIP/TRING

connections provide a matched interface to the cable. Figure-12

shows the appropriate external components to connect with the cable

for one transmit/receive channel. Table-8 summarizes the

component values based on the specific application.

TRANSMIT DRIVER POWER SUPPLY

The nominal transmit driver power supply must be 5.0V or 3.3V.

Despite of the power supply voltage, the 75

/120

lines are

driven through 9.5

series resistors and a 1:2 transformer.

However, in harsh cable environment, series resistors are re-

quired to improve the transmit return loss performance and protect

the device from surges coupling into the device.

SHORT CIRCUIT MONITOR

An internal Short Circuit Monitor (SCM), parallelly connected with

TTIPn and TRINGn, can detect short circuit in the transmit line side.

Bit SCPB in Register GCF decides whether the output driver short-

circuit protection is enabled. (Refer to

Programming Information).

When it is enabled, the max driver's output current is limited to

150mA.

LINE PROTECTION

In transmit side, the Schottky diodes D1~D4 are required to protect

the line driver and improve the design robustness. In receive side,

the series resistors of 1k

are used to protect the receiver against

current surges coupled in the device. It does not affect the receiver

sensitivity, since the receiver impedance is as high as 120k

typi-

cally.

HITLESS PROTECTION SWITCHING (HPS)

The IDT82V2048 tranceivers include an output driver tristatability

feature for T1/E1 redundancy applications. This feature greatly re-

duces the cost of implementing redundancy protection by eliminating

external relays. Details of HPS will be described in relative Application

Note.

RESET

Writing register RS can cause software reset by initiating about 1

µ

s

reset cycle. This operation set all the registers to their default value.

POWER UP

During power up, an internal reset signal sets all the registers to

default values. This procedure takes at least 2 machine cycles.

POWER DOWN

Each transmitter channel will power down by pulling pin TCLKn to

low for more than 64 MCLK cycles (if MCLK is available) or about

30us (when MCLK is not availabe). Each transmitter channel will also

power down by setting bit TPDNn in e-TPDN to 1.

All the receivers will power down when MCLK is Low. When MCLK

is clocked or High, setting bit RPDNn in e-RPDN to `1' will configure the

corresponding receiver to power down.

INTERFACE WITH 5V LOGIC

The IDT82V2048 can interface directly with 5V TTL family devices.

The internal input pads are tolerant to 5V output from TTL and CMOS

family devices.

Electrical Specification @ 25 ∞C

Part No.

Turns Ratio

(Pri: sec±2%)

OCL @ 25∞C

(mH MIN)

L

L

(

µ

H MAX)

C

W/W

(pF MAX)

STD Temp.

EXT Temp.

Transmit

Receive

Transmit

Receive

Transmit

Receive

Transmit

Receive

Package/

Schematic

T1124

T1114

1:2CT

1CT:2

1.2

1.2

.6

.6

35

35

TOU/3

TABLE - 9. TRANSFORMER SPECIFICATIONS

18

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

LOOPBACK MODE

The device provides four different diagnostic loopback configura-

tions: Digital Loopback, Analog Loopback, Remote Loopback and

Dual Loopback. In host mode, these functions are implemented by

programming the registers DLB, ALB or RLB. In hardware mode,

only analog loopback and remote loopback can be selected by pull-

ing pin LPn to High and Low respectively.

Digital Loopback

By programming the bits of register DLB, each channel of the de-

vice can be set in Local Digital Loopback. In this configuration, the

data and clock to be transmitted, after passing the encoder, is looped

back to jitter attenuator (if enabled) and decoder in the receive path,

then output on RCLKn, RDn/RDPn and CVn/RDNn. The data to be

transmitted are still output on TTIPn and TRINGn while the data re-

ceived on RTIPn and RRINGn are ignored. The Loss Detector is still

in use. Figure-11 shows the process.

Analog Loopback

By programming the bits of ALB register or pulling pin LPn to

High, each channel of the device can be set in Analog Loopback. In

this configuration, the data to be transmitted output from the line driver

are internally looped back to the slicer and peak detector in the

receive path and output on RCLKn, RDn/RDPn and CVn/RDNn. The

data to be transmitted are still output on TTIPn and TRINGn while the

data received on RTIPn and RRINGn are ignored. The Loss Detector

is still in use. Figure-12 shows the process.

The TTIPn and RTIPn, TRINGn and RRINGn cannot be connected

directly to do the external analog loopback test. Line impedance

loading is required to conduct the external analog loopback test.

Remote Loopback

By programming the bits of RLB register or pulling pin LPn to Low,

each channel of the device can be set in Remote Loopback. In this

configuration, the data and clock recovered by the Clock and Data

Recovery circuits are looped to waveform shaper and output on

TTIPn and TRINGn. The jitter attenuator is also included in loopback

when enabled in the transmit or receive path. The received data and

clock are still output on RCLKn, RDn/RDPn and CVn/RDNn while the

data to be transmitted on TCLKn, TDn/TDPn and BPVIn/TDNn are

ignored. The Loss Detector is still in use. Figure-13 shows the

process.

Dual Loopback

Dual Loopback mode is set by setting both bit DLBn in register

DLB and bit RLBn in register RLB to `1'. In this configuration, after

passing the encoder, the data and clock to be transmitted are looped

back to decoder directly and output on RCLKn, RDn/RDPn and CVn/

RDNn. The recovered data from RTIPn and RRINGn are looped back

to waveform shaper through JA (if selected) and output on TTIPn and

TRINGn. The Loss Detector is still in use. Figure-14 shows the proc-

ess.

Transmit All Ones

In hardware mode, the TAOS mode is set by pulling TCLKn High

for more than 16 MCLK cycles. In host mode, TAOS mode is set by

programming register TAO. In addition, automatic TAO signals are in-

serted by setting register ATAO when Loss of Signal occurs. Note that

the TAOS generator adopts MCLK as a timing reference. In order to

assure that the output frequency is within specification limits, MCLK

must have the applicable stability.

This TAOS mode and Digital Loopback or Analog Loopback can

be configured simultaneously. Figure-15 shows their process.

Figure - 12. Analog Loopback

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Analog

Loopback

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

19

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Figure - 15a. TAOS Data Path

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Figure - 13. Remote Loopback

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Remote

Loopback

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Figure - 14. Dual Loopback

20

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

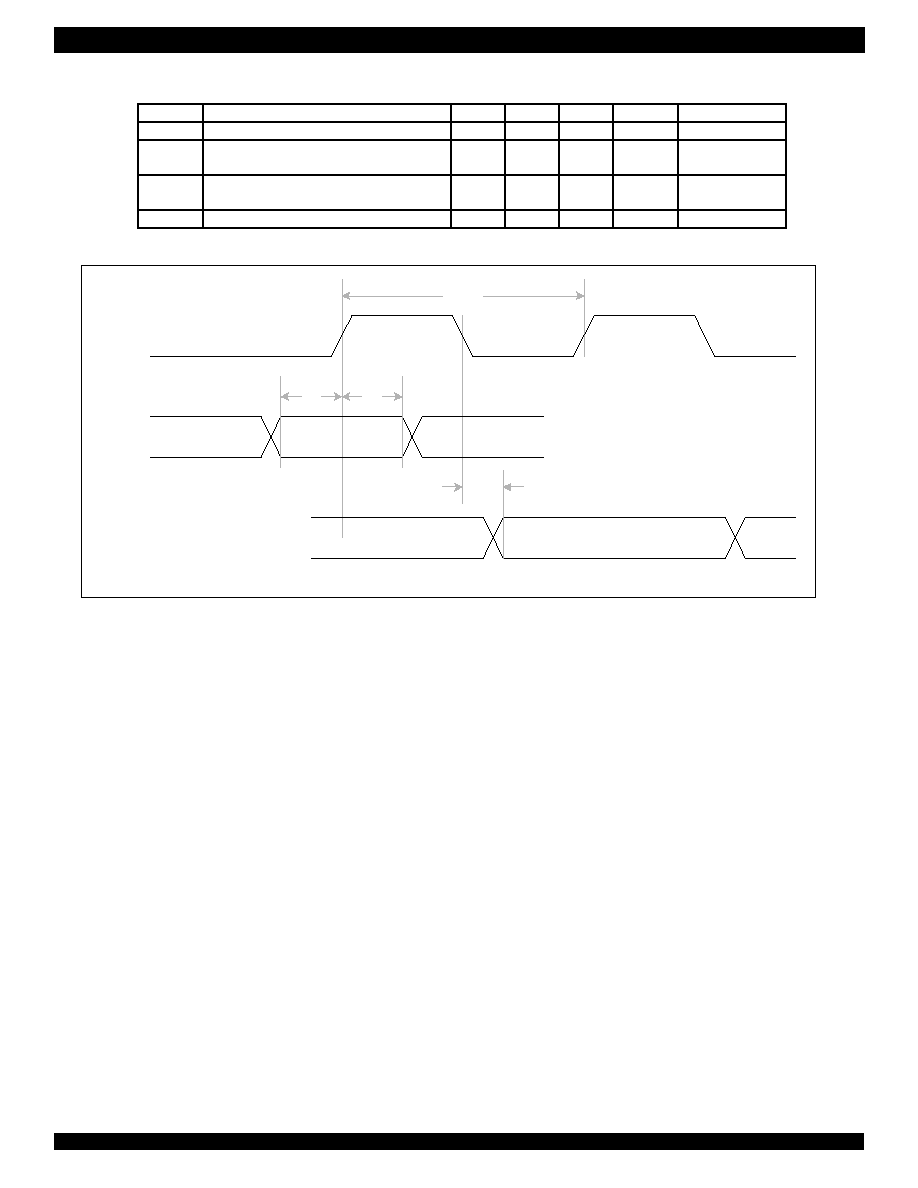

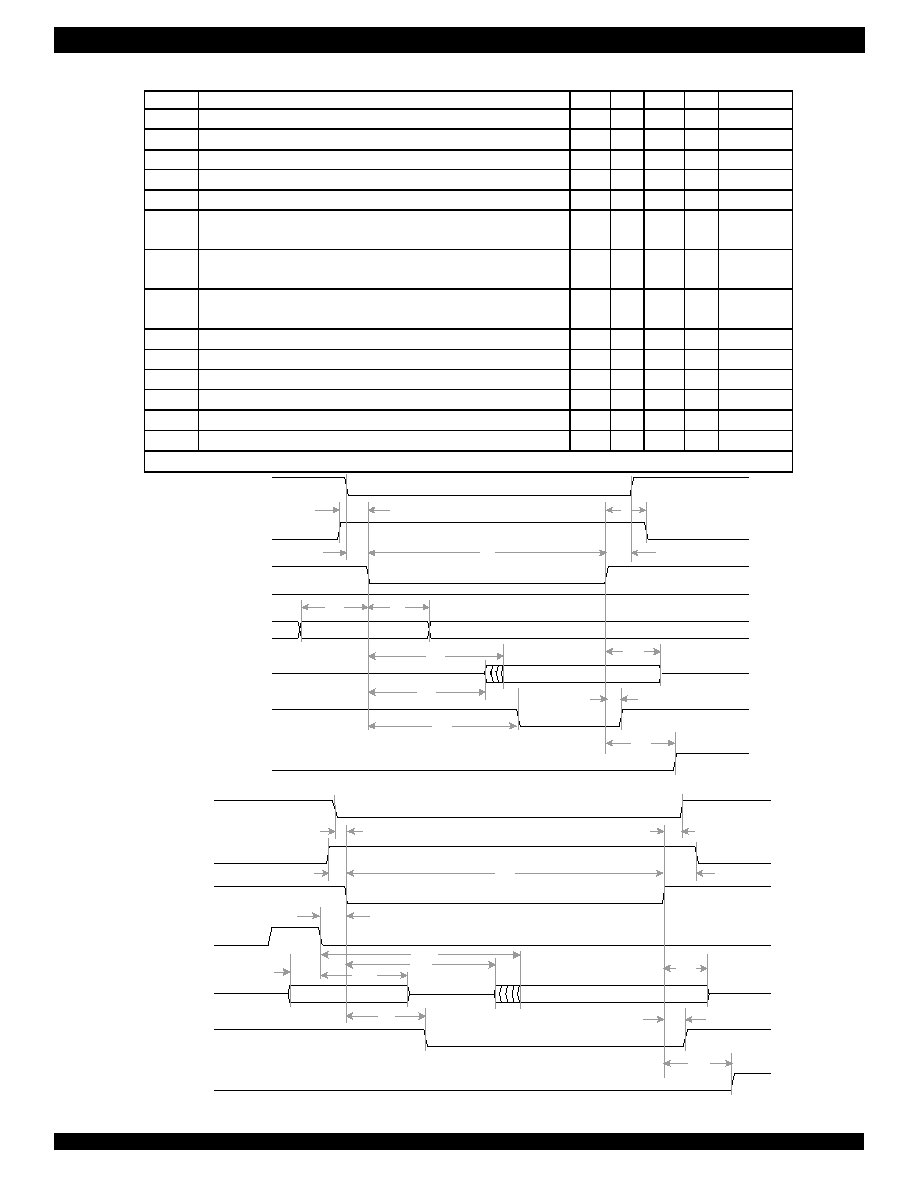

HOST INTERFACES

The host interface provides access to read and write the registers

in the device. The interface consists of serial host interface and

parallel host interface. By pulling pin MODE2 to VDDIO/2 or to High,

the device can be set to work in serial mode and in parallel mode

respectively.

Parallel Host Interface

The interface is compatible with Motorola or Intel host. Pins

MODE1 and MODE0 are used to select the operating mode of the

parallel host interface. When pin MODE1 is pulled to Low, the host

uses separate address bus and data bus. When High, multiplexed

address/data bus is used. When pin MODE0 is pulled to Low, the par-

allel host interface is configured for Motorola compatible hosts. When

High, for Intel compatible hosts. This is well described in the

Pin De-

scription. The host interface pins in each operation mode is tabu-

lated in Table-10.

Jitter

Attenuator

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Figure - 15c. TAOS with Analog Loopback

Jitter

Attenuator

HDB3/AMI

Decoder

HDB3/AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

One of Eight Identical Channels

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

Transmit

All Ones

Figure - 15b. TAOS with Digital Loopback

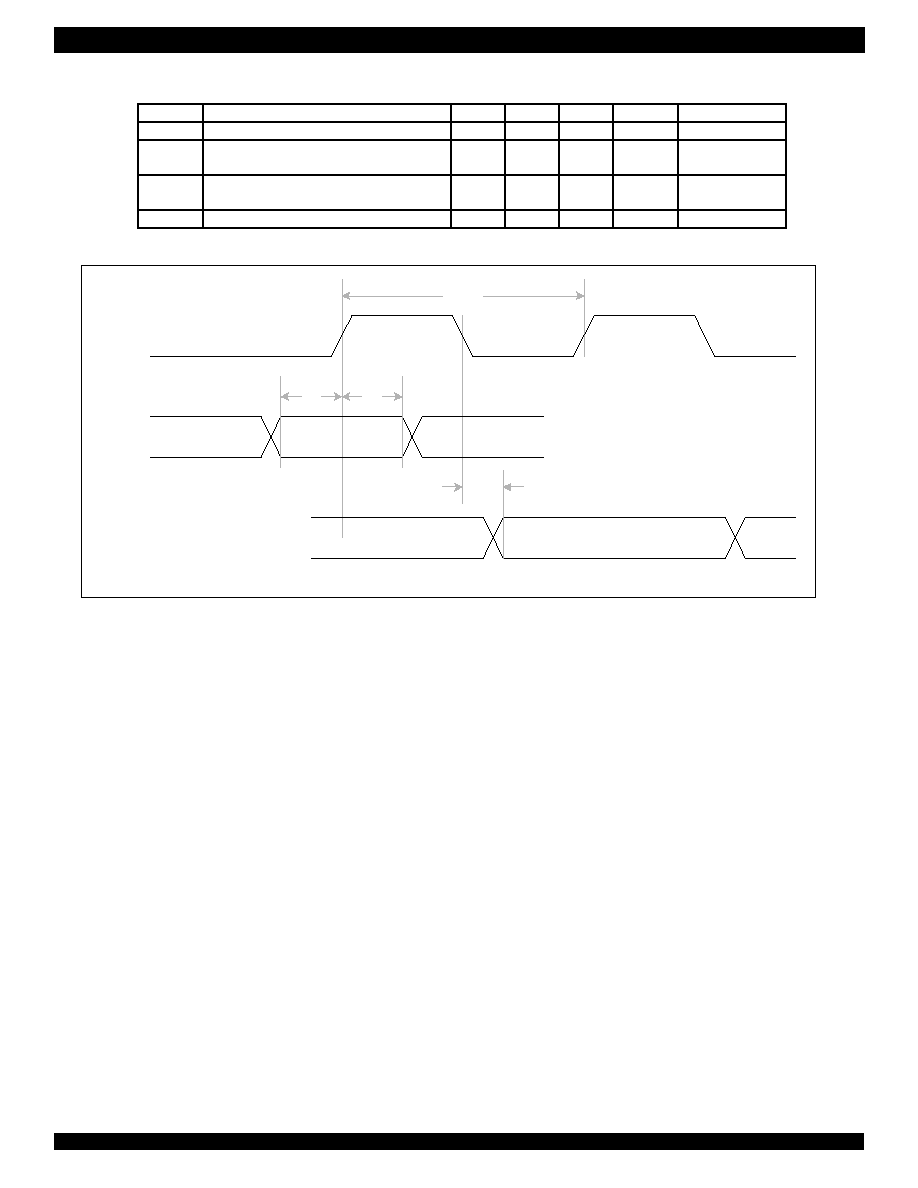

Serial Host Interface

By pulling pin MODE2 to VDDIO/2, the device operates in the serial

host Mode. In this mode, the registers are accessible through a 16-bit

word which contains an 8-bit command/address byte (bit R/W and 5-ad-

dress-bit A1~A5, A6 and A7 are ignored) and a subsequent 8-bit data

byte (D0~D7). When bit R/W is 1, data is read out at pin SDO. When bit

R/W is 0, data is written into pin SDI to the register which is indicated by

address bits A5~A1.

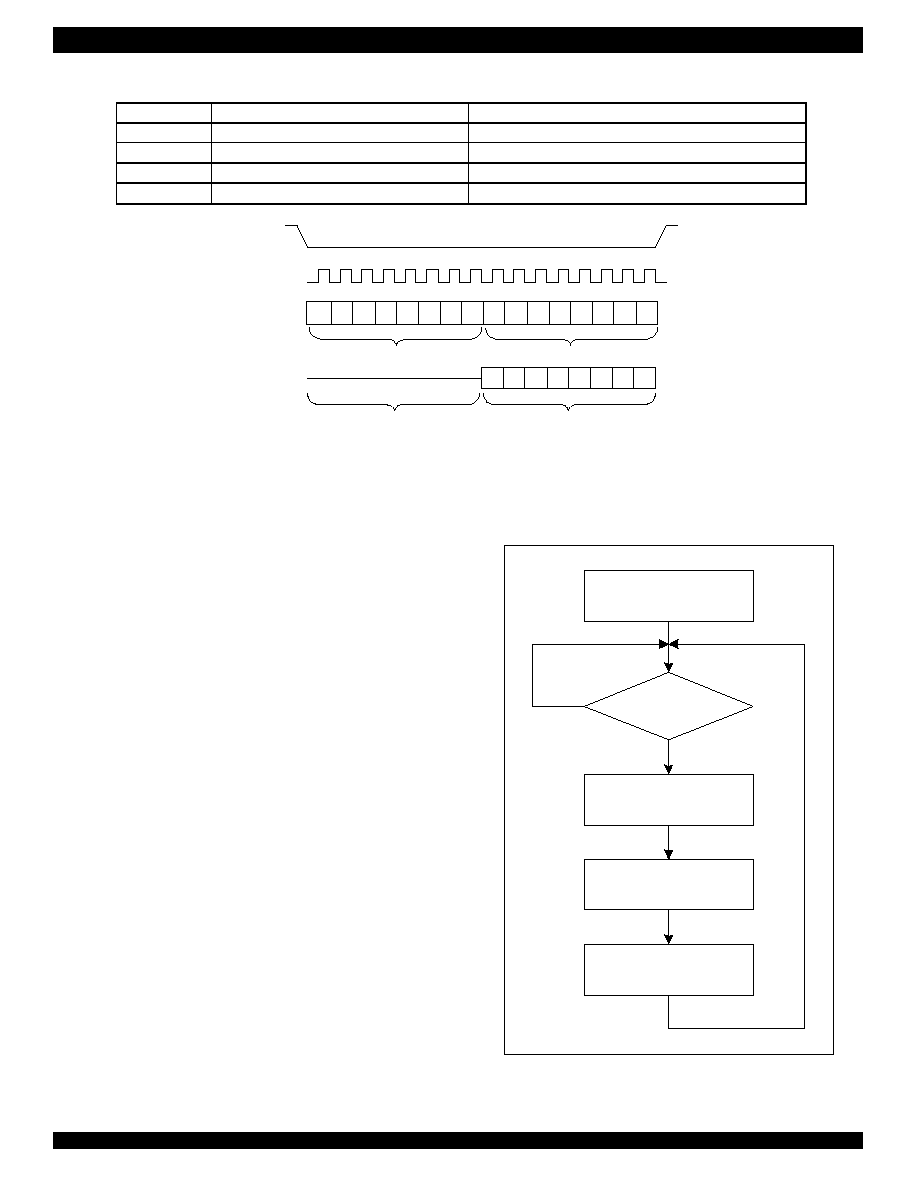

INTERRUPT HANDLING

Interrupt Sources

There are three kinds of interrupt sources:

1. Status change in the LOS (Loss of Signal) Status Register(04H).

The analog/digital loss of signal detector continuously monitors the re-

ceived signal to update the specific bit in LOS which indicates presence

or absence of a LOS condition.

21

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

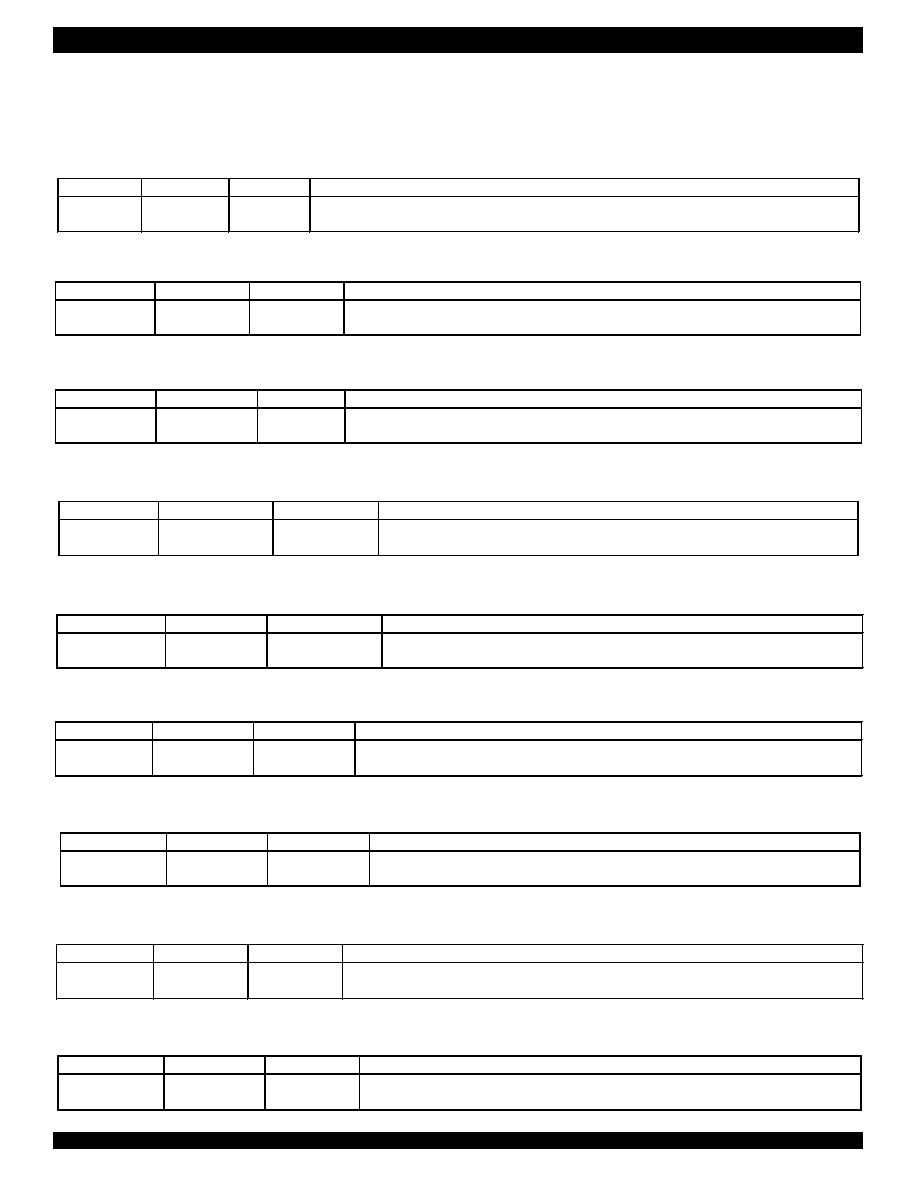

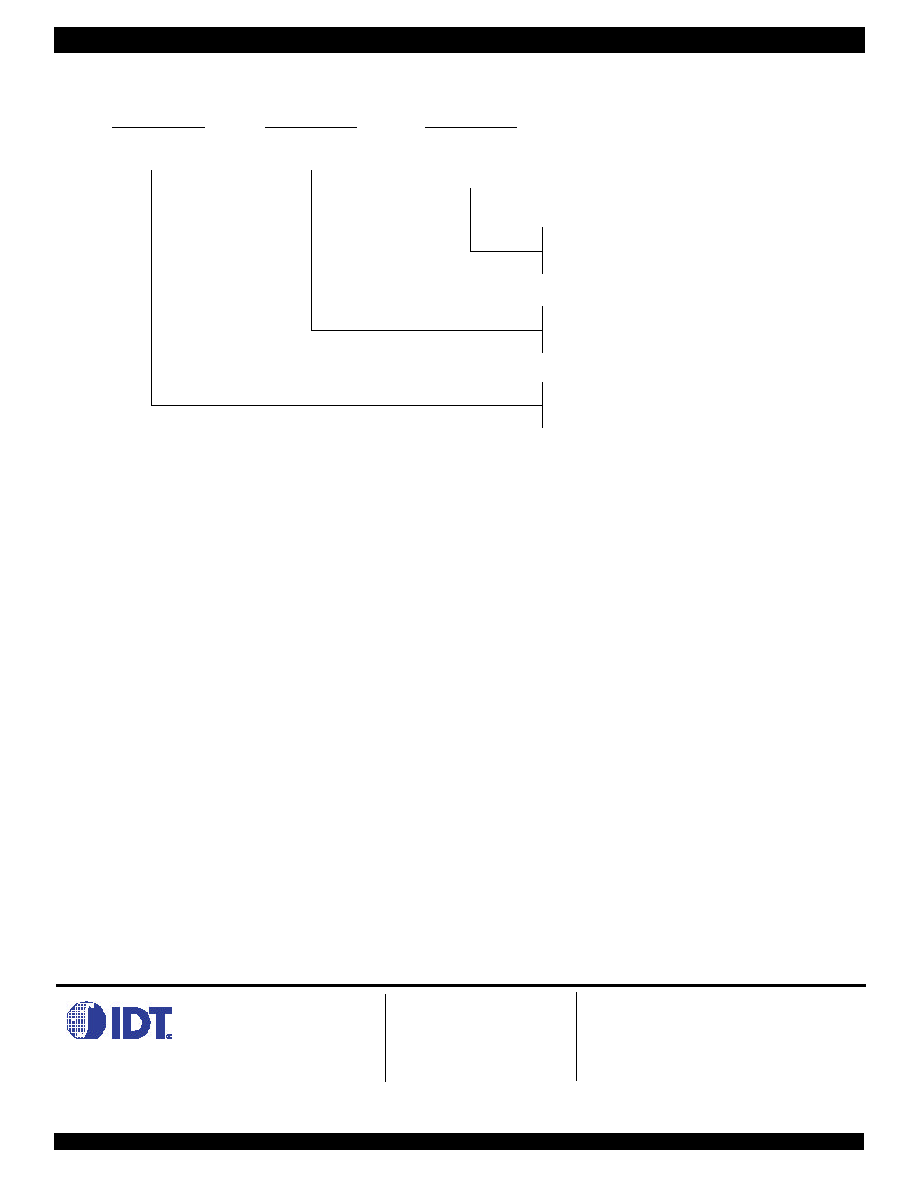

Service the Interrupt

Read Interrupt Status Register

Read Corresponding Status

Register

Interrupt Allowed

Interrupt Condition

Exist?

Yes

No

Figure - 17. Interrupt Service Routine

2. Status change in the SC (Short Circuit) Status Register(05H).

The automatic power driver circuit continuously monitors the output

drivers signal to update the specific bit in SCM which indicates pres-

ence or absence of the transmit line side short circuit condition.

3. Status change in the AIS (Alarm Indication Signal) Status

Register(13H). The AIS detector monitors the received signal to up-

date the specific bit in AIS which indicates presence or absence of a

AIS condition.

Interrupt Enable

The IDT82V2058 provides a latched interrupt output (INT) and the

three kinds of interrupts are all reported by this pin. When the Interrupt

Mask register (LOSM , SCM and AISM) is set to `1', the Interrupt Sta-

tus register (LOSI, SCI and AISI) is enabled respectively. Whenever

there is a transition (`0' to `1' or `1' to `0') in the corresponding Status

register, the Interrupt Status register will change into `1', which means

an interrupt occurs, and there will be a transition from high to low on

INT. An external pull-up resistor of approximately 10k

is required to

support the wire-OR operation of INT. When any of the three Interrupt

Mask registers is set to `0' (the power-on default value is `0'), the cor-

responding Interrupt Status register is disabled and the transition on

status register is ignored.

Interrupt Clearing

When an interrupt occurs, the Interrupt Status registers (LOSI, SCI

and AISI) are read to identify the interrupt source. And these registers

will be cleared to `0' after the corresponding Status register (LOS, SC

and AIS) being read. The Status registers will be cleared once the

corresponding conditions are met.

Pin INT is pulled High when there are no pending interrupt left.

The interrupt handling in the interrupt service routine is showed Fig-

ure-17.

A1

A3

A2

A4 A5 A6

D0 D1 D2 D3 D4 D5 D6 D7

R/W

D0 D1 D2 D3 D4 D5 D6 D7

A7

Input Data Byte

Address/Command Byte

High Impedance

Driven while R/W=1

SDI

SDO

SCLK

CS

1

2

2

MODE[2:0]

Host interface

Generic control, data, and output pin name

100

Non-multiplexed Motorola interface

CS, ACK, DS, R/W, AS, A[4:0], D[7:0], INT

101

Non-multiplexed Intel interface

CS, RDY, WR, RD, ALE, A[4:0], D[7:0], INT

110

Multiplexed Motorola interface

CS, ACK, DS, R/W, AS, AD[7:0], INT

111

Multiplexed Intel interface

CS, RDY, WR, RD, ALE, AD[7:0], INT

TABLE - 10. PARALLEL HOST INTERFACE PINS

Figure - 16. Serial Host Mode Timing

NOTE:

1. While R/W=1, read from IDT82V2058; While R/W=0, write to IDT82V2058.

2. Ignored.

22

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

Jitter

Attenuator

Jitter

Attenuator

HDB3/

AMI

Decoder

HDB3/

AMI

Encoder

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

Channel N ( 7 > N > 1 )

RTIPn

RRINGn

TTIPn

TRINGn

LOSn

RCLKn

RDn/RDPn

CVn/RDNn

TCLKn

BPVIn/TDNn

TDn/TDPn

G.772

Monitor

Transmit

All Ones

Jitter

Attenuator

Jitter

Attenuator

HDB3/

AMI

Decoder

HDB3/

AMI

Encoder

Remote

Loopback

Slicer

Peak

Detector

CLK&Data

Recovery

(DPLL)

Line

Driver

Waveform

Shaper

LOS

Detector

Channel 0

LOS0

RCLK0

RD0/RDP0

CV0/RDN0

TCLK0

BPVI0/TDN0

TD0/TDP0

Transmit

All Ones

RTIP0

RRING0

TTIP0

TRING0

Figure - 17. Monitoring Principle

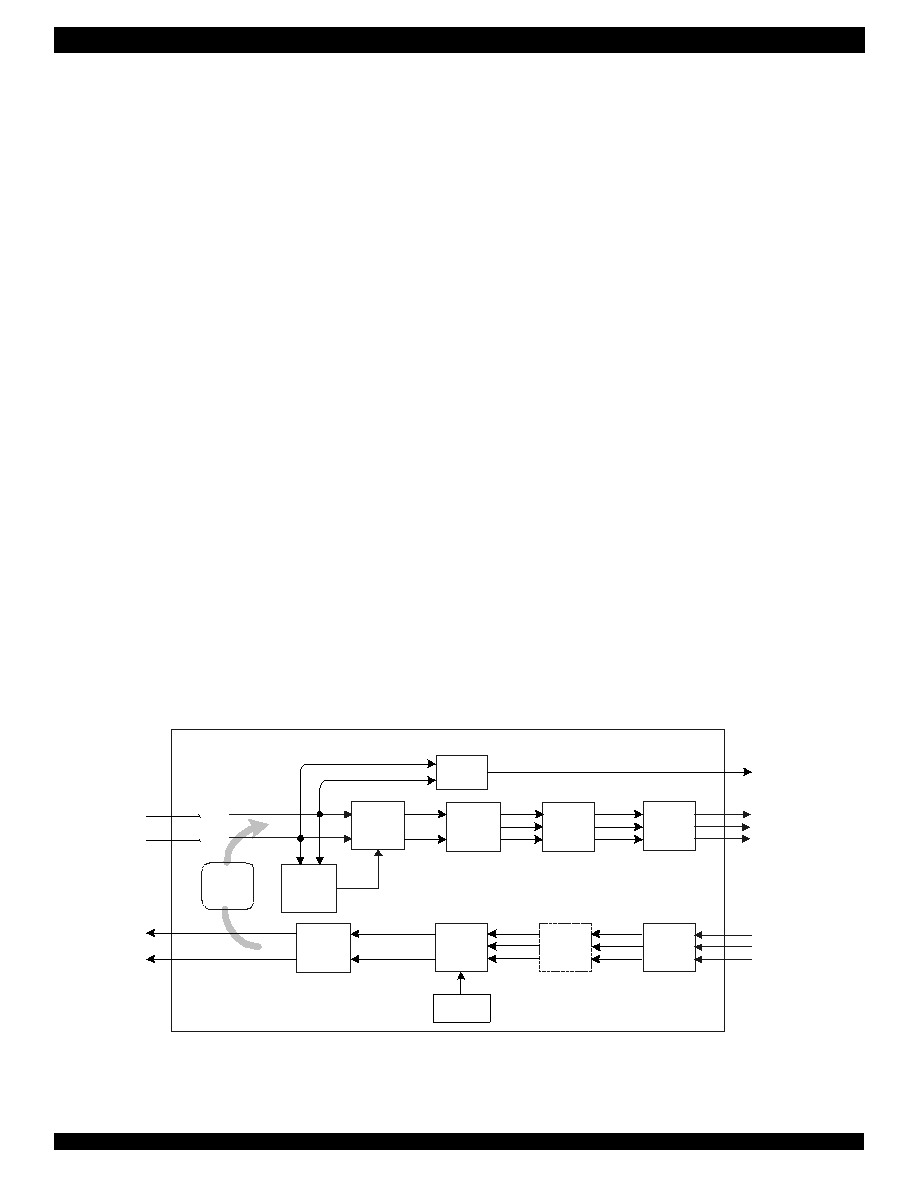

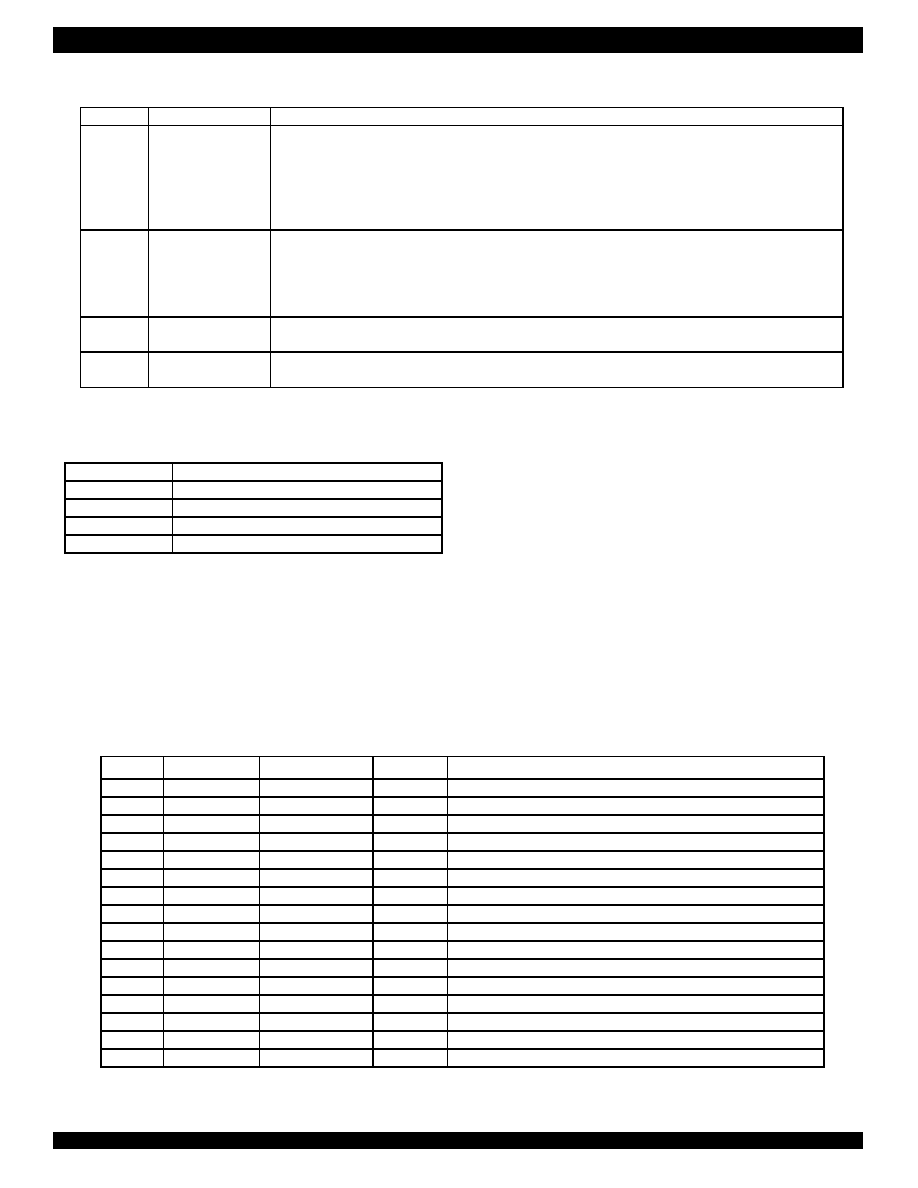

G.772 MONITORING

The eight channels of IDT82V2058 can all be configured to work as

regular transceivers. In applications using only seven channels

(channels 1 to 7), channel 0 is configured to non-intrusively monitor

any of the other channels' inputs or outputs on the line side. The

monitoring is non-intrusive per ITU-T G.772. Figure-17 shows the

Monitoring Principle. The receiver or transmitter path to be monitored

is configured by pin MC[0:3] in hardware mode or by PMON in host

mode (refer to

Programming Information for details).

The signal which is monitored goes through the clock and data

recovery circuit of channel 0. The monitored clock can output on

RCLK0 which can be used as a timing interfaces derived from E1

signal. The monitored data can be observed digitally at the output pin

RCLK0, RD0/RDP0 and RDN0. LOS detector is still in use in channel

0 for the monitored signal.

In monitoring mode, channel 0 can be configured to the Remote

Loopback. The signal which is being monitored will output on TTIP0

and TRING0. The output signal can then be connected to a standard

test equipment with an E1 electrical interface for non-intrusive

monitoring.

23

INDUSTRIAL TEMPERATURE RANGES

IDT82V2058 OCTAL E1 SHORT HAUL LINE INTERFACE UNIT

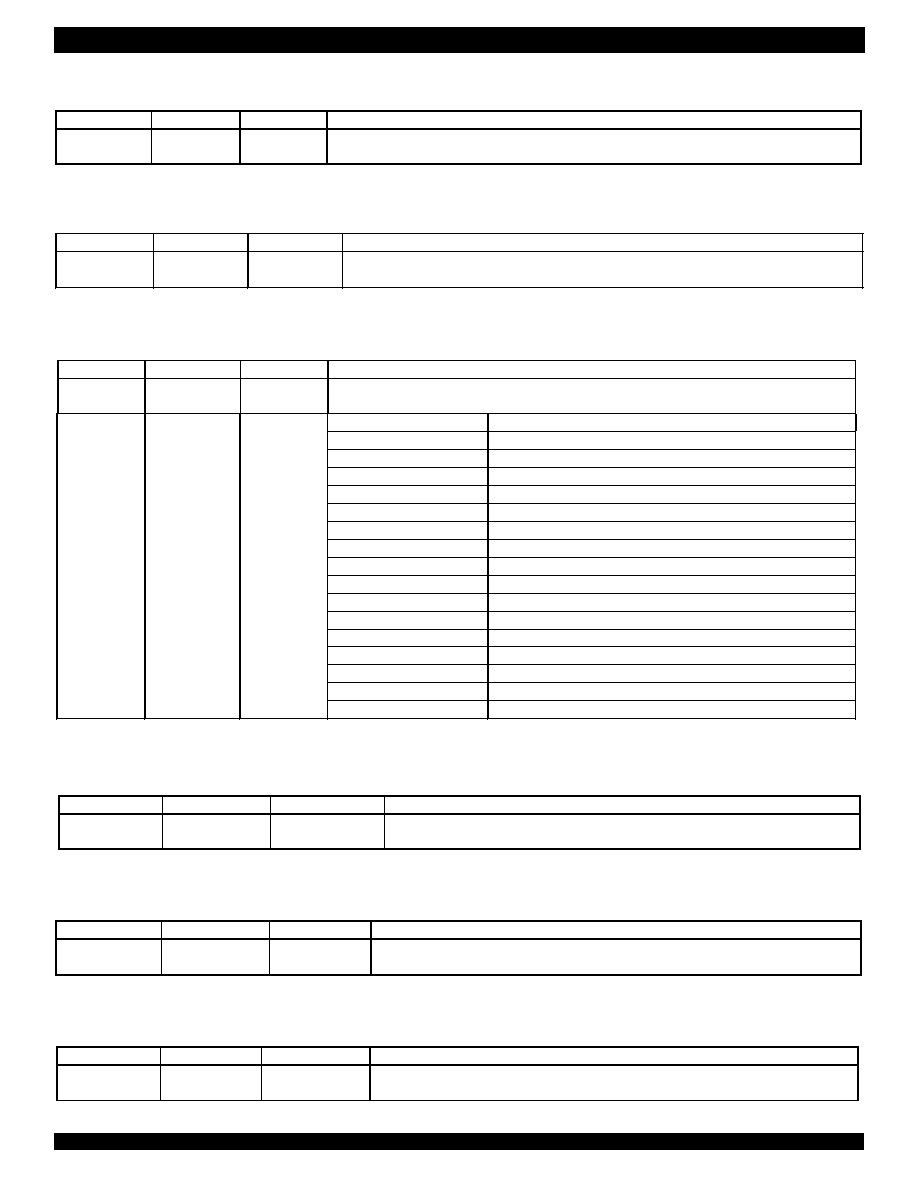

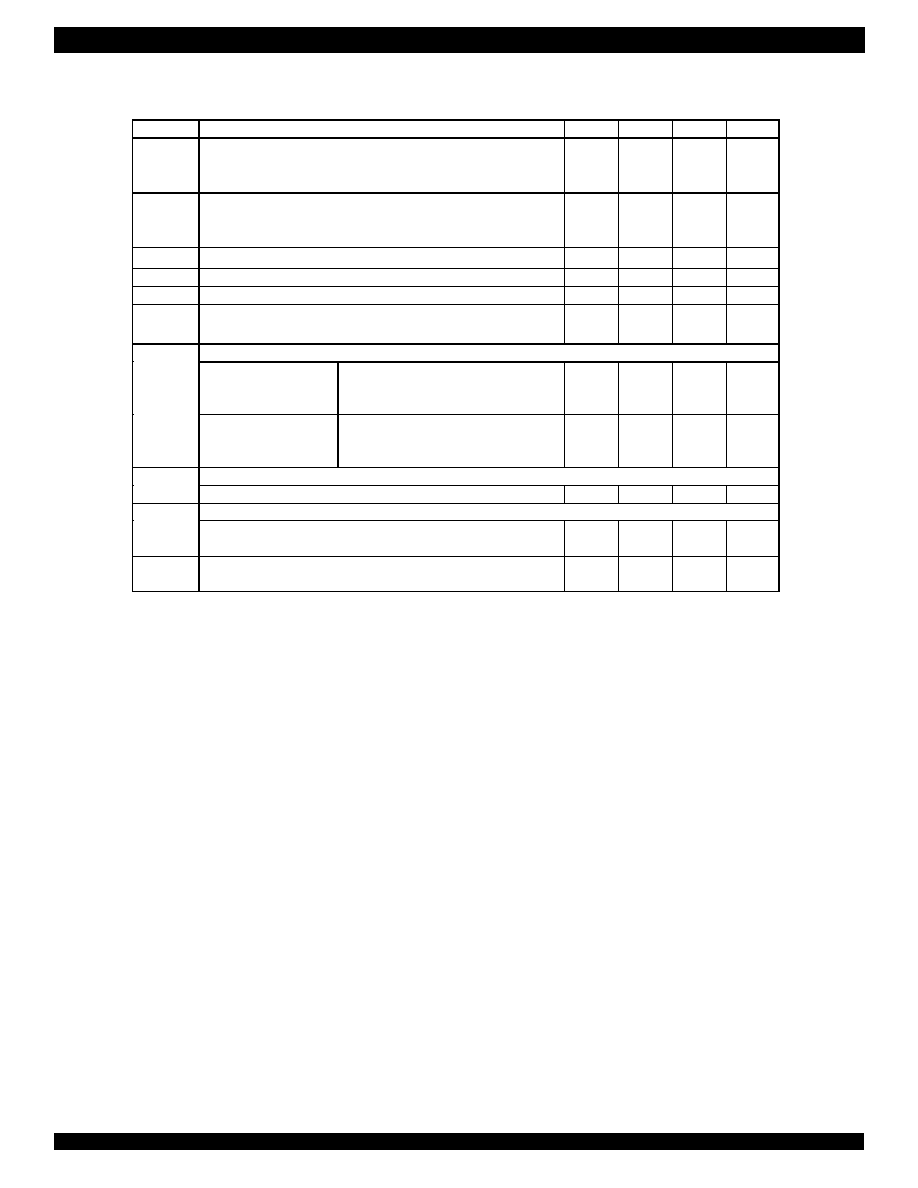

PROGRAMMING INFORMATION

REGISTER LIST AND MAP

There are 21 primary registers (including an Address Pointer Con-

trol Register), including 8 expanded registers in the device.

Whatever the control interface is, 5 address bits are used to set the

registers. In non-multiplexed parallel interface mode, the five dedicated

address bits are A[4:0]. In multiplexed parallel interface mode, AD[4:0]

Address

Hex

serial

interface

A7-A1

parallel

interface

A7-A0

Register

R/W

Explanation

00

XX00000

XXX00000 ID

R

Device ID Register

01

XX00001

XXX00001 ALB

R/W Analog Loopback Configuration Register

02