| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ILC1832M | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

ILC1832

µP Supervisory Circuit

Impala Linear Corporation

Impala Linear Corporation

1

(408) 574-3939

www.impalalinear.com

October 1999

ILC1832 1.1

The ILC1832 is a multifunction circuit which monitors micro-

processor activity, external reset and power supplies in

microprocessor based systems. Ths circuit functions

include a watchdog timer, power supply monitor, micro-

processor reset, and manual pushbutton reset input.

The power supply line is monitored with a comparator and

an internal voltage reference. RST is forced low when an

out-of-tolerance condition exists and remains asserted for

at least 250ms after V

CC

rises above the threshold voltage

(2.55V or 2.88V). The RST pin will remain logic low with

V

CC

as low as 1.4V.

The Watchdog input (ST) monitors µP activity and will assert

RST if no µP activity has occurred within the watchdog time-

out period. The watchdog timeout period is selectable with

nominal periods of 150, 600, or 1200 milliseconds.

∑ Power OK/Reset Time Delay, 250ms min.

∑ Watchdog Timer, 150 ms, 600ms, or 1.2s Typical

∑ Precision Supply Voltage Monitor, Select Between 5%

or 10% of Supply Voltage

∑ 18µA Supply Current

∑ Debounced External Reset Input

∑ 8-Pin SOIC or DIP Package

∑ Computers

∑ Controllers

∑ Critical Microprocessor Power Monitoring

∑ Intelligent Instruments

∑ Portable Equipment

ILC1832

V

CC

Top View

PBRST

RST

TD

2

1

8

6

RST

GND

ST

TOL

4

3

5

7

ETC1832N - 8 Lead Plastic DIP Package

ETC1832M - 8 Lead Plastic SOIC Package

ILC1832

µ

µ

P

V

CC

V

CC

V

CC

ST

RESET

PBRST

RST

TD

GND

TOL

I/O

Part

Package

Temp. Range

ILC1832N

8-Lead PDIP

-40∞C to +85∞C

ILC1832M

8-Lead SOIC

-40∞C to +85∞C

General Description

Features

Applications

Ordering Information

Typical Circuit

Pin-Package Configurations

Preliminary

Parameter

Symbol

Ratings

Units

V

CC

-0.3 to 7.0

V

Terminal Voltage

All other inputs

-0.3 to (V

CC

+ 0.3)

V

V

CC

250

mA

Input Current

GND All other inputs

25

mA

Operating Temperature Range

T

A

-40 to +85

∞C

Storage Temperature Range

-65 to +150

∞C

Lead Temperature (Soldering, 10 sec.)

300

∞C

Power Dissipation

700

mW

Parameter

Conditions

Min

Typ

Max

Units

Supply Voltage Range, V

CC

5.5

V

Supply Current, I

CC

V

CC

= 5V (See Note 1)

V

CC

= 3.3V (See Note 1)

18

15

30

25

µ

A

ST and PBRST Input Levels

V

IH

, V

CC

> 2.7V

V

IH

, V

CC

< 2.7V

V

IL

2.0

V

CC

≠0.4

-0.3

V

CC

+ 0.3

V

CC

+ 0.3

0.5

V

Input Leakage PBRST, I

IL

(See Note 2)

±1

µ

A

Output Voltage, RST, RST

I

SOURCE

= 350µA, V

CC

= 3.3V

2.4

V

Output Voltage, RST, RST

I

SINK

= 10mA, V

CC

= 3.3V

0.4

V

Output Voltage, RST

I

SINK

= 50µA, V

CC

= 1.4V

0.3

V

V

CC

5% Trip Point (Reset Threshold Voltage)

TOL= GND

2.80

2.88

2.97

V

V

CC

10% Trip Point (Reset Threshold Voltage)

TOL= V

CC

2.47

2.55

2.64

V

Input Capacitance, ST, TOL

C

IN

(See Note 3)

5

pF

Output Capacitance, RST, RST

C

OUT

(See Note 3)

7

pF

PBRST Min. Pulse Width, t

PB

PBRST = V

IL

(See note 4)

20

ms

PBRST Delay, t

PBD

1

4

20

ms

Reset Active Time, t

RST

250

610

1000

ms

ST Pulse Width, t

ST

20

ns

ST Timeout Period, t

TD

TD = 0V

TD = Open

TD = V

CC

62.5

250

500

150

600

120

0

250

1000

2000

ms

V

CC

Fall Time, t

F

40

µ

s

V

CC

Rise Time, t

R

0

ns

V

CC

Detect to RST Low and RST High, tRPD

V

CC

Falling at 1.66 mV/

µ

s

5

8

µ

s

V

CC

Detect to RST Open and RST Low, tRPU

V

CC

Rising

250

610

1000

ms

V

CC

= 3 to 5.5V, T

A

= Operating Temperature Range, unless otherwise noted.

Stresses above those listed under ABSOLUTE MAXIMUM RATINGS may cause permanent device failure. Functionality at

or above these limits is not implied. Exposure to absolute maximum ratings for extended periods may affect device reliability.

Operating ranges define those limits between which the functionality of the device is guaranteed.

Note 1: I

CC

is measured with PBRST and all outputs open and inputs within 0.5V of supply rails.

Note 2: PBRST has an internal 40k

(typical) pull-up resistor to V

CC

.

Note 3: Guaranteed by design at T

A

= 25∞C.

Note 4: PBRST must be held low for a minimum of 20ms to guarantee a reset.

µP Supervisory Circuit

Preliminary

Impala Linear Corporation

2

(408) 574-3939

www.impalalinear.com

October 1999

ILC1832 1.1

Electrical Characteristics

Absolute Maximum Ratings

Pin

Number

Pin

Name

Description

1

PBRST

Pushbutton reset input. This input is debounced and can be driven with external logic

signals or a mechanical pushbutton to actively force a reset. All pulses less than 1ms in

duration on the PBRST pin are ignored. Any pulse with a duration of 20ms or greater is

guaranteed to cause a reset. PBRST has an internal 40k

(typical) pull-up resistor to V

CC

.

2

TD

Time delay input. This input selects the timebase used by the watchdog timer. When TD =

0V, the watchdog timeout period is set to a nominal value of 150ms, when TD = open, the

watchdog timeout period is set to a nominal value of 600ms and when TD = V

CC

, the

watchdog timeout period is 1.2 sec nominally.

3

TOL

Tolerance select input. Selects whether 5% or 10% of V

CC

is used as the reset threshold

voltage. When TOL = 0V, the 5% tolerance level is selected and when TOL = V

CC

, a 10%

tolerance level is selected.

4

GND

Ground pin, 0V reference.

5

RST

RST is asserted high if either V

CC

goes below the reset threshold, the watchdog times out or

PBRST is pulled low for a minimum of 20ms. RST remains asserted for one reset timeout

period after V

CC

exceeds the reset threshold or after the watchdog times out or after PBRST

goes high.

6

RST

RST is asserted low if either V

CC

goes below the reset threshold, the watchdog times out or

PBRST is pulled low for a minimum of 20ms. RST remains asserted for one reset timeout

period after V

CC

exceeds the reset threshold or after the watchdog times out or after PBRST

goes high. Open-drain output.

7

ST

Input to the watchdog timer. If ST does not see a transition from high to low within the

watchdog timeout period, RST and RST will be asserted.

8

V

CC

Power supply input.

8

1

Reset

Generator

6

4

-

+

V

CC

ST

RST

GND

3

7

2

Trip Point

Select

Ref

Manual Reset

Debounce

Watchdog

Timer

Timeout

Select

5

RST

TOL

PBRST

TD

µP Supervisory Circuit

Preliminary

Pin Functions

Block Diagram

Impala Linear Corporation

3

(408) 574-3939

www.impalalinear.com

October 1999

ILC1832 1.1

Pushbutton Reset Input

The PBRST input can be driven with a manual pushbutton

switch or with external logic signals. The input is internally

debounced and requires an active low signal to force the

reset outputs into their active states. The PBRST input will

recognize any pulse that is 20ms in duration or greater and

will ignore all pulses that are less than 1ms in duration.

Power Monitor

The RST and RST pins are asserted whenever V

CC

falls

below the reset threshold voltage set by the TOL pin. A 5%

tolerance level (2.88V reset threshold voltage) can be

selected by connecting the TOL pin to ground or a 10% tol-

erance (2.55V reset threshold voltage) can be selected by

connecting the TOL pin to V

CC

. The reset pins will remain

asserted for a period of 250ms after V

CC

has resen above

the reset threshold voltage. The reset function ensures the

microprocessor is properly reset and powers up into a

known condition after a power failure. RST will remain valid

with V

CC

as low as 1.4V.

Watchdog Timer

The microprocessor can be monitored by connecting the ST

pin (watchdog input) to a bus line or I/O line. If a high-to-

low transition does not occur on the ST pin within the watch-

dog timeout period set by the TD pin (see Table 1), the RST

and RST pins will be asserted rsulting in a microprocessor

reset. RST and RST will remain asserted for 250ms when

this occurs. A minimum pulse of 75ns or any transition

high-to-low on the ST pin will reset the watchdog timer. The

watchdog timer will be reset if ST sees a valid transition

within the watchdog timeout period.

RST

t

RPD

V

CCTP

V

CCTP

t

RPU

V

CC

RST

RST

t

PDLY

t

RST

PBRST

RST

t

PB

t

TD

TD Pin

Min.

Typ.

Max.

GND

62.5 ms

150 ms

250 ms

Open

250 ms

600 ms

1000 ms

V

CC

500 ms

1200 ms

2000 ms

Industry P/N

ILC Direct Replacement

DS1832

ILC1832N

DS1832S

ILC1832M

t

SD

ST

t

TD

Power-Up/Power-Down Sequence

Watchdog Input

Pushbutton Reset

µP Supervisory Circuit

Preliminary

Circuit Description

Alternate Source Reference Guide

Impala Linear Corporation

4

(408) 574-3939

www.impalalinear.com

October 1999

ILC1832 1.1

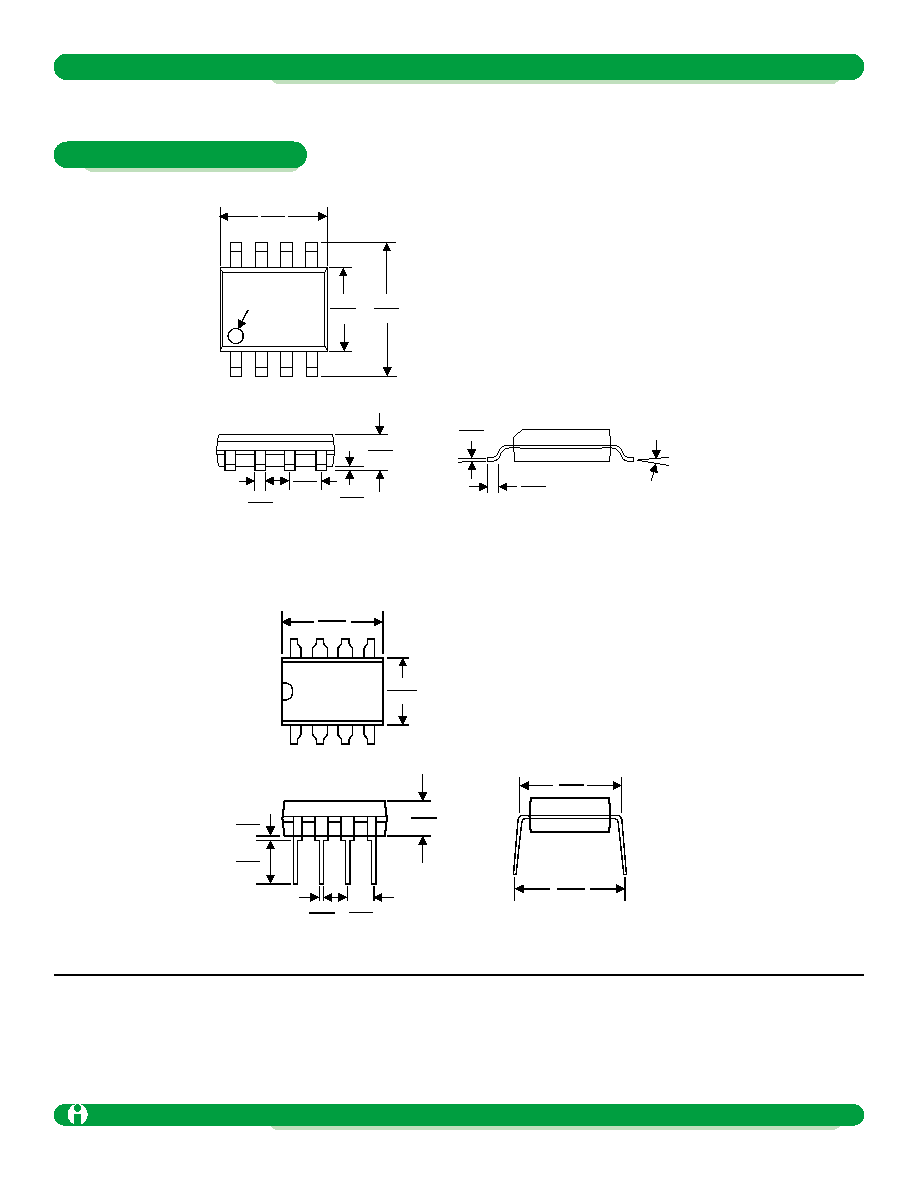

Pin 1 identifier

0.197

0.190

0.155

0.150

0.244

0.228

0.069

0.053

0.011

0.004

0.060

0.040

0.019

0.013

0.050

0.016

0.012

0.009

0.8∞

M Package, 8-Pin Small-Outline

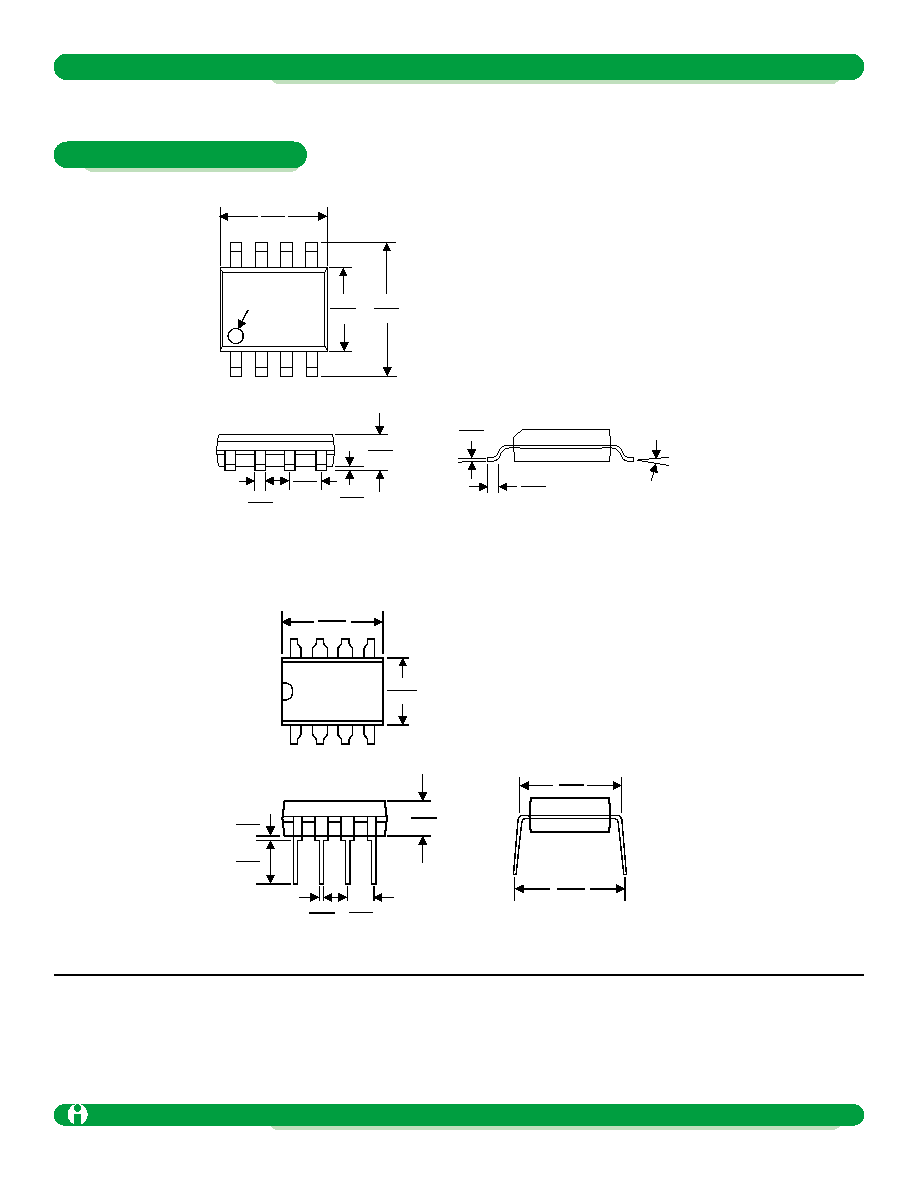

0.260

0.240

0.019

0.013

0.260

0.240

0.260

0.240

0.260

0.240

0.260

0.240

0.260

0.240

0.260

0.240

0.260

0.240

N Package, 8-Pin Plastic Dual In-Line

Devices sold by Impala Linear Corporation are covered by the warranty and patent indemnification provisions appearing

in its Terms of Sale only. Impala Linear Corporation makes no warranty, express, statutory, implied, or by description

regarding the information set forth herein or regarding the freedom of the described devices from patent infringement.

Impala Linear Corporation makes no warranty of merchantability or fitness for any purpose. Impala Linear Corporation

reserves the right to discontinue production and change specifications and prices at any time and without notice.

This product is intended for use in normal commercial applications. Applications requiring an extended temperature

range, unusual environmental requirements, or high reliability applications, such as military and aerospace, are specif-

ically not recommended without additional processing by Impala Linear Corporation.

Impala Linear Corporation assumes no responsibility for the use of any circuitry other than circuitry embodied in an

Impala Linear Corporation product. No other circuits, patents, licenses are implied.

Life Support Policy

Impala Linear Corporation's products are not authorized for use as critical components in life support devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform, when properly used in accordance with instructions for use pro-

vided in the labelling, can be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reason-

bly expected to cause the failure of the life support device or system, or to affect its safety or effectiveness.

µP Supervisory Circuit

Preliminary

Packaging Information

Impala Linear Corporation

5

(408) 574-3939

www.impalalinear.com

October 1999

ILC1832 1.1