Giant Magneto Resistive Position Sensor

Version 1.0

GMR S 4

Data Sheet

1

1999-04-01

Data Sheet

This angle sensor is based on the brand new Giant Magneto Resistive (GMR)

technology. It is outstanding for the huge tolerances it offers to the user in

assembly.

x

new type

The GMR S 4 is an angle sensor based on sputtered metallic multilayer technology. The

outstanding feature of this magnetic sensor is the fact that it is sensitive to the

orientation of the magnetic field and not to its intensity as long as the field is in a range

between 5 ... 15 kA/m. This means, the signal output of this sensor is independent

of the sensor position relative to the magnet in lateral, axial or rotational direction

in the range of several millimeters. Optimum results are achieved by using magnetic

targets like permanent magnets or magnetic pole-wheels. There is no need for a

biasing magnet! Due to the linear change of both, basic and field dependent part of the

resistance vs. temperature, simple and efficient electronic compensation of

T

C

(

R

,

R

) is

possible.

Type

Marking

Ordering Code

x

GMR S 4

s

Q62705-K5002

Features

∑ GMR sensor on copper

leadframe

∑ Sensitive to the direction, not

to the intensity of the magnetic

field

∑ Constant

T

C

of basic resistance

R

and magneto resistance

R

Applications

∑ Rotation sensing with large air

gaps according to sketch below

∑ Angle encoders

∑ Contactless potentiometers

Pin Configuration

1, 2

supply voltage

terminals

3, 4

not connected

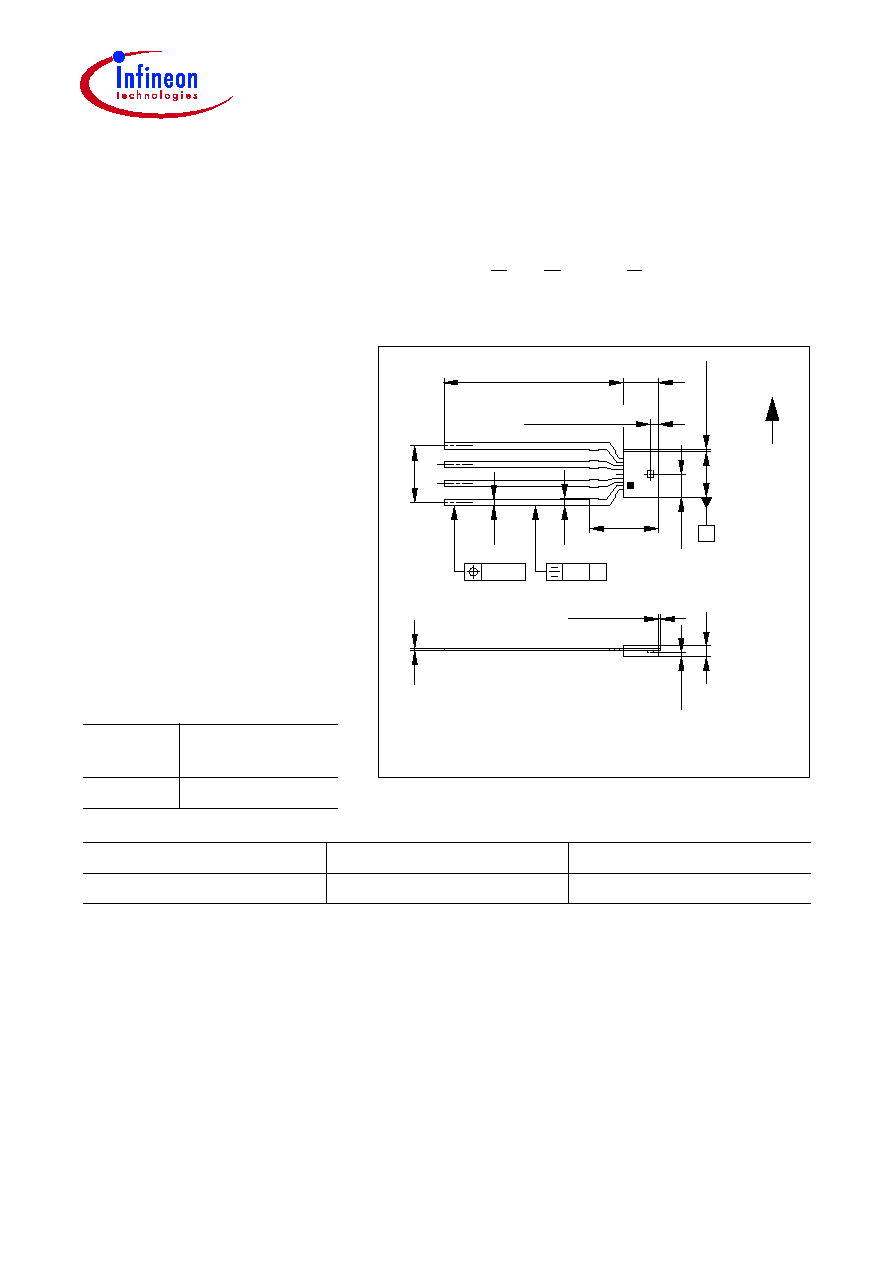

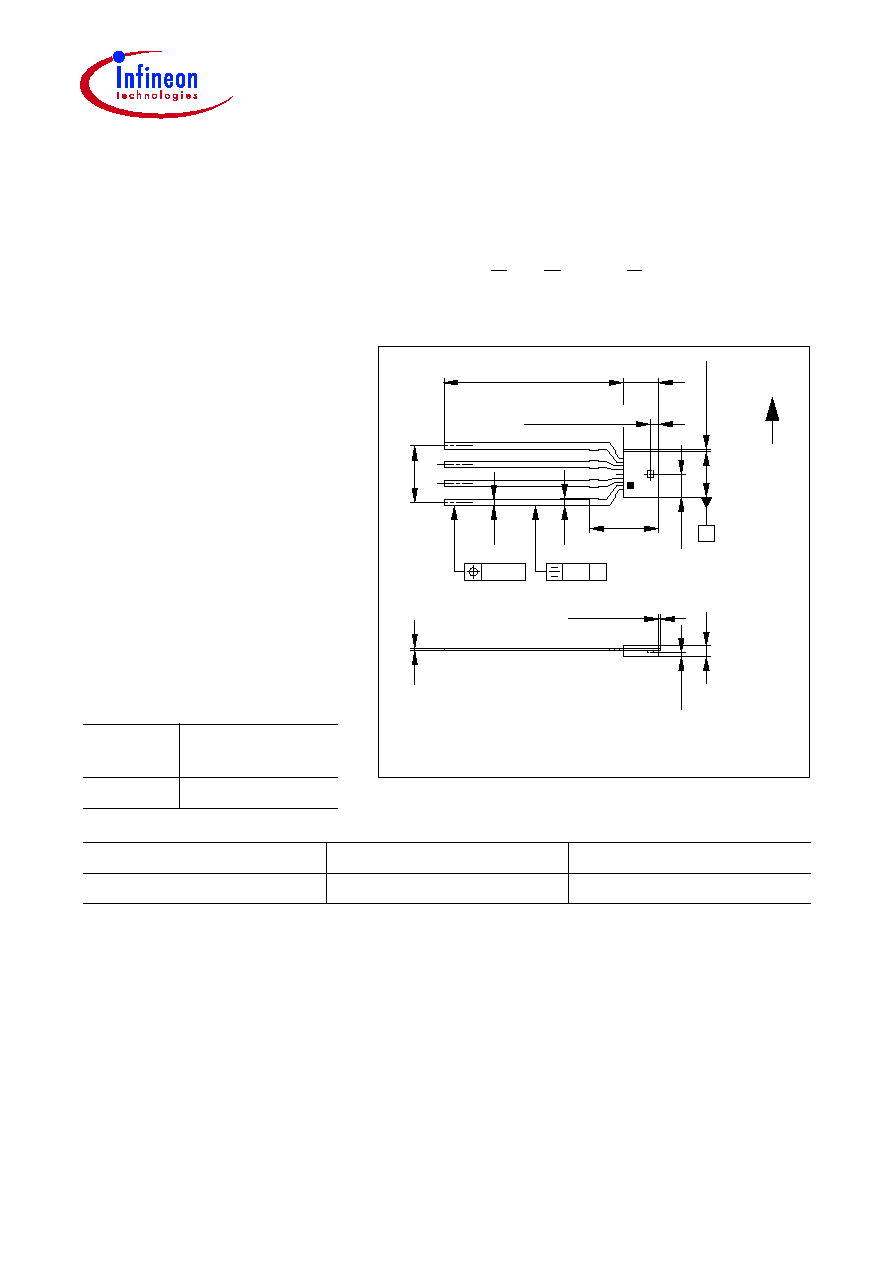

Dimensions in mm

Internal magnetization is in direction of the longest side of the

housing.

GPX06981

4

3

2

1

12.3

11.7

2.1

2.3

4.7

4.3

0.55

±0.15

3.2

3.0

±0.15

1.5

Injection flash

Flash 0.1 max

0.1 max

3 x 1.27 = 3.81

spacing

Chip center

0.35

0.55

0.5

0.35

0.2

0.3

0.7

0.6

0.28

±0.1

Chip

Approx. weight 0.05 g

1, 2 GMR access

3, 4 not connected

A

0.3

¯0.15

A

Directions of internal magnetization

GMR S 4

Data Sheet

2

1999-04-01

Maximum Ratings

Parameter

Symbol

Value

Unit

Operating temperature

T

A

≠ 40 ... + 150

∞

C

Storage temperature

T

stg

≠ 50 ... + 150

∞

C

Supply current

I

1

5

mA

Thermal conductivity

G

thC

A

G

thC

C

> 2.2

> 5

mW/K

mW/K

Magnetic field

1)

1)

larger fields may reduce the magnetoresistive effect irreversibly

H

rot

< 15

kA/m

OHS00375

Resistance

0∞

180∞

360∞

Rotating

Magnet

GMR Sensor

Output signal vs orientation of magnet

R = R

0

+ 0.5

R *

)

(1-cos

N

S

*

Principle of operation

Angle

GMR S 4

Data Sheet

3

1999-04-01

Application Hints

The application mode of the GMR position sensor is preferably as a bridge or halfbridge

circuit. In every case this type of circuit compensates for the

T

C

of the resistance value

R

0

. To compensate for the

T

C

of the GMR effect

R

/

R

0

, if there is the necessity, is left to

the application circuit and can be done for example with a NIC circuit. When operated

over a complete 360

∞

turn, a total signal of

20 mV/V is achieved at 25

∞

C with a

halfbridge. The output signal is doubled when a fullbridge circuit is used. In the case of

linear position sensing, the electrical circuit remains unchanged.

Characteristics (

T

A

= 25

∞

C)

Parameter

Symbol

Value

Unit

Nominal supply current

I

1N

4

mA

Basic resistance

R

0

> 700

Magnetoresistive effect

H

rot

= 5 ... 15 kA/m

R

/

R

0

4

%

Temperature coefficient of

basic resistance

TC

R0

+ 0.09 ... + 0.12

%/K

Temperature coefficient of

magnetoresistance

TC

R

≠ 0.12 ... ≠ 0.09

%/K

Temperature coefficient of

magnetoresistive effect

TC

R/R0

≠ 0.27 ... ≠ 0.23

%/K

Hysteresis at

H

rot

= 10 kA/m

Hys

< 2

degrees