LB Y876

BLUE LINE

TM

Hyper Micro SIDELED

Hyper-Bright LED

Vorl‰ufige Daten / Preliminary Data

2001-11-14

1

Besondere Merkmale

∑ Geh‰usetyp: weiþes SMT Geh‰use

∑ Besonderheit des Bauteils: kleine Bauform

mit extrem breiter Abstrahlcharakteristik; ideal

f¸r Hinterleuchtungen und Einkopplungen in

Lichtleiter

∑ Wellenl‰nge: 465 nm

∑ Abstrahlwinkel: Lambertscher Strahler (120∞)

∑ Technologie: GaN

∑ optischer Wirkungsgrad: 1 lm/W

∑ Gruppierungsparameter: Lichtst‰rke

∑ Verarbeitungsmethode: f¸r alle

SMT-Best¸cktechniken geeignet

∑ Lˆtmethode: IR Reflow Lˆten und

Wellenlˆten (TTW)

∑ Vorbehandlung: nach JEDEC Level 2

∑ Gurtung: 8 mm Gurt mit 3000/Rolle, ¯180 mm

oder 10000/Rolle, ¯330 mm

∑ ESD-Festigkeit: ESD-sicher bis 2 kV nach

EOS/ESD-5.1-1993

Anwendungen

∑ optimale Einkopplung in Lichtleiter

∑ Hinterleuchtung (LCD, Mobiltelefone, Tasten,

Allgemeinbeleuchtung, Werbebeleuchtung)

∑ Signal- und Symbolleuchten

∑ Automobilbereich (z. B.

Instrumentenbeleuchtung)

Features

∑ package: white SMT package

∑ feature of the device: small package with

extremely wide viewing angle; ideal for

backlighting and coupling in light guides

∑ wavelength: 465 nm

∑ viewing angle: Lambertian Emitter (120∞)

∑ technology: GaN

∑ optical efficiency: 1 lm/W

∑ grouping parameter: luminous intensity

∑ assembly methods: suitable for all

SMT assembly methods

∑ soldering methods: IR reflow soldering and

TTW soldering

∑ preconditioning: acc. to JEDEC Level 2

∑ taping: 8 mm tape with 3000/reel, ¯180 mm or

10000/reel, ¯330 mm

∑ ESD-withstand voltage: up to 2 kV acc. to

EOS/ESD-5.1-1993

Applications

∑ optimized coupling into light guides

∑ backlighting (LCD, cellular phones, keys,

general lightning, illuminated advertising)

∑ signal and symbol luminaire

∑ automotive (e. g. car radio backlighting)

2001-11-14

2

LB Y876

Anm.: -1 gesamter Farbbereich

Die Standardlieferform von Serientypen beinhaltet eine untere bzw. eine obere Familiengruppe,

die aus nur 3 bzw. 4 Halbgruppen besteht. Einzelne Halbgruppen sind nicht erh‰ltlich.

In einer Verpackungseinheit / Gurt ist immer nur eine Halbgruppe enthalten.

Note: -1 Total color tolerance range

The standard shipping format for serial types includes a lower or upper family group of 3 or 4

individual groups. Individual half groups are not available.

No packing unit / tape ever contains more than one luminous intensity half group.

Typ

Type

Emissions-

farbe

Color of

Emission

Farbe der

Lichtaustritts-

fl‰che

Color of the

Light Emitting

Area

Lichtst‰rke

Luminous

Intensity

I

F

= 10 mA

I

V

(mcd)

Lichtstrom

Luminous

Flux

I

F

= 10 mA

V

(mlm)

Bestellnummer

Ordering Code

LB Y876-J1K1-1

LB Y876-K1L2-1

blue

colorless clear

4.5 ...

9.0

7.1 ... 18.0

20 (typ.)

36 (typ.)

Q62703-Q6185

Q62703-Q6186

LB Y876

2001-11-14

3

Grenzwerte

Maximum Ratings

Bezeichnung

Parameter

Symbol

Symbol

Wert

Value

Einheit

Unit

Betriebstemperatur

Operating temperature range

T

op

≠ 40 ... + 100

∞C

Lagertemperatur

Storage temperature range

T

stg

≠ 40 ... + 100

∞C

Sperrschichttemperatur

Junction temperature

T

j

+ 100

∞C

Durchlassstrom

Forward current

I

F

20

mA

Stoþstrom

Surge current

t

10

µ

s,

D

= 0.005

I

FM

t.b.d.

A

Sperrspannung

Reverse voltage

V

R

5

V

Leistungsaufnahme

Power consumption

T

A

25 ∞C

P

tot

90

mW

W‰rmewiderstand

Thermal resistance

Sperrschicht/Umgebung

Junction/air

Sperrschicht/Lˆtpad

Junction/solder point

Montage auf PC-Board FR 4 (Padgrˆþe

16 mm

2

)

mounted on PC board FR 4 (pad size

16 mm

2

)

R

th JA

R

th JS

630

350

K/W

K/W

2001-11-14

4

LB Y876

Kennwerte (

T

A

= 25 ∞C)

Characteristics

Bezeichnung

Parameter

Symbol

Symbol

Werte

Values

Einheit

Unit

Wellenl‰nge des emittierten Lichtes

(typ.)

Wavelength at peak emission

I

F

= 10 mA

peak

428

nm

Dominantwellenl‰nge

1)

Dominant wavelength

1)

I

F

= 10 mA

dom

465 ± 3

nm

nm

Spektrale Bandbreite bei 50 %

I

rel max

(typ.)

Spectral bandwidth at 50 %

I

rel max

I

F

= 10 mA

60

nm

Abstrahlwinkel bei 50 %

I

V

(Vollwinkel)

(typ.)

Viewing angle at 50 %

I

V

2

120

Grad

deg.

Durchlassspannung

2)

(typ.)

Forward voltage

2)

(max.)

I

F

= 10 mA

V

F

V

F

3.5

4.1

V

V

Sperrstrom

(typ.)

Reverse current

(max.)

V

R

= 5 V

I

R

I

R

0.01

10

µ

A

µ

A

Temperaturkoeffizient von

peak

(typ.)

Temperature coefficient of

peak

I

F

= 10 mA; ≠10∞C

T

100∞C

TC

peak

0.004

nm/K

Temperaturkoeffizient von

dom

(typ.)

Temperature coefficient of

dom

I

F

= 10 mA; ≠10∞C

T

100∞C

TC

dom

0.03

nm/K

Temperaturkoeffizient von

V

F

(typ.)

Temperature coefficient of

V

F

I

F

= 10 mA; ≠10∞C

T

100∞C

TC

V

≠ 3.1

mV/K

Optischer Wirkungsgrad

(typ.)

Optical efficiency

I

F

= 10 mA

opt

1

lm/W

1)

Wellenl‰ngen werden mit einer Stromeinpr‰gedauer von 25 ms und einer Genauigkeit von ±1 nm ermittelt.

Wavelengths are tested at a current pulse duration of 25 ms and a tolerance of ±1 nm.

2)

Spannungswerte werden mit einer Stromeinpr‰gedauer von 1 ms und einer Genauigkeit von ±0,1 V ermittelt.

Voltages are tested at a current pulse duration of 1 ms and a tolerance of ±0.1 V.

LB Y876

2001-11-14

5

Helligkeitswerte werden mit einer Stromeinpr‰gedauer von 25 ms und einer Genauigkeit von

±

11% ermittelt.

Luminous intensity is tested at a current pulse duration of 25 ms and a tolerance of

±

11%.

Helligkeits-Gruppierungsschema

Luminous Intensity Groups

Lichtgruppe

Luminous Intensity Group

Lichtst‰rke

Luminous Intensity

I

V

(mcd)

Lichtstrom

Luminous Flux

V

(mlm)

J1

J2

K1

K2

L1

L2

4.5 ...

5.6

5.6 ...

7.1

7.1 ...

9.0

9.0 ... 11.2

11.2 ... 14.0

14.0 ... 18.0

15 (typ.)

19 (typ.)

24 (typ.)

30 (typ.)

40 (typ.)

50 (typ.)

Gruppenbezeichnung auf Etikett

Group Name on Label

Beispiel: K2

Example: K2

Lichtgruppe

Luminous Intensity Group

Halbgruppe

Half Group

K

2

2001-11-14

6

LB Y876

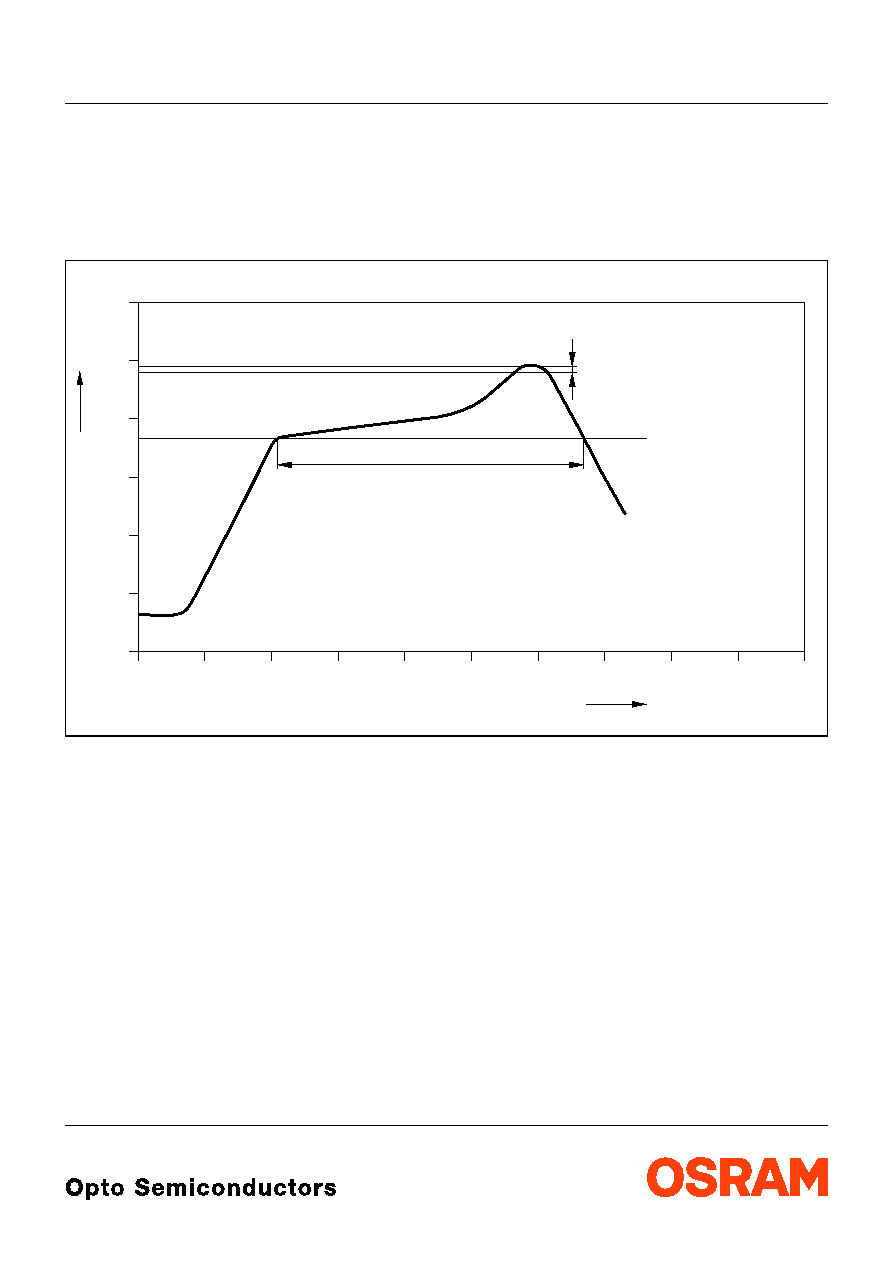

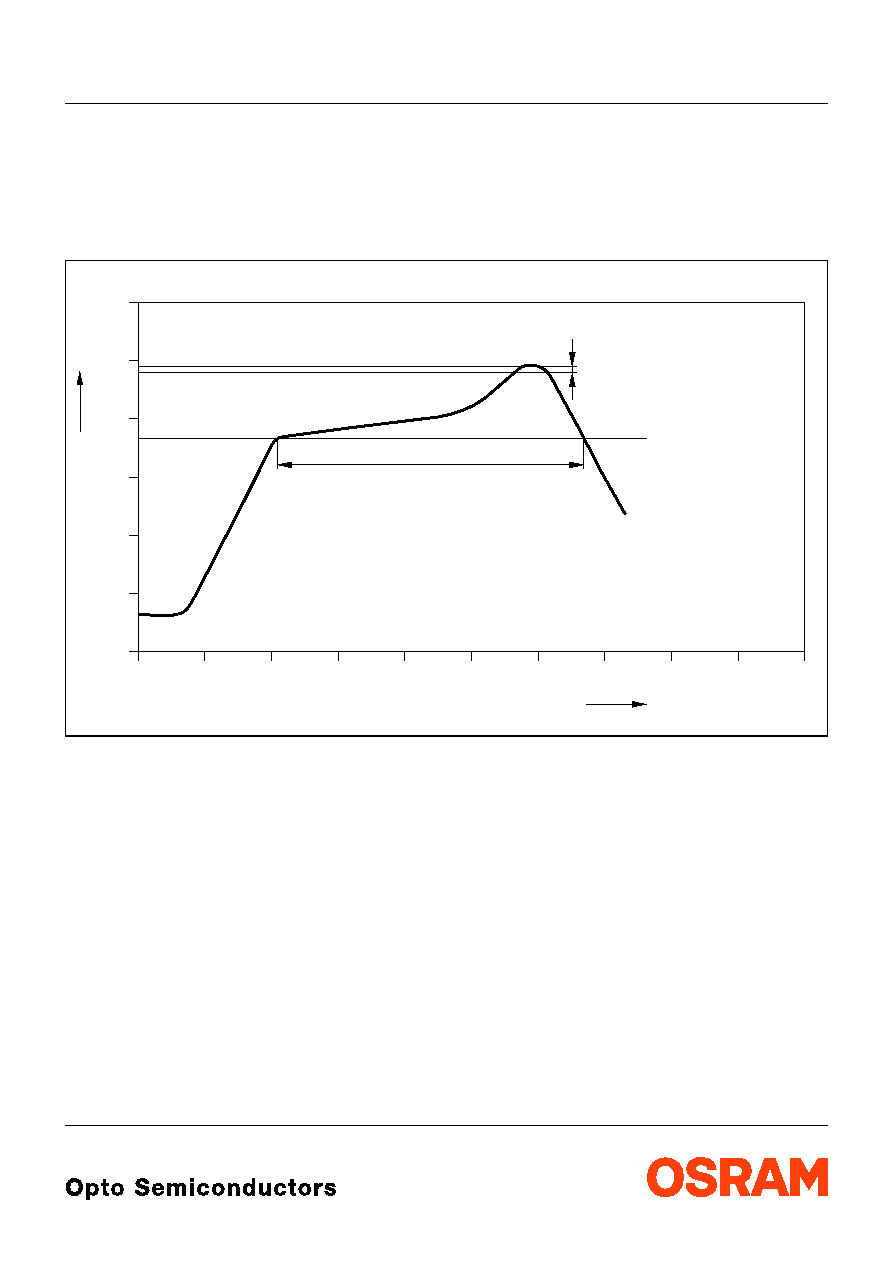

Relative spektrale Emission

I

rel

=

f

(

),

T

A

= 25 ∞C,

I

F

= 10 mA

Relative Spectral Emission

V(

) = spektrale Augenempfindlichkeit

Standard eye response curve

Abstrahlcharakteristik

I

rel

=

f

(

)

Radiation Characteristic

OHL00431

380

0

20

40

60

80

100

%

I

rel

V

blue

430

480

530

580

630

680

nm

0

0.2

0.4

1.0

0.8

0.6

1.0

0.8

0.6

0.4

0∞

10∞

20∞

40∞

30∞

OHL01660

50∞

60∞

70∞

80∞

90∞

100∞

0∞

20∞

40∞

60∞

80∞

100∞

120∞

LB Y876

2001-11-14

7

Durchlassstrom

I

F

=

f

(

V

F

)

Forward Current

T

A

= 25 ∞C

Maximal zul‰ssiger Durchlassstrom

I

F

=

f

(

T

)

Max. Permissible Forward Current

Relative Lichtst‰rke

I

V

/

I

V(10 mA)

=

f

(

I

F

)

Relative Luminous Intensity

T

A

= 25 ∞C

Relative Lichtst‰rke

I

V

/

I

V(25 ∞C)

=

f

(

T

A

)

Relative Luminous Intensity

I

F

= 10 mA

V

OHL00432

F

F

I

V

5

1.5

2 2.5 3 3.5 4 4.5 5

6

10

-1

0

10

5

1

10

5

10

2

T

OHL00451

0

F

I

0

20

40

60

80 ∞C 100

mA

5

10

15

20

25

30

temp. solder point

temp. ambient

T

T

S

A

T

A

T

S

I

OHL00433

F

-1

10

V (10 mA)

I

10

-3

-2

-1

0

1

10

10

10

10

10

0

10

1

10

2

5

5

5

5

5

mA

I

V

OHL00442

0

V

I

-20

0

20

40

60

∞C 100

I

V

(25 ∞C)

0.2

0.4

0.6

0.8

1.2

T

LB Y876

2001-11-14

8

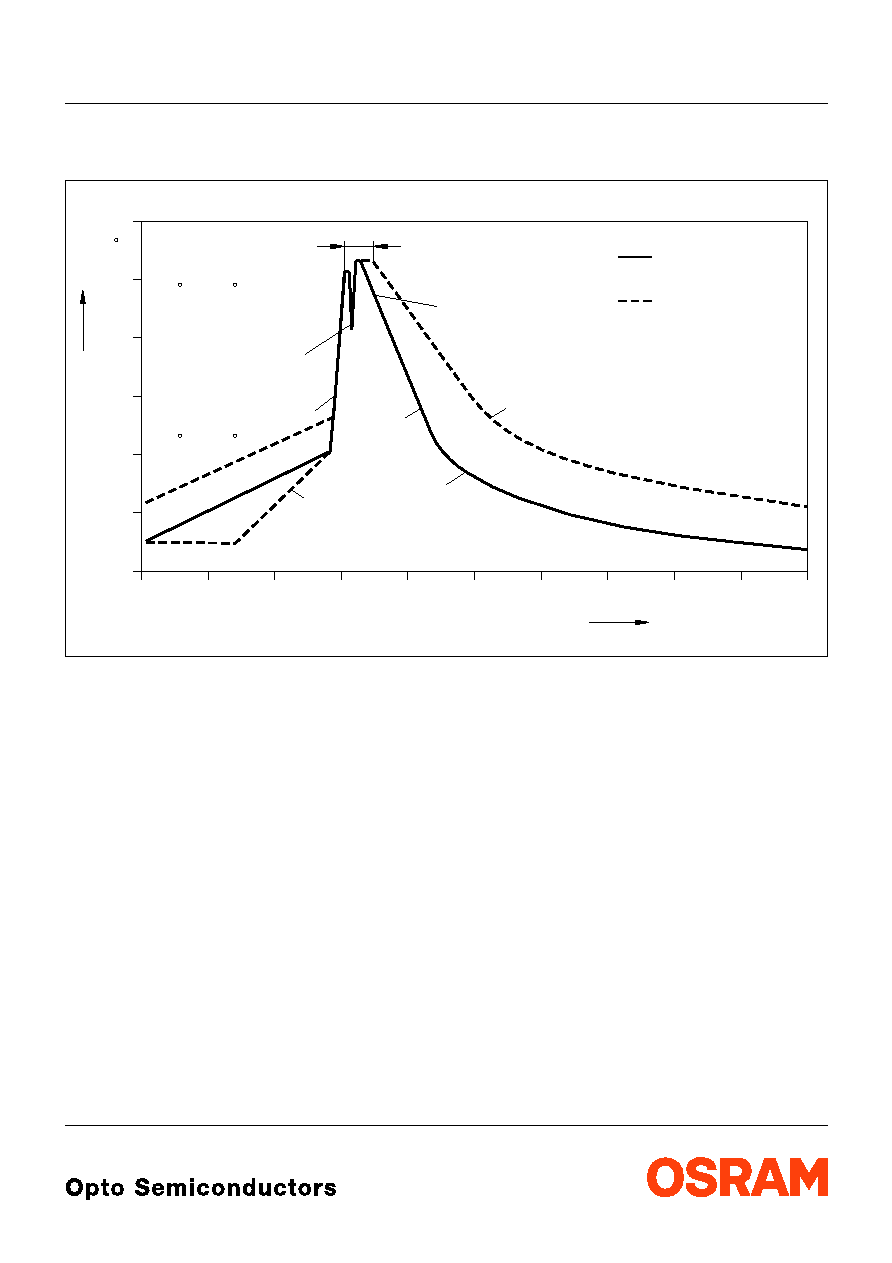

Zul‰ssige Impulsbelastbarkeit

I

F

=

f

(

t

p

)

Permissible Pulse Handling Capability

Duty cycle

D

= parameter,

T

A

= 25 ∞C

Zul‰ssige Impulsbelastbarkeit

I

F

=

f

(

t

p

)

Permissible Pulse Handling Capability

Duty cycle

D

= parameter,

T

A

= 85 ∞C

LB Y876

2001-11-14

9

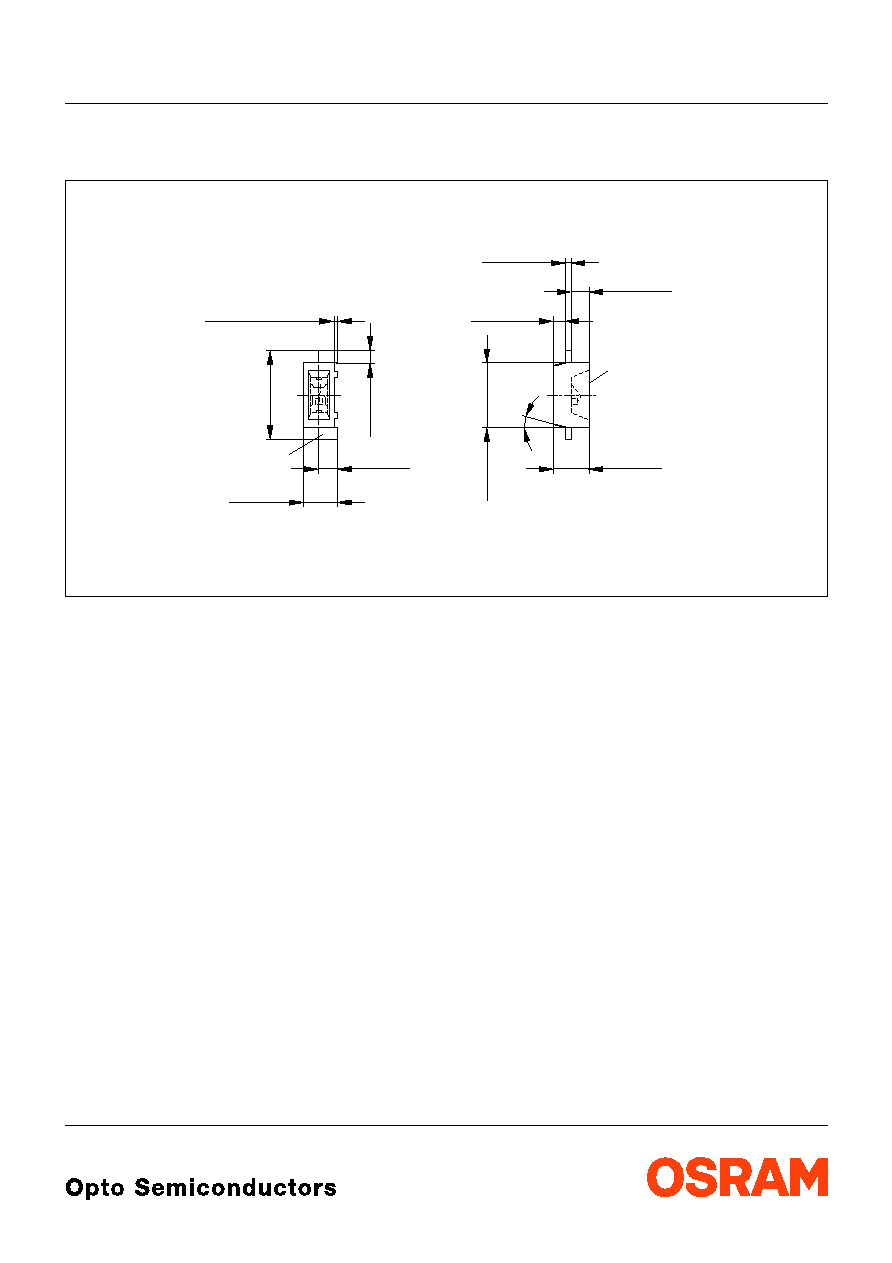

Maþzeichnung

Package Outlines

Maþe werden wie folgt angegeben: mm (inch) / Dimensions are specified as follows: mm (inch).

Gewicht / Approx. weight: 6 mg

GPLY6058

0 ... 0.1 (0 ... 0.004)

3.1 (0.122)

2.9 (0.114)

0.7 (0.028)

0.5 (0.020)

1.0 (0.039)

1.2 (0.047)

Cathode

0.3 (0.012)

0.5 (0.020)

(15

∞

)

2.3 (0.091)

2.1 (0.083)

1.3 (0.051)

1.1 (0.043)

(0.4 (0.016))

(0.6 (0.024))

0.25 (0.010)

0.20 (0.008)

Light emitting area

typ. 1.7 ◊ 0.7

2001-11-14

10

LB Y876

Lˆtbedingungen

Vorbehandlung nach JEDEC Level 2

Soldering Conditions Preconditioning acc. to JEDEC Level 2

IR-Reflow Lˆtprofil

(nach IPC 9501)

IR Reflow Soldering Profile

(acc. to IPC 9501)

OHLY0597

0

0

50

100

150

200

250

50

100

150

200

250

300

T

t

∞C

s

240-245 ∞C

10-40 s

183 ∞C

120 to 180 s

Defined for Preconditioning: up to 6 K/s

Ramp-down rate up to 6 K/s

Ramp-up rate up to 6 K/s

Defined for Preconditioning: 2-3 K/s

LB Y876

2001-11-14

11

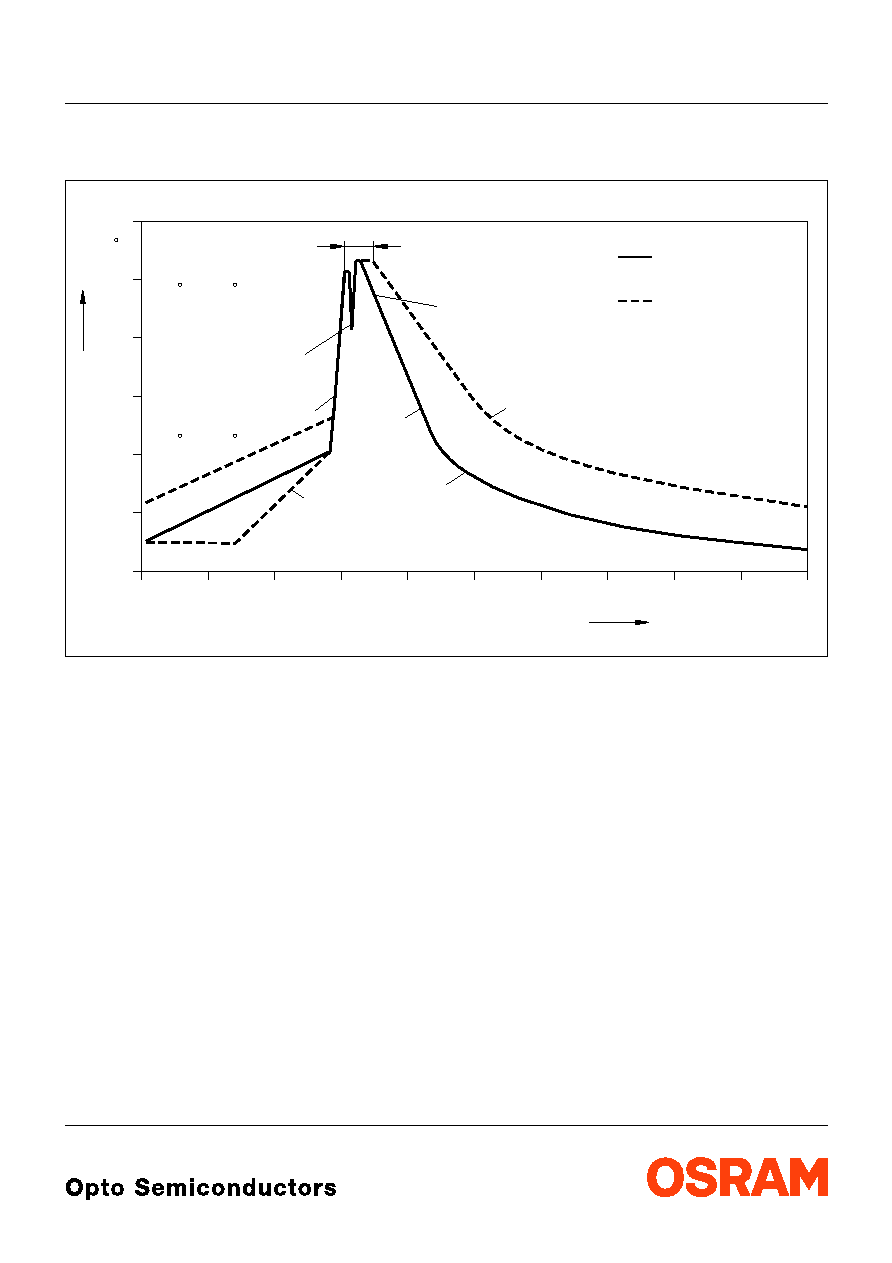

Wellenlˆten (TTW)

(nach CECC 00802)

TTW Soldering

(acc. to CECC 00802)

OHLY0598

0

0

50

100

150

200

250

50

100

150

200

250

300

T

t

C

s

235 C

10 s

C

... 260

1. Welle

1. wave

2. Welle

2. wave

5 K/s

2 K/s

ca 200 K/s

C

C

... 130

100

2 K/s

Zwangsk¸hlung

forced cooling

Normalkurve

standard curve

Grenzkurven

limit curves

2001-11-14

12

LB Y876

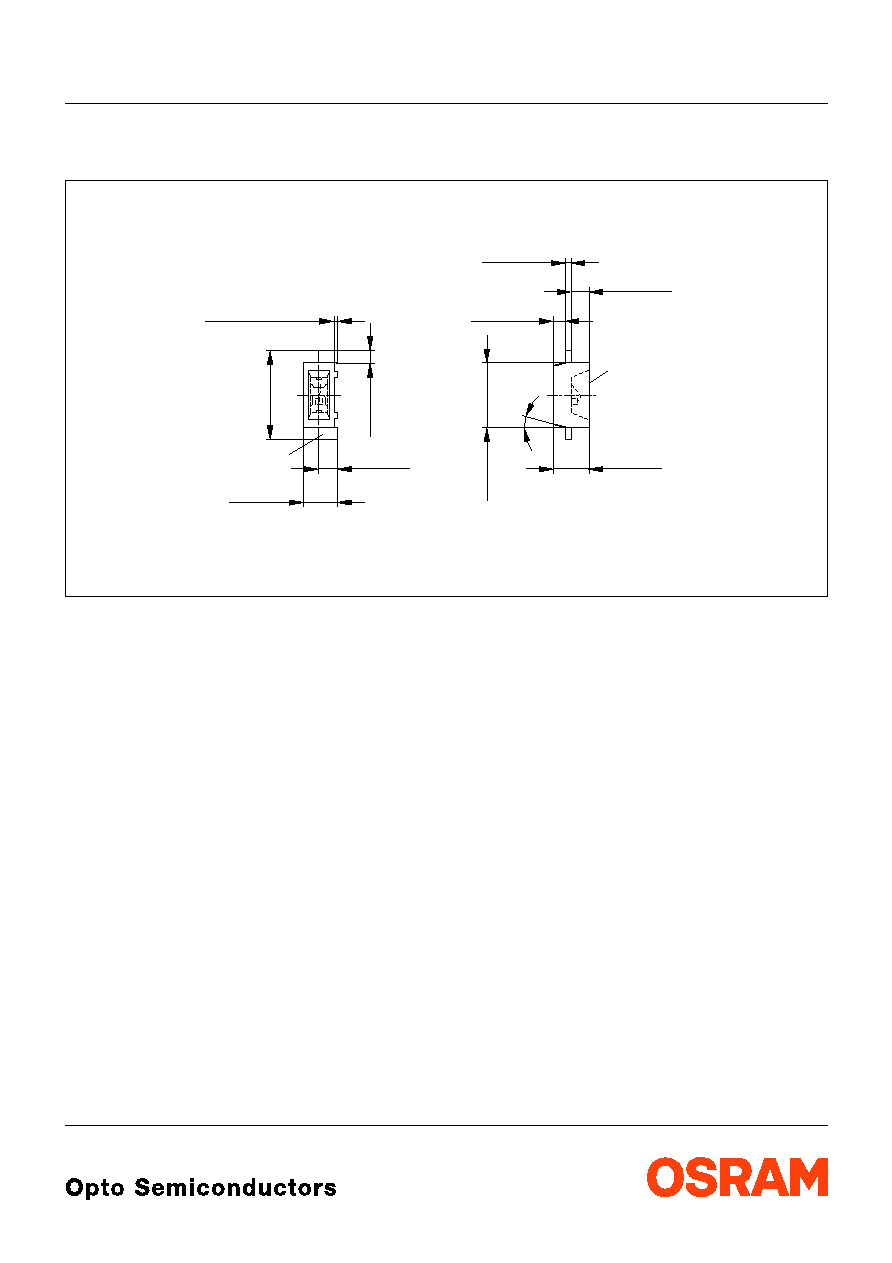

Empfohlenes LˆtpaddesignIR Reflow Lˆten

Recommended Solder PadIR Reflow Soldering

Maþe werden wie folgt angegeben: mm (inch) / Dimensions are specified as follows: mm (inch).

Geh‰use f¸r Wellenlˆten (TTW) geeignet / Package suitable for TTW-soldering

Gurtung / Polarit‰t und Lage

Verpackungseinheit 3000/Rolle, ¯180 mm oder

10000/Rolle, ¯330 mm

Method of Taping / Polarity and Orientation Packing unit 3000/reel, ¯180 mm

or 10000/reel, ¯330 mm

Maþe werden wie folgt angegeben: mm (inch) / Dimensions are specified as follows: mm (inch).

OHPY1315

0.8 (0.031)

2.2 (0.087)

0.7 (0.028)

Component location on pad

Bauteil positioniert

Padgeometrie f¸r

verbesserte W‰rmeableitung

heat dissipation

Paddesign for improved

Lˆtstopplack

Solder resist

OHAY1515

1.5 (0.059)

4 (0.157)

2 (0.079)

3.5 (0.138)

1.75 (0.069)

8.1 (0.319)

A

C

0.9 (0.035)

2.4 (0.094)

3.3 (0.130)

1.25 (0.049)

0.3 (0.012) max.

1.4 (0.055)

LB Y876

2001-11-14

13

Published by OSRAM Opto Semiconductors GmbH & Co. OHG

Wernerwerkstrasse 2, D-93049 Regensburg

© All Rights Reserved.

Attention please!

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may contain

dangerous substances. For information on the types in question please contact our Sales Organization.

If printed or downloaded, please find the latest version in the Internet.

Packing

Please use the recycling operators known to you. We can also help you ≠ get in touch with your nearest sales office.

By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For packing

material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs

incurred.

Components used in life-support devices or systems must be expressly authorized for such purpose! Critical

components

1

may only be used in life-support devices or systems

2

with the express written approval of OSRAM OS.

1

A critical component is a component used in a life-support device or system whose failure can reasonably be expected

to cause the failure of that life-support device or system, or to affect its safety or the effectiveness of that device or

system.

2

Life support devices or systems are intended (a) to be implanted in the human body, or (b) to support and/or maintain

and sustain human life. If they fail, it is reasonable to assume that the health of the user may be endangered.

Revision History: 2001-11-14

Previous Version:

2001-03-14

Page

Subjects (major changes since last revision)

4

Dominant wavelength