LCTM is a trademark of Lucent

Fiber Optics

MARCH 2001

V23818-K305-L56

(*)

Small Form Factor

Multimode 850 nm 1.0625 GBd Fibre Channel

1.3 Gigabit Ethernet 2x5 Transceiver with LCTM Connector

Extended Temperature Range (≠40∞C to 85∞C)

Preliminary

*) Ordering Information

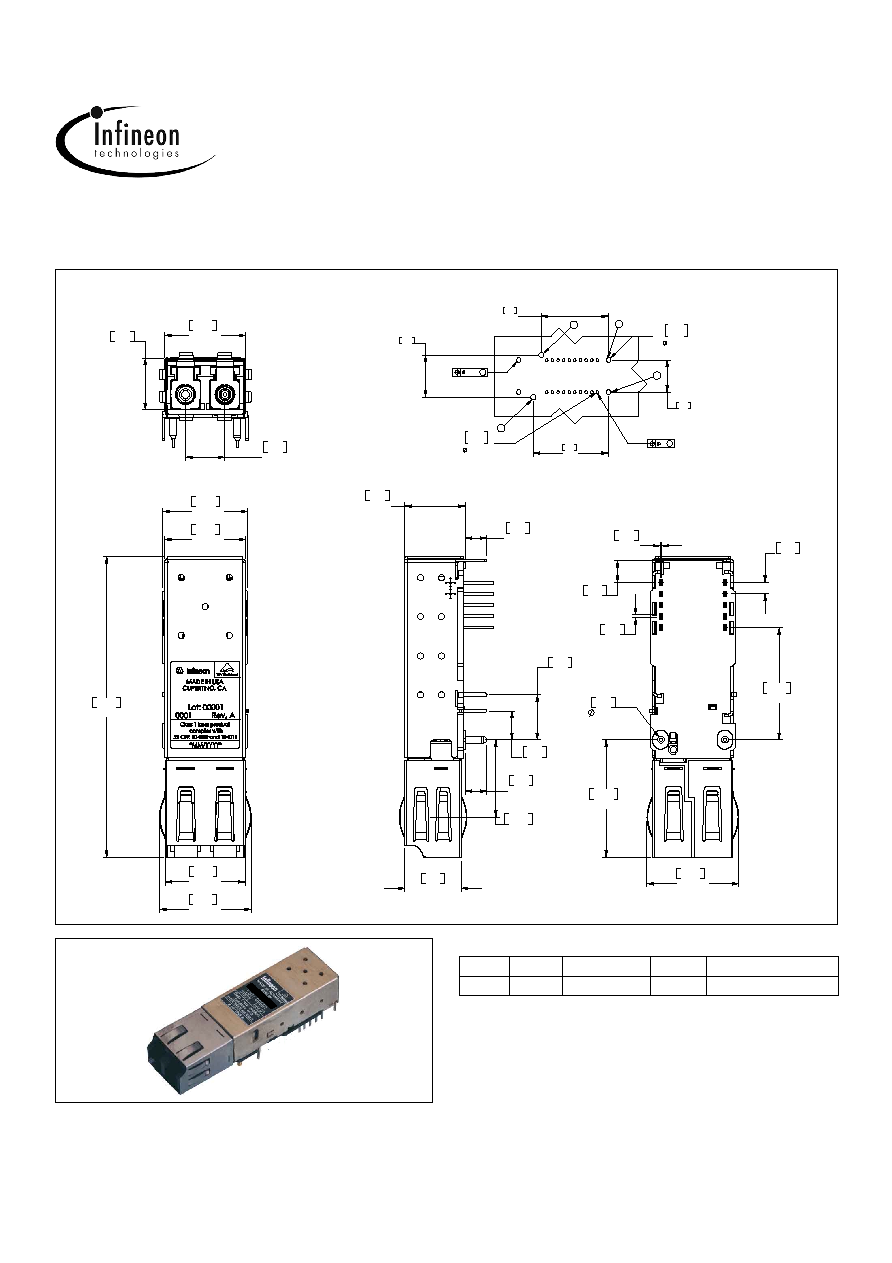

12.88

.507

8.17

.321

6.24

.246

14.56

.573

12.70

.500

13.43

.529

12.88

.507

47.65

1.876

8.92

.351

9.61

.378

3.39

.134

3.45

.136

(6X)

4.57

.180

7.11

.280

12.27

.483

14.56

.573

1.07

.042

18.59

.732

0.25

.010

0.48

.019

Circuit Board Layout

Recommended PCB Thickness: 0.1(2.54) max.

1.78

.070

3.48

.137

17.78

.700

20X

0.81

0

0

.03

-.00

+.00

6X

1.40

0

0

.06

-.00

+.00

21.34

.840

13.34

.525

10.16

.400

23.88

.940

(10X)

1

1

1

1

1. 4 optional package grounding tabs

10 pin module requires only 12 PCB holes.

0.05M

0 M

V23818-K305-L56

Dimensions in [mm] inches

V

2

3

8

1

8

-K

3

0

5

-L

5

6

Input

Output

Signal detect

Voltage

Part number

AC

AC

TTL

3.3 V

V23818-K305-L56

Fiber Optics

V23818-K305-L56, SFF, MM 850nm 1.0625 GBd Fibre Channel, 1.3 GBE 2x5 Trx (LCTM), ext.temp.

2

FEATURES

∑ Small Form Factor transceiver

∑ RJ-45 style LCTM connector system

∑ Half the size of SC Duplex 1x9 transceiver

∑ Single power supply (3.3 V)

∑ Extremely low power consumption

∑ PECL and LVPECL differential inputs and outputs

∑ System optimized for 62.5/50

µ

m graded index fiber

∑ Multisource footprint

∑ Small footprint for high channel density

∑ UL-94 V-0 certified

∑ ESD Class 1 per MIL-STD 883D Method 3015.7

∑ Compliant with FCC (Class B) and EN 55022

∑ For distances of up to 550 m

∑ Class 1 FDA and IEC laser safety compliant

∑ Extended Temperature Range ≠40∞C to 85∞C

Absolute Maximum Ratings

Exceeding any one of these values may destroy the device

immediately.

Package Power Dissipation................................................ 1.5 W

Data Input Levels (PECL) ............................................V

CC

+0.5 V

Differential Data Input Voltage .............................................1.6 V

Operating Case Temperature...............................≠40 ∞ C to 85∞ C

Storage Ambient Temperature............................. ≠40 ∞ C to 85∞C

Soldering Conditions, Temp/Time

(MIL-STD 883C, Method 2003) ........................... 250 ∞C/ 5.5 s

V

CC

max.............................................................................. 5.5 V

ECL-Output current data ...................................................50 mA

DESCRIPTION

The Infineon Gigabit Ethernet multimode transceiver ≠ part of

Infineon Small Form Factor transceiver family ≠ is based on the

Physical Medium Depend (PMD) sublayer and baseband

medium, type 1000BASE-SX (short wavelength), Fibre Channel

DC 100-M5-SN-I and 100-M6-SN-I.

The appropriate fiber optic cable is 62.5 µm or 50 µm multi-

mode fiber with LCTM connector.

Operating range for over each optical fiber type

The Infineon Gigabit Ethernet multimode transceiver is a single

unit comprised of a transmitter, a receiver, and an LCTM recepta-

cle. This design frees the customer from many alignment and

PC board layout concerns.

This transceiver supports the LCTM connectorization concept. It

is compatible with RJ-45 style backpanels for high end

Data Com and Telecom applications while providing the advan-

tages of fiber optic technology.

The module is designed for low cost SAN, LAN, WAN, Fibre

Channel and Gigabit Ethernet applications. It can be used as the

network end device interface in mainframes, workstations,

servers, and storage devices, and in a broad range of network

devices such as bridges, routers, hubs, and local and wide area

switches.

This transceiver operates at 1 and 1.25 Gbit/s from a single

power supply (+3.3 V). The full differential data inputs and out-

puts are PECL and LVPECL compatible.

Functional Description of 2x5 Pin Row Transceiver

This transceiver is designed to transmit serial data via

multimode cable.

Functional Diagram

The receiver component converts the optical serial data into

PECL compatible electrical data (RD and RDnot). The Signal

Detect (SD, active high) shows whether an optical signal is

present.

The transmitter converts PECL compatible electrical serial data

(TD and TDnot) into optical serial data. Data lines are differen-

tially 100

terminated.

The transmitter contains a laser driver circuit that drives the

modulation and bias current of the laser diode. The currents are

controlled by a power control circuit to guarantee constant out-

put power of the laser over temperature and aging.

The power control uses the output of the monitor PIN diode

(mechanically built into the laser coupling unit) as a controlling

signal, to prevent the laser power from exceeding the operating

limits.

Single fault condition is ensured by means of an integrated

automatic shutdown circuit that disables the laser when it

detects laser fault to guarantee the laser Eye Safety.

The transceiver contains a supervisory circuit to control the

power supply. This circuit makes an internal reset signal when-

ever the supply voltage drops below the reset threshold. It

keeps the reset signal active for at least 140 milliseconds after

the voltage has risen above the reset threshold. During this

time the laser is inactive.

The laser can be disabled by the TxDis input.

Fiber type

Minimum range (meters)

Typ.

62.5 micron MFF

2 to 260

400

50.0 micron MFF

2 to 550

700

10 micron SFF

Not supported

Laser

Driver

Power

Control

Receiver

o/e

o/e

Laser

e/o

Rx Coupling Unit

TD

-

TD+

TxDis

RD

-

RD+

SD

Laser

Coupling Unit

Multimode Fiber

LEN

Monitor

Automatic

Shut-Down

Fiber Optics

V23818-K305-L56, SFF, MM 850nm 1.0625 GBd Fibre Channel, 1.3 GBE 2x5 Trx (LCTM), ext.temp.

3

TECHNICAL DATA

The electro-optical characteristics described in the following

tables are valid only for use under the recommended operating

conditions.

Recommended Operating Conditions

Transmitter Electro-Optical Characteristics

Notes

1. Into multimode fiber, 62.5 µm or 50 µm diameter.

2. Laser power is shut down if power supply is below VTH and

switched on if power supply is above VTH after tRES.

Receiver Electro-Optical Characteristics

Notes

1. Average optical power at which the BER is 1 x 10E≠12. Measured

with a 2

7

≠1 NRZ PRBS and ER=9 dB.

2. An increase in optical power above the specified level will cause the

SIGNAL DETECT output to switch from a Low state to a High state.

3. A decrease in optical power below the specified level will cause the

SIGNAL DETECT to change from a High state to a Low state.

4. AC/AC for data. Load 50

to GND or 100

differential. For dynamic

measurement a tolerance of 50 mV should be added.

5. Supply current excluding Rx output load.

Parameter

Symbol

Min.

Typ.

Max.

Units

Case Temperature

T

C

≠40

85

∞

C

Power Supply Voltage

V

CC

≠V

EE

3.1

3.3

3.5

V

Transmitter

Data Input

Differential Voltage

V

DIFF

250

1600

mV

Receiver

Input Center

Wavelength

C

770

860

nm

Transmitter Symbol Min. Typ. Max. Units

Launched Power

(Average)

(1)

P

O

≠9.5

≠4

dBm

Center Wavelength

C

830

850

860

nm

Spectral Width (RMS)

l

0.85

Relative Intensity Noise

RIN

≠117

dB/Hz

Extinction Ratio (Dynamic)

ER

8

dB

Reset Threshold

(2)

V

TH

2.2

2.7

2.99

V

Reset Time Out

(2)

t

RES

140

240

560

ms

Rise Time, 20%≠80%

t

R

0.26

ns

Supply Current

75

mA

Receiver

Symbol Min.

Typ.

Max.

Units

Sensitivity

(Average Power)

(1)

P

IN

≠19

≠16.5

dBm

Saturation

(Average Power)

P

SAT

0

Signal Detect

Assert Level

(2)

P

SDA

≠24

≠18

Signal Detect

Deassert Level

(3)

P

SDD

≠30

≠27

Signal Detect

Hysteresis

P

SDA

≠

P

SDD

3

dB

Signal Detect

Assert Time

t

ASS

100

µ

s

Signal Detect

Deassert Time

t

DAS

350

Data Output

Differential Voltage

(4)

V

DIFF

0.5

0.8

1.23

V

Return Loss

of Receiver

A

RL

12

dB

Supply current

(5)

60

mA

Fiber Optics

V23818-K305-L56, SFF, MM 850nm 1.0625 GBd Fibre Channel, 1.3 GBE 2x5 Trx (LCTM), ext.temp.

4

Pin Description

Regulatory Compliance

EYE SAFETY

This laser based multimode transceiver is a Class 1 product. It

complies with IEC 60825-1 and FDA 21 CFR 1040.10 and

1040.11.

To meet laser safety requirements the transceiver shall be oper-

ated within the maximum operating limits.

Caution

All adjustments have been made at the factory prior to ship-

ment of the devices. No maintenance or alteration to the

device is required.

Tampering with or modifying the performance of the device

will result in voided product warranty.

Note

Failure to adhere to the above restrictions could result in a modifica-

tion that is considered an act of "manufacturing", and will require,

under law, recertification of the modified product with the U.S. Food

and Drug Administration (ref. 21 CFR 1040.10 (i)).

Laser Data

Required Labels

Laser Emission

Pin Name

Level/

Logic

Pin# Description

V

EEr

Receiver

Signal Ground

N/A

1

V

CCr

Receiver

Power Supply

N/A

2

SD

Signal Detect

TTL

3

Normal Operation: Logic

"1" Output, represents

that light is present at re-

ceiver input

Fault Condition: Logic "0"

Output

RD≠

Received Data

Out Not

PECL

4

RD+

Received Data

Out

PECL

5

V

CCt

N/A

6

Transmitter Power Supply

V

EEt

N/A

7

Transmitter Signal Ground

TxDis Transmitter

Disable/Enable

TTL-

Input

8

A low signal switches the

laser on.

A high signal switches the

laser off.

TD+

Transmit Data

PECL

9

Transmitter Data In

TD≠

Transmit Data

Not

PECL

10

Transmitter Data In

MS

MS

Package

Grounding

Tabs

N/A

MS1

MS2

T1

T2

T3

T4

Mounting Studs and

grounding Tabs are provid-

ed for transceiver mechan-

ical attachment to the

circuit board. They also

provide an optional connec-

tion of the transceiver to

the equipment chassis

ground.

The holes in the circuit

board must be tied to

chassis ground.

Feature

Standard

Comments

Electrostatic Discharge

(ESD) to the Electrical

Pins

MIL-STD 883D

Method 3015.7

Class 1 (>1000 V)

Immunity:

Electrostatic Discharge

(ESD) to the Duplex SC

Receptacle

EN 61000-4-2

IEC 61000-4-2

Discharges of

±

15 kV

with an air discharge

probe on the recepta-

cle cause no damage.

Immunity:

Radio Frequency

Electromagnetic Field

EN 61000-4-3

IEC 61000-4-3

With a field strength

of 3 V/m rms, noise

frequency ranges

from 10 MHz to

1 GHz. No effect on

transceiver perfor-

mance between the

specification limits.

Emission:

Electromagnetic

Interference (EMI)

FCC Class B

EN 55022

Class B CISPR 22

Noise frequency

range:

30 MHz to 6 GHz

Wavelength

850 nm

Total output power (as defined by IEC: 7 mm

aperture at 1.4 cm distance)

<675 µW

Total output power (as defined by FDA: 7 mm

aperture at 20 cm distance)

<70 µW

Beam divergence

12

∞

Class 1 Laser Product

IEC

Complies with 21 CFR

1040.10 and 1040.11

FDA

10 9 8 7 6

1 2 3 4 5

Tx

Rx

Indication of

laser aperture

and beam

Fiber Optics

V23818-K305-L56, SFF, MM 850nm 1.0625 GBd Fibre Channel, 1.3 GBE 2x5 Trx (LCTM), ext.temp.

5

APPLICATION NOTES

EMI-Recommendation

To avoid electromagnetic radiation exceeding the required limits

please read the following recommendations:

Whenever high speed Gigabit switching components are

located on the PCB (also multiplexers, clock recoveries ...) any

opening of the machine may generate radiation even at differ-

ent locations. Thus every mechanical opening or aperture

should be as small as possible.

On the board itself every data connection should be an imped-

ance matched line (e.g. strip line, coplanar strip line). Data,

Datanot should be routed symmetrically, via's should be

avoided. A symmetrically matching resistor of 100

should be

placed at the end of each matched line. An alternative termina-

tion can be provided with a 50

resistor at each (D, Dn). In DC

coupled systems an artificial 50

resistance can be achieved

as follows: For 3.3 V: 125

to V

CC

and 82

to V

EE

, for 5 V:

82

to V

CC

and 125

to V

EE

at Data and Datanot. Please con-

sider whether there is an internal termination inside an IC or a

transceiver.

It is recommended that chassis GND and signal GND should

remain separate if there are openings or apertures of the hous-

ing nearby. Sometimes signal GND is the most harmful source

of radiation. Connecting chassis GND and signal GND at the

plate/ bezel/ backside wall e.g. by means of a fiber optic trans-

ceiver may result in a huge amount of radiation. Even a capaci-

tive coupling between signal GND and chassis may be harmful

if it is to close to an opening or an aperture.

If a separation of signal GND and chassis GND is not possible,

it is strongly recommended to provide a proper contact

between signal GND and chassis GND at almost every location.

This concept is suitable to avoid hotspots. Hotspots are places

of highest radiation which could be generated if only a few con-

nections between signal and chassis GND are available. Com-

pensation currents would concentrate at these connections,

causing radiation.

For the SFF transceiver a connection of the 4 housing pins to

chassis GND is recommended. If no separate chassis GND is

available on the users PCB the pins should be connected to sig-

nal GND. In this case take care of the notes above.

Please consider that the PCB may behave like a waveguide.

With an

r

of 4, the wavelength of the harmonics inside the

PCB will be half of that in free space. In this case even small

PCBs may have unexpected resonances.

Multimode 850 nm Gigabit Ethernet/Fibre Channel 2x5 Transceiver, AC/AC

Values of R1/2/3/4 may vary as long as proper 50

termination

to V

EE

or 100

differential is provided. The power supply filter-

ing is required for good EMI performance. Use short tracks

from the inductor L1/L2 to the module V

CC

Rx/V

CC

Tx.

The transceiver contains an automatic shutdown circuit. Reset

is only possible if the power is turned off, and then on again.

(V

CC

Tx switched below V

TH

).

Application Board available on request.

VCSEL

Driver

Signal

Detect

Limiting

Amplifier

Pre-

Amp

RD-

RD+

Tx+

Tx-

Serializer/

Deserializer

Gigabit

Transceiver

Chip

ECL/PECL

Driver

Receiver

PLL etc.

Infineon Transceiver

V23818-K305-L56

1

5

4

3

2

6

10

9

7

SD to upper level

V

EEt

TD+

TD-

V

CCt

V

CCr

SD

RD-

RD+

V

EEr

V

CC

R7

R8

L1

L2

C2

C1

R3

R4

R1

R2

C3

V

CC

SerDes

3.3 V

V

CC

3.3 V

100

TTL level

8

TxDis

C1/2/3 = 4.7

µ

F

L1/2

= 1

µ

H

R1/2

= Depends on SerDes chip used

R3/4

= Depends on SerDes chip used

R7/8 = Biasing (depends on SerDes chip)

Place R1/2/3/4/7/8 close to SerDes chip

Place R5/6 close to Infineon transceiver